High strength steel with yield strength to be 900-1000MPa grade and production method of high strength steel

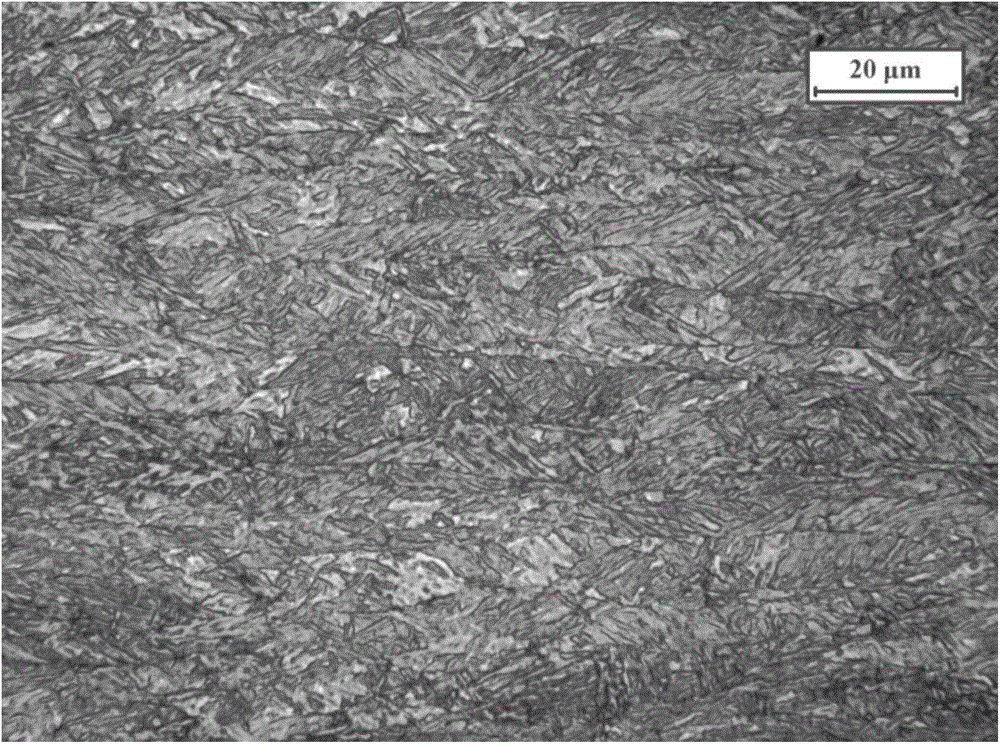

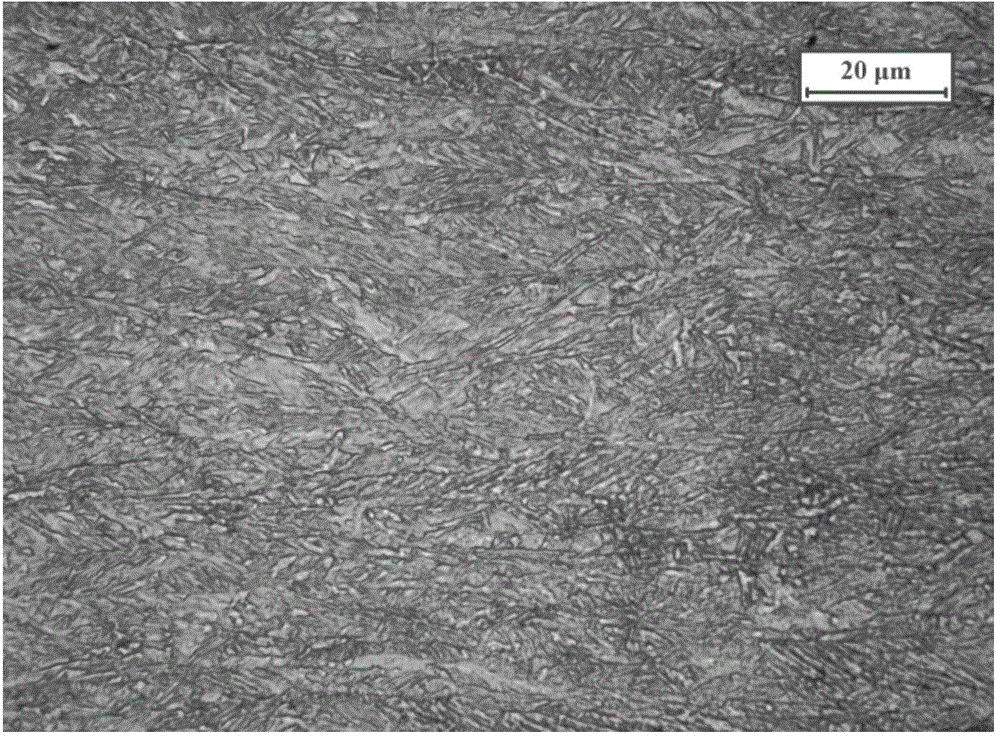

A yield strength and production method technology, applied in the field of tempered martensite, can solve the problems of high Cr content, no consideration of heredity, and no control of the comprehensive performance of joint plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the embodiments.

[0052] The production process flow of the ultra-high-strength steel of the present invention is: converter or electric furnace steelmaking→out-of-furnace refining→continuous casting→heating→rolling→cooling→heat treatment.

[0053] The production method of the 900-1000MPa grade high-strength steel according to the embodiments 1-10 of the present invention comprises the following steps:

[0054] 1) Use a 50kg vacuum electric furnace for smelting, and the components are shown in Table 1. The smelted molten steel is poured into a slab with a thickness of 120 mm and heated in an electric furnace.

[0055] 2) Use multiple passes to roll the cast slab into a steel plate with a target thickness of 10mm, the final rolling temperature is 820-920 °C, and the final rolling temperature Tf satisfies: Ar 3 <Tf<Tnr; the final pass reduction ratio is set to 17%.

[0056] 3) On-line laminar coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com