Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

532results about How to "Obvious weight loss effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

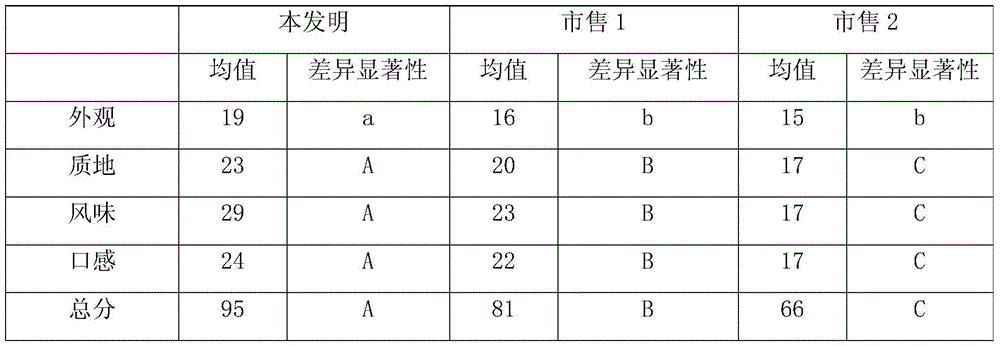

Fruit and vegetable probiotic tablet and preparation method thereof

ActiveCN104489646AHigh survival rate of live bacteriaImprove stabilityNatural extract food ingredientsFood ingredient functionsCelluloseDrug biological activity

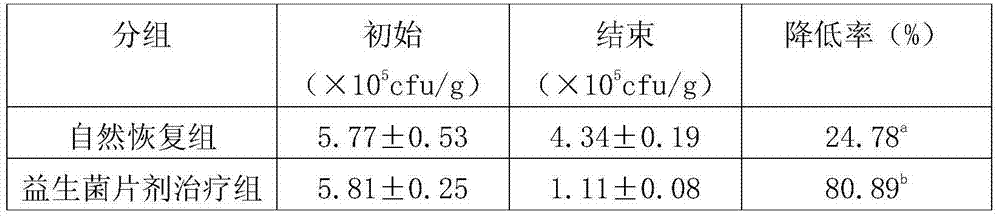

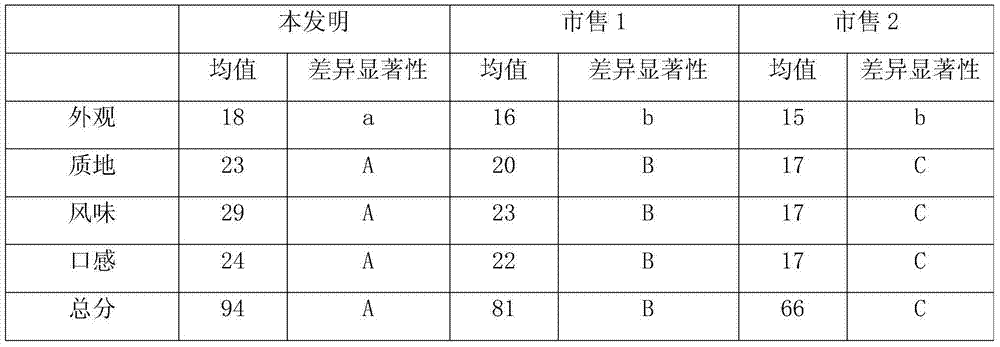

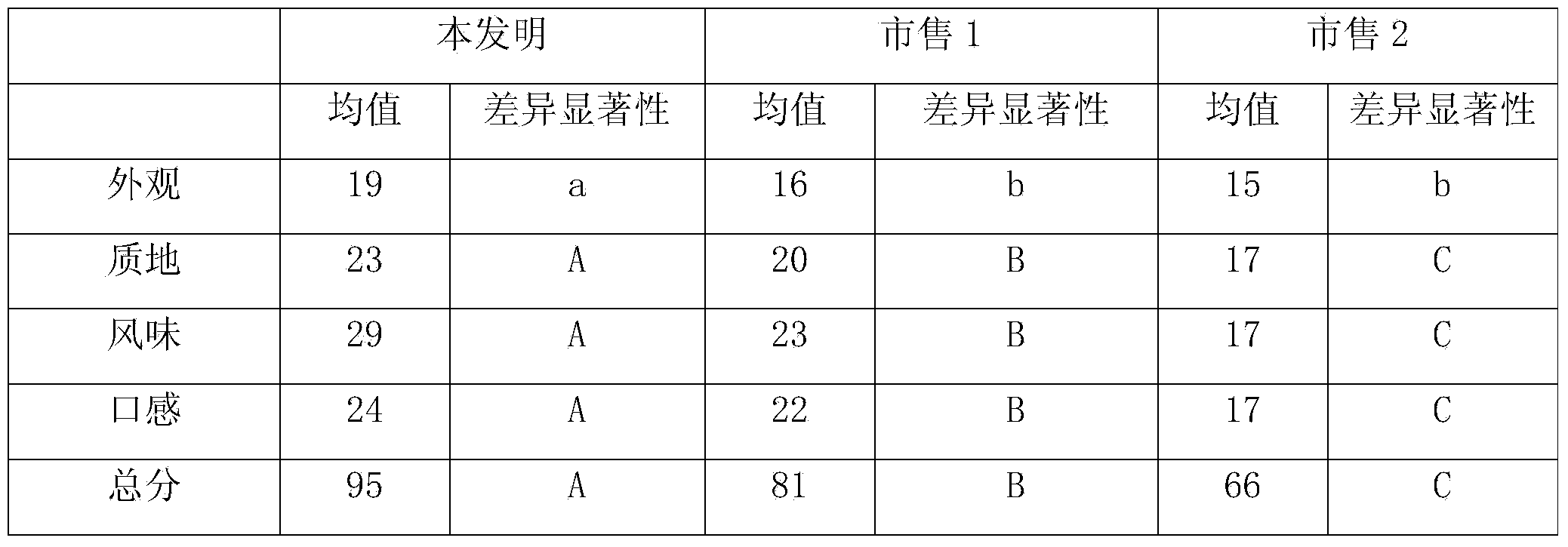

The present invention discloses a fruit and vegetable probiotic tablet and a preparation method thereof. The fruit and vegetable probiotic tablet uses probiotic powders such as lactobacillus plantarum powder as the main raw material, and the preparation method scientifically mixes modified dietary fibers, fruit and vegetable powder, oligosaccharides, plant extracts, protein powder, tea leaf extracts and traditional Chinese medicine extracts and etc., thus improves the content of soluble celluloses which are of real significance for probiotic flora, enhances the physiological activity of celluloses, thereby increases the species of intestinal probiotic flora as well as significantly enhances the colonization ability and time of endogenous and exogenous probiotics in the human intestinal tracts, effectively inhibits the growth and reproduction of harmful intestinal bacteria, especially gram-negative bacteria, and fully regulates the composition of the intestinal probiotic flora. The prepared fruit and vegetable probiotic tablet has a high biological activity, a long human intestinal colonization time, and a significant weight loss effect, and is suitable for a wide range of people.

Owner:南京旭优食品技术有限公司

Weight-losing fruit and vegetable powder

InactiveCN104286756AReduce intakeObvious weight loss effectVitamin food ingredientsAcidic food ingredientsAdditive ingredientTea leaf extract

The invention discloses weight-losing fruit and vegetable powder which has the characteristics that natural plants with weight-losing effects are taken as raw materials; effective ingredients in the raw materials are retained to the maximum extent by low-temperature extraction and biological enzymolysis technologies; weight-losing factors with relatively good weight-losing effects, such as dietary fibers, plant extracts, tea leaf extract, spice extract, Chinese herbal medicine extracts, probiotic powder, probiotic factors and bamboo charcoal powder, are scientifically compounded on the basis of existing nutritional fruit and vegetable powder; meanwhile, nutritional ingredients with weight-losing effects, such as protein powder, malt extract and malt flour are also compounded, and nutrients such as compound amino acids, vitamins and minerals are added; mainly proceeding from the aspects of satisfying the satiety feel, regulating gastrointestinal florae, protecting the health by traditional Chinese medicines, sucking and removing fat and the like, the digestion and absorption self-regulation capability of a human body is improved, the uptake and secondary synthetic routes of human fat are reduced, the normal nutrient uptake and metabolic level of the human body cannot be influenced, and a good cycle of health protection and weight reduction is realized.

Owner:天津天绿健科技有限公司

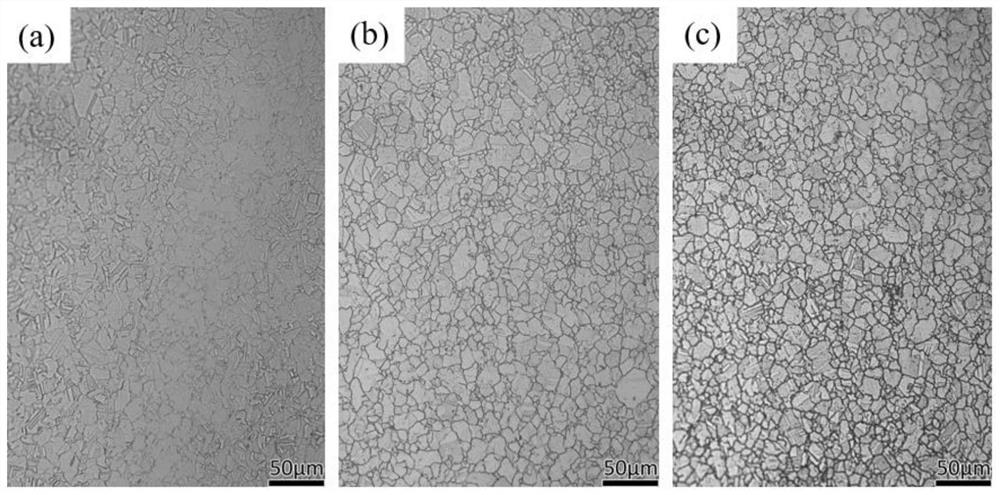

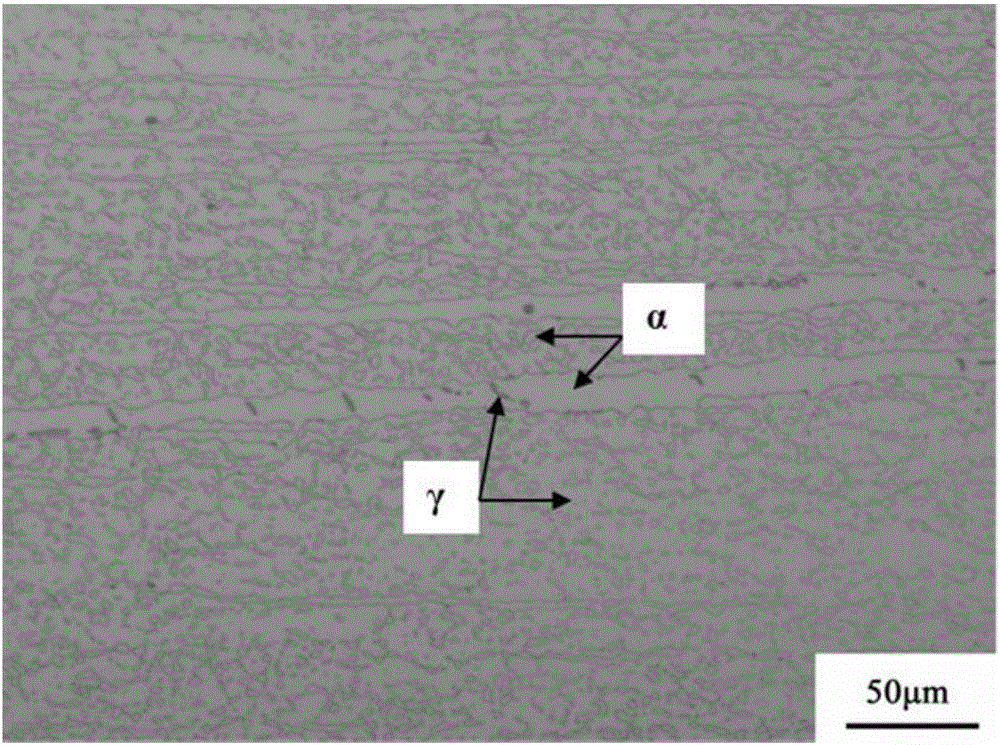

Low-density and high-toughness automobile-used steel board and preparation process

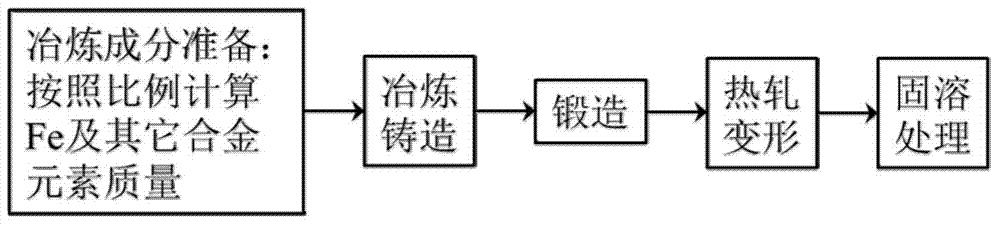

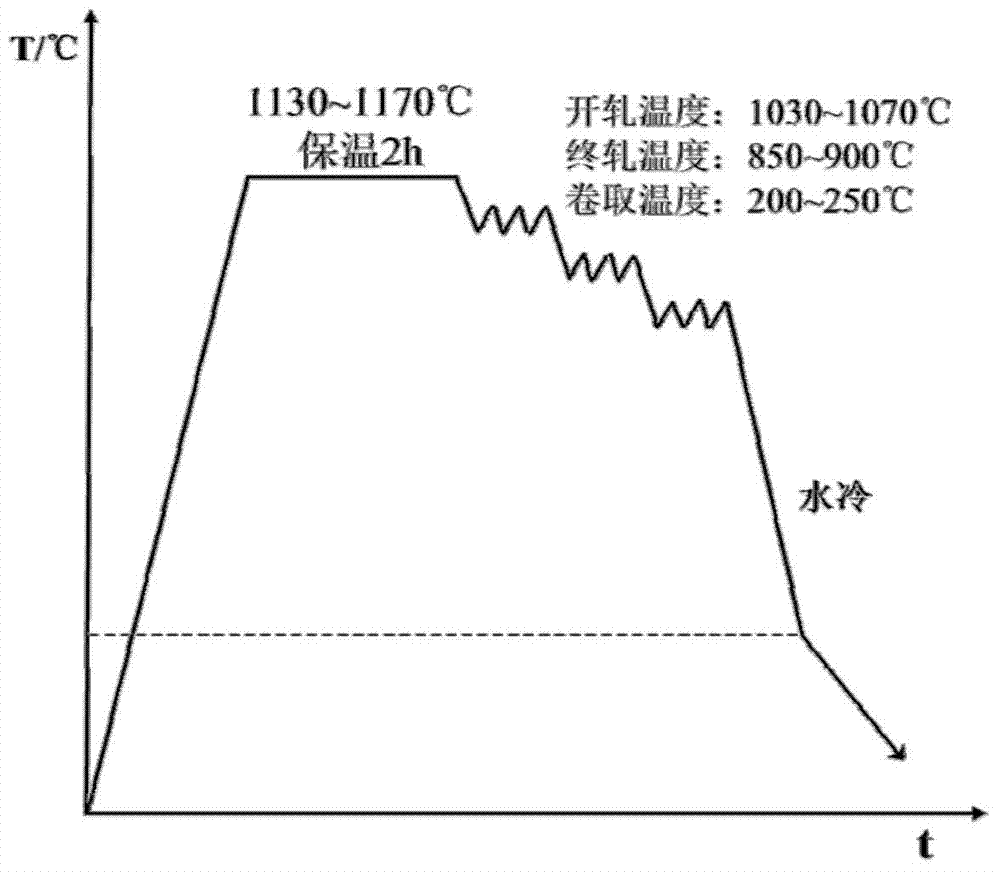

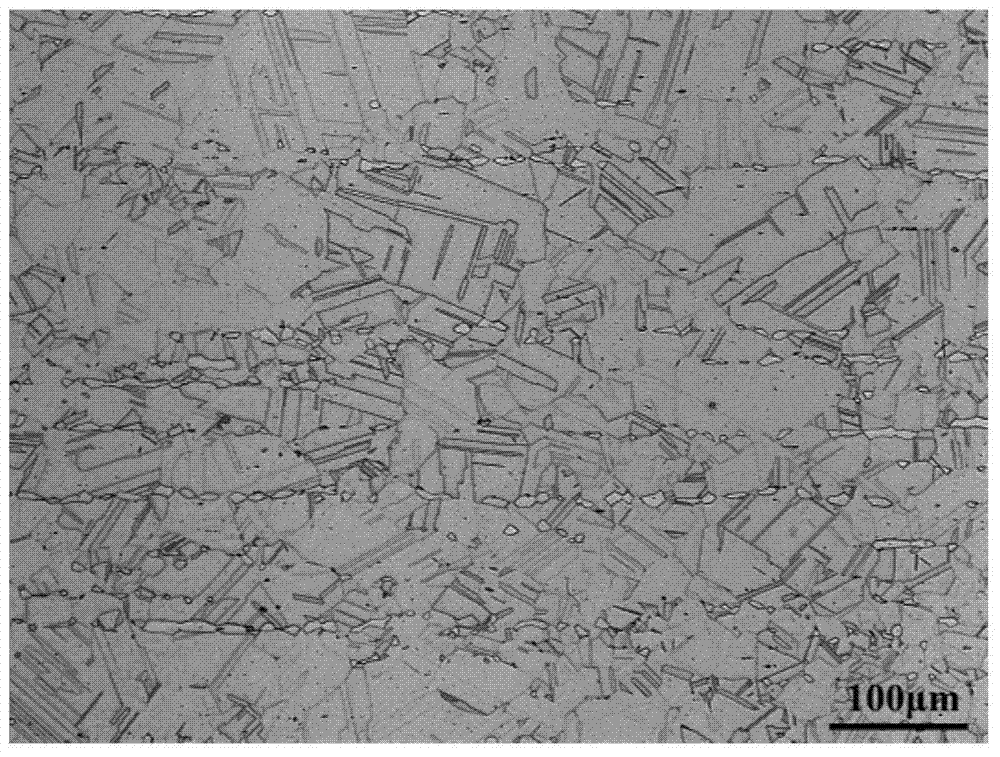

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

Fruit-vegetable nutrition powder and preparation method thereof

InactiveCN104921128AReduce intakeObvious weight loss effectNatural extract food ingredientsFood ingredient functionsDigestionBULK ACTIVE INGREDIENT

The invention discloses fruit-vegetable nutrition powder and a preparation method thereof. The fruit-vegetable nutrition powder and the preparation method thereof have the advantages that natural plants having weight losing effects are taken as raw materials, low-temperature extraction and biological enzymolysis techniques are adopted, active ingredients in the natural plants are maintained to the greatest extent, weight-losing factors good in weight losing effect, such as dietary fibers, plant extracts, tea extracts, spice extracts, Chinese herb extracts, probiotics powder, probiotics factors and bamboo charcoal powder, are compounded on the basis of existing fruit and vegetable nutrition powder scientifically, nutrient substances with weight losing effects, such as albumen powder, malt extracts and wheat malt powder, are also compounded, nutrients such as compound amino acids, vitamins and mineral substances are added, and automatic regulation, digestion and absorption level and capability of human bodies are maintained and improved in terms of satiety, stomach and intestine flora regulation, traditional Chinese medicine health care, fat absorption and removal and the like, so that intake and secondary synthetic approaches of fat of the human bodies are reduced, normal nutrient ingestion and metabolic levels of the human bodies are not affected, and a virtuous circle of health-care weight loss is achieved.

Owner:邵素英

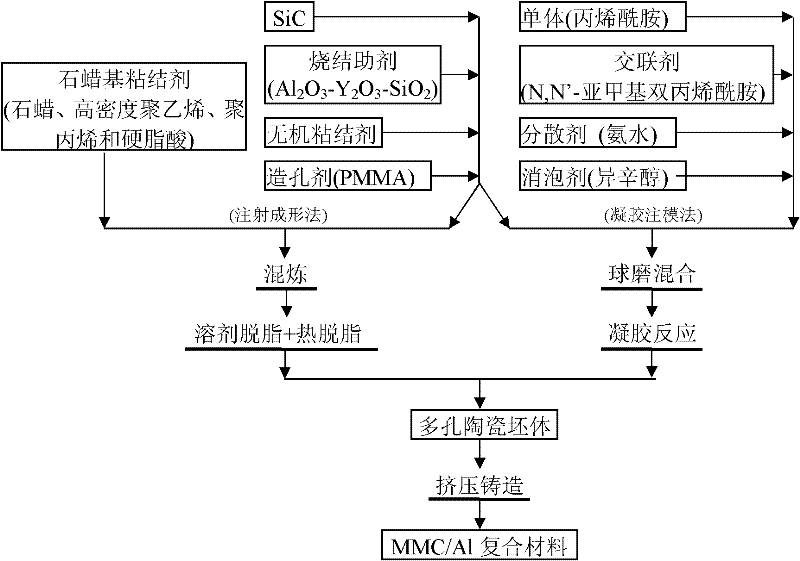

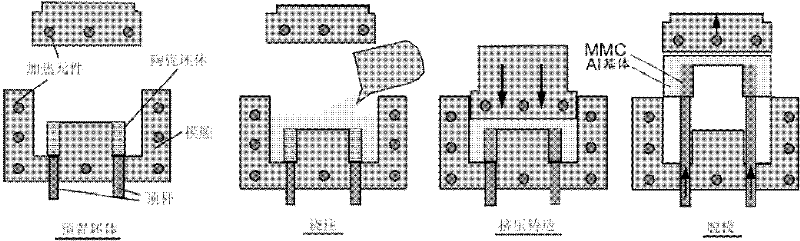

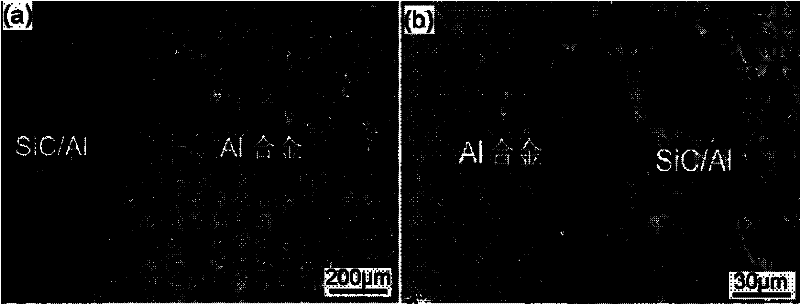

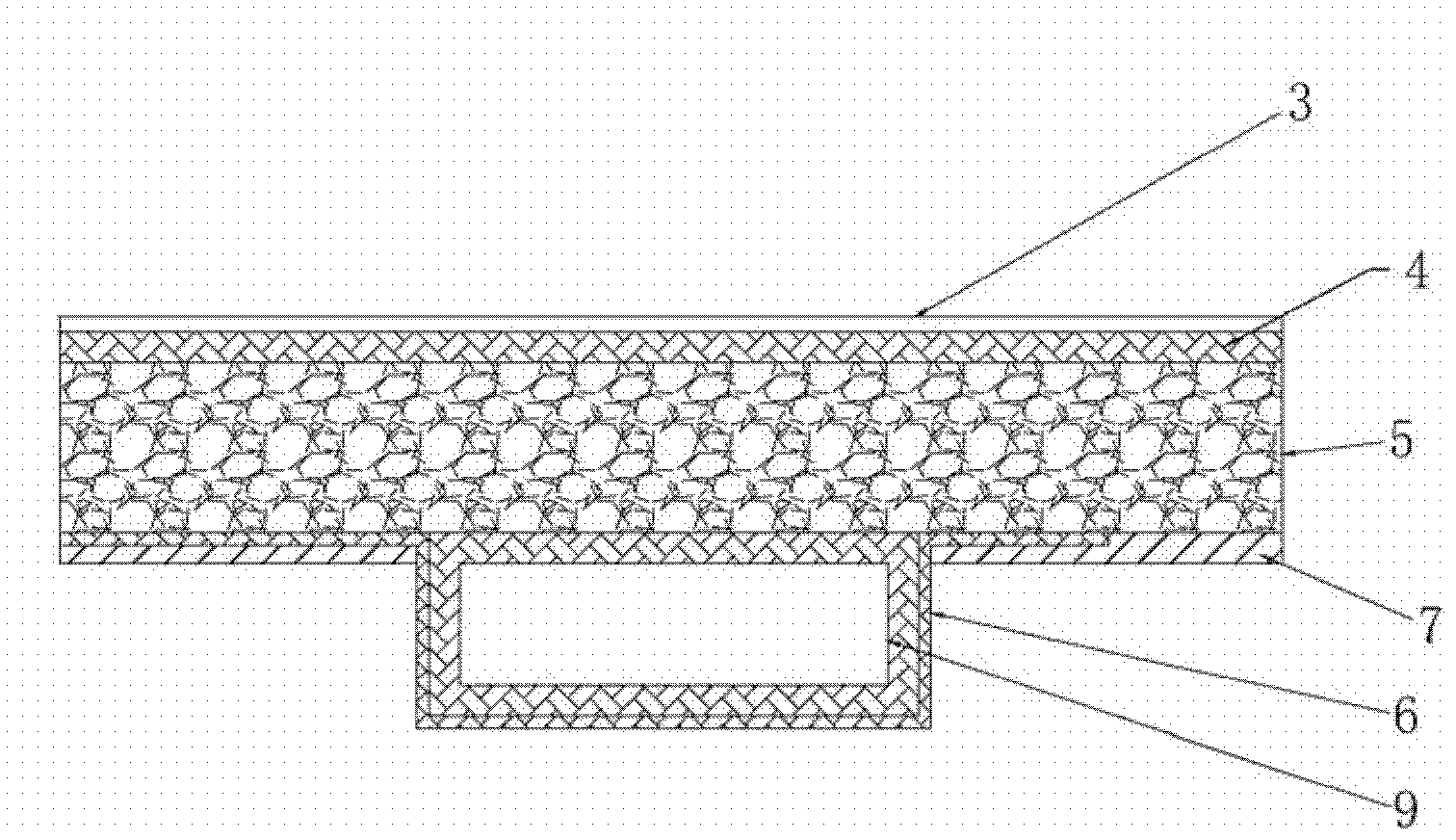

Method for preparing selectively enhanced aluminum-based composite from ceramic particles

The invention relates to a method for preparing selectively enhanced aluminum-based composite from ceramic particles and belongs to the field of metal matrix composites (MMCs). The preparation method comprises the following steps: firstly, preparing porous ceramic blanks; and secondly, putting the porous ceramic blanks at a part needing to be enhanced, injecting molten alloy into a mould at 750-1,100 DEG C, applying pressure of 20-50MPa to forcibly fill the molten alloy into the porous ceramic blanks and a mold cavity, and solidifying, thus obtaining the selectively enhanced aluminum-based composite. The method has the advantages that a foaming technology, an injection molding and a gel casting process are combined, thus leading the porous ceramic blank to have designability; the MMC reinforcement and an aluminum matrix are integrally formed by adopting extrusion casting process, thus fully playing the advantages of high strength and high toughness of the aluminum matrix and wear resistance of the MMC reinforcement. The composite has the advantages of high thermal conductivity, good radiation capability, excellent wear resistance and light weight.

Owner:UNIV OF SCI & TECH BEIJING

Fat-reducing and weight-losing composite and preparation method thereof

InactiveCN101698028AGood treatment effectAct quicklyMetabolism disorderPlant ingredientsMedicineCurative effect

The invention discloses a functional composite which is prepared by plant raw materials and a preparation method thereof, in particular to a fat-reducing and weight-losing composite and preparation method thereof. The composite comprises the following raw materials: medlar, glossy privet fruit, cassia seed, haw, rehmannia and astragalus. The composite can be prepared into any one of normal oral formulations, remarkably treats and prevents fatness, has the total effective rate to the fatness more than 98%, has no rebound, and is suitable for fat persons and fashionable persons who want to keep fit.

Owner:苏庆文

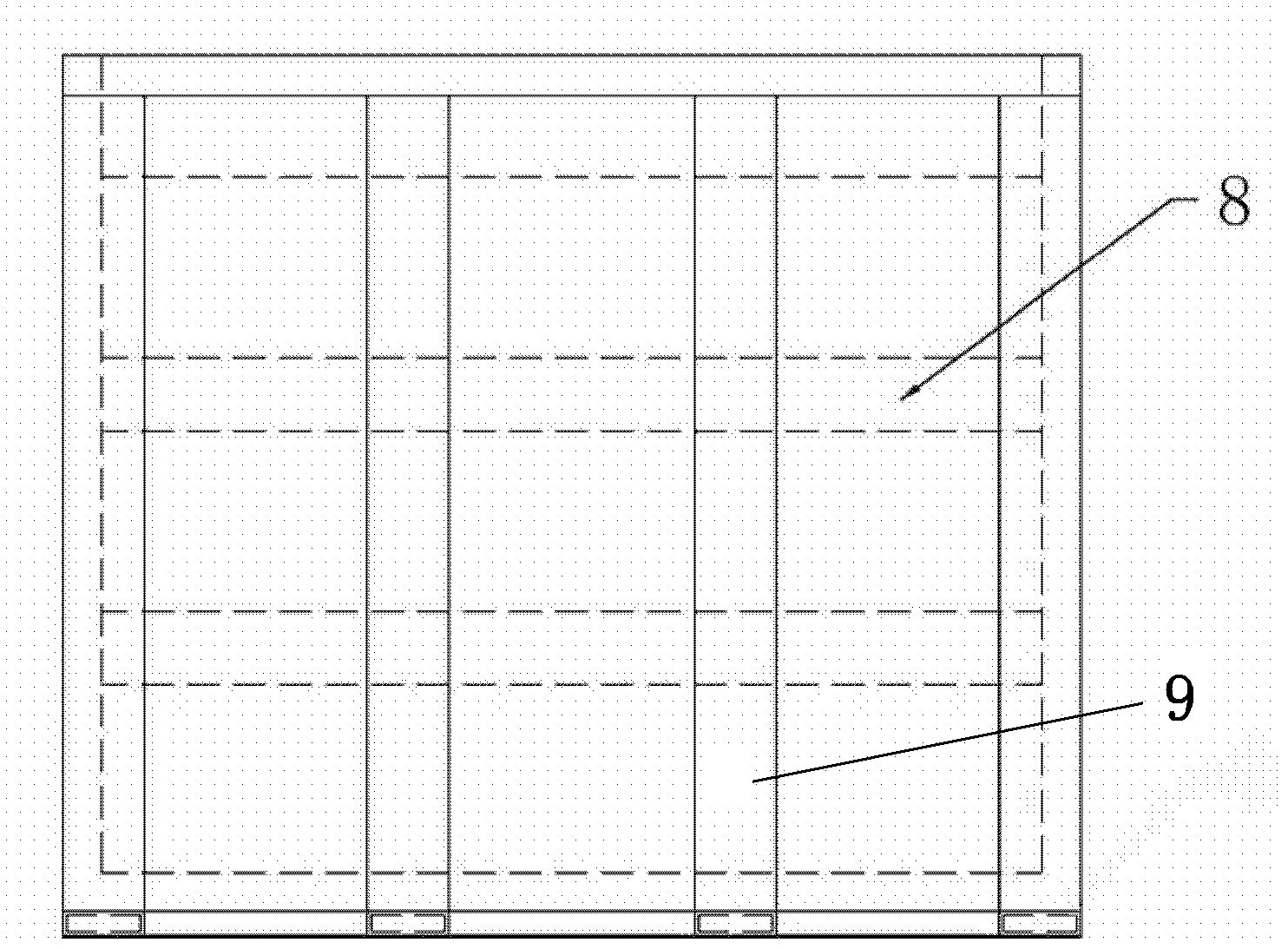

Magnesium alloy cellular board and manufacturing technique

InactiveCN101269553AImprove efficiencySolving the problem of overweight structuresVehicle componentsThin material handlingHigh intensityHoneycomb like

The invention relates to a magnesium alloy cellular plate and a production process thereof, the magnesium alloy cellular plate is formed by an upper panel, a lower panel, and a cellular core construction which are adhered and connected together, and is characterized in that magnesium alloy sheets are rolled to make the upper panel and the lower panel, the cellular core structure is a regular hexagon cellular-shaped structure which is made of magnesium alloy foil material through the processes of rolling, cutting, plastic bending precision molding, and positioning bonding. The magnesium alloy cellular plate has the advantages of high intensity and ultra-light weight, and can be widely used as the parts such as the wall plate, the floor plate, and the partition, etc. in the transportation equipment such as the spacecraft, the aircraft, the light high-speed train, and the urban rain train, etc., and the obvious weight-loss effect is achieved.

Owner:DALIAN JIAOTONG UNIVERSITY +1

Plant weight-losing and fat-reducing composite compatible to L-carnitine

ActiveCN103055057AAvoid absorptionReduce intakeOrganic active ingredientsMetabolism disorderNatural productTartrate

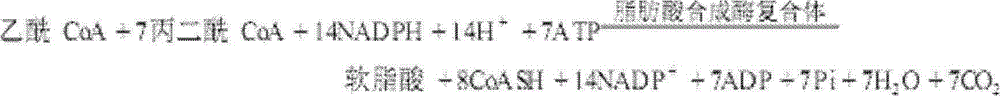

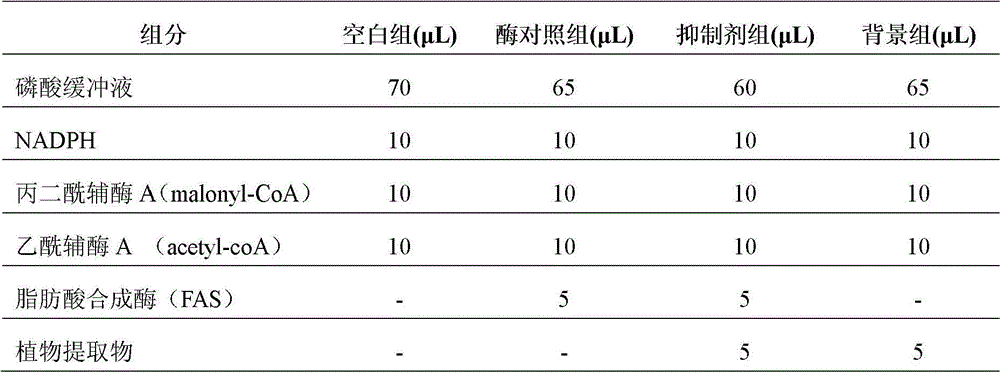

The invention provides an L-carnitine combination formula with weight-losing and fat-reducing efficacy and a method for screening the L-carnitine combination formula. A weight-losing and fat-reducing composite which has compatibility effect with L-carnitine is obtained by screening natural products and extracts by taking a triacylglycerol enzyme, amylopsin, fatty acid synthetase, an auxiliary enzyme B as target spots. An optimal composite formula comprises lotus leaves, folium llicis latifoliae, hawthorns, rhizoma alismatis extracts, the L-carnitine, or L-carnitine tartrate and related auxiliary materials. The weight-losing and fat-reducing composite comprises the following components respectively by weight percent (with usage amount in parts by weight): 2%-20%, 1%-15%, 5%-25%, 2%-20%, 20%-85% and 0.5%-10%. The weight-losing and fat-reducing composite provided by the invention is conductive to reducing the redundant fat inside a body and can be used for accelerating the breakdown of the fat inside the body, transforming the fat into energy and inhibiting the absorption of an organism on the fat and saccharide, thereby achieving the purposes of naturally controlling and reducing the weight.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES +1

Seasoning fruit and vegetable powder

InactiveCN104305054AReduce intakeObvious weight loss effectVitamin food ingredientsAcidic food ingredientsAdditive ingredientDigestion

The invention discloses seasoning fruit and vegetable powder. Natural plants with the antiobesity effect are used as raw materials, and the low-temperature extraction and biological enzymolysis technologies are adopted to preserve the effective ingredients to the largest extent; on the basis of the conventional fruit and vegetable powder, antiobesity factors with better antiobesity effect, such as dietary fibers, plant extracts, tea extracts, spice extracts, Chinese herb extracts, probiotic powder, beneficial factors and bamboo charcoal powder, are scientifically compounded, nutrient substances with the antiobesity effect, such as albumen powder, malt extracts and wheat malt powder, are further compounded, and compound amino acid, vitamins, minerals and other nutrients are added. Mainly aimed at various purposes of achieving satiety, adjusting bacterial colonies in the stomach and the intestines, preserving health through traditional Chinese medicines, and suctioning and discharging fat, the seasoning fruit and vegetable powder can maintain and improve the self-adjusted digestion and absorption levels and capacities of human bodies, reduce fat ingestion and secondary synthesis pathways of human bodies, have no effects on normal nutrient digestion and metabolism levels of human bodies, and achieve a virtuous circle for health preservation and weight loss.

Owner:天津天绿健科技有限公司

Traditional Chinese medicine tea capable of losing weight

InactiveCN104248727ACombination scienceObvious weight loss effectMetabolism disorderTea substituesAdditive ingredientLicorice roots

The invention provides a traditional Chinese medicine tea capable of losing weight, which comprises the following ingredients by weight ratio: 10-20g of exocarpium benincasae, 10-15g of cassia seed, 10-15g of haw, 8-10g of coix seeds, 8-10g of lotus leaf, 5-8g of Poria cocos, 5-8g of dried orange peel and 4-6g of honey-fried licorice root. The traditional Chinese medicine tea has advantage of scientific composition compatibility, the physical function can be naturally recovered by promoting metabolism, invigorating energy and invigorating spleen, so that normal metabolism can be realized, and the purpose of reducing fat can be reached, the tea capable of losing weight can be taken as a beverage for long-term administration, and has obvious fat-reducing effect.

Owner:QINGDAO UNITED INNOVATION TECHN SERVICES PLATFORM

Diet tea

The invention discloses diet tea which is prepared from the following traditional Chinese medicine herbs in parts by weight: 50 parts of diet tea, 20 parts of cortex albiziae, 10 parts of Chinese-date, 5 parts of the fruit of Chinese wolfberry, 5 parts of white mustard seeds, 5 parts of honeysuckle, 3 parts of folium artemisiae argyi, 3 parts of dry ginger, 3 parts of hawthorn, 3 parts of myrrh, 3 parts of cynanchum glaucescens, 3 parts of semen euryales, 2 parts of red ginseng, 2 parts of Chinese violet, 2 parts of oldenlandia diffusa, 2 parts of poria cocos and 2 parts of oriental wormwood. The diet tea disclosed by the invention is safe and reliable, free of harm to human body digestive systems and absorption systems and free of toxic and side effects, can nourish qi and blood and prompt normal metabolism of human bodies, and at the same time has the effects of lowing cholesterol and blood fat; the lose weight effect is remarkable, the weight is unlikely to rebound after people stop taking the diet tea; meanwhile the raw materials of the diet tea are cheap and easy to access, so that the diet tea has the advantage of low cost, and is applicable to popularization to the market.

Owner:ZHENGZHOU UNIV

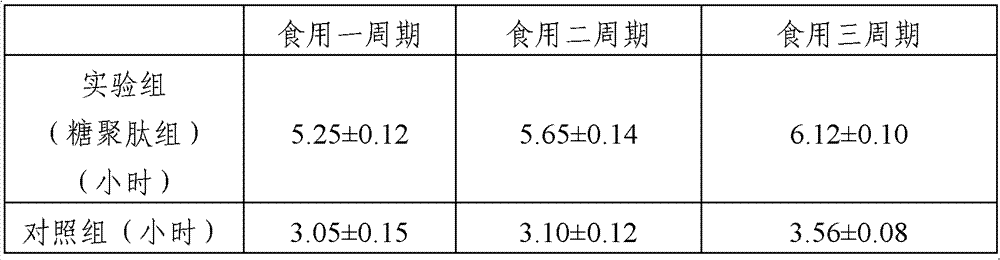

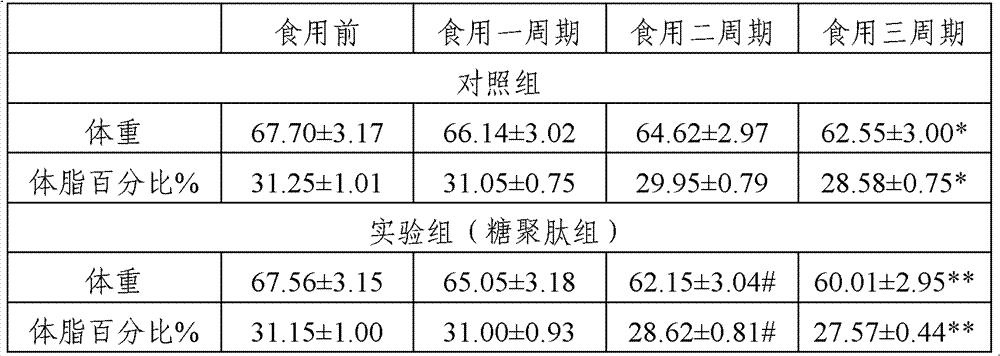

Composition for weight reduction and its preparation method and use

The invention provides a composition for weight reduction and its preparation method and use. The composition for weight reduction comprises: by weight, 15 to 45 parts of dietary fibers, 10 to 40 parts of protein powder, 1 to 40 parts of carbohydrate and 1 to 5 parts of casein glycomacropeptide. The composition for weight reduction comprises casein glycomacropeptide having the specific ratio and thus retention time of foods in the stomach is prolonged and gastric emptying time is delayed so that the frequency and the amount of food taking caused by hunger sensation are controlled and weight reduction is realized easily. Through the synergistic effect of the dietary fibers and casein glycomacropeptide, the composition for weight reduction can obviously prolongs satiety time. The composition for weight reduction can be used as weight-reduction meal replacement powder to replace a lunch food or a dinner food so that good weight reduction effects are obtained.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

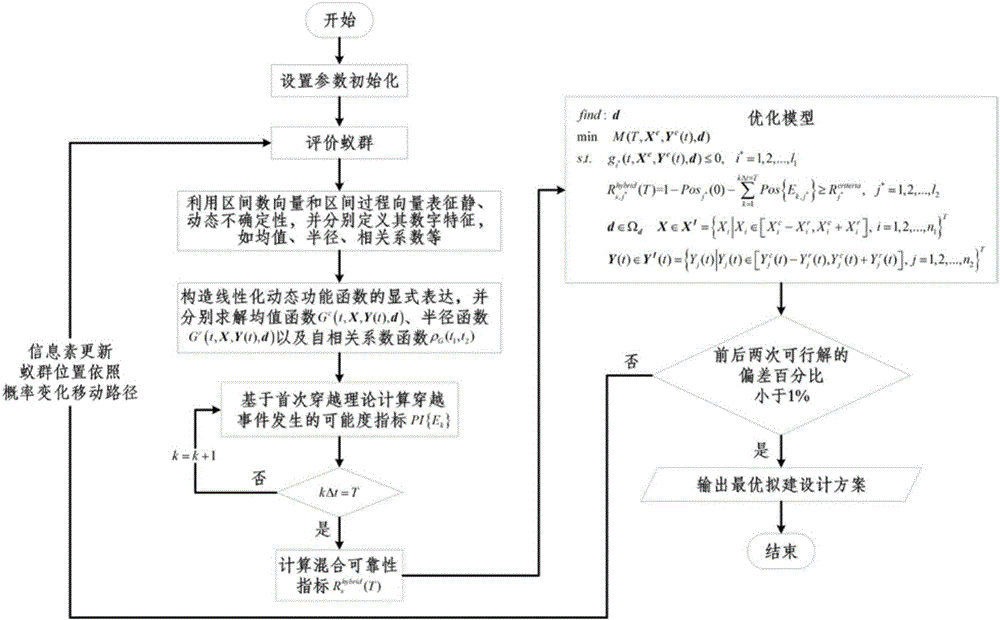

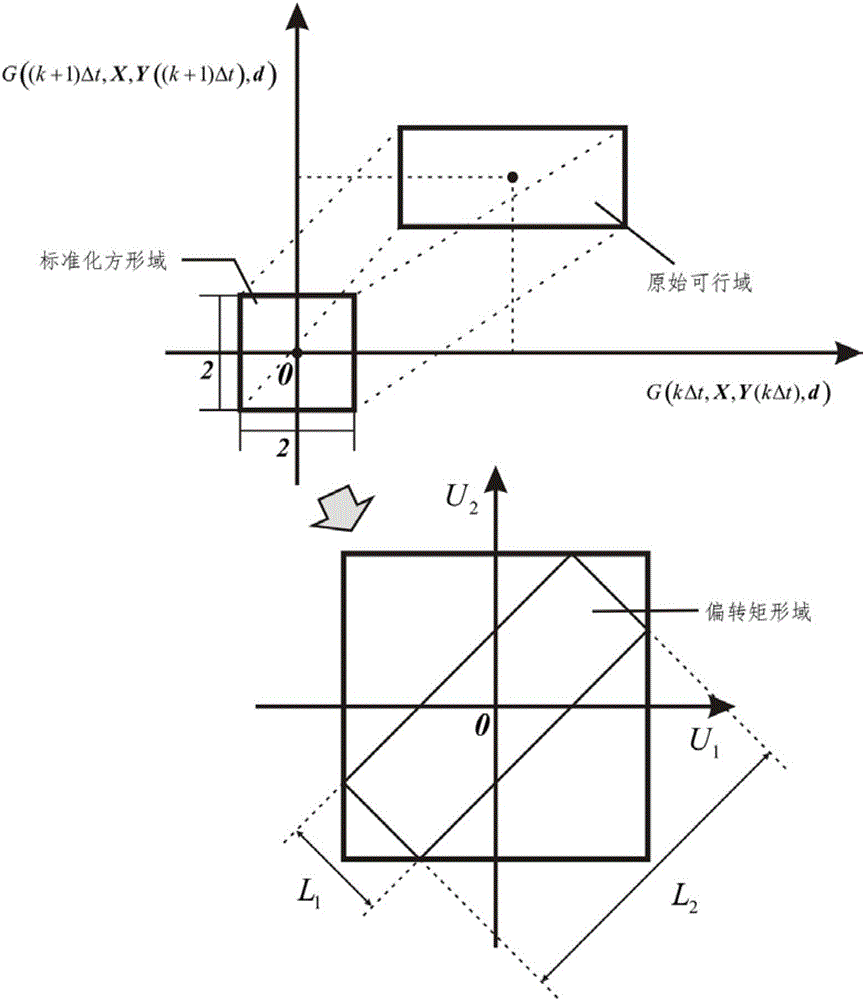

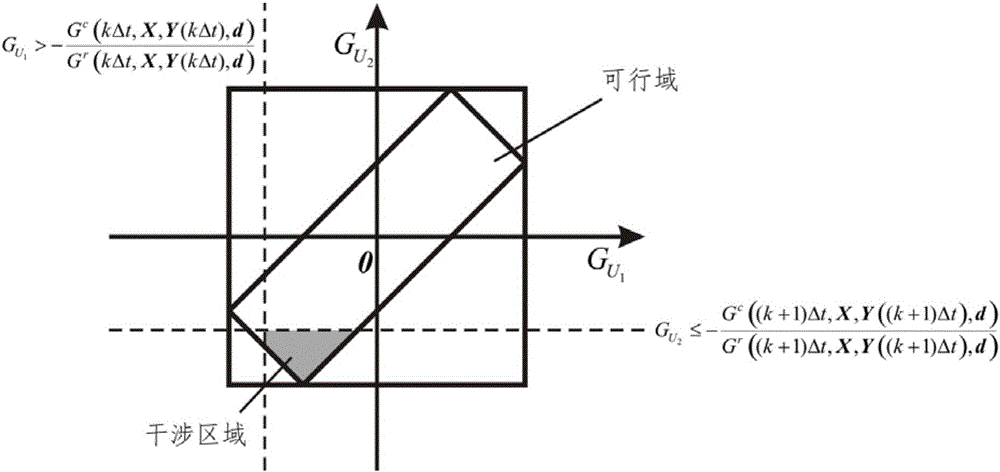

Static and dynamic hybrid uncertainty-oriented non-probabilistic reliability optimization design method for ready-built structure

InactiveCN105956336AObvious weight loss effectMake up for and perfect limitationsGeometric CADProbabilistic CADResponse processDependability

The invention discloses a static and dynamic hybrid uncertainty-oriented non-probabilistic reliability optimization design method for a ready-built structure. According to the method, multisource uncertainty conditions in an actual engineering structure are comprehensively considered, a quantitative index for effectively assessing the safety performance of the structure in a full-life period by static and dynamic hybrid uncertainty parameters is established, and the non-probabilistic reliability optimization of the ready-built structure is finished by taking the quantitative index as a design constraint condition. The method comprises the steps of firstly, reasonably representing an intrinsic law of static and dynamic hybrid uncertainty by utilizing an interval number and an interval process; secondly, constructing a dynamic function based on a response process of the ready-built structure in combination with an interval mathematic operation rule, and defining and analyzing a digital characteristic of the function by virtue of a discretization means; thirdly, defining and giving out an explicit expression of a hybrid reliability index of the structure by utilizing a first-passage theory; and finally, establishing a hybrid reliability-based non-probabilistic reliability optimization model of the ready-built structure, and performing quick iteration and robust solving of an optimization process in combination with an intelligent ant colony algorithm.

Owner:BEIHANG UNIV

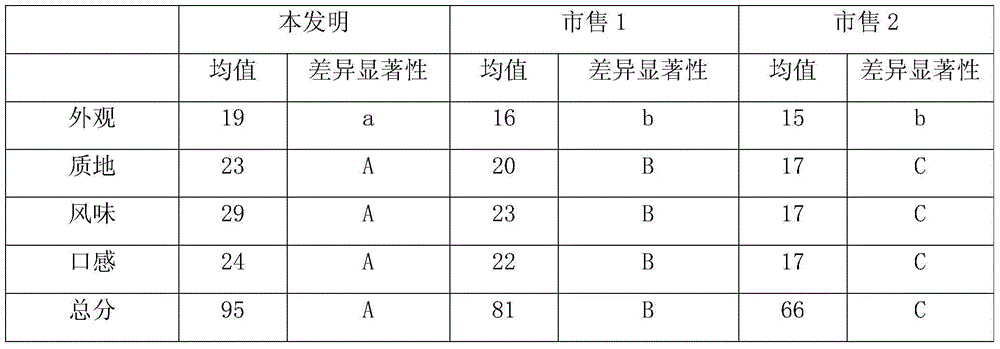

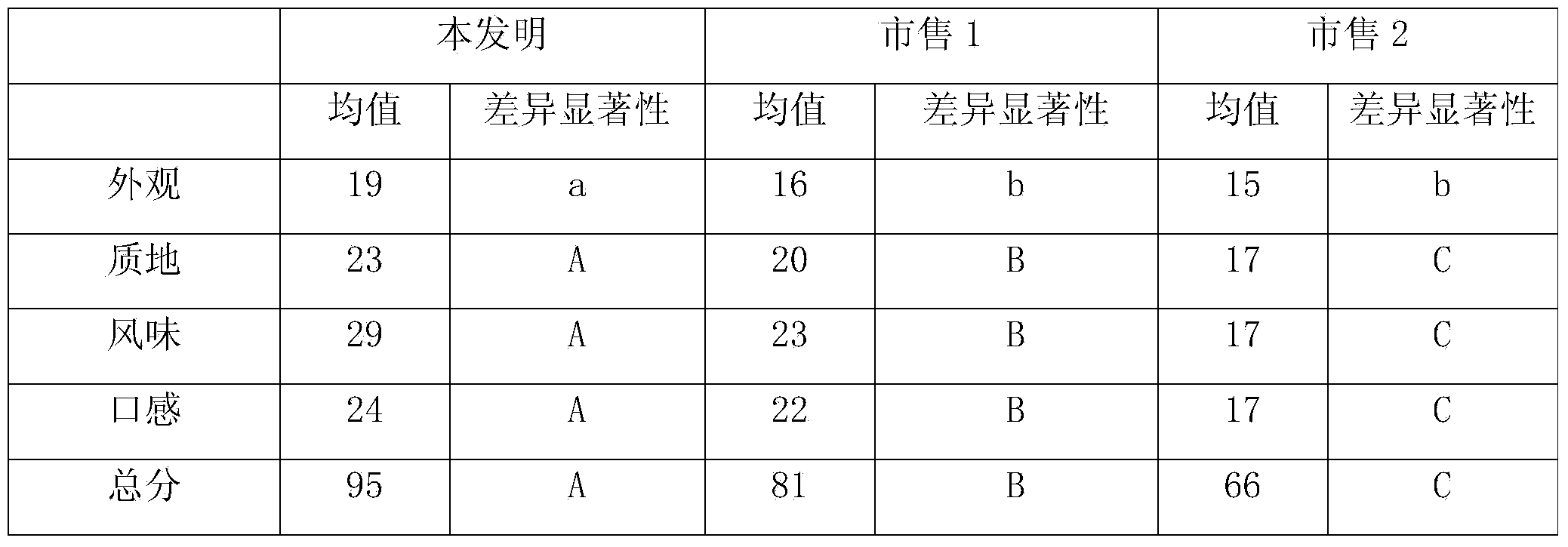

Diet yogurt and preparation method thereof

The invention provides a diet yogurt. The diet yogurt comprises the following components in part by weight: 80 to 120 parts of skimmed milk, 15 to 25 parts of cassia occidentalis, 5 to 15 parts of smoked plum, 5 to 15 parts of plantain seed, 5 to 15 parts of lotus leaf, and 5 to 15 parts of hawthorn. The diet yogurt also comprises 10<6> to 10<9> cfu / ml of probiotics. The invention also provides a preparation method for the yogurt. The diet yogurt is rich in nutrition, raw materials are common, and by combination of the cassia occidentalis, the lotus leaf, the plantain seed, the smoked plum and the hawthorn, the diet yogurt has the effect of reducing blood sugar if the yogurt is drunk for a long time. The diet yogurt has a scientific formulation, has the effect of protecting pancreas islet, improving glycome metabolism and reducing sugar absorption, and therefore has the remarkable effect of reducing blood sugar.

Owner:MASHI MANOR NANJING FOOD

Multi-effect weight-losing health-care product

InactiveCN102578576AObvious weight loss effectWith hypolipidemicPre-extraction tea treatmentFood preparationGynostemmaMulti effect

The invention discloses a multi-effect weight-losing health-care product which comprises the following raw materials in parts by weight: 15-30 parts of hawthorn, 5-10 parts of chrysanthemum, 5-10 parts of balsam pear, 5-10 parts of fructus aurantii, 10-20 parts of cassia seed, 5-10 parts of rhizoma alismatis, 1-8 parts of root of red-rooted salvia, 1-8 parts of lotus leaf, 1-8 parts of liquorice, 1-3 parts of red date, 1-5 parts of pericarpium citri reticulatae and 1-5 parts of gynostemma pentaphylla. According to the above mode, the multi-effect weight-losing health-care product has a good weight losing effect and also has the advantages of lowering blood fat, lowering blood sugar and enhancing the immunity of human bodies.

Owner:苏州爱斯欧蒂生物科技有限公司

High efficiency weight reduction medicine or health-care food

InactiveCN1406622AImmunomodulatoryImmune regulationMetabolism disorderUnknown materialsWeight decreasingCholesterol

Owner:北京中科天鹤生物技术有限公司

Composite board and preparation method thereof, and dumper compartment

InactiveCN103010316AAddressing Layered FailuresSolve wear resistanceSynthetic resin layered productsWood layered productsEngineeringPolydicyclopentadiene

The invention discloses a composite board which comprises two skin layers, wherein an intermediate layer is formed between the two skin layers and an inner stiffening beam is arranged between the two skin layers, a core material is filled in the intermediate layer, an outer stiffening beam is arranged between the core material and at least one skin layer, and a polydicyclopentadiene layer is arranged outside the at least one skin layer. The invention also discloses a preparation method of the composite board. The invention further discloses a dumper compartment comprising the composite board. The dumper compartment has the characteristics of strong bearing capacity, remarkable weight reducing effect, oil consumption saving, carbon dioxide emission reducing, long service life and the like.

Owner:蓝星环境工程有限公司

Diet tea with corn stigma

InactiveCN103493924ALow priceObvious weight loss effectPre-extraction tea treatmentAnimal scienceLycium barbarum fruit

The invention discloses diet tea with corn stigma. The diet tea with the corn stigma is made of raw materials including, by weight, 100 parts of the corn stigma, 7-18 parts of parched semen cassiae, 5-12 parts of fructus crataegi, 1-10 parts of green tea, 1-8 parts of neroli, 0.5-8 parts of stevia rebaudiana, 1-8 parts of roses, 1-9 parts of radix ophiopogonis, 3-12 parts of peach kernel, 2-10 parts of lotus leaves and 3-12 parts of lyceum barbarum. Since the corn stigma is taken as the main raw material matching with the semen cassiae, the fructus crataegi, the green tea, the neroli, the stevia rebaudiana, the roses, the radix ophiopogonis, the peach kernel, the lotus leaves and the lyceum barbarum, the diet tea with the corn stigma has functions of diuretic and laxative therapies, reduction of blood fat and weight loss, is green and healthy, remarkable in weight loss effect without bounce if a person insists on drinking the diet tea for a long time, low in material cost, and especially suitable for purely obese people.

Owner:李文德

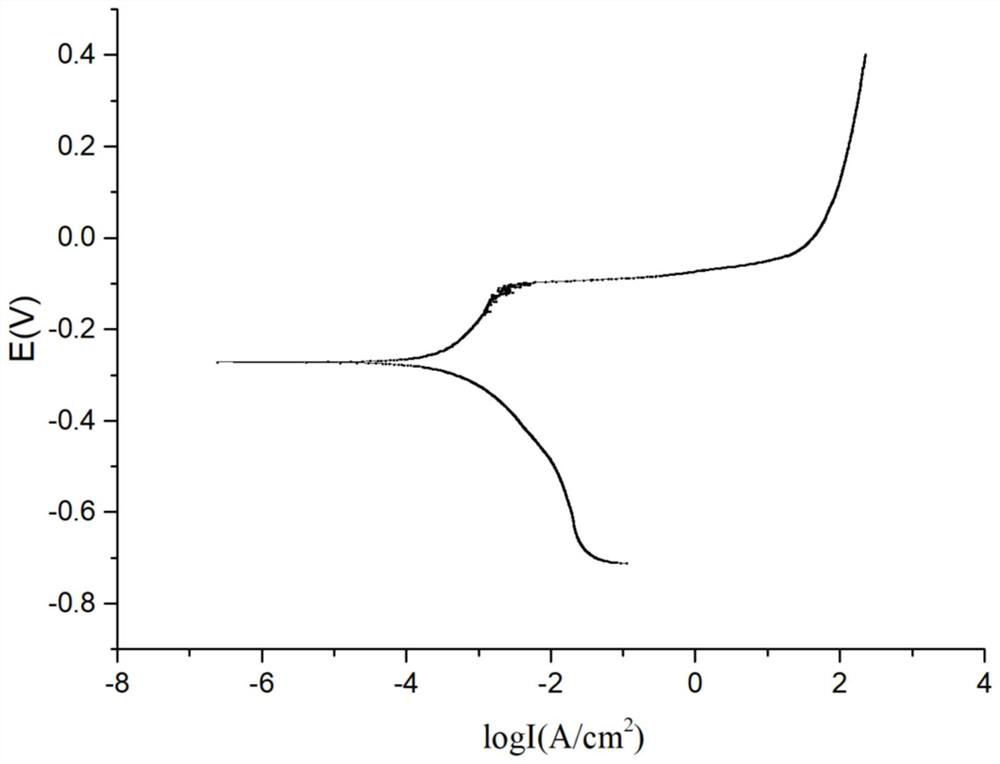

Corrosion-resistant high-strength light steel and preparation method

ActiveCN112899579AReduce consumptionLow densityMetal-working apparatusIngotUltimate tensile strength

The invention discloses corrosion-resistant high-strength light steel and a preparation method, and belongs to the technical field of alloy steel. The steel comprises the following chemical components of, in percentage by weight, 1.4wt%-1.7wt% of C, 25wt%-30wt% of Mn, 10wt%-12wt% of Al, 3wt%-5wt% of Cr, 0.05wt%-0.1wt% of Nb, less than or equal to 0.003wt% of S, less than or equal to 0.003wt% of P and the balance Fe and inevitable impurities. The preparation method comprises the following steps that a vacuum induction furnace is adopted for smelting, a cast ingot is manufactured through casting, and the cast ingot is homogenized for 10 hours-15 hours at the high temperature of 1100 DEG C-1200 DEG C; the cast ingot is subjected to homogenization treatment and then forged into a square billet; the forging stock is heated to 1180 DEG C-1200 DEG C, and the temperature is maintained for 2 hours-4 hours; 5 passes-8 passes of hot rolling are conducted on the homogenized forging stock, the forging stock is water-cooled to the room temperature, and the corrosion-resistant high-strength light steel is obtained; and the density of the steel is smaller than 6.5 g / cm < 3 >, the yield strength is 1000 MPa-1200 MPa, the tensile strength is 1100 MPa-1300 MPa, the ductility is larger than 20%, and the steel has corrosion resistance superior to that of common steel and has wide application potential in the fields of automobiles, ships, hydropower, wind power and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of weight-reducing fruit and vegetable powder

InactiveCN104381884AReduce intakeObvious weight loss effectFood shapingFood preparationDigestionHydrolysis

The invention discloses a preparation method of weight-reducing fruit and vegetable powder. Natural plants with weight-reducing effects are taken as raw materials, and effective constituents in the raw materials are kept to the greatest extent by adopting a low-temperature extraction and biological hydrolysis technology; weight-reducing factors with relatively good weight-reducing effects such as dietary fibers, a plant extract, a tea extract, a spice extract, a Chinese herbal medicine extract, probiotics powder, probiotics factors and bamboo charcoal powder are scientifically compounded based on the existing fruit and vegetable nutrition powder; meanwhile, nutrient substances with weight-reducing effects such as protein powder, a malt extract and wheat malt flour are compounded, and nutrients such as compound amino acid, vitamins and minerals are added, so that from multiple angles of regulating of flora of stomach and intestines, preserving health by traditional Chinese medicines, absorbing and eliminating fat, and the like, the self-regulating level and capability of digestion and absorption of a human body are kept and improved, the uptake and secondary synthetic route of the body fat are reduced, the normal nutrient substance uptake and metaboilic level of the human body is not affected, and virtuous cycle of health weight reducing is realized.

Owner:天津天绿健科技有限公司

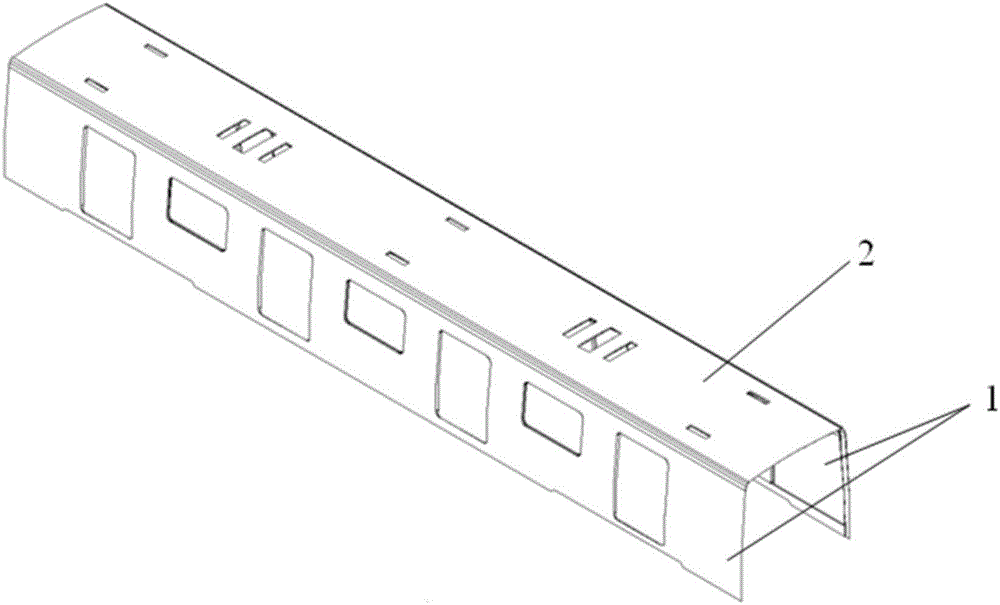

Vehicle body structure for railway vehicle and forming method

InactiveCN106379347ASimplify the assembly processHigh dimensional accuracyRailway roofsAxle-box lubricationFiberHeat-affected zone

The invention relates to a vehicle body structure for a railway vehicle. The side walls and the vehicle top are integrated in the vehicle body; the vehicle body is in the form of a sandwich structure with paper honeycomb core material filled between inner and outer carbon fiber coverings; the inner and outer carbon fiber coverings of the vehicle body, including the intersecting areas of the side walls of the vehicle body and the vehicle top, all have carbon fiber pre-soaked material continuous paving forming structures; overlapping areas are arranged at the edge of all paving layers of the carbon fiber pre-soaked materials. According to the invention, the side walls and the vehicle top in the vehicle body structure are integrated, so that the overall size precision of the vehicle body structure is increased and the assembling technical process of the vehicle body structure is simplified; connecting welding lines between the side walls and the vehicle top in the traditional metal vehicle body can be effectively avoided; the influences of welding heat affected zone and residual stress can be eliminated; the overall strength and rigidity of the vehicle body structure can be increased; the weight of the vehicle body can be effectively reduced; compared with the traditional metal vehicle body structure, the vehicle body structure has the advantages that the weight reduction effect is obvious and the vehicle body structure can meet the design requirements for the lightweight vehicle body structure of the railway vehicle at present.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

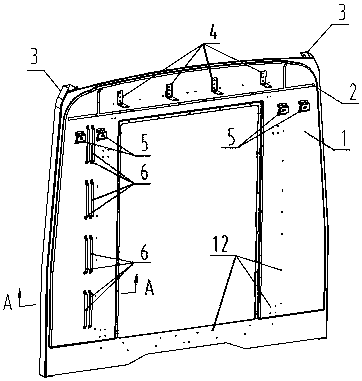

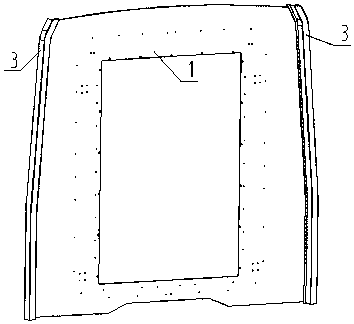

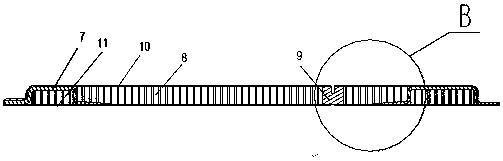

Manufacturing method of composite material cabin door of foam sandwich structure

A manufacturing method for a foam sandwich structure composite material hatch, the technical points of which include designing and optimizing the overall structure and layering of the hatch, completing the design and manufacture of molds, selecting fiber cloth and according to the size of the actual product According to the requirements, the material is cut, the foam material and embedded parts are selected, and the preparation of the prefabricated body is completed. The release cloth, the flow guide net and the glue injection support are laid in sequence on the inner skin cloth, and the air duct is fixed around the prefabricated body. Cover with sealing tape and vacuum bag film, connect the exhaust pipe and carry out process combination, vacuumize at room temperature, prepare the required resin in the material barrel, introduce the resin into the prefabricated body, and after the resin infiltrates the fiber, according to the curing process of the resin, room temperature or Heating and curing, after curing, cool down to room temperature naturally, turn off the vacuum system, and post-process the parts after demoulding; this technical solution has obvious weight reduction effect, strong designability, stable product shape and size, excellent thermal insulation performance, and good damping The noise reduction performance is obvious.

Owner:AVIC COMPOSITES

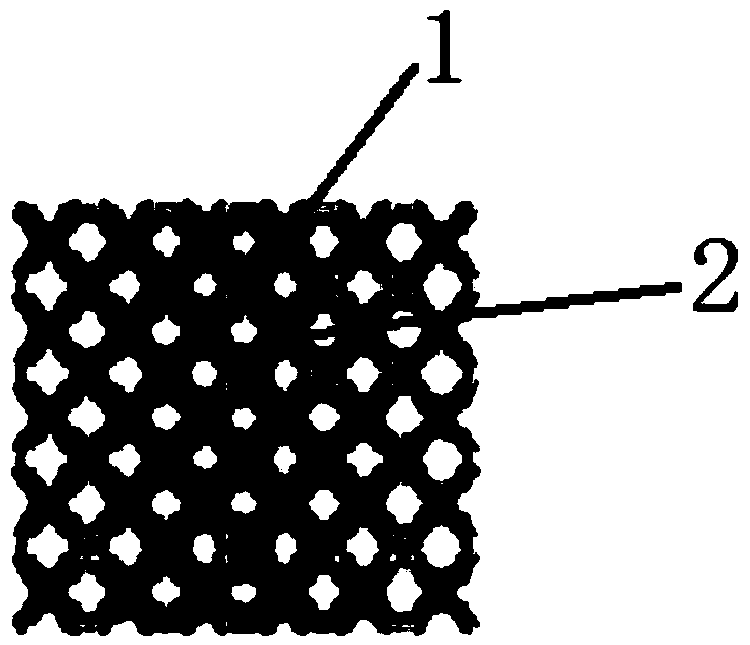

Metal bone trabecula and bone implant comprising metal bone trabecula

PendingCN107647941AMeet the stiffnessMeet the intensityBone implantJoint implantsHuman bodyBone Trabeculae

The invention discloses a metal bone trabecula. The metal bone trabecula comprises at least three crossed metal bone trabecula supports, a micro-topological grid structure is embedded into the metal bone trabecula, and at least three intersection points are formed between the micro-topological grid structure and the metal bone trabecula supports. The bone trabecula is formed by regularly or irregularly arranging hollowed-out unit structure bodies in a three-dimensional space, the weight reducing effect is obvious, meanwhile, the requirement of rigidity and strength of different areas of partscan be met at the same time, stress shielding is avoided, and good matching of high strength and high weight reduction ratio can be achieved; in addition, after growing into the bone trabecula structure comprising a micro-topological grid, human body sclerotin can be fused with bone, bone ingrow can be induced to the largest extent, and accordingly long-term biological fixation of a prosthesis canbe achieved. Meanwhile, the invention further discloses a bone implant comprising the metal bone trabecula. The bone implant can achieve personalized customization through 3D printing, the process issimplified, and the economic cost is greatly reduced.

Owner:GUANGZHOU HUATAI 3D MATERIAL MFG TECH CO LTD

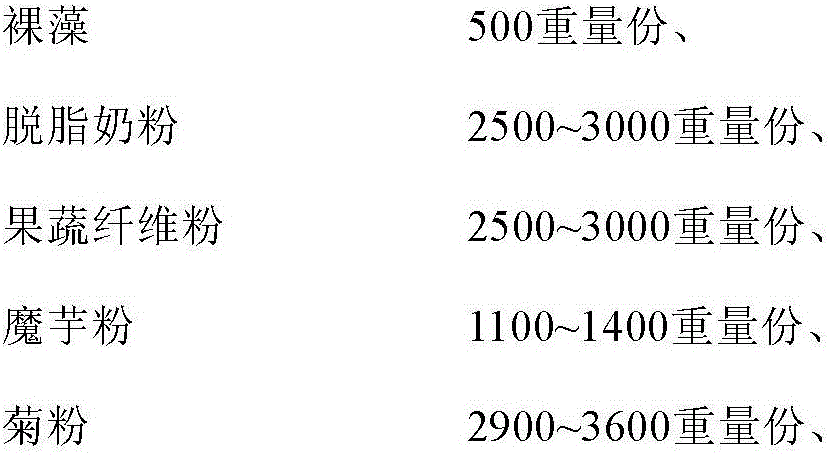

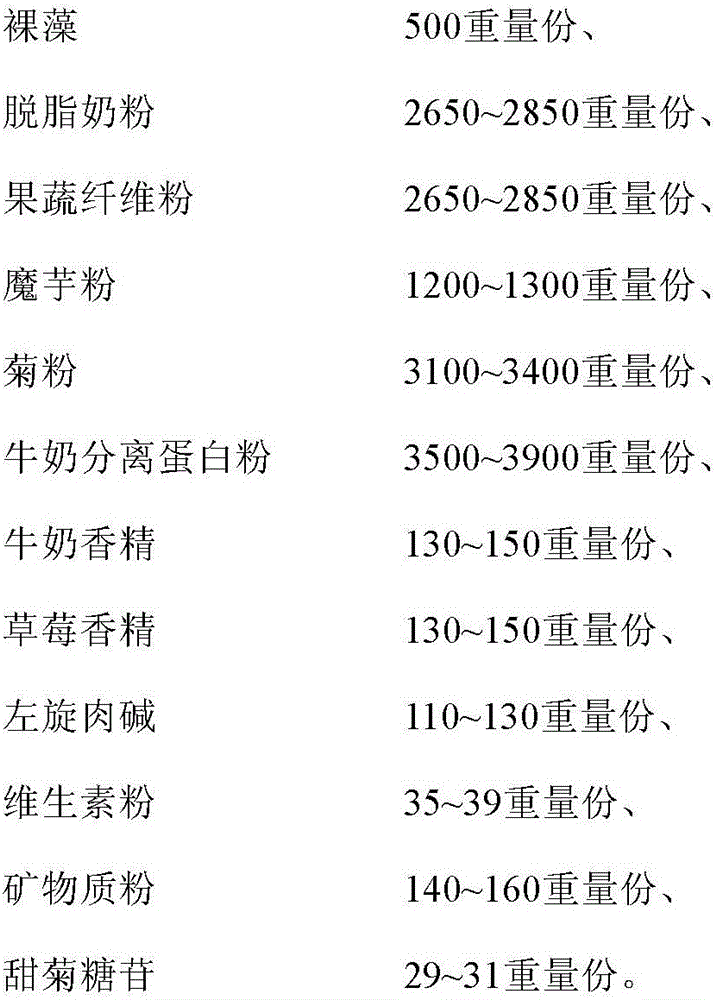

Protein dietary fiber meal replacement powder and preparation method thereof

InactiveCN106261439AObvious weight loss effectNo hungerVitamin food ingredientsFood ingredient functionsFiberMeal replacement

The invention relates to protein dietary fiber meal replacement powder and a preparation method thereof. The dietary fiber solid beverage is prepared from the following ingredients of euglena, skim milk powder, fruit and vegetable fiber powder, Konjac flour, inulin, vitamin powder, mineral substance powder and the like. The protein dietary fiber meal replacement powder is used as a nutrition meal replacement product; the function of comprehensively supplementing the human body nutrition can be realized at low quantity; in addition, the excellent technical effects shown by the specification of the invention can be shown, for example, the protein dietary fiber meal replacement powder shows the excellent function characteristics such as the excellent fat losing effects and no hunger sense.

Owner:SHENZHEN WANHE PHARMA

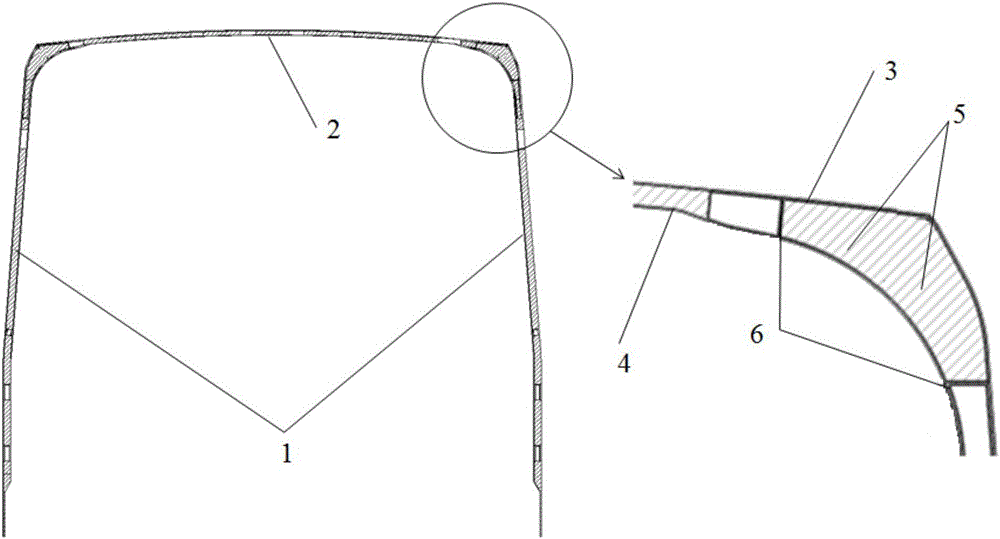

Carbon fiber composite end wall structure for subway

InactiveCN107792103AHigh specific strengthObvious weight loss effectAxle-box lubricationRailway bodiesAdhesiveHoneycomb

The invention provides a carbon fiber composite material end wall structure for subway, which includes an end wall interlayer structure, a grounding copper bar, a drainage pipe, a wiring trough installation hanger, an electrical cabinet installation seat and a cable tie rod. The end wall interlayer structure includes an integral reinforcement frame, Honeycomb sandwich core, end wall inserts, inner skin and outer skin, the overall reinforcement frame, honeycomb sandwich core, and end wall inserts are all built between the inner skin and outer skin, and the overall reinforcement frame adopts an integrated hat-shaped structure , the two sides of the overall reinforced frame are respectively provided with honeycomb sandwich, the end wall inserts are set in the honeycomb sandwich, the end wall inserts are provided with threaded holes, and the grounding copper bar is connected to the inner skin of the end wall sandwich structure by glue riveting The upper part of the side; this kind of carbon fiber composite material end wall structure for subway can give full play to the characteristics of high specific strength and large specific modulus of carbon fiber composite materials, and the effect of weight reduction is outstanding; the integrated design simplifies the redundant traditional welding structure , reduce the assembly workload.

Owner:HENGSHEN

Toxin-expelling and fat-eliminating tea

The present invention is making process of toxin-expelling and fat-eliminating tea with main components including lotus leaf 28-58 wt%, cassia seed 32-56 wt% and haw. The toxin-expelling and fat-eliminating tea can reduce weight, promote blood circulation and metabolism, remit fatigue and raise resistance of body to diseases.

Owner:姜继红

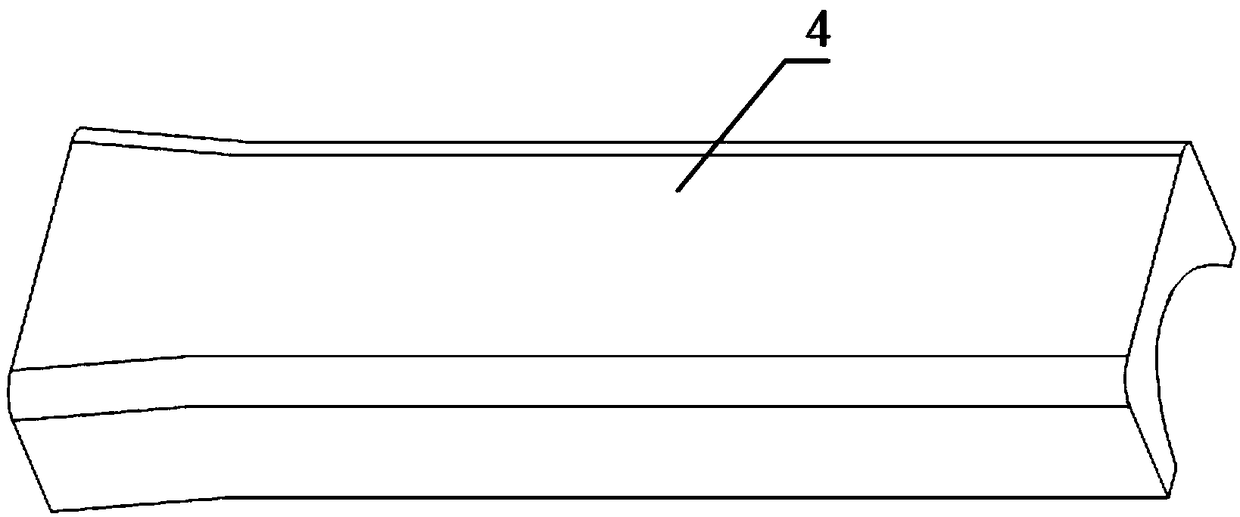

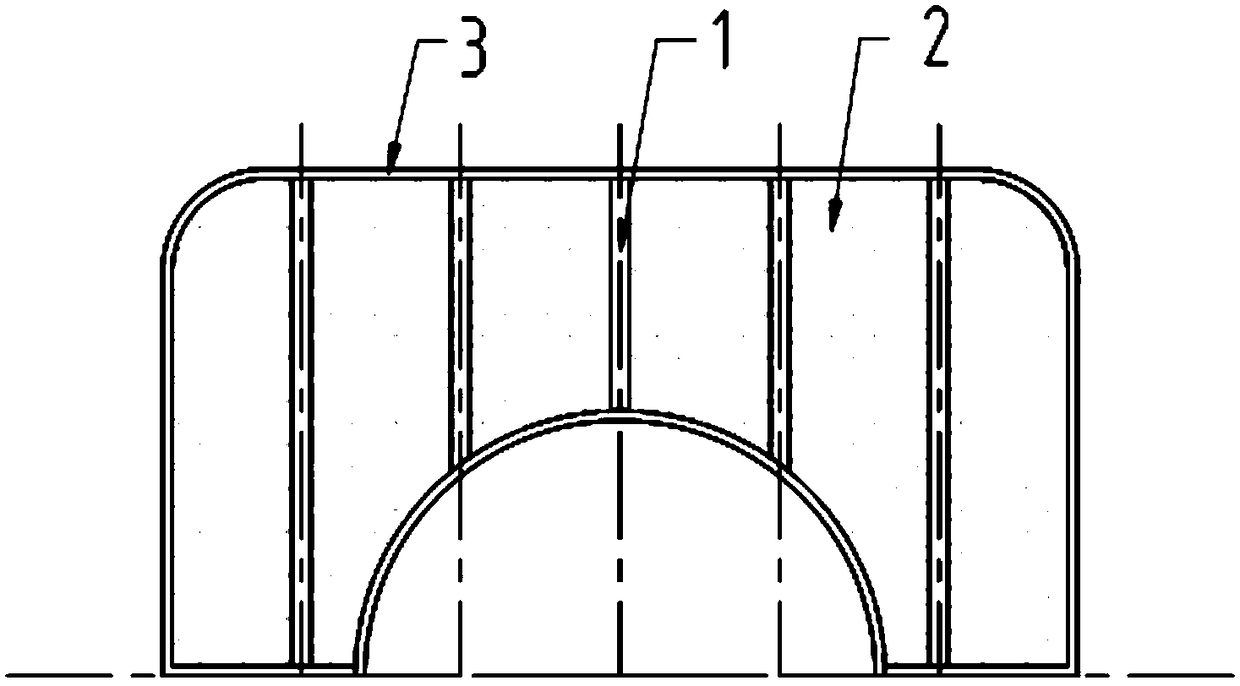

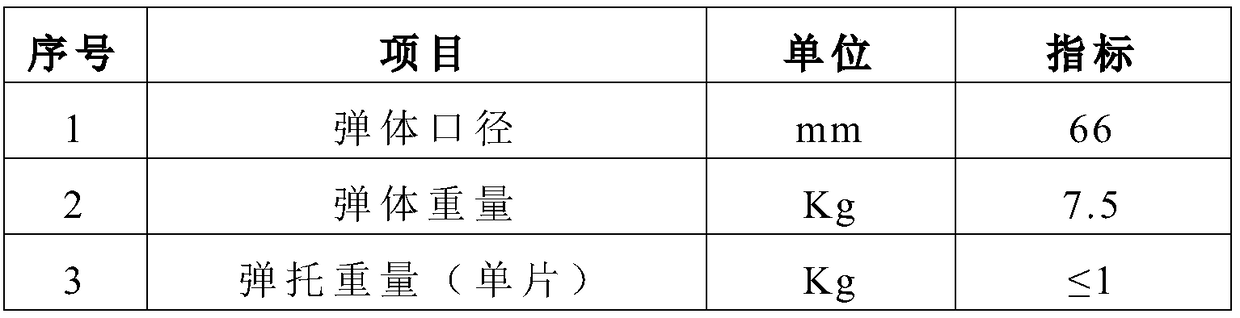

Light composite sabot and manufacturing method thereof

The invention discloses a light composite sabot and a manufacturing method thereof. The light composite sabot comprises a sabot sandwich structure and a skin laying on the surface of the sabot sandwich structure, wherein the sabot sandwich structure is manufactured by alternately bonding and processing n reinforcing ribs and (n+1) foam boards. The manufacturing method comprises the following stepsthat (1) the thickness of the skin, and the thickness and number of the reinforcing ribs and the foam boars are set; (2) the reinforcing ribs are manufactured through fiber materials A in a layer laying mode; (3) the foam boards and the reinforcing ribs are bonded together alternately through adhesives and heat and solidified into a sandwich structure blank board; (4) a sabot sandwich structure with the needed structural size are machined; (5) the skin is manufactured through fiber materials B in a layer laying mode, and the fiber materials B coated with shaping agents are laid on the surfaceof the sabot sandwich structure coated with the adhesives layer by layer, and a preformed body of the sabot is obtained; and (6) product forming is conducted through a resin transfer molding technology, and then the sabot product is obtained. According to the light composite sabot and the manufacturing method thereof, the weight reduction effect is remarkable, under the same using condition, thespeed of ammunitions is higher, and the power of the ammunitions is larger.

Owner:湖北三江航天江北机械工程有限公司

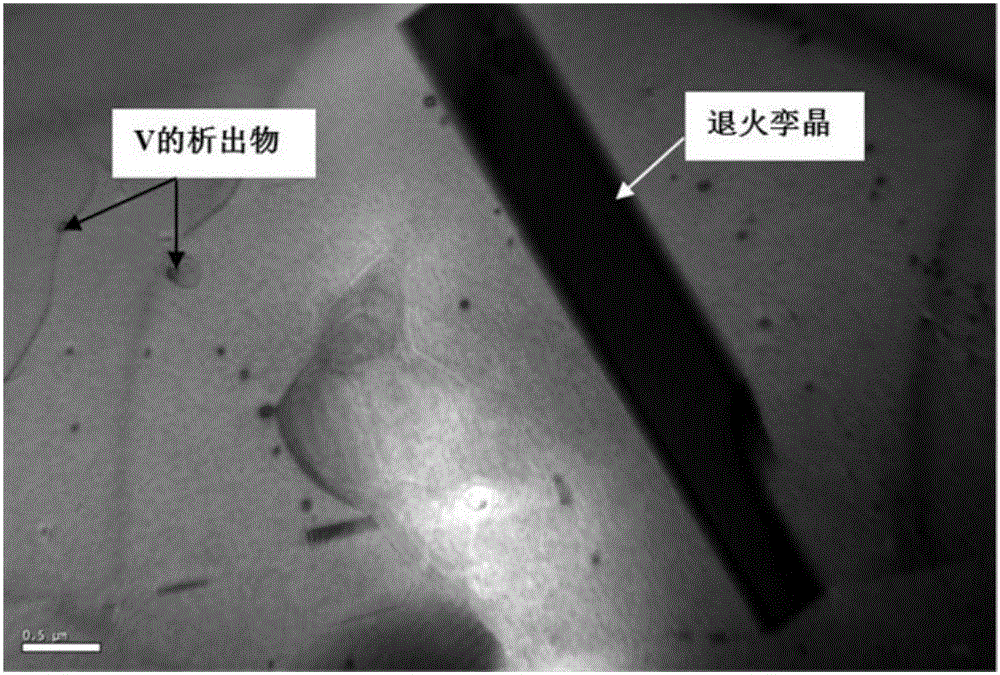

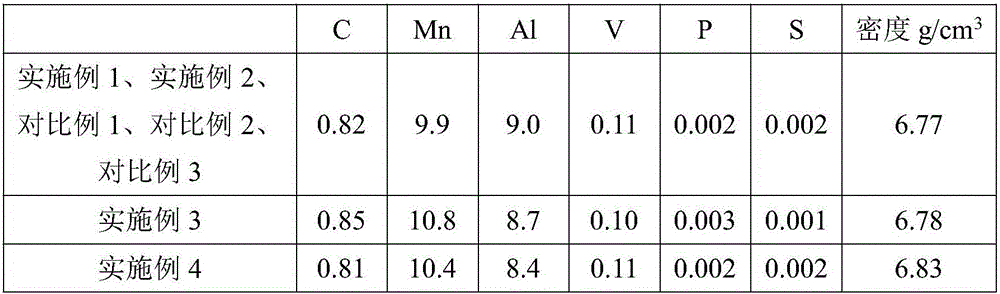

Preparation method for hot-rolled low-density steel with strength and ductility product being greater than or equal to 40 GPa.%

The invention discloses a p reparation method for hot-rolled low-density steel with the strength and ductility product being greater than or equal to 40 GPa.% and belongs to the field of metal materials. Chemical components of the hot-rolled low-density steel with the strength and ductility product being greater than or equal to 40 GPa.% comprise, by mass, 0.6-1.0% of C, 8-12% of Mn, 7-11% of Al, 0.01-0.2% of V, less than or equal to 0.003% of P, less than or equal to 0.002% of S and the balance Fe and inevitable impurities. The preparation process comprises the steps of smelting, forging, hot rolling and solid solution hardening treatment, the structure of the obtained low-density steel comprises annealing twins, precipitates of nanoscale vanadium exist in the twins, and the strengthening effect is obvious. The steel has the characteristics of low density and high strength and ductility, and the strength and ductility product is greater than or equal to 40 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

Corn high-strength flour, corn slimming noodle and preparing method

InactiveCN101341943AHigh viscosityImprove toughnessMetabolism disorderFood preparationEnzyme digestionCorn flour

The invention relates to corn high gluten flour, corn weight losing noodles, and preparation methods thereof, wherein, preparation method of the corn high gluten flour: the weight percent of all components is as follows: 18 percent to 45 percent of corn puffing powder, 50 percent to 80 percent of refined corn flour, 0.04 percent to 0.06 percent of Alpha-amylase, 0.15 percent to 0.2 percent of glucose oxidase, and 1 percent to 5 percent of neutral endotrypsin; all the components are evenly mixed by the proportion and put into a biological enzyme digestion machine to be stirred and have enzyme digestion reaction for 15min to 20min under normal temperature. In the invention, Alpha-amylase is added in the enzyme digestion reaction, so that the corn high fine meal viscosity is obviously improved, the toughness is good and the nutrition is rich; noodles prepared by mixing the corn high gluten flour and auxiliary materials has the function of losing weight.

Owner:郭洪伟

Weight reducing tea and making method thereof

InactiveCN103828954ADiet Negative EffectsDiet influencePre-extraction tea treatmentDietary habitMomordica grosvenori

The invention belongs to the technical field of healthcare foods, and particularly provides a weight reducing tea and a making method thereof. The weight reducing tea is prepared from the following components in parts by weight: 48-61 parts of lotus leaves, 43-66 parts of hawthorn, 19-36 parts of cassia seeds, 14-26 parts of rose, 9-21 parts of momordica grosvenori and 4-11 parts of leaves of broadleaf holly. The weight reducing tea disclosed by the invention has the advantages that the traditional Chinese medicine weight reducing tea does not contain fat absorption blocking agent, thus the diet of persons taking the weight reducing tea is not influenced by any negative effects, and the persons taking the weight reducing tea can keep the daily dietary habits without special forbidden foods.

Owner:裴锡平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com