Method for preparing selectively enhanced aluminum-based composite from ceramic particles

A composite material and reinforced aluminum-based technology, applied in ceramic products, applications, household appliances, etc., can solve the problem that a single aluminum-based composite material cannot meet the requirements of mechanical properties, thermophysical properties and wear resistance at the same time, and achieve heat dissipation Good performance, excellent wear resistance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

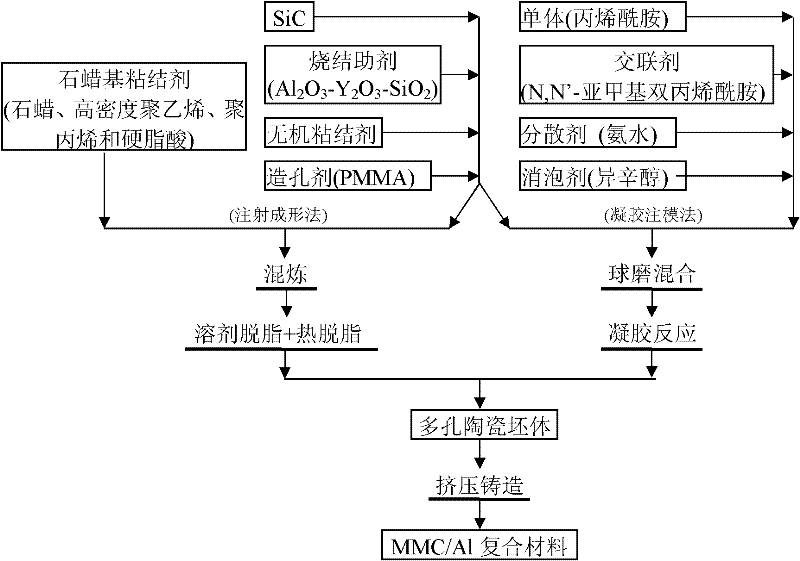

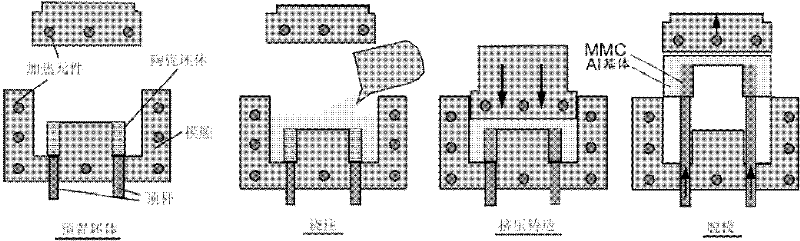

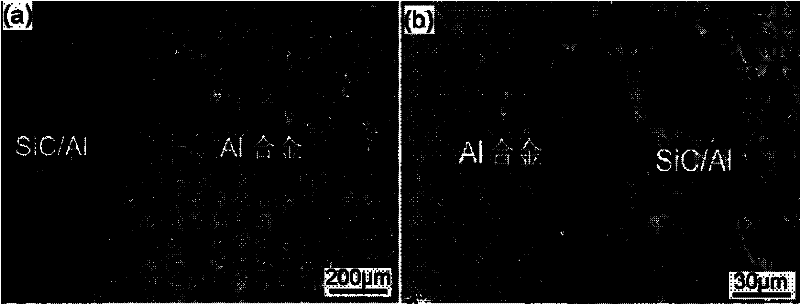

[0025] Example 1: Preparation of an aluminum-based composite material with a ceramic phase volume fraction of 35% in the MMC reinforcement

[0026] The powder raw materials are SiC particles with a particle size of 24 μm, polymethyl methacrylate (PMMA) with a particle size of 100 μm, an inorganic binder, and Al with a purity greater than 98%. 2 o 3 , Y 2 o 3 and SiO 2 powder.

[0027] Preparation of porous ceramic body: firstly, Al 2 o 3 , Y 2 o 3 and SiO 2 Al 2 o 3 -Y 2 o 3 -SiO 2 Sintering aids. Then add 10wt.% Al to SiC powder 2 o 3 -Y 2 o 3 -SiO 2 Sintering aid and 3wt.% inorganic binder (sodium silicate) to obtain mixed powder A. Next, 20% by volume of pore-forming agent PMMA was added to mixed powder A to obtain mixed powder B. The mixed powder B was mixed on a ball mill at a speed of 200 rpm for 8 hours. The mixed powder B and the polymer component paraffin-based binder (65wt.% paraffin, 15wt.% high-density polyethylene, 15wt.% polypropylene and 5 we...

Embodiment 2

[0029] Example 2: Preparation of an aluminum-based composite material with a ceramic phase volume fraction of 45% in the MMC reinforcement

[0030] The powder raw materials are SiC particles with a particle size of 40 μm, polymethyl methacrylate (PMMA) with a particle size of 300 μm, an inorganic binder, and Al with a purity greater than 98%. 2 o 3 , Y 2 o 3 and SiO 2 powder.

[0031] Preparation of porous ceramic body: firstly, Al 2 o 3 , Y 2 o 3 and SiO 2 Al 2 o 3 -Y 2 o 3 -SiO 2 Sintering aids. Then add 20wt.% Al in SiC powder 2 o 3 -Y 2 o 3 -SiO 2 Sintering aid and 2wt.% inorganic binder (sodium silicate) to obtain mixed powder A. Next, 10% by volume of pore-forming agent PMMA was added to mixed powder A to obtain mixed powder B. The mixed powder B was mixed on a ball mill at a speed of 250 rpm for 12 hours. Mixed powder B and polymer component paraffin-based binder (60wt.% paraffin, 20wt.% high-density polyethylene, 15wt.% polypropylene and 5 weight ...

Embodiment 3

[0033] Example 3: Preparation of a large-sized aluminum matrix composite material with a ceramic phase volume fraction of 45% in the MMC reinforcement

[0034] The powder raw materials are SiC particles with a particle size of 40 μm, polymethyl methacrylate (PMMA) with a particle size of 300 μm, an inorganic binder, and Al with a purity greater than 98%. 2 o 3 , Y 2 o 3 and SiO 2 powder.

[0035] Preparation of porous ceramic body: firstly, Al 2 o 3 , Y 2 o 3 and SiO 2 Al 2 o 3 -Y 2 o 3 -SiO 2 Sintering aids. Then add 10wt.% Al to SiC powder 2 o 3 -Y 2 o 3 -SiO 2 Sintering aid and 3wt.% inorganic binder to obtain mixed powder A. Next, 30% by volume of pore-forming agent PMMA was added to mixed powder A to obtain mixed powder B. The mixed powder B was mixed on a ball mill at a speed of 250 rpm for 24 hours. Mix acrylamide and N,N'-methylenebisacrylamide at a mass ratio of 24:1, and dissolve them in deionized water at a total mass concentration of 20% to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com