Combined anti-impact structure of rotor made from composite material, as well as preparation device and preparation method thereof

A composite material and preparation device technology, which is applied in the field of composite rotating body combined impact-resistant structure and its preparation device, can solve the problems of increased weight and limited impact resistance, and achieve the effect of improving connection strength and fiber positioning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

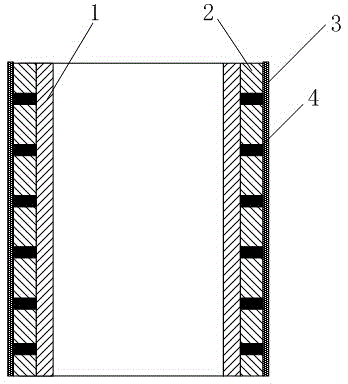

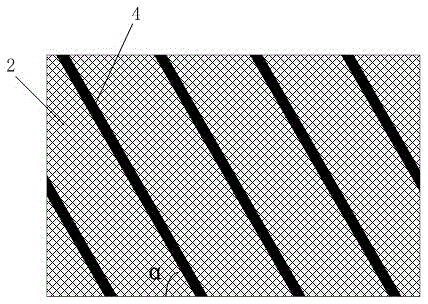

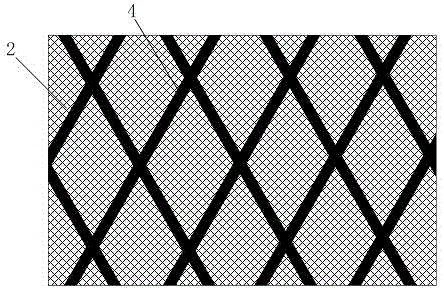

[0039] Composite material rotary combined impact-resistant structure, including: a metal thin-walled cylinder 1 covered and fixed sequentially from the inside to the outside, the inner aramid fiber wrapping layer 2 and the outer aramid fiber wrapping layer 3, the inner aramid fiber wrapping layer The fiber wrapping layer 2 is impregnated with resin at intervals so that the inner aramid fiber wrapping layer 2 has a partially hollow structure, and the outer aramid fiber wrapping layer 3 is evenly impregnated with resin.

[0040] The metal thin-wall cylinder 1 is made of aluminum alloy.

[0041] The resin is a high toughness, high temperature epoxy resin.

[0042] The preparation device of the combined impact-resistant structure of the composite rotary body includes an aramid fiber roll 12, an intermittent dipping roll, a continuous dipping roll 8, and a metal mandrel 5. One end of the fiber yarn 6 is wound on the aramid fiber roll 12, and the other One end passes through the tr...

no. 2 example

[0056] The material of the metal thin-walled cylindrical body 1 in the first embodiment is changed to titanium alloy.

[0057] The materials of the inner aramid fiber wrapping layer 2 and the outer aramid fiber wrapping layer 3 are replaced by carbon fiber materials from aramid fiber materials.

[0058] Change the intermittent dipping roller to the boss dipping roller 9, the boss dipping roller 9 is composed of a center roller 13 and several dipping bosses 14 arranged in gaps, and the lower part of the boss dipping roller 9 is placed to hold the resin glue During the rotation of the boss dipping roller 9, the top of the dipping boss 14 can extend into the container and dip into the glue solution, then rotate to the highest point and contact the fiber yarn 6, so that the resin infiltrates the fiber yarn 6.

[0059] In this embodiment, by changing the winding direction of the winding mandrel 5, the resin in the inner aramid fiber wrapping layer 2 is controlled to be arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com