Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

355 results about "Thin walled cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

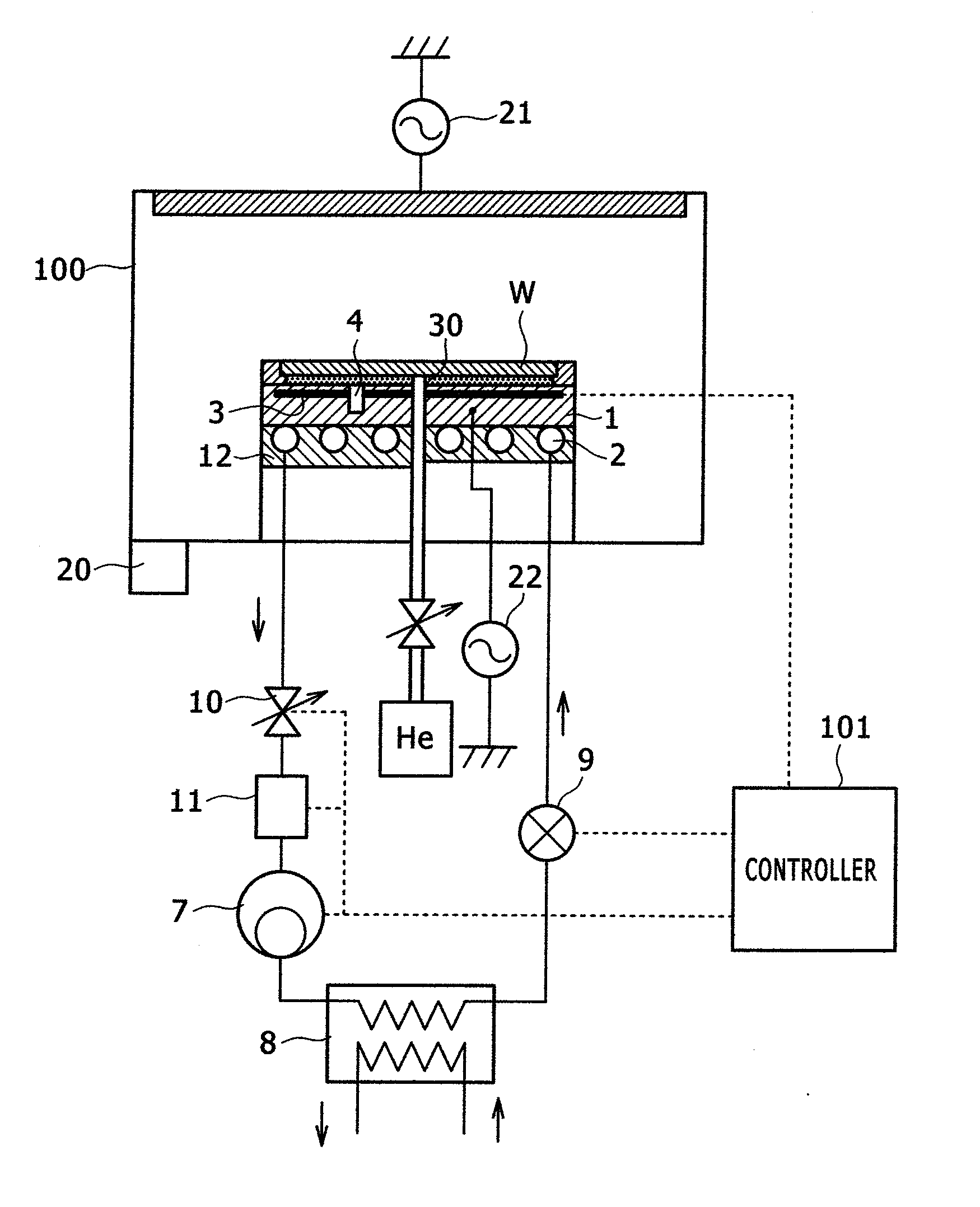

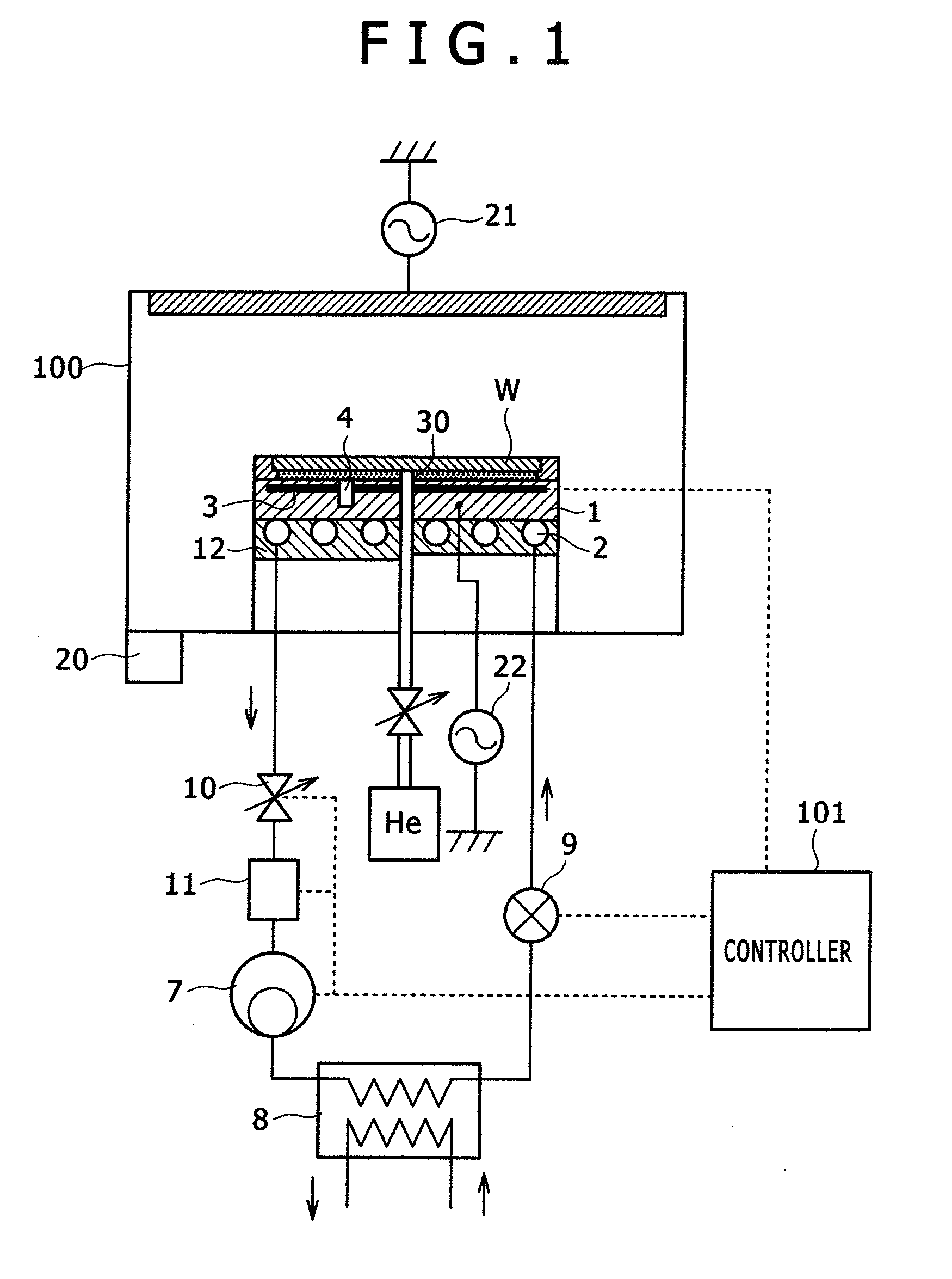

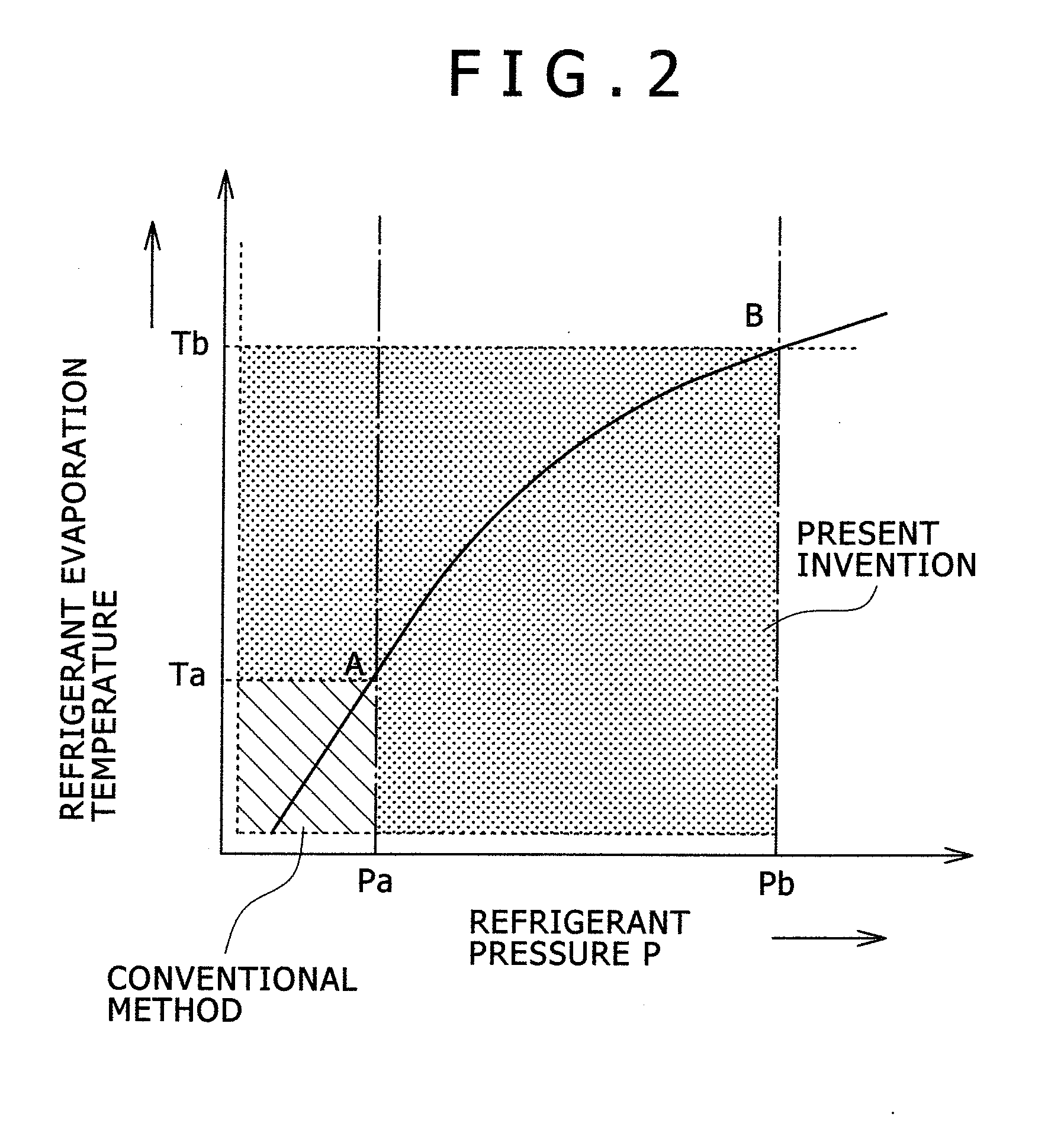

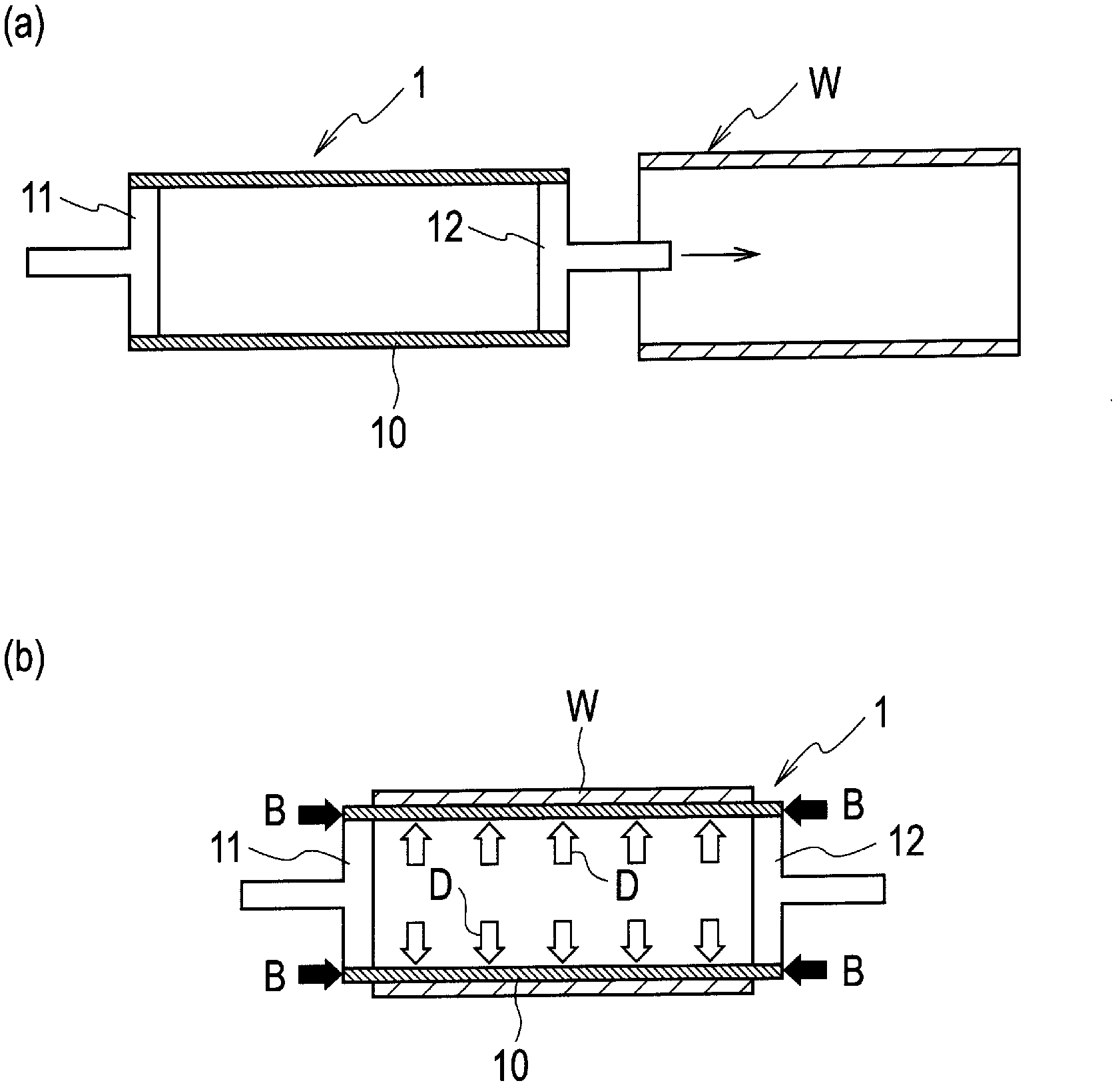

Plasma processing apparatus

ActiveUS20080289767A1High bias powerWide temperature rangeMechanical apparatusDomestic cooling apparatusIn planeEtching

The present invention provides a temperature control unit for an electrostatic adsorption electrode that is capable of controlling the wafer temperature rapidly over a wide temperature range without affecting in-plane uniformity while high heat input etching is conducted with high wafer bias power applied. A refrigerant flow path provided in the electrostatic adsorption electrode serves as an evaporator. The refrigerant flow path is connected to a compressor, a condenser, and a first expansion valve to form a direct expansion type refrigeration cycle. A second expansion valve is installed between the electrostatic adsorption electrode and the compressor to adjust the flow rate of a refrigerant. This makes it possible to compress the refrigerant in the refrigerant flow path of the electrostatic adsorption electrode and adjust the wafer temperature to a high level by raising the refrigerant evaporation temperature. Further, a thin-walled cylindrical refrigerant flow path is employed so that the thin-walled cylinder is deformed only slightly by the refrigerant pressure.

Owner:HITACHI HIGH-TECH CORP

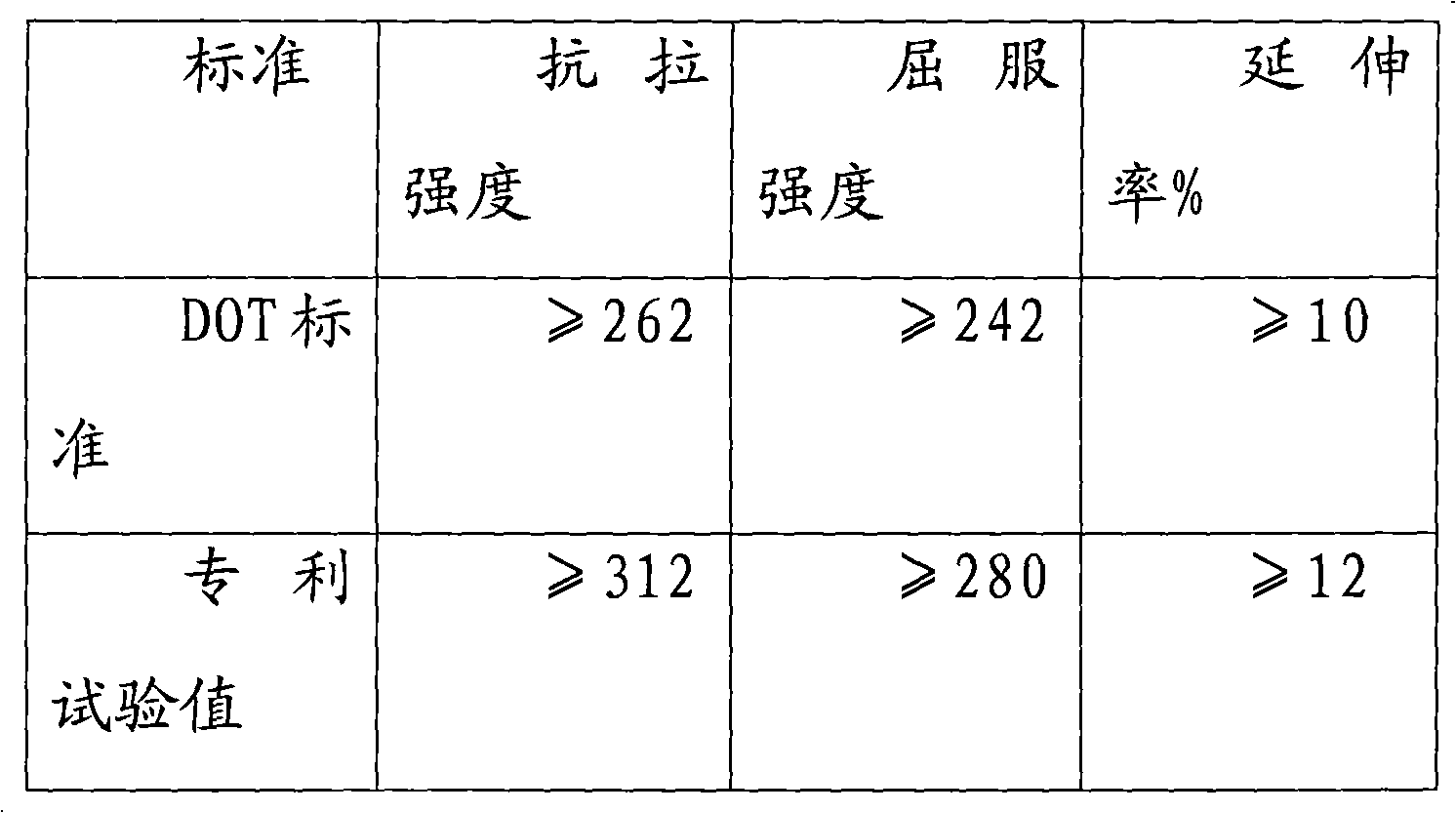

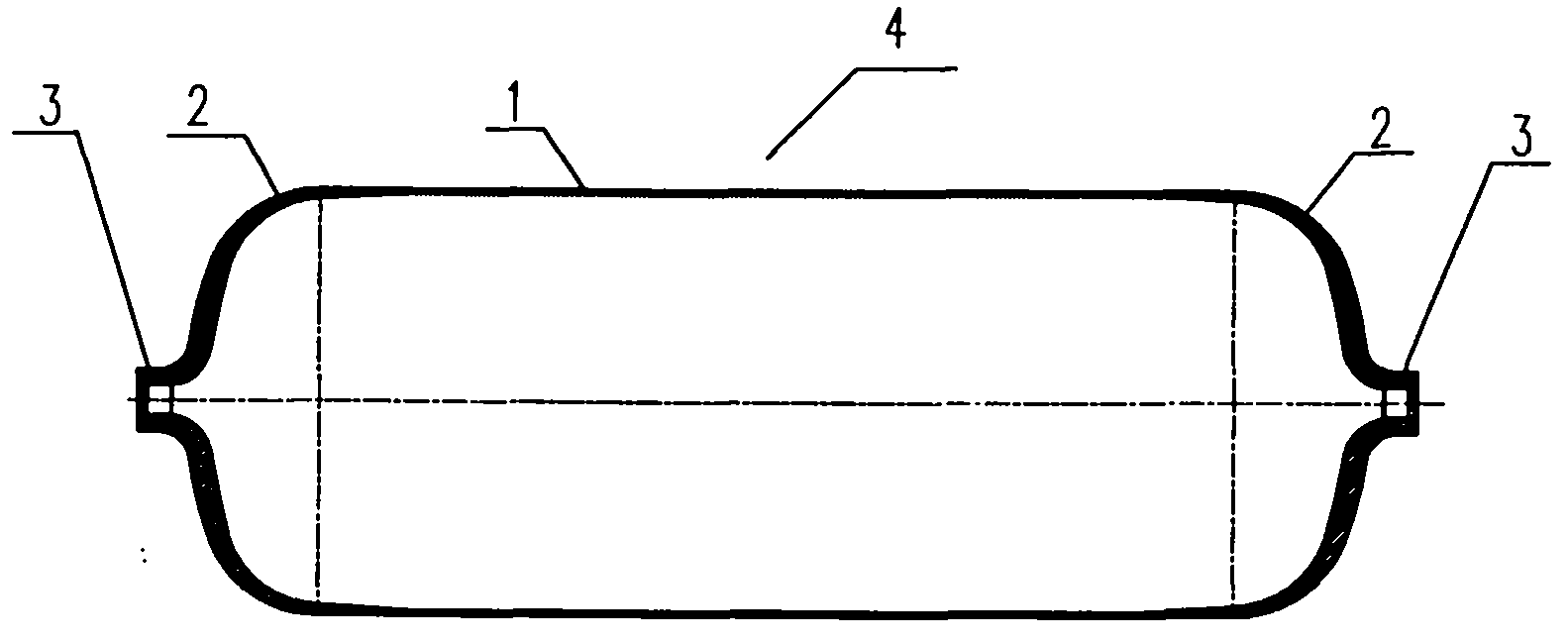

Method for manufacturing aluminum liner of vehicular composite cylinder

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

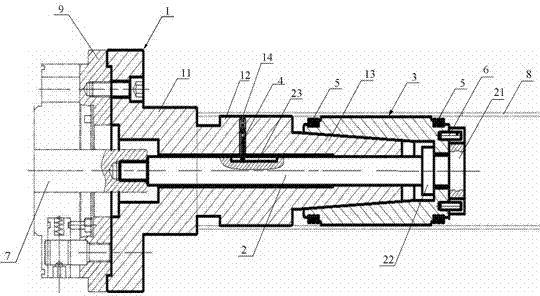

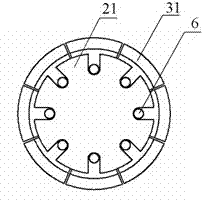

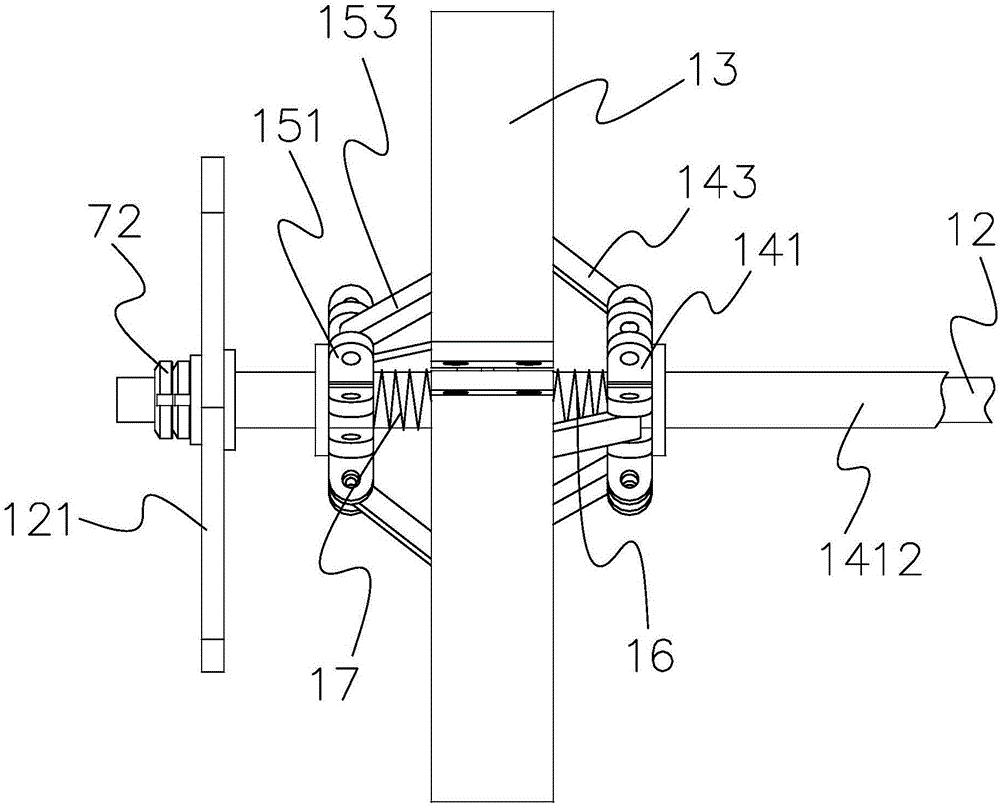

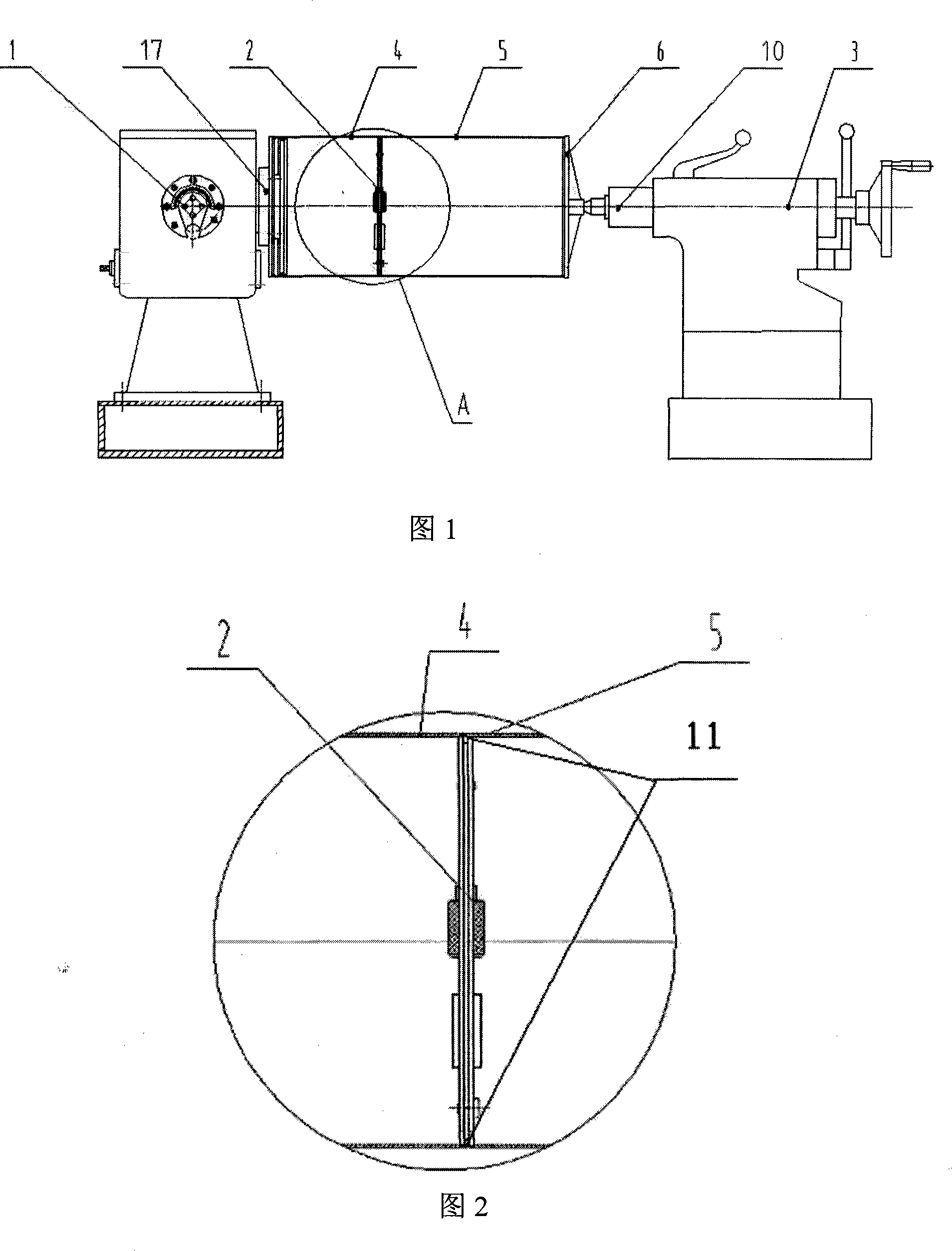

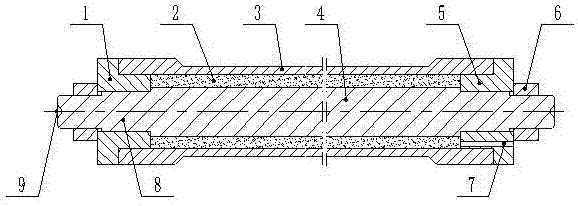

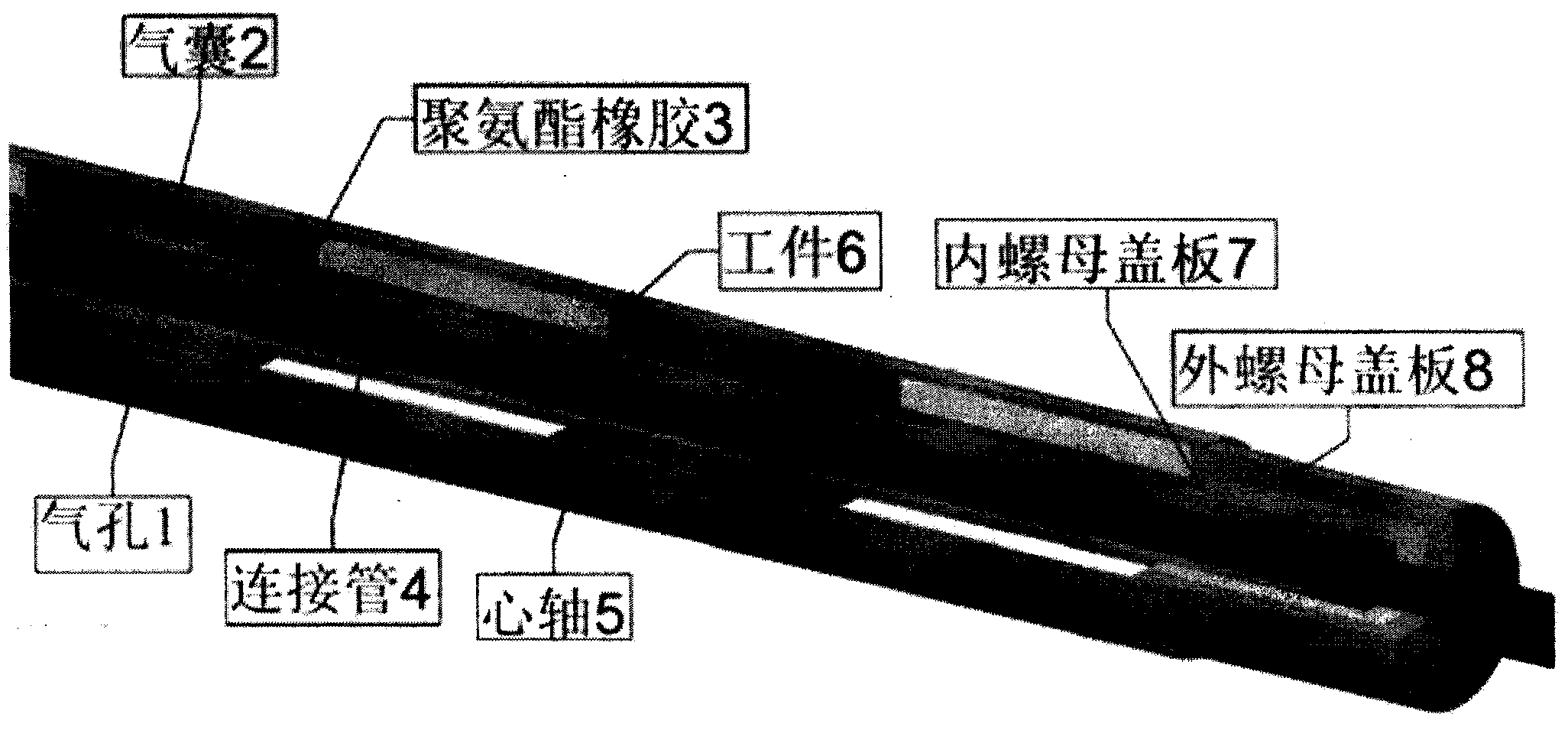

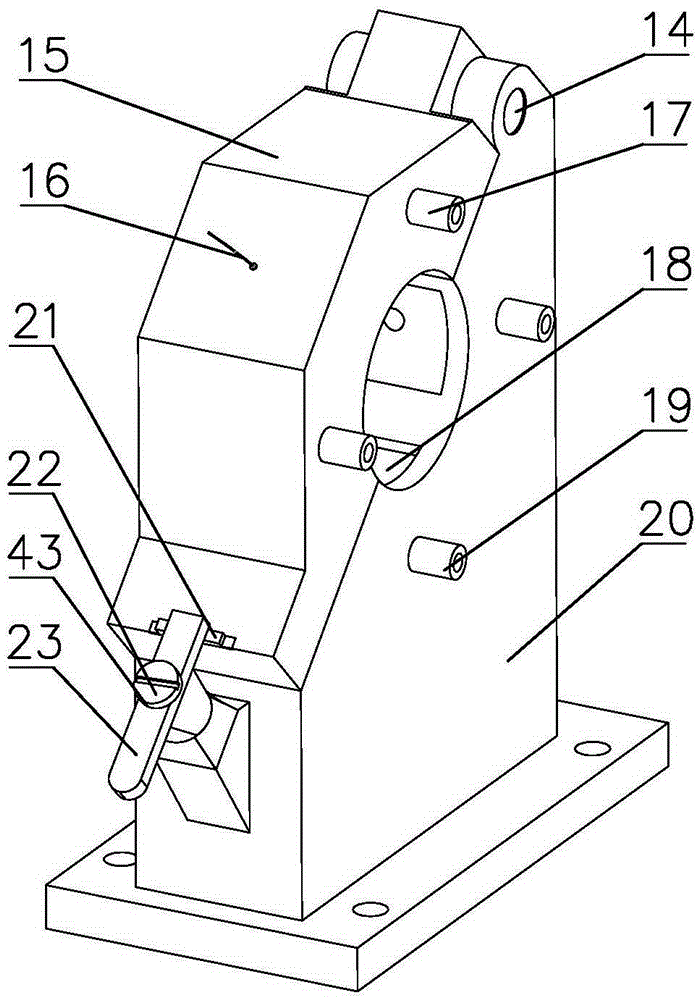

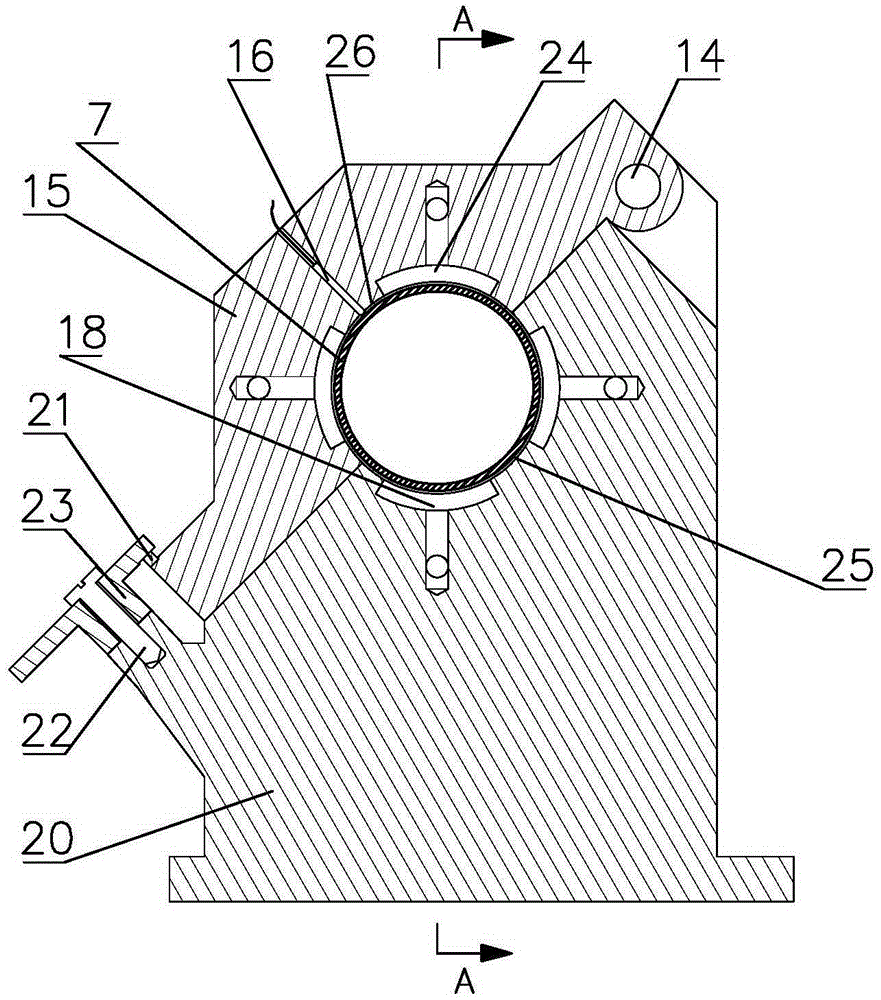

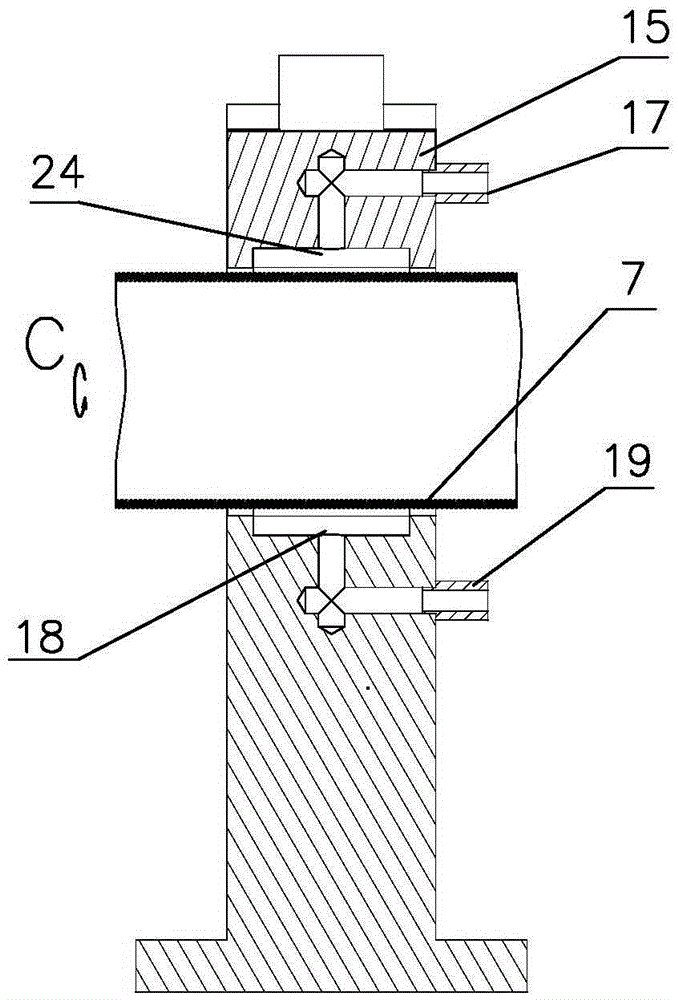

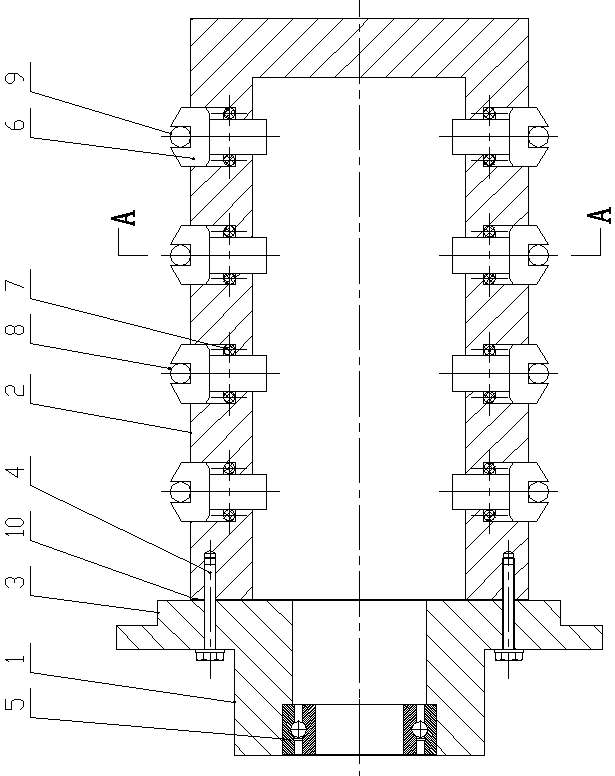

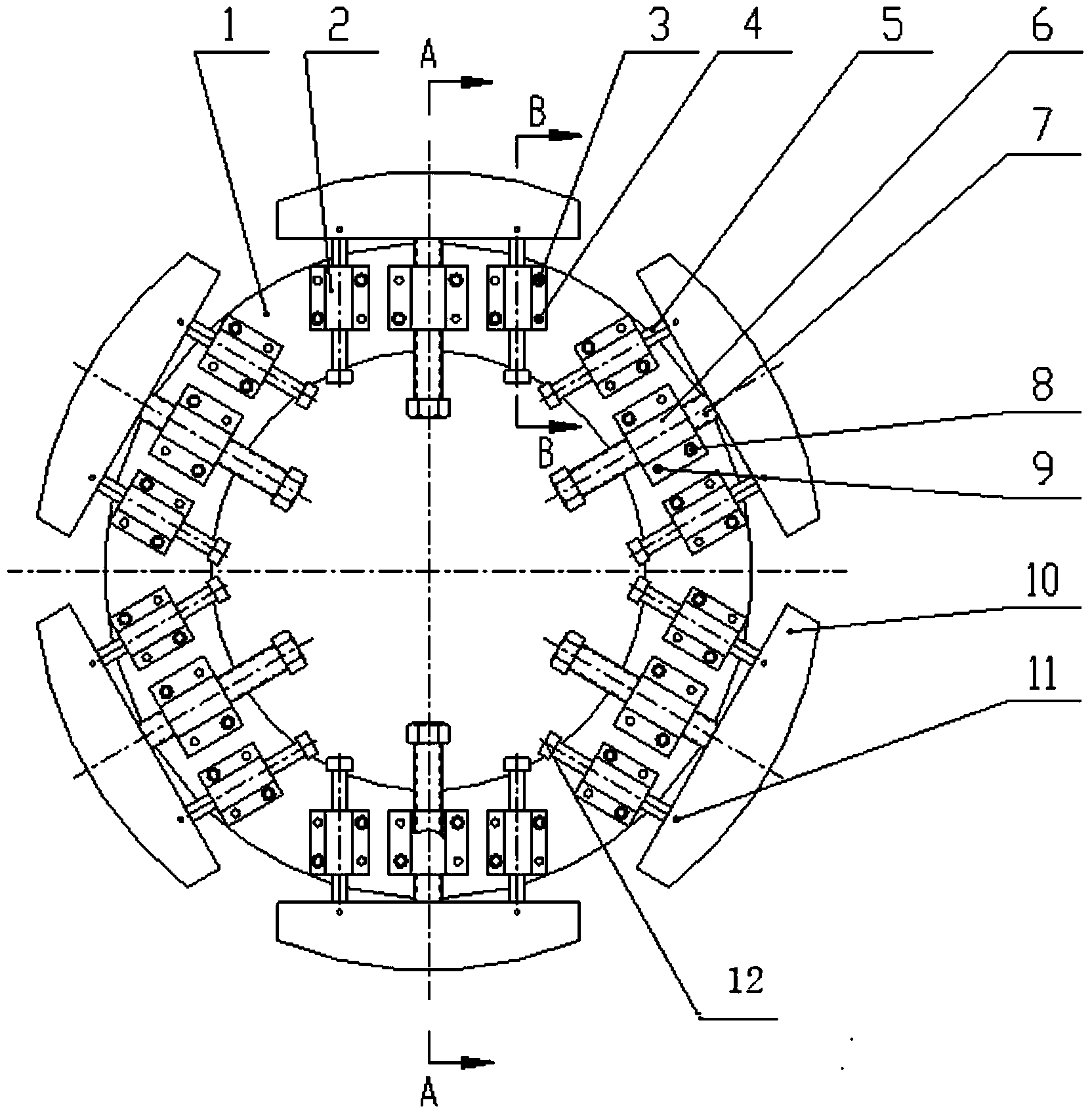

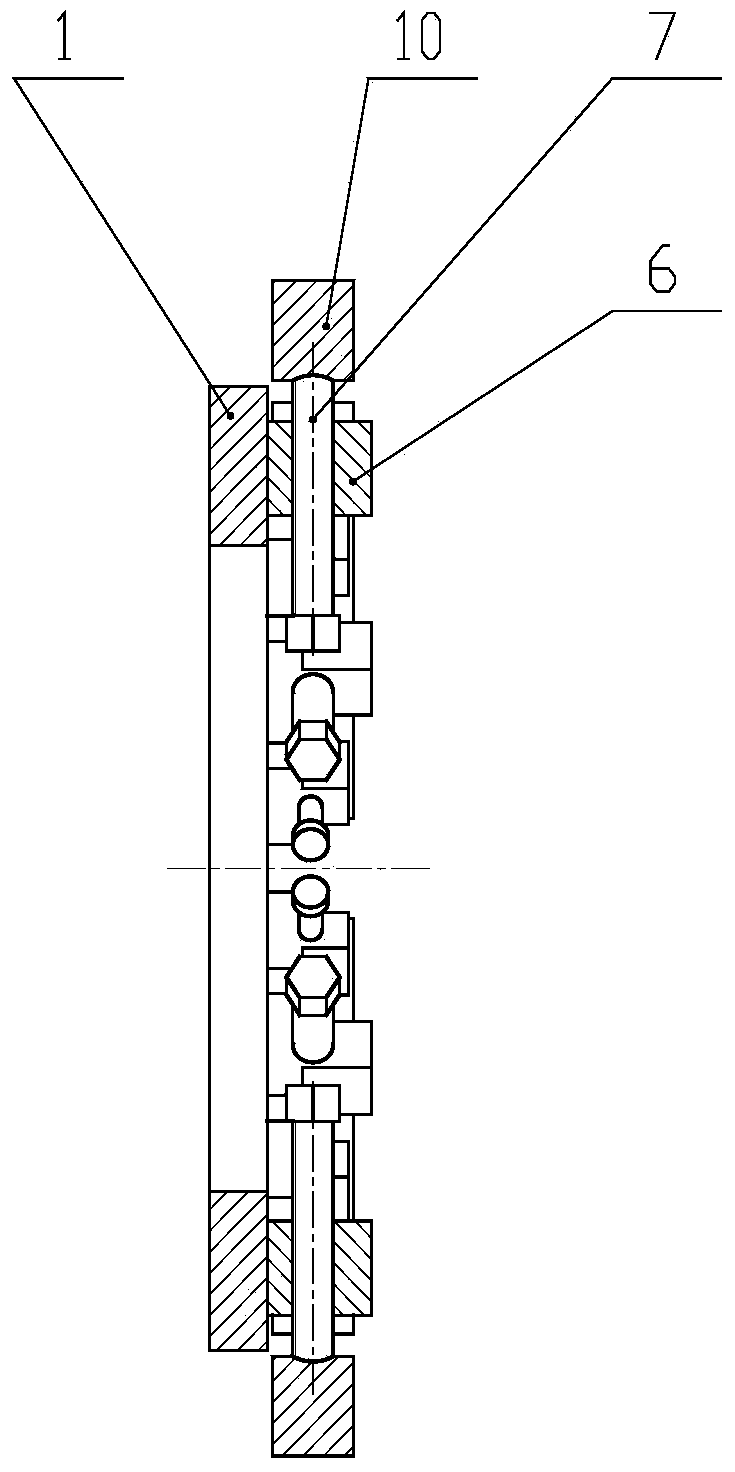

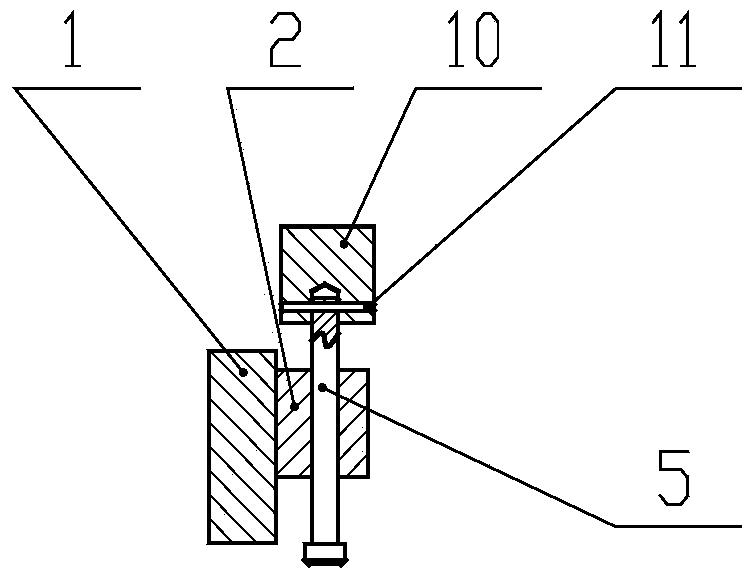

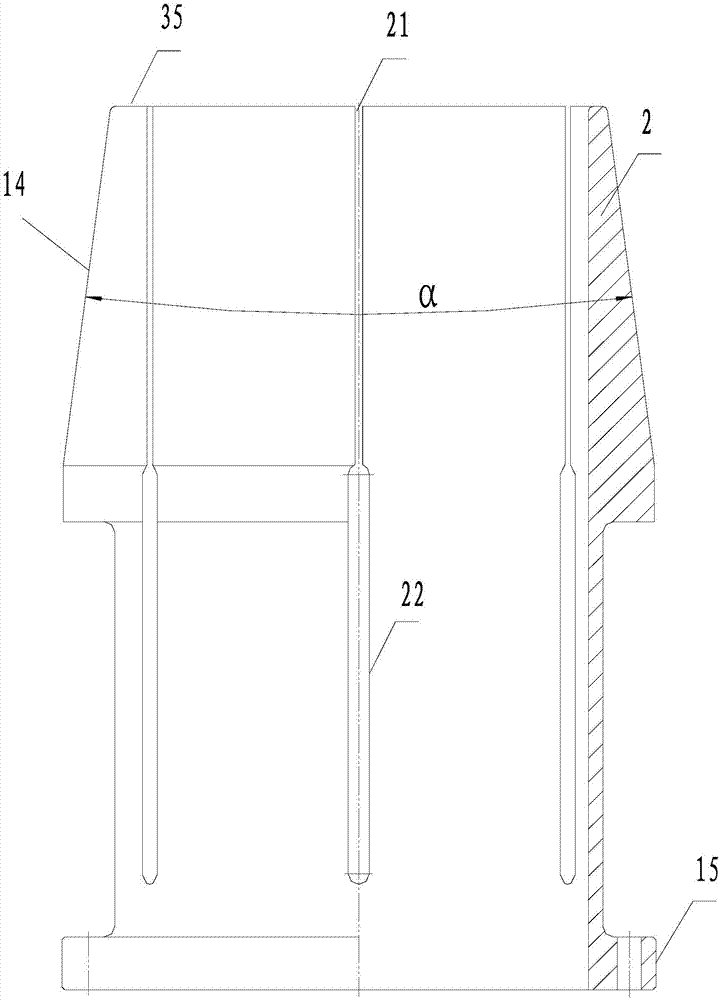

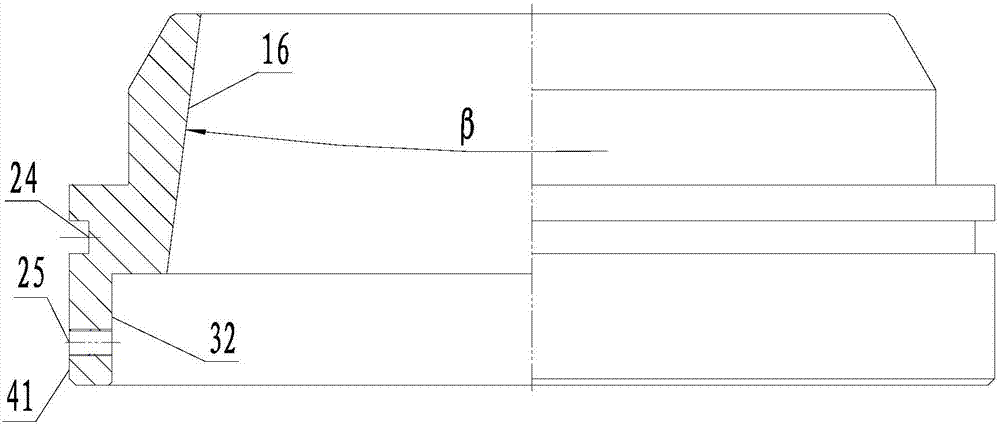

Automatic expansion core clamp for thin-walled cylinder parts

InactiveCN103962598AImprove rationalityImprove reliabilityExpansion mandrelsProduction rateIntegrated design

The invention discloses an automatic expansion core clamp for thin-walled cylinder parts. The automatic expansion core clamp comprises a core shaft and a cylindrical expansion sleeve, wherein the core shaft consists of a fixing part, a limiting part and a taper shaft part; the inner wall of the cylindrical expansion sleeve is tapered; a through hole is formed in the closed end of the expansion sleeve; grooves are formed in the outer walls of two ends of the expansion sleeve; a retainer ring is arranged in each groove; a connecting shaft extends into central through holes in the core shaft and the expansion sleeve; one end of the connecting shaft is connected with a piston rod; a flange is arranged at one end, positioned outside the expansion sleeve, of the connecting shaft; a limiting flange is formed at the position close to the inner side surface of the closed end of the expansion sleeve; an axial key groove is formed in the outer wall, corresponding to a screw hole, of the connecting shaft; a screw is arranged in the screw hole, and one end of the screw extends into the key groove. By using a hydraulic source as a power source, the labor intensity is further alleviated, and the labor production rate is increased; the clamp is directly connected with a machine tool spindle through the screw, so that the rotation accuracy of the clamp is ensured; by virtue of the integrated design of the clamp, the reasonableness and the reliability of a clamp structure are greatly improved.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

Multi-component force sensor

InactiveCN101210850AConsistent radial mechanical propertiesIncreased longitudinal stabilityForce measurementEngineeringStrain type

The invention provides a strain type force measuring device, more particular a sensor capable of simultaneously measuring component forces of a non-coplanar force at 6 different degree-of-freedom directions. Flanges (2) are arranged at the two ends of a thin-walled cylinder (1) and opened with mounting holes (3), an electric resistance strain gage and a temperature compensation strain gage are adhered on a specific position of the wall of the thin-walled cylinder (1) with a specific manner, and the electric resistance strain gage is bridged. The invention has the advantages of uniform radial mechanical properties, good longitudinal stability, simple structure, light weight, low inertia, no intervals and frictional force, high measurement accuracy and wide application range; and is suitable for measuring either small load and high load with large structure.

Owner:CHINA HELICOPTER RES & DEV INST

Butt welding positioning device for thin-walled cylinder with seal head

InactiveCN102416549ASolve the problem of joint positioningAccurate coaxial positioningWelding/cutting auxillary devicesAuxillary welding devicesButt weldingProcess equipment

The invention discloses a butt welding positioning device for a thin-walled cylinder with a seal head, and belongs to the technical field of process equipment. The device is mainly technically characterized by comprising a pressing plate, a pipe sleeve, a pull rod, a support body, a cone, a bulging block, a copper cushion block, a countersunk screw, a band spring, an adjusting nut, a gasket and a locking nut, wherein the pressing plate is adjusted by the adjusting nut to position a workpiece; the cone is pulled by the pull rod to jack and bulge the three-flap bulging block; the bulging block centers, bulges and clamps the workpiece to be welded; the taper of the inner wall of the bulging block is the same as that of the external surface of the cone; and a radial annular groove is formed on the surface of the copper cushion block. The assembly positioning problem of the thin-walled cylinder with the seal head and a thin-walled hollow cylinder during butt welding can be effectively solved, welding deformation is effectively reduced, and the device has the advantages that: the device has a simple structure, is convenient to assemble and disassemble and is operated and used reliably.

Owner:江南工业集团有限公司

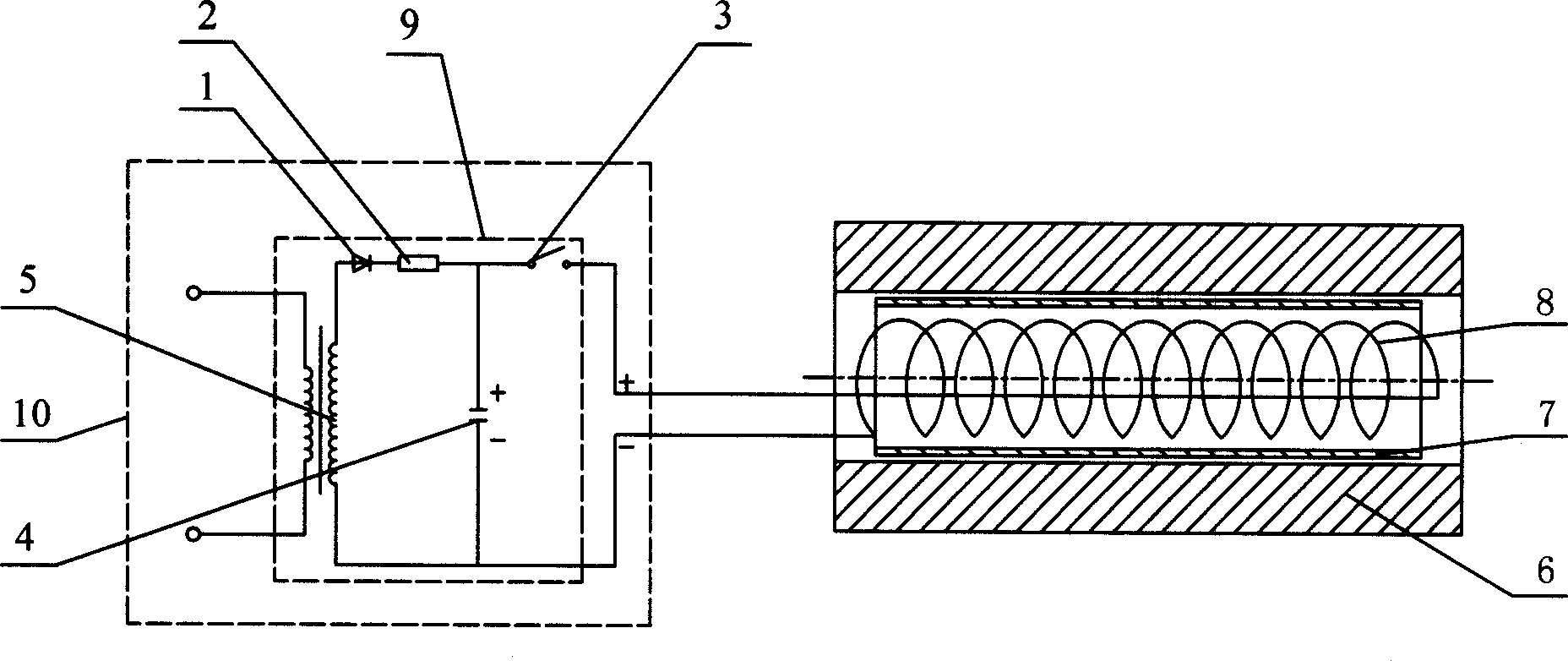

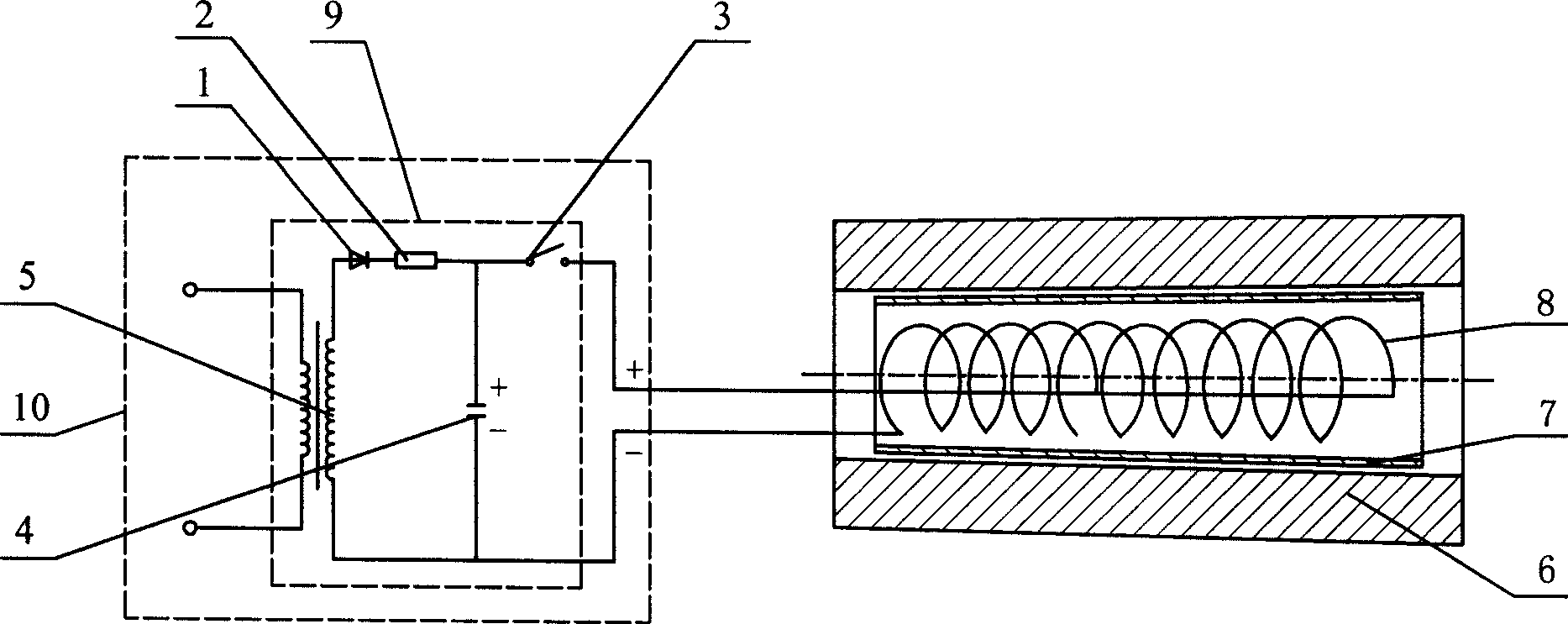

Method for increasing the circular degree of the metal thin-walled cylinder using pulse magnetic pressure

The invention discloses a method for improving roundness of a metal thin-wall cylindrical workpiece by pulsed magnetic pressure, and relates to a method for improving roundness of a metal thin-wall cylindrical workpiece. The method solves the problems that the existing cylindrical workpiece shape correction method has the disadvantages of complex mechanism and die, uneasy operation and low accuracy of shape correction, and the existing cylindrical workpieces have the disadvantages of easy wearing surface, residual stress, short service life, difficult sealing, high cost and difficult operation, both of which are not favorable for the small-batch and diversified development trend. The method comprises the following steps: step one: the metal thin-wall cylindrical workpiece is arranged in a high-accuracy shape correction die, and magnetic impulse processed coils are placed in the cylindrical workpiece; step two: a high-frequency pulse capacitor bank is used for discharging the magnetic pulse processing coils, high-frequency pulse acts on the cylindrical workpiece to cause the cylindrical workpiece to generate high-speed deformation and generate impact contact and adhere to the die. The invention has the advantages of simple mechanism and die, high machining accuracy, long service life and low cost, and is favorable for the small-batch and diversified development trend, etc.

Owner:HARBIN INST OF TECH

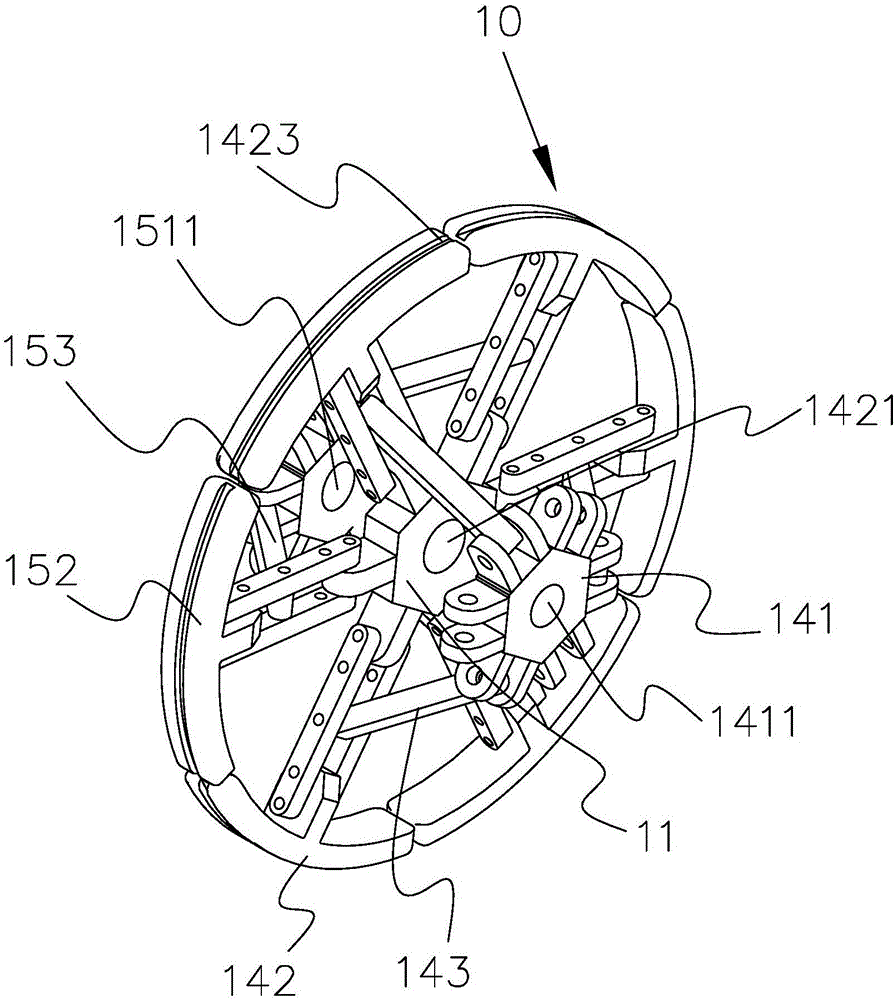

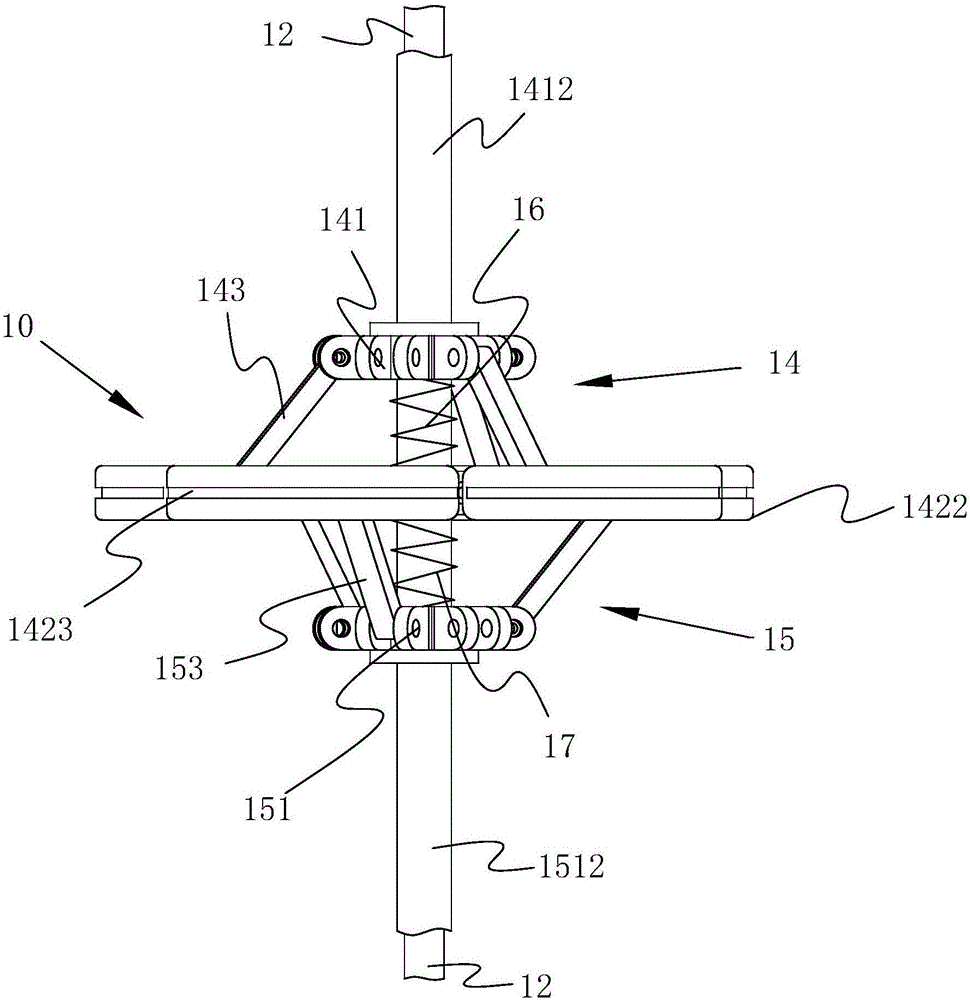

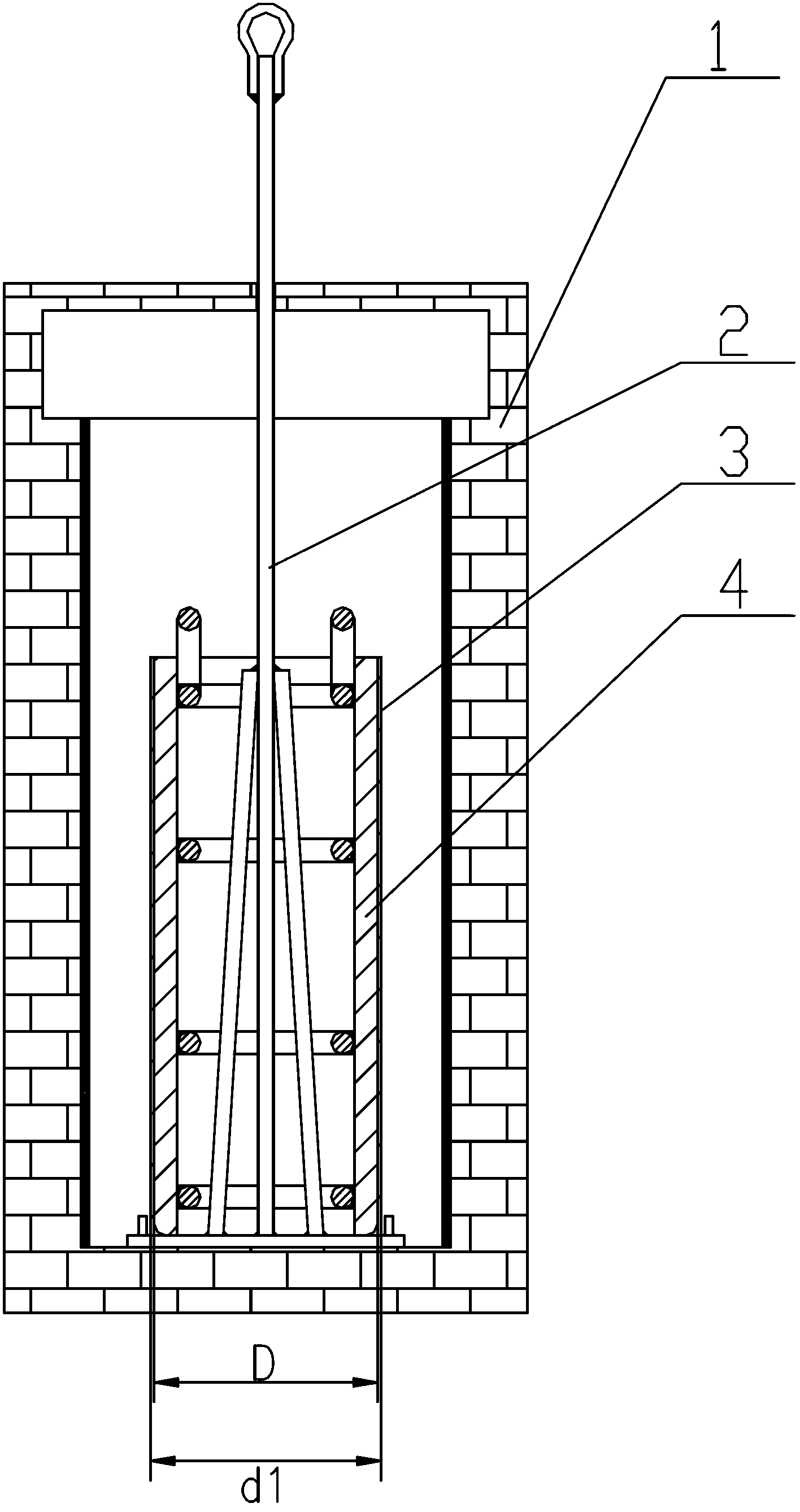

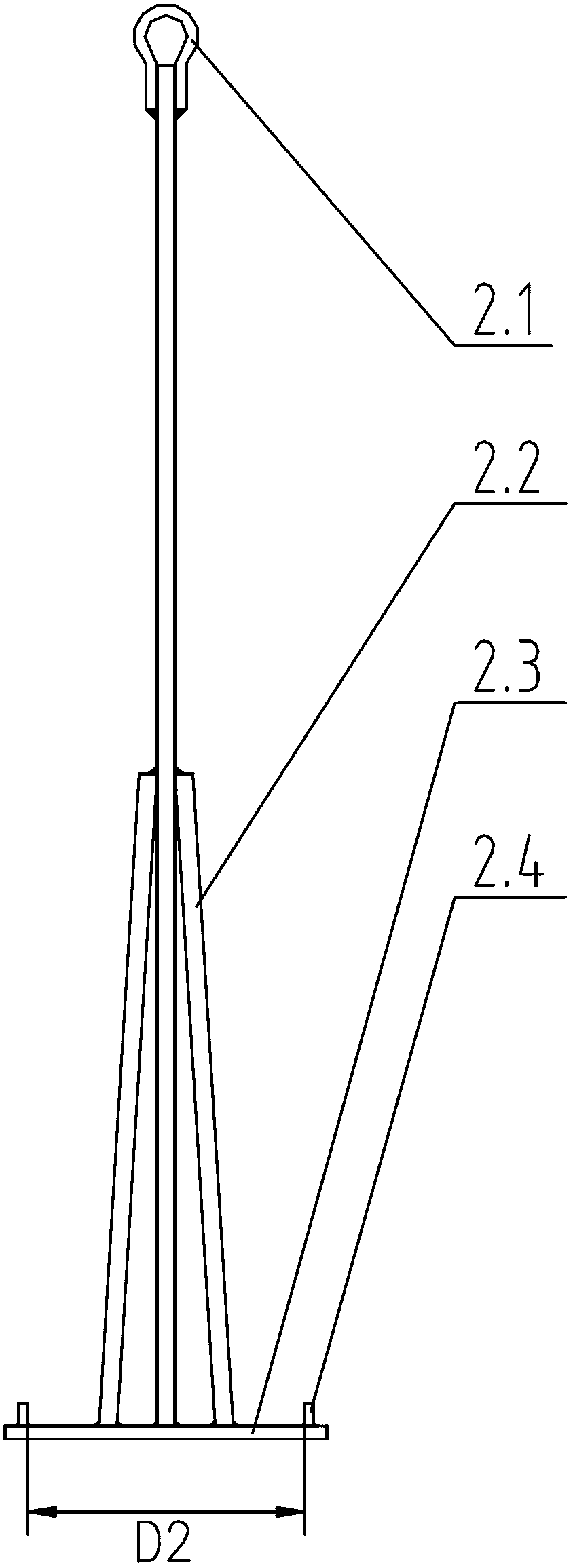

Thin-walled cylinder anti-deformation clamp and laser cladding machine for repairing cracks

ActiveCN106312320AWill not deformImprove coaxialityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled cylinder

The invention provides a thin-walled cylinder anti-deformation clamp which comprises a center plate, a center shaft, an outer shroud ring, a first umbrella stand mechanism and a second umbrella stand mechanism. The first umbrella stand mechanism and the second umbrella stand mechanism are the same in structure and connection arrangement. The second umbrella stand mechanism comprises a second end plate, second supporting rings and second connecting rods. A third axle hole is formed in the center position of the second end plate. A first axle hole, a second axle hole and the third axle hole are sequentially formed in the center shaft. A second push rod is arranged on the end face of the second end plate. A second spring is arranged between the center plate and the second end plate. According to the technical scheme, by means of cooperation of a three-claw chuck, an ejection piece and the clamp, the coaxiality of welded cylinders is high, butt weld joints cannot deform, and the weld joint quality is high; and meanwhile, a tail frame can move along ground guide rails, and therefore the thin-walled cylinder anti-deformation clamp can be suitable for welding of thin-walled cylinders different in specification length, and the practicality performance is greatly improved.

Owner:PUTIAN UNIV

Automatic turnover device for conveying forklift hub brake drum assembly

The invention relates to an automatic turnover device for conveying a forklift hub brake drum assembly. The automatic turnover device comprises a motor, a speed reducer, a rotating shaft and a clamping mechanism, two sides of the rotating shaft are arranged at the tops of two vertical support legs through bearings and bearing blocks respectively, the two support legs are positioned on two sides of a conveying mechanism respectively, the rotating shaft is parallel to a power plate chain on a power plate chain output rail, one end of the rotating shaft is connected with the speed reducer and the motor, the clamping mechanism is arranged on the rotating shaft and comprises a pair of clamping arms, each clamping arm comprises a cantilever plate, one end of each cantilever plate is fixedly connected with the rotating shaft, a thin-walled cylinder is arranged at the other end of each cantilever plate, a piston rod of each thin-walled cylinder is parallel to the rotating shaft, the outer end of the piston rod of each thin-walled cylinder is connected with a connecting plate, two clamp plates are arranged on each connecting plate in a splayed manner to form a pair, and two pairs of clamp plates on the pair of clamping arms are folded. Labor intensity is reduced, and product quality is improved.

Owner:ANHUI HELI CO LTD

Thin walled cylinder girth laser welding tong

InactiveCN101229612ARealize rotary motionAccurate splicingWelding/cutting auxillary devicesAuxillary welding devicesGyrationEngineering

The invention discloses a circular seam laser welding fixture for a thin-wall cylinder, which comprises a head frame, an extended ring, a rear frame of a machine tool and a top plate. When in operation, the extended ring is placed between the head frame and the rear frame of the machine tool and sleeved in a place where two workpieces to be welded are spliced; one non-splicing end of the workpiece is retained and positioned on a spindle of the head frame while the other non-splicing end is attached to a positioning surface of a baffle; a top point of the rear frame of the machine tool is arranged in a top point hole of the baffle. By adopting a retractable extended ring, the invention realizes the correct splicing and retaining of the thin-wall cylinder; the gyration of the cylinder can be realized by a way that the head frame with the function of turning drives a head part of the cylinder and a tail part of the cylinder is supported by the rear frame and the top plate; meanwhile, the splicing precision also meets the requirement of the laser welding. A worm-and-gear mechanism of the spindle in the head frame can accomplish the precise gyration of the workpiece and the head frame with a turnover function is convenience for feeding and discharging of a longer workpiece. The invention has the advantages of precise positioning, reliable and convenient fixture, convenient application, high efficiency, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

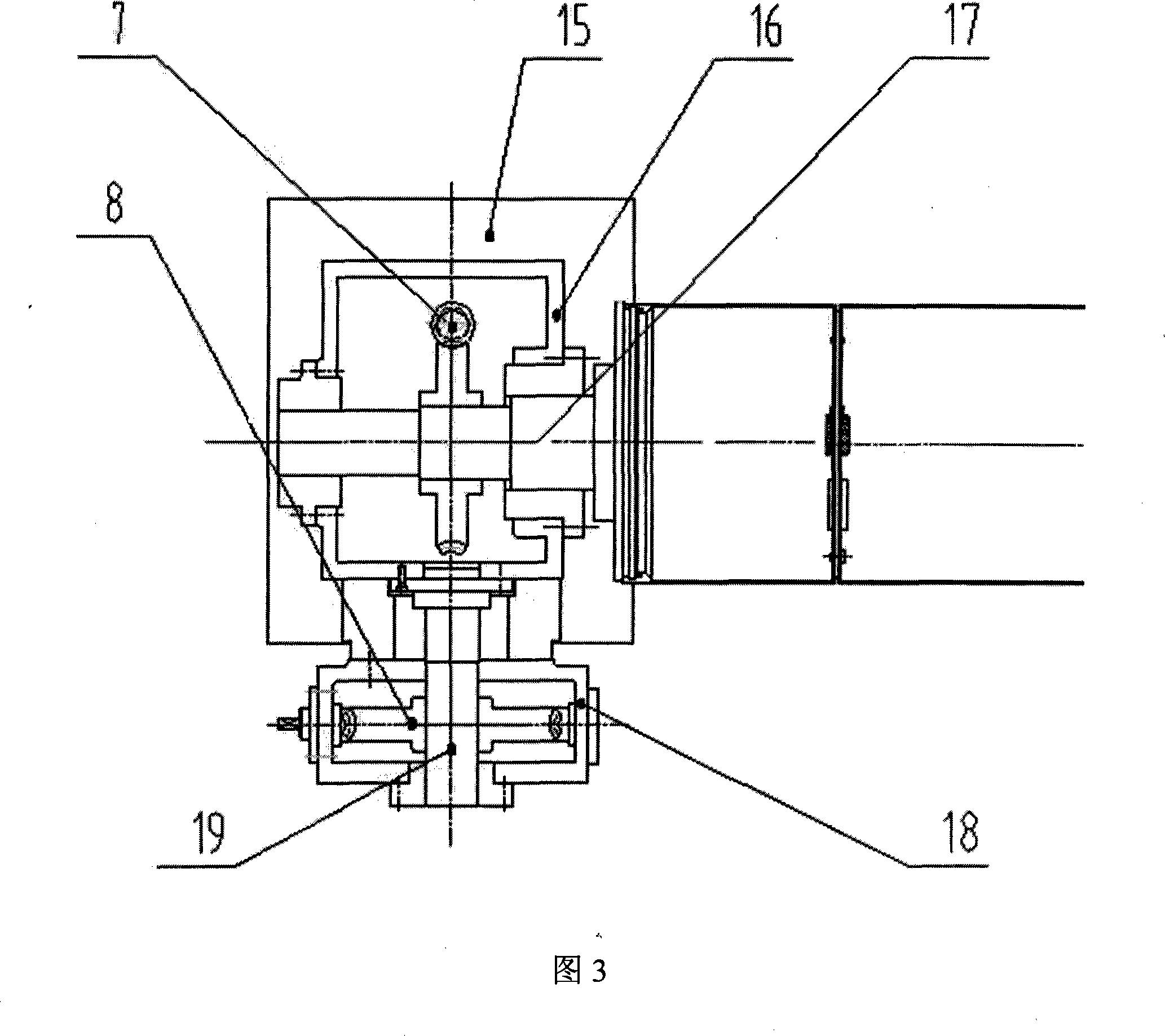

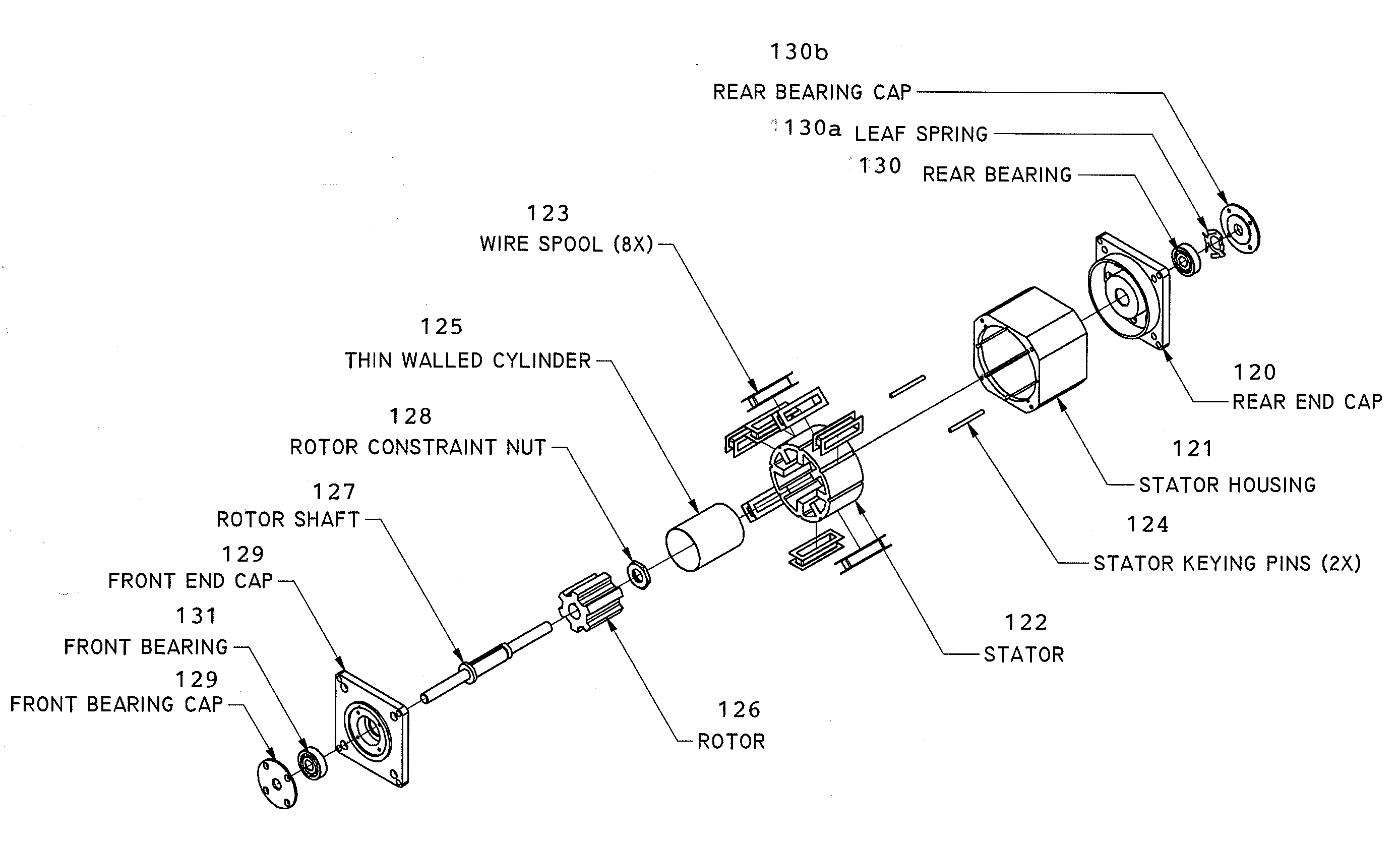

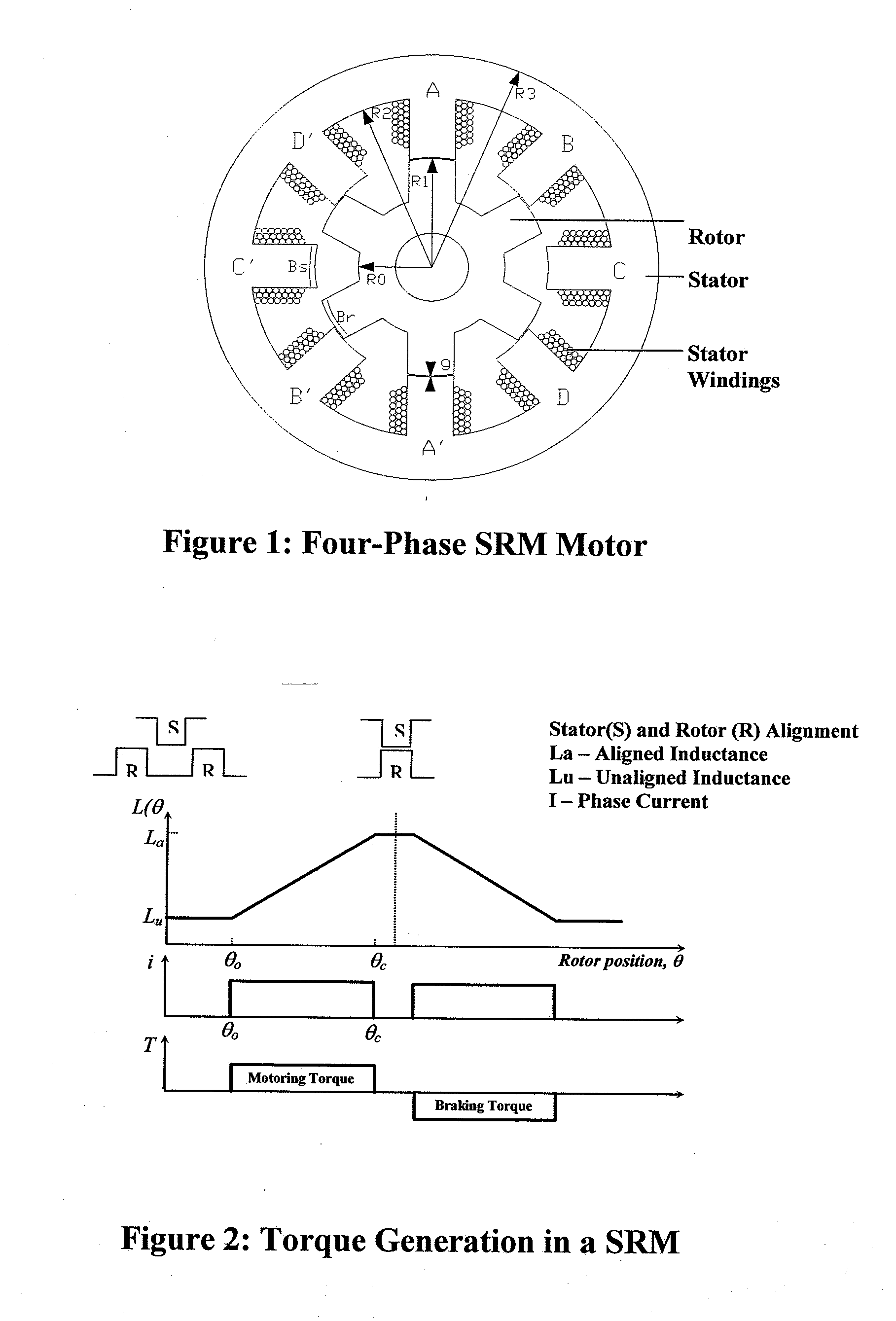

Motor for high temperature applications

ActiveUS20120025636A1Avoid debrisAvoid the needWindings insulation materialWindings insulation shape/form/constructionEpoxyAdhesive

A high temperature motor has a stator with poles formed by wire windings, and a rotor with magnetic poles on a rotor shaft positioned coaxially within the stator. The stator and rotor are built up from stacks of magnetic-alloy laminations. The stator windings are made of high temperature magnet wire insulated with a vitreous enamel film, and the wire windings are bonded together with ceramic binder. A thin-walled cylinder is positioned coaxially between the rotor and the stator to prevent debris from the stator windings from reaching the rotor. The stator windings are wound on wire spools made of ceramic, thereby avoiding need for mica insulation and epoxy / adhesive. The stator and rotor are encased in a stator housing with rear and front end caps, and rear and front bearings for the rotor shaft are mounted on external sides of the end caps to keep debris from the motor migrating into the bearings' races.

Owner:HONEYBEE ROBOTICS

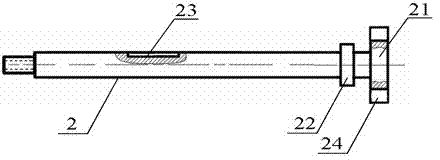

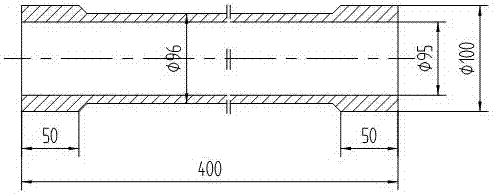

Turning tool and machining method of thin-walled cylindrical workpiece

InactiveCN107414100ASimple structureEasy to operatePositioning apparatusTurning machinesParaffin oilsEngineering

The invention provides a turning tool and a turning method for thin-walled cylindrical workpieces. The turning tooling includes a mandrel, plug without hole, plug with hole and nut. The mandrel passes through the inner hole of the workpiece, and the two ends are respectively installed with plugs without holes and with holes, and the nuts at both ends of the mandrel are tightened, the mandrel and the workpiece are combined into one, and the wax injection hole is injected into the mandrel and the workpiece. Fill the cavity with paraffin. The processing steps of thin-walled cylindrical parts using this turning tool include: 1) rough turning the outer circle, inner hole and end face; 2) finishing turning inner hole and end face, the length conforms to the drawing size; 3) finishing turning inner hole to the drawing requirements; 4) Combine the tooling with the workpiece; 5) Position and install the two ends of the mandrel with thimbles; 6) Use coolant to finish the outer circle to the requirements of the drawing. By adopting the above-mentioned turning tool and processing method, the problem of deformation of the thin-walled cylindrical workpiece in turning is solved, and the machining accuracy of the thin-walled cylindrical workpiece is guaranteed.

Owner:XINXING ENERGY EQUIP

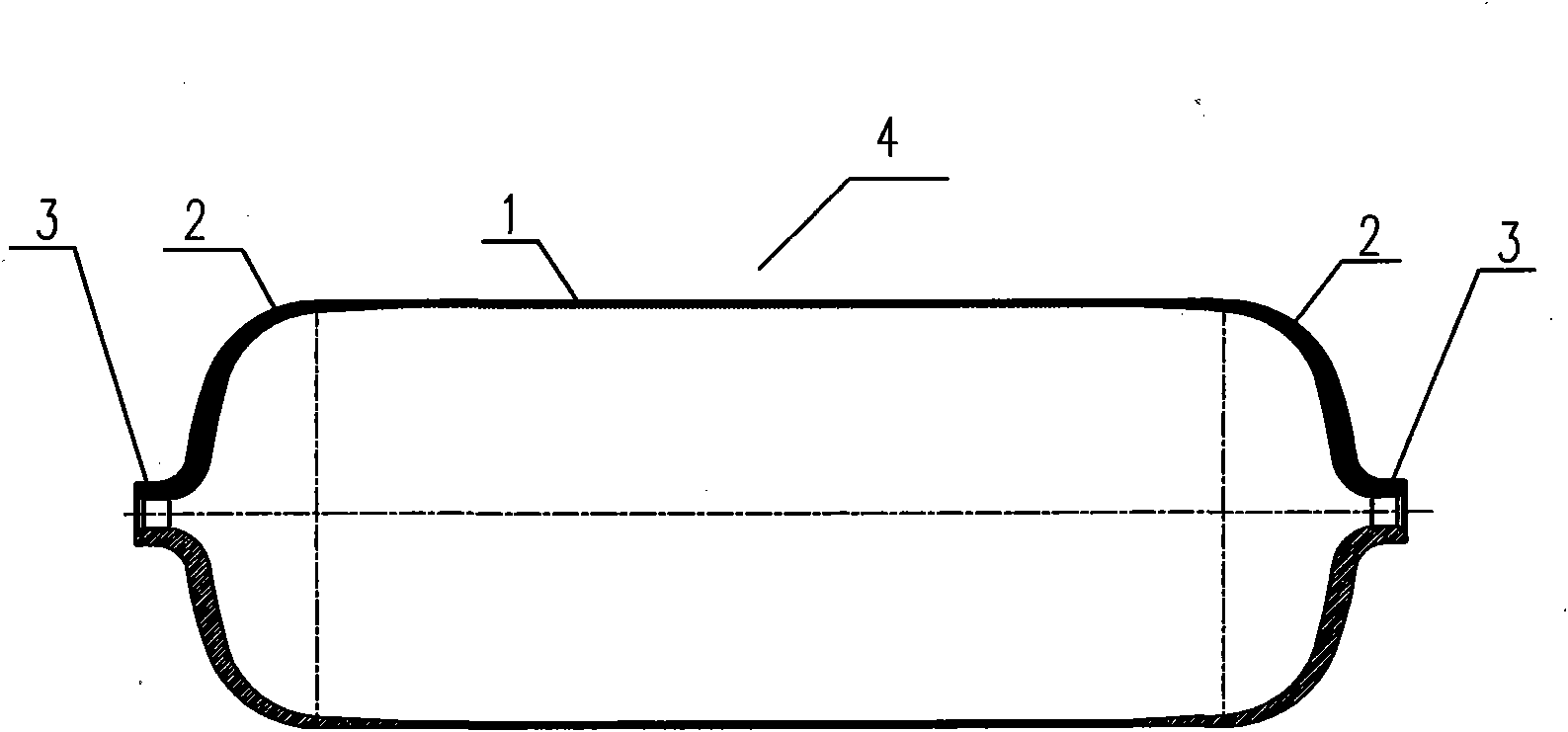

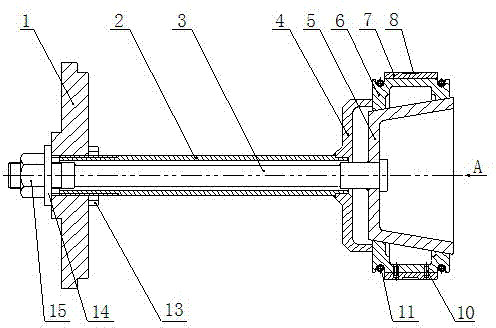

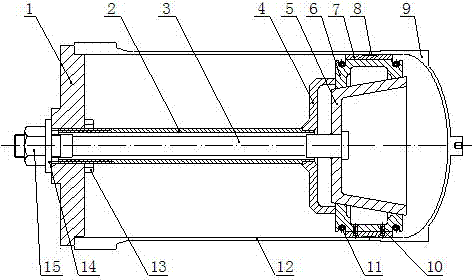

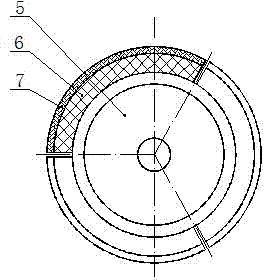

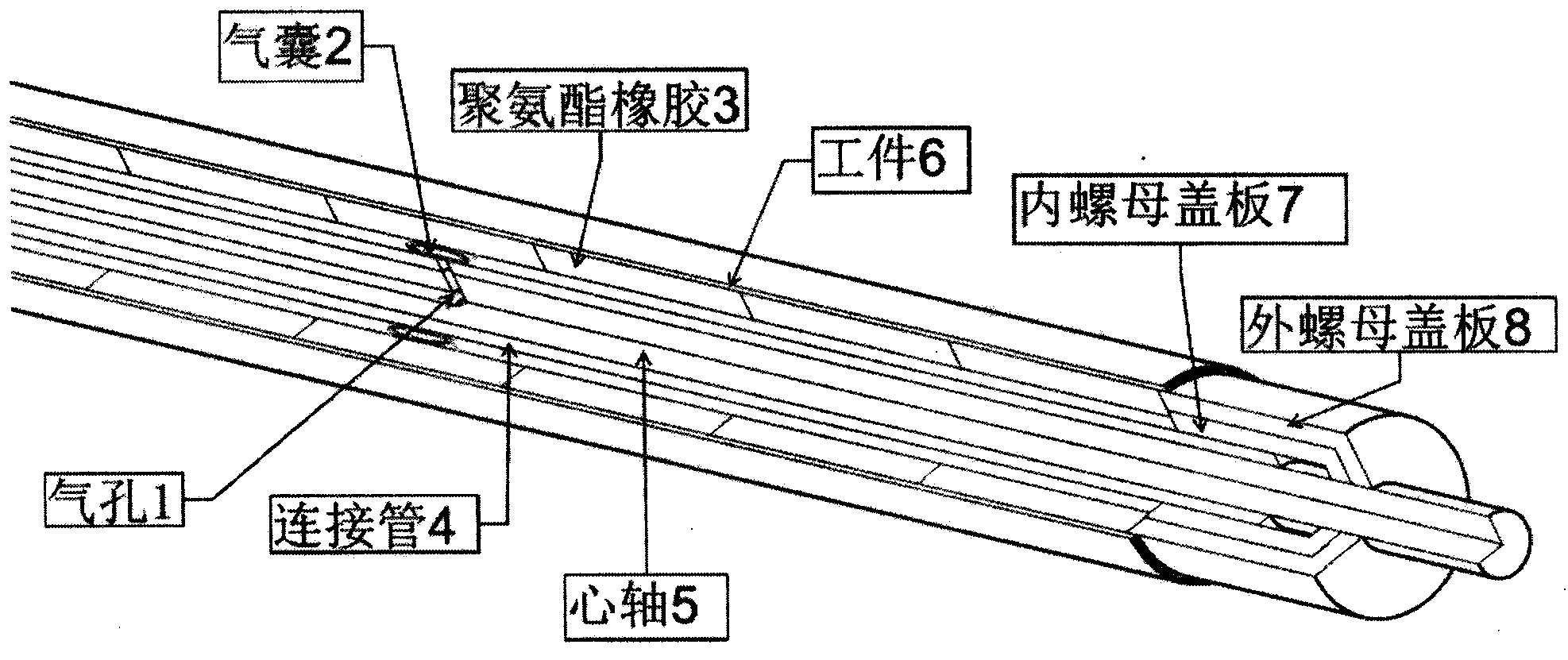

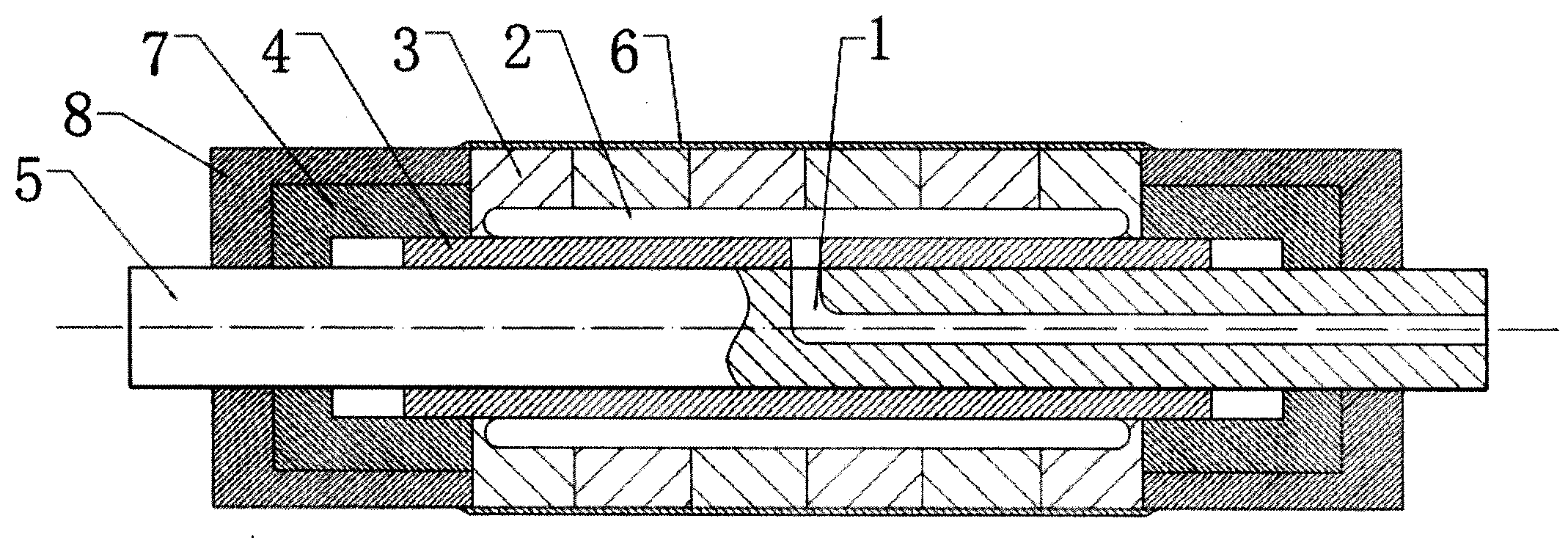

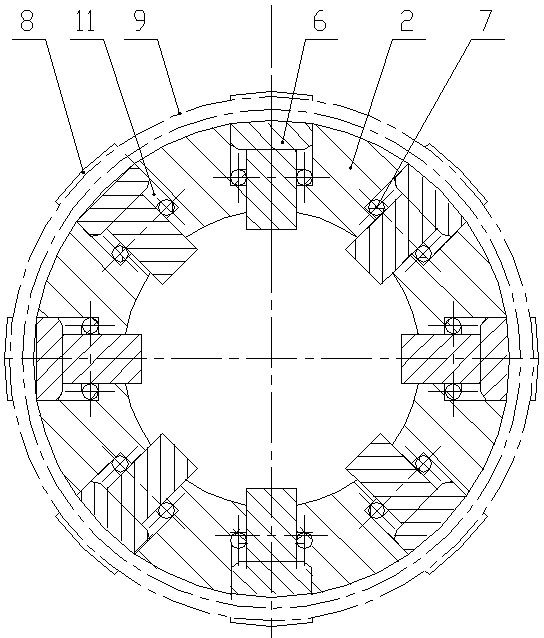

Method and clamp for clamping thin-walled cylinder-shaped workpieces

The invention discloses a method and a clamp for clamping thin-walled cylinder-shaped workpieces. The clamp is composed of an air bag 2, polyurethane rubber 3, a connecting pipe 4, a mandrel 5, an inner nut cover plate 7 and an outer nut cover plate 8. Through the radial elastic deformation of the air bag 2 and the polyurethane rubber 3 and the holding power of the connecting pipe 4, the inner nut cover plate 7 and the outer nut cover plate 8, the thin-walled cylinder-shaped workpieces can be evenly clamped. The method and clamp for clamping the thin-walled cylinder-shaped workpieces are characterized in that the connecting pipe 4, the air bag 2 and the polyurethane rubber 3 are sequentially mounted on the mandrel 5, afterwards, the inner nut cover plate 7 is screwed down first, then the outer nut cover plate 8 is arranged to be screwed down, and thus the thin-walled cylinder-shaped workpieces can be assembled through the retention clamp.

Owner:NANJING AGRICULTURAL UNIVERSITY

Diameter and shape precision control method of thin-walled cylinder and special tool thereof

The invention discloses a diameter size and shape precision control method of a thin-walled cylinder of a rocket chamber shell. The diameter size and shape precision control method comprises the following steps of: 1) thin-walled cylinder diameter design before sizing; 2) thin-walled cylinder pre-heating treatment; 3) installation of special thermal bulging core die; 4) thermal bulging treatment of a thin-walled cylinder; 5) discharging and cooling; 6) appearance detection of the thin-walled cylinder; and 7) repetition of sizing treatment. By utilizing the diameter size and shape precision control method provided by the invention, quantitative thermal bulging with proper plastic stretching is carried out on the thin-walled cylinder by using the special thermal bulging core die, so that the diameter size is accurately controlled, and the appearance correction effect is good. The diameter size and shape precision of the obtained thin-walled cylinder are higher, so that the product design precision requirements can be entirely met.

Owner:AEROSPACE SCI & IND KET TECH CO LTD

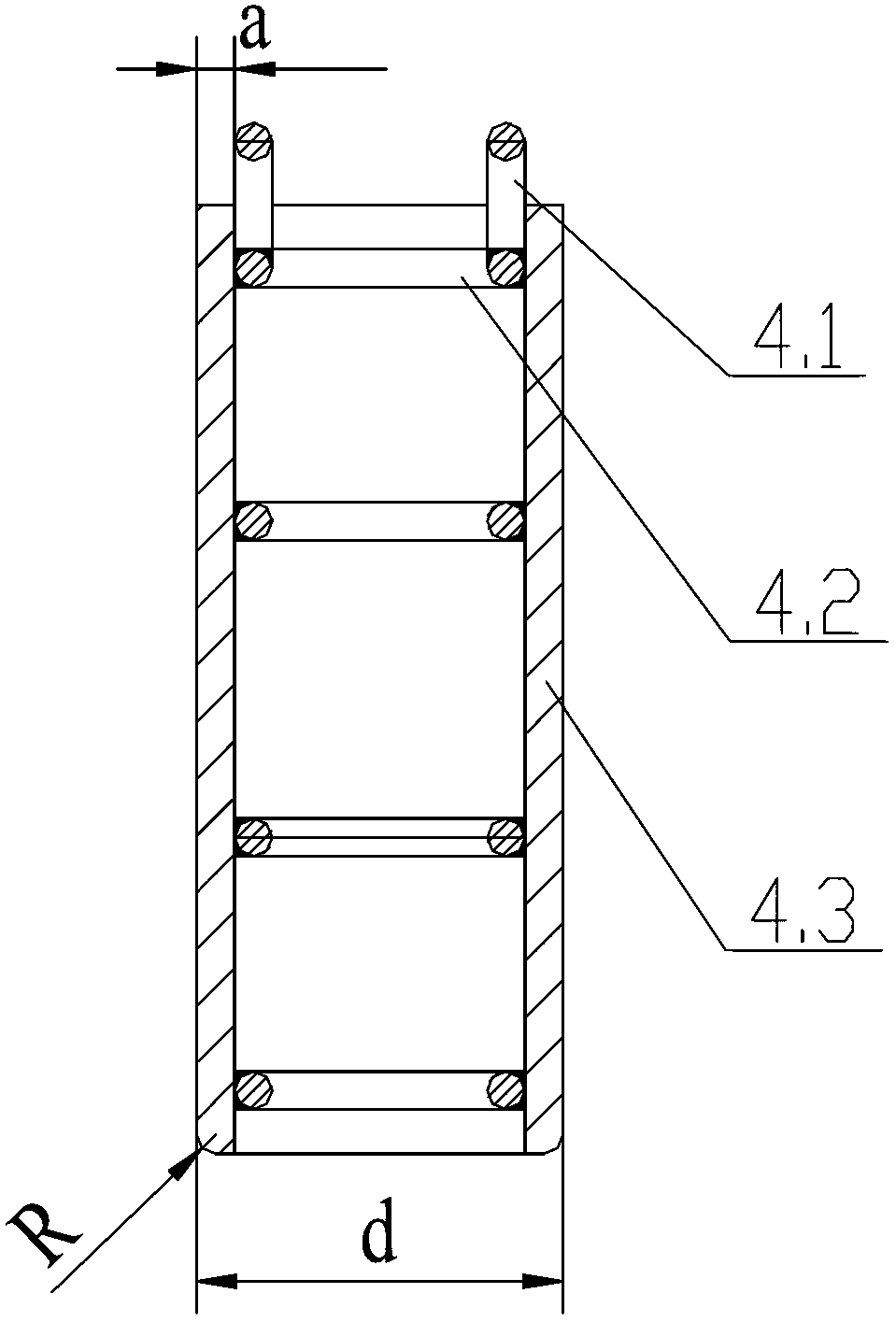

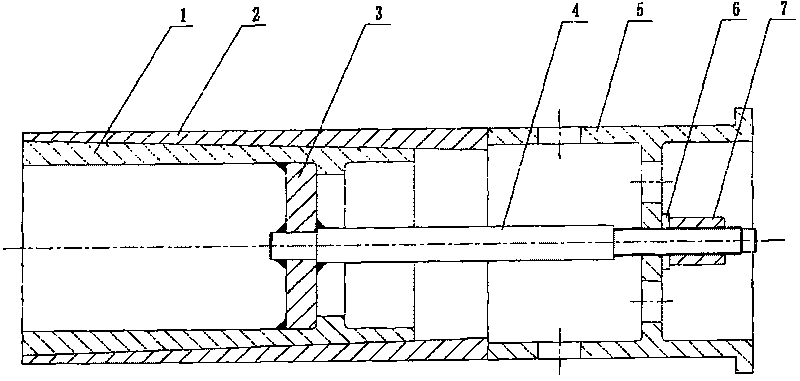

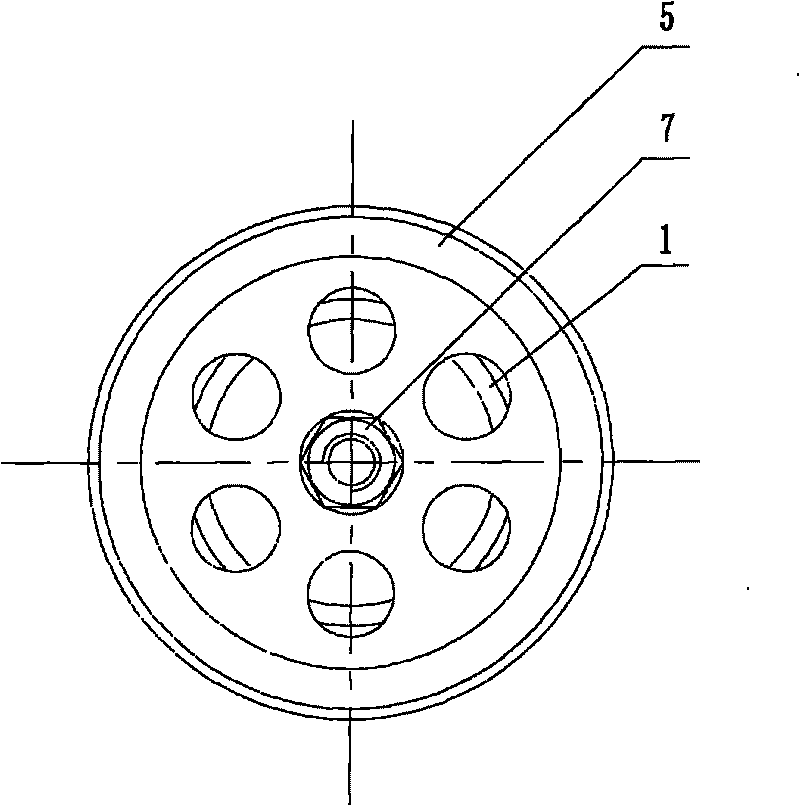

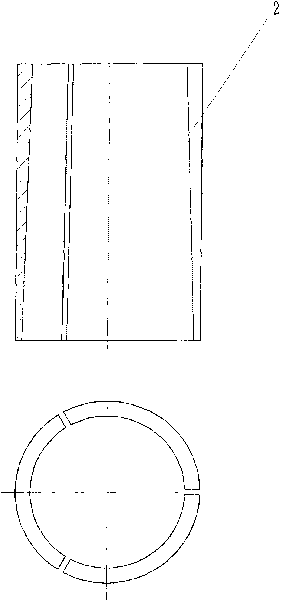

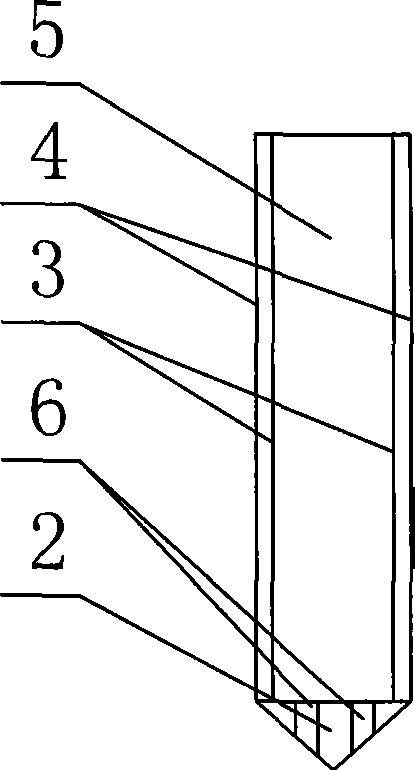

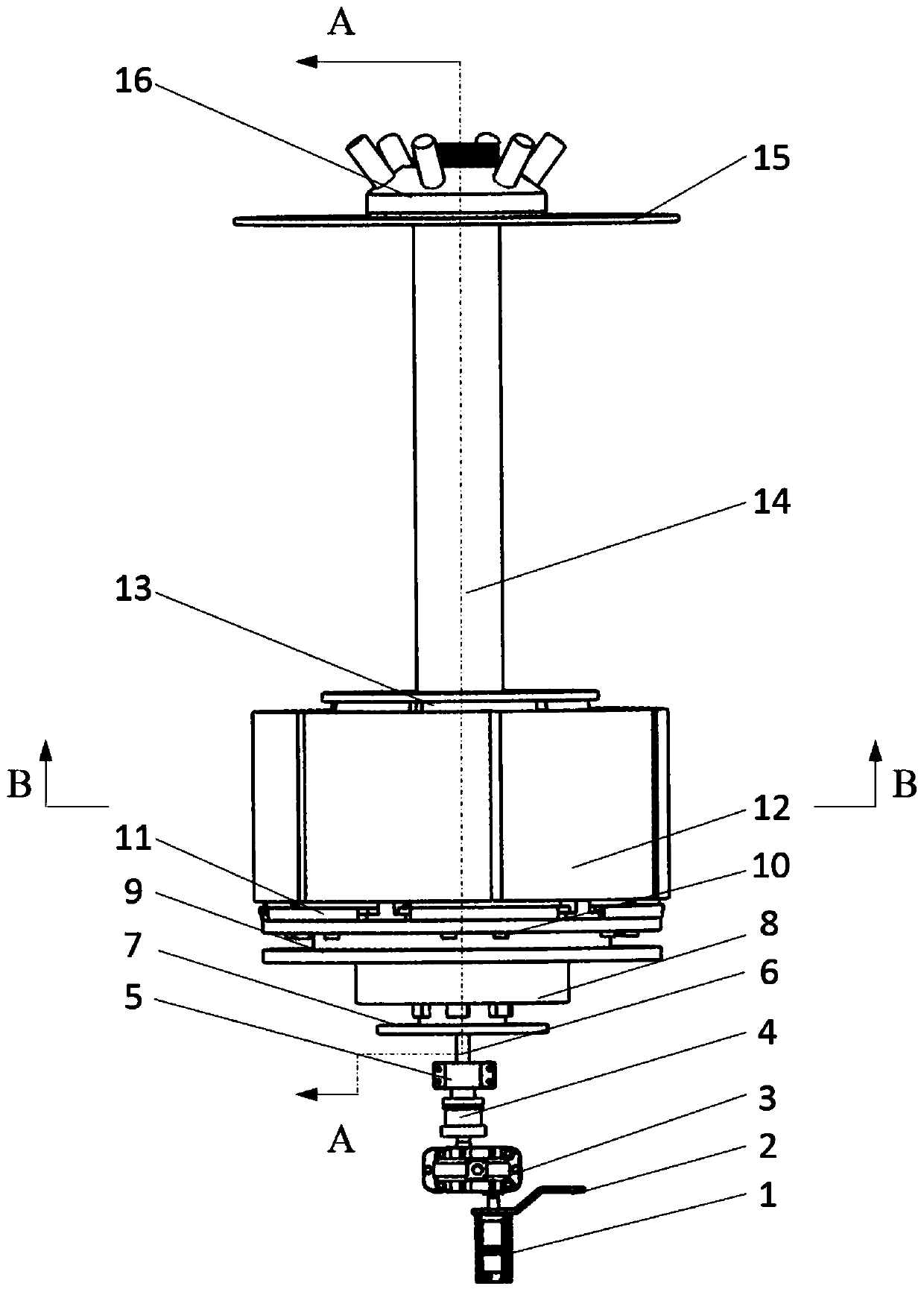

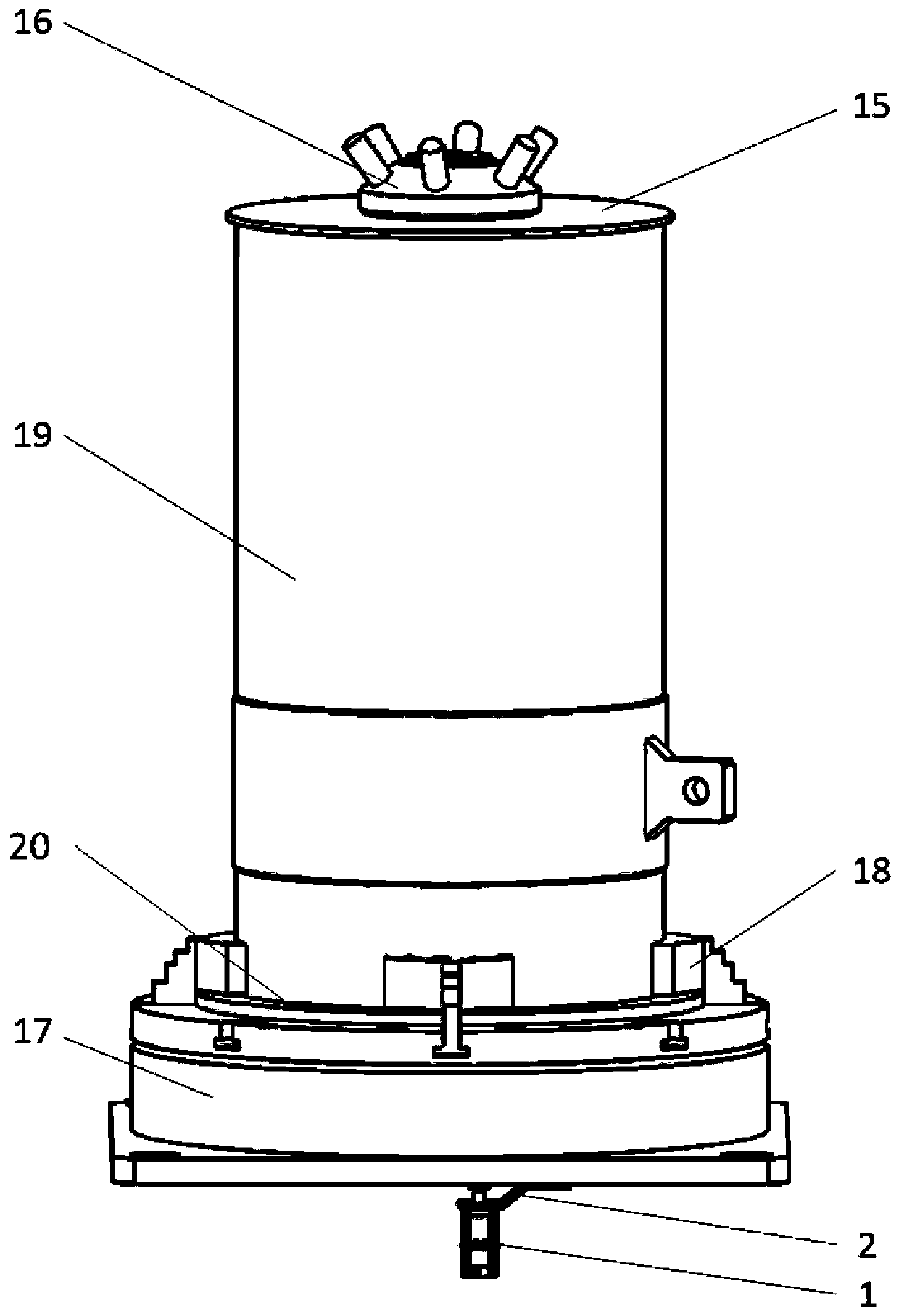

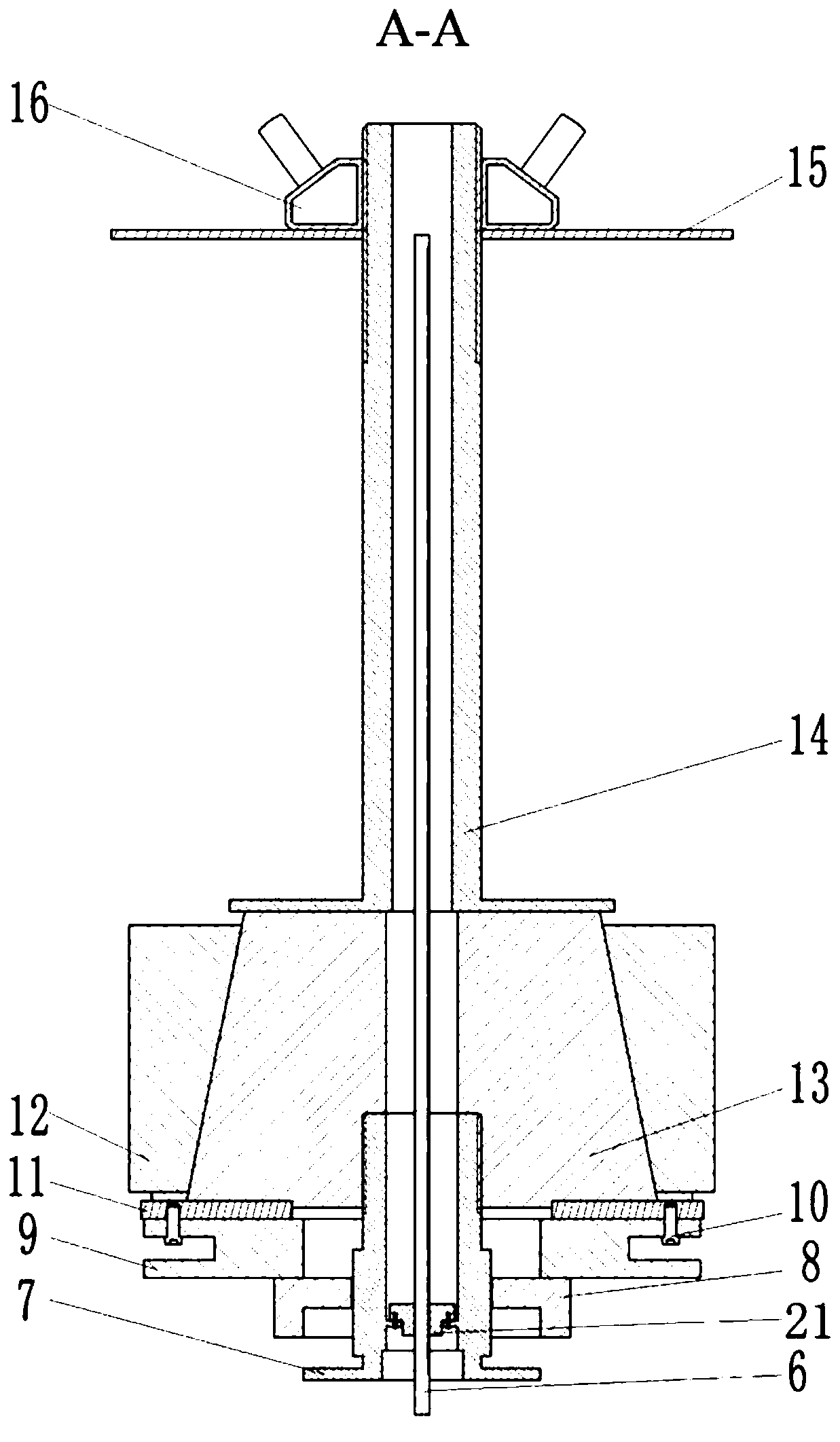

Tempering adjusting device of thin-walled cylinder body

InactiveCN101709357AReduce irregular deformationHigh precisionFurnace typesHeat treatment furnacesThin walled cylinderQuenching

The invention discloses a tempering adjusting device of a thin-walled cylinder body, belonging to the technical field of technological equipment. The tempering adjusting device is mainly used for tempering adjustment of the metal thin-walled cylinder body after heat treatment quenching and has the main technical characteristic of comprising a cone 1, a movable swelling block 2, a pulling plate 3, a screw 4, a check ring 5, a gasket 6 and a large nut 7, wherein the movable swelling block 2 is divided into three equal conical petals; the outer surface cone angle of the cone 1 is consistent to the inner surface cone angle of the movable swelling block 2 and is matched with the cone 1 through the three-petal type movable swelling block 2 with conicity; and the movable swelling block 2 swells the thin-walled cylinder body to be round under the action of the axial movement of the screw 4. The invention synchronously adjusts and tempers the quenched thin-walled cylinder body, can effectively eliminate the quenching deformation of the thin-walled cylinder body and enhance the tempering precision and has simple and reasonable structure, convenient and reliable operation, low manufacturing cost, and the like.

Owner:JIANGNAN MACHINERY GROUP CO LTD

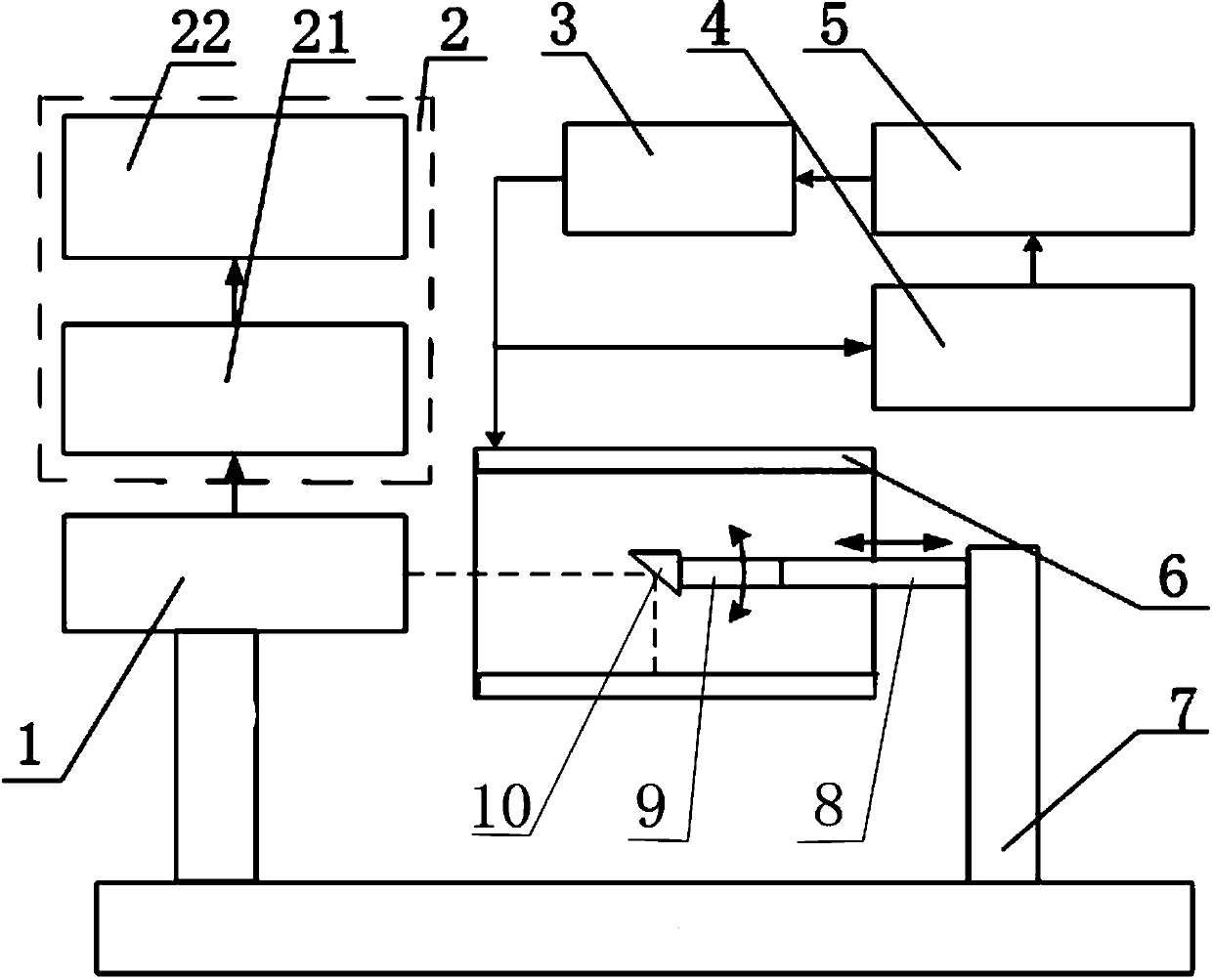

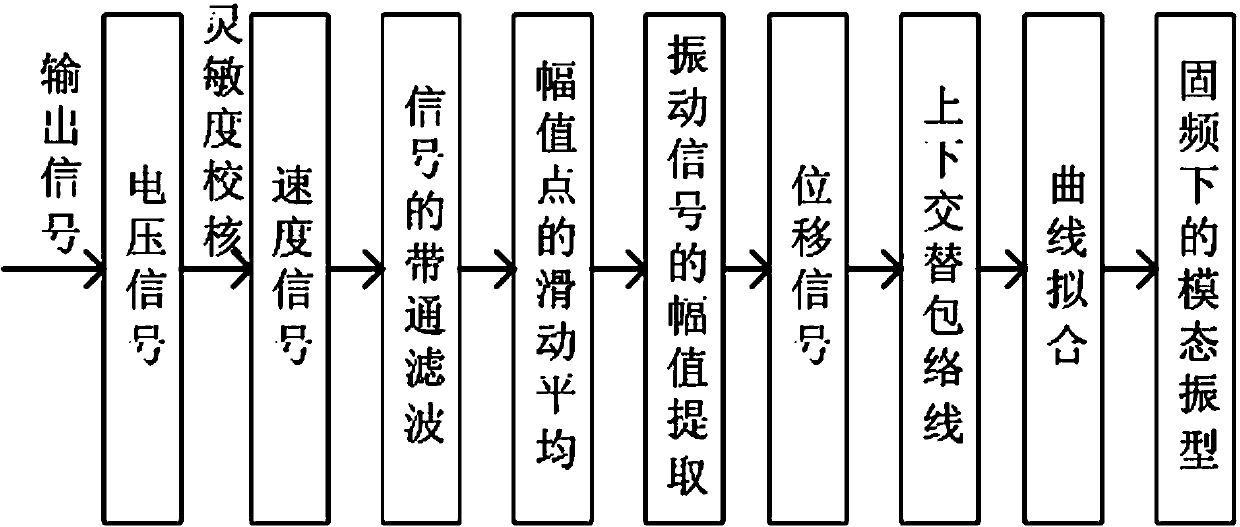

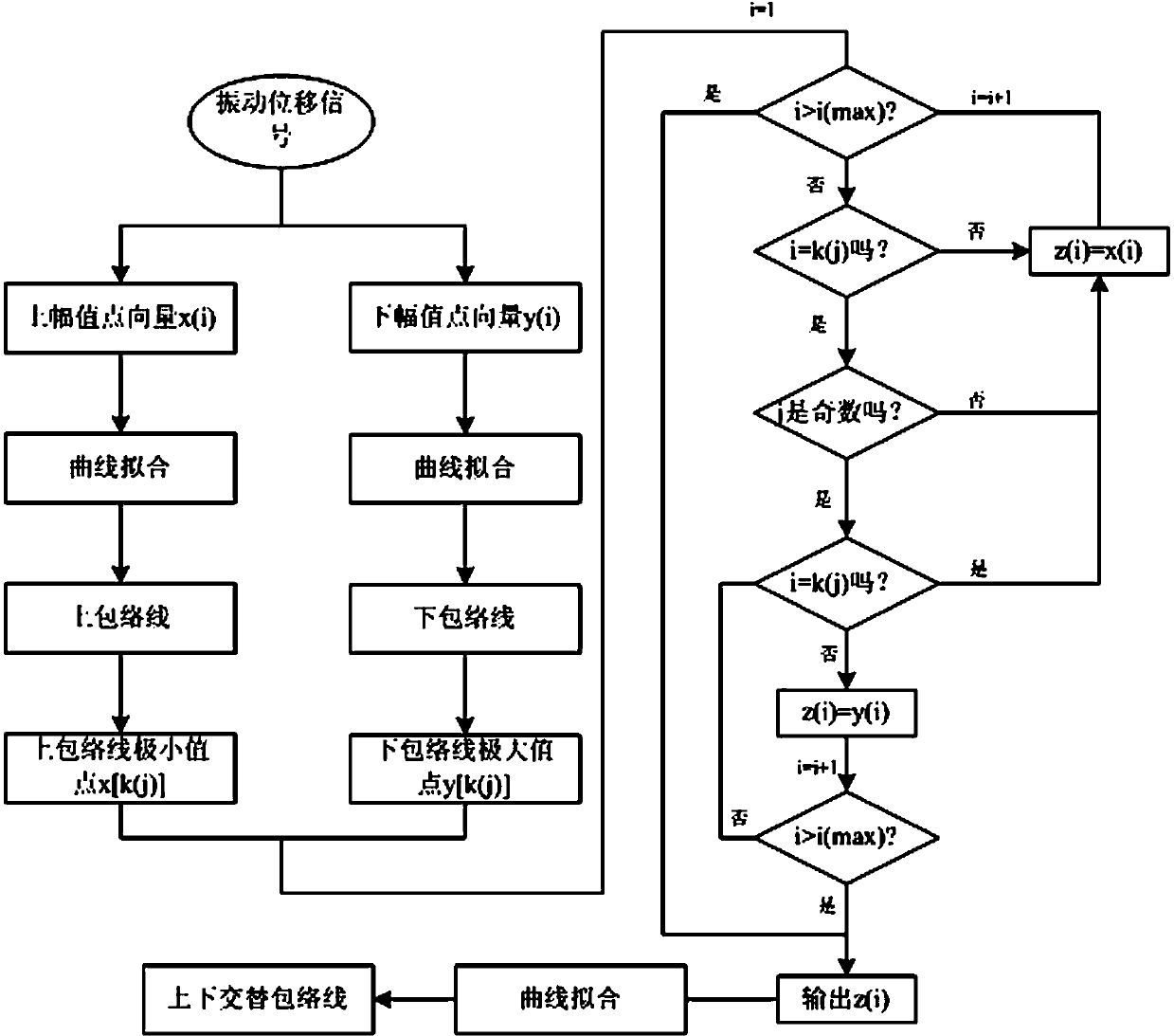

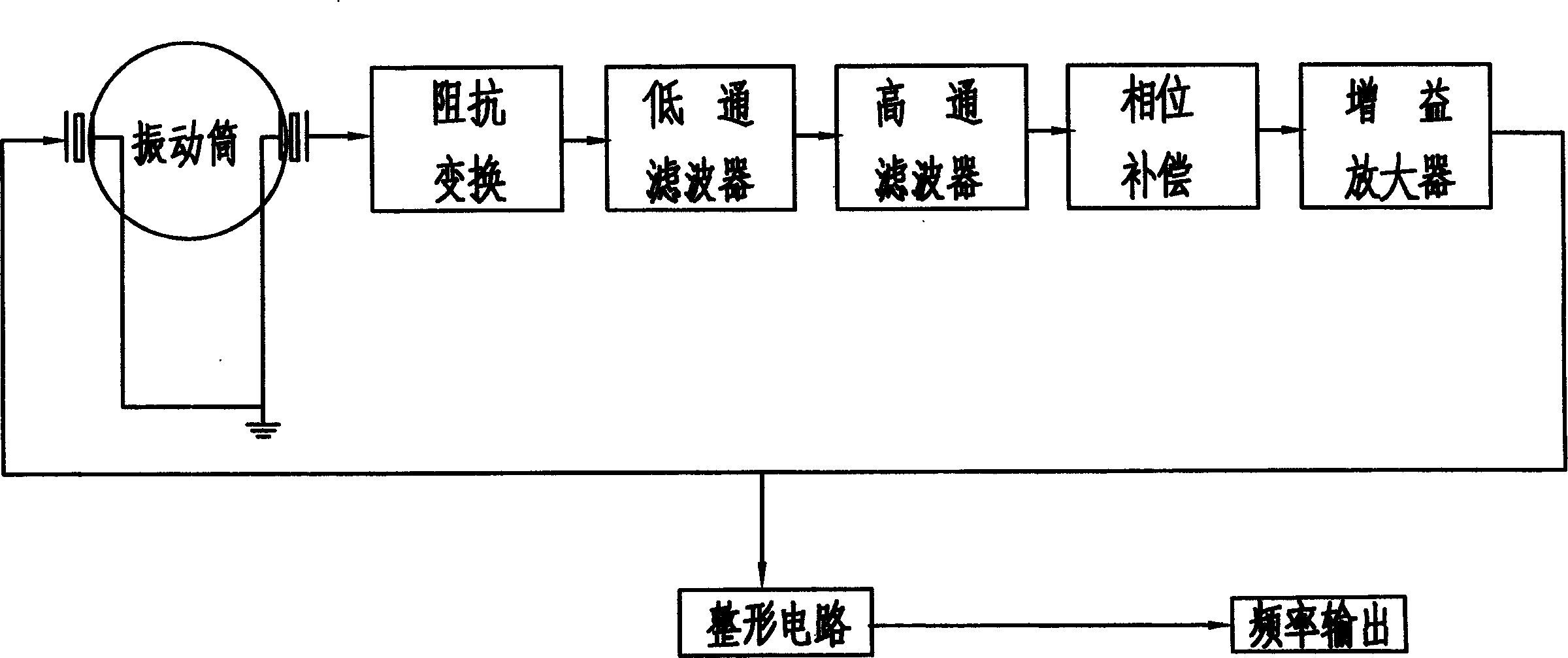

Thin-wall cylinder modal test system and method for single-point laser continuous scanning vibration test

ActiveCN103364071AGuaranteed to be verticalHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansContinuous scanningData acquisition

The invention discloses a thin-wall cylinder modal test system and method for a single-point laser continuous scanning vibration test. The thin-wall cylinder modal test system for the single-point laser continuous scanning vibration test comprises a thin-wall cylinder, a laser vibrometer, a right-angle prism with a 45-degree angle, a vibration exciter and a data acquisition system, wherein the thin-wall cylinder is suspended on a bracket; the right-angle prism with the 45-degree angle is arranged on the thin-wall cylinder center line in the thin-wall cylinder and fixedly arranged at one end of a rotation motion control system; the rotation motion control system is arranged on the end part of a linear motion control system; the linear motion control system is fixedly arranged on the bracket and parallel to the axis of the thin-wall cylinder; a laser head of the laser vibrometer is arranged on the bracket and opposite to the inclined surface of the right-angle prism with the 45-degree angle; the laser vibrometer is connected with the data acquisition system; the laser vibrometer is connected with the thin-wall cylinder by an elastic top rod. The thin-wall cylinder modal test system and method disclosed by the invention have the advantages of high test precision and test efficiency for the thin-wall cylinder vibration modal.

Owner:HUNAN UNIV OF SCI & TECH

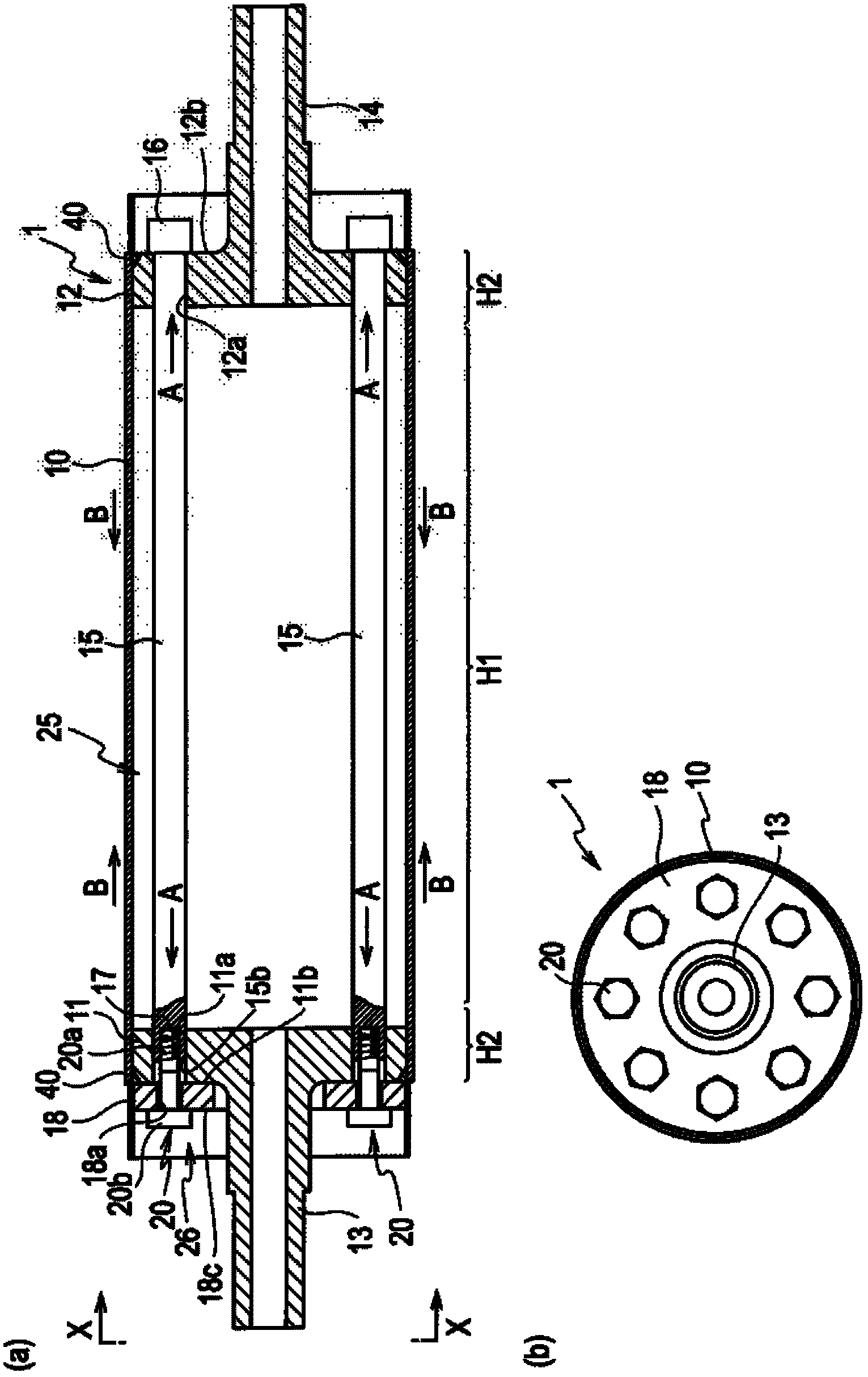

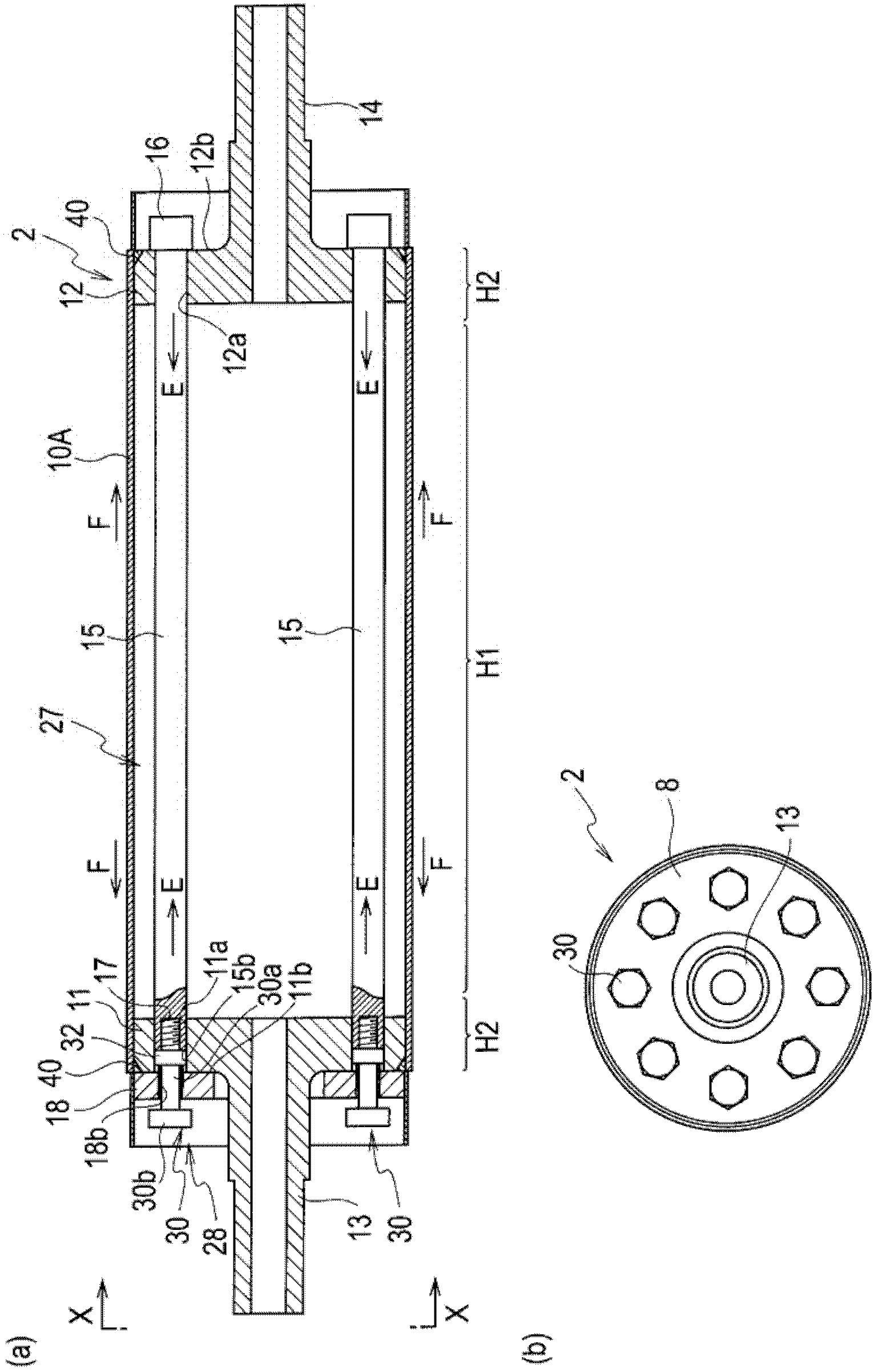

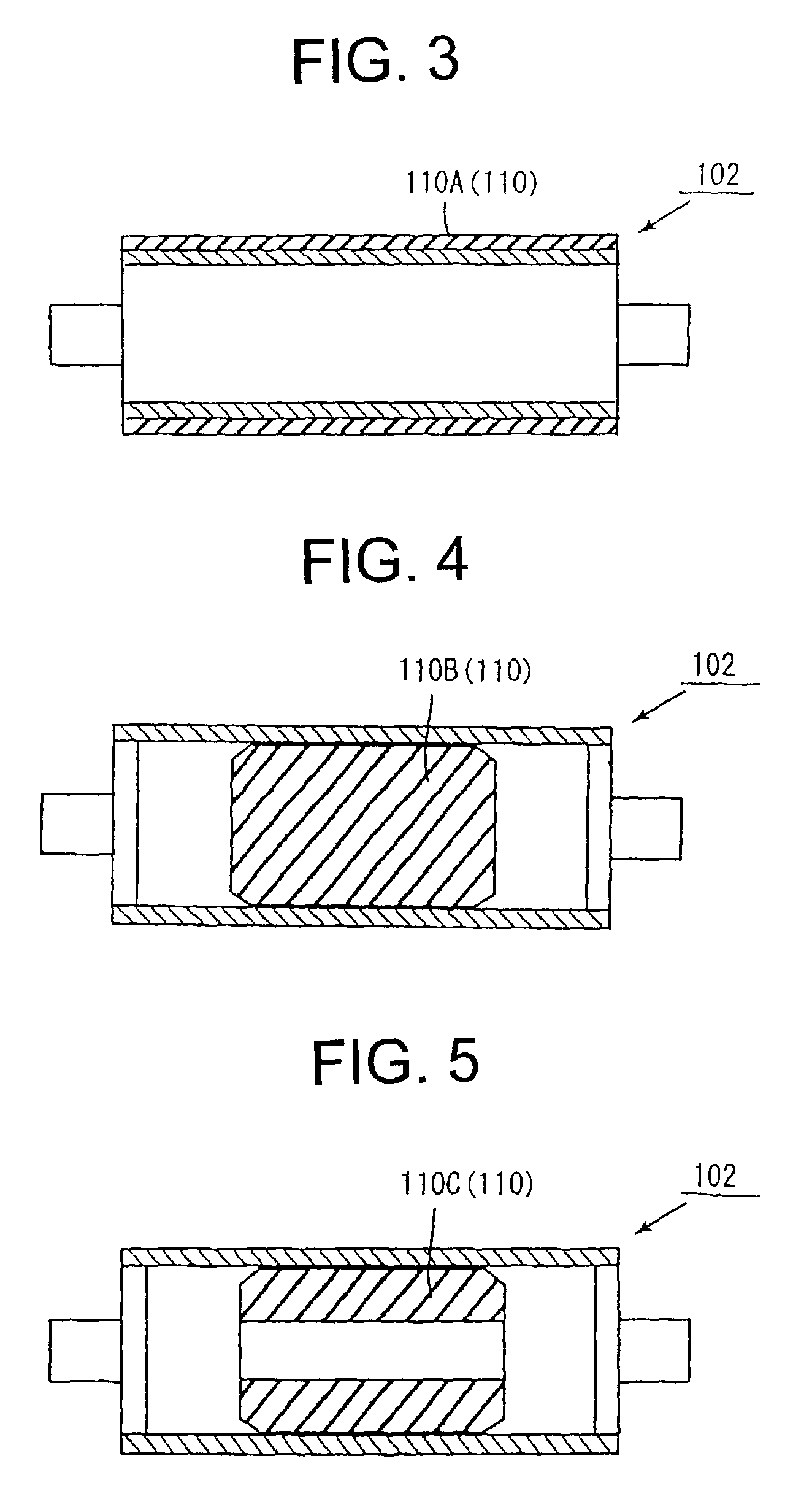

Jig for holding thin cylindrical work, method for processing thin cylindrical work, and sheet film forming roll

InactiveCN102427903AImprove cylindricityImprove surface roughnessSleeve/socket jointsWorkpiecesSheet filmEngineering

A holding jig (1, 2, 3) for a thin cylindrical work (W) includes a holding member (10, 10A, 10B) which holds the work (W) from an inner peripheral side and a diameter changing unit (25, 27) which changes a diameter of the holding member (10, 10A, 10B). The holding member (10, 10A, 10B) is made of metal and has a cylindrical shape and an elastically expandable or contractible diameter. The holding member (10, 10A, 10B) is configured with an outside diameter of the holding member (10, 10A, 10B) being held smaller than an inside diameter of the work (W) at the time of insertion into an inner periphery of the work (W) and being expanded after inserted into the inner periphery of the work (W) to hold the work (W) from an inner peripheral side of the work (W) with an outer peripheral surface in close contact with an entire inner peripheral surface of the work (W). The diameter changing unit (25, 27) applies at least one of an axial external force in a compressing direction or an axial external force in a tensile direction to both ends of the holding member (10. 10A, 10B) to change the diameter of the holding member (10, 10A, 10B).

Owner:TOSHIBA MASCH CO LTD

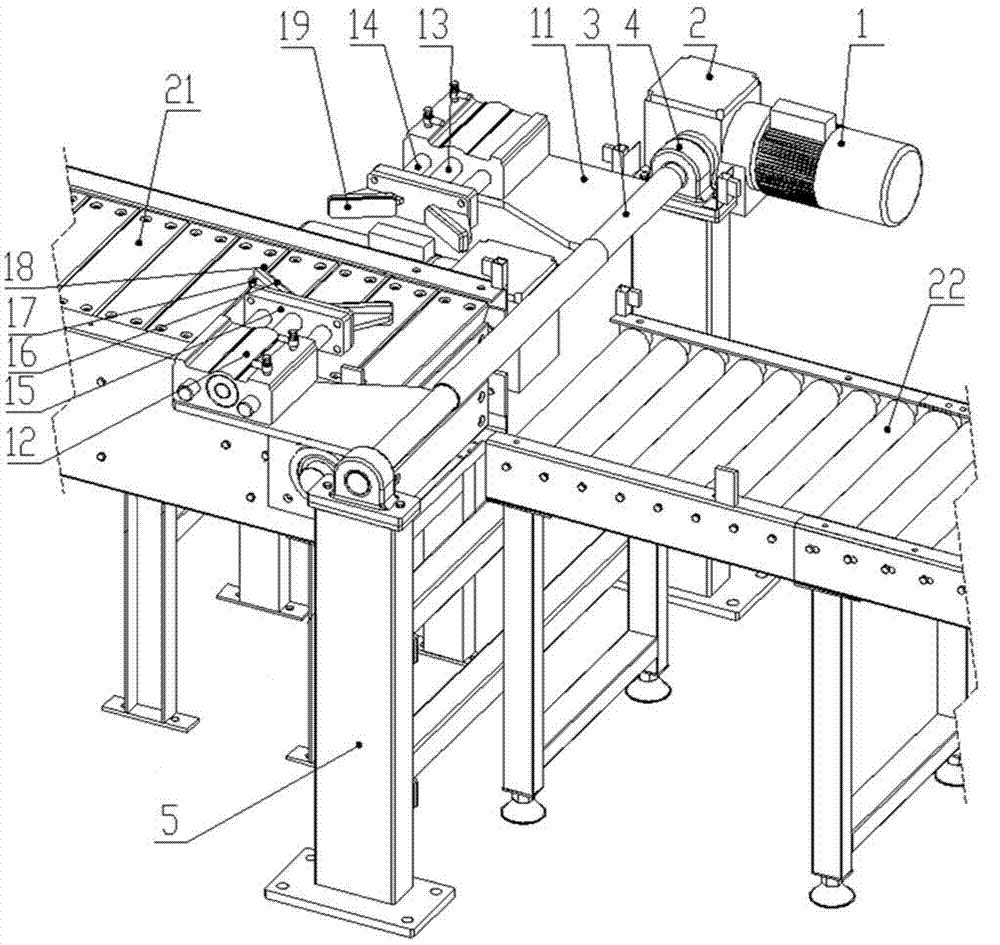

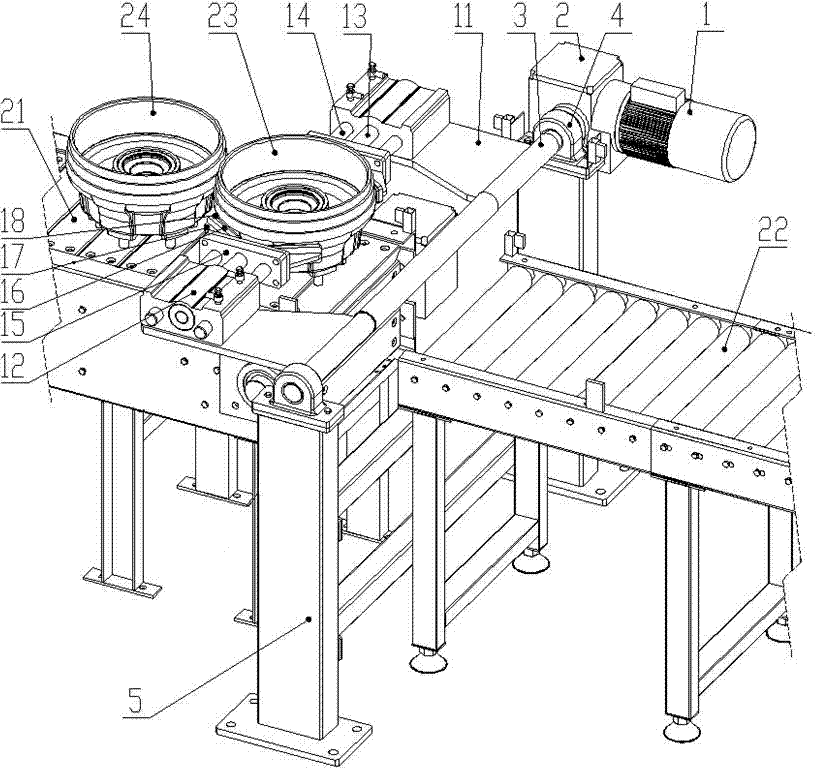

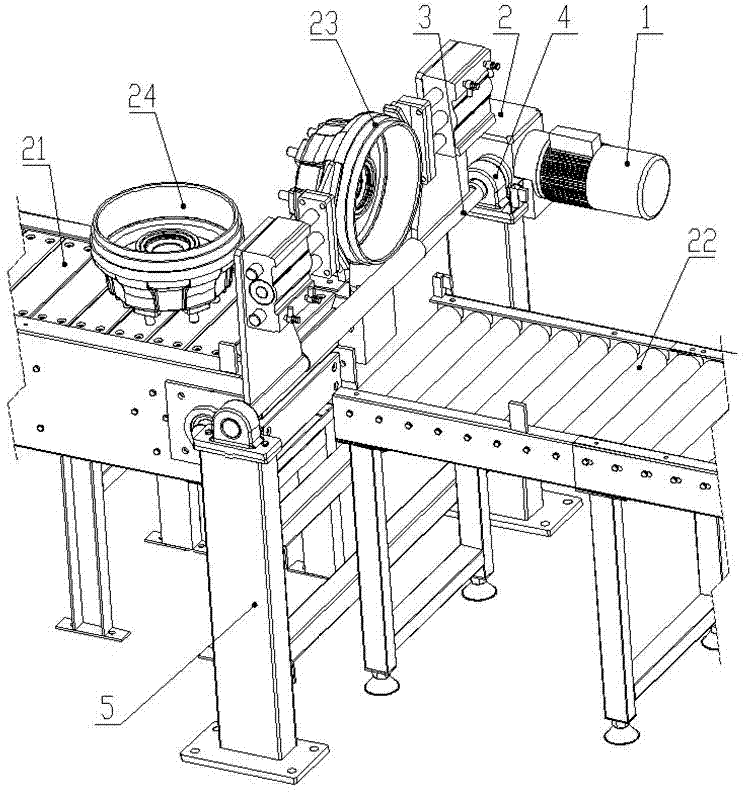

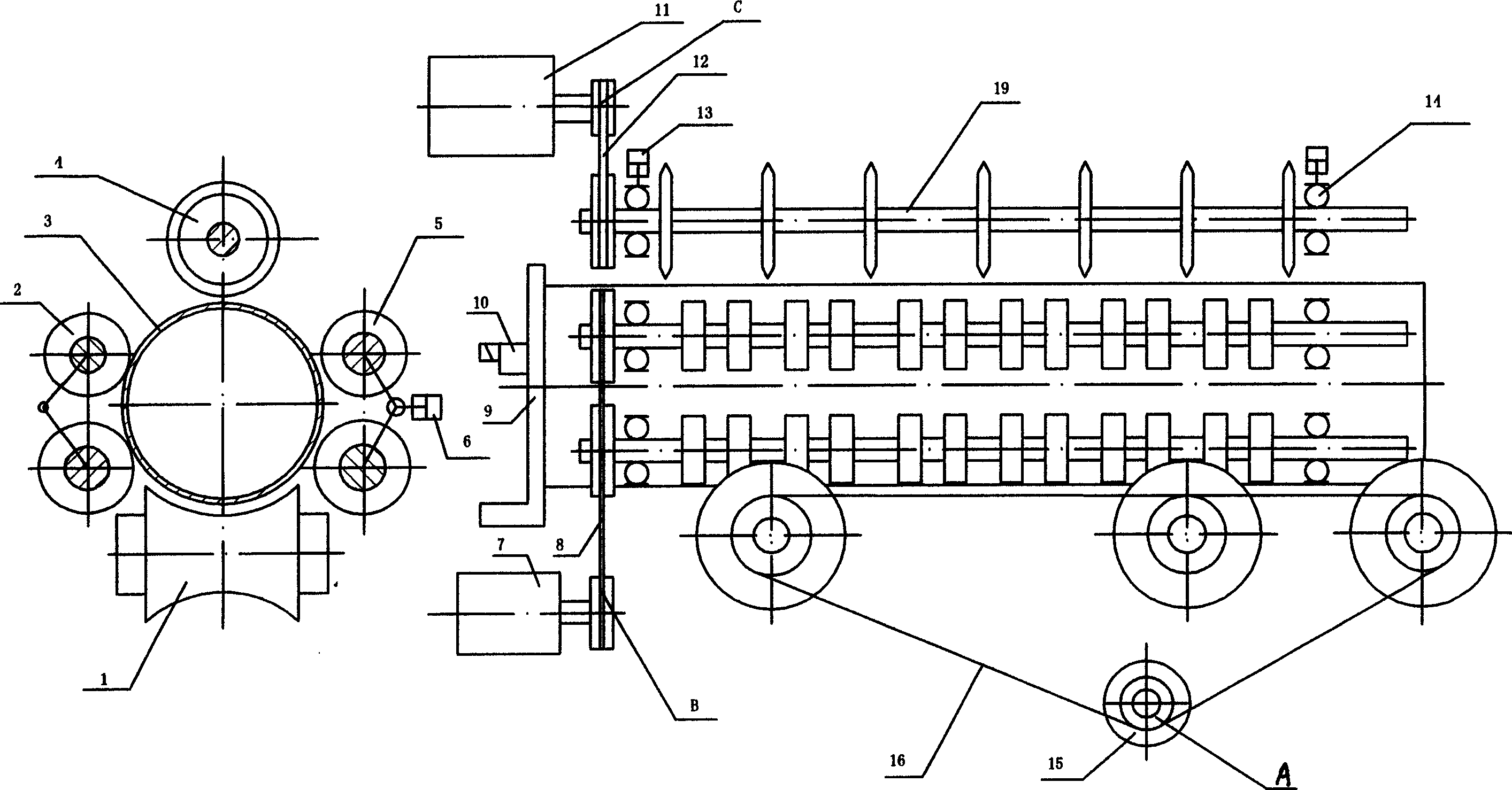

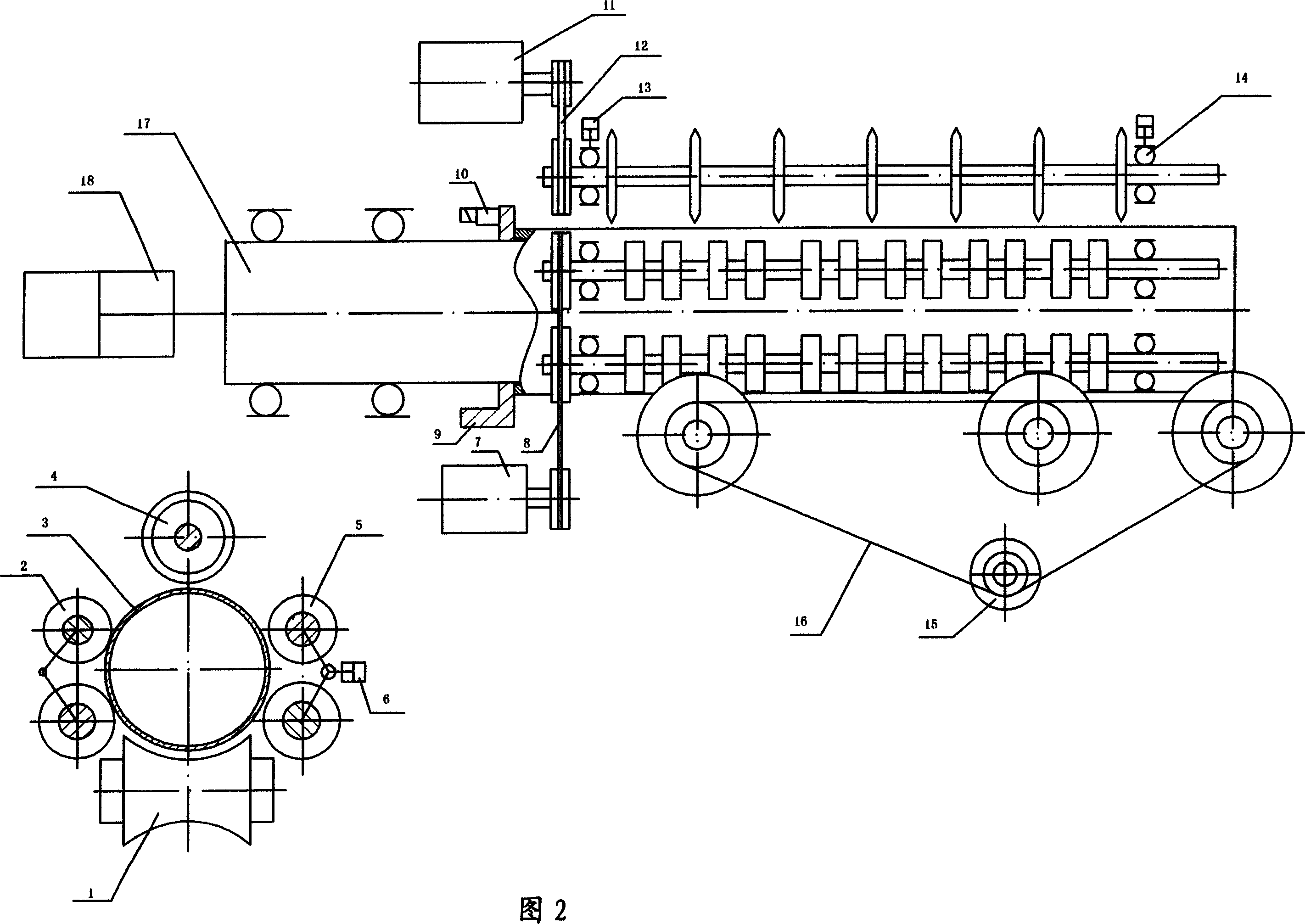

Rapid length-measuring cutting process and apparatus for thin wall cylinder

ActiveCN1557590AHigh speedFewer processing stepsTube shearing machinesMetal working apparatusEngineeringKnife blades

The present invention is fast fixed length thin-wall cylinder cutting process and apparatus. The cutting process includes the following steps: for the feeding assembly to deliver the cylinder to cutting position; for the rotating assembly to rotate the cylinder; for the cutter rotating assembly to drive the cutter to cut. The feeding assembly includes cylinder feeding mechanism and feeding wheel with rotating shaft connected to the output of the cylinder feeding mechanism; the rotating assembly includes rotating mechanism and rotating wheel with rotating shaft connected to the output of the rotating mechanism; and the cutter rotating assembly includes cutter driving mechanism, several cutters and cutter rotating shaft connected to the output of the cutter driving mechanism. The present invention has fast cutting sped, less cutting steps, accurate size and other advantages.

Owner:SHENZHEN XINTIAN TECH

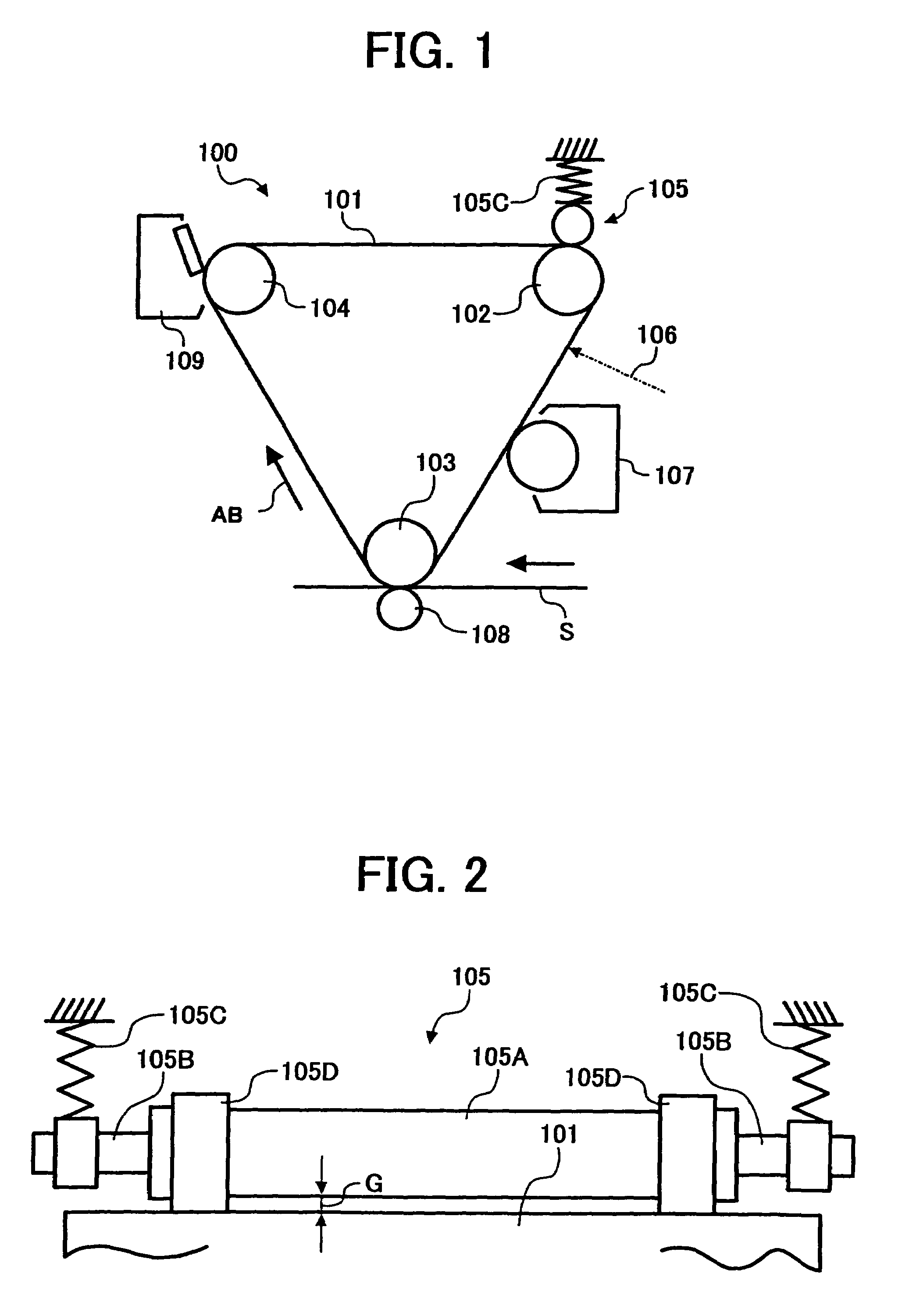

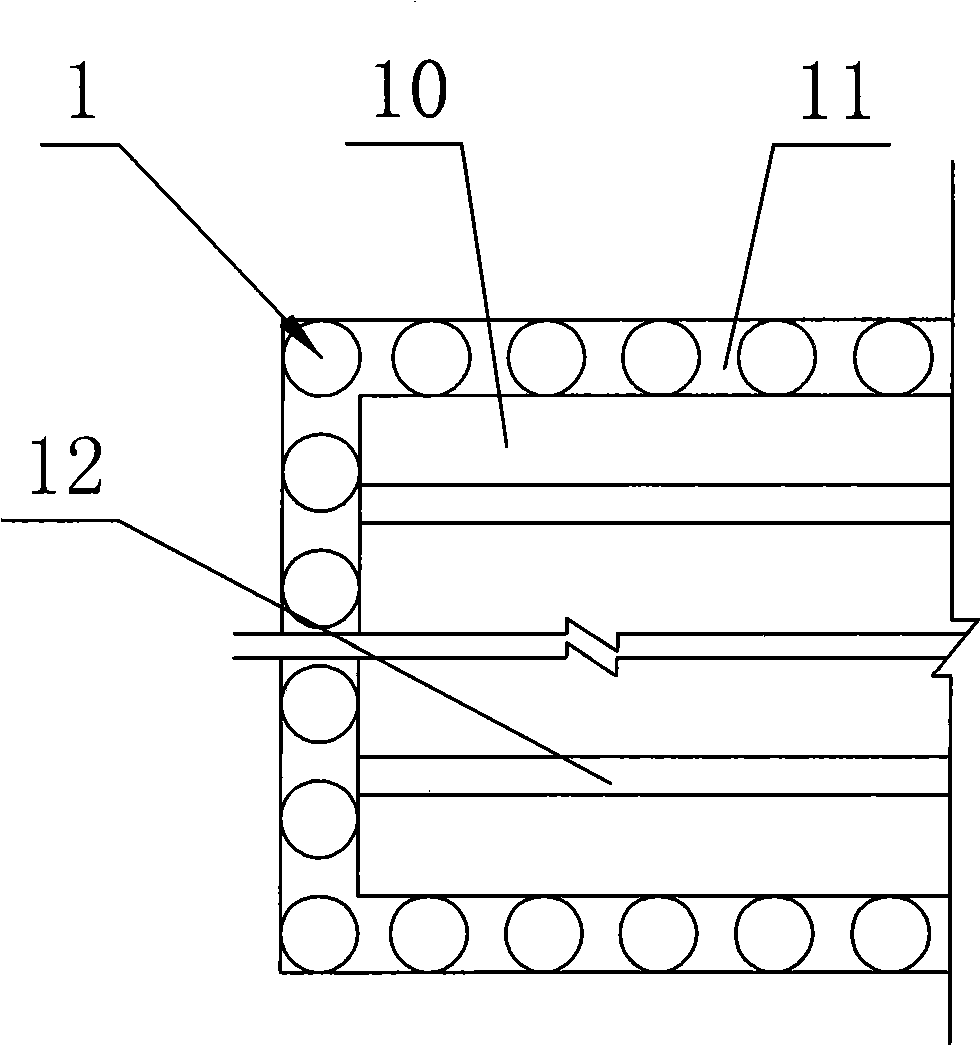

Radial locating unit and locating and clamping device for internal grinding of thin-walled cylinder workpieces

ActiveCN105397636AGuaranteed automaticImprove radial positioning accuracyRevolution surface grinding machinesGrinding work supportsEngineeringMachining process

The invention discloses a radial locating unit and locating and clamping device for internal grinding of thin-walled cylinder workpieces, belonging to the technical field of machining processes. The radial locating unit comprises a supporting base and a supporting cover, wherein one end of the supporting cover is pivoted to the supporting base; the supporting base is provided with a clamping curved surface I, and the supporting cover is provided with a clamping curved surface II, so that workpieces are clamped; the supporting base is provided with a fixing part capable of fixing the supporting cover when the supporting cover and the supporting base are buckled; the clamping curved surface I is provided with inward concave structures to form hydraulic chambers I; the clamping curved surface II is also provided with inward concave structures to form hydraulic chambers II; and the locating and clamping device also comprises a hydraulically-supported axial locating driving unit. The radial locating unit and the locating and clamping device are uniform in clamping force, difficult to deform, more suitable for internal grinding of workpieces with small diameters and capable of improving the locating rigidity and precision, avoiding damage of the surfaces of the workpieces, effectively cooling grinding wheels and the workpieces and reducing thermal strain.

Owner:DALIAN UNIV OF TECH

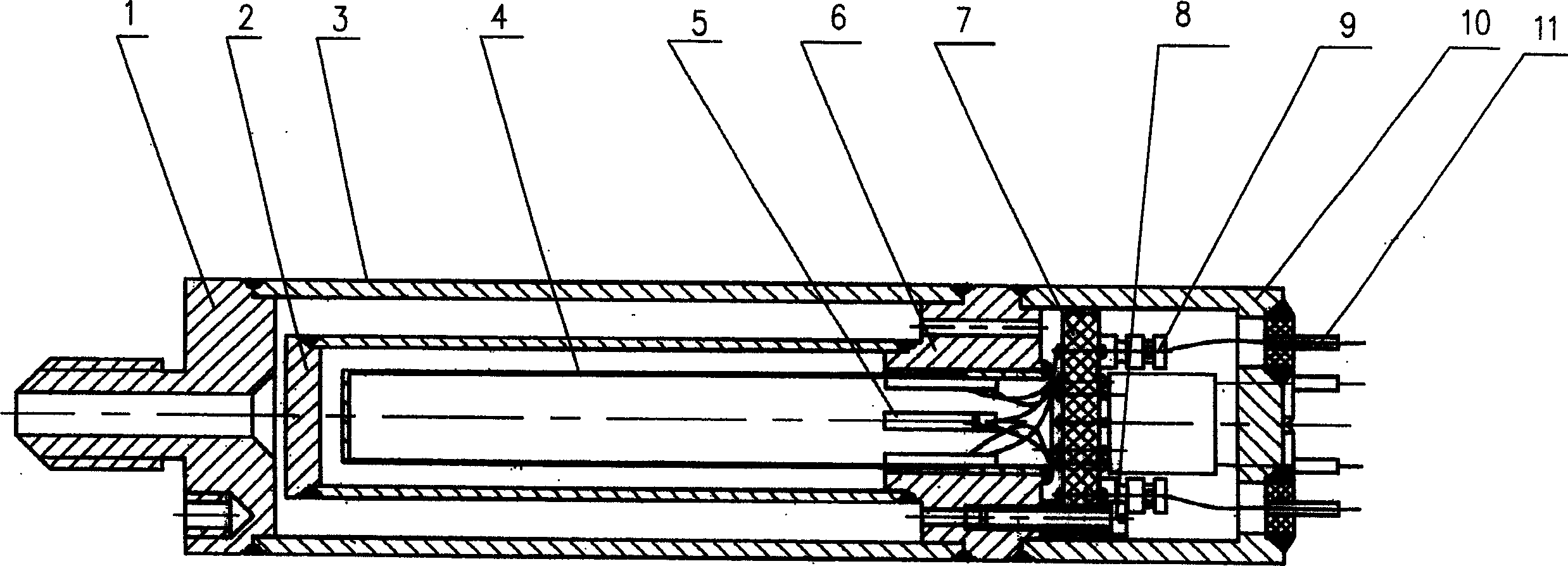

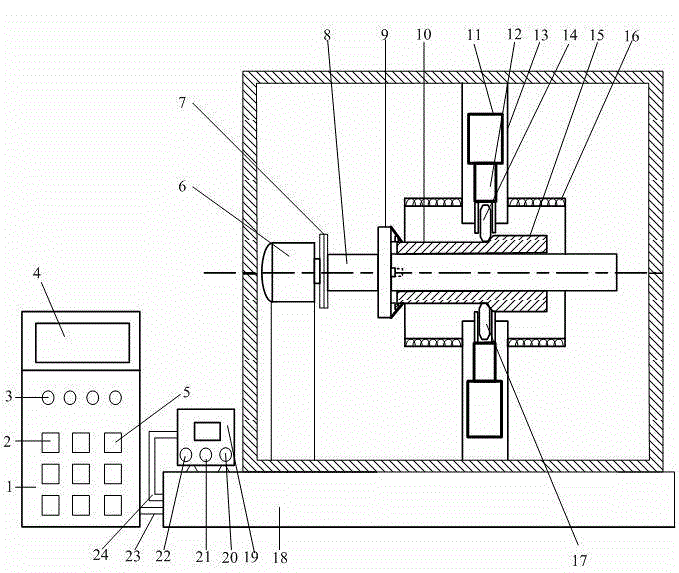

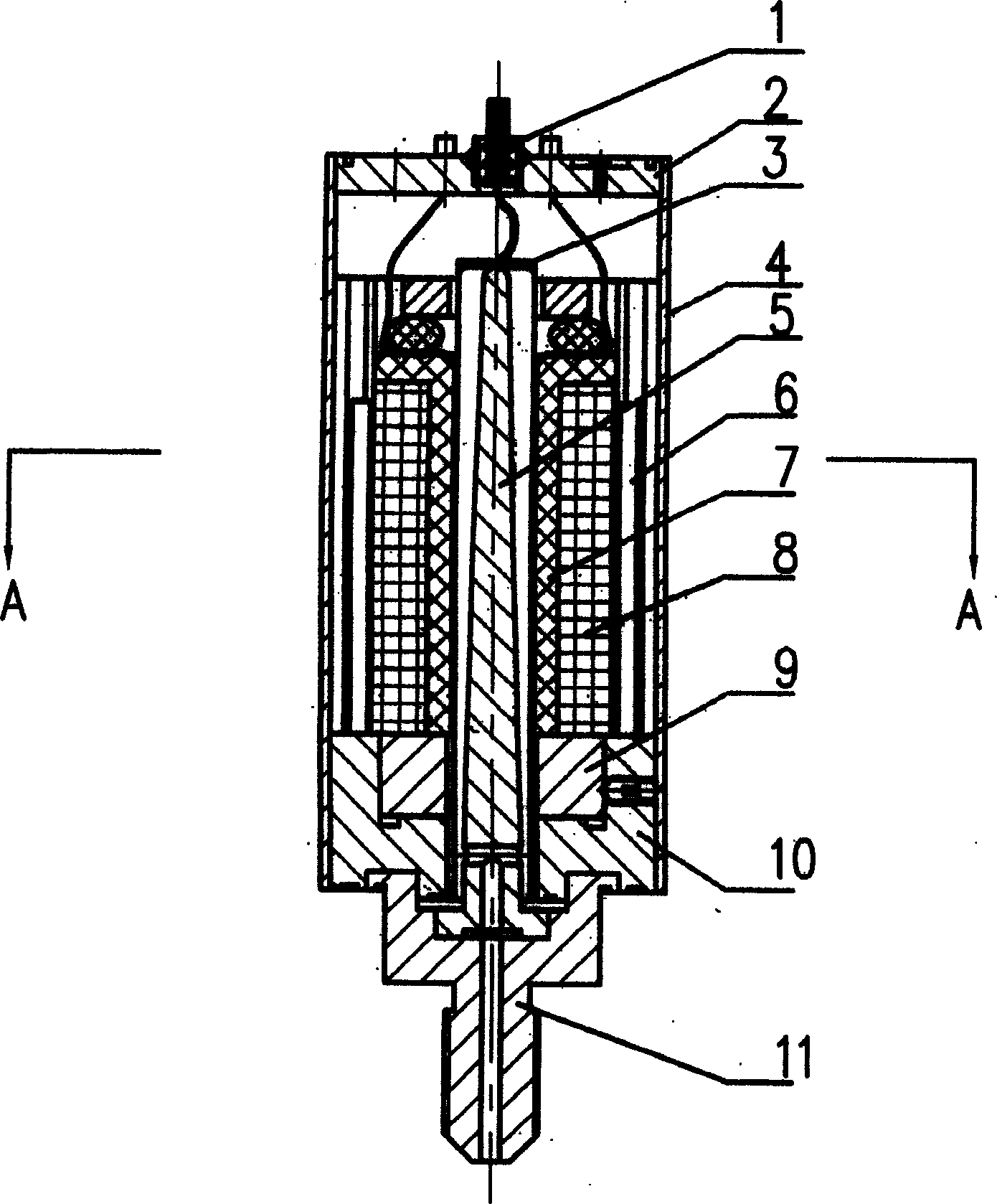

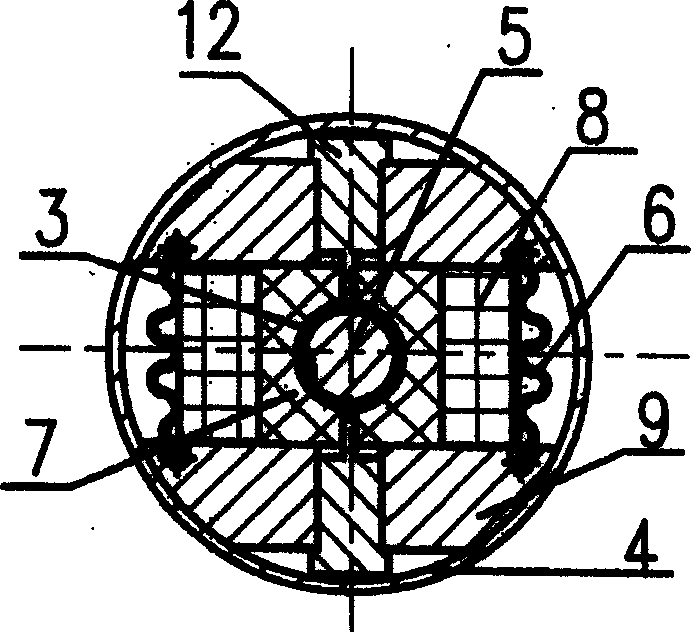

Pressure sensor of piezoelectric excitation vibrating cylinder

InactiveCN1546970AHigh precisionImprove stabilityFluid pressure measurement using piezo-electric devicesElectricityPiezoelectric actuators

The invention is a kind of piezoelectric driving vibration cylinder pressure sensor, which belongs to vibration cylinder pressure sensor; the product has a high precision, excellent stability, and the structure is simple, easy to be produced; the invention includes the sensitive elements and motivation circuit; the sensitive elements include pressure aperture, a vacuum protecting cylinder, an outer cylinder, a thin-wall cylinder, a piezoelectric element, a cover ring, a cover base, connectors, insulator and inner wiring board; the cover base is set with an insulator, the thin-wall cylinder and the vacuum protecting cylinder are connected by cover ring; the aperture and the cover ring are connected through an outer cylinder. A pair of piezoelectric elements is pasted at two sides of the sensitive thin-wall cylinder, the wire on the piezoelectric element passes through the connector on the inner wiring board, and connects with the outer circuit through insulator; the sensitive element structure is welded with vacuum electron beam welding type.

Owner:TAIYUAN AERO INSTR

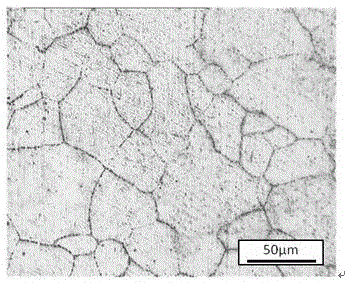

Ultrasound spinning forming technique for magnesium alloy cylinders

InactiveCN104438536AHighlight substantiveGood mechanical propertiesMechanical vibrations separationInstabilityHardness

The invention discloses an ultrasound spinning forming technique for magnesium alloy cylinders, aiming to solve the problems that swelling, instability and forming technique control difficultly of magnesium alloys are easily caused in the process of large-deformation spinning during plastic deformation of spinning forming due to poor plastic deformation performance. An ultrasound-generating processing device is introduced on the basis of conventional spinning forming equipment to enable the high-strength thin-walled magnesium alloy cylinders to be obtained by an ultrasound spinning device. The ultrasound spinning forming technique has the advantages that the processing technique is advanced, textures of processed magnesium alloy spinning cylinders are twinborn textures and recrystallization textures, thin-walled cylinders with wall thickness of 1mm are obtained after ultrasound spinning of magnesium alloy as-cast cylinder blanks with original cylinder blank wall thickness of 20mm, the average Vickers hardness of final cylinders is 124.7HV, the tensile strength is 285Mpa, and the elongation is 3.2%, so that the ultrasound spinning forming technique is a quite ideal plastic forming technique for the magnesium alloys.

Owner:TAIYUAN UNIV OF TECH

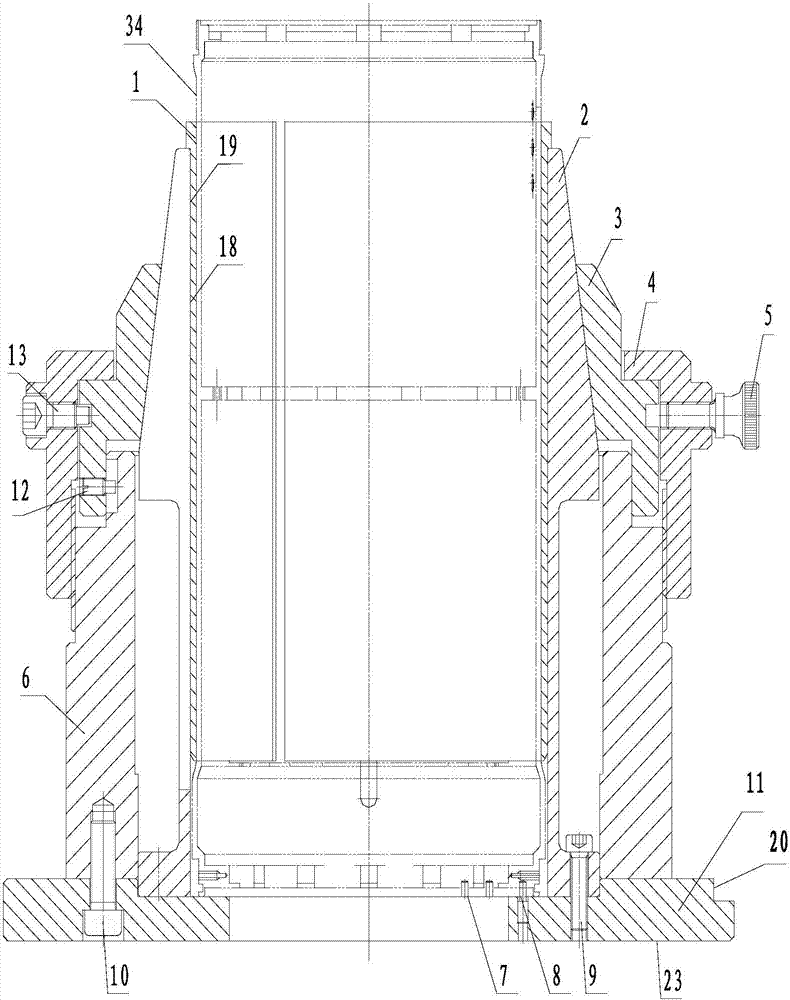

Hydraulic clamp for positioning and automatically clamping thin-walled steel sleeve through inner hole and using method thereof

PendingCN109262292APlay the role of sealing hydraulic oilEasy to stretchWork clamping meansPositioning apparatusProduction lineEngineering

A hydraulic clamp for positioning and automatically clamping a thin-walled steel sleeve through an inner hole comprises a connecting barrel which is transparent in a left-right mode and a cylinder barrel with the open left end. The right end of the connecting barrel is coaxially fixedly connected with a flange, the flange is coaxially fixedly connected with the left end of the cylinder barrel, theinner wall of a left port of the connecting barrel is provided with a bearing for being connected with a hydraulic oil pipe, and a plurality of groups of radial telescopic clamping mechanisms with the same structure are evenly disposed on the outer ring of the cylinder barrel in the axial direction. The invention positions and clamps a thin-walled cylinder sleeve in a mode of hydraulic positioning through a plurality of supporting point inner holes, the centering precision is high, and the problem of workpiece deformation caused by uneven clamping force is solved. At the same time, since insufficient installation margin is reserved between the outer ring of the cylinder barrel and the inner hole of the thin-walled cylinder sleeve and mounting and taking out are facilitated, automatic clamping of a production line is achieved easily, human labor is replaced, and production efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

Method for welding thin-walled cylinder with magnet sleeved inside in seal housing component

ActiveCN103537788ASimple and fast operationQuality improvementElectron beam welding apparatusSteam pressureEngineering

The invention provides a method for welding a thin-walled cylinder with a magnet sleeved inside in a seal housing component. The welding efficiency of the aluminum alloy thin-walled seal housing component can be obviously improved through the method, quality is stable, a connector is bright, fusion is even, and continuous and compact welding beads can be formed. According to the technical scheme, the method comprises the following steps that the butt joint positions of inner and outer housing welding joints are closely attached through a clamp, and annular welding joint pulse electron beam tack welding is carried out on the circumferential seam crossing of an assembled component; a deflection distance occurring to an electron beam caused by Lorentz force is compensated by an electron beam deflection angle; the total heat input amount of the electron beam is controlled with the impulse waveform of the pulse electron beam, the impulse waveform is steep in the front and gentle in the back, and welding is carried out through heat generated when beam flow ascends and descends; under the condition that small pulse power is set and steam pressure is reduced, a pulse back edge is prolonged by 3-5s, slow reduction is carried out, the focal position of the electron beam is adjusted to be within the range 0.55mm below the surface of a workpiece, the surface of a connector to be welded is melted and integrally welded, and the continuous welding beads are formed.

Owner:四川泛华航空仪表电器有限公司

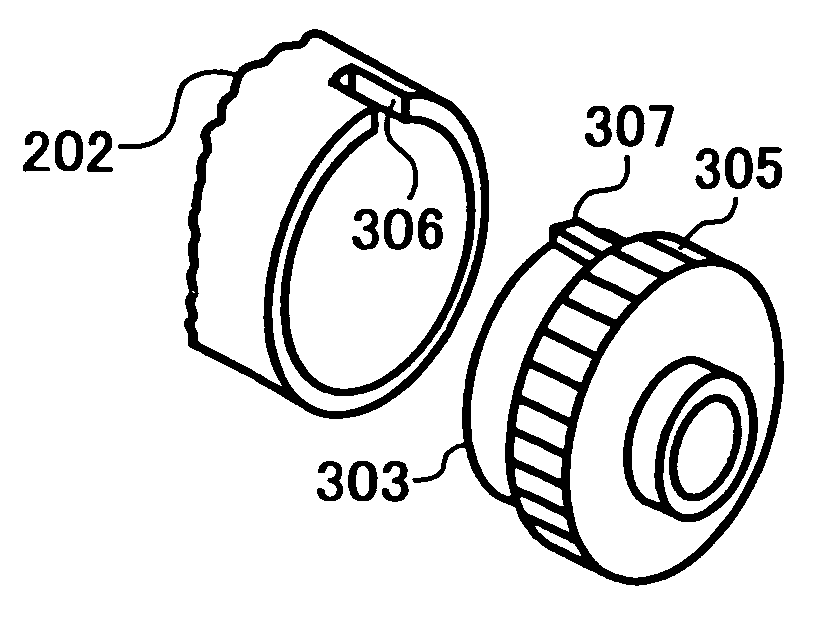

Image forming apparatus, drum unit, image forming module, and method of insertion and removal of a damper into and from an image carrier drum

An image forming apparatus includes a photoreceptor belt formed by either a belt or a thin-walled cylinder. A charging unit that sets bias characteristics of the photoreceptor belt has an arrangement to approach towards the photoreceptor belt. A damper is provided on a side of the photoreceptor belt opposite to the side facing the charging unit. The damper absorbs vibrations in the photoreceptor belt through a supporting plate.

Owner:RICOH KK

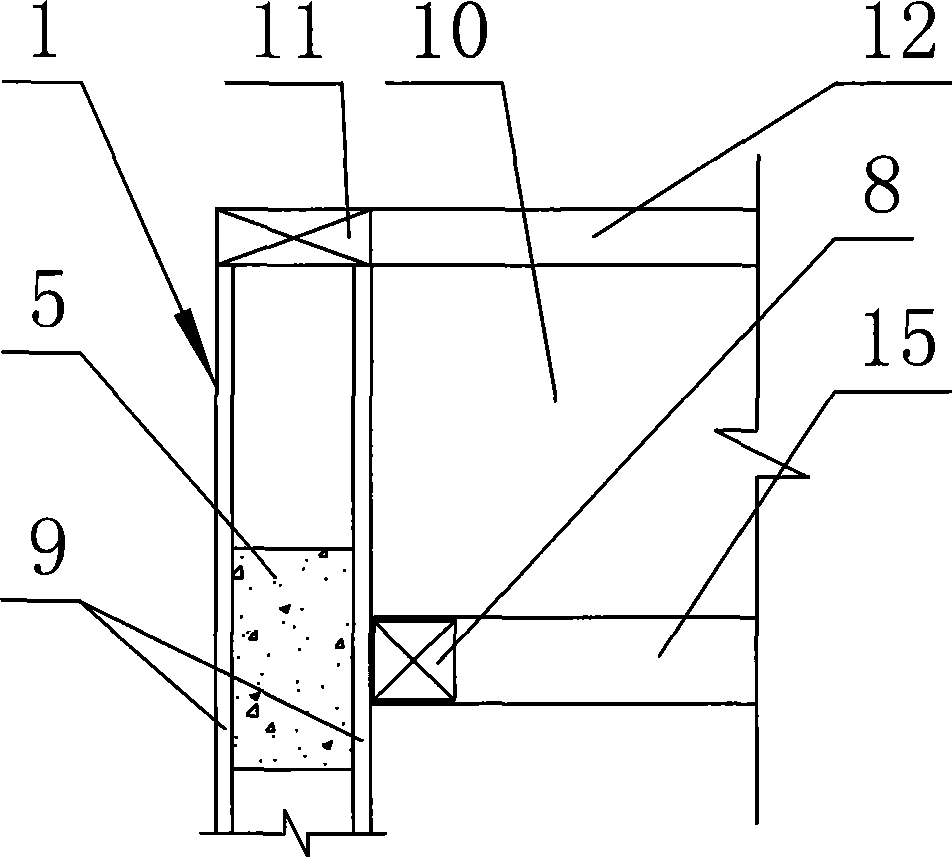

Construction method for building foundation pit enclosure structure with thin-walled cylinder pile as fender post

The invention discloses a construction method for a building foundation pit enclosure structure by using a thin-wall tubular pile as an enclosure pile, which comprises the following steps: a, discharging a pile head and mounting an inner steel cylinder template and an outer steel cylinder template; b, downwards pressing the pile head (2); c, welding an embedded piece; d, placing a steel reinforcement cage; e, pouring concrete for the tubular wall (9) of the thin-wall tubular pile; f, filling a core; g, repeating steps a to f to carry out the construction of the next enclosure pile (1); h, pouring a coping beam and an inner support at the elevation place of the coping beam; i, welding a connecting reinforcement (14) on the embedded piece; j, binding an enclosed purlin reinforcement (13) and an inner support reinforcement (16); k, mounting a template; and l, pouring concrete for an enclosed purlin (8) and an inner support (15) at the elevation place of the enclosed purlin. The construction method for the building foundation pit enclosure structure by using the thin-wall tubular pile as the enclosure pile is safe and environment-friendly, has low cost and low waste rate, and can ensure the quality of the enclosure pile.

Owner:HANGZHOU XIAOHONG CONSTR GRP

Thin-walled cylinder part automatic internal supporting clamp and clamping method

ActiveCN111230164ASimple and fast operationHigh degree of automationExpansion mandrelsElectric machineryScrew system

The invention belongs to the technical field of clamping, and relates to a thin-walled cylinder part automatic internal supporting clamp and a clamping method. According to the clamping method, the thin-walled cylinder part automatic internal supporting clamp is adopted, the clamp is composed of a power driving system, a positioning and clamping device and an auxiliary device; vertically clampingthe thin-wall cylinder part is carried out, a motor lead screw system is used for driving a taper mandrel to move in the axial direction, an inner supporting expansion sleeve is driven to move in theradial direction, inner supporting clamping of the thin-wall cylinder part is achieved, the clamp is provided with the rigid inner supporting expansion sleeve with the force expanding characteristic,the structure is simple, small driving force is converted into large inner supporting force, even inner supporting is achieved; uniformly distributed radial force is applied to the surface of the inner part of the thin-walled part, so that the local rigidity of a machining area is greatly improved; the servo motor lead screw system is adopted for driving, the motion precision is high, the stability is good; and a clutch braking system is adopted, braking is rapid, self-locking can be achieved, and the clamping reliability is effectively improved.

Owner:DALIAN UNIV OF TECH

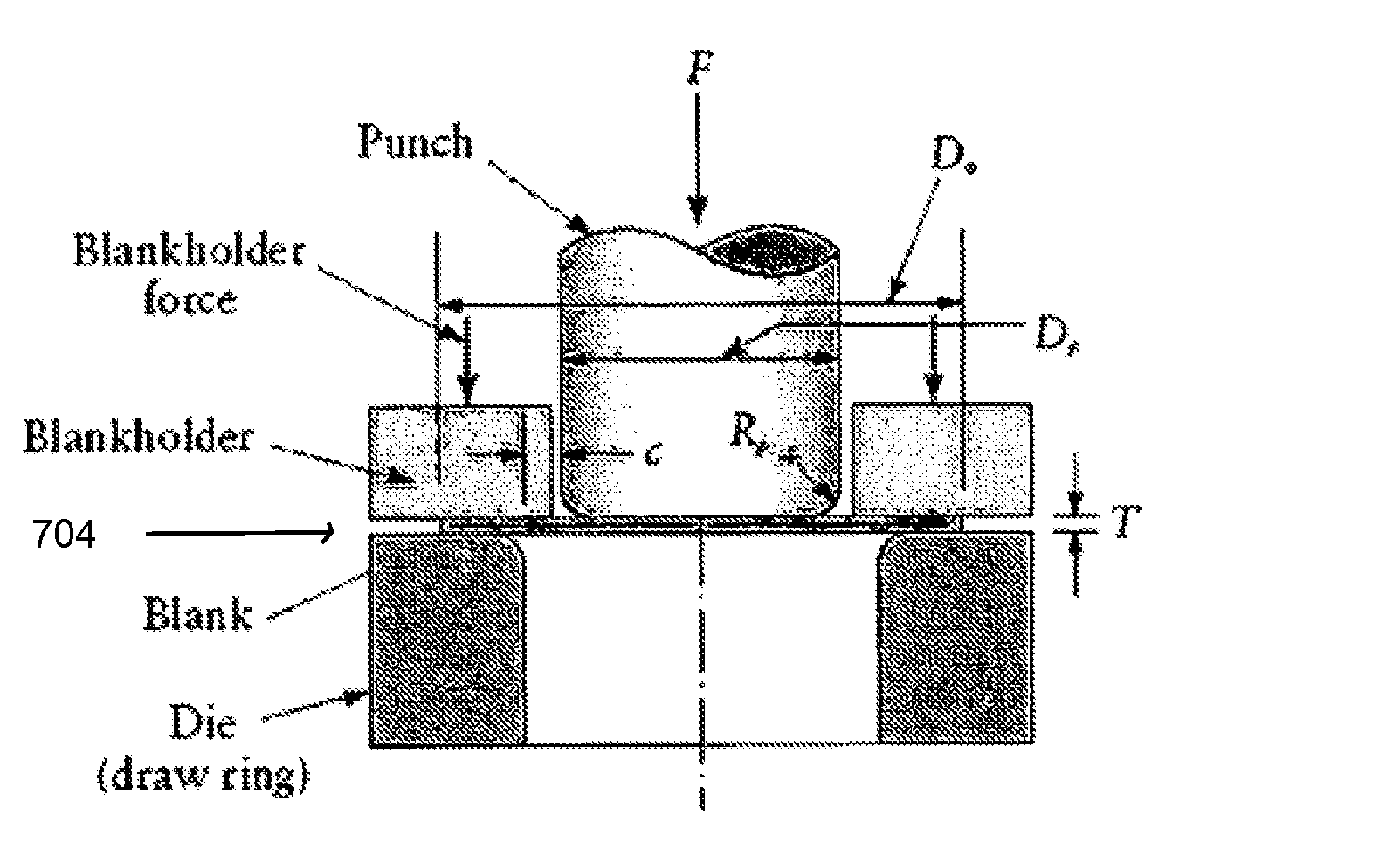

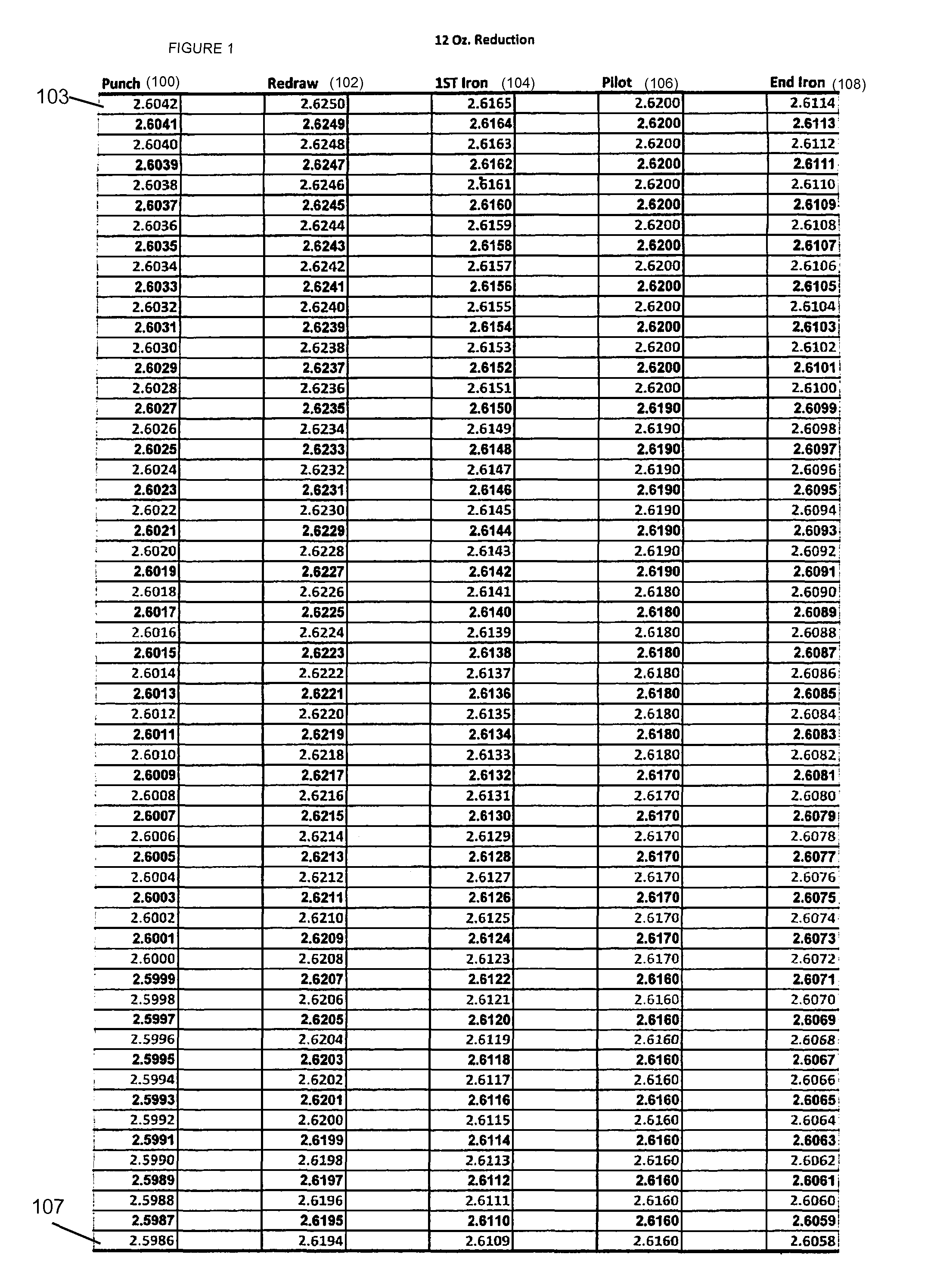

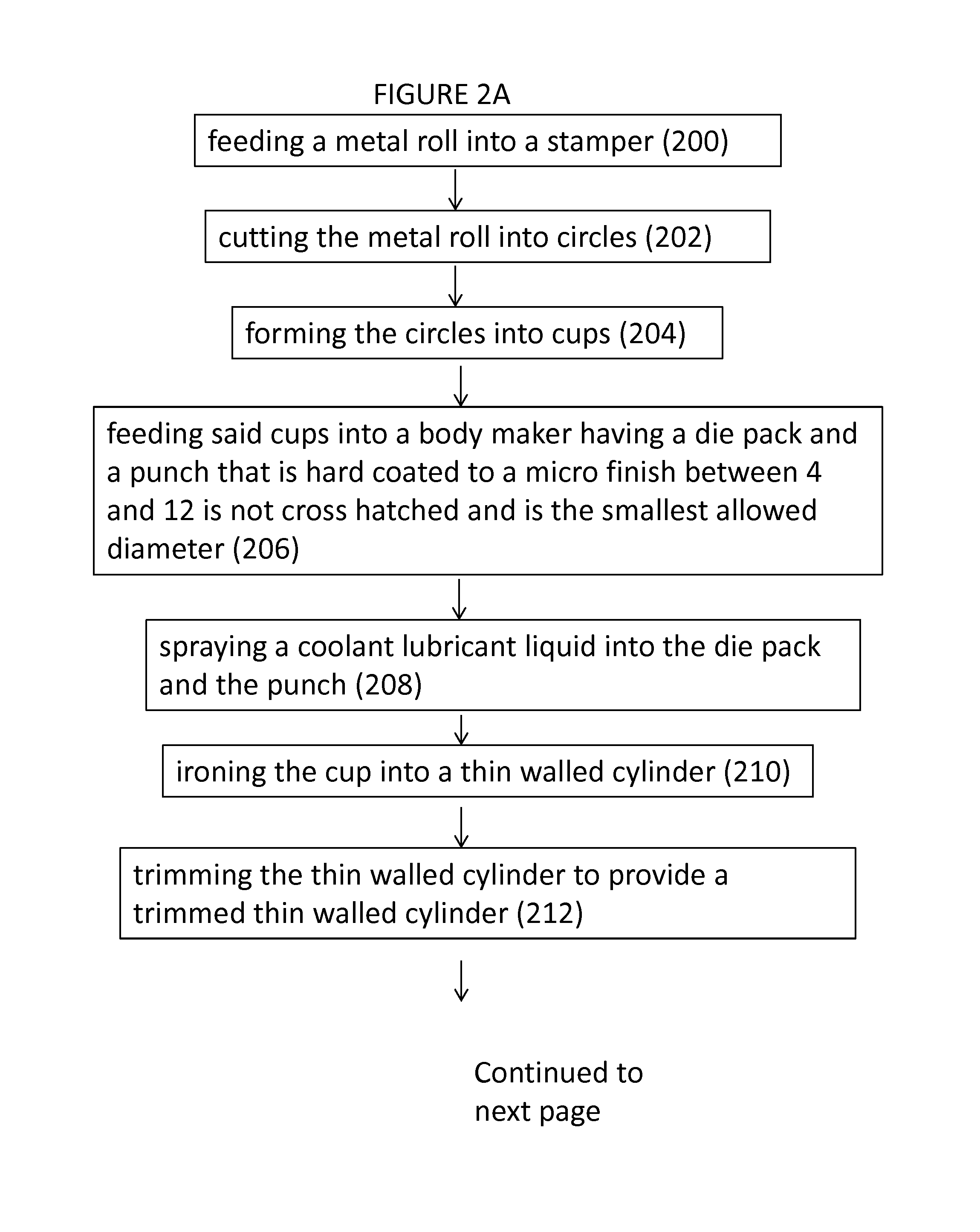

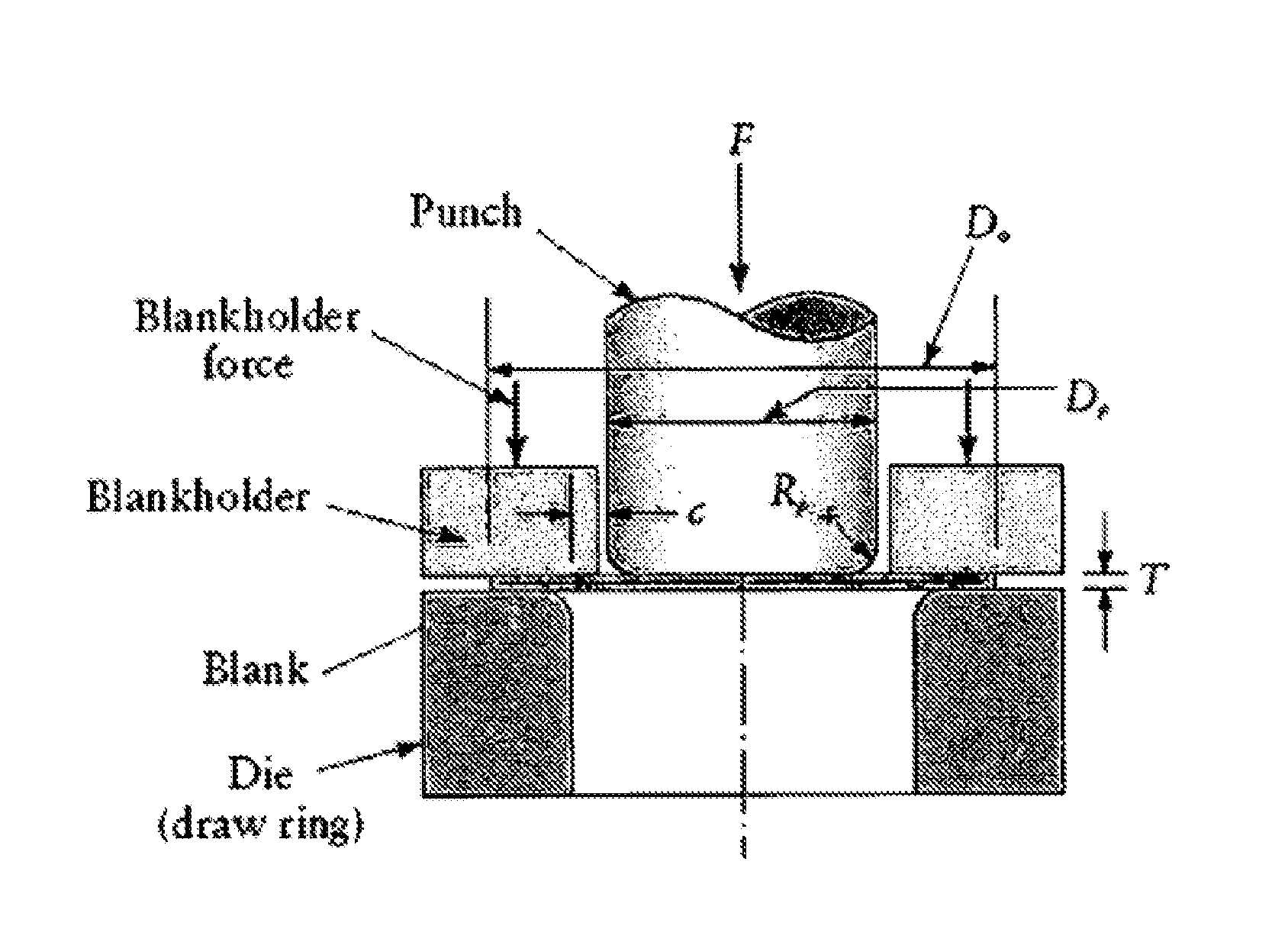

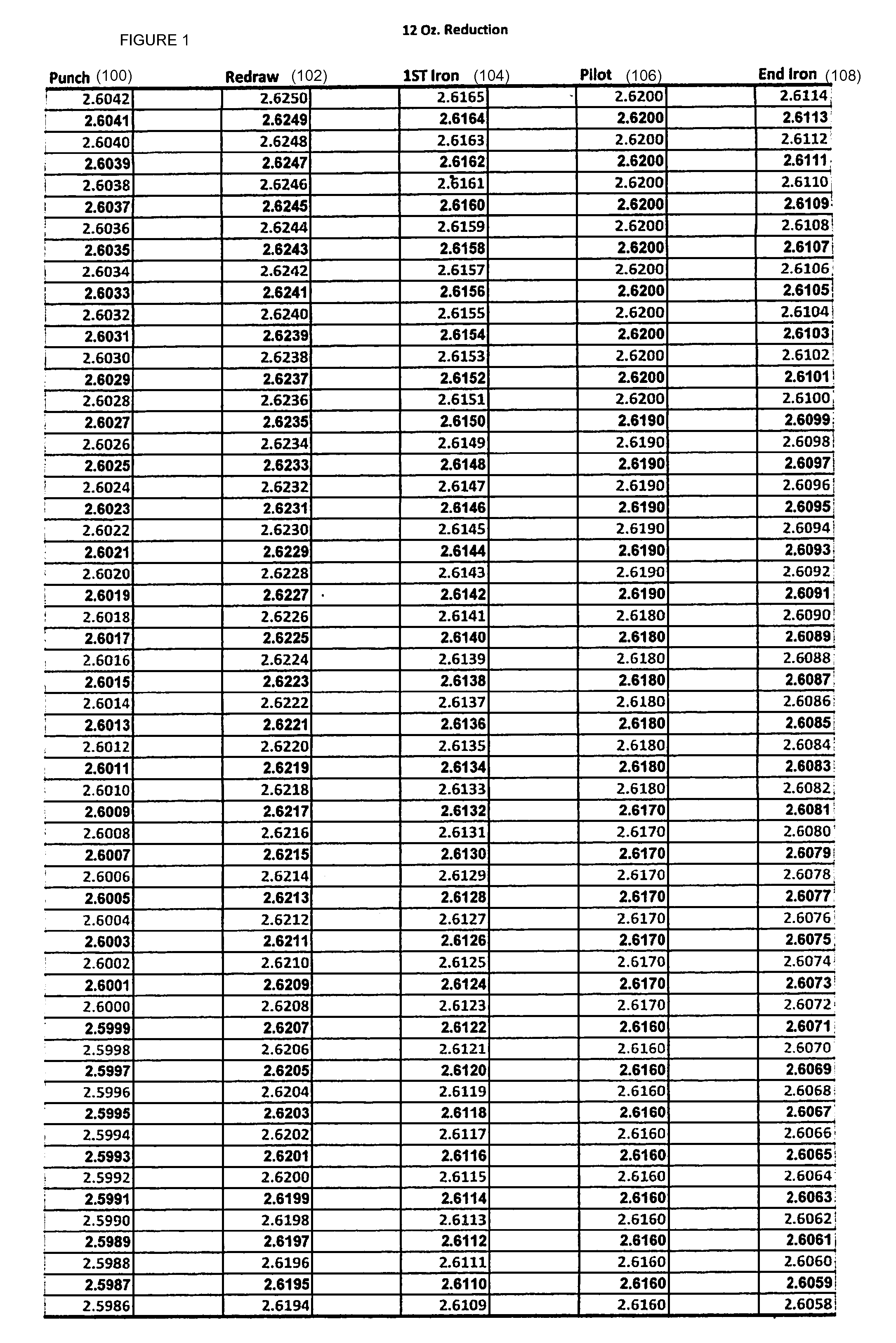

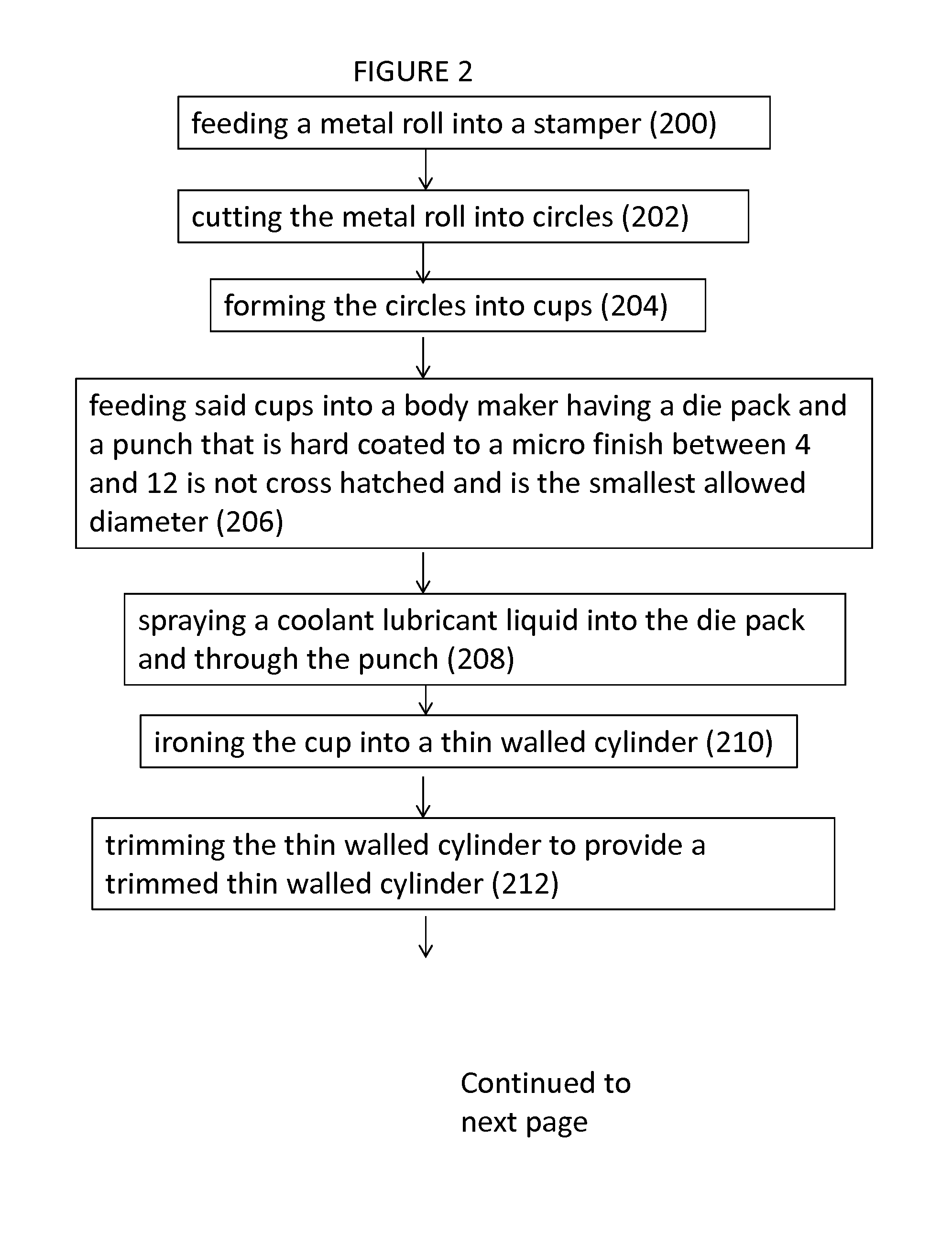

Methods and processes of manufacturing two piece cans

A method of drawing and ironing metal into a can comprising the steps of: feeding a metal roll into a stamper; cutting the metal into circles; forming the circles into cups; feeding the cups into a body maker having a die pack with at least three dies and a punch hard coated to a micro finish between 4 and 12, not cross hatched and is the smallest allowed diameter; spraying a coolant lubricant liquid into the die pack and through the punch; ironing the cup into a thin walled cylinder; trimming the thin walled cylinder; washing, rinsing, drying and decorating the trimmed thin walled cylinder; spray coating the inside of the can with a protective coating; necking the trimmed thin walled cylinder; forming a lip on the top of the tapered thin walled cylinder; testing the trimmed thin walled cylinder for defects; and palletizing the thin walled cylinder.

Owner:FARNHAM ENTERPRISES

Methods and processes of manufacturing two piece cans

A method of drawing and ironing metal into a can for beverages, food and products, the method comprising the steps of: feeding a metal roll into a stamper; cutting the metal into circles; forming the circles into cups; feeding said cups into a body maker, wherein said body maker has a die pack having at least three dies and a punch, wherein the at least three dies and the punch are hard coated to a micro finish between 4 and 12, and the punch is not cross hatched and is the smallest allowed diameter; spraying a coolant lubricant liquid into the die pack and the through the punch; ironing the cup into a thin walled cylinder; trimming the thin walled cylinder to provide a trimmed thin walled cylinder; washing, rinsing and drying the trimmed thin walled cylinder; decorating the trimmed thin walled cylinder; spray coating the inside of the can with a protective coating; necking the trimmed thin walled cylinder to provide a tapered thin walled cylinder; forming a lip on the top of the tapered thin walled cylinder; testing the trimmed thin walled cylinder for defects; and palletizing the thin walled cylinder.

Owner:FARNHAM ENTERPRISES

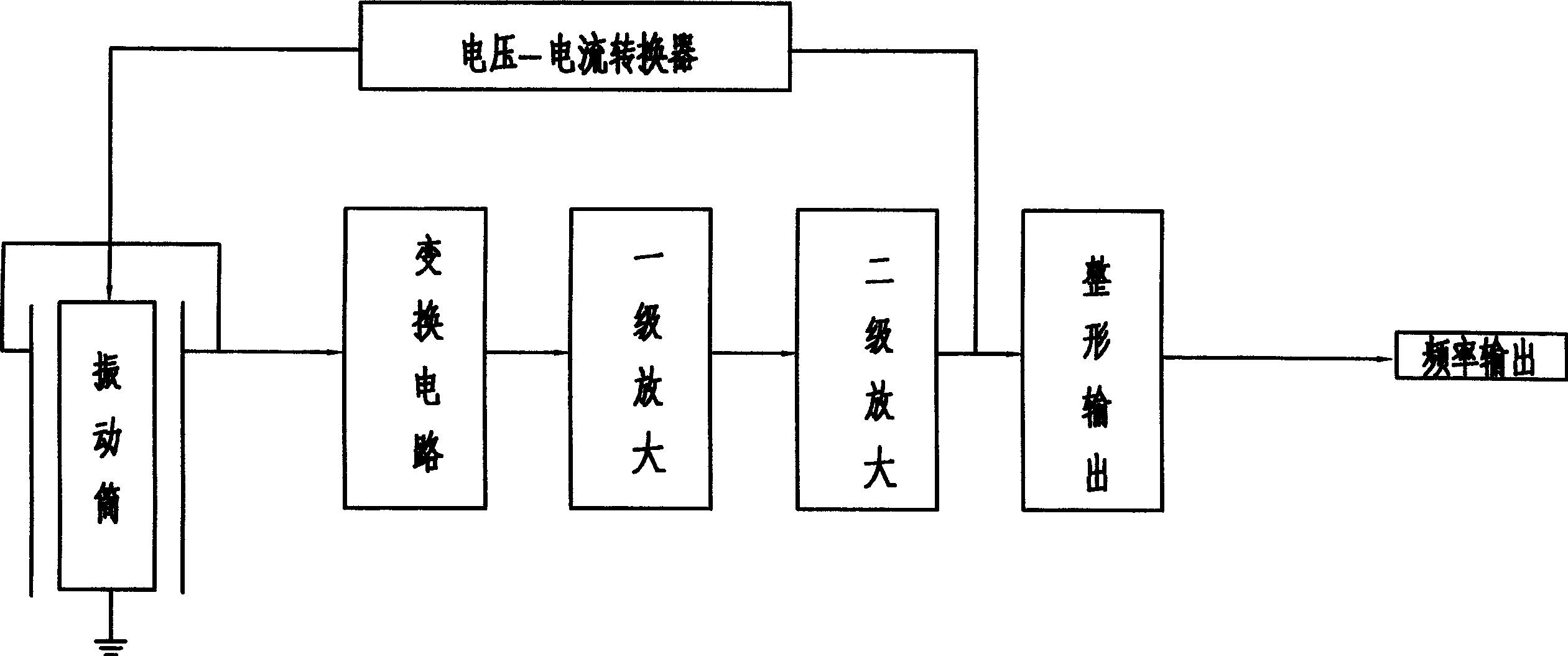

Pressure sensor of magnetic excitation vibrating cylinder

InactiveCN1546968ASmall weightOverall small sizeFluid pressure measurement by electric/magnetic elementsCapacitanceCeramic capacitor

The invention is a kind of magnetism motivation vibration cylinder pressure sensor, which belongs to resonance pressure sensor; the measuring precision is high, the structure is simple, the size and weight is small; the invention includes sensitive elements and motivation circuit; the sensitive elements include insulator, insulator base, thin-wall cylinder, vacuum cavity protecting cylinder, conducting core, spring presser bits, ceramic capacitance, rare earth magnet, soft magnet, base, pressure accessing aperture, localization pin and wires; the two ends of the vacuum cavity protecting cylinder are connected with the insulator base and the thin-wall cylinder base, and forms a vacuum cavity; the conducting core is set in the thin-wall cylinder, the upper part is connected with the aperture tightly, the rare earth magnet is set at two sides of the magnet or around the magnet through the spring presser bits; there distributes four symmetrical arc ceramic capacitances boards which has gap with the thin-wall cylinder around the cylinder, the ceramic capacitance boards are fixed through localization pin and soft magnet.

Owner:TAIYUAN AERO INSTR

Thin-walled cylinder body welding and shaping clamp

ActiveCN103639639AImprove general performanceSuitable for weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled cylinder

Owner:AECC AERO SCI & TECH CO LTD

Positioning clamping device for machining of complex inner shape of thin-wall cylindrical workpiece

InactiveCN107234464AImprove rigidityGuaranteed geometric tolerancePositioning apparatusMetal-working holdersMachining vibrationsConical forms

The invention discloses a positioning clamping device for machining of a complex inner shape of a thin-wall cylindrical workpiece. The positioning clamping device comprises a base, a clip spring, a taper sleeve and a pressing threaded sleeve. The base is of a cylindrical structure, the taper sleeve is arranged at the upper end of the base, and the upper portion of an inner hole of the taper sleeve is provided with a second conical surface; the taper sleeve is connected with the pressing threaded sleeve which is in threaded connection with the side wall of the base, the clip spring is installed in an inner hole of the base, and the upper portion of the clip spring is provided with a first conical surface matched with the conical shape of the inner hole of the taper sleeve and provided with a groove joint which is axially formed; and the first conical surface is arranged in the second conical surface, and the lower portion of the clip spring is provided with a cylindrical surface which is matched with a positioning hole of the bottom of the base. According to the positioning clamping device, the structure is simple, operation is convenient, the taper sleeve is matched with the conical surface on the upper portion of the clip spring in the base, the taper sleeve is controlled by the pressing threaded sleeve to downwards move to achieve clamping of a clip spring on the thin-wall cylindrical type part, the stiffness of the part is improved, the shape and position tolerance of the part is ensured, the problem of vibration during thin-wall part machining is solved, and the machining efficiency and machining quality of the part are greatly improved.

Owner:江南工业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com