Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Improve internal and external surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing aluminum liner of vehicular composite cylinder

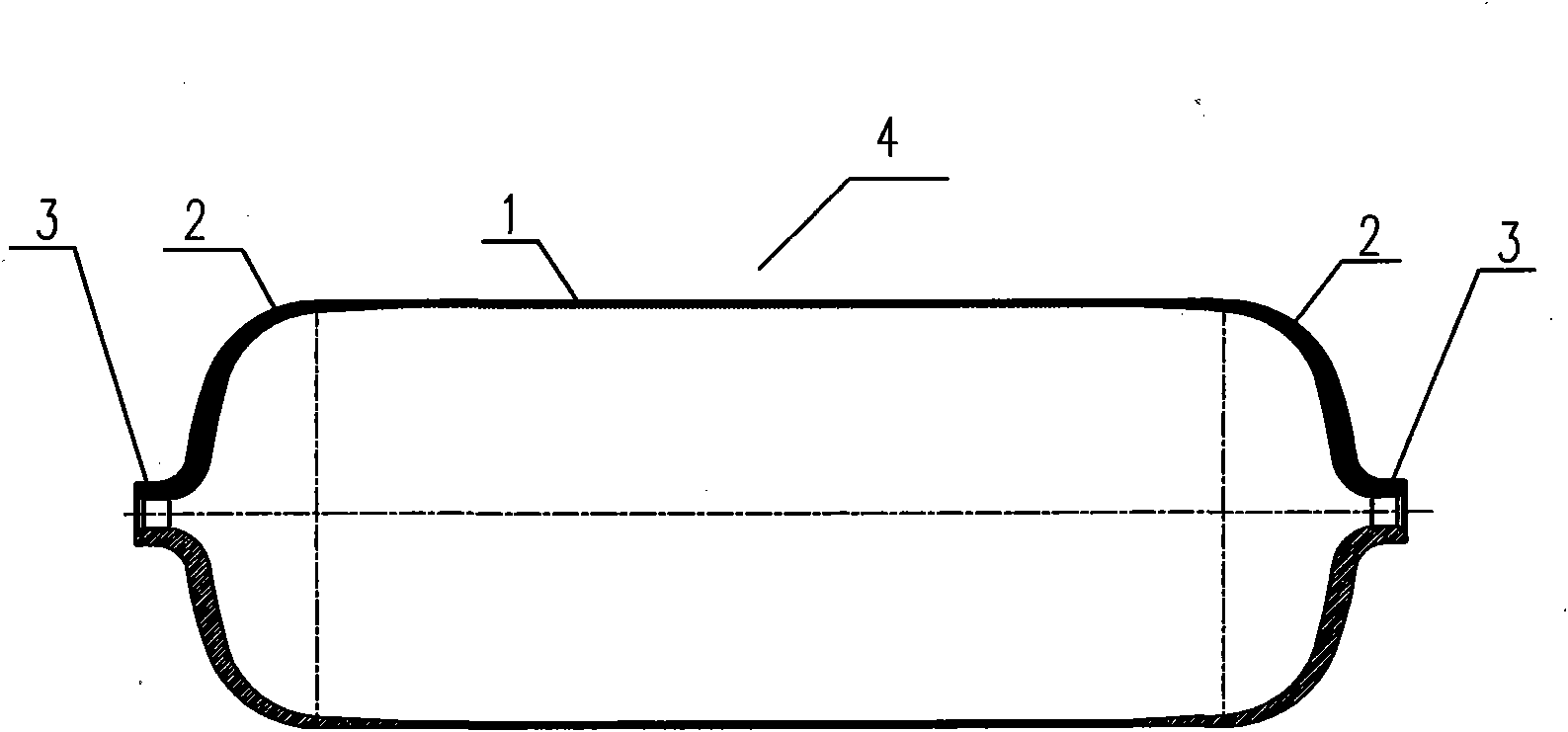

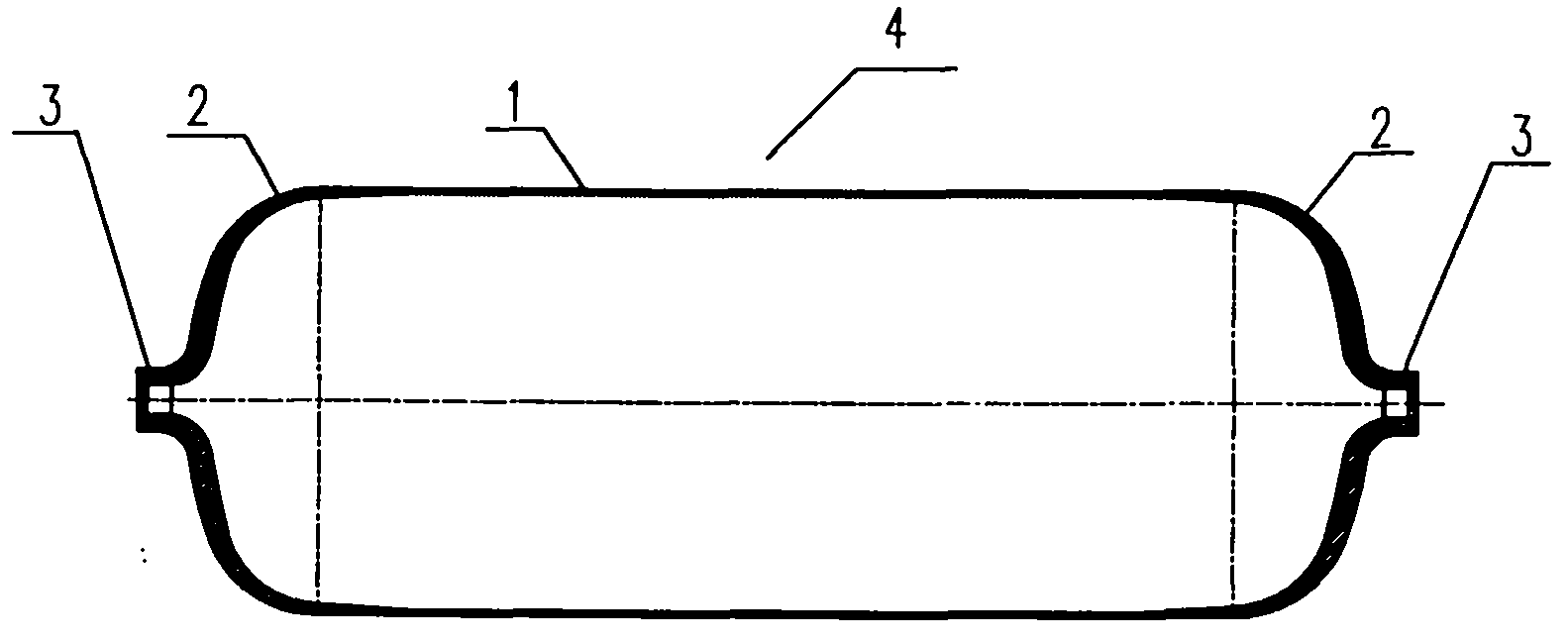

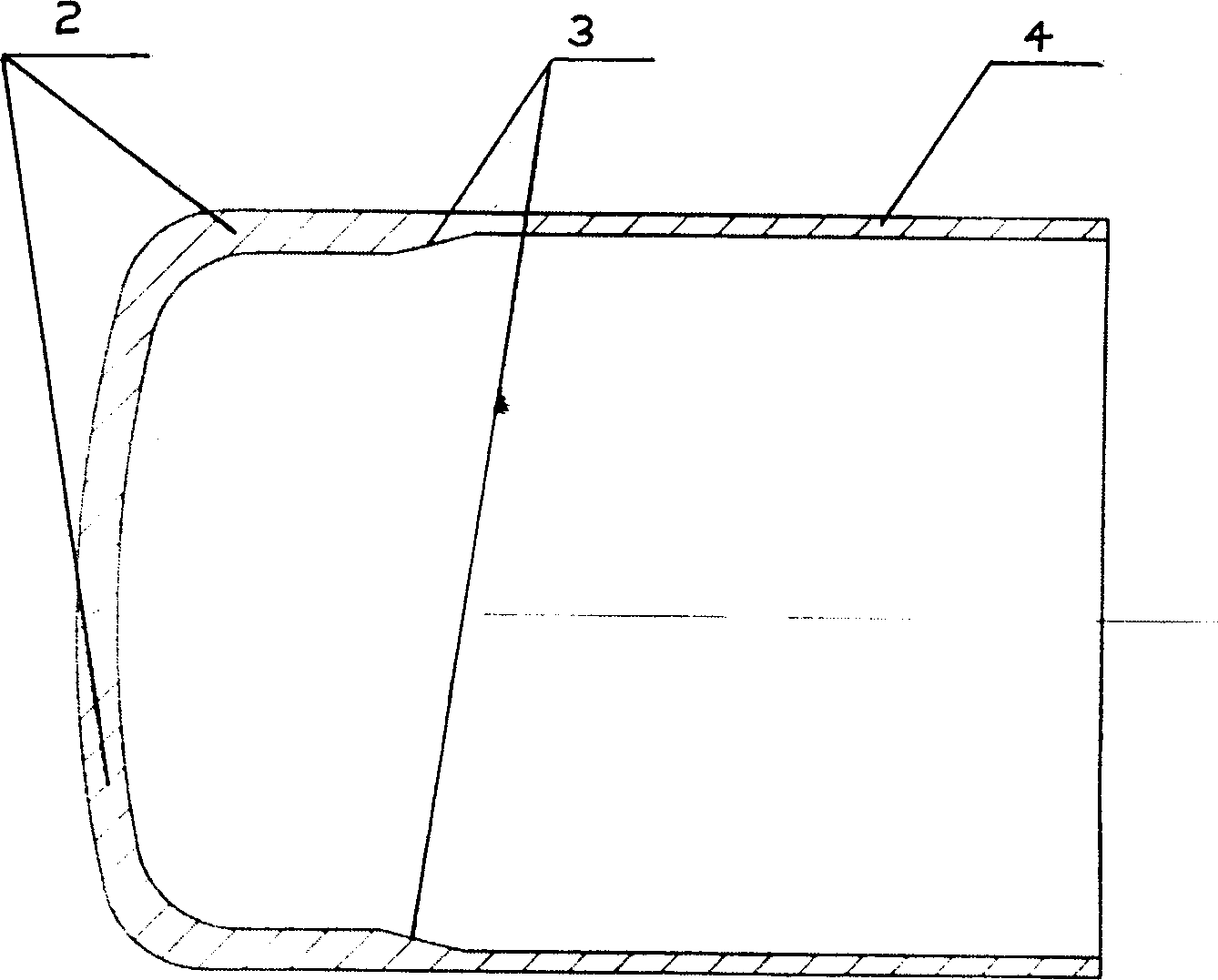

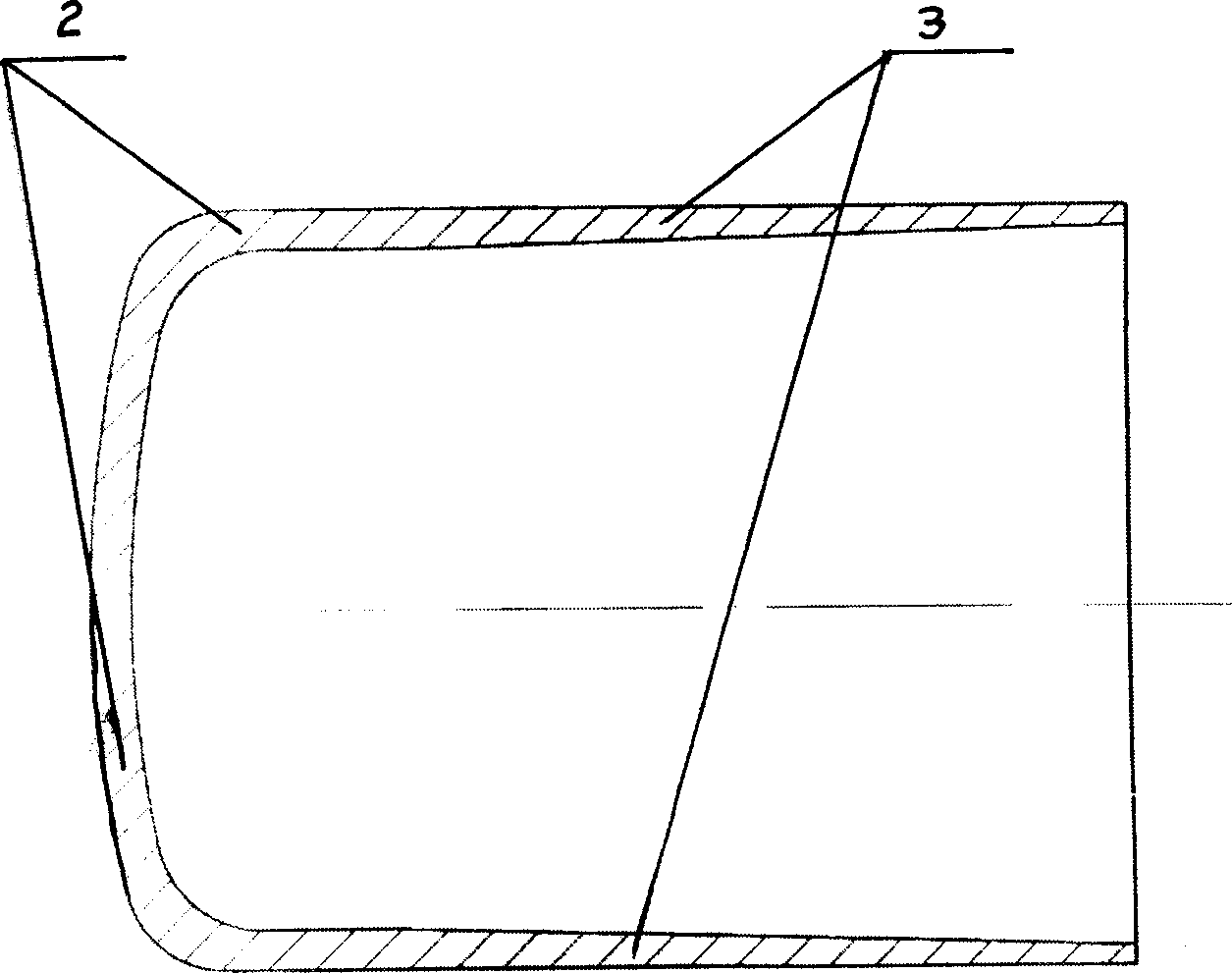

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of metal micro-nano hollow sphere powder

ActiveCN102274975AControllable processing parametersLow costMaterial nanotechnologyMicro nanoMetallic materials

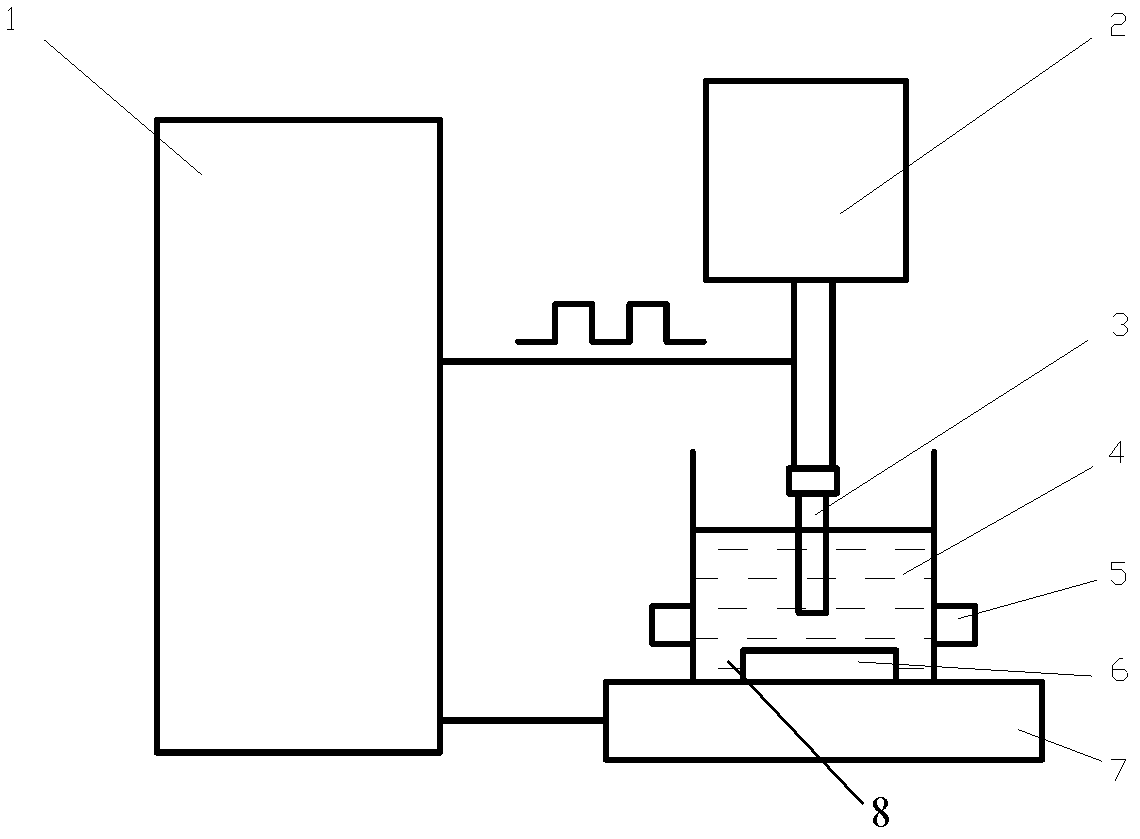

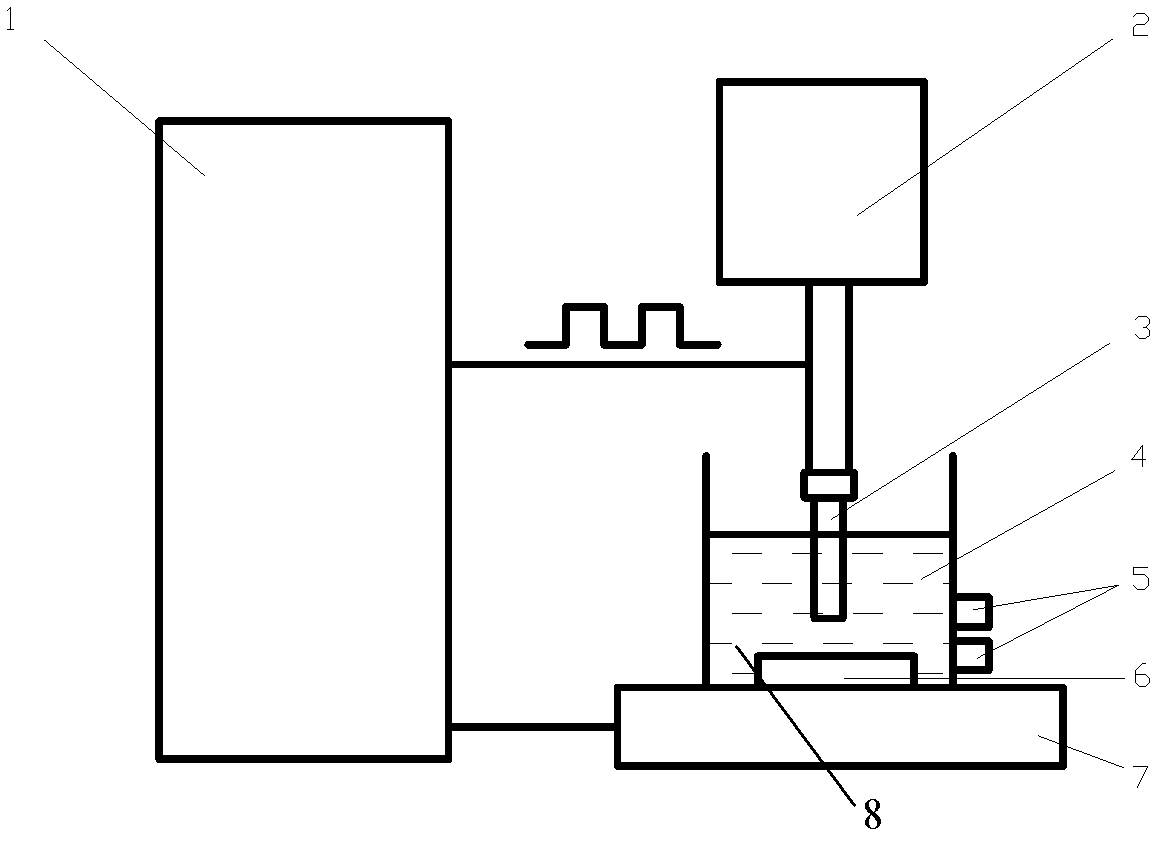

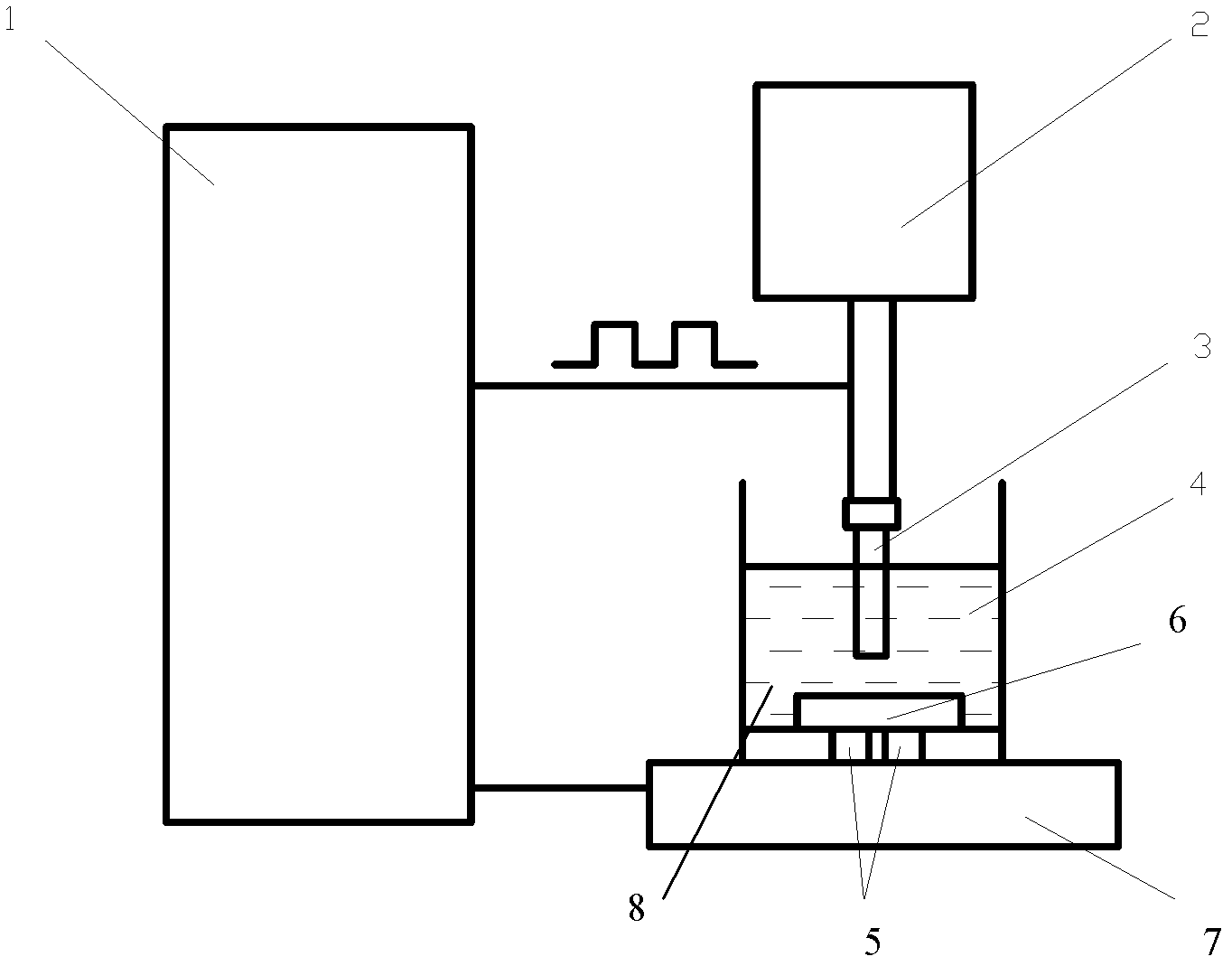

The invention discloses a method for preparing metal micro-nano hollow spherical powder. The method comprises the main contents of: correspondingly immersing a tool electrode and a workpiece electrode into a working fluid, wherein a gap required by spark discharge is kept between the tool electrode and workpiece electrode; and switching on a pulse power supply to enable the tool electrode and the workpiece electrode to generate spark discharge to be molten and gasified, and meanwhile implementing supersonic vibration on the working fluid between the tool electrode and the workpiece electrode during the spark discharge process, so that the working fluid in the gap generates micro-bubbles, and molten and gasified metal materials of the tool electrode and the workpiece electrode are attached and sedimentated on the surfaces of the micro-bubbles to form metal micro-nano hollow spheres. By adopting the method disclosed by the invention, the prepared metal micro-nano hollow spherical powder has high degree of hollowness, the particle diameter ranges from 20 nanometers to 100 micrometers, the wall surface is not larger than 1 micrometer, and the proportion of the hollow spheres is high. The micro-nano hollow sphere exhibits special outstanding performances in terms of physics, chemistry, electromagnetics and photology, and can be widely applied to the fields of chemistry, metallurgy, material, aerospace and the like.

Owner:SICHUAN UNIV

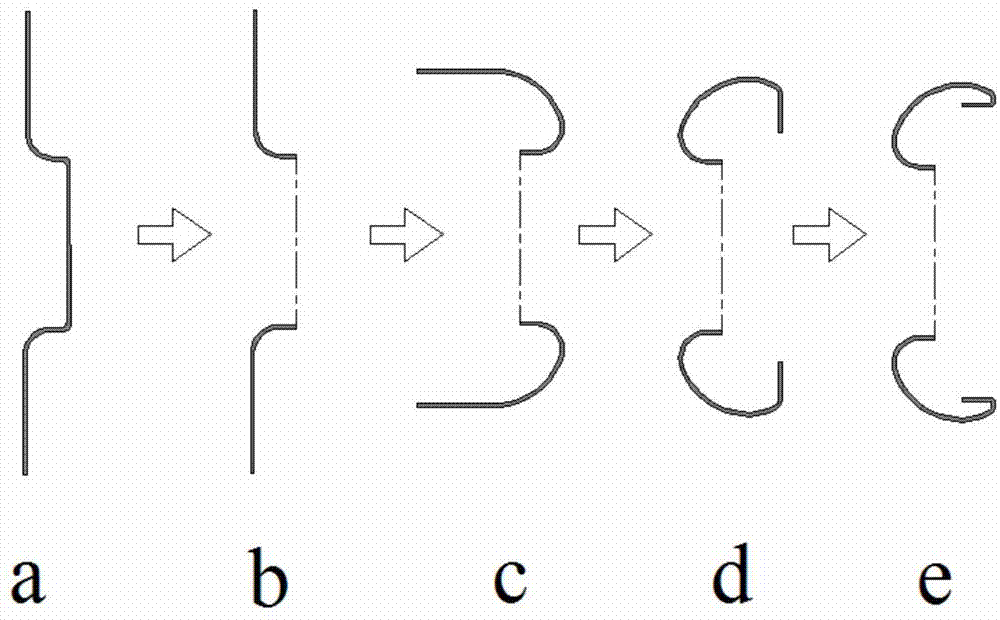

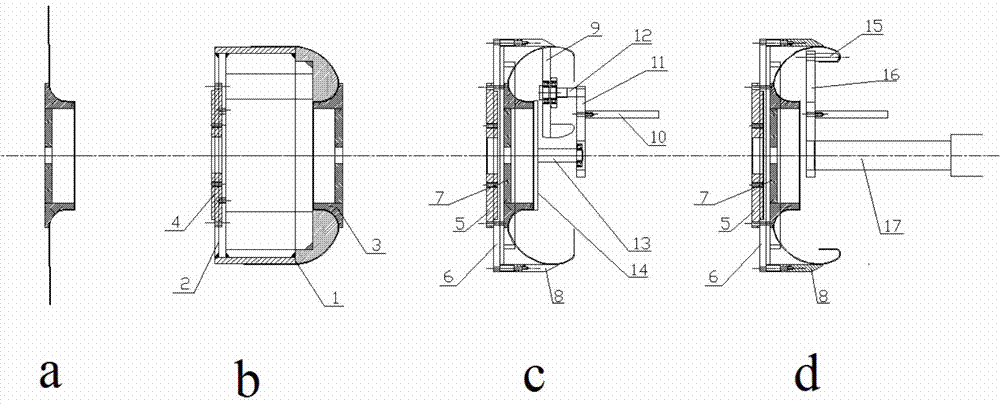

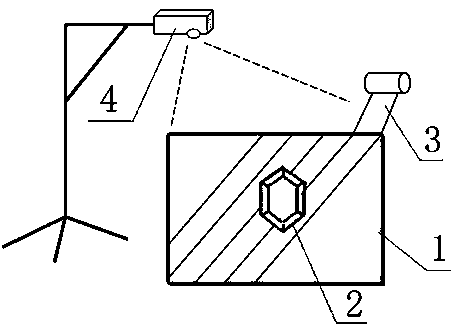

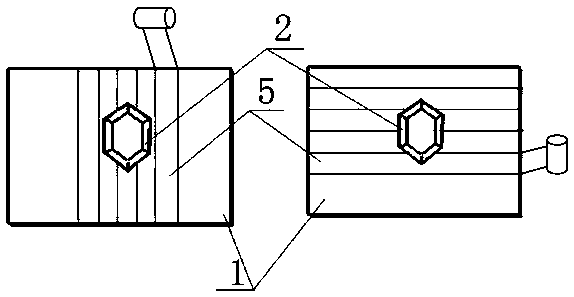

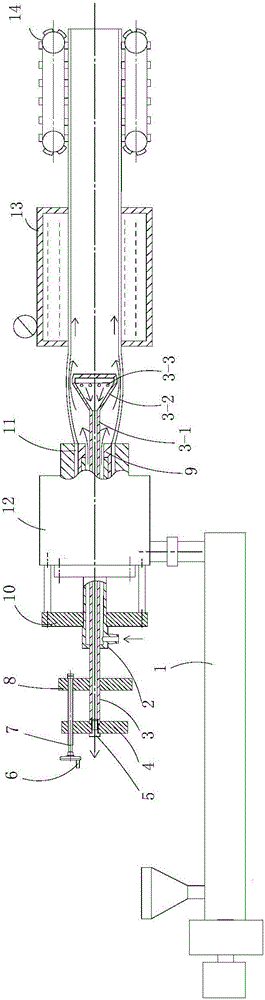

Spinning forming process of extra-high-voltage shielding cover

ActiveCN103522021AImprove internal and external surface qualityNice appearanceShaping toolsEngineeringProcessing cost

The invention discloses a spinning forming process of an extra-high-voltage shielding cover. A computer digitally controlled spinning machine is adopted to integrally process a plate material into the extra-high-voltage shielding cover. The spinning forming process comprises the following steps of blanking, preliminary spinning, inner hole turning, drawing and spinning, primary edge turning, trimming, secondary edge turning and polishing cleaning. The extra-high-voltage shielding cover produced by adopting the process is light in weight, small in thickness and high in material utilization rate. The welding processing is not needed, a welding device is not needed, all of processing can be finished only through one spinning machine, operation is simple and convenient, and the processing cost is reduced. A unique inner-turnup bending and spinning process is adopted, edges of workpieces are wrapped inside the workpieces, direct contact between the workpiece edges and the outside environment is avoided, the corrosion resistance is improved, and the service life is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

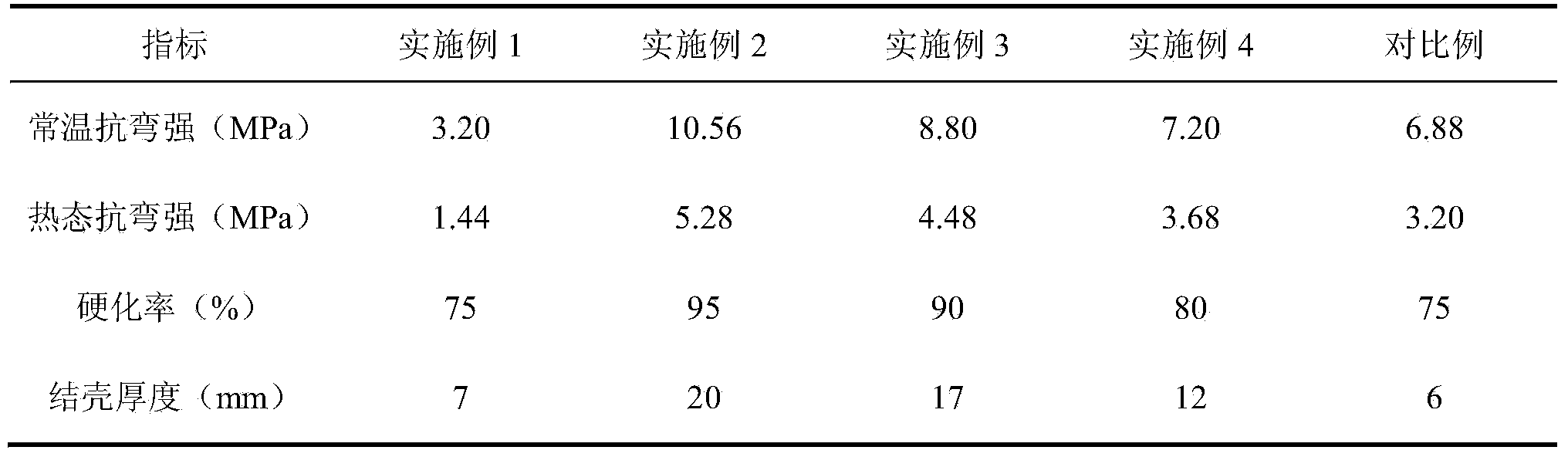

Shelling resistant pre-coated sand and preparation method thereof

ActiveCN104014718AFast curing rateIncrease hardening rateFoundry mouldsFoundry coresFirming agentUltimate tensile strength

The invention discloses shelling resistant pre-coated sand and a preparation method thereof. The shelling resistant pre-coated sand is characterized by comprising raw sand, a bonding agent the weight of which is 1-4% that of the raw sand, a curing agent the weight of which is 1-15% that of the bonding agent, 0.1-0.5% of coupling agent and 0.1-1.0% of additive. By adding the additive, the curing speed of the curing agent to the bonding agent is increased, the hardening rate of the pre-coated sand is improved and the shelling tendency is reduced; by optimizing the content of each component, the overall strength of the pre-coated sand is improved, the gas evolution amount of the pre-coated sand is greatly reduced and the defect of core piercing is alleviated; the shelling resistant pre-coated sand has strong shell resistance, is high in strength and low in gas evolution amount, is capable of remarkably alleviating or eliminating defects such as shelling and core piercing and effectively improving qualities of the inner and outer surface of a shell core, and is suitable for production of shell core sand cores.

Owner:CHENGDE BEIYAN CASTING MATERIAL

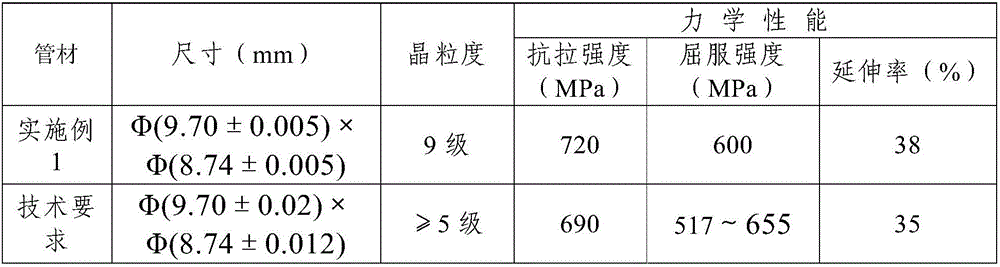

Large-diameter thin-wall cupronickel tube short process production method

The invention discloses a large-diameter thin-wall cupronickel tube short process production method and belongs to the technical field of metal materials. Specific to the problems that large-scale extrusion equipment up to 5000 tons is needed to produce large-diameter thin-wall cupronickel tubes through a traditional technique of semi-continuous casting solid ingot casting, punching, extruding, acid pickling, drawing and annealing, the finished product rate is low and the cost is high, the invention provides a method for producing the large-diameter thin-wall cupronickel tubes. Hot and cold combination casting horizontal continuous casting is adopted to producing large-size cupronickel tube blanks, and then a hole enlargement or / and hole shrinkage drawing is adopted to machining and forming the large-diameter thin-wall cupronickel tubes. The method has the advantages of being small in equipment investment, short in technical process, free of acid pickling and the like. The outer diameter of horizontal continuous casting tube blanks is 110-350 mm, the wall thickness is 5-30 mm, the elongation coefficient of hole enlargement drawing pass is 0.80-1.0, and the elongation coefficient of hole shrinkage drawing pass is 1.1-1.5; the outer diameter of machined products is 100-320 mm, and the wall thickness is 3-20 mm.

Owner:UNIV OF SCI & TECH BEIJING

Technology forming method of small and medium-sized unmanned aerial vehicle composite material outer wing

ActiveCN110193955AImprove shock absorptionImprove resistance to damageInternal combustion piston enginesSilicon rubberFront edge

The invention relates to a technology forming method of a small and medium-sized unmanned aerial vehicle composite material outer wing. The method comprises the following steps of forming mold manufacturing, front edge silicon rubber core mold manufacturing, film bag body manufacturing, outer wing front edge manufacturing, and outer wing main body manufacturing; after surface treatment is correspondingly carried out on bonding areas corresponding to the outer wing front edge and a main body front beam surface, and structure double-sided adhesive tapes with the same shape as that of the bondingareas are tore to remove isolation paper on one sides, the adhesive surfaces are adhered to the bonding areas of the outer wing front edge, then solating films on the other sides of the structural adhesive tapes are tore, and the outer wing front edge is horizontally embedded into a boss of the corresponding position of the outer wing main body through a positioning groove at the left end of theouter wing front edge so as to obtain a composite material integral structure outer wing product. According to the technology forming method, the problem of limitation of multiple curing forming, andthe uniformity of the product quality and the thickness are improved.

Owner:XIAN AISHENG TECH GRP +1

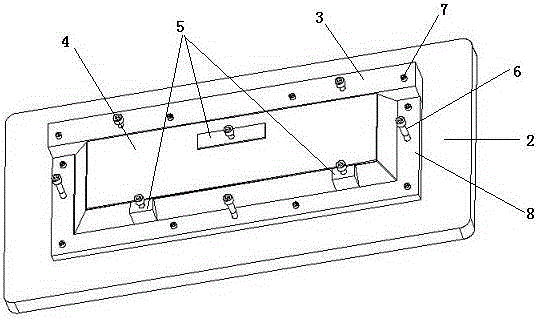

Mold for integrally preparing I-shaped longitudinally-horizontally-stiffened composite panel

ActiveCN108943775AHigh dimensional accuracyImprove internal and external surface qualityDomestic articlesResin-Based CompositeMaterials science

The invention belongs to the technical field of resin matrix composite forming, and relates to a mold for integrally preparing an I-shaped longitudinally-horizontally-stiffened composite panel. According to the mold for integrally preparing the I-shaped longitudinally-horizontally-stiffened composite panel provided by the invention, a design idea adopting a combined type inner core mold is provided, an uncovered part of an I-shaped flange is designed to be a U-shaped core mold capable of being demolded freely, and then a C-shaped forming mold formed through a block design is connected to the outer surface of the U-shaped core mold through a bolt; and when the longitudinally-horizontally-stiffened panel prepared by adopting the core mold is demolded, the U-shaped core mold can be firstly demolded, and then the C-shaped forming mold is sequentially taken out according to the design sequence along the direction perpendicular to an I-shaped stiffener web member. Meanwhile, based on an RTMforming process requirement, a whole set of design idea of the forming mold suitable for the I-shaped longitudinally-horizontally-stiffened panel is provided.

Owner:AVIC BASIC TECH RES INST

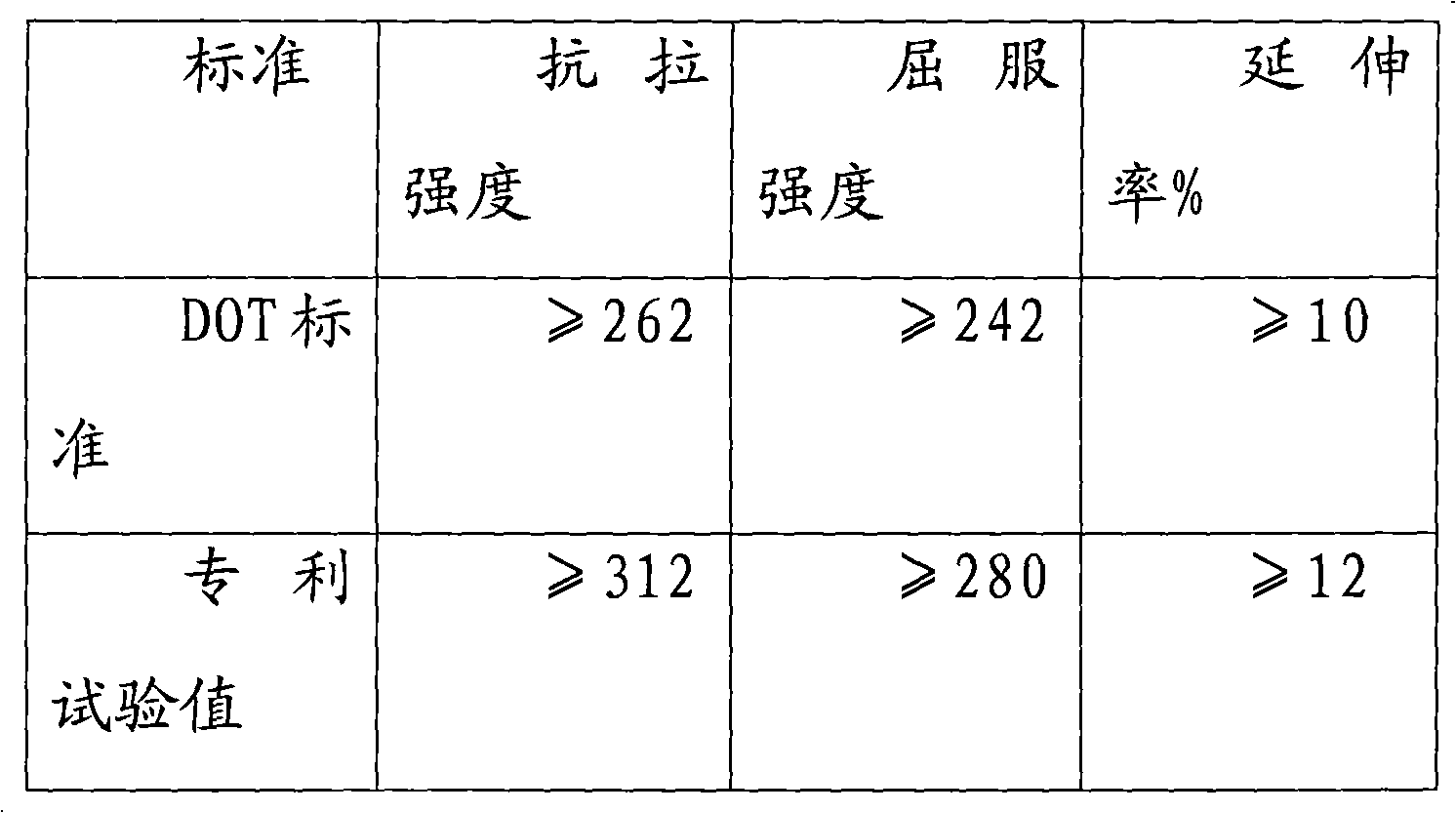

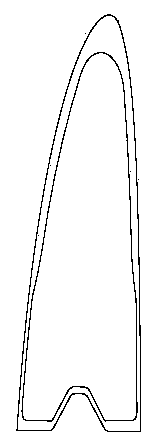

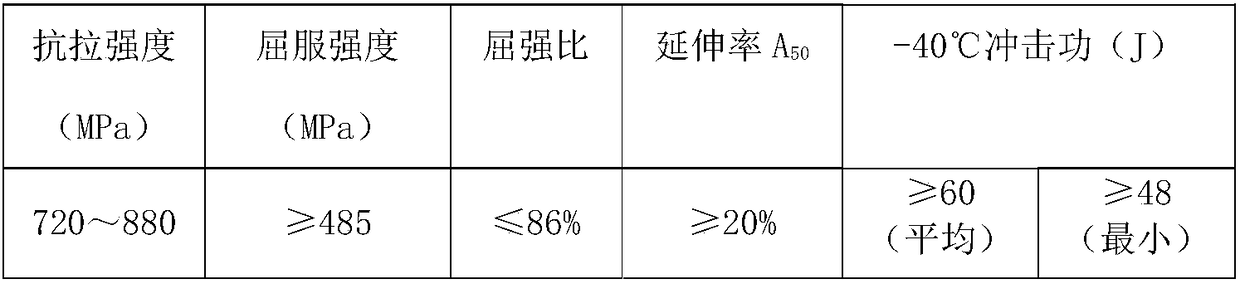

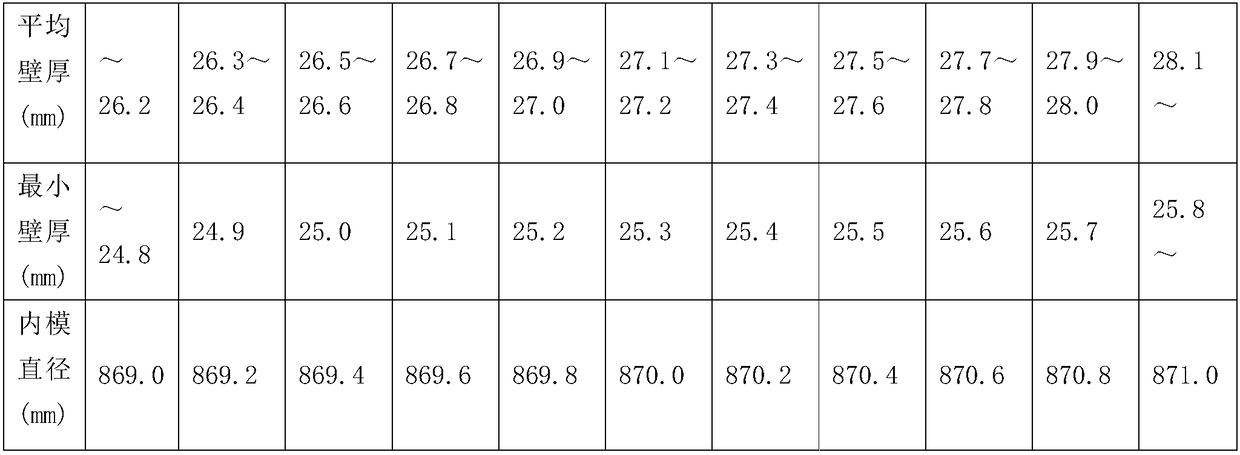

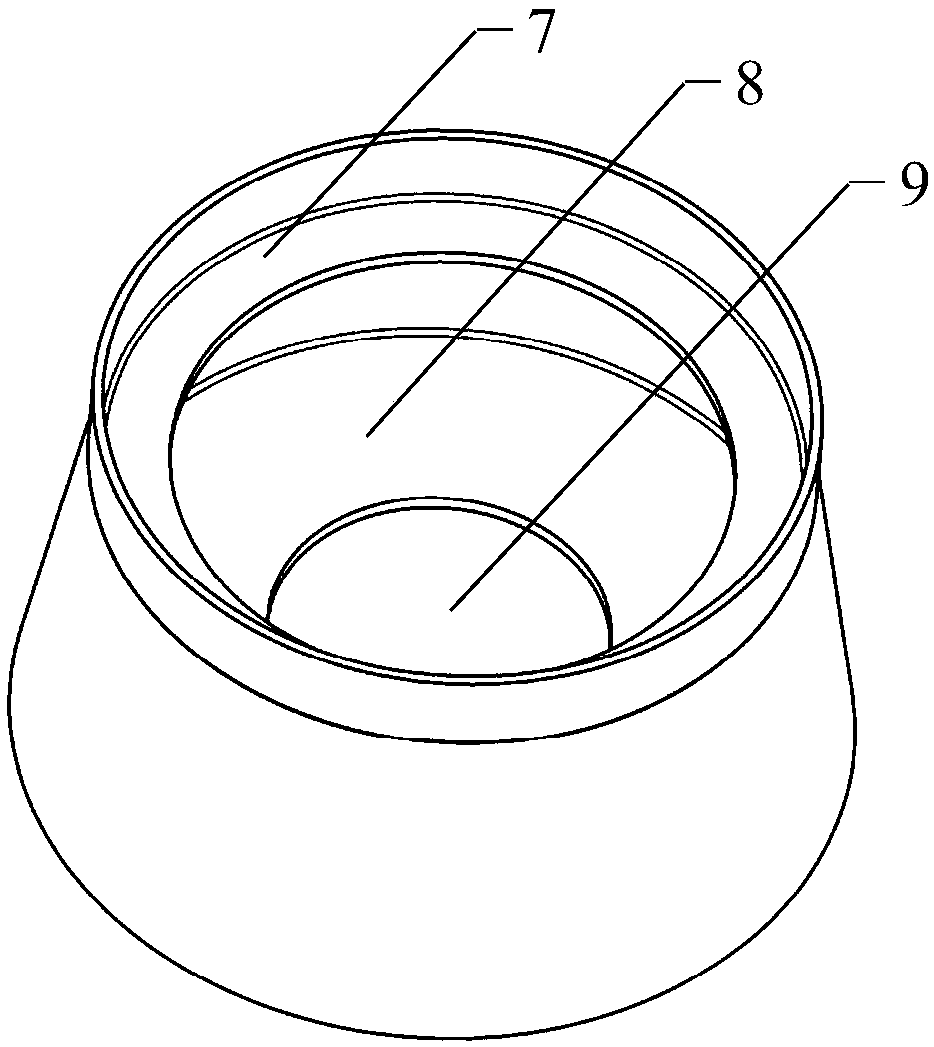

Manufacturing method of seamless steel pipe for long pipe trailer gas cylinder with diameter of 920mm

The invention provides a manufacturing method of a seamless steel pipe for a long pipe trailer gas cylinder with a diameter of 920mm, and belongs to the manufacturing technology of large diameter seamless steel pipes. The manufacturing method comprises the steps that the chemical composition of seamless steel pipe materials is optimized, and the hardenability of the composition is improved; afterusing a 820 cross rolling mill to pierce, a waste pipe is rolled, a jacking type hot expanding unit is used for expanding the diameter, a hydraulic type straightening machine and a six-roll straightening machine are used for two-step straightening and rounding, and a precision cold drawing unit is used for two cold pullout. According to the manufacturing method of the seamless steel pipe for the long pipe trailer gas cylinder with the diameter of 920mm, the manufacturing cost is low, the material utilization rate is high, and the mode of production is flexible; and moreover, the phi 920mm seamless steel pipe manufactured by the method has high geometric accuracy, good internal and external surface quality, good hardenability and high comprehensive performance, and the range of the actual weight of a finished product exceeding the theoretical weight does not exceed 7.5%.

Owner:DEXIN STEEL PIPE CHINA

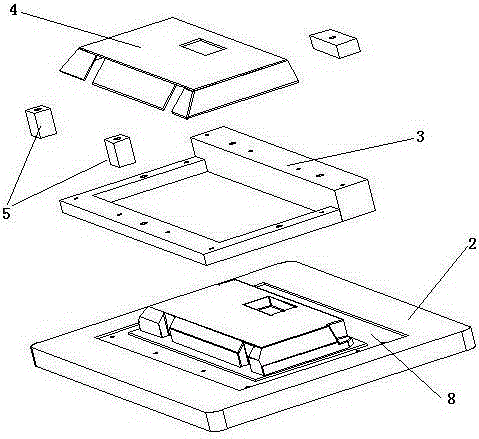

RTM (resin transfer molding) mold for partition type rotating structure composite parts

ActiveCN108995250AHigh dimensional accuracyGood internal and external surface qualityDomestic articlesIn planeFlange

The invention belongs to the technical field of molding of resin-based composites and relates to an RTM (resin transfer molding) mold for partition type rotating structure composite parts. The mold comprises an upper mold, a lower mold, a middle partition combined type inner mandrel, an upper partition inner mandrel, an outer mold and moving sliders. During mold assembly, the middle partition combined type inner mandrel is placed into a positioning groove of the lower mold firstly, then the upper partition inner mandrel is placed on the middle partition combined type inner mandrel, the outer mold is placed on the bottom surface of the lower mold, the moving sliders are placed on the periphery of the outer mold, the upper and the lower mold are assembled oppositely, the gap between the upper mold and the lower mold is reduced gradually under the fastening effect of bolts, and the moving sliders move in plane to enable the outer mold to be placed in a theoretical position under the action of lateral inner mold surfaces of the upper mold and the lower mold. By design of the combined steel inner mandrels, the mandrels can be prevented from falling out of the inner cavities of the semi-closed partitions, and dimensional accuracy of the inner mold surfaces and flanges of the rotating structure is guaranteed.

Owner:AVIC BASIC TECH RES INST +1

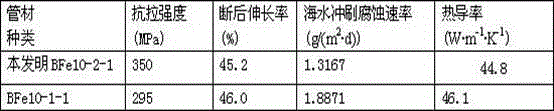

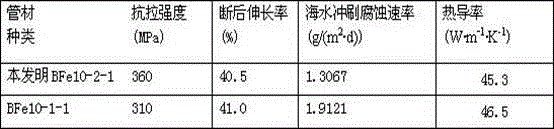

High-iron cupronickel alloy pipe and short-process production method thereof

The invention relates to a high-iron cupronickel alloy pipe and a short-process production method thereof, and belongs to the technical field of metal materials. Compared with a BFe10-1-1 alloy, the cupronickel alloy BFe10-2-1 provided by the invention is increased in alloy iron element content from 1.0wt%-1.5wt% to 1.6wt%-2.5wt%, thereby greatly enhancing the corrosion-resistant property and mechanical property of the alloy. According to the short-process production method, a pipe billet with high inner-outer surface quality and high-axial orientation columnar crystal structure is prepared by adopting a heat-cold combined casting horizontal continuous casting technology, so that the cold machining property of high-iron cupronickel is greatly enhanced; the continuous casting pipe billet is directly subjected to cold rolling and / or cold-draw forming, a pipe is subjected to finished product annealing by adopting a proper annealing schedule to eliminate microsegregation, the average size of a recrystallized grain is controlled to 20-40 micrometers, the volume fraction of a precipitated phase is reduced to be less than 2%, so that the cupronickel pipe with excellent mechanical property and corrosion-resistant property is obtained. Compared with a BFe10-1-1 pipe produced through the traditional method, the BFe10-2-1 high-iron cupronickel pipe disclosed by the invention has the advantages of more excellent integral using property, short production process and high production efficiency and finished product rate.

Owner:UNIV OF SCI & TECH BEIJING

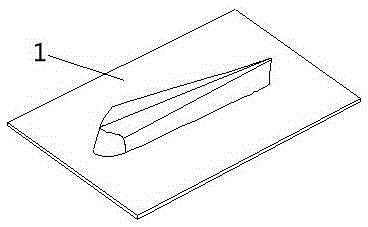

Forming method of cavity type composite material part with lateral edge and convergence hole

InactiveCN105346103ASolve the problem that cannot be demoldedImprove internal and external surface qualityMaterials scienceAutoclave

The invention discloses a forming method of a cavity type composite material part with a lateral edge and a convergence hole. The forming method comprises the following steps: laying a prepreg piece on the outer surface of a male die (1) to form a material layer; taking the pre-compacted material layer off from the male die (1), putting the material layer into a combined female die (4) in a way with the opening of the material layer directed upwards, sequentially putting a soft die (2) and a core die (3) into the cavity of the material layer; packaging the combined female die (4) and the material layer into a vacuum bag and further performing compacting; sending the combined female die (4) and the material layer into an autoclave to enable the material to be solidified for formation; after solidifying for formation is completed, opening the combined female die (4) and taking out the solidified and formed finished product of the part. Since a laying method characterized by the combination of the male die (1) and the female die (4) is adopted and the problem of unloading of the core die is solved by adopting the soft die, parts of same kind can be smoothly formed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Equipment for inner overflow and outer overflow down-draw molding of glass pipe, and design method thereof

ActiveCN110255865AEvenly distributedImprove internal and external surface qualityGlass forming apparatusDesign optimisation/simulationEngineeringMaterial supply

The invention belongs to the technical field of glass pipe manufacturing, and particularly discloses equipment for inner overflow and outer overflow down-draw molding of a glass pipe, and a design method thereof. A purpose of the present invention is to solve the problem of how to produce a glass pipe with excellent surface quality and small thickness deviation. The equipment comprises an inner overflow device and an outer overflow device, wherein the inner overflow device comprises a first annular material supply barrel, a cylindrical core part and an inner overflow disc, and the outer overflow device comprises a second annular material supply barrel, a cylindrical core part and an outer overflow disc. According to the present invention, the flow rate of the glass liquid outflowing from the outlet can be uniformly distributed through the first narrow channel formed in the inner overflow device, the overflow is performed by using the inner overflow disc, the flow rate of the glass liquid outflowing from the outlet can be uniformly distributed through the second narrow channel formed in the outer overflow device, and the glass liquid is subjected to overflow by using the outer overflow disc, such that the good surface characteristic is formed so as to mold the glass pipe with excellent inner and outer surface quality and small thickness deviation.

Owner:CDGM OPTICAL GLASS

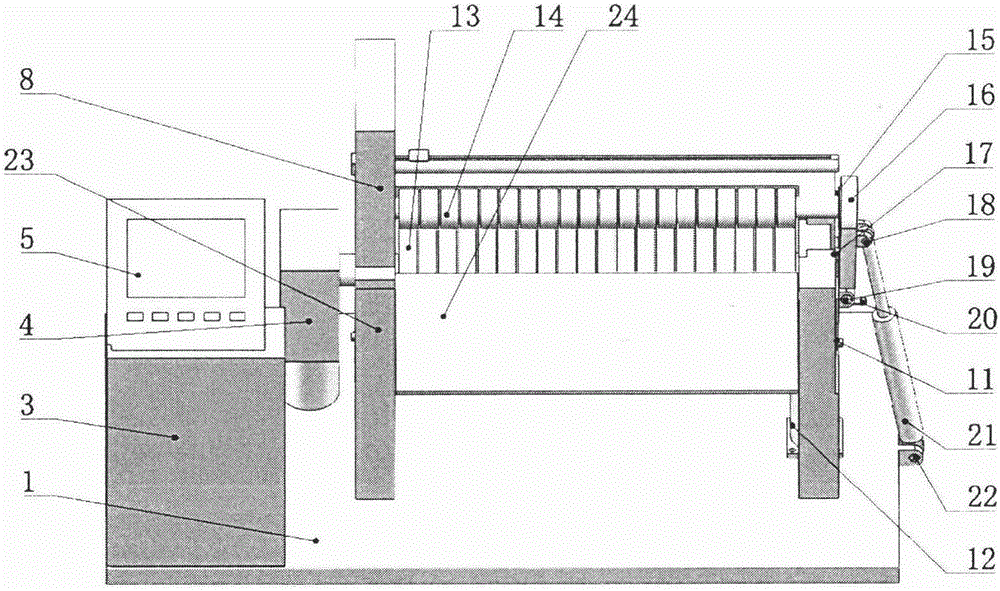

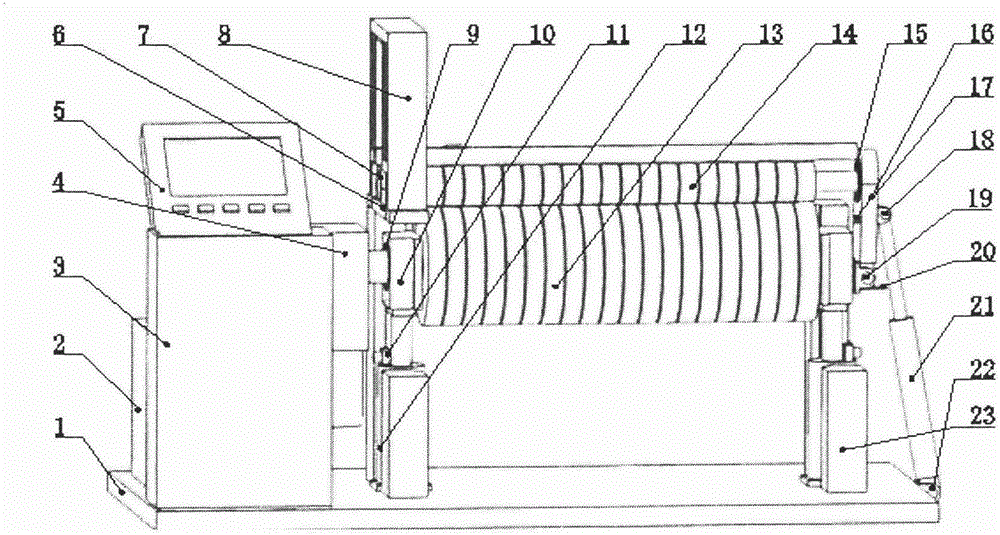

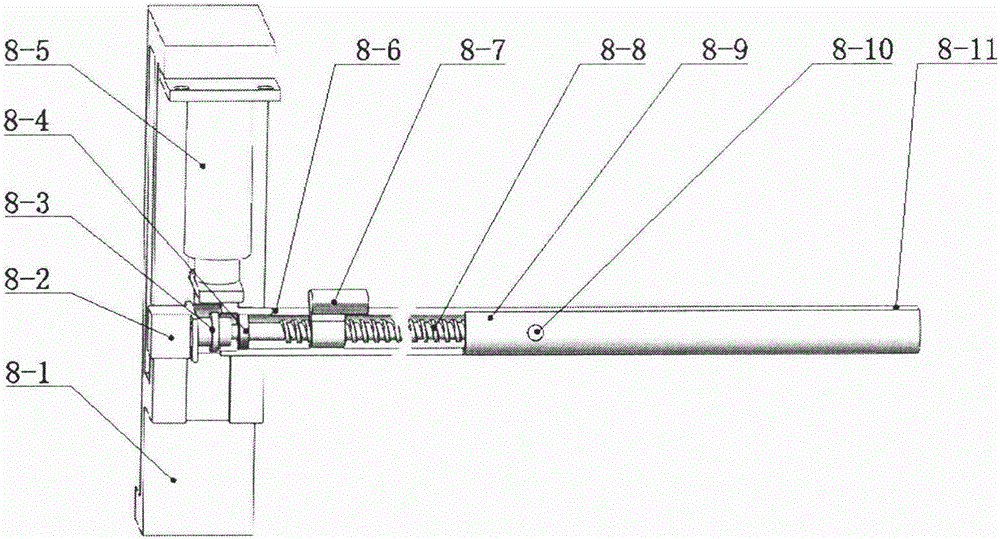

Numerical control two-roll rolling machine provided with two flexible rolls

ActiveCN106345861AGood internal and external surface qualityIncrease flexibilityEjection devicesHardnessAutomation

The invention discloses a numerical control two-roll rolling machine provided with two flexible rolls and belongs to the technical field of machine manufacturing of rolling machines. Aiming at the problem that cylinders have scratches on surfaces when being rolled by the conventional two-roll rolling machine, the numerical control two-roll rolling machine adopts two polyurethane rubber rolls, the diameter of the upper rubber roll is smaller than that of the lower rubber roll, the hardness of a polyurethane rubber layer of the upper rubber roll is higher than that of a polyurethane rubber layer of the lower rubber roll, when a cylinder is rolled, the outer surface quality of a cylindrical part can be better, movement of a lower rubber roll lifting hydraulic cylinder is controlled through hydraulic servo under the condition that the upper rubber roll is not replaced, the distance between the upper rubber roll and the lower rubber roll is changed, cylinders with different diameters in a certain range and multi-curvature cylinders can be rolled, a structure-optimized unloading device is adopted and assisted by automation control, formed ends are prevented from being rolled together with tail ends when sheets are rolled by automatically lifting a cross beam, automatic unloading is realized, the rolling precision is further improved, and the automation degree is further increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

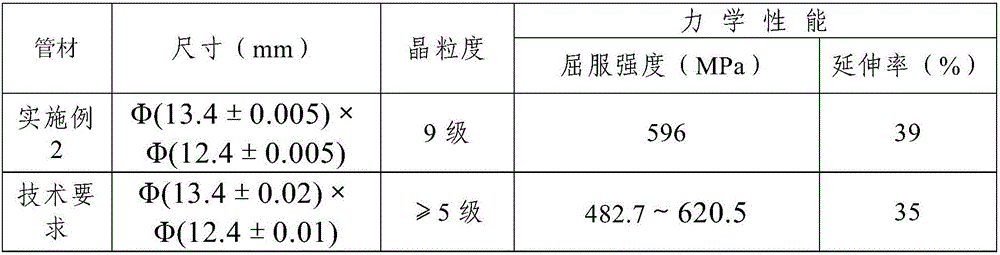

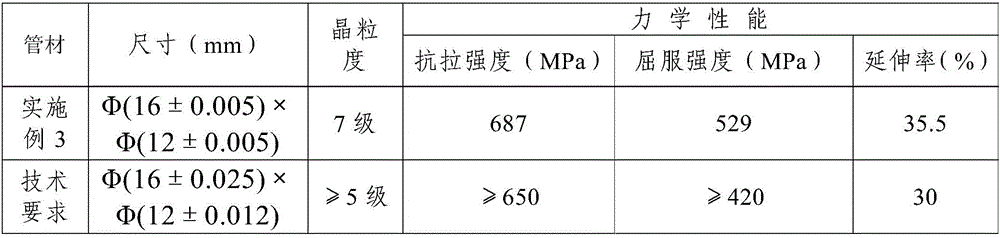

Processing method for improving quality of inner surface of austenite stainless steel tube

InactiveCN106755770AIncrease productivityStable and reliable dimensional accuracyFurnace typesHeat treatment furnacesSteel tubeThin walled

The invention provides a processing method for improving quality of an inner surface of an austenite stainless steel tube. The method comprises the following step: successively carrying out solution treatment, straightening, pulling of a fixed mandrel and aftertreatment on a rolled austenite stainless steel insertion tube to obtain the austenite stainless steel tube with the high-quality inner surface. The processing method is simple in process, easy to implement, high in production efficiency and low in energy consumption; and the austenite stainless steel tube processed by the method is good in quality of the inner surface and the outer surface, even in structure and excellent in mechanical property; the yield of one-time detection in nondestructive test reaches 90% or above; and therefore, the processing method can be widely applied to the processing industry of stainless steel thin-walled slender tubes.

Owner:西安诺博尔稀贵金属材料股份有限公司

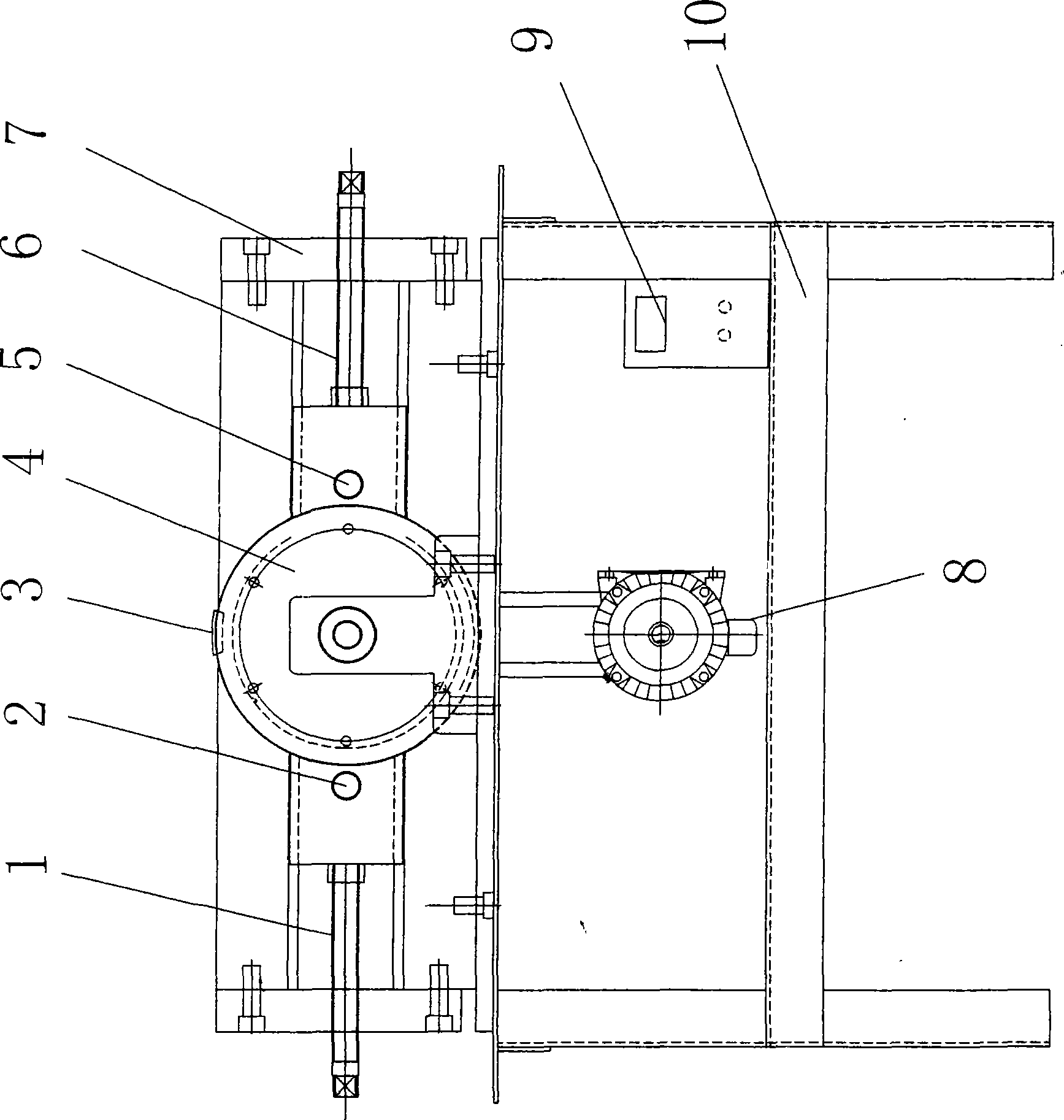

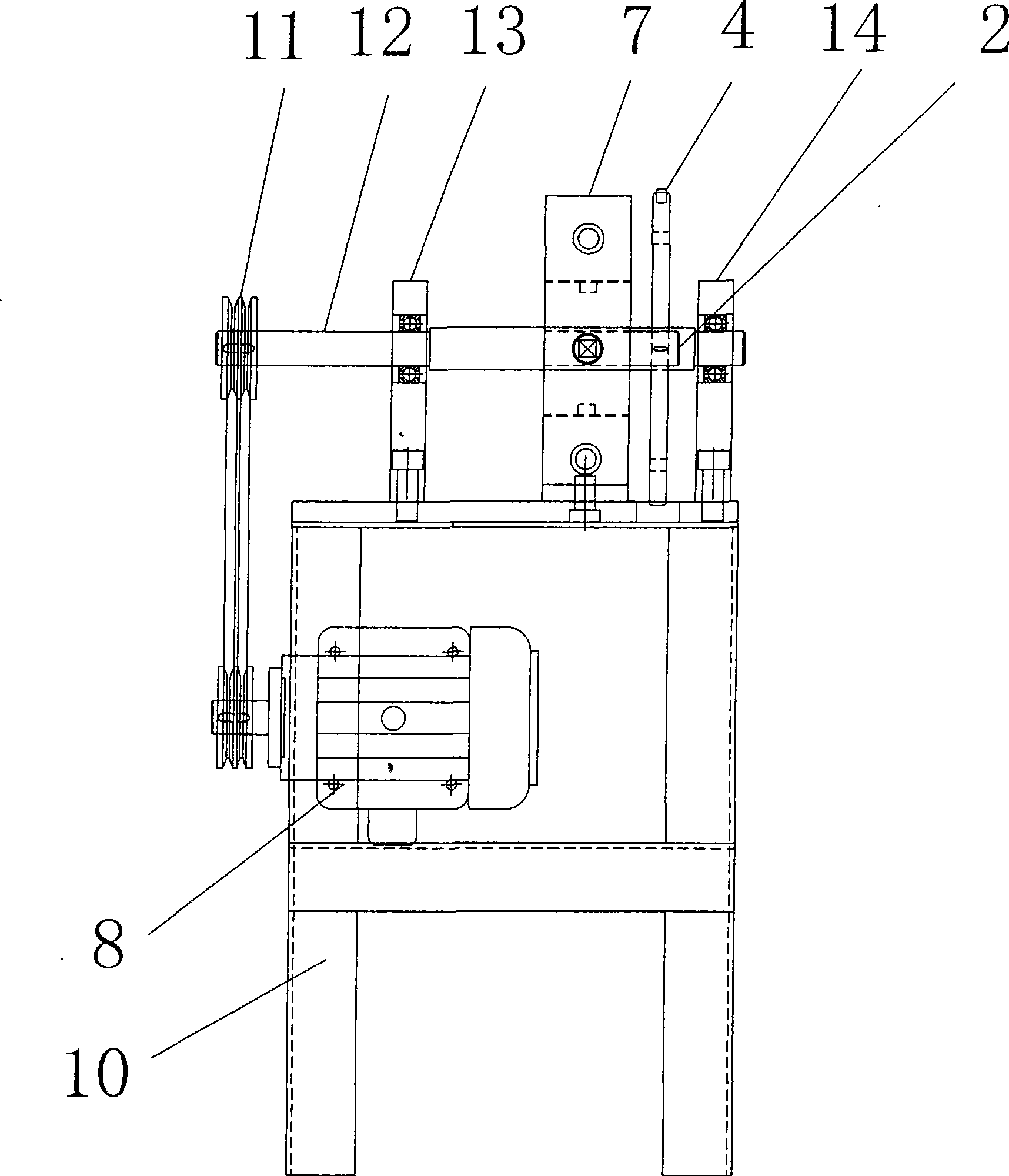

Rolling carving machine for metal pipe fittings

A rolling carving machine for metal pipe fittings belongs to the manufacture technical field of metal pipe fittings and mainly comprises a stand (10) provided with an electric motor (8) and a controller (9), a front supporting frame (14) and a rear supporting frame (13) which are both arranged at the upper part of the stand (10), a drive shaft (12) which is arranged between the front supporting frame (14) and the rear supporting frame (13) and provided with a rolling print wheel (4), a fixing frame (7) arranged at two sides of the rolling print wheel (4) at the upper part of the stand (10), a left bearing shaft (2) with a left-adjusting bolt (1), a right bearing shaft (5) with a right-adjusting bolt (6), and the like, wherein the left bearing shaft (2) and the right bearing shaft (5) are arranged on the fixing frame (7). The invention has reasonable integral structure design, simple structure, convenient operation and reliable work, is suitable to carve on the circumferences of various pipe fittings of red copper pipe fittings, and the like, can effectively improve the production efficiency, improve the product quality, shorten the production period and lower the production cost.

Owner:ZHEJIANG COPPER PROCESSING INST +1

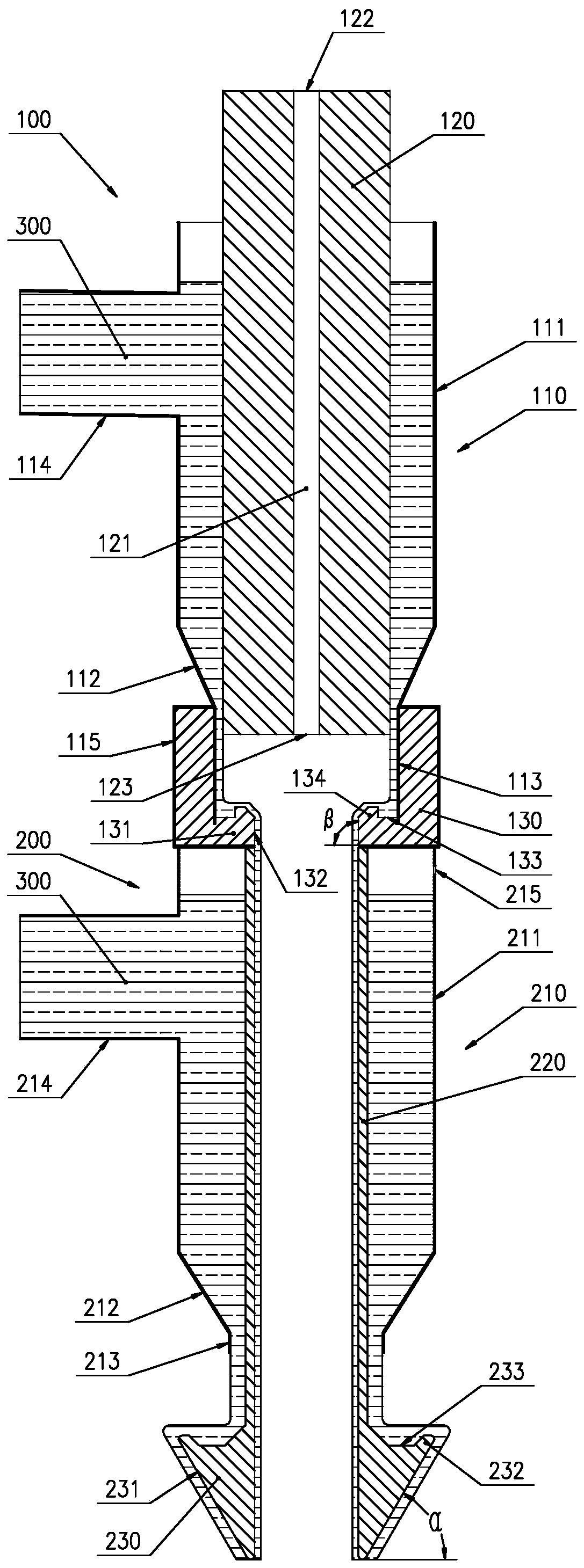

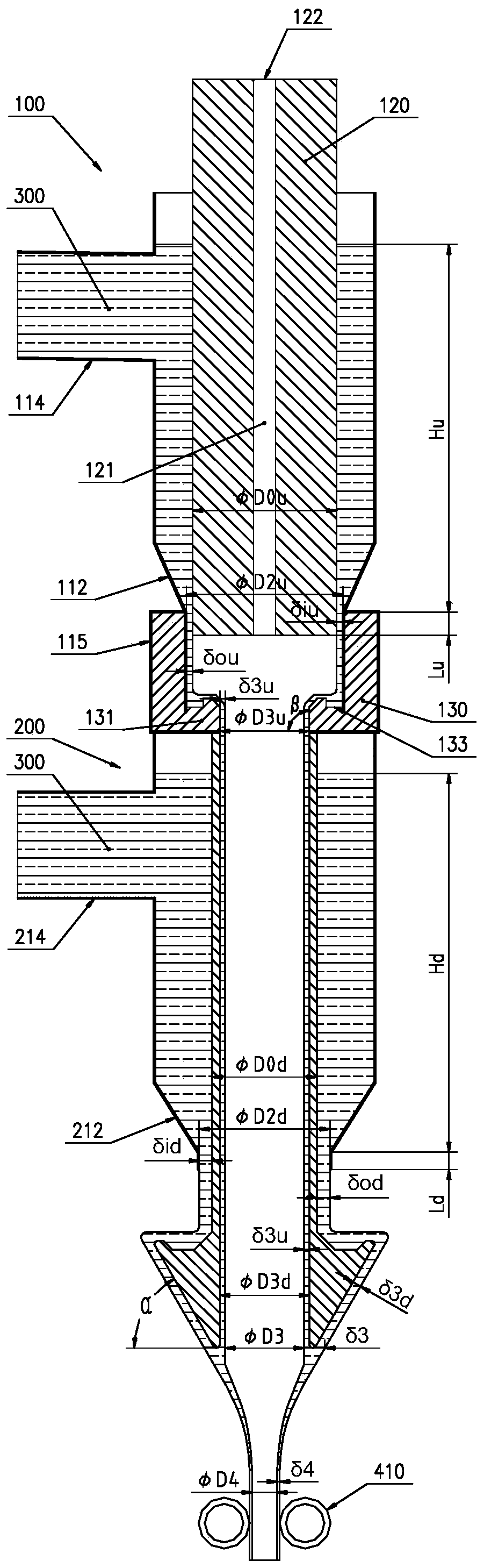

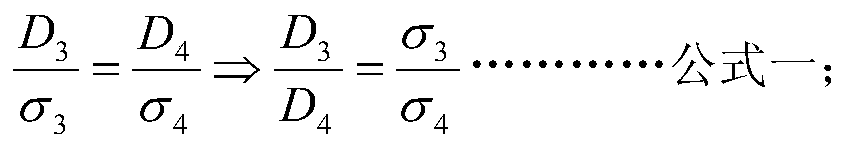

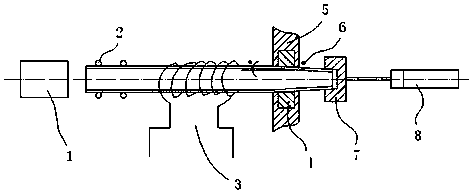

Large-diameter thin-wall seamless tube rotation extrusion forming method

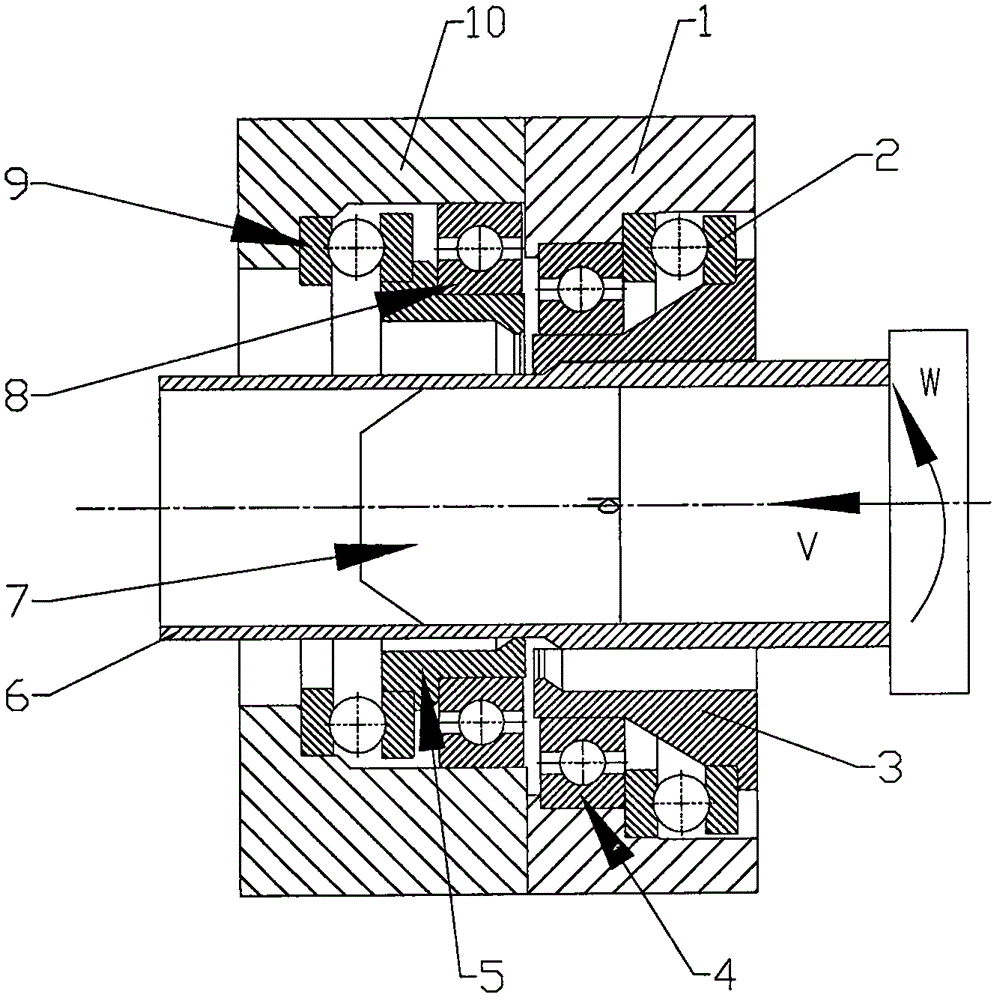

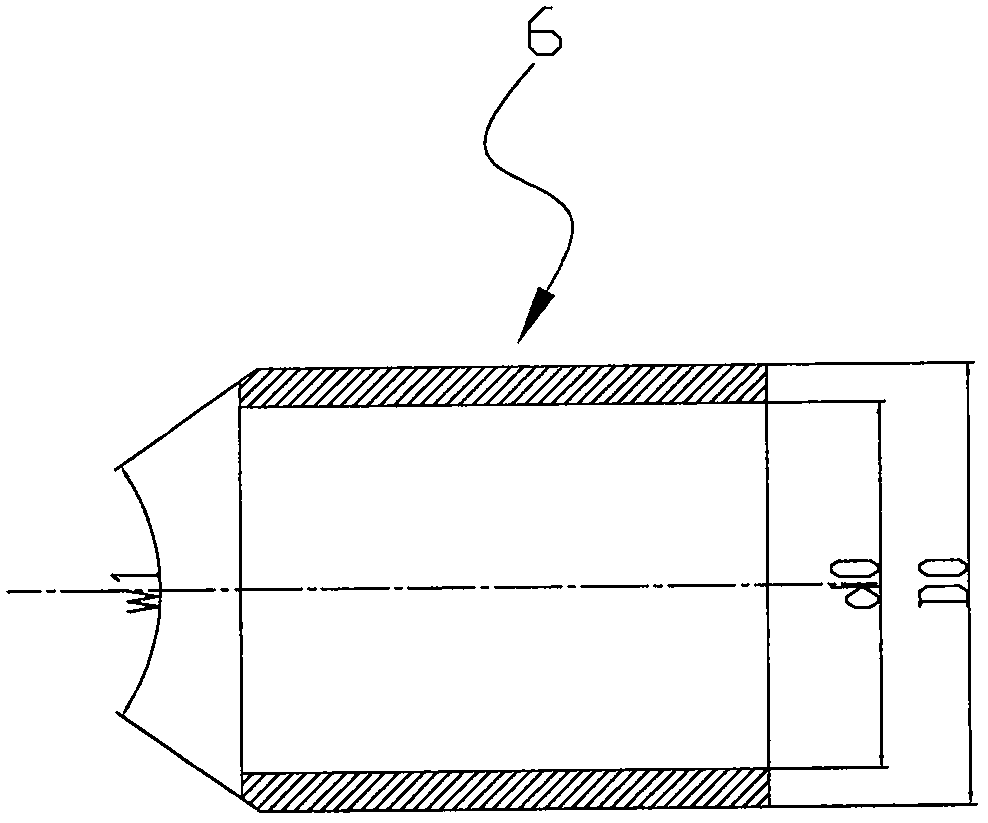

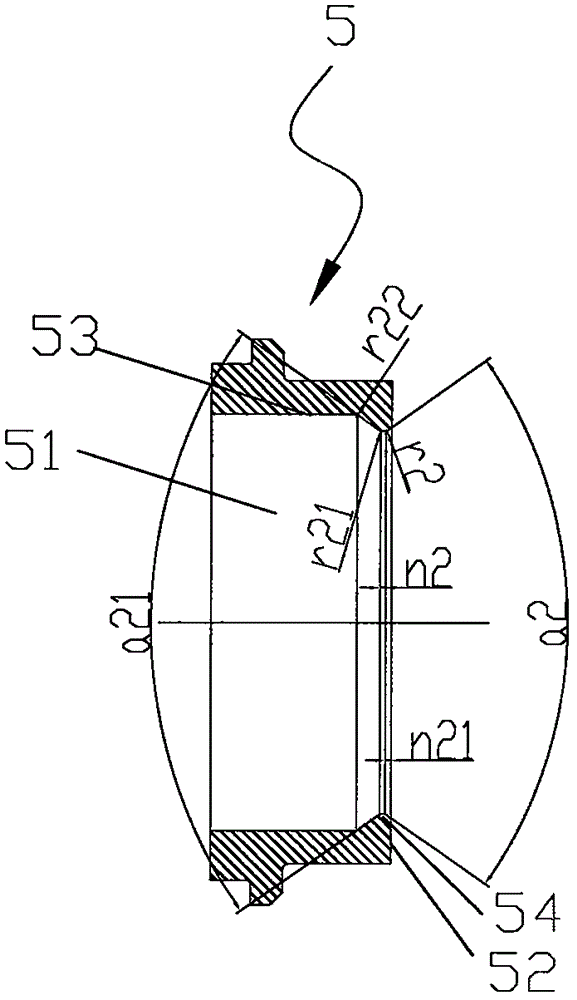

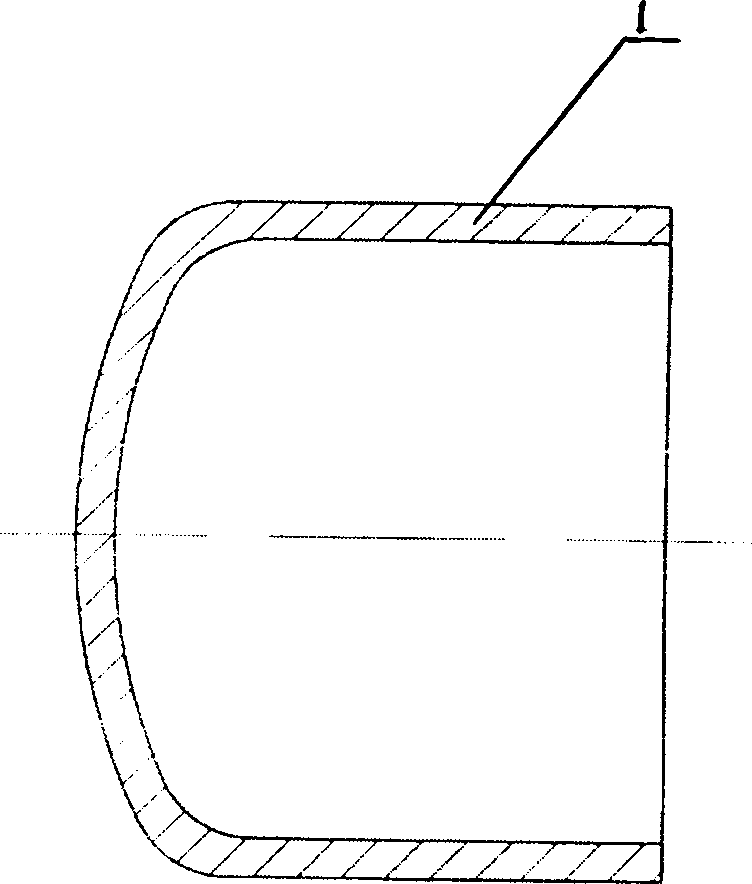

ActiveCN106734301AWide range of metal materialsHigh dimensional accuracyExtrusion diesExtrusion mandrelsRolling-element bearingThrust bearing

The invention provides a large-diameter thin-wall seamless tube rotation extrusion forming method. A tubular product blank with D0 and d0 as the external diameter and the internal diameter generates rotational motion with an angular velocity of omega and axial motion with a leftward speed upsilon under the action of a core rod and is sequentially subjected to extrusion deformation of an extrusion wheel and correction deformation of a shape correction wheel to obtain a high-precision tubular product with D and d as the external diameter and the internal diameter, wherein a circular passage is formed in the center of the extrusion wheel; the extrusion wheel is mounted on a right permanent seat through an extrusion wheel thrust bearing and an extrusion wheel antifriction bearing; the extrusion wheel thrust bearing bears axial thrust when the tubular product deforms; the extrusion wheel antifriction bearing ensures that the extrusion wheel can be driven to rotate when the tubular product forms; the shape correction wheel is mounted on a left permanent seat through a shape correction wheel thrust bearing and a shape correction wheel antifriction bearing; the shape correction wheel thrust bearing bears axial thrust when the tubular product deforms; and the shape correction wheel antifriction bearing ensures that the shape correction wheel can be driven to rotate when the tubular product forms. The large-diameter thin-wall seamless tube rotation extrusion forming method inherits the advantages of the three-dimensional pressure stress state forming of the extrusion process.

Owner:ZHONGBEI UNIV

Method for rolling high-precision titanium alloy pipes

ActiveCN104148439AImprove ovalityEliminate bumpsWork treatment devicesMetal rolling arrangementsMetallurgyMicrometer

The invention relates to a method for rolling high-precision titanium alloy pipes. A prepared titanium alloy pipe billet is rolled in a combination way of two rollers and three rollers, and the rolling method adopts single feeding and double slew. The value Q of two-roller rolling is 0.4-2, the value Q of multiple-roller rolling is 0.4-9, and the amount of clearance is 0.2-2mm. The rolled finished pipe is processed in a way of outer surface grinding and inner surface honing to obtain the titanium alloy pipes, wherein the outer surface roughness Ra is less than or equal to 0.6 micrometers, the inner surface roughness Ra is less than or equal to 0.2 micrometers, the outside-diameter size tolerance is less than or equal to 0.04mm, the inside-diameter size tolerance is less than or equal to 0.03mm, and the wall-thickness size tolerance is less than or equal to 3 percent of a nominal wall thickness. Compared with the prior art, the method has the advantages that the size tolerance precision of the obtained products is relatively high, and the inside and outside surface quality is relatively good.

Owner:宁夏中色金航钛业有限公司

Variable-wall metal tube and its making process

The present invention relates to one kind of variable wall thickness metal barrel and its making process. The variable wall thickness metal barrel is suitable for use in aviation, aerospace, weapon, chemical, petroleum and other fields. The variable wall thickness metal barrel has thick wall bottom part, middle transition part and thin wall upper part connected successively to form one integral. It is made with equal wall thickness tube and through rotary extrusion. The product of the present invention has novel structure, high surface quality, high size accuracy and reasonable making process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method for welded steel pipe for boiler

The invention discloses a preparation method for a welded steel pipe for a boiler. The preparation method for the welded steel pipe for the boiler includes steps of steel billet winding prevention, longitudinal shearing, forming, welding, burr removing, weld heat treating, sizing, non-oxidizing heat treatment, shaping, flaw detection, cutting, head cutting and truncation, coating and packaging. The preparation method for the welded steel pipe for the boiler has advantages of easiness and convenience in operation, easiness in implementation, high forming efficiency, good product quality, high yield and the like; the prepared welded steel pipe has advantages of high inner surface quality and outer surface quality, no damage and flaw, good size stability and stability and the like, and the prepared welded steel pipe can serve as a steel pipe for a middle-high pressure boiler.

Owner:JIANGSU CHANGSHU HUANTONG IND

A short-process production method for large-diameter thin-walled copper-nickel pipes

The invention discloses a short-process production method of a large-diameter thin-walled white copper pipe, which belongs to the technical field of metal materials. Aiming at the traditional "semi-continuous casting solid ingot-piercing extrusion-pickling-drawing-annealing" process to produce large-diameter thin-walled copper-nickel pipes requires more than 5,000 tons of large-scale extrusion equipment, and the yield is low and the cost is high. The present invention proposes a method of horizontal continuous casting of large-sized white copper pipe blanks using hot and cold combined molds, and then adopts diameter expansion or / and diameter reduction drawing to process and form large-diameter thin-walled white copper pipes, which has the advantages of small equipment investment, short process flow, No pickling and other advantages. The outer diameter of the horizontal continuous casting tube blank is 110~350mm, the wall thickness is 5~30mm, the extension coefficient of the drawing pass for expanding diameter is 0.80~1.0, the extension coefficient for drawing pass for reducing diameter is 1.1~1.5, and the outer diameter of the processed product is 100~ 320mm, wall thickness 3~20mm.

Owner:UNIV OF SCI & TECH BEIJING

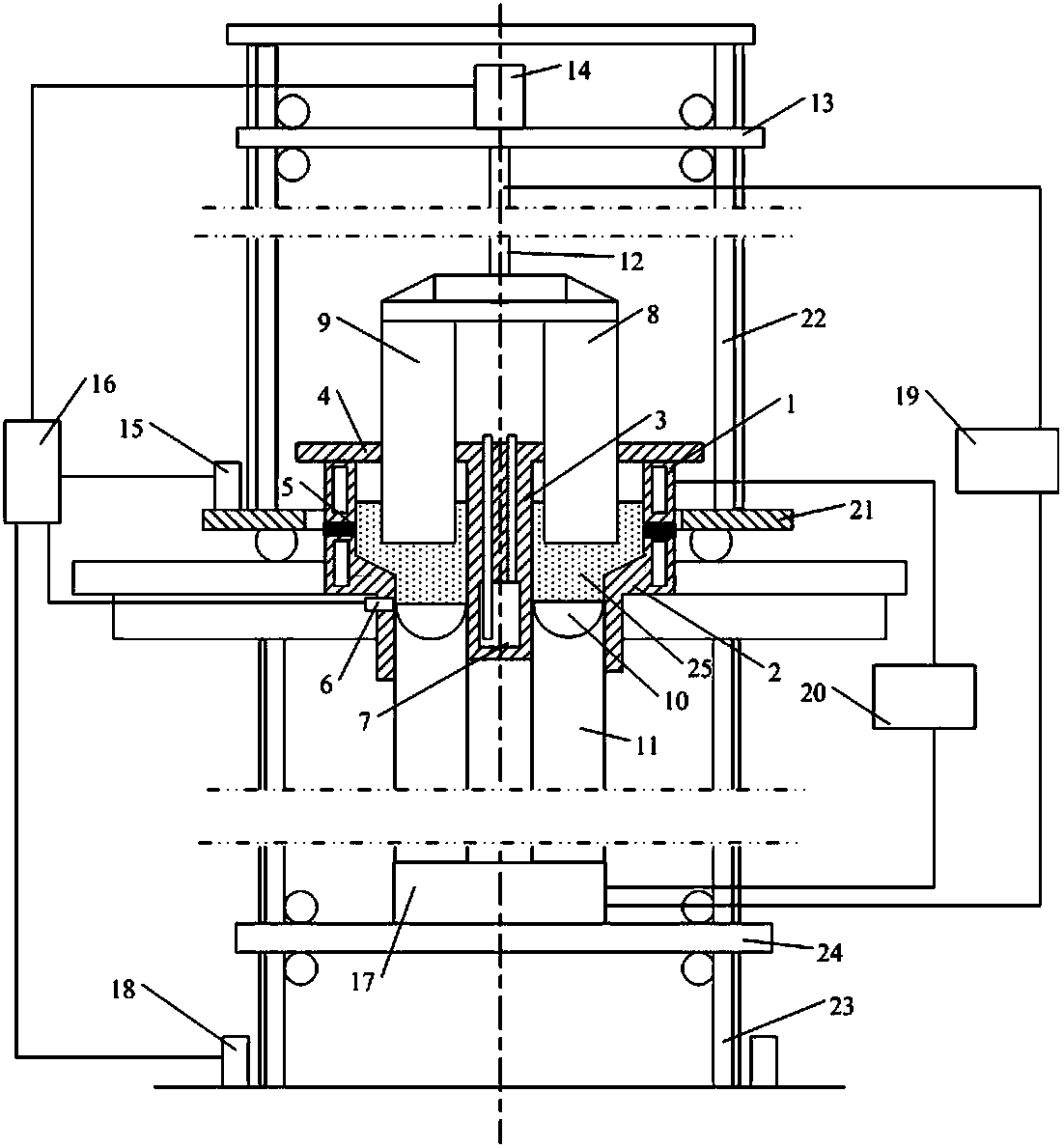

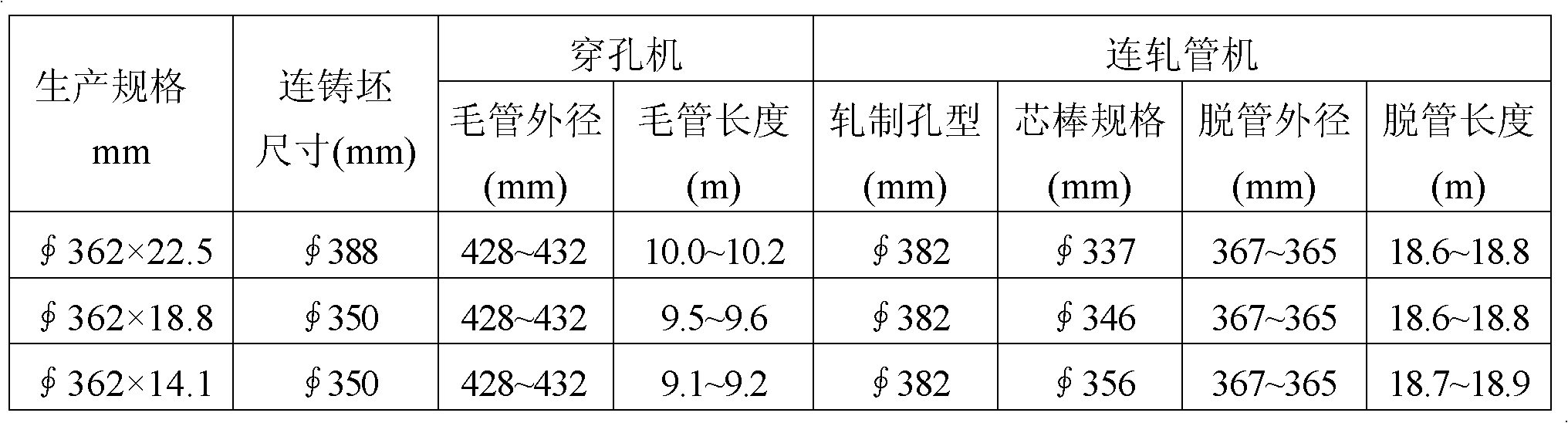

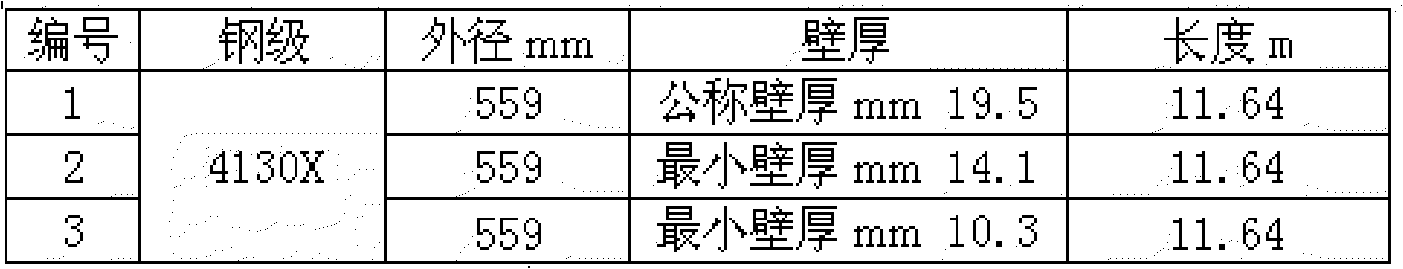

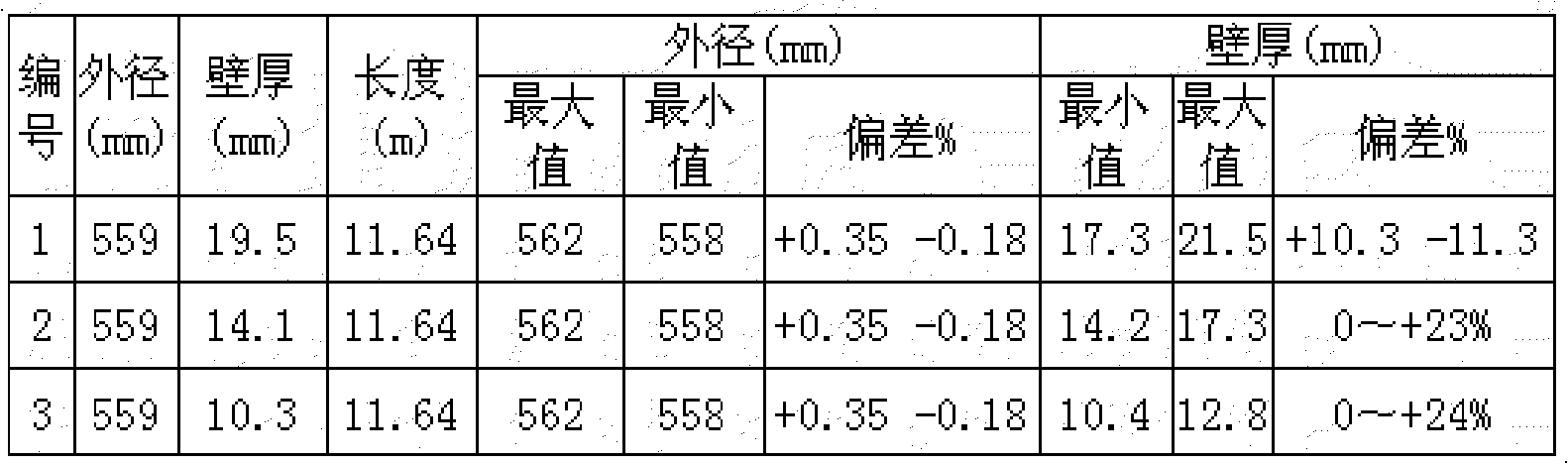

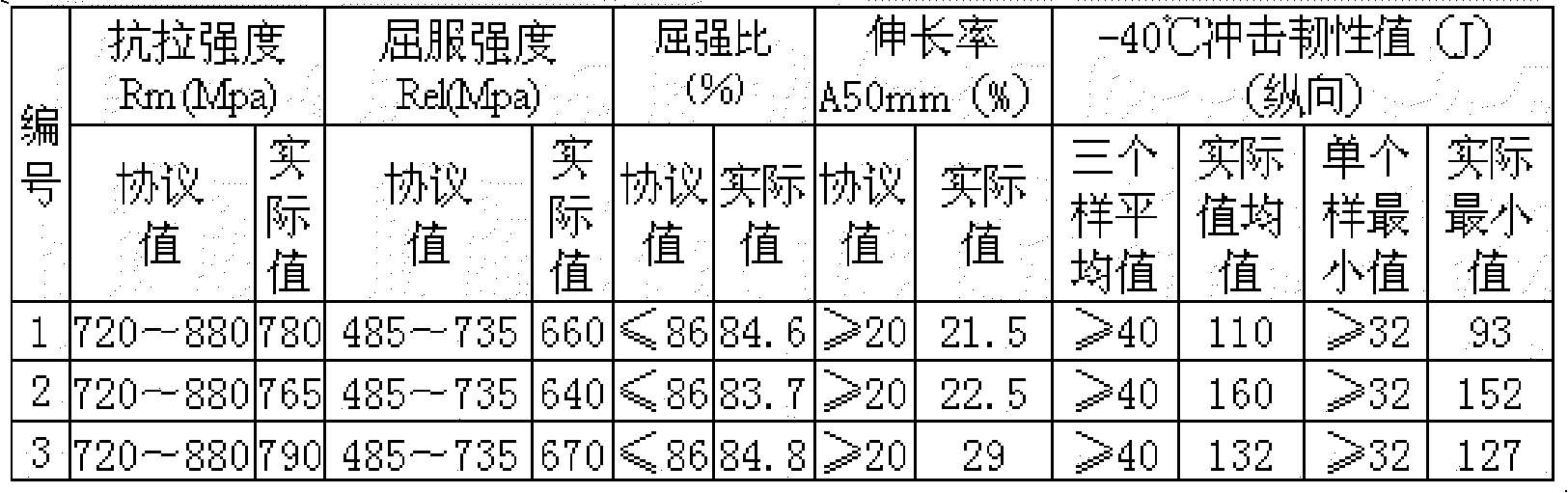

Method for producing large-diameter seamless steel pipe for gas cylinder

ActiveCN102039313BHigh dimensional accuracyImprove internal and external surface qualityMetal rolling arrangementsGas cylinderMetallurgy

The invention relates to a method for producing a large-diameter seamless steel pipe for a gas cylinder, in particular to the method for producing the large-diameter seamless steel pipe for the gas cylinder in a pushing diameter-expansion way, which belongs to the field of manufacture of seamless steel pipes. The technical problem to be solved is to provide the method for producing the large-diameter seamless steel pipe for the gas cylinder, wherein the large-diameter seamless steel pipe has high geometric dimension precision and high quality of inner and outer surfaces. The technical scheme adopted by the invention is that: circular continuously cast blooms are processed to form pipe blanks by a 340 retained mandrel pipe mill (MPM), and pushing diameter-expansion is performed to obtain the large-diameter seamless steel pipes, wherein the overall-length wall thickness tolerance and wall thickness and section ranges of the pipe blanks provided by the 340MPM are controlled to be less than or equal to 1.8mm, and the thermal external diameter phi is 367 to 365mm; and the single lightweight high-pressure gas cylinder pipes can be produced, and have the external diameters of 550mm, the external diameter tolerance of + / -1 percent, the wall thicknesses of 10 to 20mm, the wall thickness tolerance of 0 to +25 percent, the lengths of 11.0 to 12.5m, high dimension accuracy and high quality of inner and outer surfaces. The method ensures production simplicity and low cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

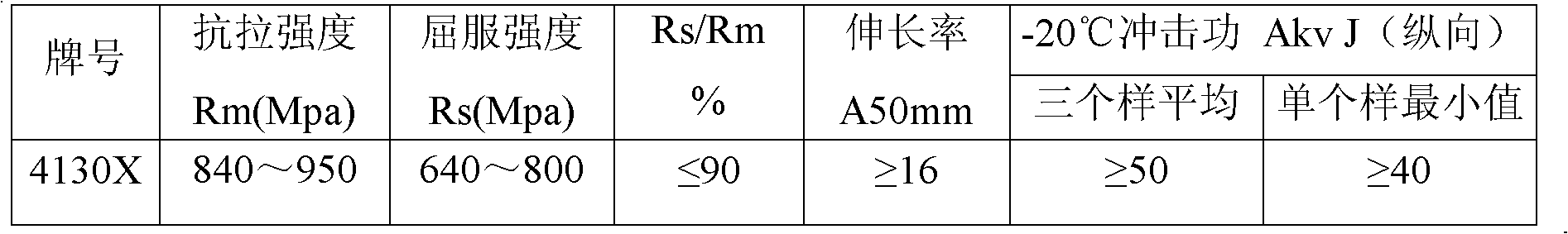

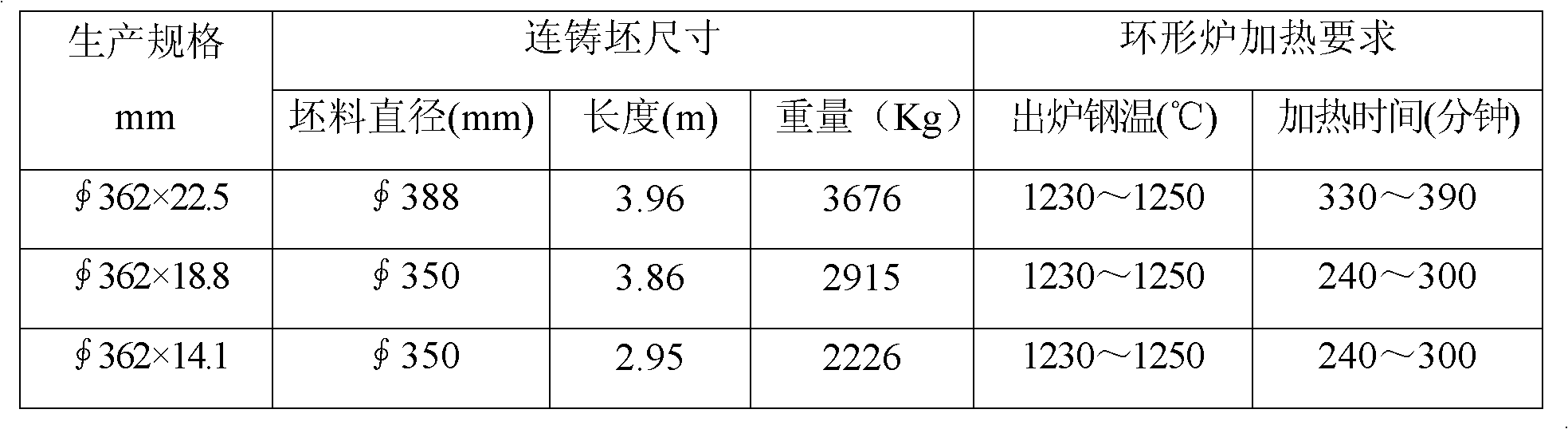

Method for producing seamless steel pipes used for large-diameter high-pressure gas cylinders

ActiveCN101444792BImprove internal and external surface qualityIncrease productionRoll mill control devicesFurnace typesGas cylinderMetallurgy

Owner:攀钢集团成都钢铁有限责任公司

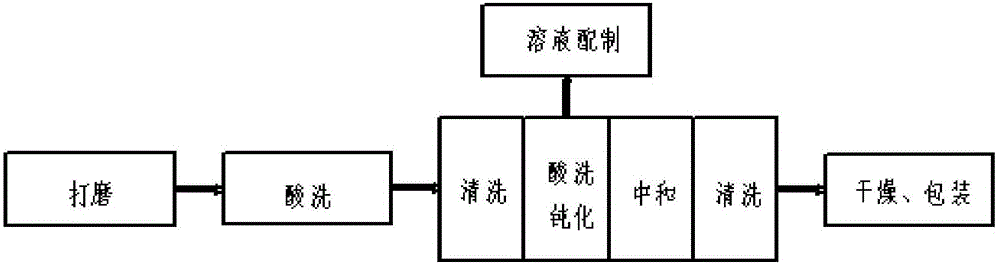

Surface treatment process for stainless steel

InactiveCN106756975AUniform colorImprove internal and external surface qualityMetallic material coating processesSlagTreatment field

The invention belongs to the surface treatment field and particularly relates to a surface treatment process for stainless steel. According to the surface treatment process, the surface quality of stainless steel equipment can be improved. The surface treatment process comprises the following steps: (A) pretreatment: firstly polishing the stainless steel surface, removing welding slag and spatter, removing oil stain and oxides on the surface and in a weld joint by virtue of acid pickling paste, and finally, removing internal and external impurities with clean water; (B) dipping the stainless steel into acid pickling passivation liquid until a silver white passivation film is formed on the surface and the color is uniform; (C) dipping the stainless steel into neutralizing liquid; and (D) soaking the stainless steel with clean water so as to remove surface-adhering solutions and impurities, and drying. The surface treatment process has the advantages that the surface color of the stainless steel is uniform and good in consistency, the surface quality of the stainless steel is high, furthermore, the service life of equipment or a part can be prolonged, the cost is low, the efficiency is high, and the like.

Owner:LUZHOU NORTH CHEM IND

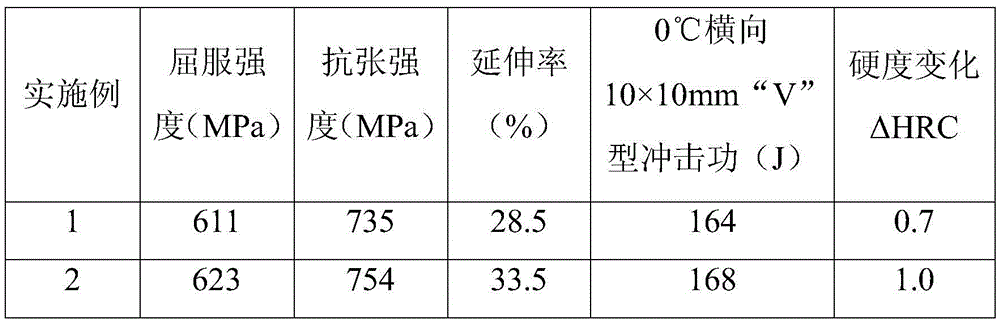

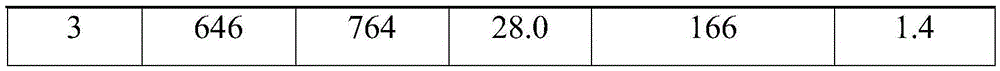

H2S corrosion-resistant 80-ksi casing steel for shale gas and preparation method thereof

ActiveCN105483528AReduce in quantityEasy to shapeElectric furnaceProcess efficiency improvementSteelmakingQuenching

The invention discloses H2S corrosion-resistant 80-ksi casing steel for shale gas. The casing steel is prepared from, by weight, 0.25%-0.29% of C, 0.20%-0.35% of Si, 0.90%-1.10% of Mn, 0.95%-1.15% of Cr and the balance Fe, residual elements and unavoidable impurities. The invention further discloses a preparation method of the H2S corrosion-resistant 80-ksi casing steel for the shale gas. The preparation method comprises the steps of steelmaking, wherein pig iron and waste plain carbon steel are adopted as raw materials in the steelmaking process, a deoxidizing agent is added in the steel tapping process, static blowing treatment is performed in a VD vacuum chamber, and argon blowing and sealing gasket adding for protection are performed during pouring; pipe manufacturing, wherein the temperature of a heating zone ranges from 1210 DEG C to 1270 DEG C, and the temperature of a soaking zone ranges from 1240 DEG C to 1260 DEG C; heat treating, wherein the heat treatment technologies of spraying and inner axial flow water cooling quenching, air cooling tempering and straightening under the temperature are adopted. According to the casing steel, the yield strength is 552-655 MPa, the tensile strength is larger than or equal to 655 MPa, the transverse 10*10-mm V-shaped impact energy at 0 DEG C is larger than or equal to 40 J, the elongation is larger than or equal to 19%, and the allowed hardness change delta HRC is smaller than or equal to 3.0.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

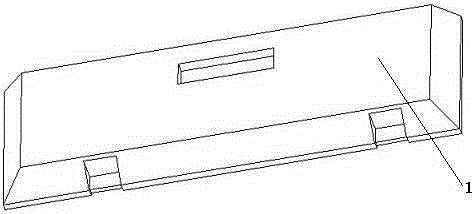

Autoclave die for improving surface quality of workpiece and method

InactiveCN105235236AGuaranteed surface qualitySolve the problem of poor quality of non-film surfaceEngineeringMechanical engineering

The invention relates to the field of manufacturing of dies, in particular to an autoclave die for improving the surface quality of a workpiece and a method. The autoclave die for improving the surface quality of the workpiece comprises a die body, a frame, a pressing plate, a pressing block, a demoulding bolt and a fastening bolt, wherein an annular groove is formed in the periphery of the workpiece on the die body, and the frame is embedded in the annular groove and provided with a demoulding bolt hole and a fastening bolt hole. According to the autoclave die, the die body guarantees the inner surface quality of the workpiece, and the frame, the pressing plate and the pressing block guarantee the outer surface quality of the workpiece. Accordingly, the autoclave die guarantees the roughness of the inner and outer surfaces of the workpiece and is simple in structure and low in cost.

Owner:HENGSHEN

Drawing method of special-shaped titanium tube

The invention discloses a drawing method of a profiled titanium tube. The drawing method comprises the steps of smearing a lubricant on a tubing, drying the tubing, and carrying out drawing on the tubing through adopting an isothermal heating drawing system. The isothermal heating drawing system sequentially comprises a variable frequency speed regulating feeding device used for feeding, a guide supporting wheel group, a coil type superaudio heater, a profiled external mold and an automatic hydraulic fixture, wherein a photoelectric sensor is mounted outside the profiled external mold; a hydraulic speed regulating pulling machine is connected at the back of the automatic hydraulic fixture; the tubing is fed into the coil type superaudio heater to be heated through the variable frequency speed regulating feeding device and the guide supporting wheel group; then, the heated tubing enters the profiled external mold; when the photoelectric sensor captures an induction signal of a tube head of the tubing, the automatic hydraulic fixture clamps the tube head; and the hydraulic speed regulating pulling machine pulls the automatic hydraulic fixture to draw the tubing into a profiled titanium tube finished product. According to the drawing method, the tubing can be formed through one-time drawing, the working efficiency is high, and the quality of the profiled titanium tube obtained through drawing is high.

Owner:常熟市异型钢管有限公司

Method for manufacturing martensitic stainless steel continuous casting billet extruded seamless pipe

The invention discloses a method for manufacturing a martensitic stainless steel continuous casting billet extruded seamless pipe. The method comprises the following steps of firstly, preparing a martensitic stainless steel continuous casting billet; secondly, peeling and segmenting the surface of the continuous casting billet; thirdly, drilling the continuous casting billet and processing a bellmouth on the end face; fourthly, cleaning and preheating the continuous casting billet; fifthly, carrying out induction heating and lubricant rolling on the continuous casting billet; sixthly, addinga lubricant to the bell mouth and expanding the hole; seventhly, carrying out induction heating again, adding lubricant inside and rolling the continuous casting billet with lubricant outside; and eighthly, preparing a tool and a mold and performing extrusion molding. According to the extrusion method for the martensitic stainless steel continuous casting billet provided by the invention, the rawmaterial is the continuous casting round billet, the defects of loose center, shrinkage holes and the like of the continuous casting billet are removed through outside peeling and inside drilling, thecenter quality of the continuous casting billet is improved through hole expanding, and the martensitic stainless steel seamless pipe is produced through an extrusion process. The seamless steel pipeproduced in the invention is low in manufacturing cost and good in inner and outer surface quality, and the size of the steel pipe can meet the requirements of customers.

Owner:江阴华润制钢有限公司

Automatic belt laying method for hexagonal hole of composite

InactiveCN110588020AHigh positioning accuracyNo overlapDomestic articlesLaser projectorMechanical engineering

The invention discloses an automatic belt laying method for a hexagonal hole of a composite. The automatic belt laying method comprises the following steps that a, the edges of a hexagon are chamfered, a mold positioned by the hexagonal hole is made, and the mold is fixed and laid on the upper surface of a tool table by demolding cloth through projection of a laser projector; b, unidirectional prepregs with the resin content of 34% are taken out of a freezer and loaded to a material roll U-shaped shaft of an automatic belt laying machine; c, the unidirectional prepregs are heated to 60 DEG C,the laying angle precision of a material belt is + / -1 degree, the clearance value is set as 1 mm, the preimpregnated material belt is laid on the outer surface of the hexagonal positioning hole in themold through the automatic belt laying machine to form a material layer, and the hexagonal positioning hole and the material layer are packaged in a vacuum bag to be vacuumized and compacted; d, thevacuum bag is conveyed into an autoclave, so that a part is cured and formed; and e, the mold is opened, and the cure-formed material layer is taken out to obtain the finished part. The problem aboutautomatic belt laying of the hexagonal hole design of a composite component can be solved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Large-section hollow profile extrusion forming method and device with small-opening die utilized

The invention discloses a large-scale hollow profile extrusion forming method and device with a small-opening die utilized. The method includes the steps that inflation is conducted on a blank piece extruded from a die head through compressed air, a layer of narrow-seam-shaped air cushion with the same shape as the hollow shape of a product is formed in the blank piece, the blank piece is tightly attached to the inner wall of a vacuum shaping sleeve under further expansion of the air cushion, the hollow pipe product is formed under the synergistic effect of the air cushion and vacuum shaping, and the purpose that large-section hollow profiles are prepared continuously through the small-opening die is achieved. The device comprises an extrusion machine, the die head and a vacuum cooling shaping device which are sequentially connected. An inflation device is arranged in the die head and comprises a core rod, an air inlet pipe and an inner cold-air plug. The air inlet pipe is arranged in the middle of the core rod. The rod portion of the inner cold-air plug is arranged in the air inlet pipe. The head portion of the inner cold-air plug is arranged in a space between the die and the vacuum cooling shaping device. A blank forming runner is formed between the outer wall of the core rod and the die head. The method and device are simple in principle and easy to operate and control, and meanwhile the obtained product is wide in use range.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com