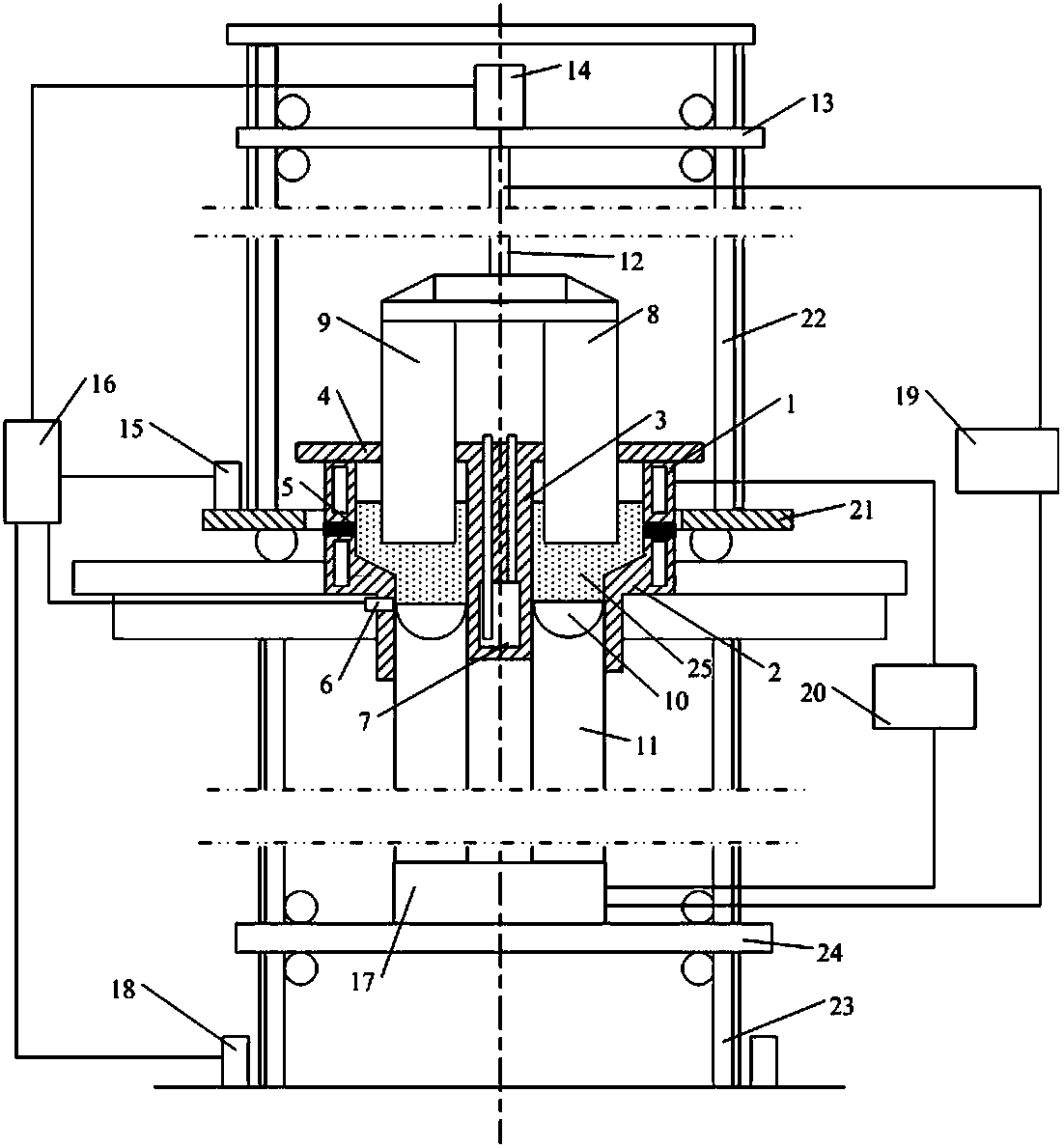

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

An electroslag remelting and generator technology, applied in the field of metallurgy, can solve problems such as affecting product quality, changing the structure of steel ingots, and low forging yield, achieving easy production preparation, reducing heating times, and improving filling ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Prepare multiple consumable electrode groups, each consumable electrode group consists of two parts of the same size; each part has 5 consumable electrodes; two parts of the same size of the consumable electrode group , symmetrically distributed in parallel on both sides of the beam;

[0051] 2. Add the slag material into the slag melting furnace, and turn on the electricity to melt the slag material into liquid slag; the composition of the slag material contains CaF by weight percentage 2 35%, CaO 35%, Al 2 o 3 10%, MgO 5%, SiO 2 15%;

[0052] 3. Before the slag pouring, the consumable electrode group is lowered by the consumable electrode lifting device and inserted into the electroslag remelting hollow ingot crystallizer; before the slag pouring, the electroslag remelting process and the whole process before the stripping In the middle, the cooling water cavity of the water cooling sleeve is passed with cooling water, and the water cooling device of the uppe...

Embodiment 2

[0070] Slag composition contains CaF by weight percentage 2 40%, CaO 30%, Al 2 o 3 15%, MgO 1%, SiO 2 14%;

[0071] Electroslag remelting method is the same as embodiment 1, and difference is:

[0072] (1) In step 6, when the current reaches 9kA, stop injecting liquid slag;

[0073] (2) In step 8, adjust the voltage of transformer I to 63~68V (the process setting value of voltage), and the current to 18~20kA (the process setting value of current), when the current of transformer II reaches 5.5kA, adjust The output voltage of transformer II keeps its current at 9k A; (3) In step 10, when the height of the remaining part of the consumable electrode of a consumable electrode group is 60mm, exchange the consumable electrode group;

[0074] (4) The size of the crystallizer is Φ900mm in diameter of the outer mold, and Φ500mm in diameter of the inner mold; the amount of liquid slag is to ensure that the height of the slag pool is 300~350kg / furnace steel, the voltage is 72~76V,...

Embodiment 3

[0077] Slag composition contains CaF by weight percentage 2 39%, CaO 34%, Al 2 o 3 14%, MgO 3%, SiO 2 10%;

[0078] Electroslag remelting method is the same as embodiment 1, and difference is:

[0079] (1) In step 7, when the current reaches 9kA, stop injecting liquid slag;

[0080] (2) In step 8, adjust the voltage of transformer I to 62~66V (the process setting value of voltage), and the current to 22~24kA (the process setting value of current), when the current of transformer II reaches 6kA, through the adjusted The output voltage keeps its current at 10k A;

[0081] (3) In step 10, when the height of the remaining part of the consumable electrode of a consumable electrode group is 50mm, exchange the consumable electrode group;

[0082] (4) The diameter of the T-shaped outer mold is Φ900mm, and the diameter of the inner mold is Φ200mm; the amount of liquid slag is to ensure that the height of the slag pool is 360~380kg / furnace steel, the voltage is 62~66V, the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com