Automatic belt laying method for hexagonal hole of composite

A technology of hexagonal holes and composite materials, which is applied to other household appliances, household appliances, household components, etc., to achieve good lubrication, large thermal expansion, and improve the quality of internal and external surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

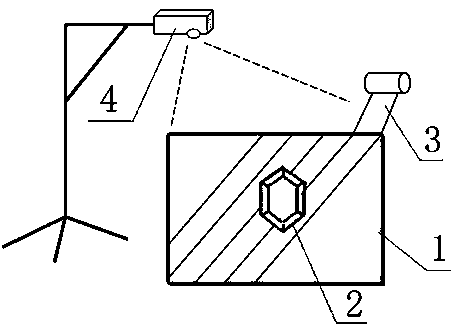

[0022] Such as figure 1 Shown, a kind of composite material hexagonal hole automatic tape laying method comprises the following steps:

[0023] a. Chamfer the edges of the hexagon to make a mold 2 with hexagonal hole positioning, and use a laser projector to project the mold 2 through the release cloth 3 and fix it on the upper surface of the tooling table 1;

[0024] b. Take the unidirectional prepreg with a resin content of 34% from the freezer, thaw it in the purification room for more than 6 hours until the tape 5 package bag is free of water vapor and water drops, and load it on the U-axis of the automatic tape laying machine;

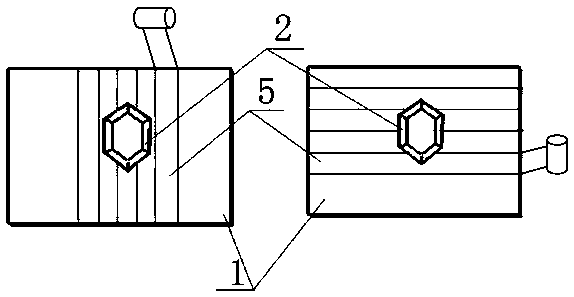

[0025] c. Heating temperature to 60°C, laying angle accuracy of tape 5 is ±1°, gap value is set to 1mm, laying parameter speed on the automatic tape laying machine is ≤20m / min, pressure roller pressure is 5bar, and roller length can be adjusted Choose 75-150mm, such as figure 2 As shown, the automatic tape laying machine lays the prepreg materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com