Surface treatment process for stainless steel

A surface treatment, stainless steel technology, applied in the direction of metal material coating process, etc., can solve the problems of high grinding labor intensity, inconsistent polishing patterns and high cost, and achieve the effect of improving the quality of inner and outer surfaces, uniform surface color, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

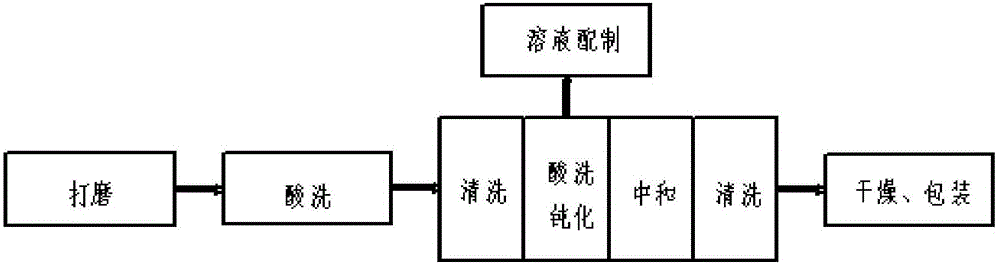

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Surface treatment of injector equipment

[0028] A. Pretreatment:

[0029] (1) Grind the surface first to remove welding slag and spatter;

[0030] (2) Then use pickling paste to remove oil stains and oxides on the surface and welds;

[0031] (3) Finally, use clean water to remove internal and external impurities;

[0032] B. Immerse the stainless steel in the pickling passivation solution, including the following components in volume percentage: 30% nitric acid, 7% hydrofluoric acid, and the rest are water, wherein nitric acid is calculated by 100% concentration, and hydrofluoric acid is calculated by 100% concentration. Soak for 150min until a silver-white passivation film is formed on the surface with uniform color;

[0033] C. Then immerse the injector equipment in the neutralizing liquid NaOH with a concentration of 10-20%;

[0034] D. Soak in clean water to remove the solution and impurities attached to the surface, dry, and then pack for protection....

Embodiment 2

[0036] Embodiment 2 Surface treatment of steel pipe parts

[0037] A. Pretreatment:

[0038] (1) Grind the surface first to remove welding slag and spatter;

[0039] (2) Then use pickling paste to remove oil stains and oxides on the surface and welds;

[0040] (3) Finally, use clean water to remove internal and external impurities;

[0041] B. Immerse the stainless steel in the pickling passivation solution, including the following components in volume percentage: 30% nitric acid, 7% hydrofluoric acid, and the rest are water, wherein nitric acid is calculated by 100% concentration, and hydrofluoric acid is calculated by 100% concentration. Soak for 120min until a silver-white passivation film is formed on the surface with uniform color;

[0042] C. Then immerse the steel pipe in 10-20% neutralizing solution NaOH;

[0043] D. Soak in clean water to remove the solution and impurities attached to the surface, dry, and then pack for protection.

[0044] The surface color of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com