Treatment liquid and method or preparing Ti/Zr-containing yellow passive film on surface of aluminum alloy

A technology of aluminum alloy surface and yellow passivation film, which is applied in the coating process of metal materials, etc., can solve the problems of film forming speed and processing cost gap, complex process, high processing temperature, etc., and achieve improved corrosion resistance and easy film formation The effect of excellent quality and protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

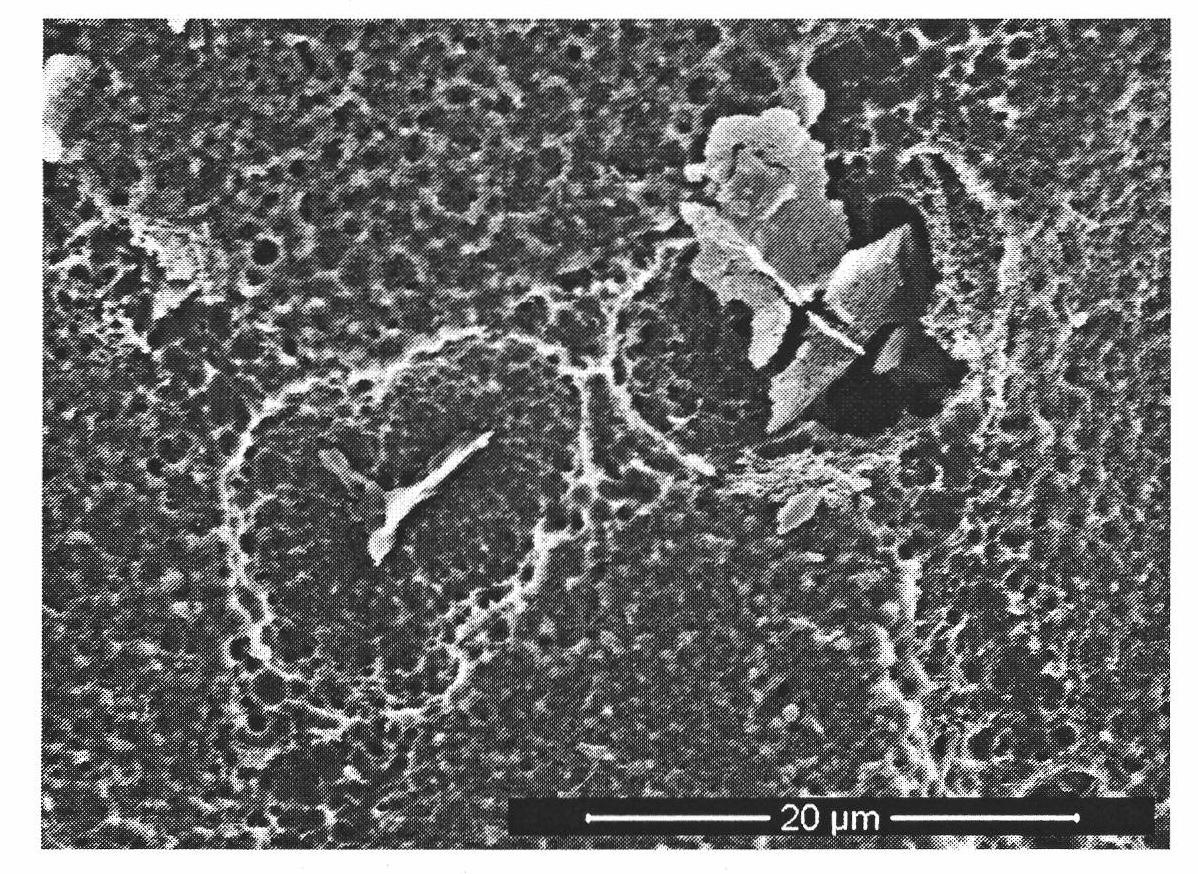

[0046] Example 1: 6063 aluminum alloy profile (thickness 3mm) surface coloring titanium zirconium conversion treatment

[0047] The process for preparing a yellow chemical passivation film containing Ti / Zr on the surface of an aluminum alloy comprises the following steps:

[0048] (1) Pretreatment: ① Cut 6 samples of 30×30mm from 6063 large-size aluminum alloy profiles (thickness 3mm) and punch holes, polish the surface of the aluminum alloy to 1000# with SiC water sandpaper, and clean the surface with tap water. The object is cleaned and dried, and the aluminum wire is connected at the perforated place; ②Immerse the sample piece in an alkaline solution at 50°C for 2 minutes, and then rinse it with deionized water for later use. The components in the alkaline solution The concentration is sodium hydroxide 50g / L, anhydrous sodium carbonate 5g / L; ③Immerse the sample in a mixed acid solution at 25°C for 1min, then rinse it with deionized water, and dry it with a hair dryer for la...

Embodiment 2

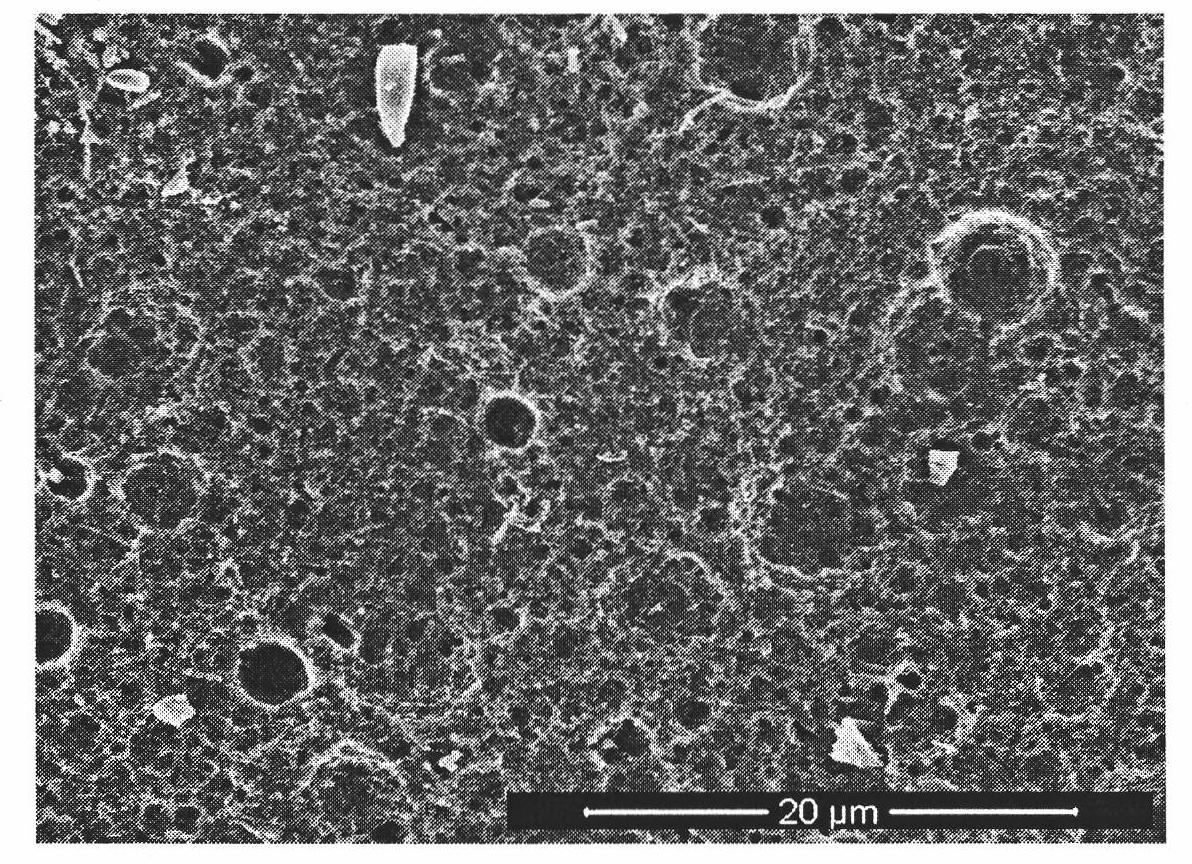

[0065] Example 2: 6063 aluminum alloy profile (thickness 3mm) surface coloring titanium zirconium conversion treatment

[0066] A method for chemical conversion treatment of titanium and zirconium on the surface of an aluminum alloy, comprising the following steps:

[0067] (1) Pretreatment: ① Cut 6 samples of 30×30mm from 6063 large-size aluminum alloy profiles (thickness 3mm) and punch holes, polish the surface of the aluminum alloy to 1000# with SiC water sandpaper, and clean the surface with tap water. ②Immerse the sample piece in an alkaline solution at 45°C for 3 minutes, and then rinse it with deionized water for later use. The concentration of each component in the alkaline solution is sodium hydroxide 40g / L , anhydrous sodium carbonate 5g / L; ③Immerse the sample in a mixed acid solution at 25°C for 1min, then rinse it with deionized water, and dry it with a hair dryer for later use. The composition of the mixed acid solution is nitric acid 10%wt, phosphoric acid 2.5%w...

Embodiment 3

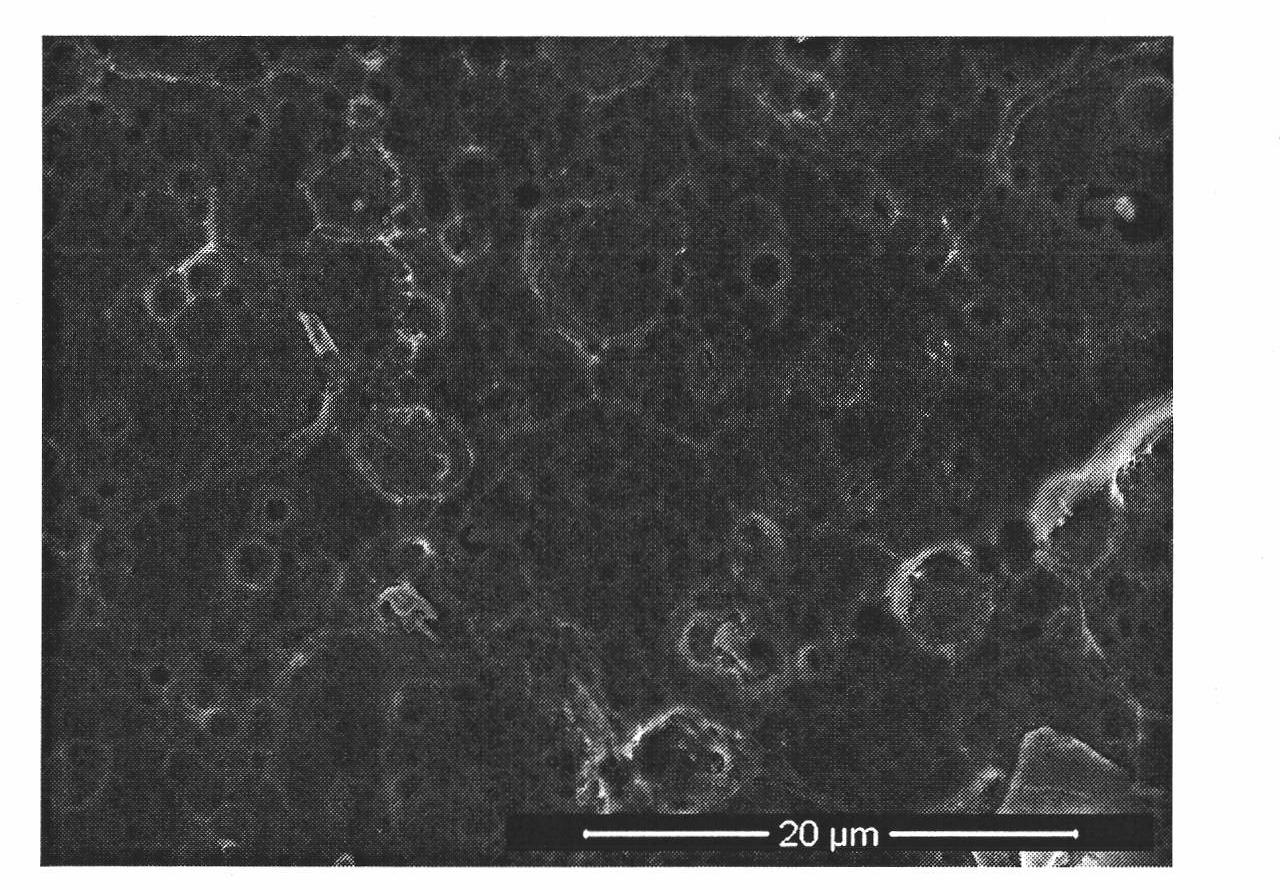

[0081]Example 3: 6063 aluminum alloy profile (thickness 3mm) surface coloring titanium zirconium conversion treatment

[0082] A method for chemical conversion treatment of titanium and zirconium on the surface of an aluminum alloy, comprising the following steps:

[0083] (1) Pretreatment is the same as in Example 1.

[0084] (2) Preparation of a treatment solution containing a Ti / Zr yellow passivation film on the surface of an aluminum alloy: 100 ml of a colored titanium-zirconium conversion treatment solution was prepared, wherein the various components and concentrations in the treatment solution were as follows: fluorotitanic acid 2.0 g / L; Fluorozirconic acid 2.0g / L; manganese salt 5.0g / L; organic acid 2.0g / L. Dissolve each component: 0.2 g of fluotitanic acid; 0.2 g of fluozirconic acid; 0.5 g of manganese salt; 0.2 g of organic acid in water, adjust the pH value of the solution to 3.0, and add water until the volume of the treatment solution is 100 ml. After the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com