Drawing method of special-shaped titanium tube

A special-shaped and titanium tube technology, which is applied in the drawing field of special-shaped titanium tubes, can solve the problems of difficulty in ensuring the strength and performance of the tubes, increasing costs, and large resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

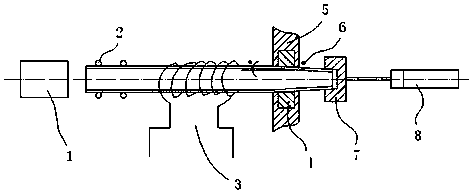

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] A drawing method for a special-shaped titanium tube comprises the steps of drawing a tube with an isothermal heating drawing system after smearing a lubricant on the tube and drying it.

[0020] The lubricant is made of the following components by mass: 8-12 parts of graphite powder, 45-50 parts of lime, 30-40 parts of soapy water and 6-10 parts of resin, among which, the mass fraction of sodium stearate is generally used It is 10~20% soapy water. Spread the lubricant evenly on the pipe to be drawn, and form a lubricating film after drying. When the titanium tube is drawn and deformed, it will produce a serious mucous membrane, so the cho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com