Method for manufacturing aluminum liner of vehicular composite cylinder

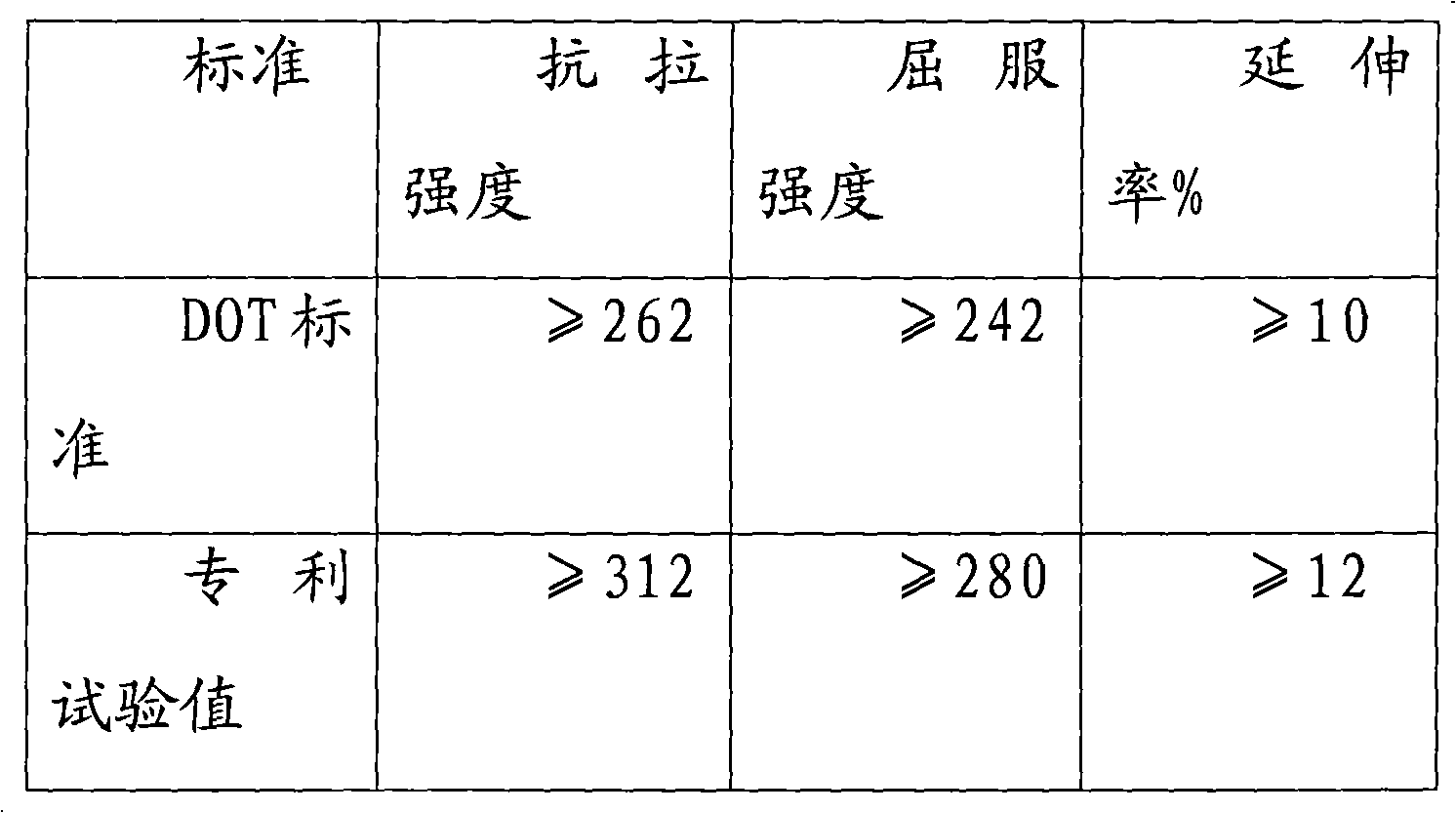

A manufacturing method and technology of aluminum liners, applied in the field of manufacturing aluminum liners of composite gas cylinders for vehicles, can solve the problems of low production costs and achieve the effects of low production costs, small weight-to-capacity ratio, and high geometric dimension accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

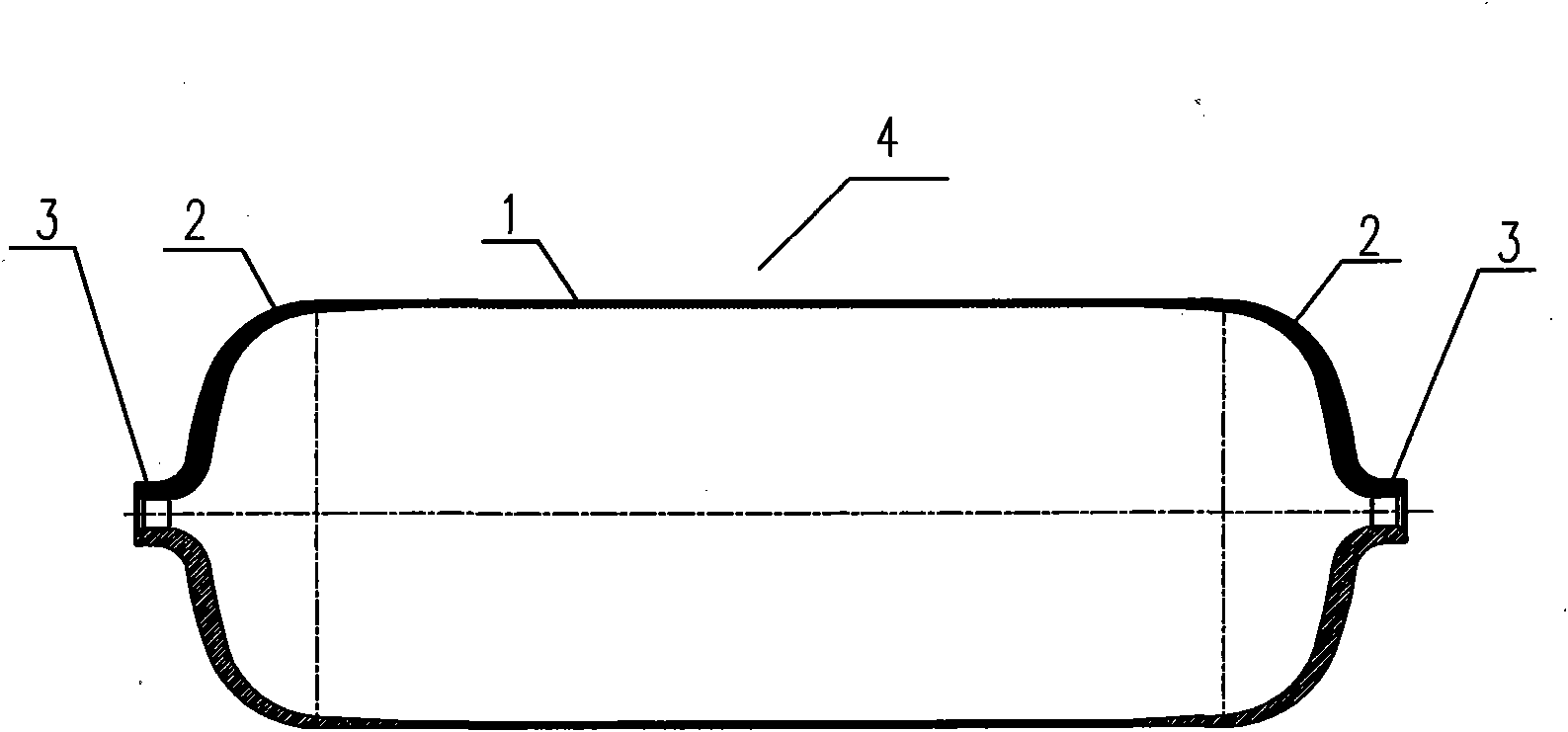

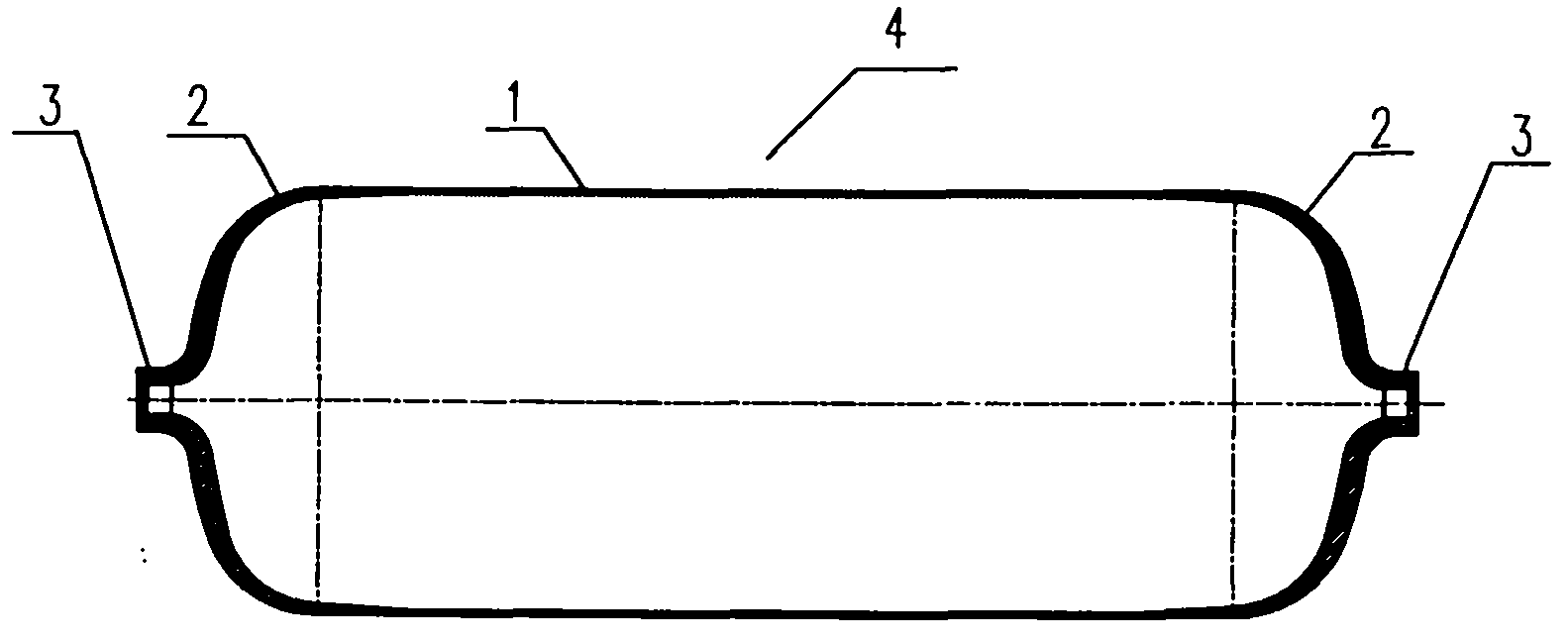

Image

Examples

Embodiment

[0064] The present invention takes the aluminum liner with a nominal volume of 300L and a specification of 406×4.5mm as the implementation target. The material is 6061 aluminum alloy seamless pipe, which has undergone wall thickness reduction, spinning closing, T6 (solution aging) heat treatment, It is made through processes such as mouth processing and product testing, and the specific process steps are as follows:

[0065] 1. Select the raw material of 6061 aluminum alloy seamless pipe with a specification of 428×15mm, and inspect its surface quality, diameter and wall thickness.

[0066] 2. According to the design requirements, the aluminum alloy seamless pipe of the length required for blanking is sawed.

[0067] 3. Select the size of the strong-rotation mandrel: 397mm, clean the surface of the mandrel, and carry out strong-rotation thinning of the aluminum alloy seamless tube material into a preform.

[0068] 4. Use a carbide band saw to align both ends of the preform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com