Variable-wall metal tube and its making process

A metal cylinder and cylinder bottom technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of potential safety hazards, difficulty in achieving strength, etc., and achieve the effect of novel and unique structure, weight reduction, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

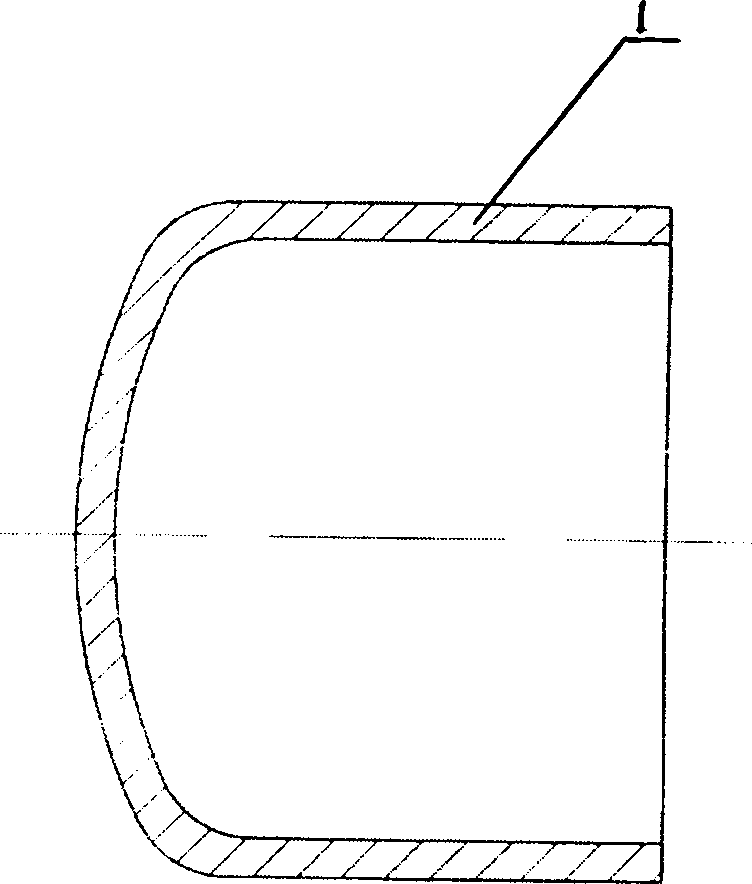

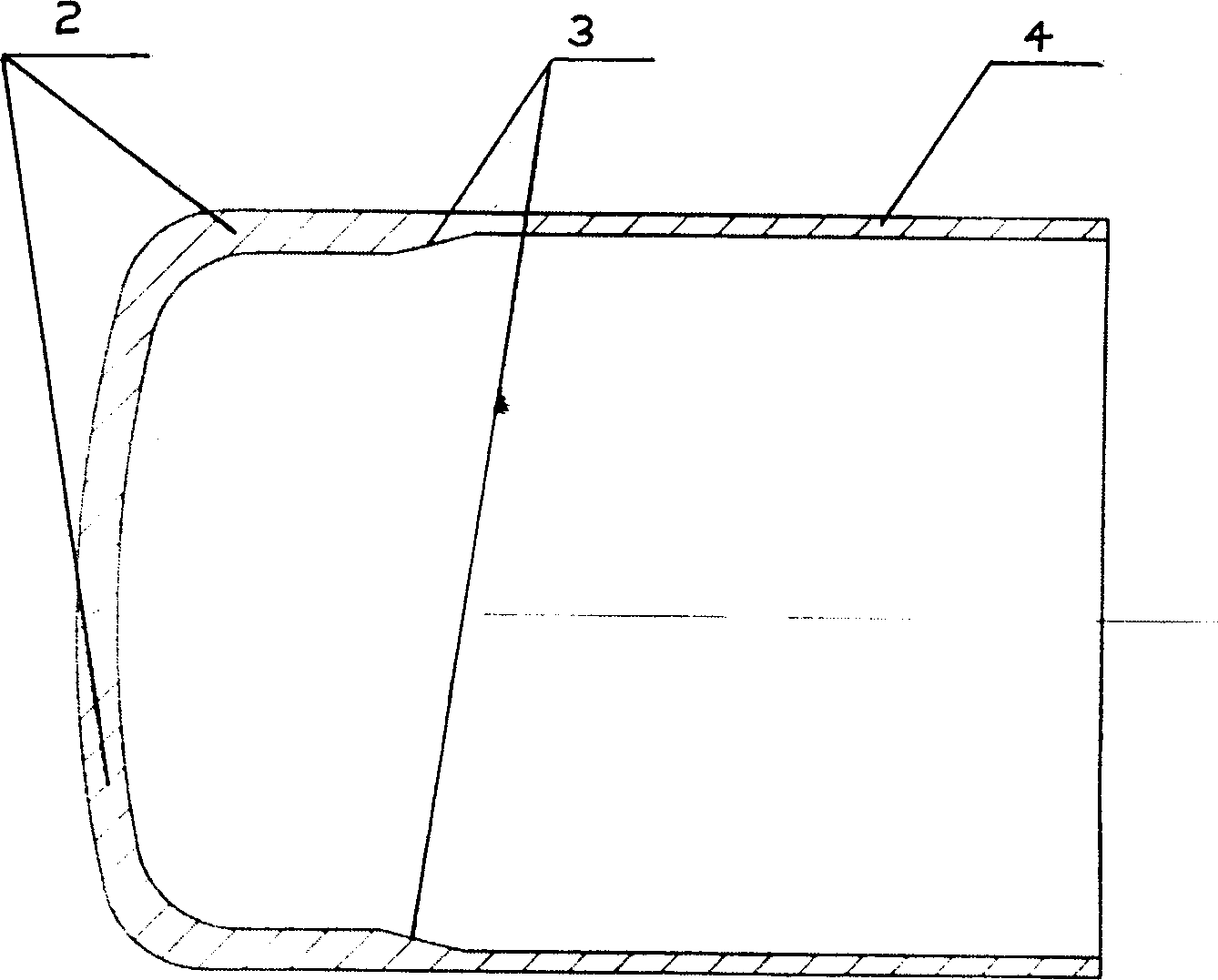

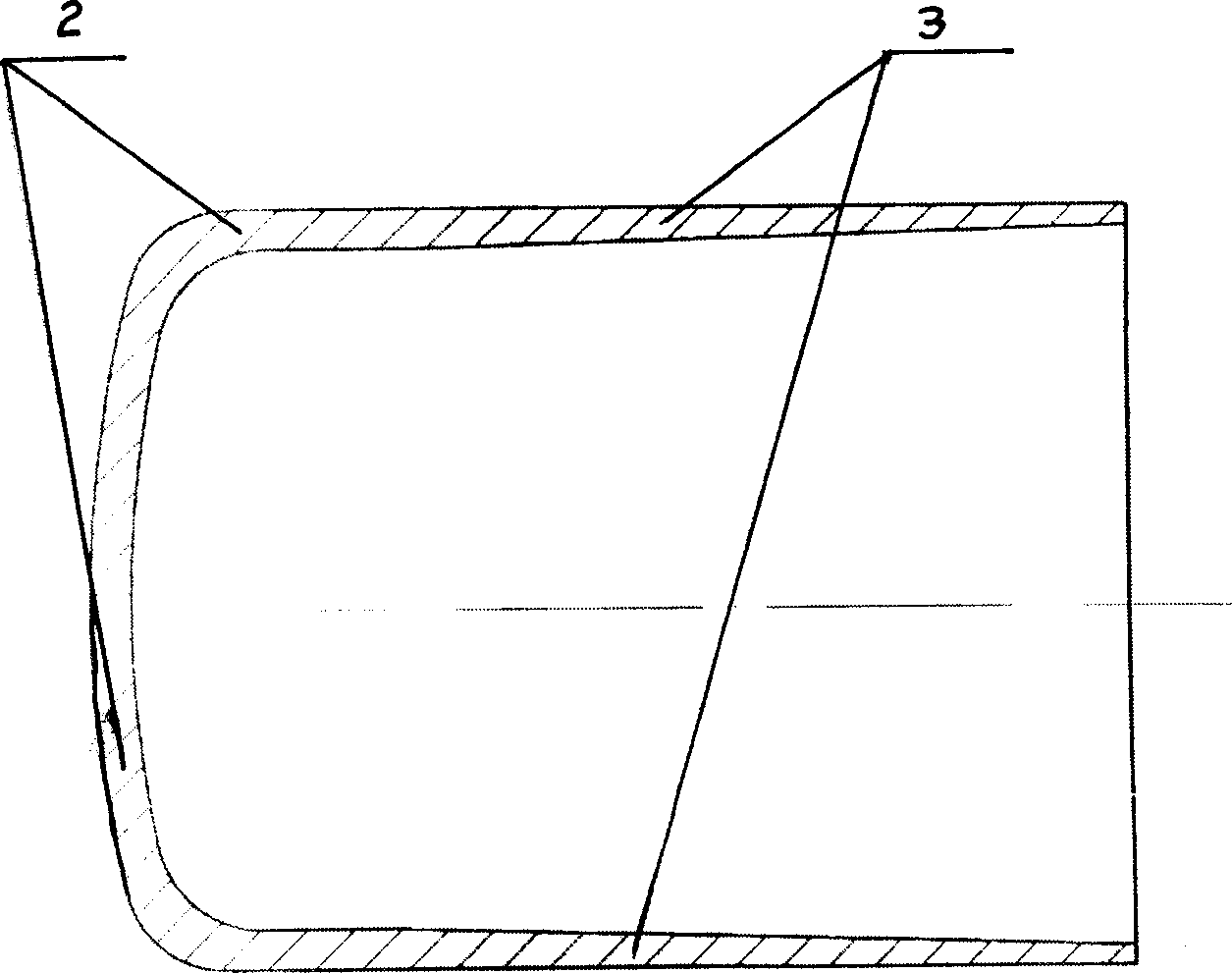

[0024] The present invention is further described as follows in conjunction with accompanying drawings.

[0025] Use Ti-451 alloy plate to make equal wall thickness cylinder 1; evenly coat molybdenum disulfide (or graphite milk) lubricant on the inner surface of equal wall thickness cylinder and the surface of spinning die 5; then coat the inner surface with lubricant The cylinder body with equal wall thickness is set on the spinning die, and the thrust is applied by moving the tail top die 6 to the right, so that the cylinder body with equal wall thickness is pressed against the spinning die; the spinning machine drives the tail top die, spinning die, Cylinders with equal wall thickness rotate synchronously;

[0026] Turn on the heating device 8 to make the equal-wall thickness cylinder reach the deformation temperature, and adjust the power of the heating device at any time during the deformation process to control the temperature fluctuation range of the deformation part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com