Processing method for improving quality of inner surface of austenite stainless steel tube

A technology of austenitic stainless steel and processing method, applied in the field of stainless steel pipe processing, can solve the problems of large fluctuation of flaw detection pass rate, high production cost, low production efficiency of rolling processing, etc., and achieve stable and reliable dimensional accuracy and good dimensional stability. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

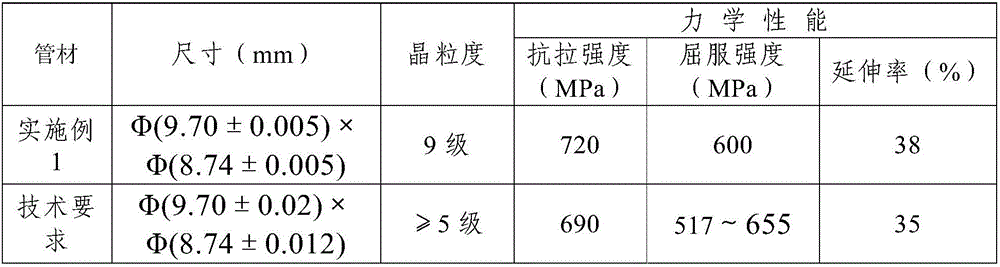

Embodiment 1

[0022] In this embodiment, the austenitic stainless steel cladding tube for the nuclear power reactor core control component in the rolling state is processed to improve the inner surface quality of the tube and meet the technical requirements for the nuclear grade cladding tube. In this embodiment, the processing method for improving the inner surface quality of the austenitic stainless steel cladding tube includes the following steps:

[0023] Step 1, solid solution: solid solution is carried out on the rolled austenitic 304L stainless steel cladding tube with the specification of Φ10.0mm (outer diameter) × 0.52mm (wall thickness) × 5m (length) by means of electric contact heating For treatment, the austenitic stainless steel cladding tube is rapidly heated to 1020°C under the condition of a current of 300A, and after reaching the temperature, the power is turned off and the water is quenched to obtain a solid solution austenitic stainless steel cladding tube;

[0024] Step ...

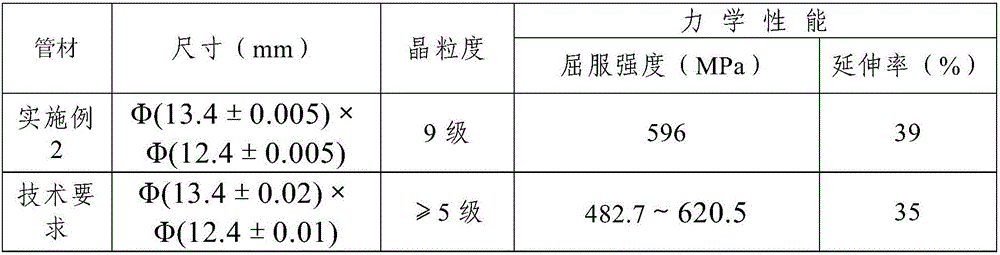

Embodiment 2

[0032] In this embodiment, the rolled austenitic stainless steel locking tube is processed to improve the inner surface quality of the tube so as to meet the technical requirements of the nuclear-grade locking tube. In this embodiment, the processing method for improving the inner surface quality of the austenitic stainless steel locking tube includes the following steps:

[0033] Step 1, solid solution: solid solution treatment is carried out on the rolled 304L austenitic stainless steel pipe with specifications of Φ14.5mm (outer diameter) x 0.53mm (wall thickness) x 8.5m (length) by means of electric contact heating , under the condition of a current of 100A, the temperature of the austenitic stainless steel pipe is raised to 850 ° C, and after reaching the temperature, the power is turned off and the water is quenched to obtain a solid solution state of the austenitic stainless steel pipe;

[0034] Step 2, straightening: use a straightening machine to straighten the austeni...

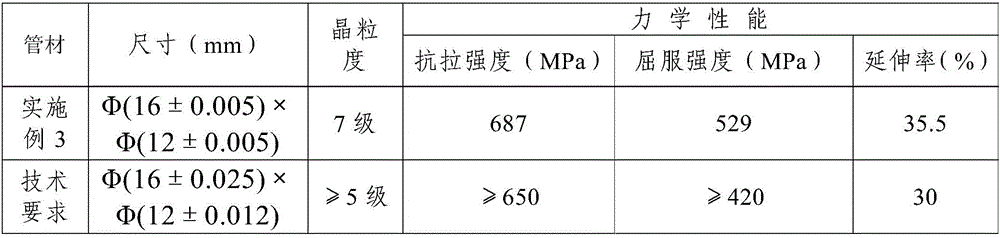

Embodiment 3

[0042] In this embodiment, the rolled austenitic stainless steel pipe is processed to improve the quality of the inner surface of the pipe so as to meet the technical requirements. In this embodiment, the processing method for improving the quality of the inner surface of the austenitic stainless steel pipe comprises the following steps:

[0043] Step 1, solid solution: adopt the method of electric contact heating to carry out solid solution treatment on the rolled austenitic 316L stainless steel threaded casing with the specification of Φ17mm (outer diameter)×2.1mm (wall thickness)×10m (length), The temperature of the austenitic stainless steel threaded casing is raised to 1040°C under the condition of a current of 880A, and after reaching the temperature, the power is turned off and the water is quenched to obtain a solid solution state of the austenitic stainless steel threaded casing;

[0044] Step 2, straightening: use a straightening machine to straighten the austenitic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com