Method for producing large-diameter seamless steel pipe for gas cylinder

A technology of seamless steel pipe and production method, applied in metal rolling and other directions, can solve the problems of poor outer surface quality, low output and high production cost, and achieve the effects of good inner and outer surface quality, high dimensional accuracy and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The present invention takes circular continuous casting billet as billet, and adopts 340MPM restraint mandrel continuous pipe rolling machine+push type diameter expanding method to produce. It is characterized in that: during the push-type diameter expansion process, the temperature of the heated steel pipe should be controlled at 900-950°C, and the pushing speed: 90-120mm / min. Preferably 100-110 mm / min. The specific implementation method comprises the following steps:

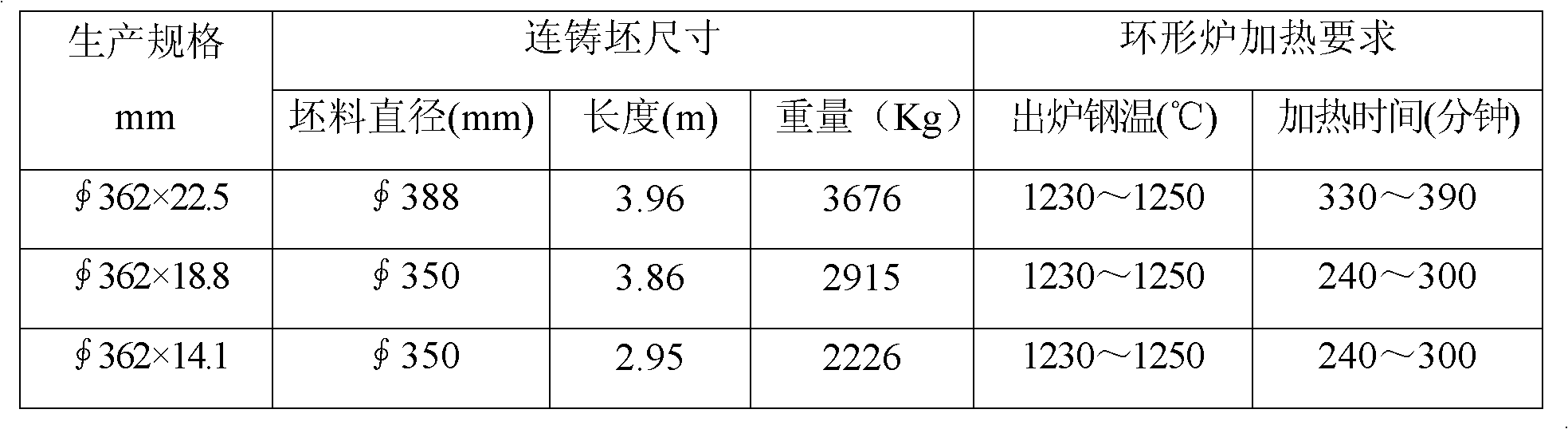

[0032] a. Blank heating

[0033] Choose converter or electric furnace + refining outside furnace + vacuum treatment to smelt circular continuous casting slabs (with specifications of ∮350mm and ∮388mm), and heat them in a ring heating furnace. The furnace maintains a slightly reducing atmosphere, and the heating must not have yin and yang sides, heating impermeability, overheating or overburning. The heating time of ∮350mm round continuous casting slab is 240-300 minutes; the heating time of ∮388mm r...

Embodiment 1

[0060] a. Blank heating

[0061] The circular continuous casting slabs smelted by LF refining furnace + VD vacuum treatment were measured, weighed and sawn;

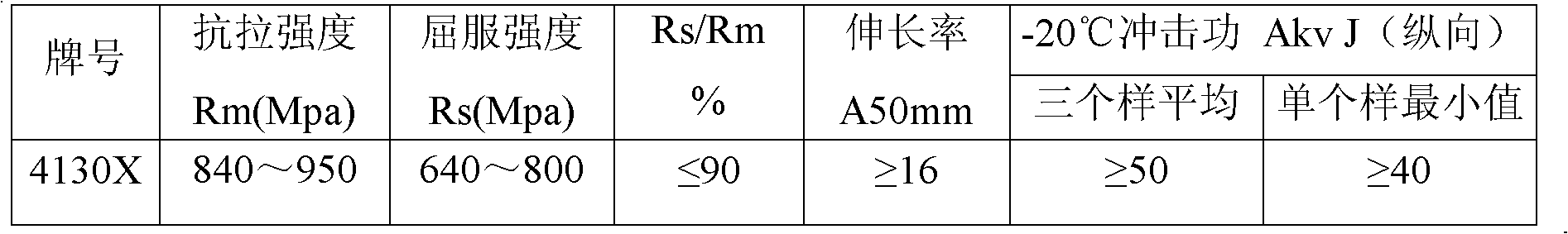

[0062] table 3

[0063] Billet diameter (mm)

Blank length (m)

Billet weight (Kg)

∮388

3.96

3676

∮350

3.86

2915

∮350

2.95

2226

[0064] The furnace maintains a slightly reducing atmosphere, and the heating must not have yin and yang sides, heating impermeability, overheating or overburning. The heating parameters are shown in Table 4.

[0065] Table 4

[0066]

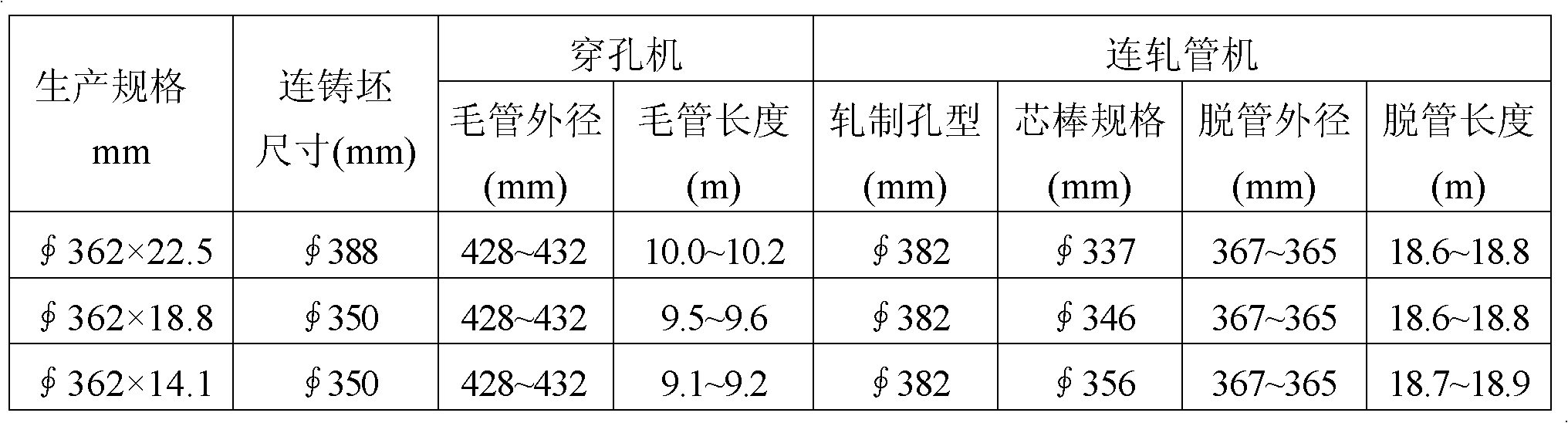

[0067] b. Conical roll piercer perforation:

[0068] After heating the billet in the ring furnace, according to different production specifications, the corresponding perforated plug size is selected, and the outer diameter of the capillary tube is controlled at 428-432mm.

[0069] c. 340MPM continuous pipe rolling mill:

[0070] The 5 racks form an angle of 45° with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com