Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

335 results about "Superficial mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superficial soft tissue masses are common in clinical practice and the expanding availability of radiologic imaging has increased radiologists’ familiarity with these entities. Superficial soft tissue masses are quite diverse and include tumors, as well as many nonmesenchymal tumor-like lesions.

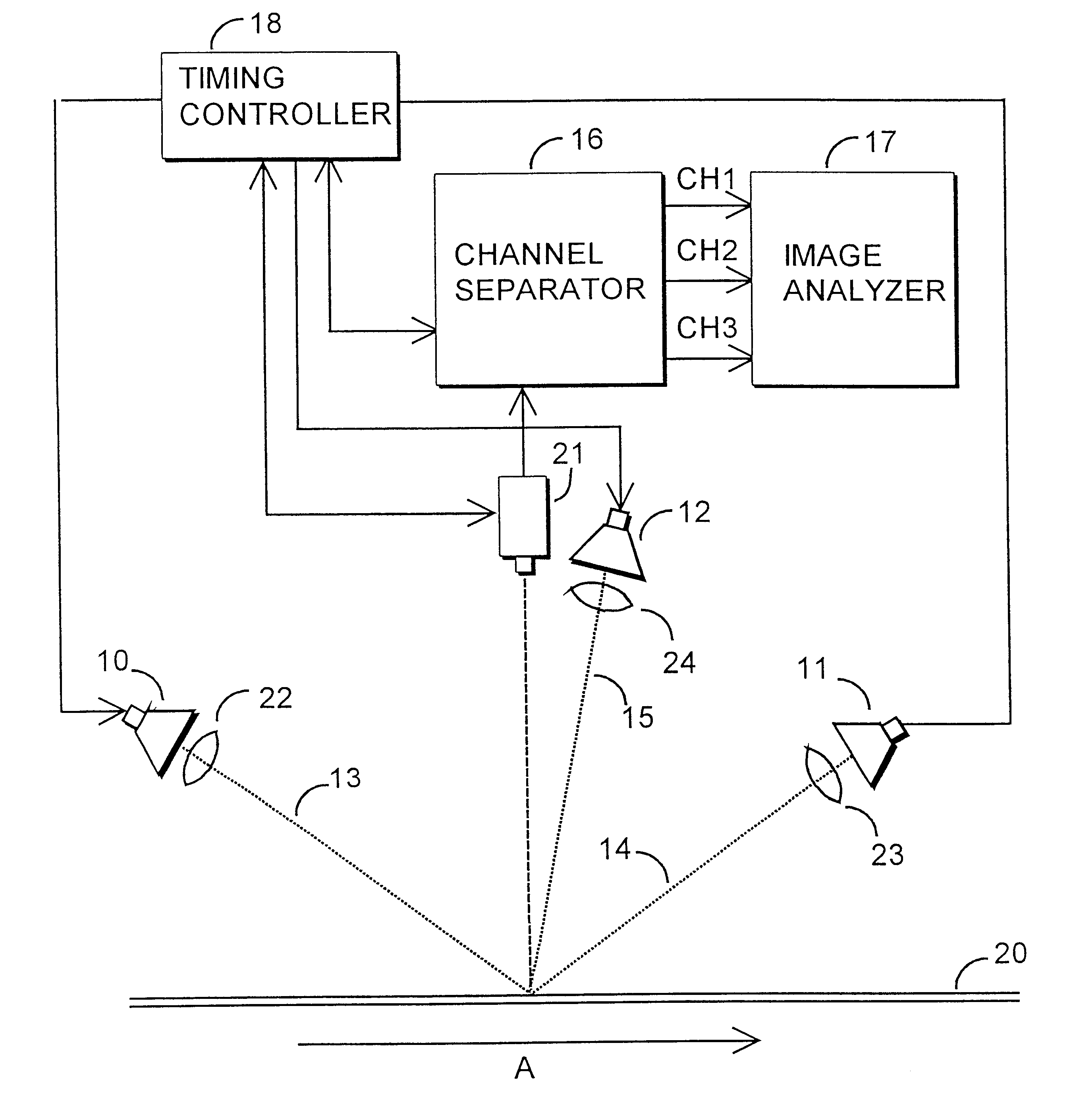

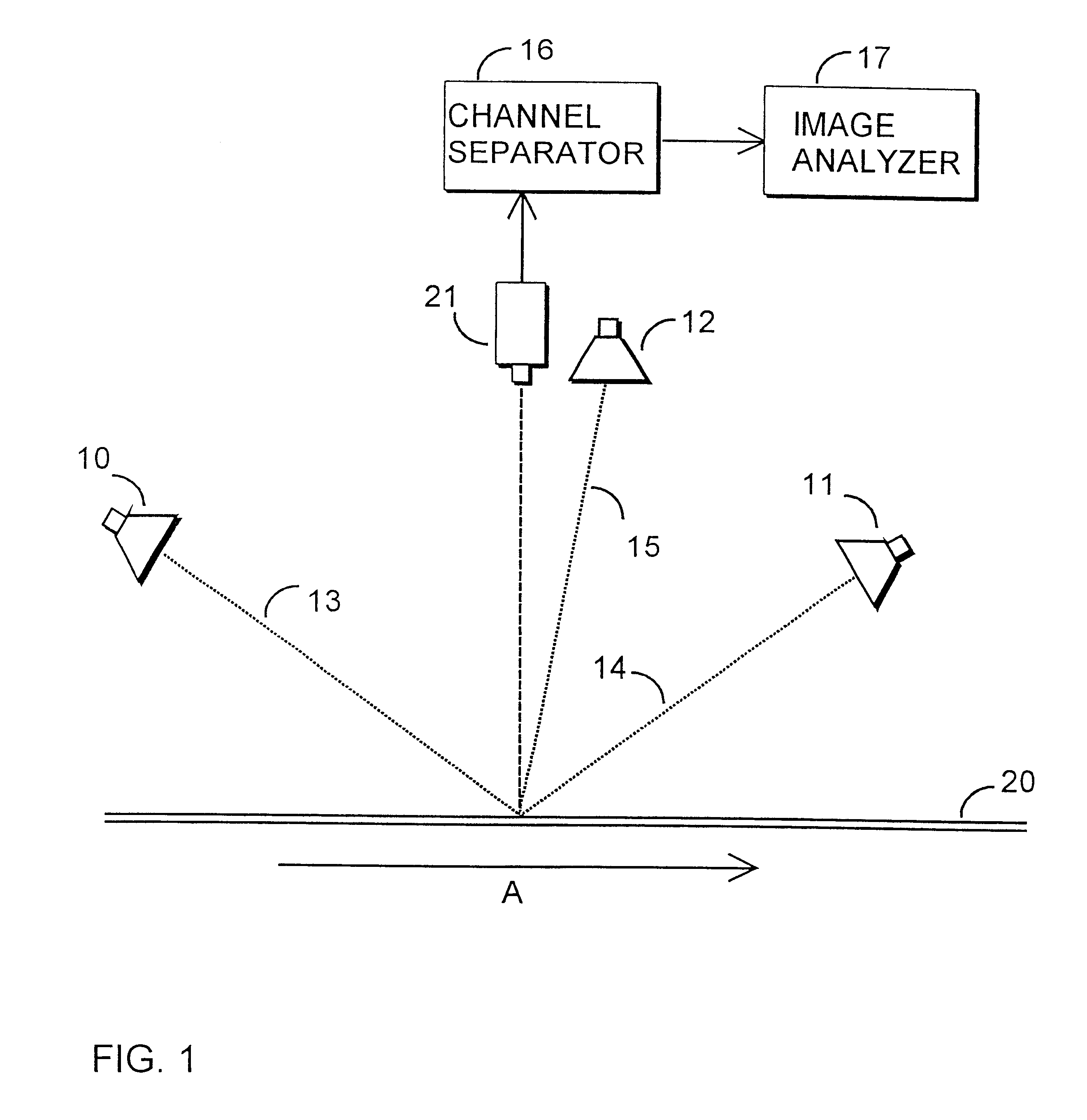

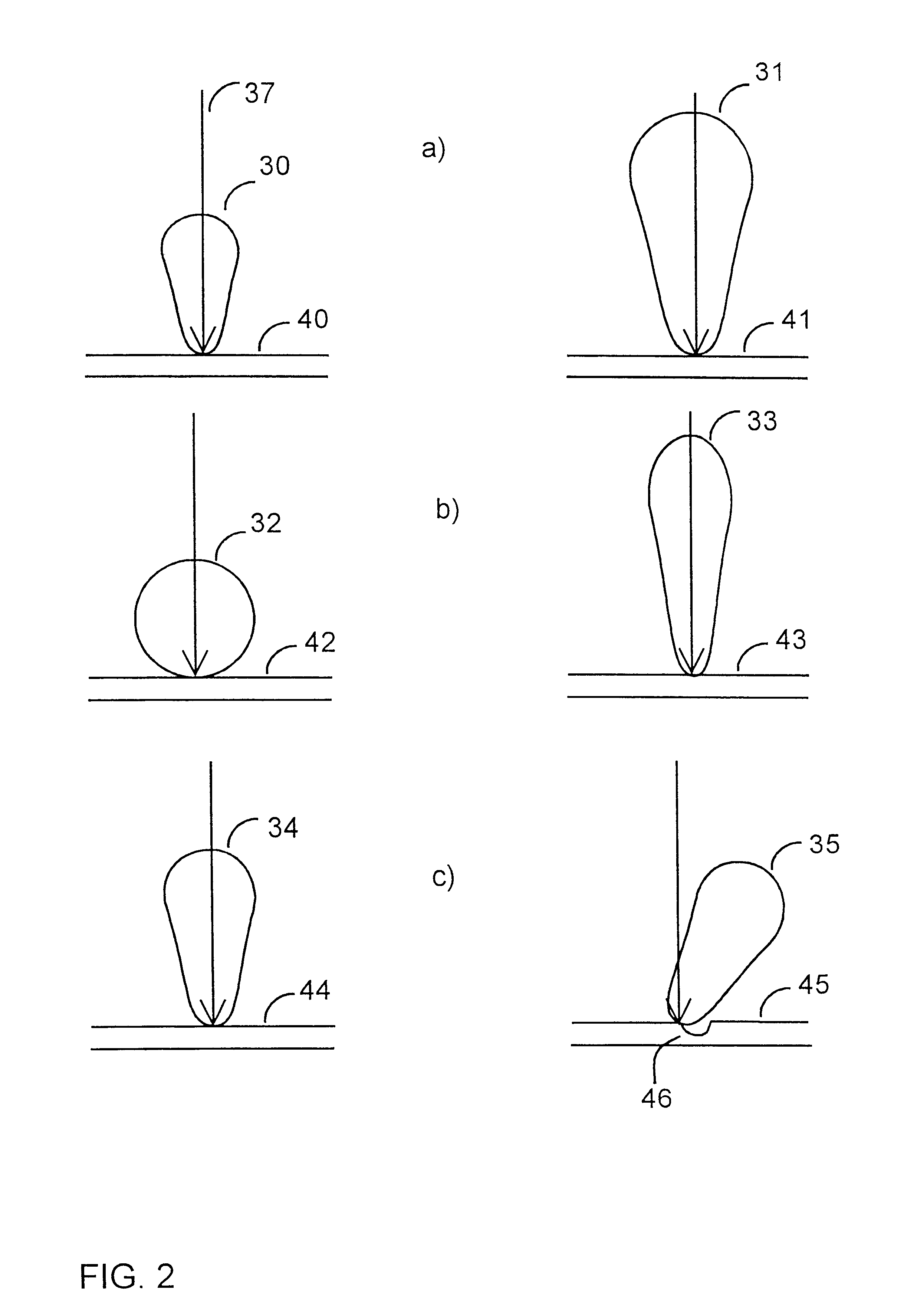

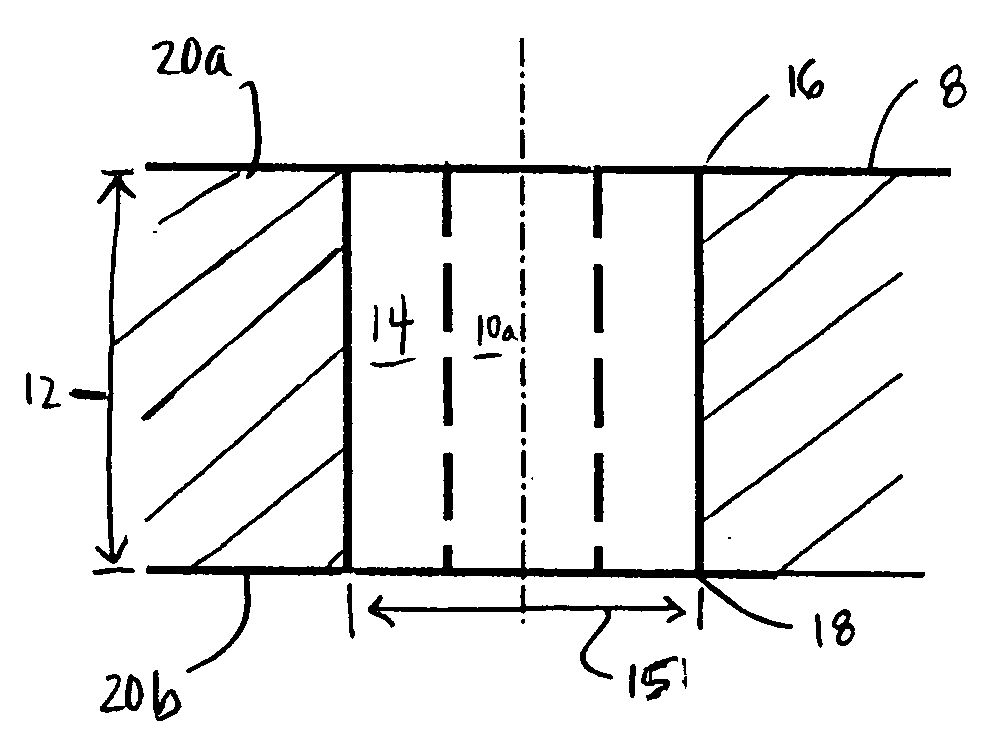

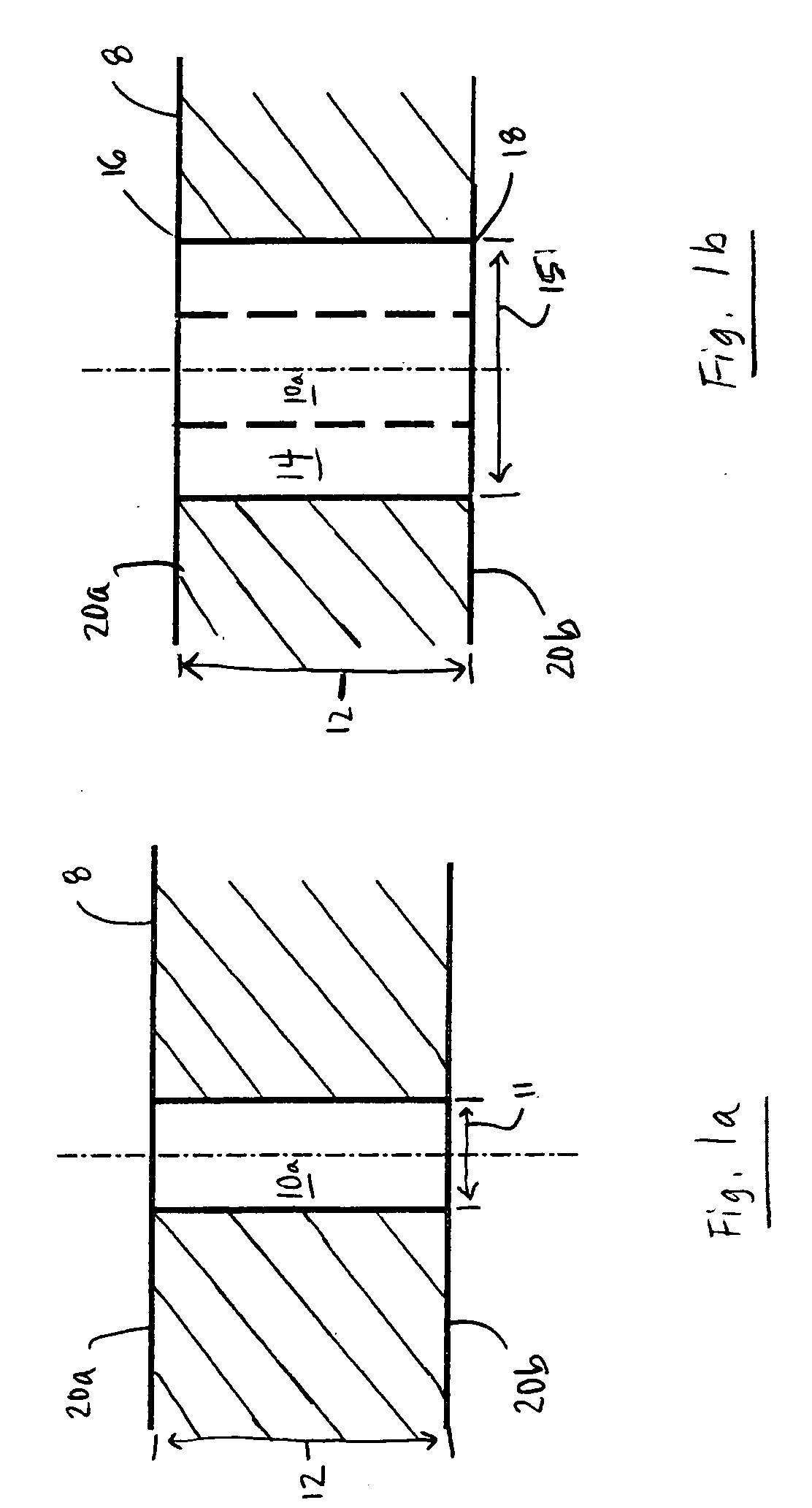

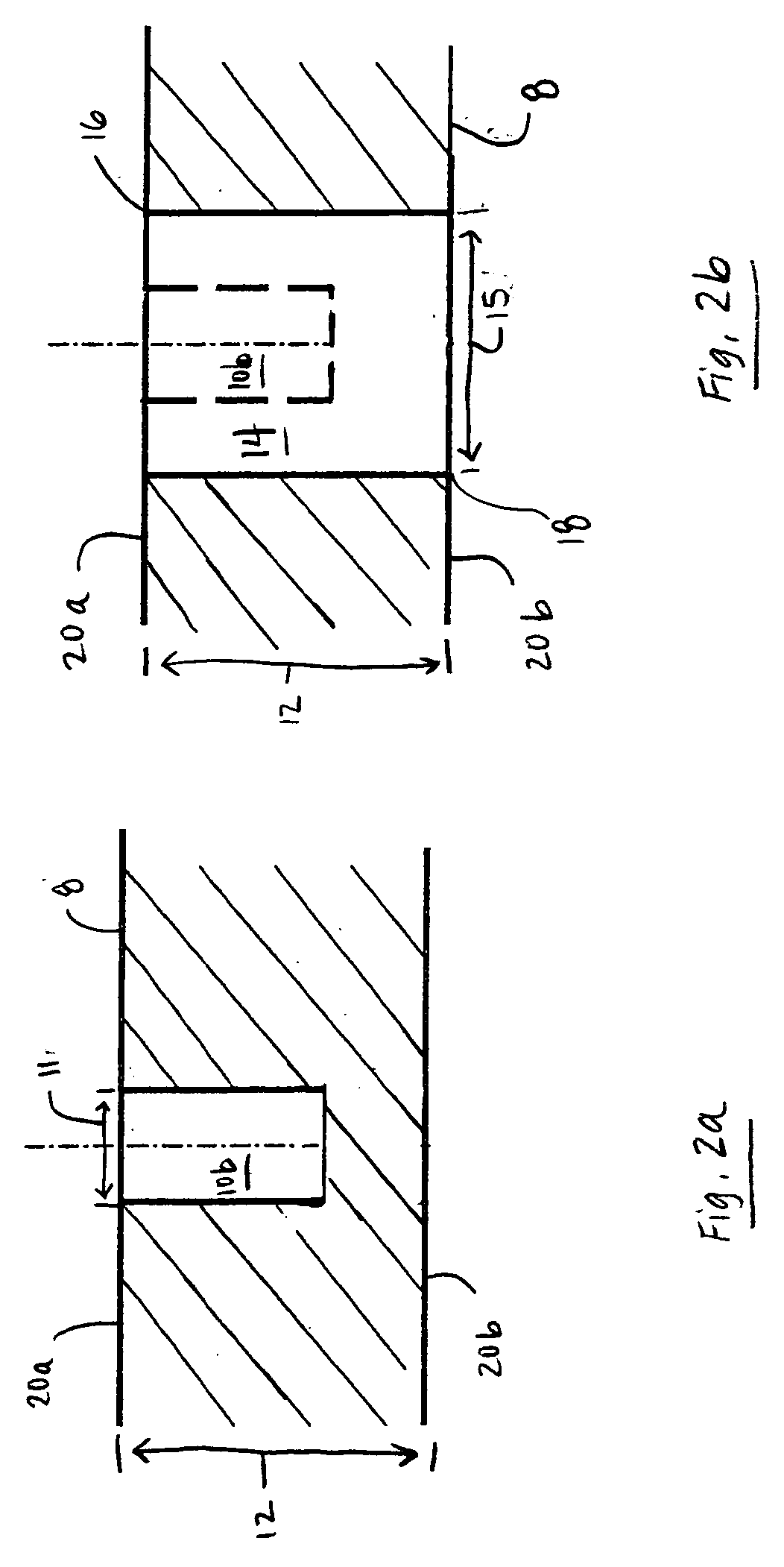

Arrangement and method for inspection of surface quality

InactiveUS6327374B1Enhances analysis of D characteristicEasy to analyzeScattering properties measurementsCharacter and pattern recognitionSuperficial massLine scan

The invention relates to a method for automatic inspection of the surface 20 of a moving object, in which a region on the object's surface is illuminated from at least two different illumination directions 13-15. The object's illuminated surface region is imaged with a camera to provide image information for analysis. The light sources in the different illumination directions 13-15 are pulsed to illuminate the object's surface region at different times, the pulsing frequency being >1 kHz The object's illuminated surface region is imaged as lines with a line scan camera 21 in sync with the above pulsing. The invention also relates to an arrangement for inspecting the surface 20 of a moving object, the arrangement comprising at least two light sources 10-12 in at least two different illumination directions 13-15 for illuminating the surface region of the object under inspection; a camera for imaging the object's surface region; and an image analyzer for analyzing the image information acquired from the object's surface 20 by imaging. The light sources 10-12 illuminate the object's surface 20 from the different illumination directions 13-15 at different times, and the camera is a line scan camera 21. The arrangement further comprises a timing controller 18 for synchronous pulsing of the light sources 10-12 and the at least one line scan camera 21, the pulsing frequency of the light sources 10-12 being >1 kHz.

Owner:THERMO RADIOMETRIE +1

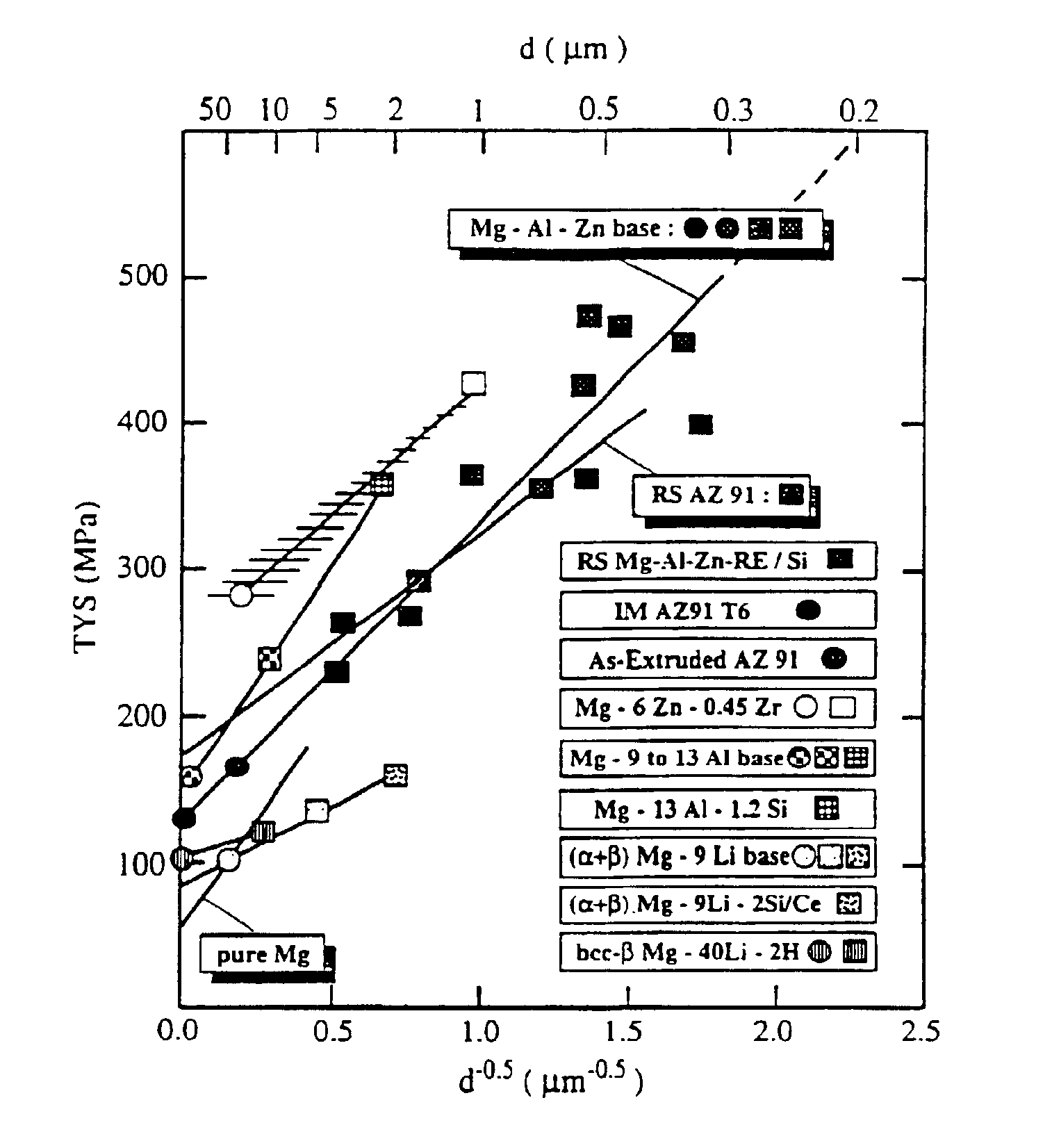

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

Aluminum alloy surface strengthening method using laser melting and coating

InactiveCN101012561APrevent excessive meltingPrevent collapseMetallic material coating processesLaser beam welding apparatusSoluble glassWavelength

The invention discloses a reinforcing method of aluminium alloy surface fused and covered by laser, which comprises the following steps: 1. predisposing aluminium alloy base; 2. allocating laser fusing and covering material with the bulk rate of Al-Si alloy powder and SiC ceramic powder at 1:(4-2); setting the Si content in the Al-Si alloy at 10-15(wt%) with grain size at - 140-+325; setting the grain size of SiC at -200; 2. modulating evenly blended fusing and covering material into paste through soluble glass; coating on the surface of aluminium alloy with thickness at 0.8-1.2mm; drying at 100-150 deg.c for 0.5-2h; 4. adopting crossflow CO2 laser to irradiate the coated layer on the surface of aluminium alloy base; setting the output power of laser at 3-4kW and optical beam scanning velocity at 2-5mm / s and optical spot dimension at 1-4mm; protecting fusing pond through high-purity argon in the laser fusing and covering course with argon flow at 20-30L / min.

Owner:TIANJIN POLYTECHNIC UNIV

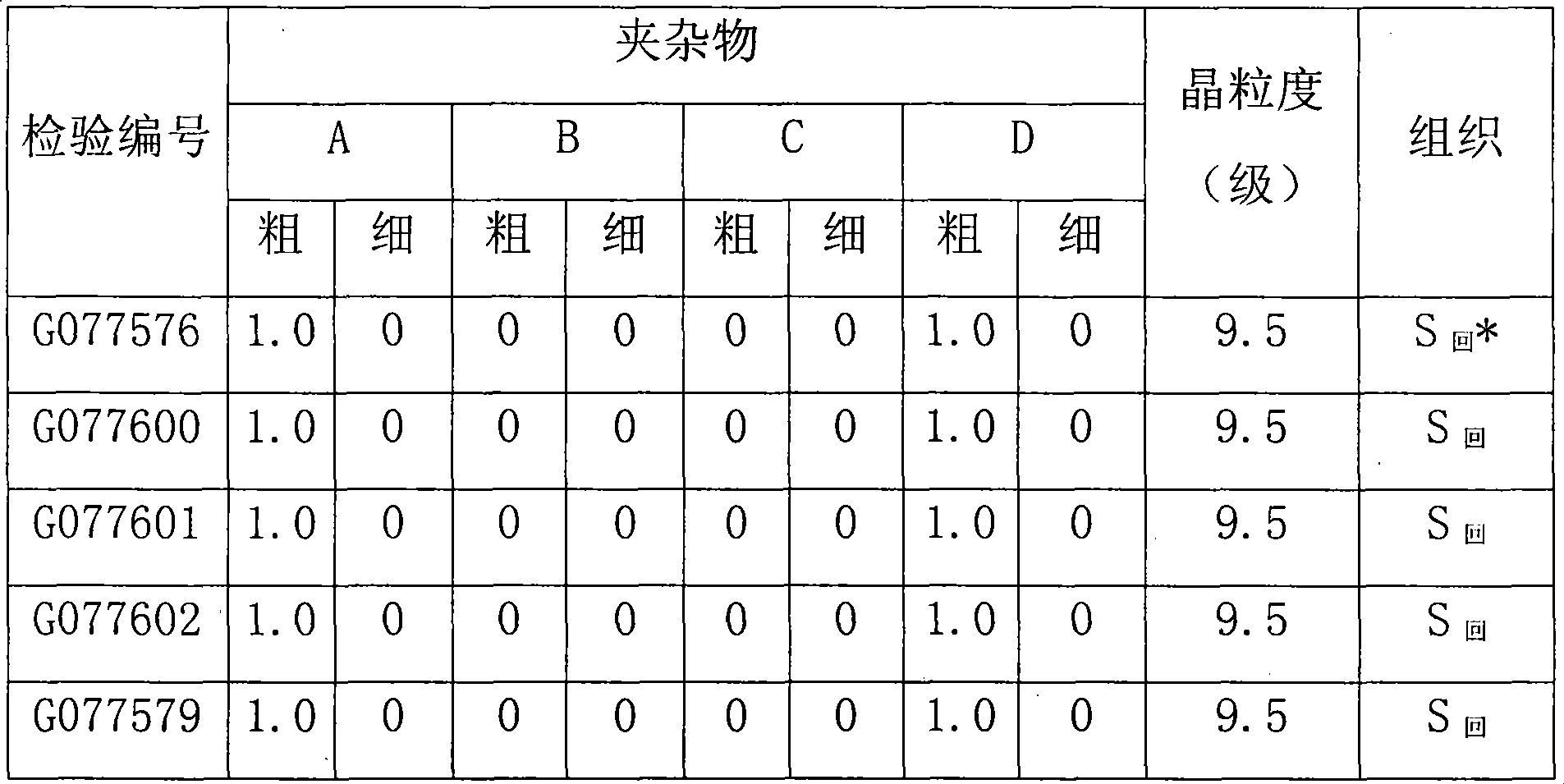

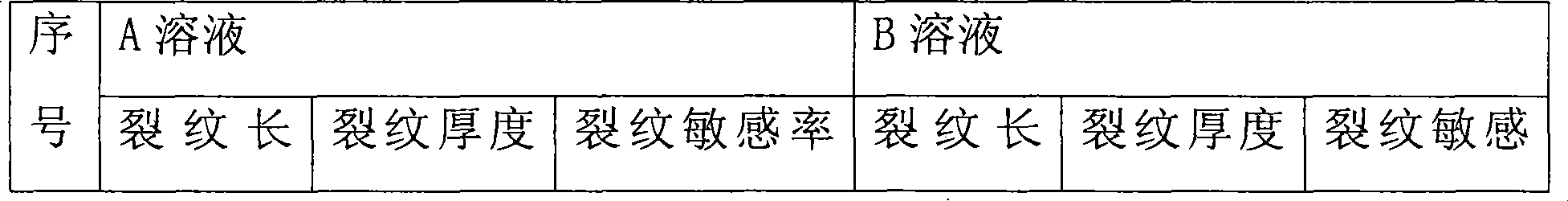

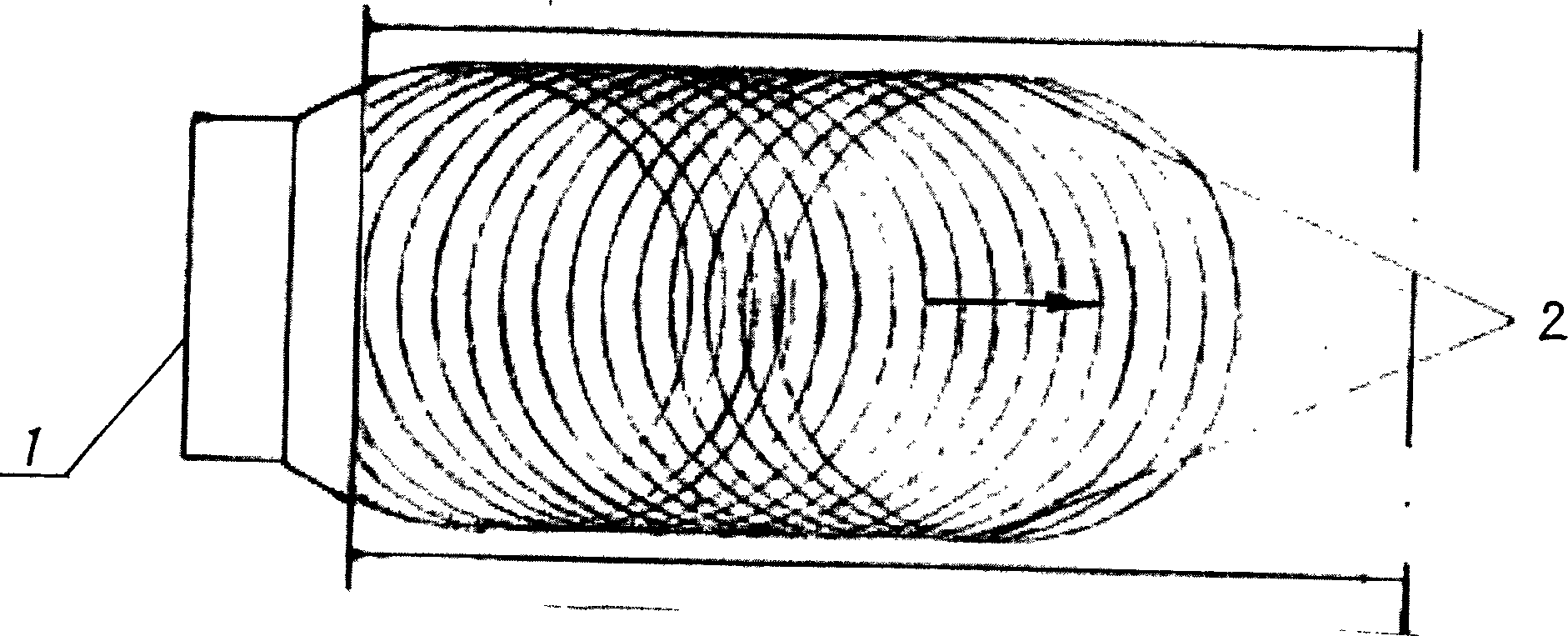

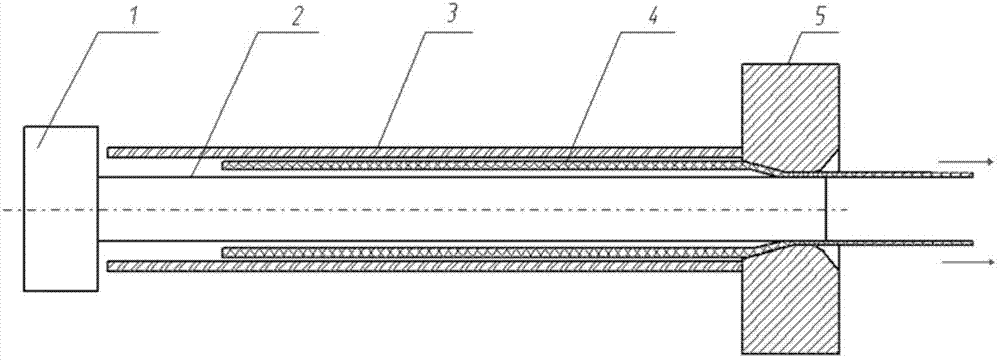

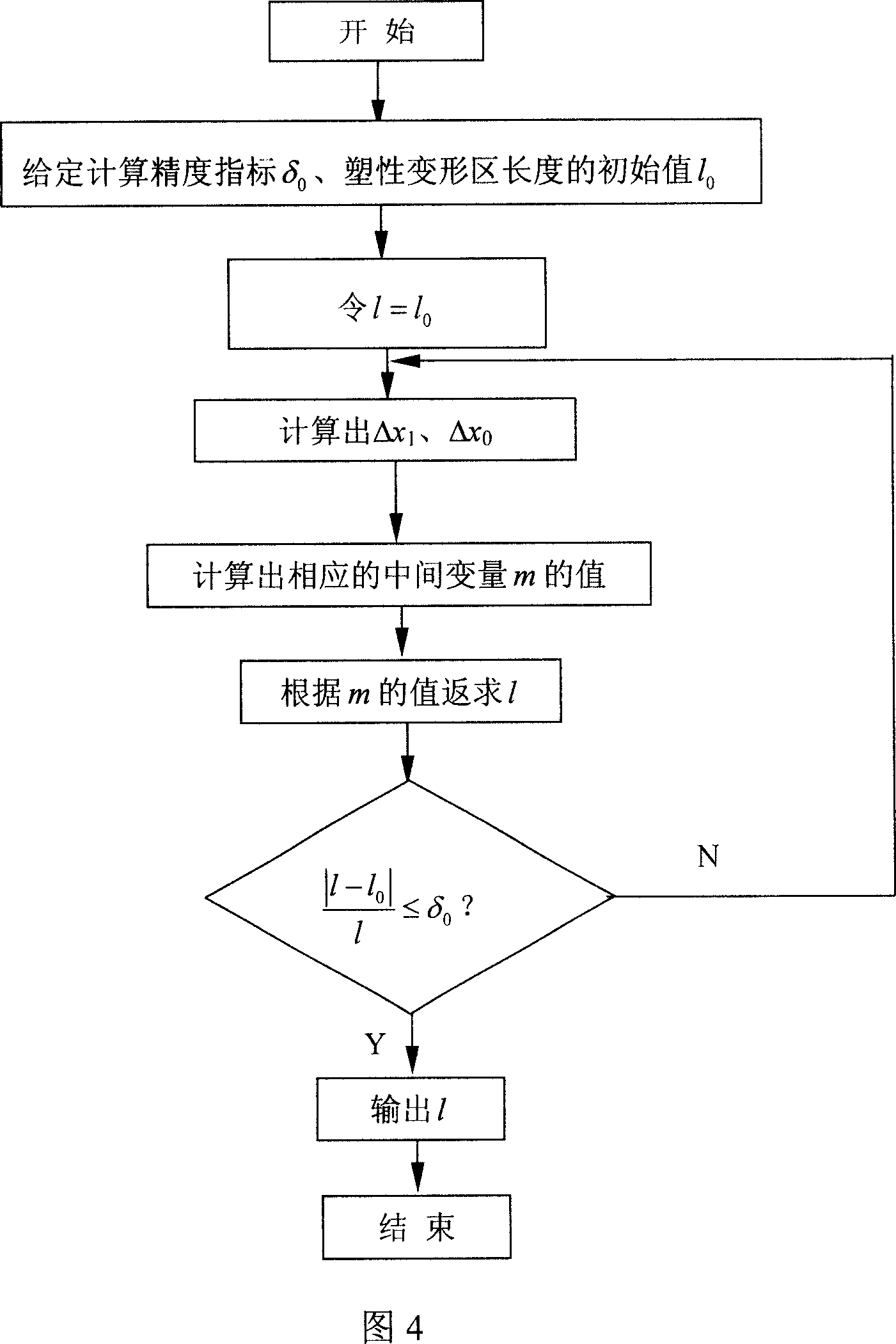

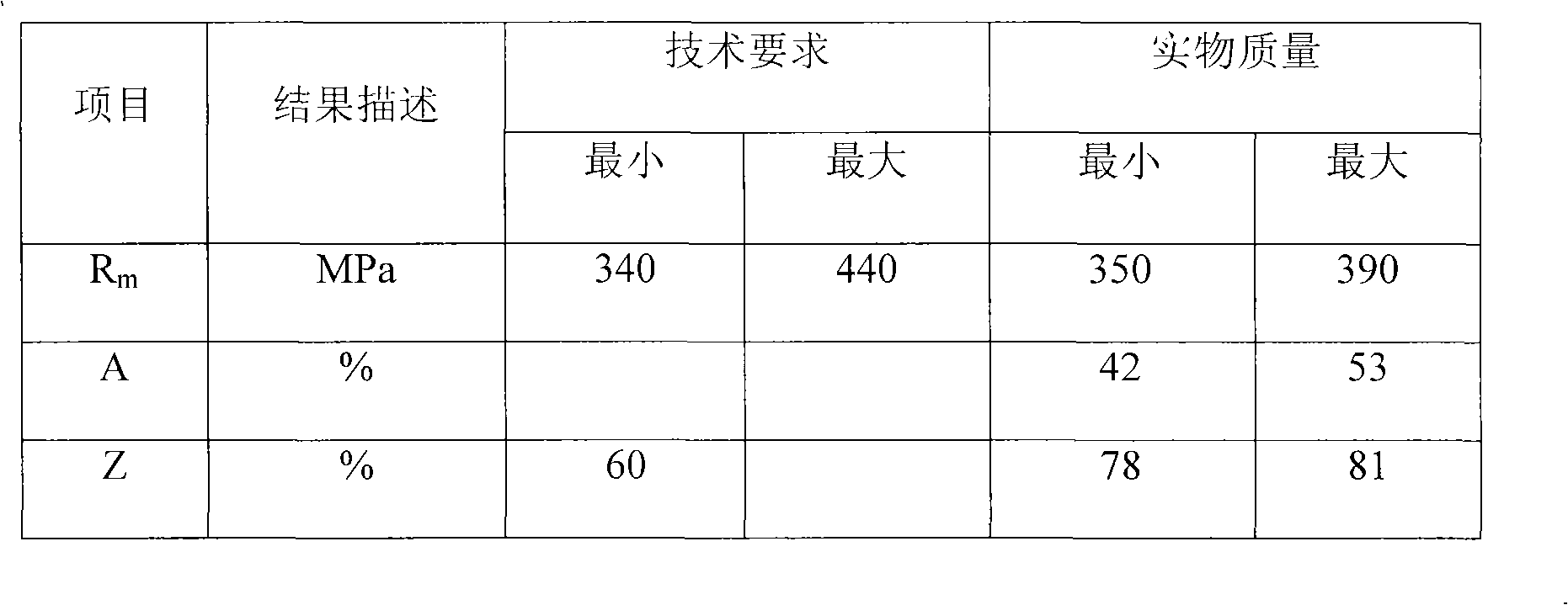

Manufacture method of large caliber high steel grade corrosion proof seamless steel tube in diameter phi 219.0-460.0mm

ActiveCN101417296AReduce adverse effectsImprove mechanical propertiesTemperature control deviceFurnace typesSuperficial massPetroleum

The invention provides a production method of a large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm, which comprises the steps of the techniques of: steel making, tube rolling, thermal treatment and processing of the steel tube, and the like, and produces the large caliber high steel-grade corrosion-resistant seamless steel tube with the diameter of phi 219.0-phi460.0mm. The method has the effects of solving the problem of extremely unfavorable influence of the harmful elements such as P, S, and the like on the corrosion resistance of a petroleum-special tube and obtaining a high-quality round billet, adopts the combination of phi 460 three-roller retained mandrel POF rolling mill with high-end thermal rolling control technique to obtain fine quality tube bodies with different sizes, and obtains pipeline tubes with eligible surface quality and combination property by reasonable thermal treatment technique and the control technique of the residual stress of the steel tube, which not only has high strength and excellent corrosion-resistant property but also has good toughness. The invention has the beneficial effects that the steel tube has good physical-chemical properties, high tube body size precision, and convenience for use as well as being beneficial for the safety of long-distance delivery ducts, and can be widely used for the acid oil-gas fields containing hydrogen sulfide.

Owner:TIANJIN STEEL PIPE MFG CO LTD

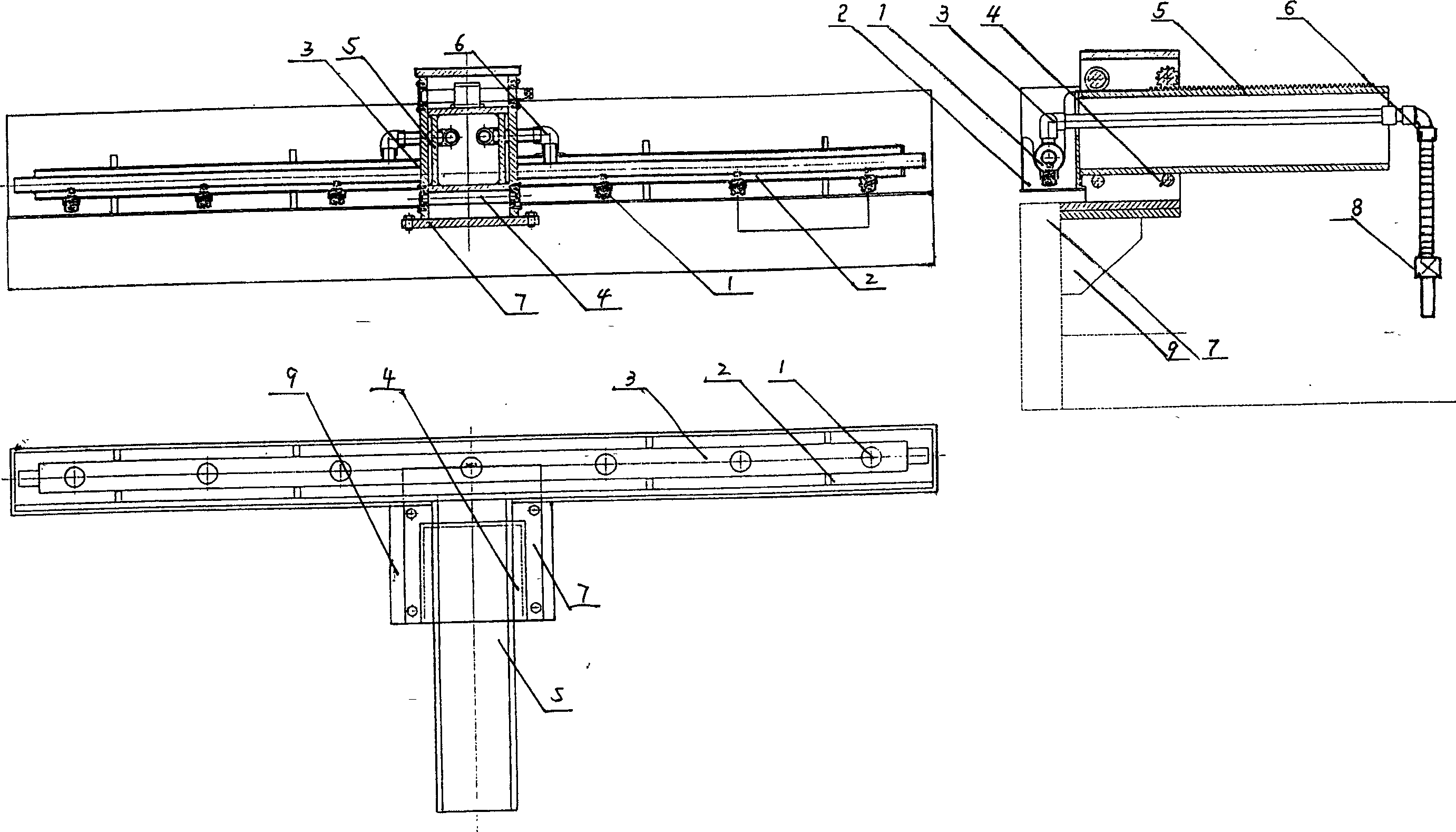

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1603021AControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsForced-airEngineering

The invention simultaneously solves building the contact organization, the performance is uneven question. The invention has provides a kind of gas spray cooling system and the method, namely after the spinning machine, style touches in front of the air blower a section of air cooled table place above, two sides symmetrical establishes the gas spray chiller, first builds above the contact from the coil, key to builds the contact to leave the atomization to cool, then style touches the forced-air cooling line again from the underneath forced-air cooling, and uses the' good spirit installment concentratly blowing the contact place. The intensity difference between the line material build contact through the gas spray cooling system and the no build contact is fall to 5~7MPa; The overall intensity of the line material may enhance 20~25MPa; Improves the surface quality; Simultaneously decreases the ambient temperature, improves the operating environment.

Owner:UNIV OF SCI & TECH LIAONING

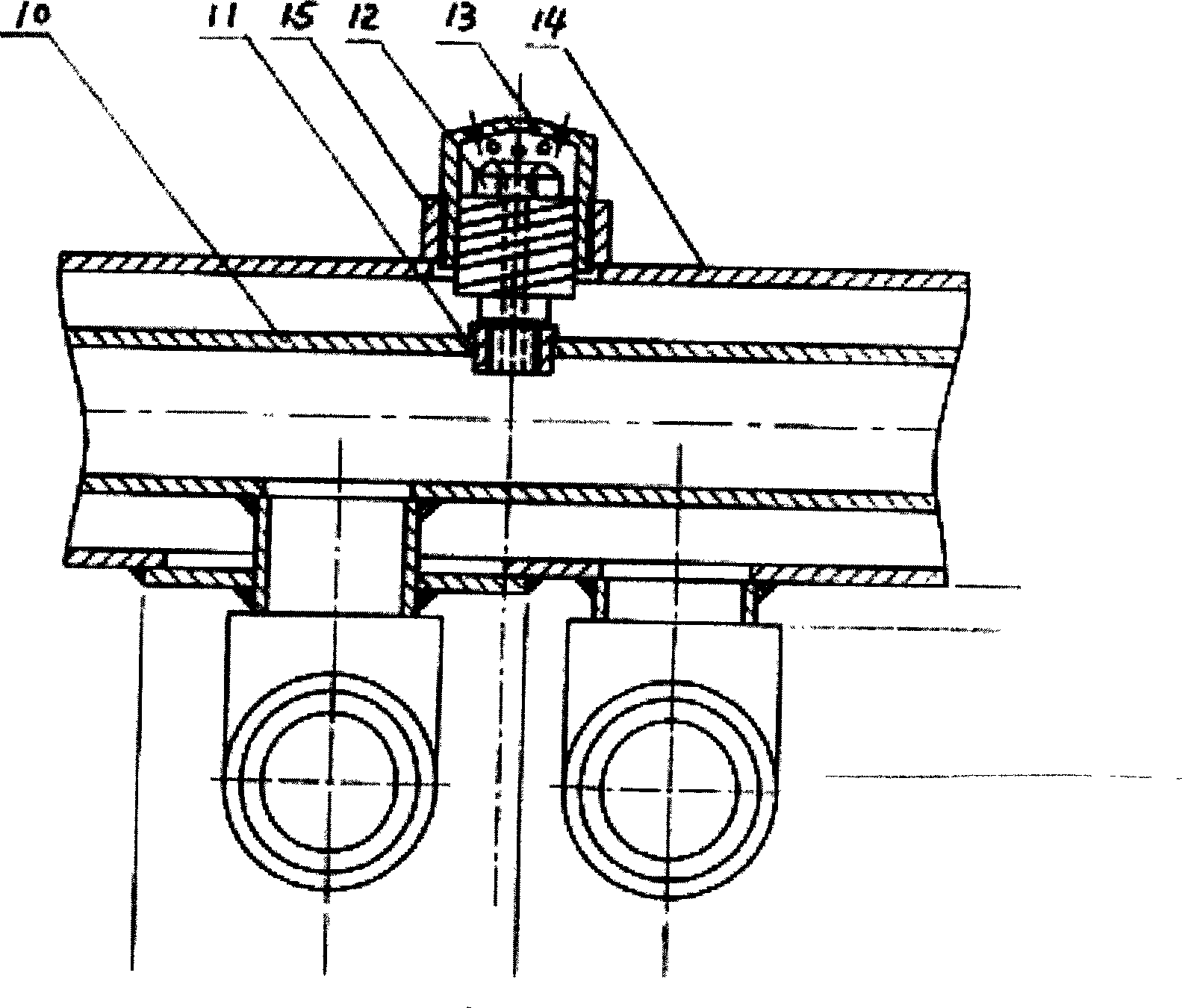

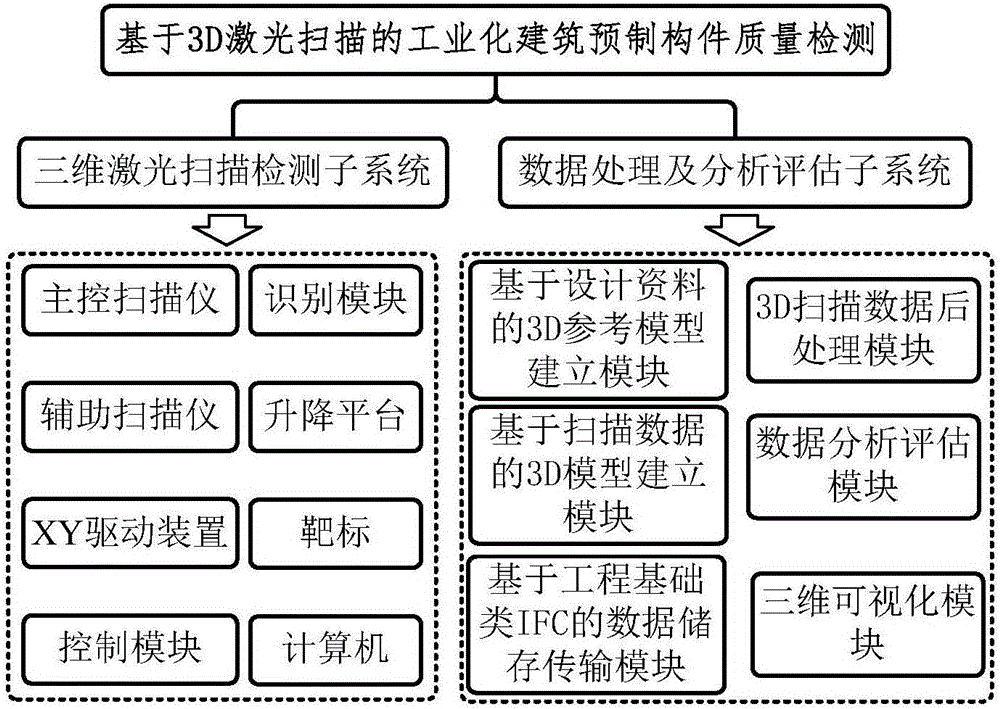

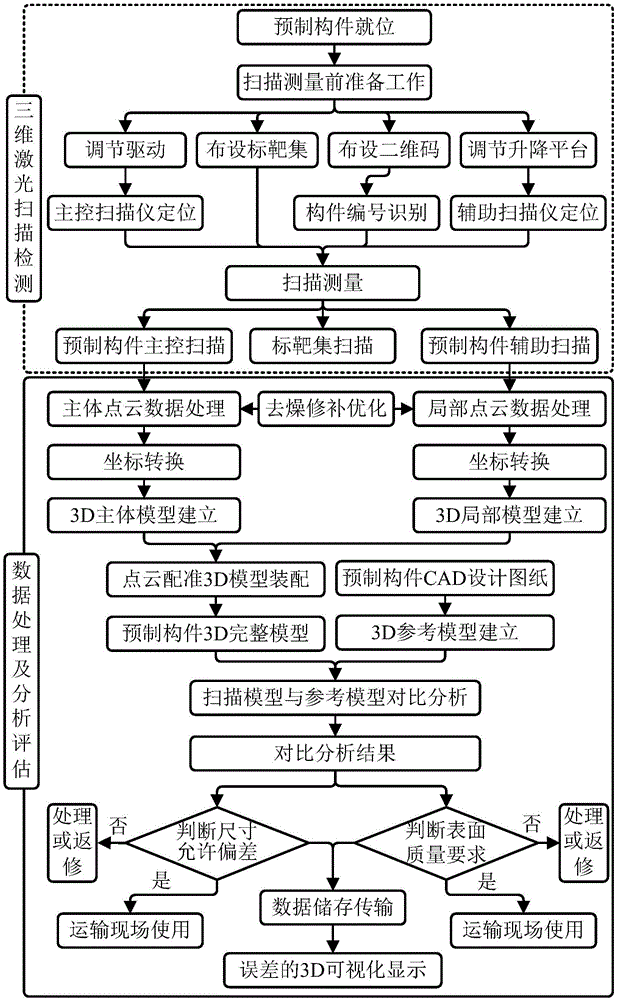

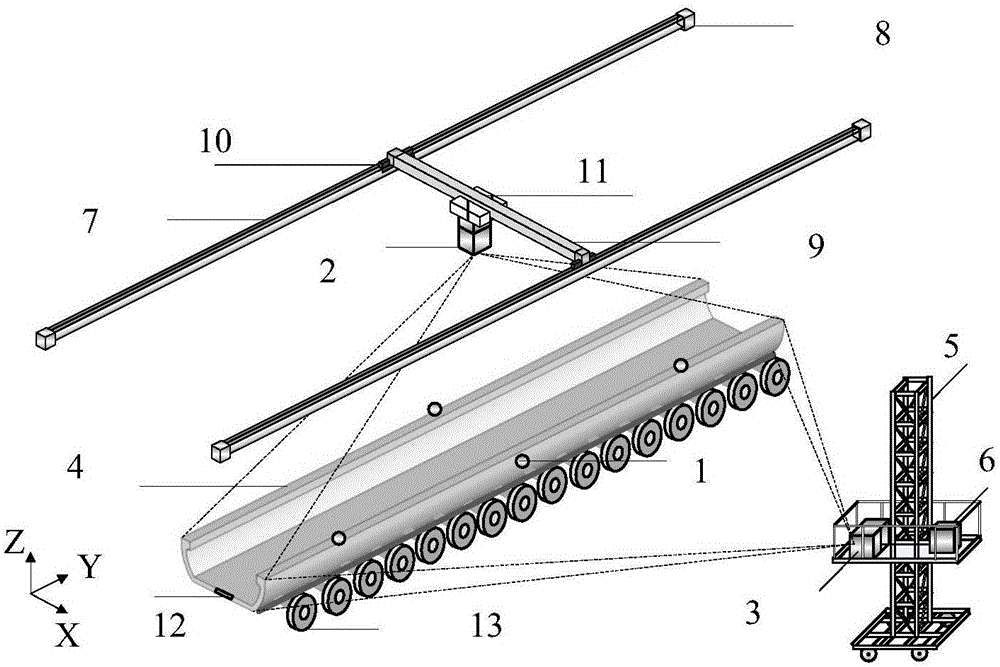

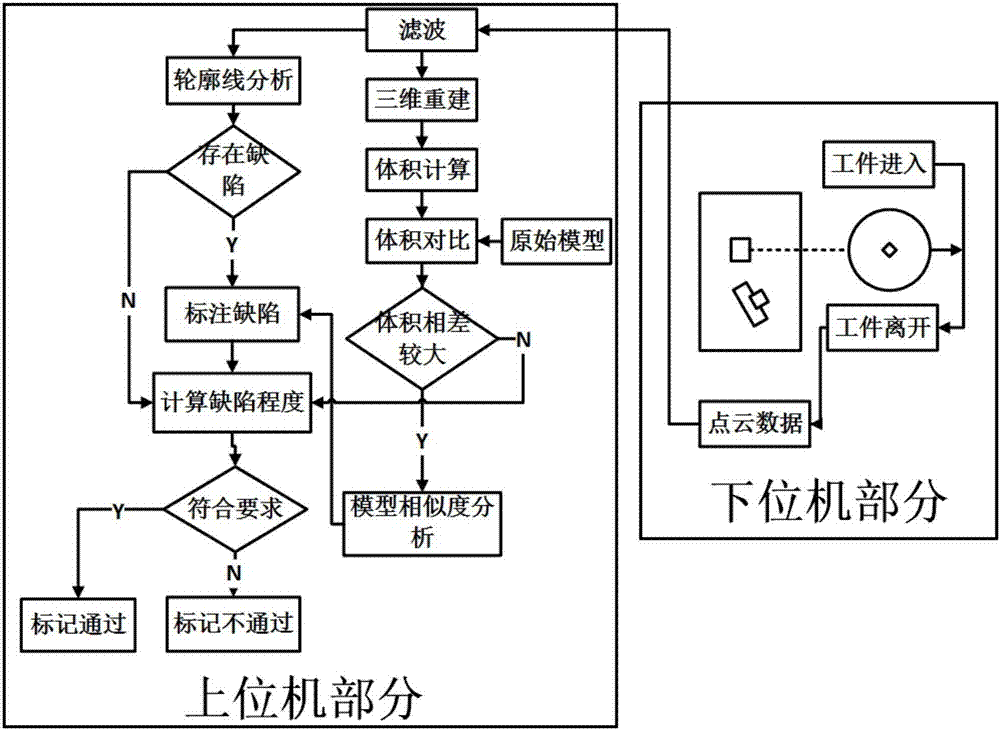

3D laser scanning based building prefabricated part quality detection system and method

ActiveCN106370670ASolve technical inefficienciesOptically investigating flaws/contaminationUsing optical meansPoint cloudLaser scanning

The invention provides a 3D laser scanning based building prefabricated part quality detection system and method. Prefabricated part point cloud data is acquired through a master control and scanning of an auxiliary scanner, a 3D scanning mode obtained based on the prefabricated part point cloud data and a design model are compared and analyzed to achieve evaluation of prefabricated part size and surface quality, and the technical problem that size and surface quality detection of an existing industrial building prefabricated concrete part are completed manually and the efficiency is low can be solved.

Owner:SHANGHAI CONSTRUCTION GROUP

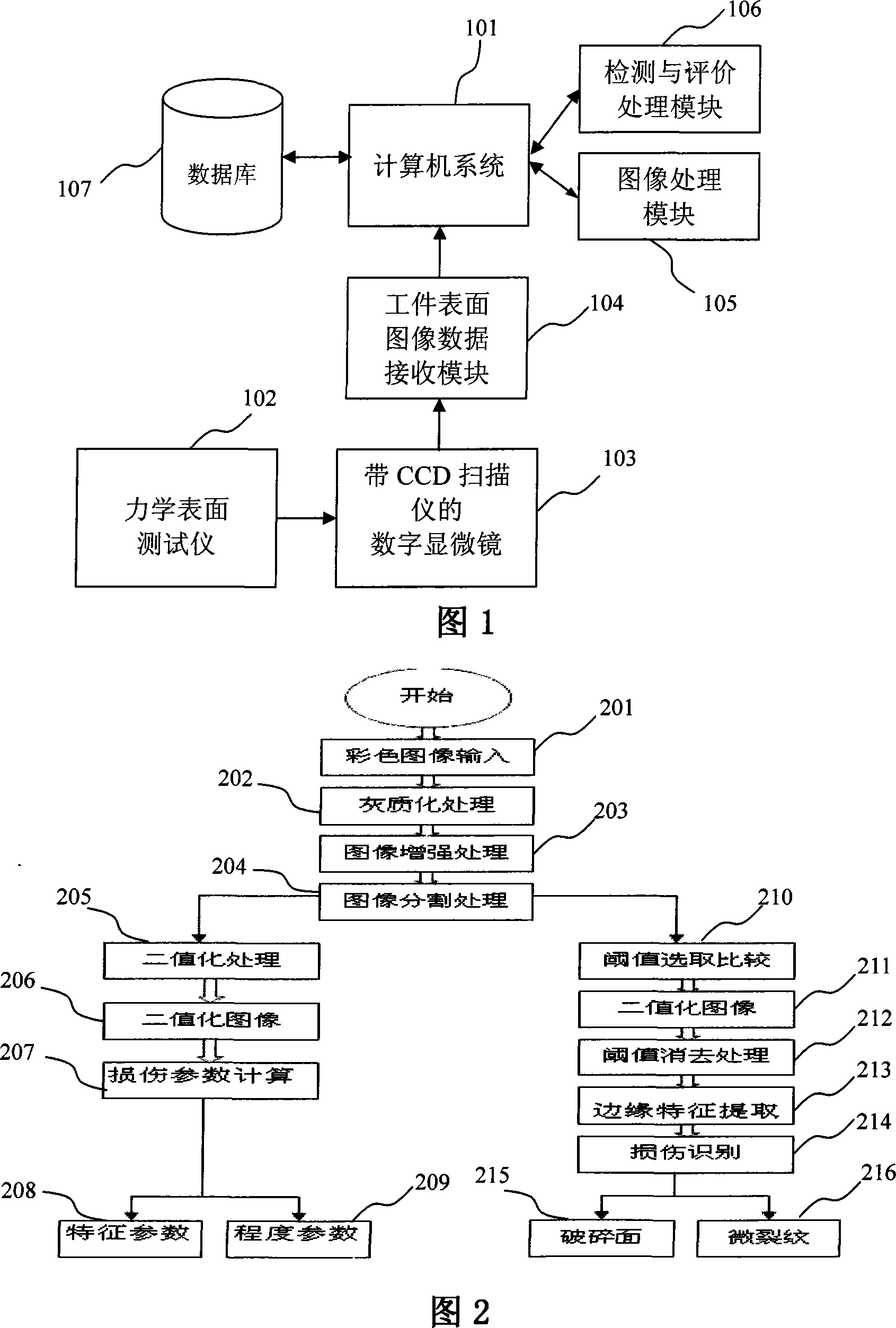

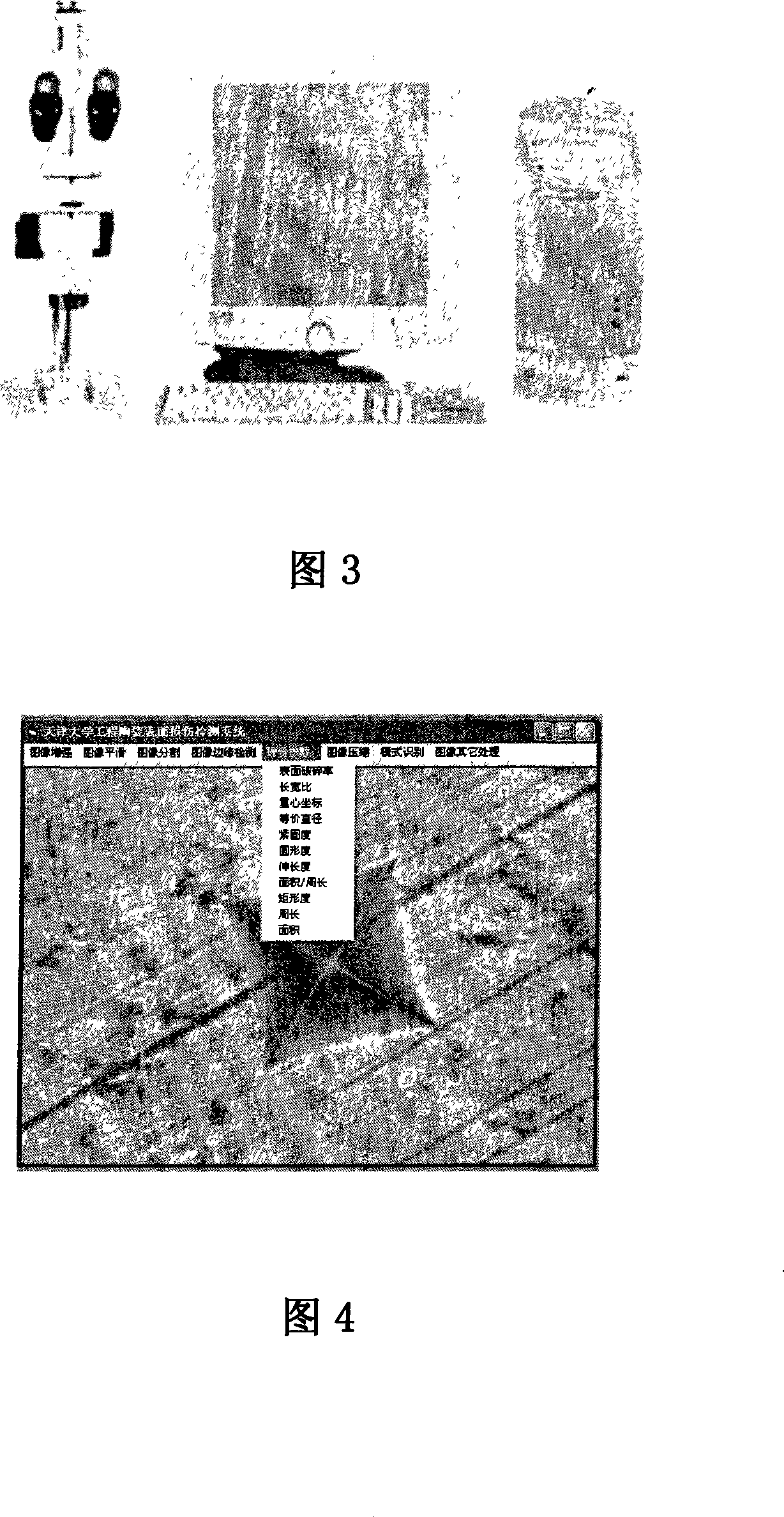

Ceramic working surface damnification detecting system

InactiveCN101178367ALow costOptically investigating flaws/contaminationSoftware systemMachined surface

The invention discloses a ceramic processing surface damage detection system, which collects the processing status of the processing surface in the high-efficiency precision grinding process and the characteristic data of the grinding surface topography by the computer, and performs classification processing to obtain the edge contour characteristics of the damage, and identify The macro-quantitative index surface breakage rate, stability, diffusion and damage characteristic parameters that characterize the damage degree of the processed surface are extracted, combined with computer digital image processing technology and algorithms, to complete the detection and evaluation of ceramic surface processing damage. Compared with the existing technology, the system can effectively detect the surface damage type, characteristics, and surface damage degree of advanced ceramics and other related materials, and can be used as an important reference index for comprehensively evaluating the surface quality of ceramic processing. The detection software written in the system is simple and practical, low in cost, more conducive to popularization, reliable and effective, and has greater economic benefits.

Owner:TIANJIN UNIV

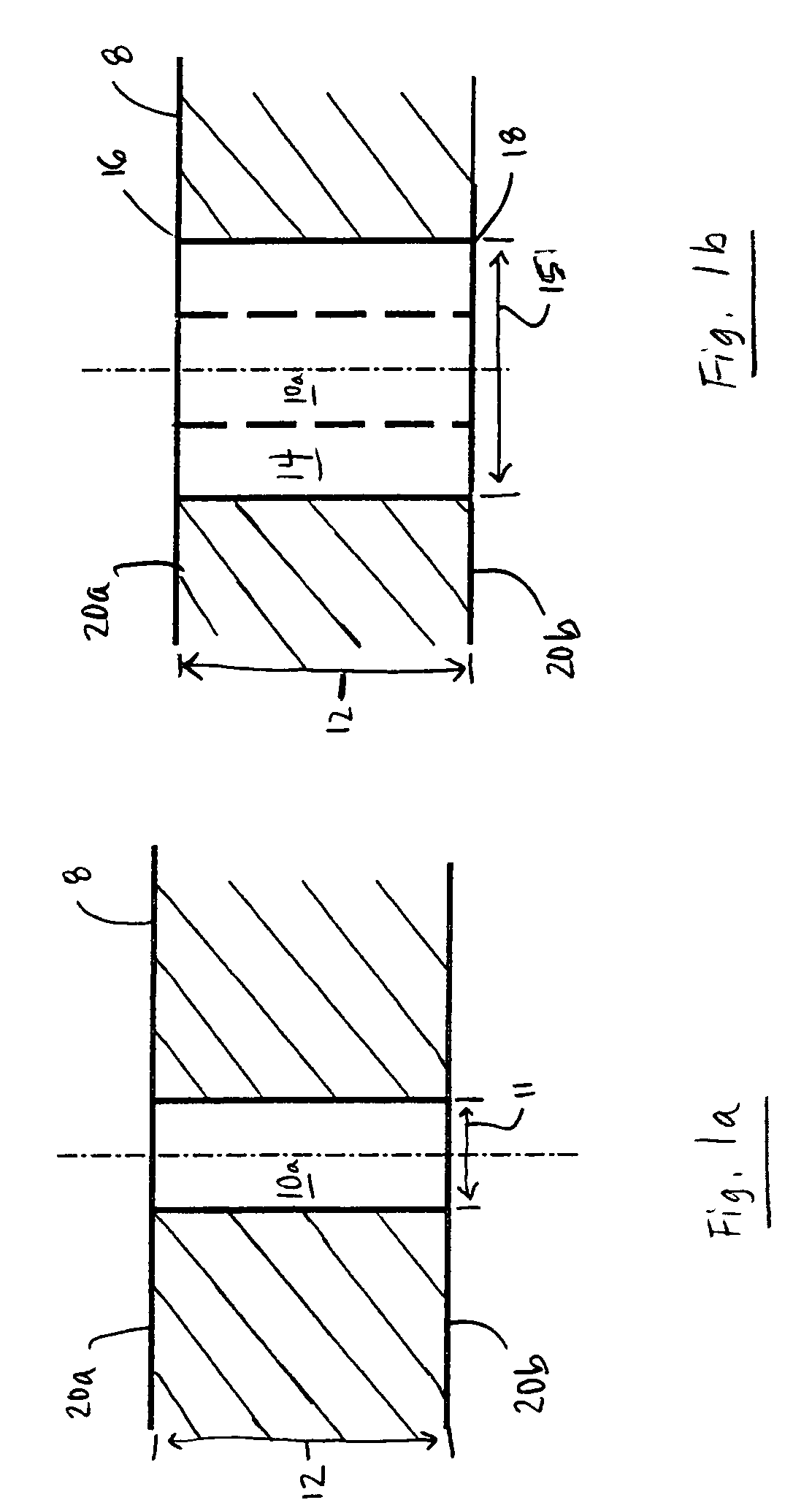

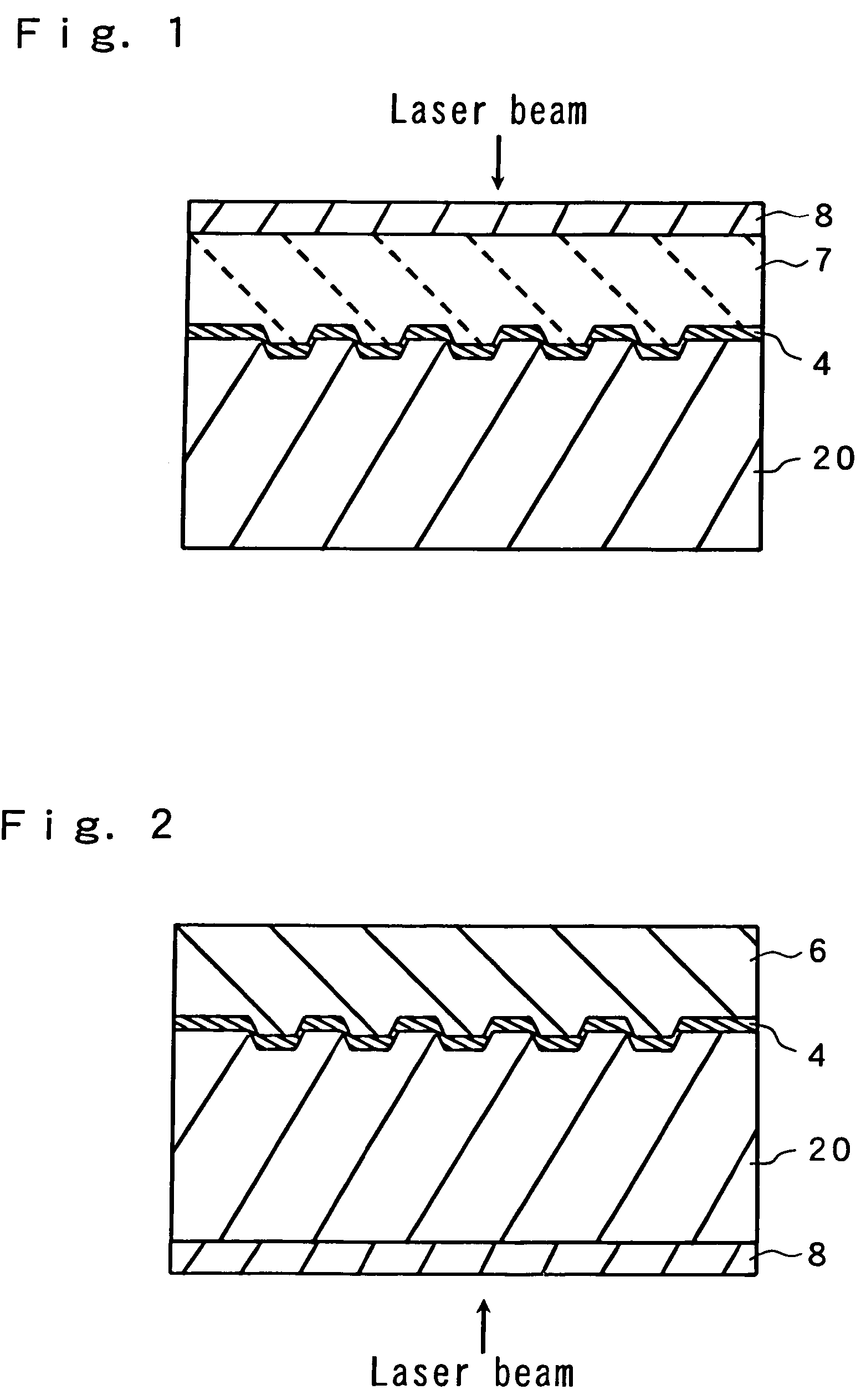

Methods of drilling through-holes in homogenous and non-homogeneous substrates

InactiveUS20050230365A1Minimum thermal damageImprove performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energyPilot hole

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

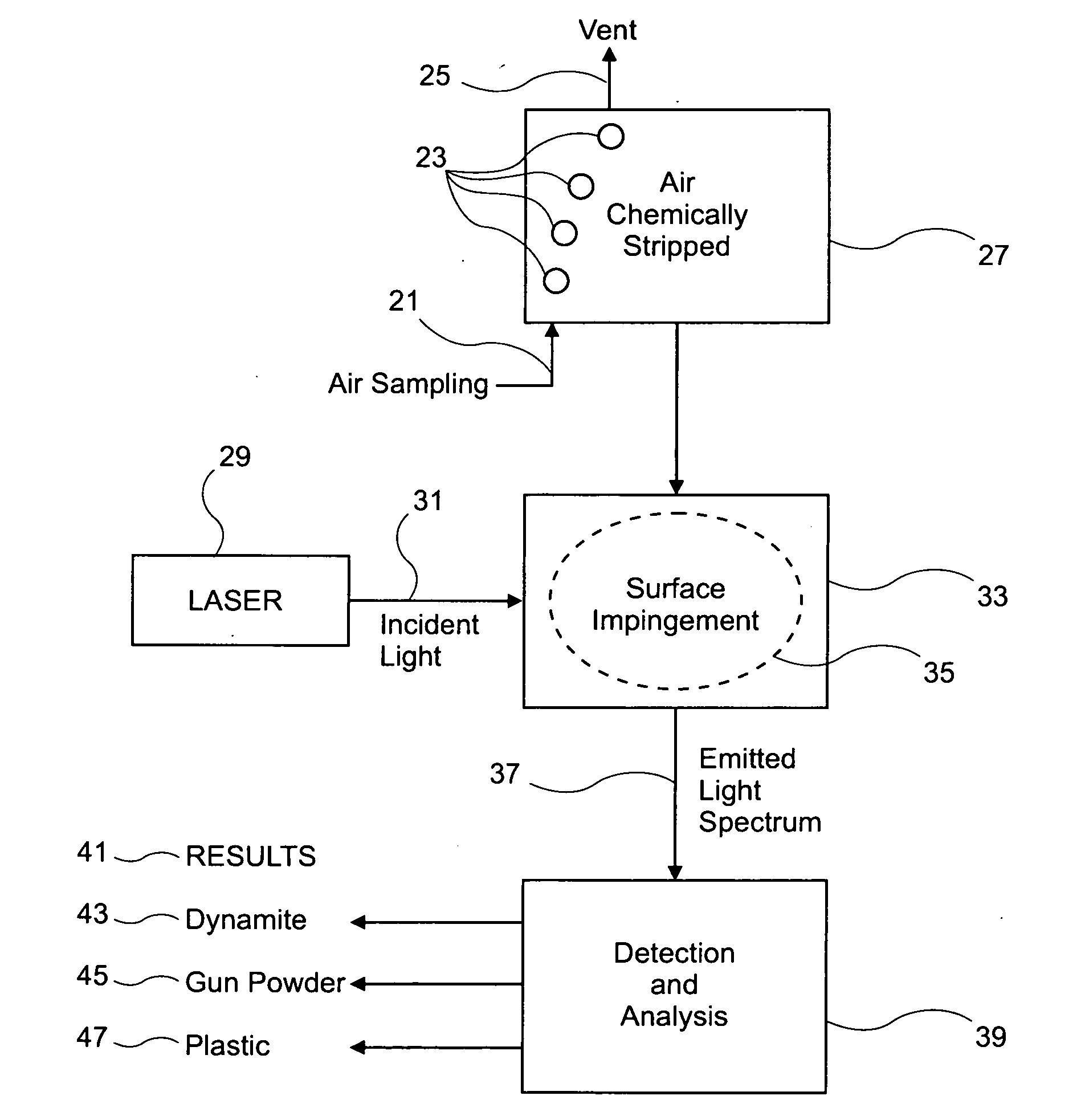

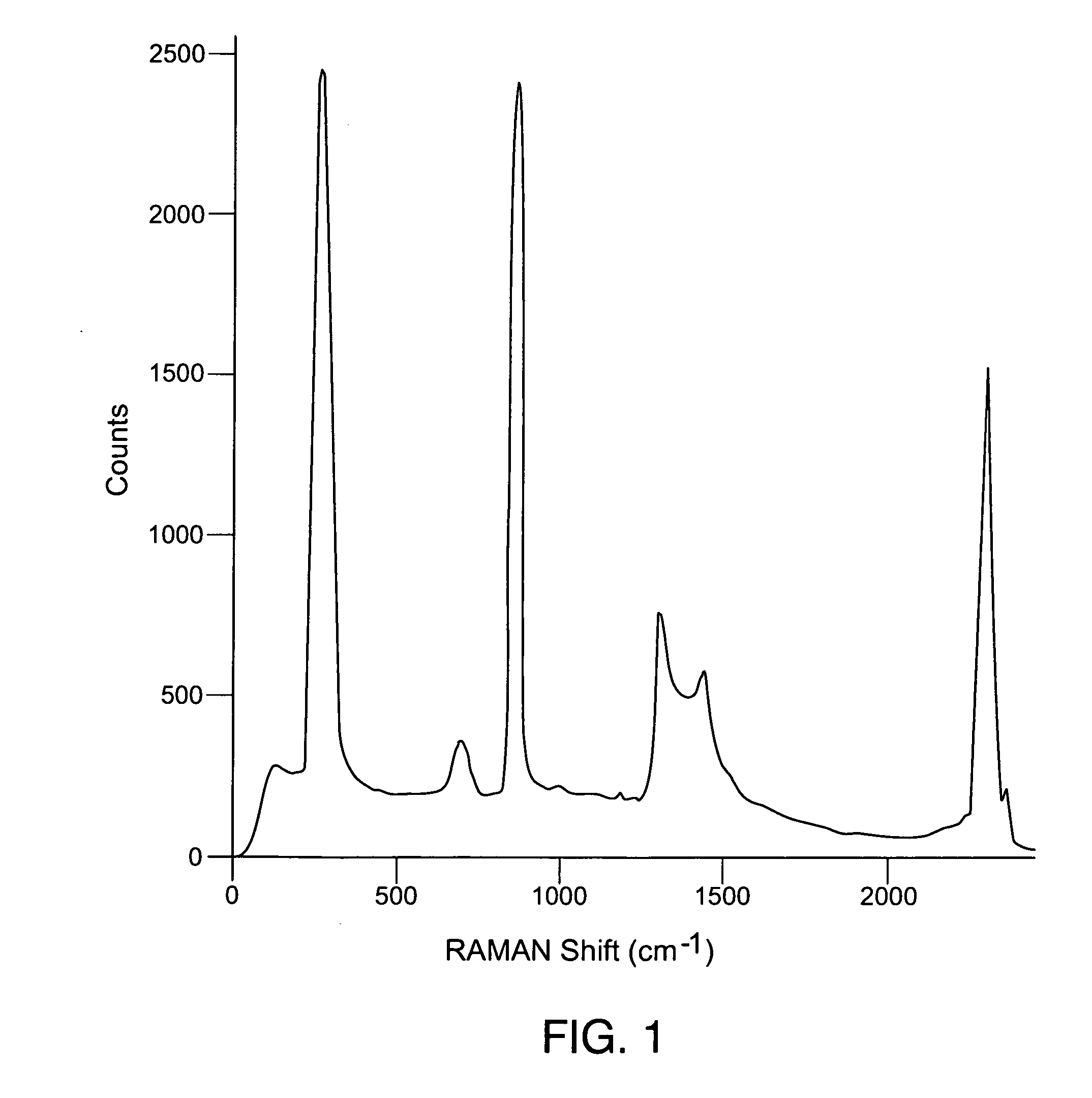

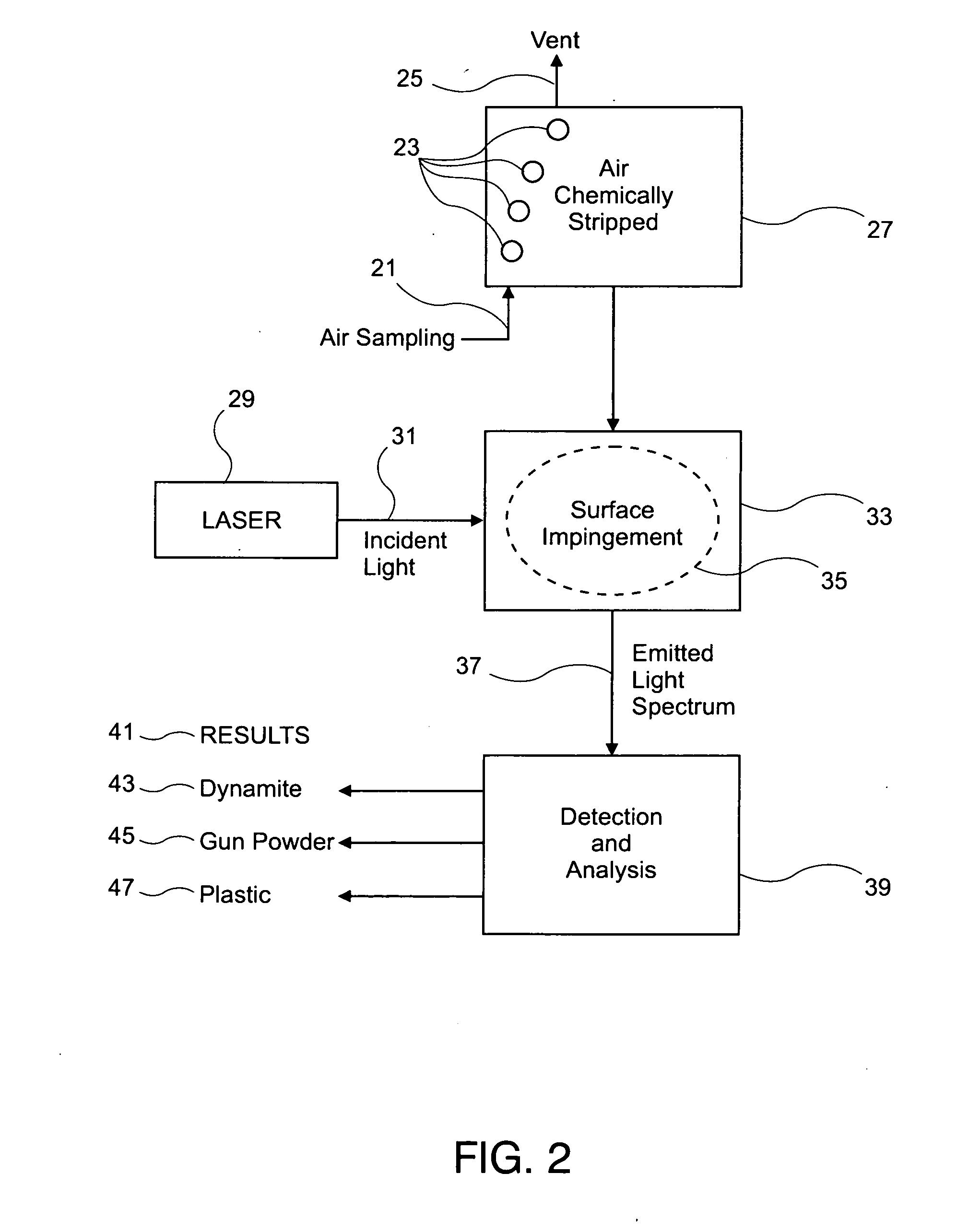

Enhancing Raman spectrographic sensitivity by using solvent extraction of vapor or particulate trace materials, improved surface scatter from nano-structures on nano-particles, and volumetric integration of the Raman scatter from the nano-particles' surfaces

InactiveUS20080268548A1Maximize interactionIncrease and decrease travel timeChemiluminescene/bioluminescenceBiological testingSuspended particlesMass ratio

This invention is a method to enhance by orders of magnitude accurate, real-time, stand-off detection by a sensor using Raman spectra of one or more trace compounds of interest (particularly explosives, bioterror organisms, or Volatile Organic Compounds). A colloid, whose medium of suspension is a liquid solvent with a weak Raman spectrum and in which are suspended particles of a noble metal that are preferentially nano-sized to maximize the surface-to-mass ratio for each particle, forms an impingement base. A sample of this colloid is air-pumped through a sampling module, exposed to air potentially carrying trace molecules from the compound of interest, then sent to a detection module that subjects the sample to Raman spectroscopy. The result is first corrected to obtain a unique Raman spectra from the trace molecules, then matched against Raman spectra in a database. Extensions include modifying, flushing, further processing, or recirculating the colloid sample.

Owner:NANO CHOCOLATE LAB

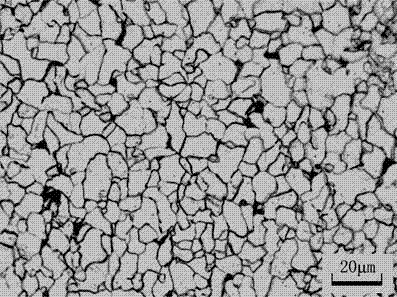

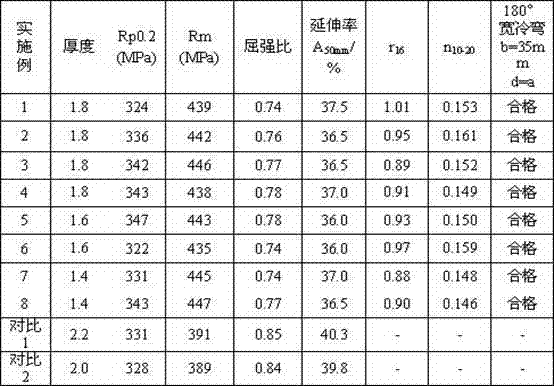

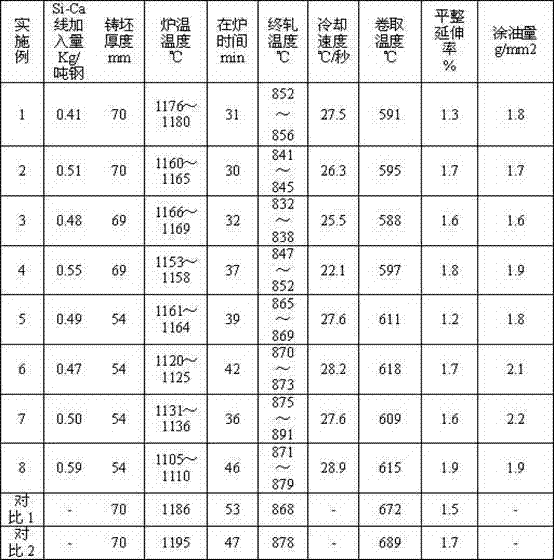

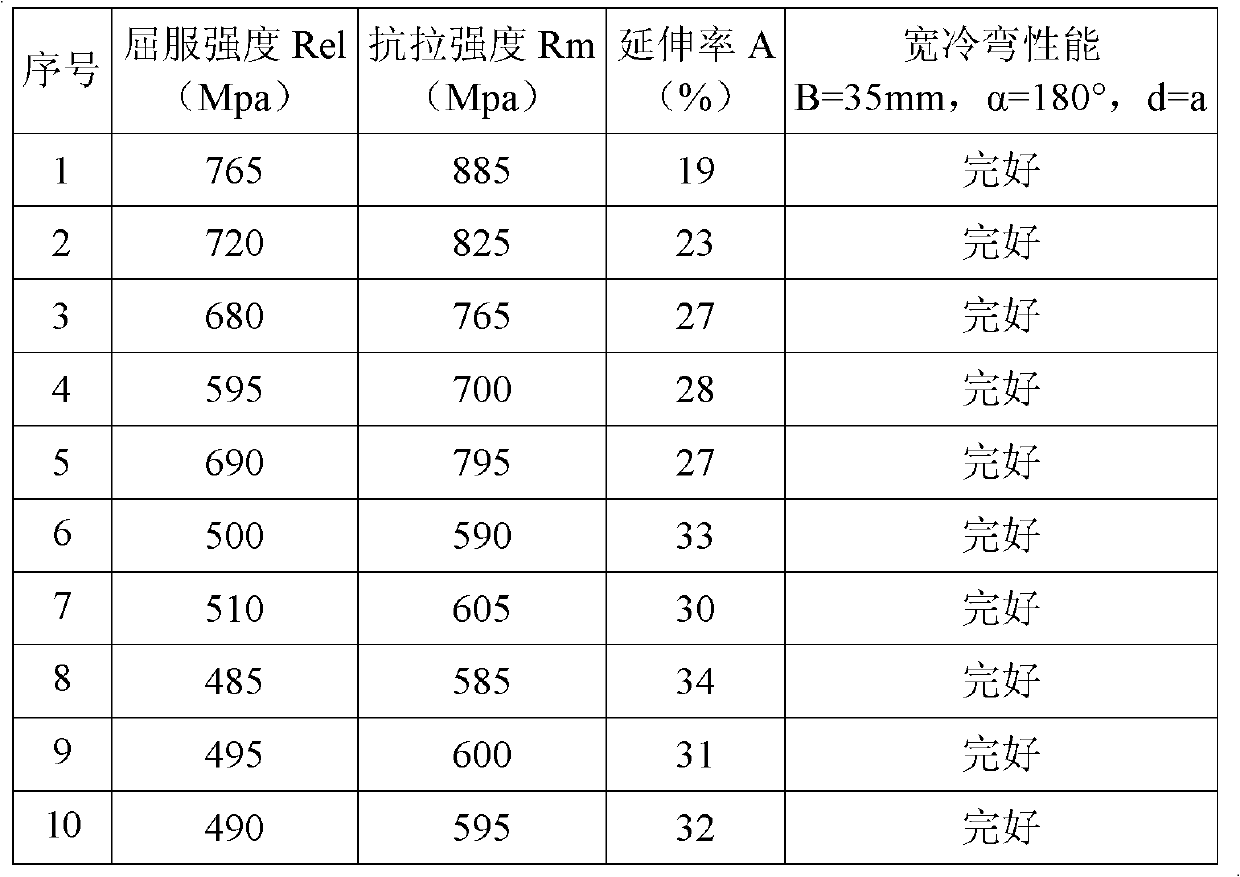

Sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for automobile and production method thereof

InactiveCN102787273ALow yield ratioImprove surface qualityWork treatment devicesMetal rolling arrangementsCar manufacturingHigh pressure water

The invention relates to a sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for an automobile, which comprises the following chemical components by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 0.60-1.30% of Mn, 0.025% of P or less, 0.012% of S, 0.02-0.04% of Ti and 0.010-0.030% of Als. The preparation method of the sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water by controlling the pressure at 25-35Mpa, controlling rolling, cooling by laminar flow, curling, pickling by acid, levelling by controlling the extension rate at 2% or lower, and finishing by adopting static oil removal. The produced thin hot-rolled pickled steel for the automobile, which has the tensile strength of 400MPa or higher and the thickness of 1.8 mm or lower, has the characteristics of low yield ratio, high surface quality, short production cycle and low cost, achieve the match of high strength and good stamping performance and can replace the cold-rolled high-strength steel to manufacture the automobile.

Owner:武钢集团有限公司

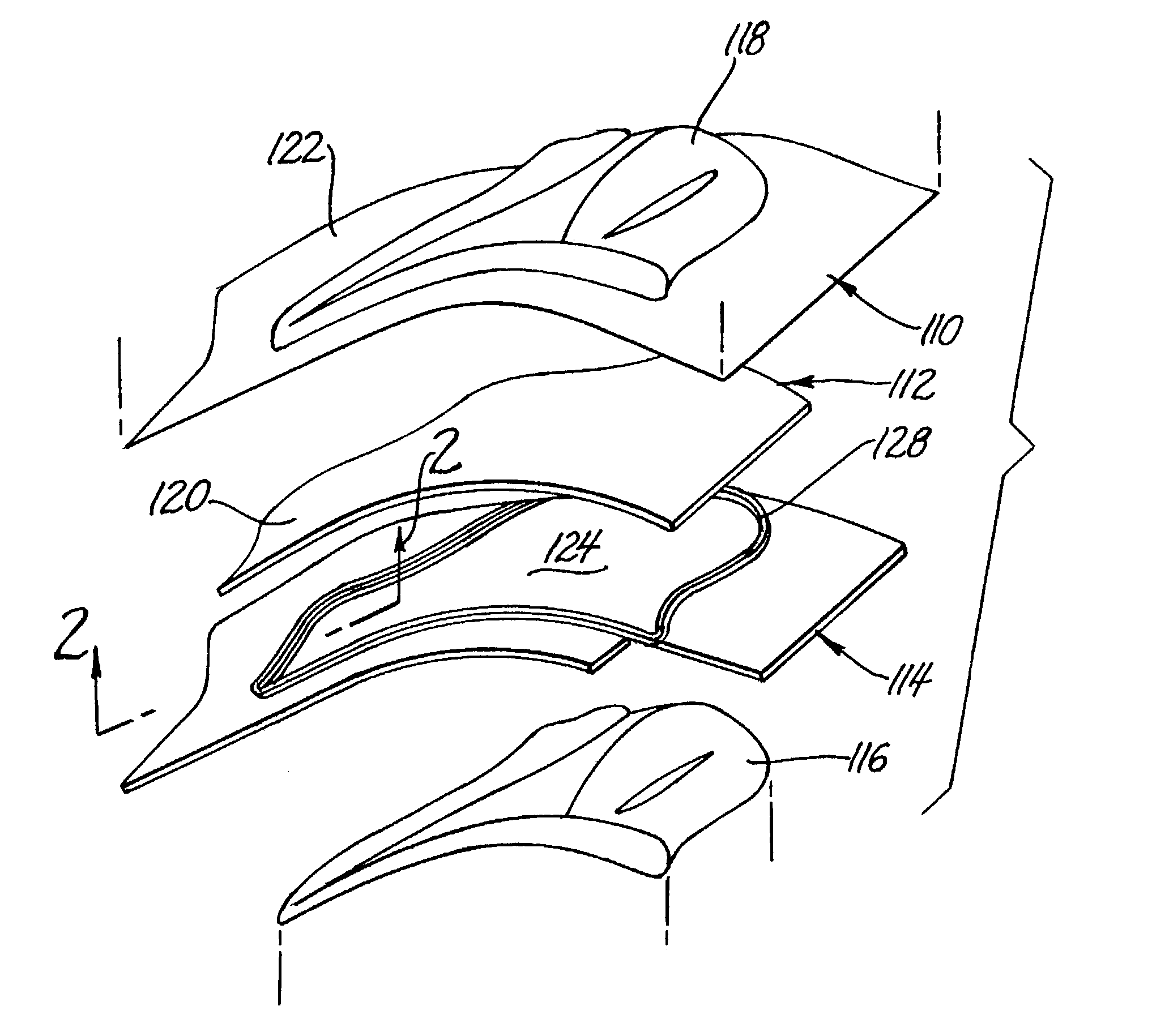

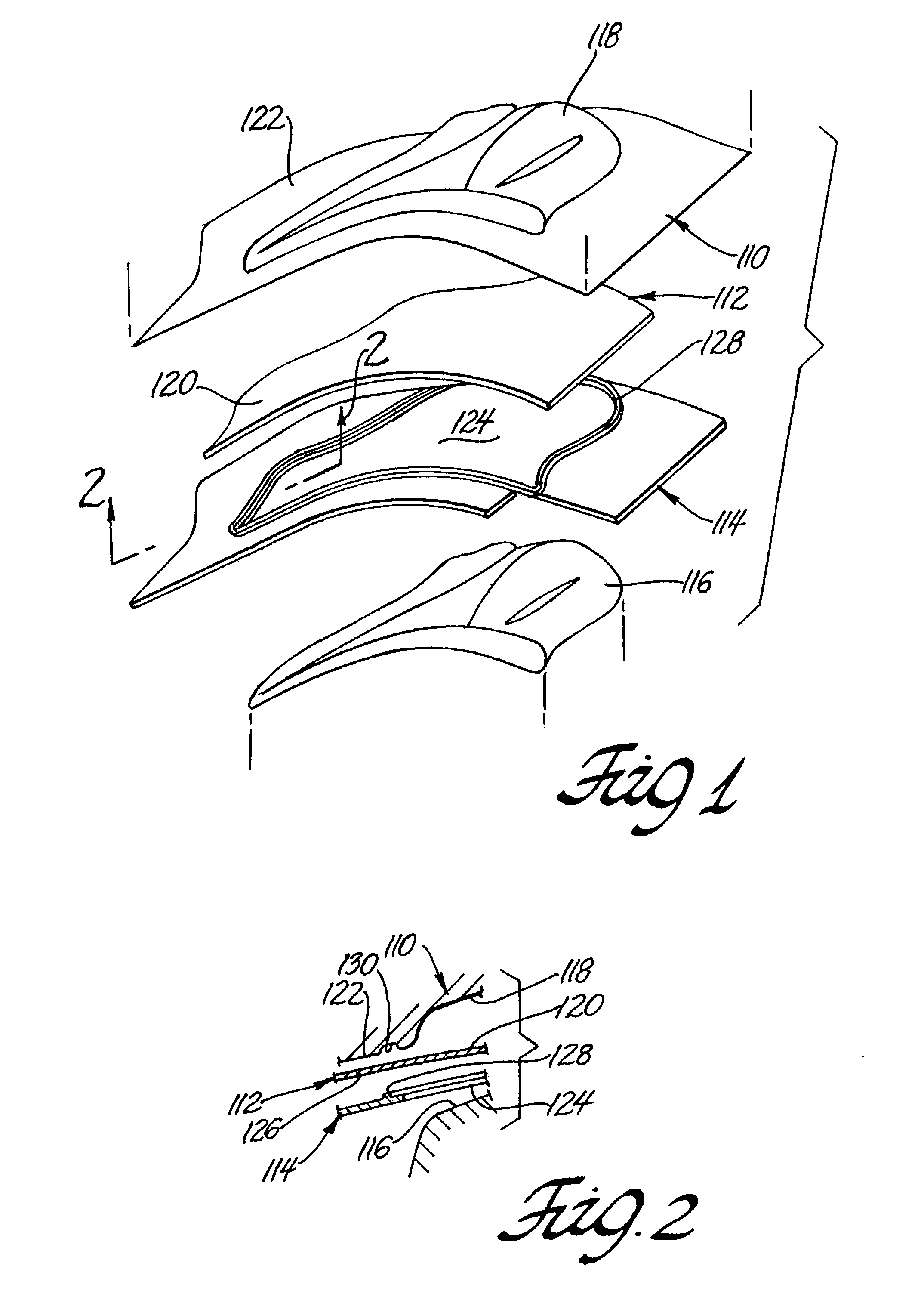

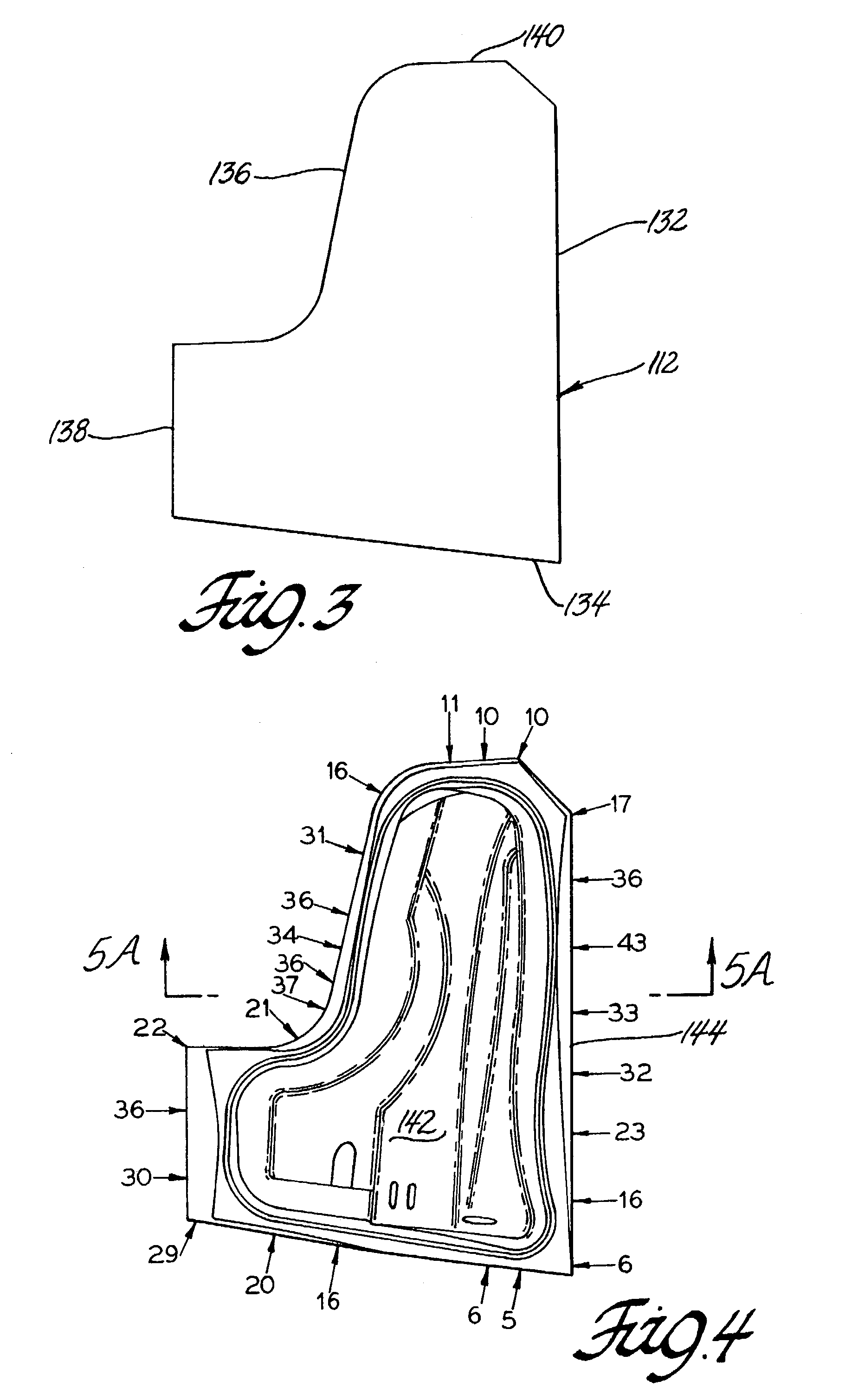

Draw-in map for stamping die tryout

ActiveUS7130708B2Rapid productionMinimum effortShaping toolsSpecial data processing applicationsMetal formingSize determination

Sheet metal forming is a manufacturing process in which flat sheet metal is drawn into a die cavity to form a product shape. Draw-in amount is the single most important stamping index that controls all forming characteristics (strains and stresses), formability failures (splits, wrinkles) and surface quality (distortions) on a panel. Adaptation of a new die set for repetitively stamping sheet metal parts to a part design specification is simplified by using a math-based simulation of the stamping operation under specified engineering stamping conditions for the specified part. The stamping simulations are used to create an engineered draw-in map comparing selected locations on the peripheral edge of the stamped part with corresponding locations on the peripheral edge of its original sheet metal blank. The resulting map of sheet metal draw-in dimensions reflect suitable displacements of the metal sheet between the binder ring and binder surface of the female die member at all such locations as the punch member of the die set executes its stamping operation. The engineered draw-in dimensions for a simulated part identify specific locations for adjustment of the binder ring / binder surface system in adapting the die set for production of parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

Precise machining method for capillary tube for biodegradable magnesium alloy intravascular stent

ActiveCN103394545ASmall sizeImprove surface qualityRoll mill control devicesMetal rolling arrangementsStress reliefIntravascular stent

The invention discloses a precise machining method for a capillary tube for a biodegradable magnesium alloy intravascular stent. The method comprises the following steps of: step 1, performing stress relief annealing and machining on a magnesium alloy extrusion bar to obtain a tube blank; step 2, extruding the tube blank to obtain a seamless extrusion tube blank, and performing stress relief annealing; step 3, performing multi-pass rolling and annealing on the annealed seamless extrusion tube blank to obtain a thin tube blank; and step 4, performing multi-pass drawing and annealing on the thin tube blank to obtain the capillary tube for the biodegradable magnesium alloy intravascular stent. The capillary tube produced by the method disclosed by the invention is accurate in dimension (a wall thickness error is not greater than 5%), can be more than 1 metre long, is high in surface quality, uniform in matrix structure, excellent in mechanical property, low in machining cost and high in machining efficiency, and can be subjected to industrialized batch production.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

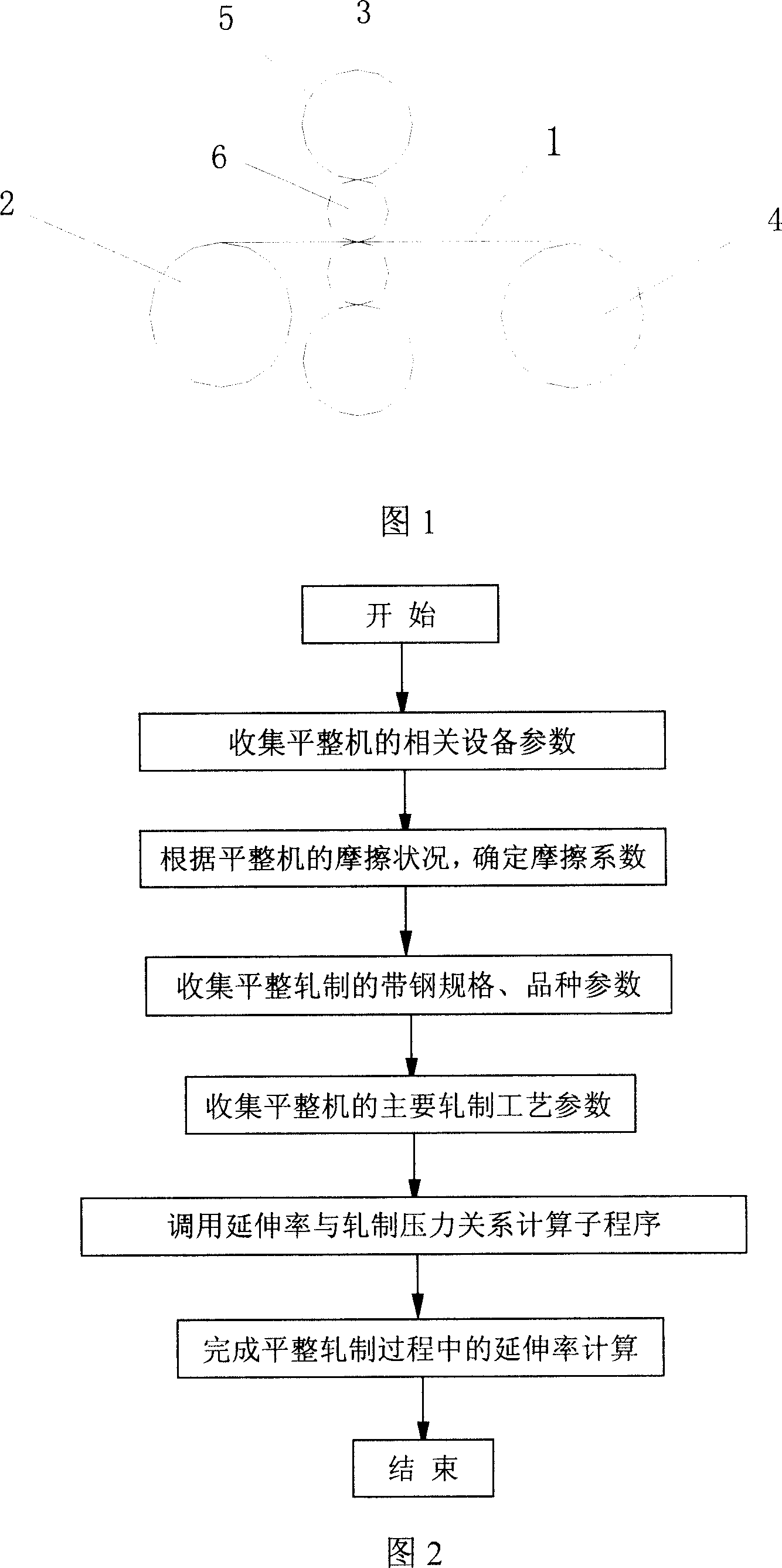

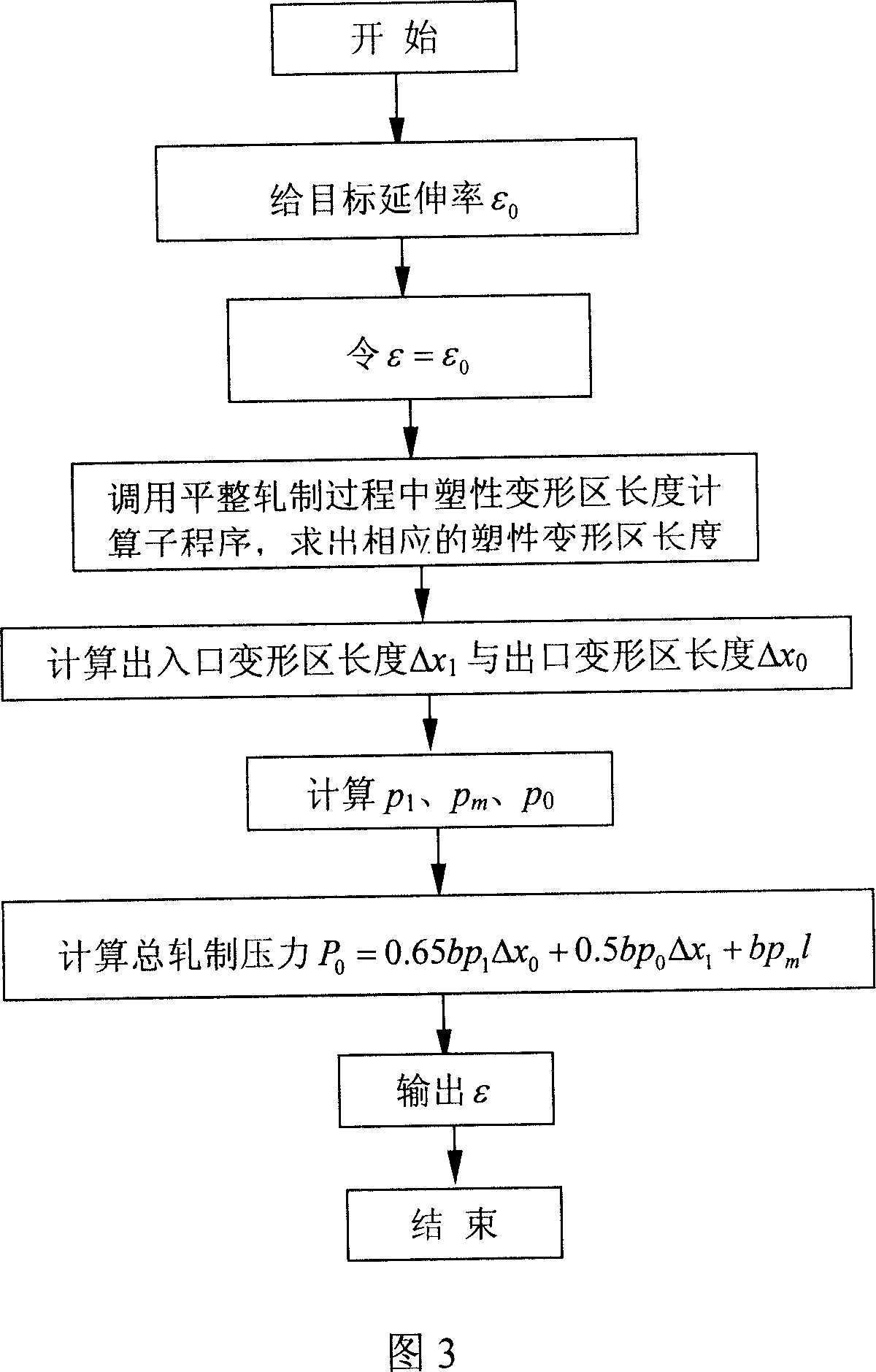

Method for comprehensive control of elongation coefficient and plate shape of steel band during even rolling process

InactiveCN101003063AImprove mechanical propertiesQuality improvementProfile control deviceMetal rolling arrangementsControl objectiveStrip steel

A method for controlling the elongation percentage, plate shape, etc in the skin rolling procedure of band steel features that an elongation percentage control unit, a plate shape control unit and an integrated control unit for both elongation percentage and plate shape are used, which use respectively three different optimizing algorithms to be used in a single iterative calculation procedure consisting of multiple optimizing calculation sub-procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

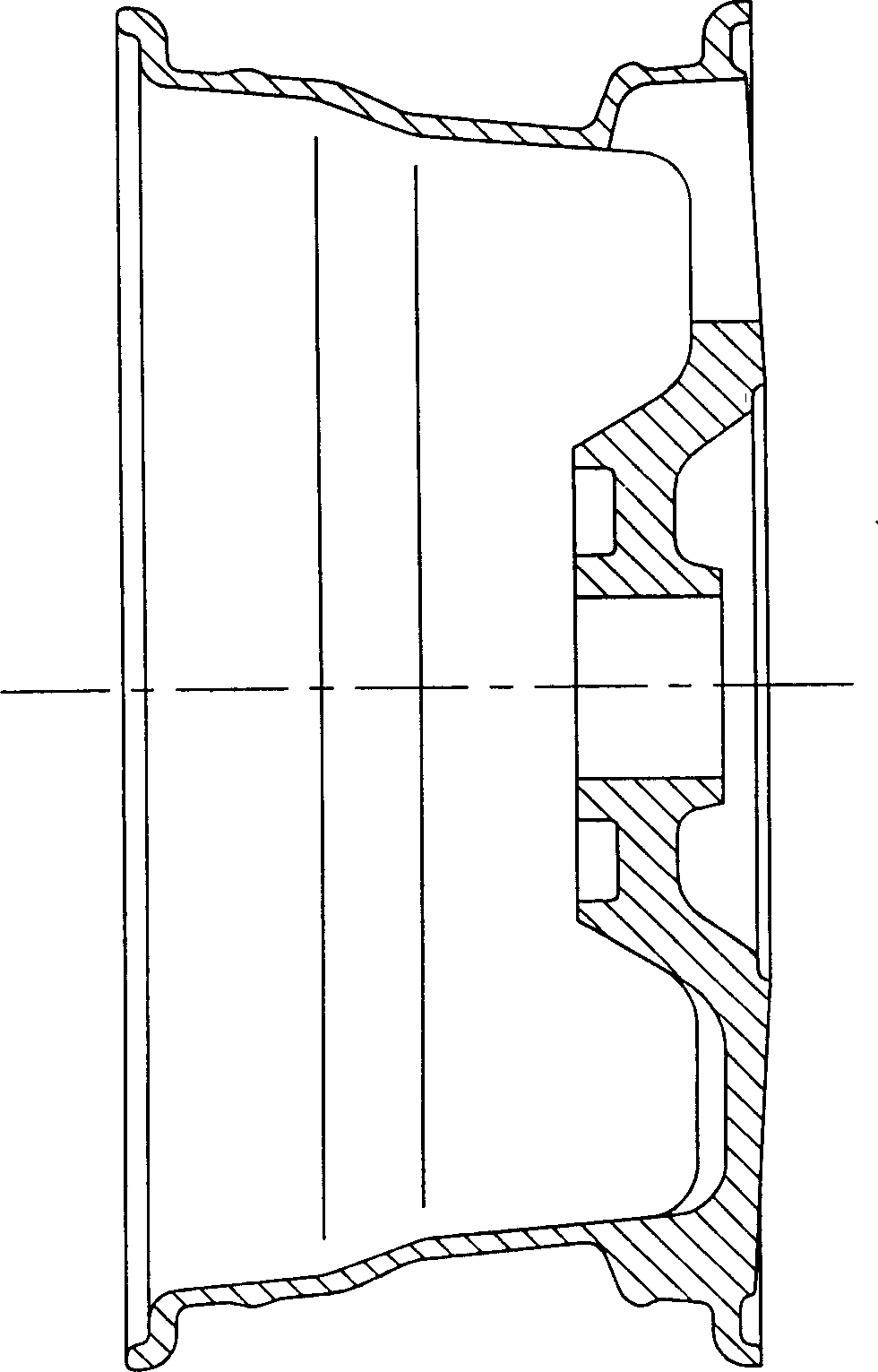

Casting extruding compound shaping method of magnesium alloy automobile hub

InactiveCN1429717AFine internal organizationDense internal organizationDisc wheelsGraphiteSuperficial mass

A technology for forming the Mg-alloy hub of car features three procedures of preshaping, upsetting-squeezing formation and fine trimming and includes such steps as casting a blank; after preshaping,making allowance for apsetting-squeezing formation; upsetting-squeezing formation and deformation degree during isothermal squeezing by using the critical-controlled deformation method; coating graphite lubricant inside the die; and fine trimming. Its advantages are fine crystal grains, and high mechanical performance and surface quality.

Owner:ZHONGBEI UNIV

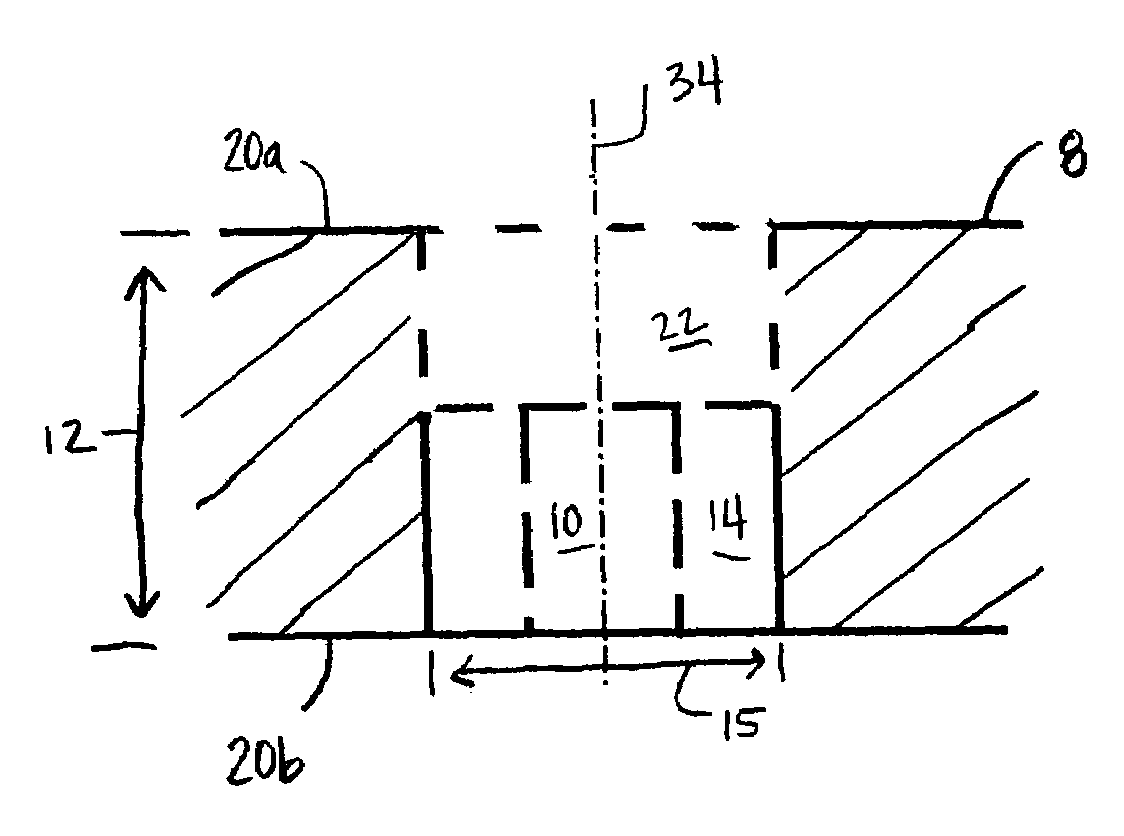

Methods of drilling through-holes in homogenous and non-homogenous substrates

InactiveUS7057133B2Efficient and economicalMinimal damageSemiconductor/solid-state device detailsSolid-state devicesThermal energyHeat-affected zone

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

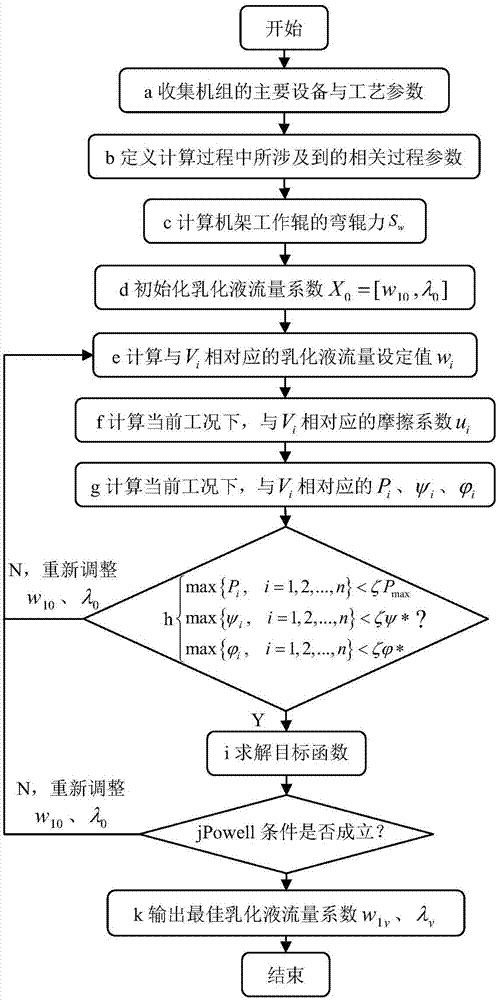

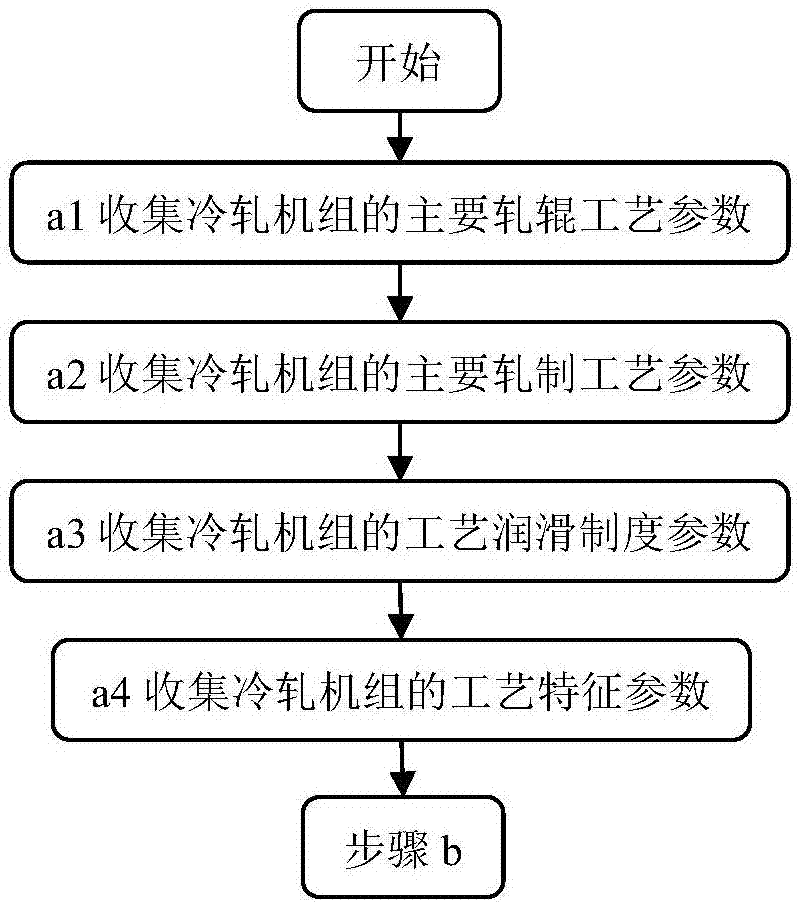

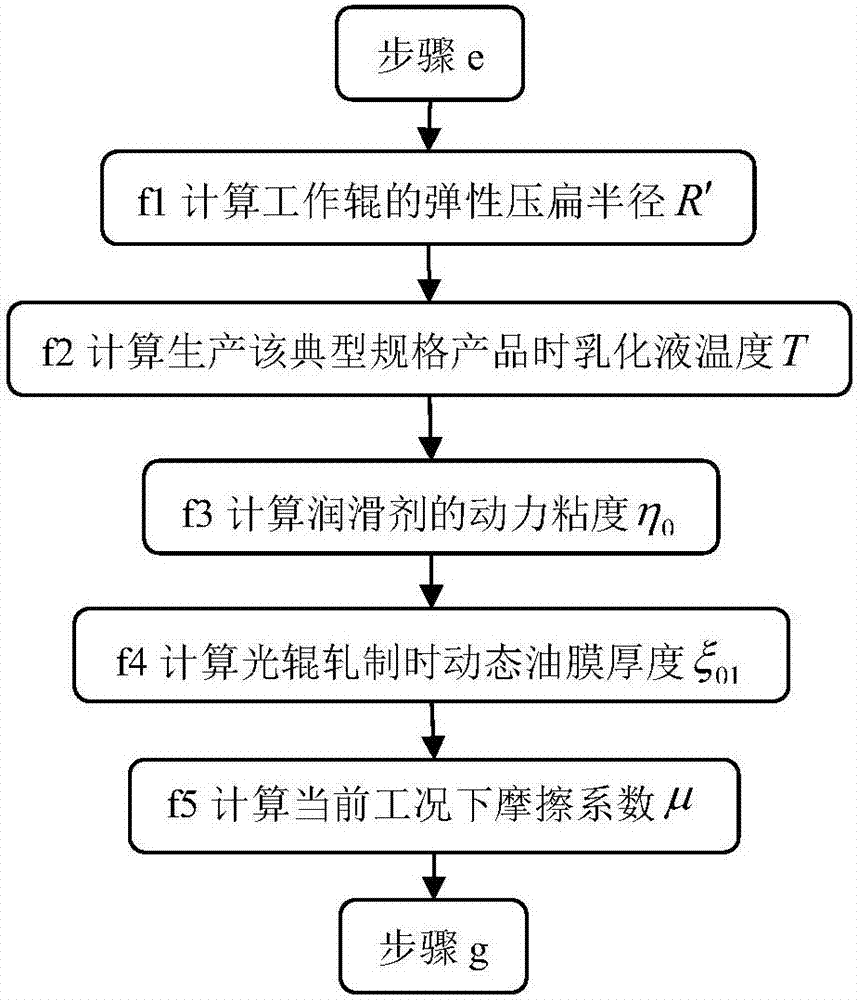

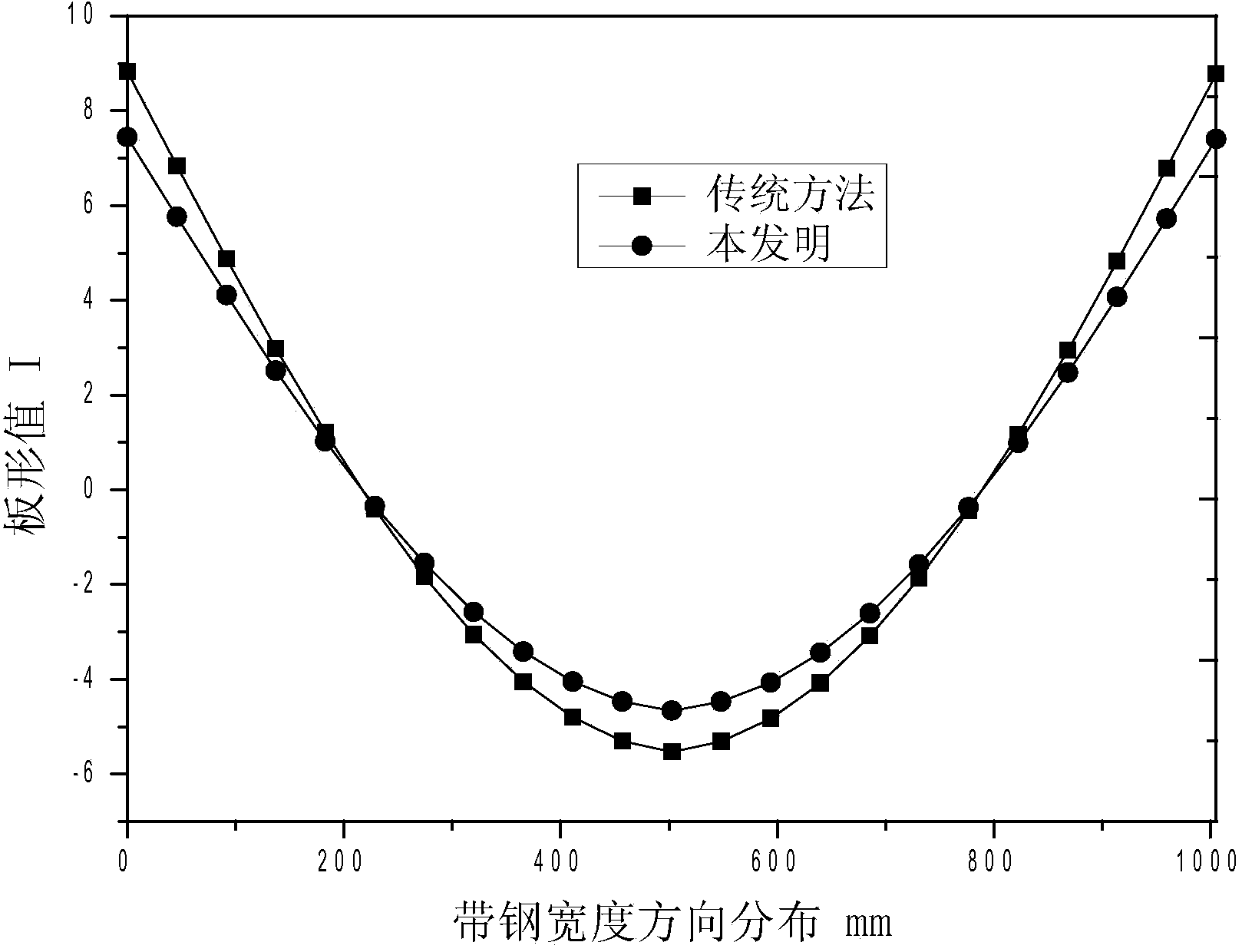

Optimal setting method for relationship curve of emulsion flow and rolling speed in cold rolling process

ActiveCN106909723ASmall fluctuationQuality assuranceForecastingDesign optimisation/simulationEmulsionStrip steel

Provided is an optimal setting method for the relationship curve of the emulsion flow and the rolling speed in the cold rolling process. The method mainly comprises the following steps: 1, collecting main equipment and process parameters of a cold rolling unit; 2, defining the process parameters involved in the optimization process of the emulsion flow; 3, calculating the roll bending force of a rack working roll; 4, initializing the emulsion flow coefficient; 5, calculating the set value of the emulsion flow corresponding to Vi; 6, calculating the friction coefficient mui corresponding to Vi; 7, calculating the rolling pressure, slipping factor and thermal slipping injury index corresponding to Vi; 8, solving the objective function; 9, outputting the best emulsion flow coefficient, and determining the relationship curve of the best emulsion flow and speed. The method has the advantages that the overall fluctuation rate and the maximum fluctuation rate of the rolling pressure can be kept smaller during the speed-up and speed-down process, and it is ensured that the slipping and thermal slipping defects are prevented from occurring in the rolling process, thus the surface quality and the strip shape control precision of strip steels are improved.

Owner:YANSHAN UNIV

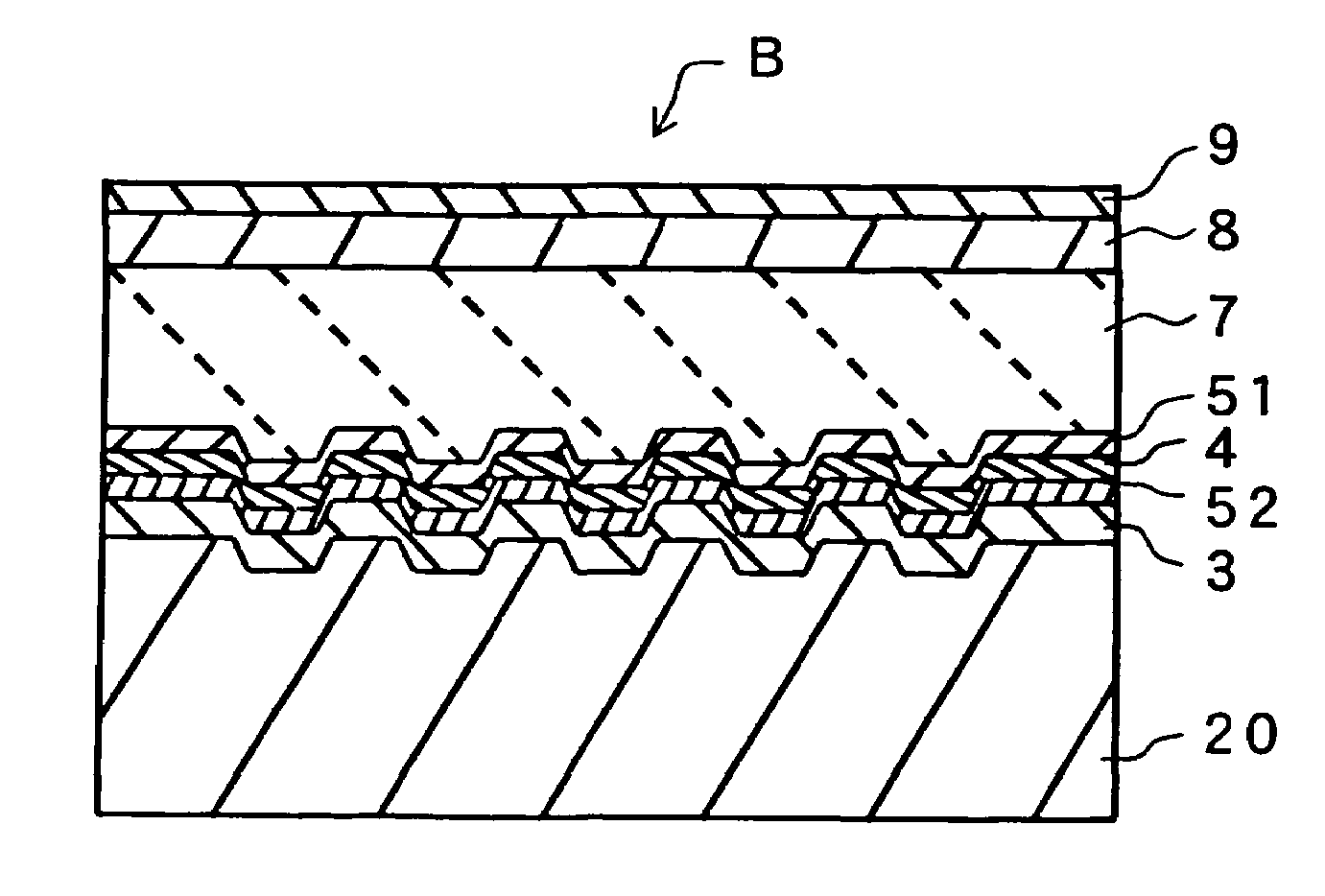

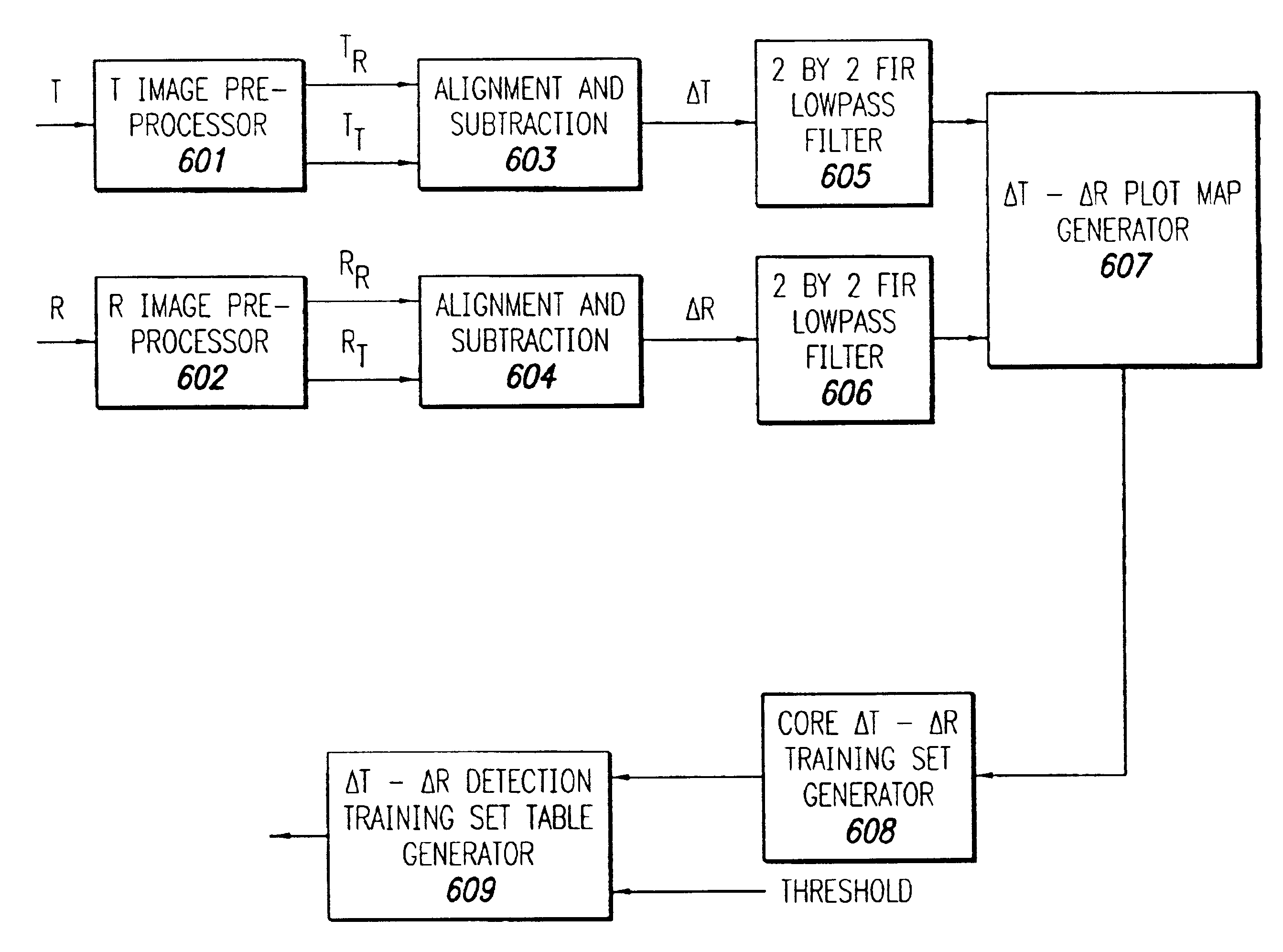

Method of evaluating optical information medium

ActiveUS7092091B2Simple methodCombination recordingRecord information storageComputer scienceSuperficial mass

A method for evaluating an optical information medium by judging quantitatively and reproducibly the surface quality of the optical information medium by the use of a novel artificial fingerprint liquid as an evaluation dispersion liquid including: adhering, under predetermined conditions, the evaluation dispersion liquid; measuring a recording / reproducing characteristic (e.g. error rate) of the medium with the evaluation dispersion liquid droplets adhered to the medium surface; and judging the optical information medium as an acceptable medium when the measured recording and / or reproducing characteristic is equal to, or better than, a predetermined value.

Owner:TDK CORPARATION

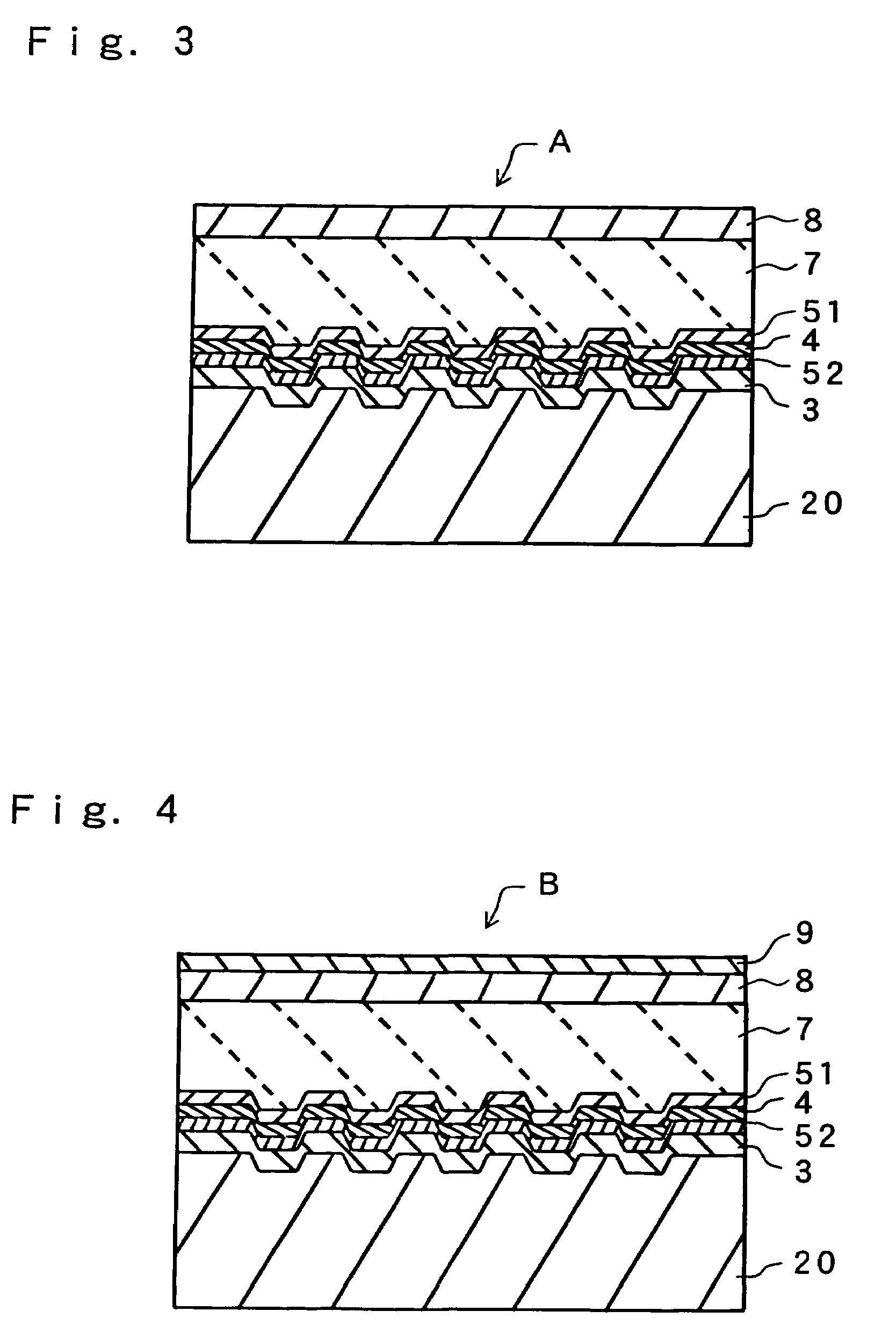

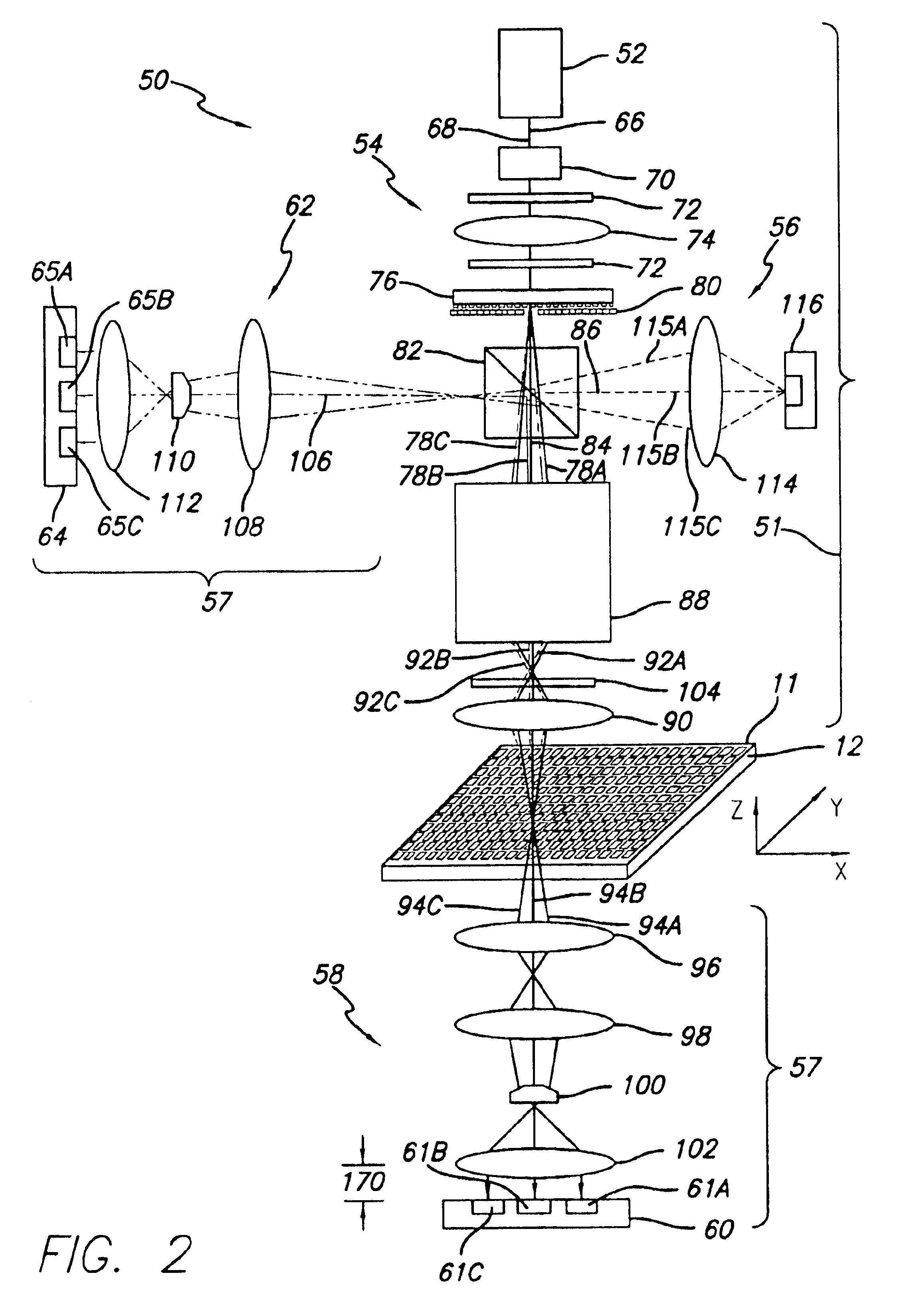

Dual stage defect region identification and defect detection method and apparatus

InactiveUS6850321B1Character and pattern recognitionOptically investigating flaws/contaminationDual stageLaser scanning

A method and apparatus for inspecting patterned substrates, such as photomasks, for unwanted particles and features occurring on the transmissive as well as pattern defects. A transmissive substrate is illuminated by a laser through an optical system comprised of a laser scanning system, individual transmitted and reflected light collection optics and detectors collect and generate signals representative of the light transmitted and reflected by the substrate. The defect identification of the substrate is performed using transmitted and reflected light signals from a baseline comparison between two specimens, or one specimen and a database representation, to form a calibration pixelated training set including a non-defective region. This calibration pixilated training set is compared to a transmitted-reflected plot map of the subject specimen to assess surface quality.

Owner:KLA TENCOR CORP

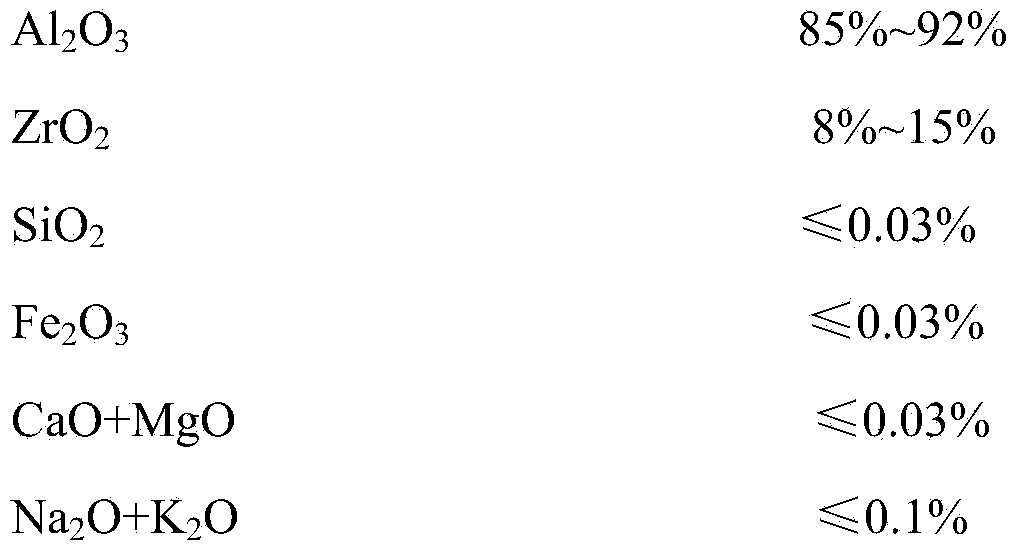

Thin-walled circular type investment casting shell and preparation method thereof

ActiveCN104368757AImprove high temperature performanceGood collapsibilityFoundry mouldsFoundry coresWaxSurface layer

The invention relates to a thin-walled circular type investment casting shell and a preparation method thereof, aiming at solving the defects that for the existing high-temperature alloy large thin-walled complicated circular type casting shell production technology, the casting pouring steel leaks, the surface quality is bad, the casting is difficult to clean, the size precision is low and the like, and belonging to the technical field of an aeroengine. A shell is made of new surface layer refractory powder, a back layer refractory powder and a sand lining material, and the invention provides a formula for all layers of paints of the shell; in addition, the invention further provides a manufacturing method of the thin-walled circular type investment casting shell, and the manufacturing method comprises the following steps: performing oil removal treatment on the surface of a wax mold module, carrying out paint preparation, sand lining and drying, shell dewaxing and shell roasting procedures, and particularly, the reinforcement step is added during the sand lining process, so that the shell has excellent high-temperature performance and good collapse performance at low temperature, and can bear molten metal with the pouring temperature being higher than 1600 DEG C, and can be used for casting high-temperature alloy large thin-walled circular vacuum castings such as K4169, K438, K418 and K4648.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

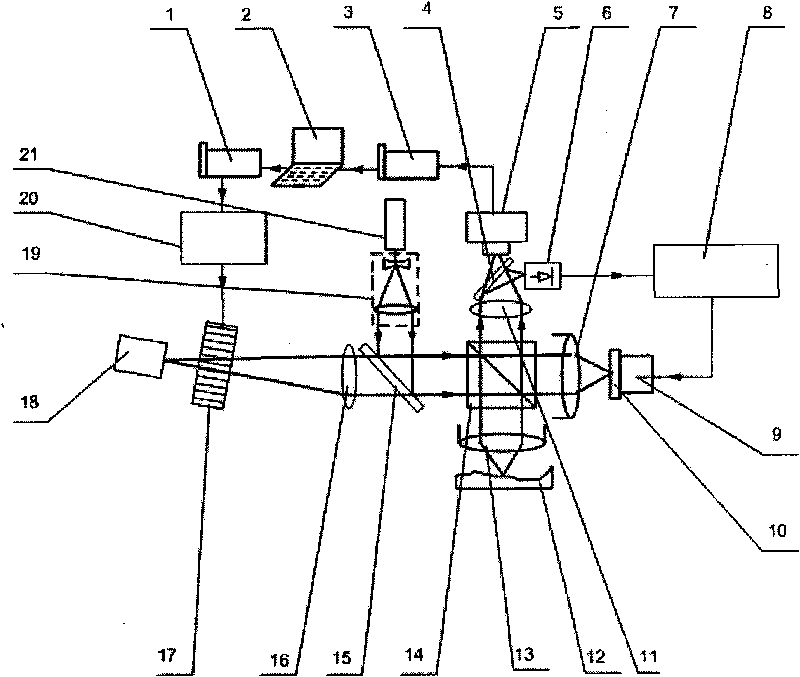

System for quickly measuring surface quality

InactiveCN101718520AShort reaction timeFast measurementUsing optical meansEnvironmental noiseAcousto-optics

The invention discloses a system for quickly measuring surface quality. The system comprises two sets of common-path interferometers, wherein one set of reference interferometer for noise compensation is specially used for detecting noises such as vibration, air disturbance and the like in environment, and eliminating the influence of interference of the background noises through negative feedback; and the other set of main interferometer for measurement controls wavelength of optical wave incident to the interferometers by using an acousto-optic filter, and can quickly acquire a three-dimensional feature of a surface to be measured by processing a generated interference signal by using large-scale parallel computation based on GPGPU. The system can measure the surface quality in real time, does not need mechanical light path scanning in the process of measurement, and can reach a high measurement speed. The system can be updated one time in 1 to 2 seconds on average, and can be updated more frequently after being optimized. The system can reduce influence of environmental noise on the measurement by adding the active optical path compensation technology, achieves measurement accuracy of sub-nano range, reduces cost, saves a usually expensive high-precision translation stage and can be used for processing workshops with more interference.

Owner:ZHEJIANG UNIV

Chemical mechanical polishing pulp for sapphire substrate underlay

ActiveCN101016439AFine working devicesPolishing compositions with abrasivesBoron carbideSurface roughness

The invention discloses chemical mechanical polishing liquor for blue stone underlay, which is characterized by the following: this liquor includes pH adjusting agent, surface activator, water medium and compound grinding particle; the compound grinding particle is constructed through coating one deck particle on the surface of base material particle boron carbide. The polishing speed of blue stone underlay can reach 180nm / min and surface coarseness can decrease to below 7.5.

Owner:浙江新创纳电子科技有限公司

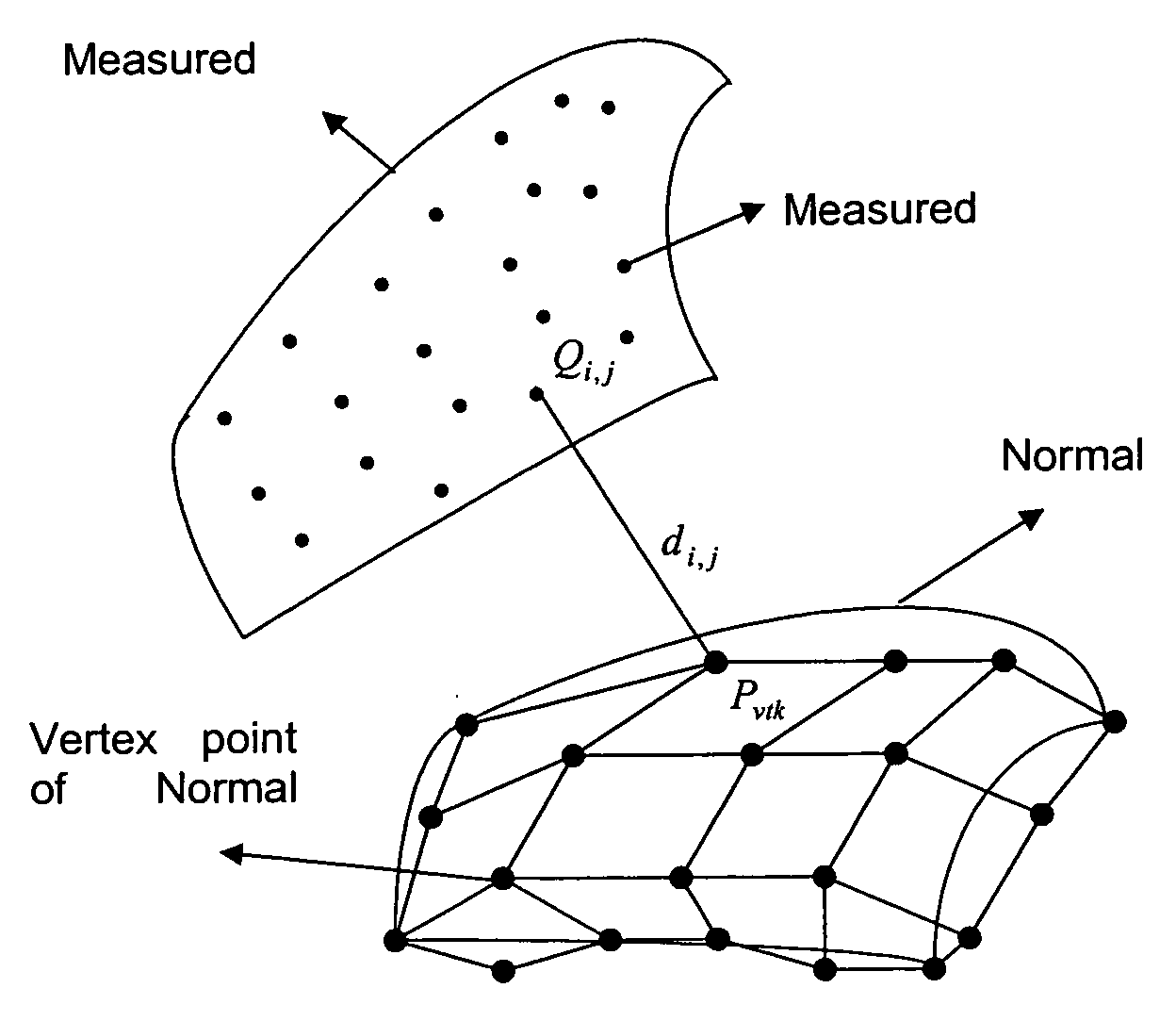

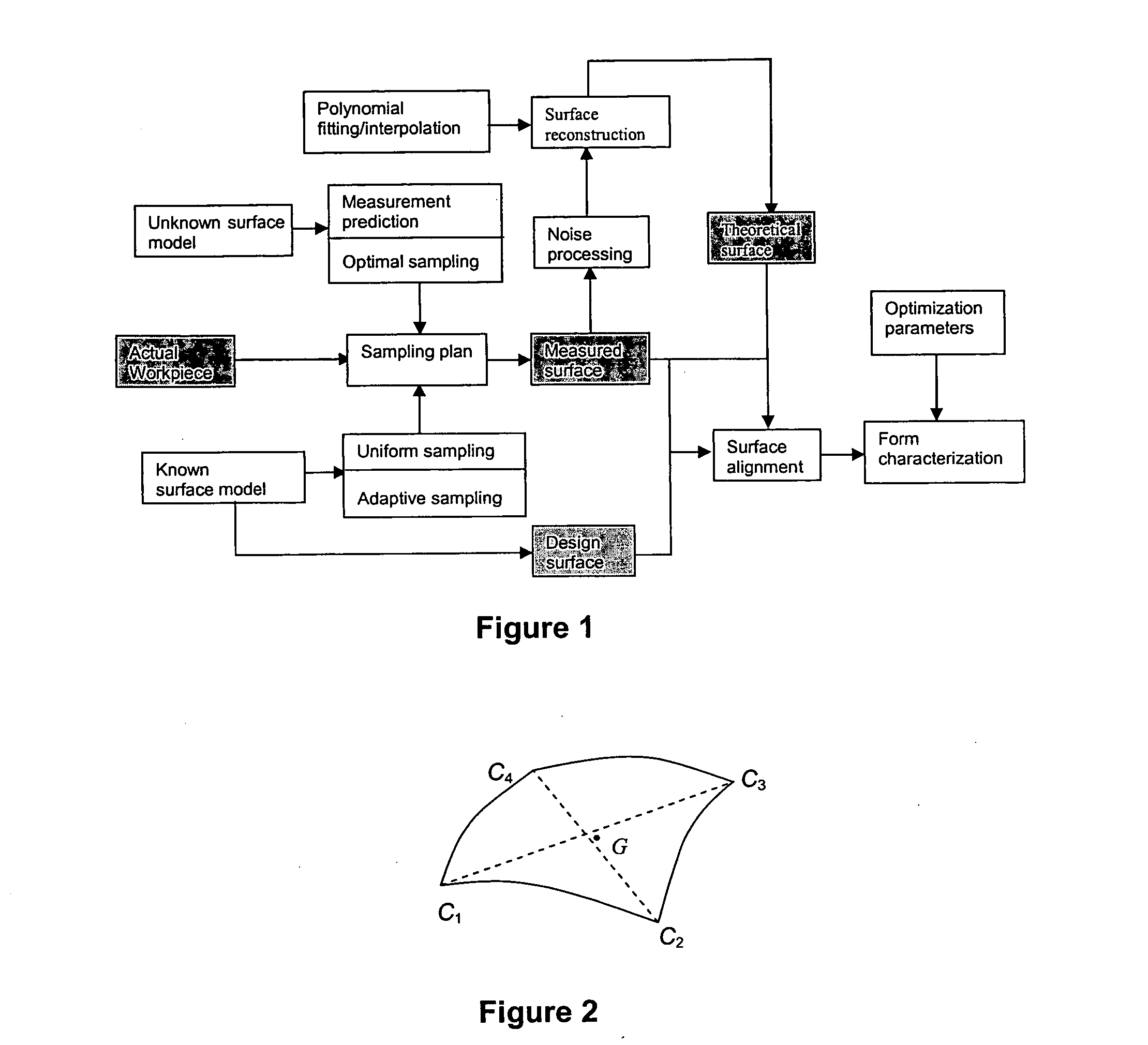

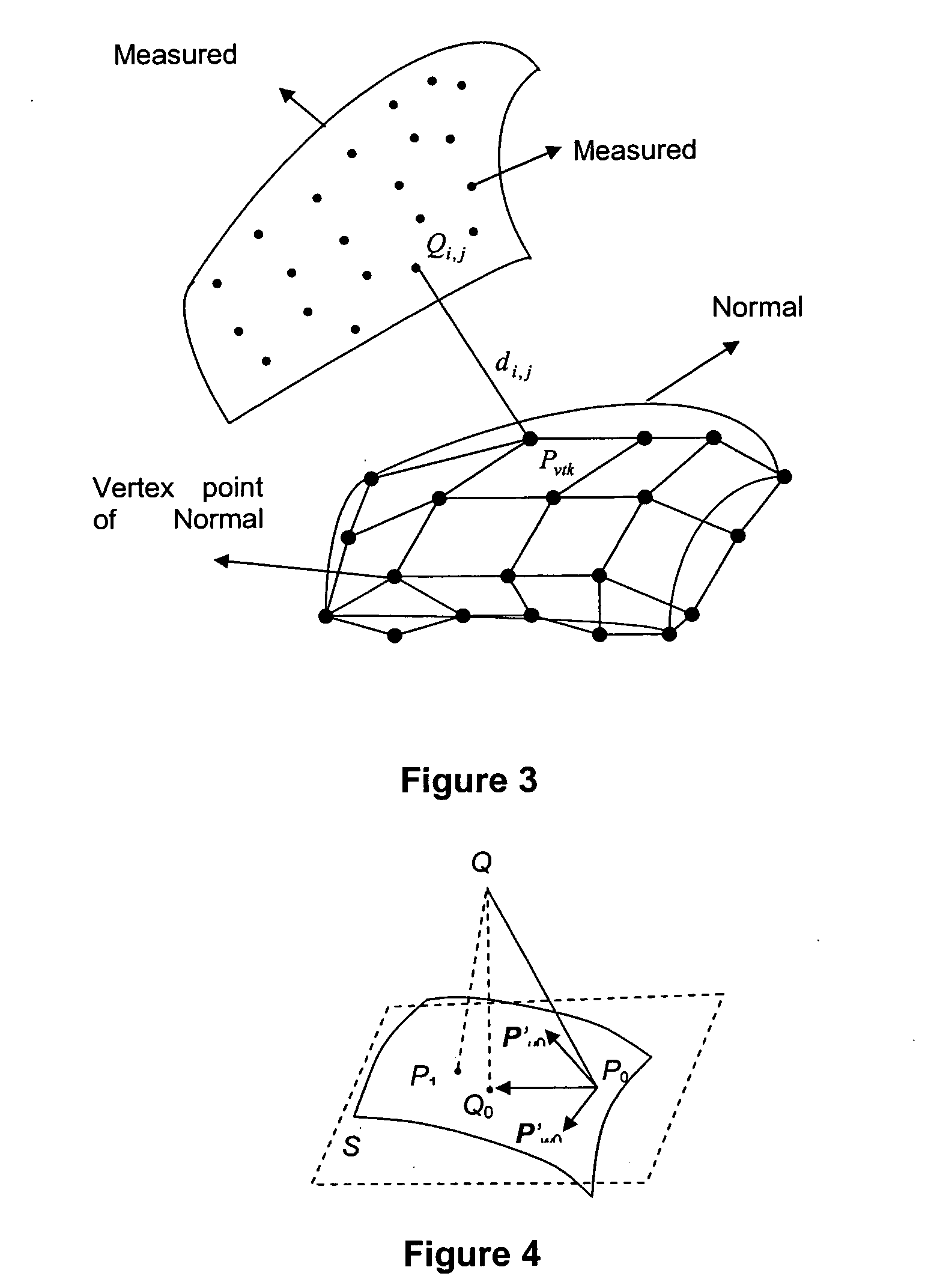

Methods and apparatus of aligning surfaces

ActiveUS20070195084A1Improperly formedCathode-ray tube indicatorsComputation using non-denominational number representationPhotonicsEngineering

Ultra-precision freeform surfaces are important to the development of complex and micro-optical-electro-mechanical devices used in many photonics and telecommunication products such as F-theta lenses for laser printers. These surfaces are complex and large scale surface topologies with shapes that generally possesses no rotational symmetry. Due to the geometrical complexities of these ultra-precision freeform surfaces, it is difficult to characterize the form accuracy and surface quality of freeform optical surfaces. The method of this invention is based on feature-point pre-fixture, and iterative precision alignment algorithm, which can provide sufficient capability of form characterization for ultra-precision freeform surfaces with form accuracy down to below sub-micrometer range

Owner:THE HONG KONG POLYTECHNIC UNIV

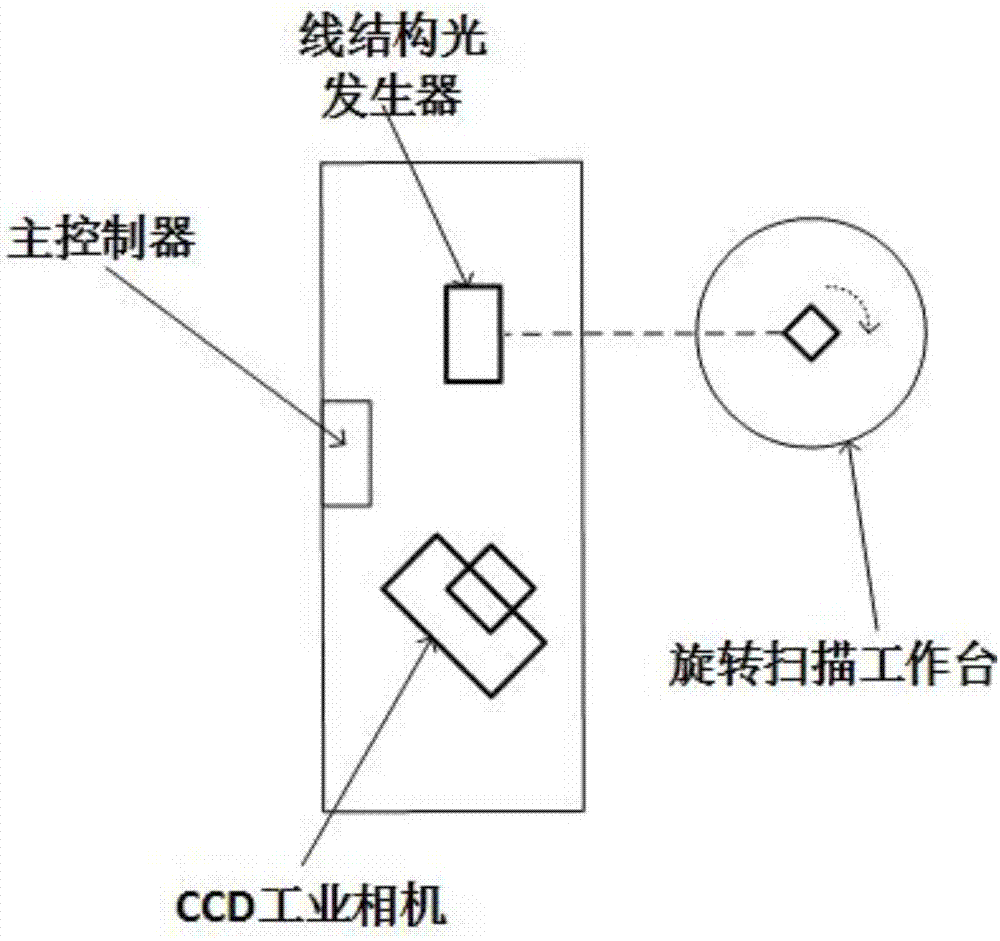

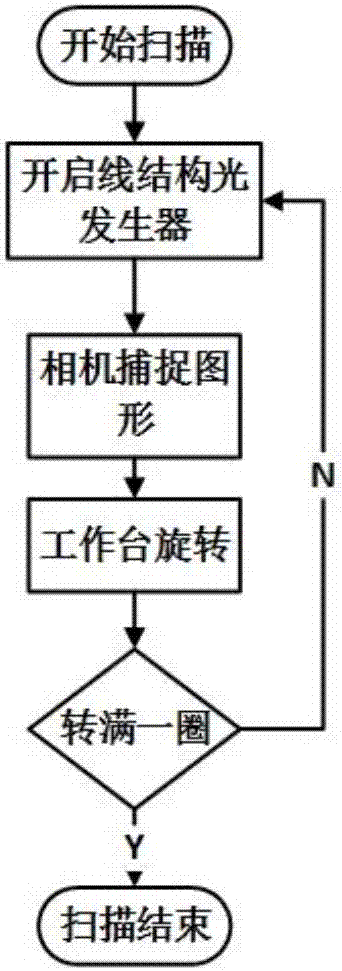

Line structured light-based cast workpiece surface quality detection method and system thereof

InactiveCN106872476AOvercome efficiencyOvercoming detectionOptically investigating flaws/contaminationPoint cloudSuperficial mass

The invention discloses a line structured light-based cast workpiece surface quality detection method and a system thereof. The method comprises the following steps: scanning a workpiece by using line-structured lights and an imaging unit to obtain three-dimensional point cloud of the workpiece, slicing the original three-dimensional model of the workpiece and carrying out planar vectorization on the three-dimensional point cloud of the workpiece to obtain three-dimensional contour data of the original three-dimensional model and the workpiece to be detected, carrying out rotating, movement, fitting pre-estimation and other operations on the obtained three-dimensional contour data, calculating the similarity layer by layer, marking a part with low similarity, and calculating the integral similarity of the original three-dimensional model and the workpiece to be detected. Compared with the prior art, the method disclosed in the invention can be used to detect the problems of cast workpieces through an automatic and quantified flawless detection technology, and solves the problems of low efficiency, incomplete detection and unable quantification of manual detection.

Owner:WUHAN UNIV OF TECH

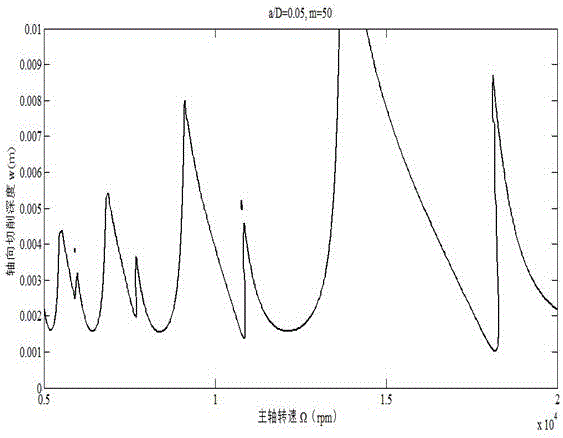

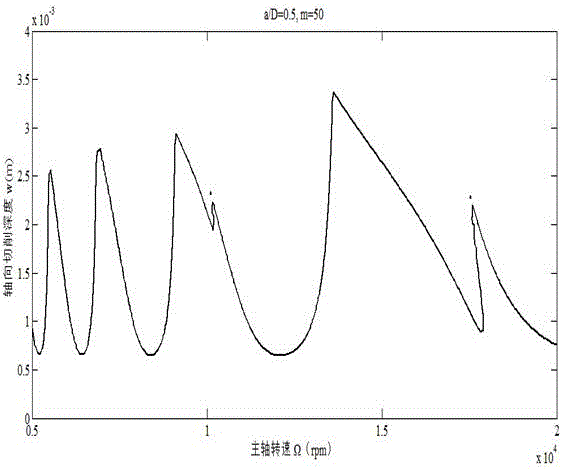

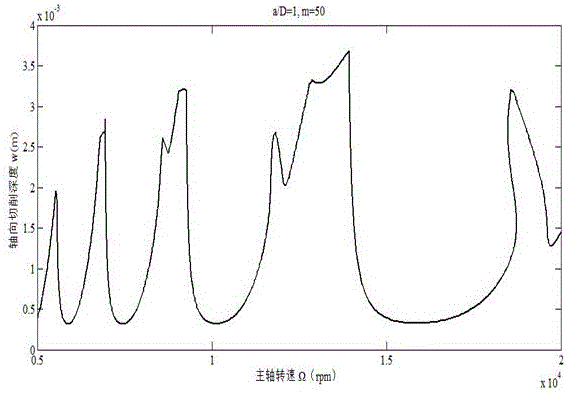

Method for predicting milling stability based on Gear formula

InactiveCN106647625AImprove surface qualityEfficient processingProgramme controlComputer controlNumerical controlManufacturing technology

A method for predicting milling stability based on Gear formula is used mainly for selecting reasonable cutting parameters for processing parts and is characterized in that forced periodic vibration is discretized into equally spaced small regions by using Gear formula so as to obtain a transfer matrix of a milling system, a characteristic value of the transfer matrix of the milling system is judged through Fourier theory so as to predict stability of the milling system, computing efficiency and computing precision are improved, and theoretical support is provided for manufacture technicians to select reasonable cutting parameters to improve surface quality of a part. In high-speed numerical control processing, reasonable cutting parameters are selected according to stable lobe graphs, it is ensured that high-speed efficient processing is achieved without fluttering, processing parameters are optimized, high surface quality is obtained, and precision processing is achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

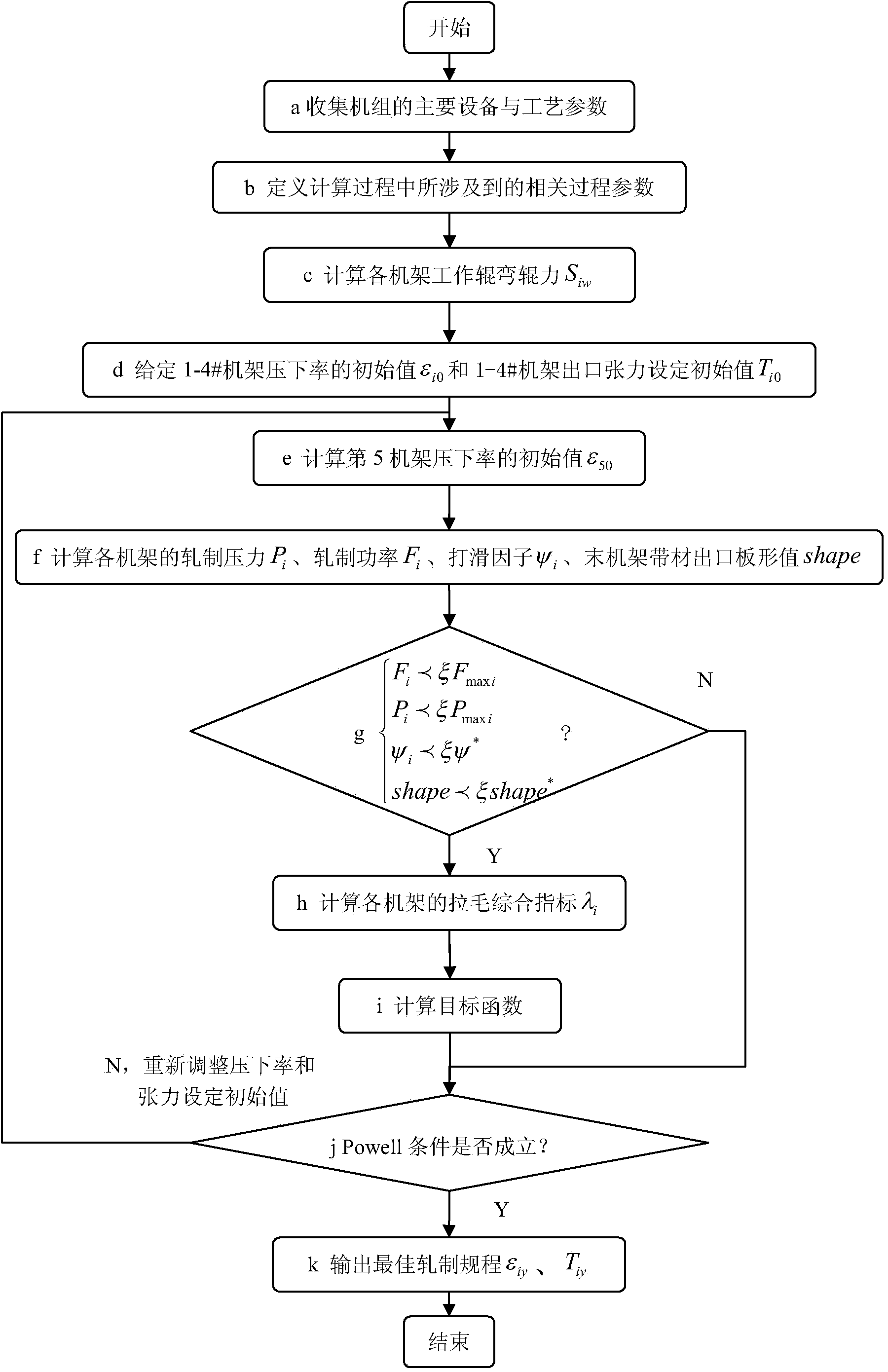

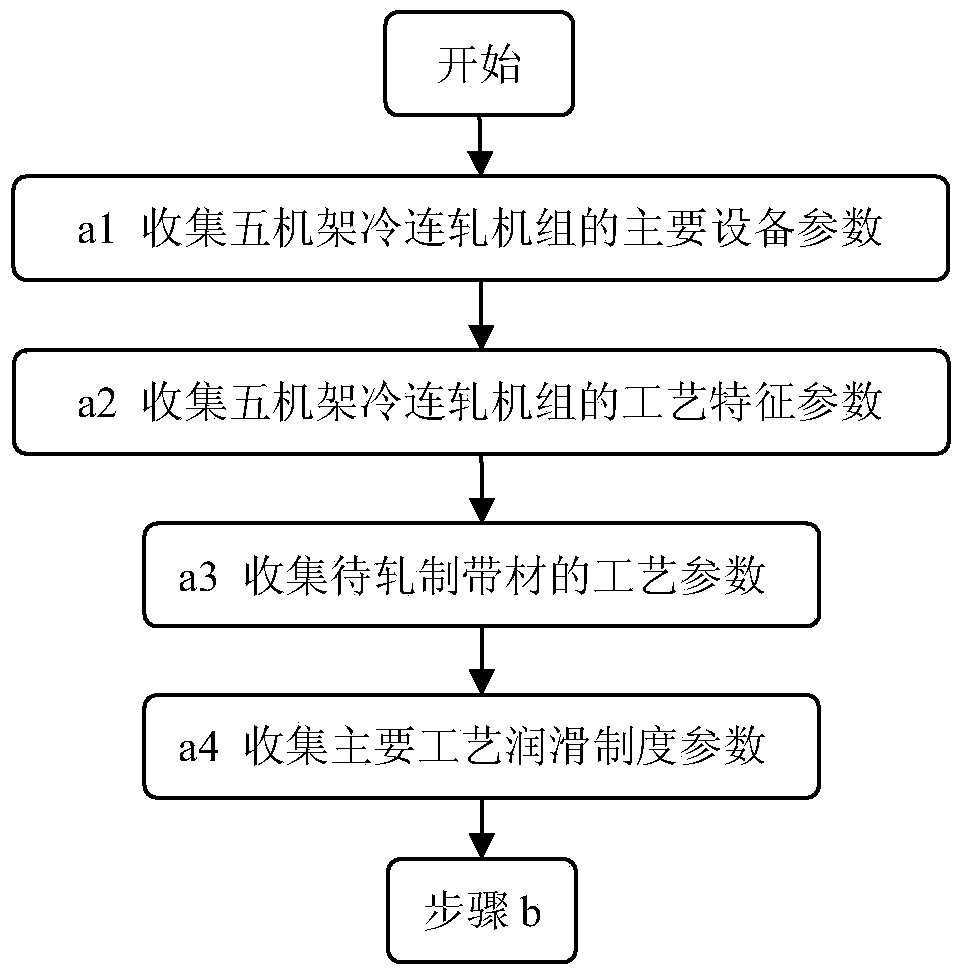

Rolling schedule comprehensive optimization method for cold continuous rolling unit taking scratch prevention as objective

InactiveCN103586286AEvenly distributed relative power headroomEvenly distributedRolling equipment maintainenceMeasuring devicesReduction rateStrip steel

A rolling schedule comprehensive optimization method for a cold continuous rolling unit taking scratch prevention as an objective mainly comprises the following steps that 1, main equipment and technological parameters of the cold continuous rolling unit with five machine frames are collected; 2 procedure parameters involved in a rolling schedule optimization procedure are defined; 3, the ability of the unit to regulate the outlet plate shapes is improved; 4, initial values of reduction rates epsilon<i0> of the first machine frame, the second machine frame, the third machine frame and the fourth machine frame and initial values of outlet tension force T<i0> of the first machine frame, the second machine frame, the third machine frame and the fourth machine frame are given; 5, an initial value of the reduction rate of the fifth machine frame is calculated; 6, rolling pressure, rolling power, slipping factors, and the outlet plate shape value of each machine frame are calculated; 7, the value of a scratch comprehensive judgment index lambada of each machine frame is calculated; 8, an optimized objective function is calculated; 9 the optimal rolling schedule is output; the steps are executed through a computer. By means of the rolling schedule comprehensive optimization method, the scratch comprehensive judgment index of each machine frame can be predicted accurately, the occurrence possibility of scratch defects is reduced to the greatest extent, production efficiency is increased, and outlet surface quality of strip steel is improved.

Owner:山东冠洲股份有限公司

Aluminiferous low-carbon cold heading wire rod steel and production method thereof

The invention relates to a wire rod steel and a production method thereof, aiming at overcoming the defect that at present, spinning has overhigh temperature, so as not to be beneficial to reducing iron scale or adopting overhigh roller speed as well as full phase transition of the steel and growing up of ferrite, thus reducing the properties of drawing and cold heading of steel. The measurement is that the aluminiferous low-carbon cold heading wire rod steel has the chemical components based on the weight percentage: 0.04-0.08% of C, 0.01-0.05% of Si, 0.35-0.55% of Mn, less than or equal to 0.030% of P, less than or equal to 0.035% of S, 0.02-0.06% of Als and the rest of Fe and unavoidable impurity. The technique is that continuously cast bloom is heated up to 950-1040 DEG C with the section temperature being less than or equal to 30 DEG C; the start rolling temperature is 900-1000 DEG C, and the finishing temperature is 950-990 DEG C; after the water is cooled, the spinning is at 880-900 DEG C; when the spinning is cooled to 615-680 DEG C, the cooling velocity is 0.7-1.1DEG / s. The invention ensures the mechanical property, microscopic constitution, surface quality and cold heading property to reach the requirements of the user.

Owner:武钢集团有限公司

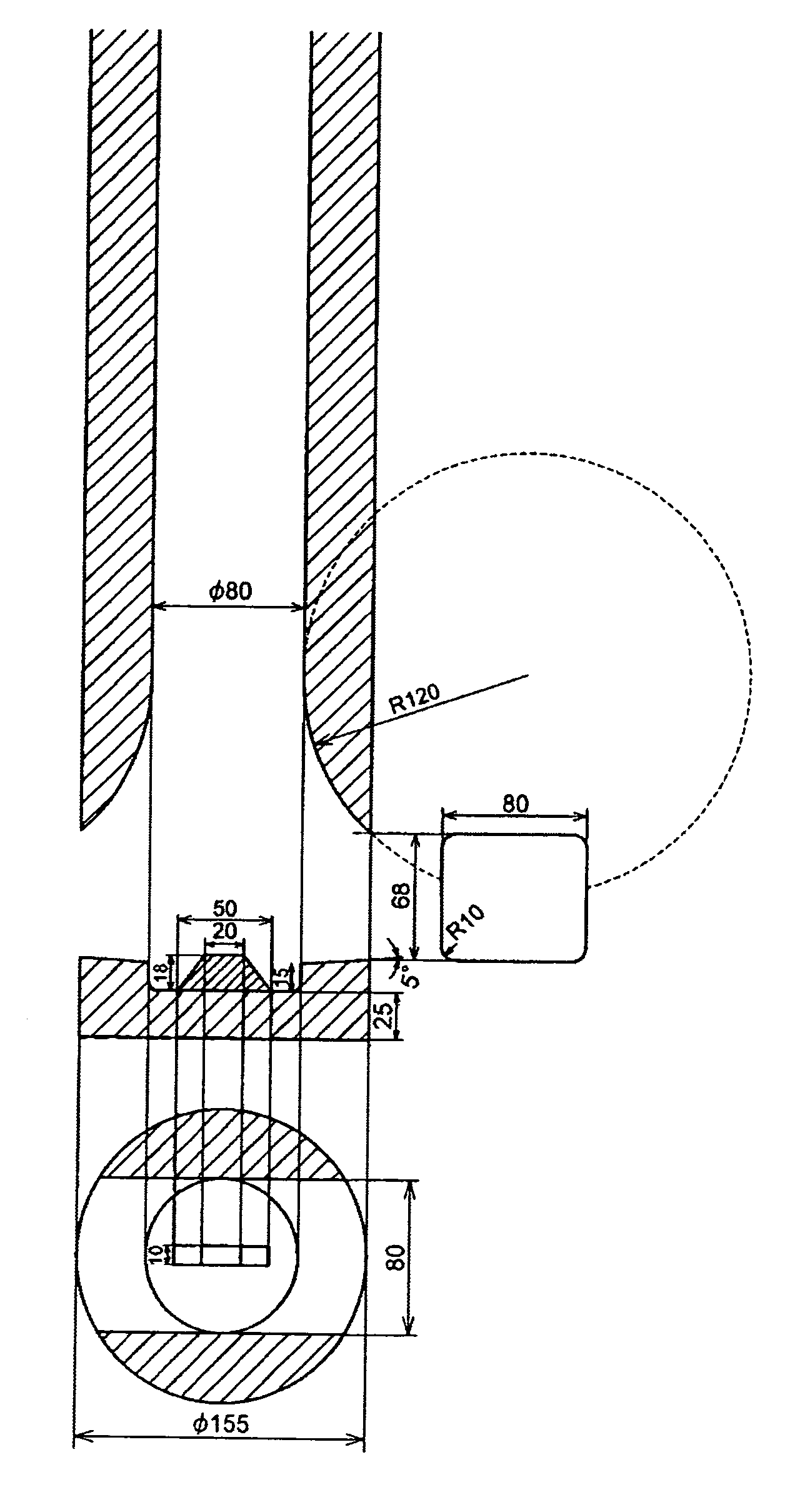

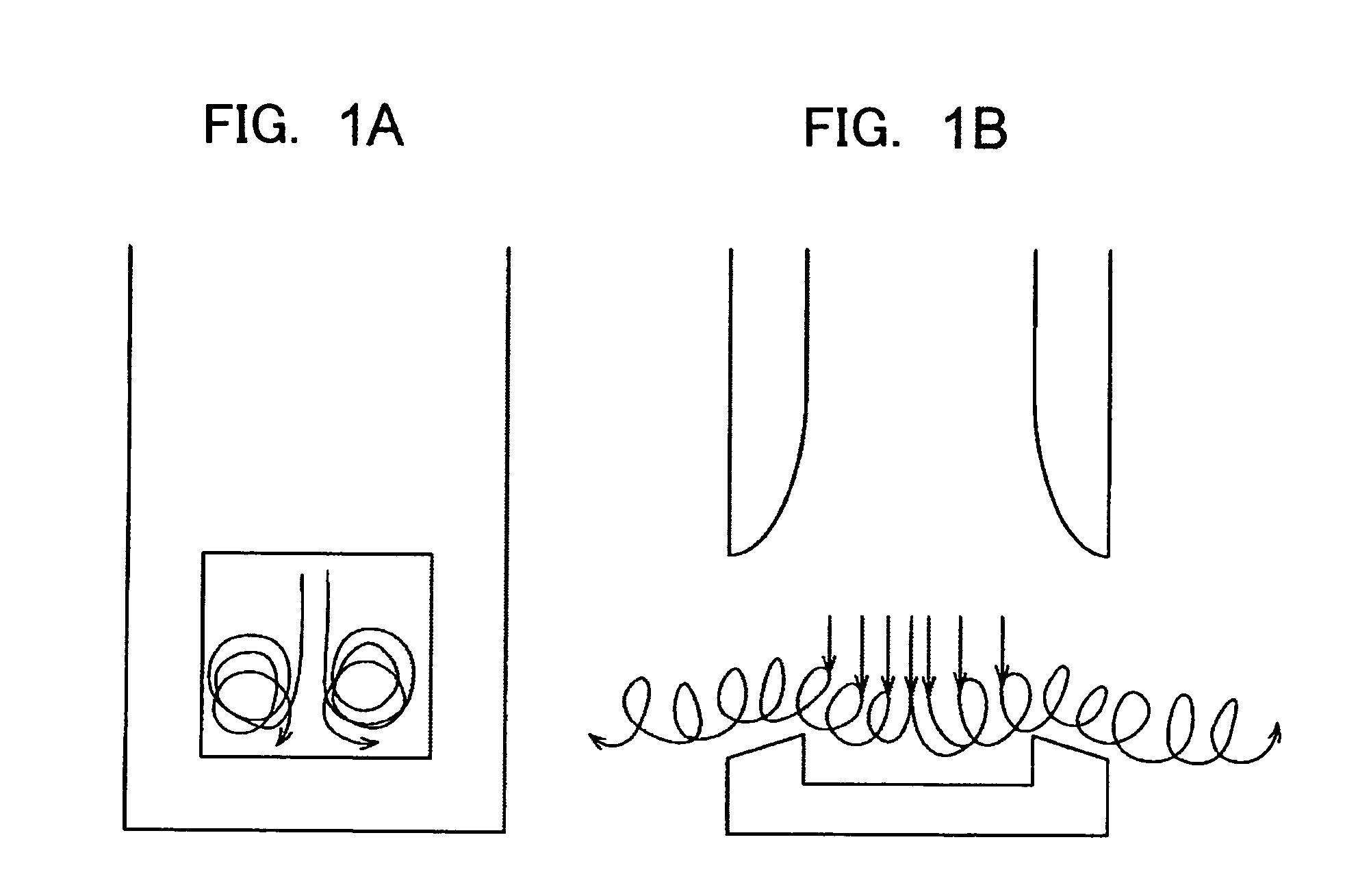

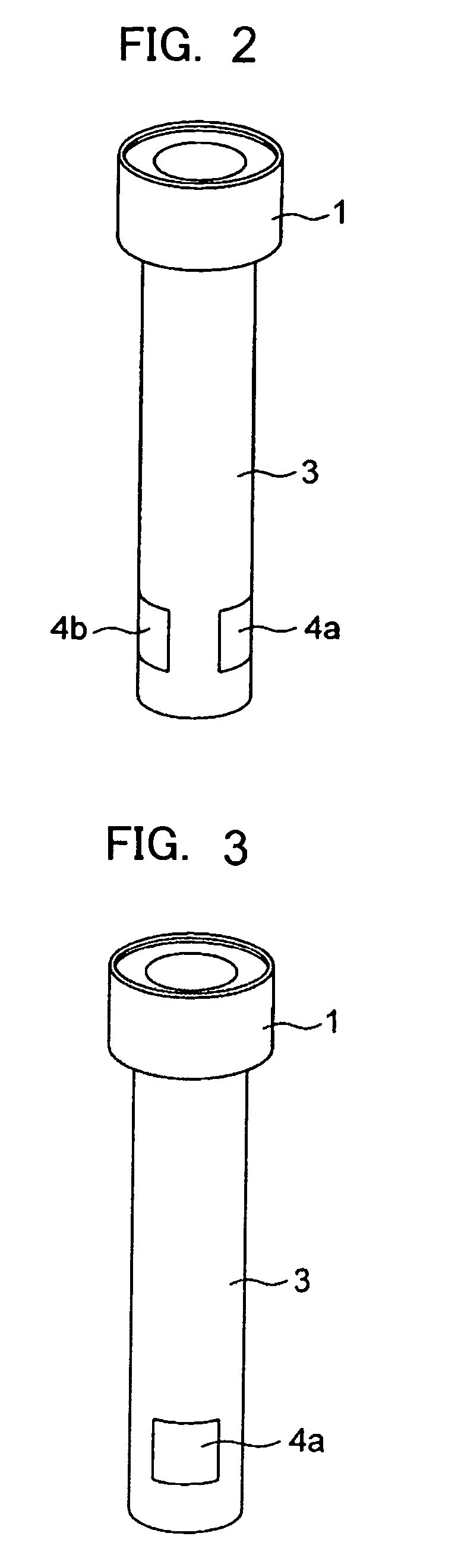

Immersion nozzle for continuous casting and continuous casting method using the immersion nozzle

InactiveUS20070158884A1Stable slab qualityImprove efficiencyMelt-holding vesselsManufacturing convertersMaximum depthSelf excited oscillation

An immersion nozzle for continuous casting which enables improvement in quality of a slab surface and increase in the efficiency of casting by suppressing the self-excited oscillation of a flow in a mold without using a complicated mechanism such as a swirl flow generating immersion nozzle is to be provided. A first immersion nozzle for continuous casting is a nozzle comprising a cylindrical body and a pair of outlet ports formed to face each other in a side wall in the vicinity of a bottom part of the cylindrical body, wherein a ridge-shaped projection extending parallel with the discharge direction projected on a cross section of the nozzle is formed on an inner surface of the bottom part, which is formed in a waterfall basin-like recessed shape having a maximum depth of 5 mm to 50 mm. A second immersion nozzle for continuous casting is a nozzle comprising a cylindrical body and a pair of outlet ports formed to face each other in a side wall in the vicinity of a bottom part of the cylindrical body, wherein each sectional area of the outlet ports vertical to a discharge direction projected on a cross section or longitudinal section of the nozzle is decreased toward an exit.

Owner:SUMITOMO METAL IND LTD

Alloy plate strip for hand phone battery case and manufacturing method thereof

InactiveCN101037742AImprove surface qualityHigh thickness accuracyTemperature control deviceRollsPunchingElectrical battery

Alloy plate trip for the battery case of mobil telephone and its preparation method is disclosed, in order to solve the problem that the alloy plate trip for the existing battery case of mobil telephone has poor stamping properties and the quality defect of the alloy is easy to be caused because of the complex arts. The alloy plate trip for the battery case of mobil telephone of the invention comprises Mn, which is 1.10-1.30 wt.% of overall composition, and Mg, which is 0.02-0.05 wt.% of overall composition. The method for preparing the alloy plate trip for the battery case of mobil telephone of the invention includes the steps of: smelting, casting, uniformizating, face milling, hot rolling, cold rolling and final finishing. The alloy plate trip for the battery case of mobil telephone of the invention has good-quality surface, high-precision thickness and good stamping properties, and all kinds of properties of the plate trip is steady with high intensity and higher plasticity and good deep punching moldability, and the quality defect of the alloy can be reduced effectively in case that the preparation method is simpler than traditional method.

Owner:NORTHEAST LIGHT ALLOY CO LTD

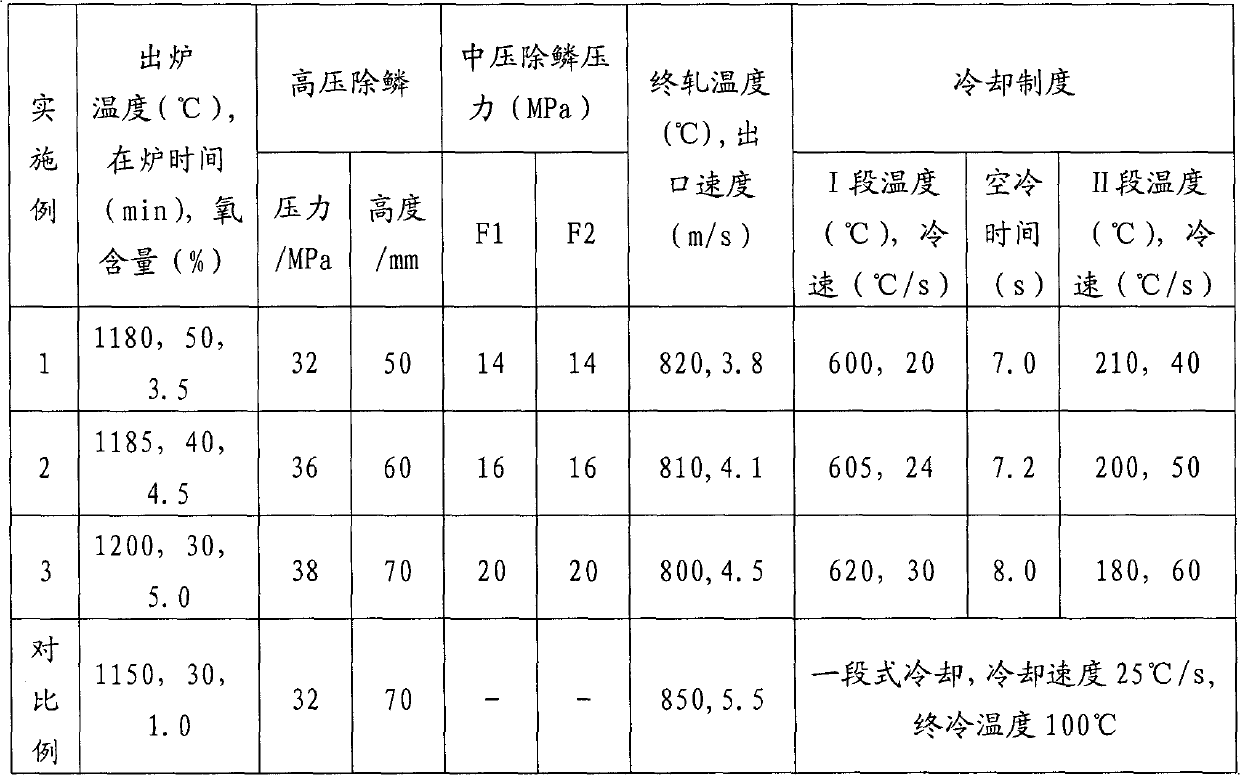

CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality

ActiveCN101906571AImprove performanceStable controlTemperature control deviceWork treatment devicesHigh surfaceHigh pressure water

The invention relates to a CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality, which solves the problems that the existing economical hot-rolled dual-phase steel has serious surface iron scales and instable structure property control. The technical scheme comprises molten iron desulfurization, converter blowing, argon blowing, refining, continuous casting, soaking, finish rolling, cooling and coiling. The steel comprises the following chemical components in percentage by weight: 0.03 to 0.065 percent of C, 0.45 to 0.55 percent of Si, 1.20 to 1.55 percent of Mn, less than or equal to 0.012 percent of S, less than or equal to 0.020 percent of P, 0.015 to 0.060 percent of Als, and the balance of Fe and inevitable impurities. In the manufacturing method, the plate blank tapping temperature of a soaking furnace is controlled to be between 1,180 and 1,200 DEG C in the soaking step, the oxygen content volume percent in the furnace is 3.5 to 5.0 percent, the time inside the furnace is 30 to 50 minutes, and the plate blank after soaking is subjected to high-pressure water descaling and then is subjected to the finish rolling. The dual-phase steel produced by the manufacturing method has stable structure property control, no obvious iron scales on the surface, and excellent performance indexes.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com