Immersion nozzle for continuous casting and continuous casting method using the immersion nozzle

a technology of immersion nozzle and continuous casting, which is applied in the direction of melt-holding vessels, manufacturing tools, manufacturing converters, etc., can solve the problems of high troublesome quality, and noticeable problems, and achieve the effect of reducing the design cost of electromagnetic force method, and stably discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0063] Hereinafter, the effect of the present invention will be explained with comparison between Examples and Comparative examples of the present invention.

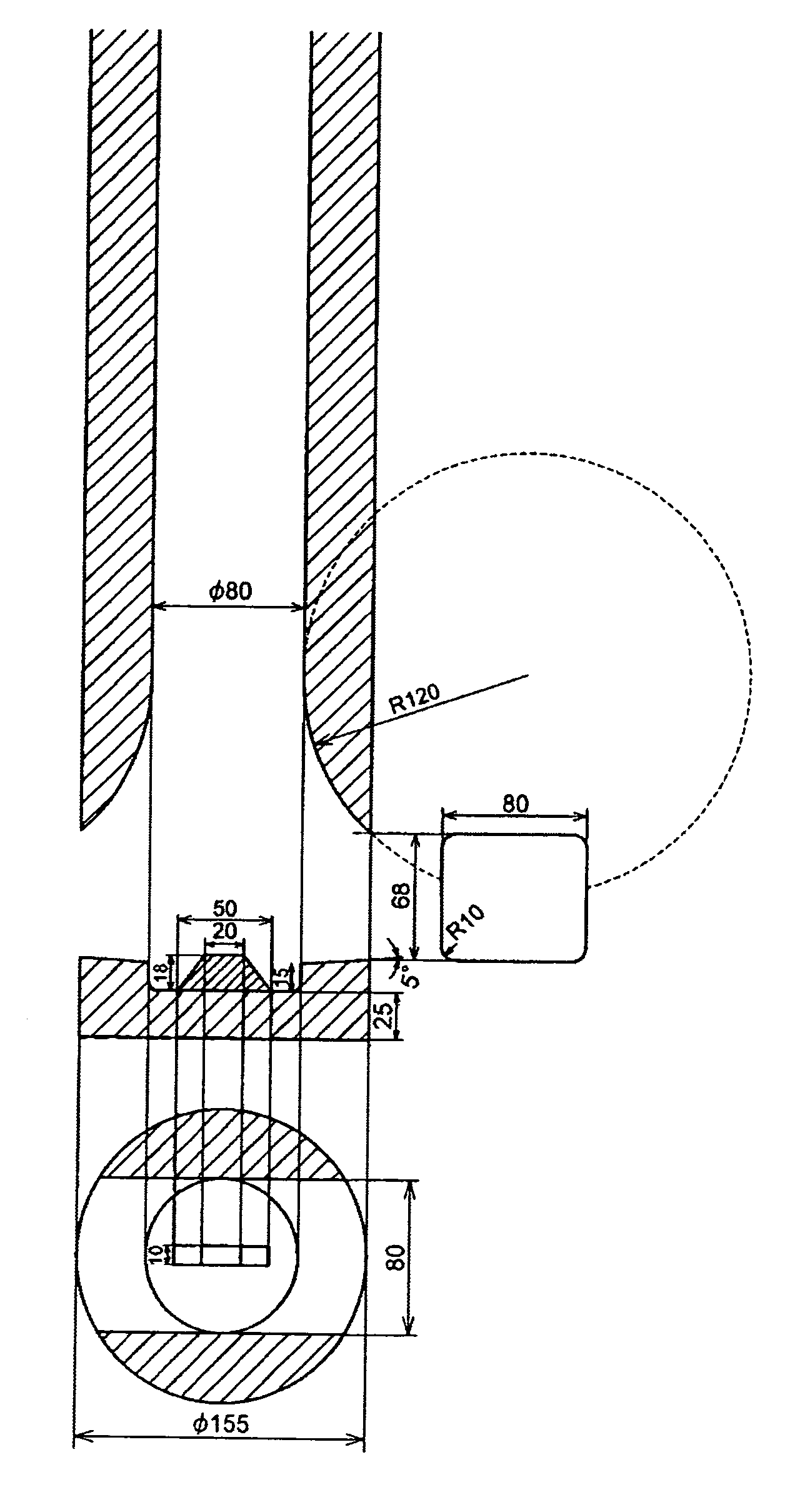

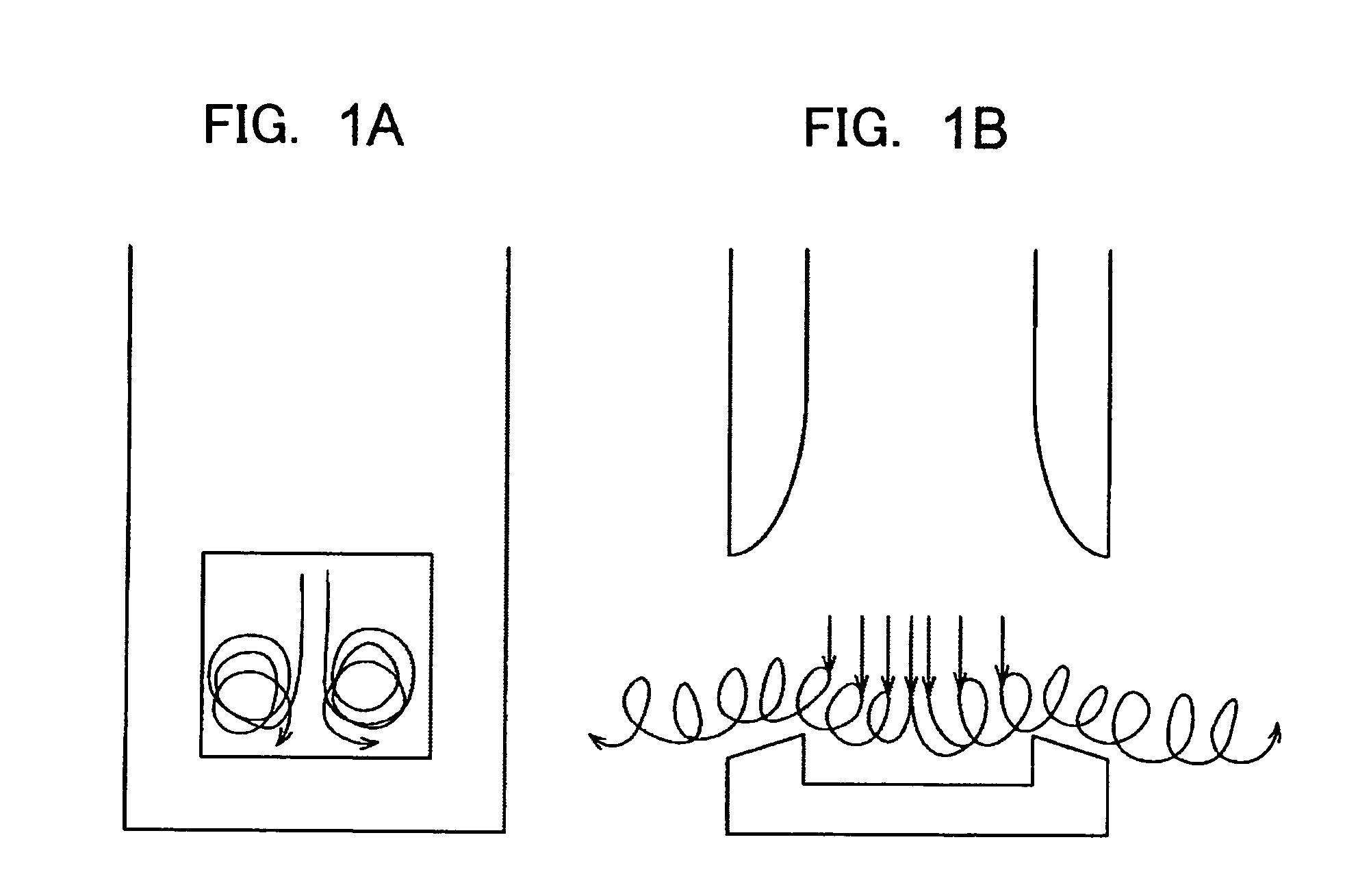

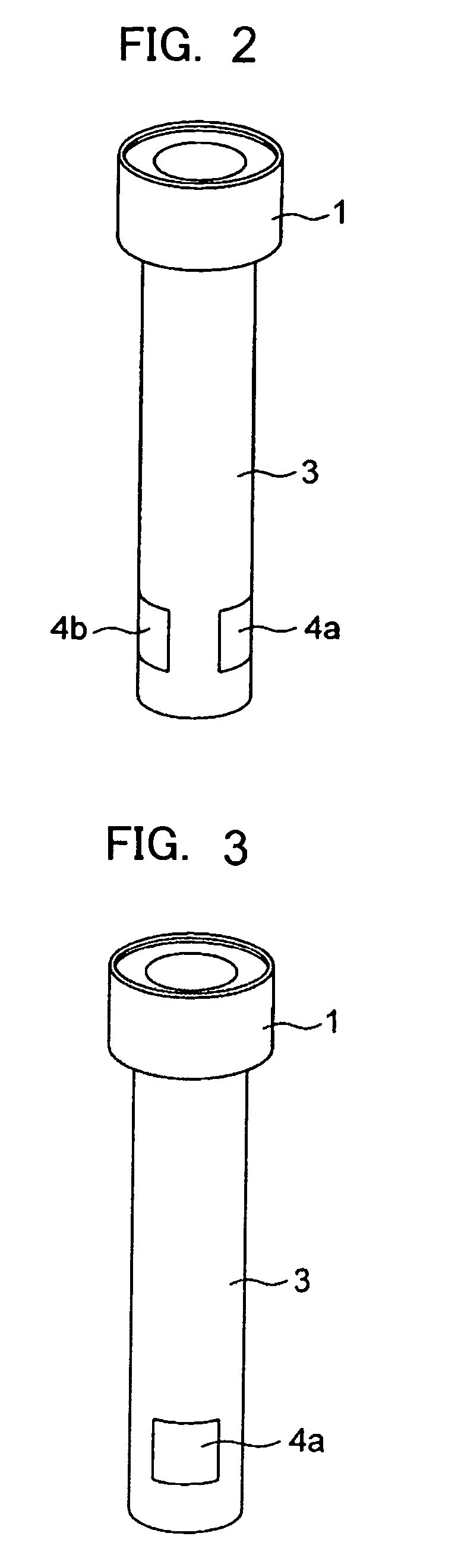

[0064] Immersion nozzles for continuous casting comprising a cylindrical body and a pair of outlet ports formed to face each other in a side wall in the vicinity of a bottom part of the cylindrical body used in Examples 1 to 6 and Comparative examples 7 to 9 are shown in Table 1.

TABLE 1Example12345Inner surface form at bottam part of nozzleWaterfallFlat formWaterfallWaterfallWaterfallbasin-basin-basin-basin-like formlike formlike formlike formMaximum depth of waterfall basin-like150151515recess (mm)Plain form of waterfall basin-like recessEllipse—RoundEllipseEllipse80 × 90φ80 (mm)90 × 110 (mm)90 × 110 (mm)(mm)Maximum height of ridge-shaped projection150 (No18815at bottom part (mm)projection)Side form of ridge-shaped projection atBase: 90 mm—Base: 50 mmBase: 110 mmBase: 110 mmbottam partIsoscelesUpper base:Height: 8 mmIsoscele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com