Precise machining method for capillary tube for biodegradable magnesium alloy intravascular stent

A magnesium alloy blood vessel and precision machining technology, which is applied in the field of precision machining of capillary tubes for degradable magnesium alloy stents, can solve the problems of poor plasticity at room temperature of magnesium alloys and processing and production, and achieve excellent mechanical properties, high processing efficiency, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

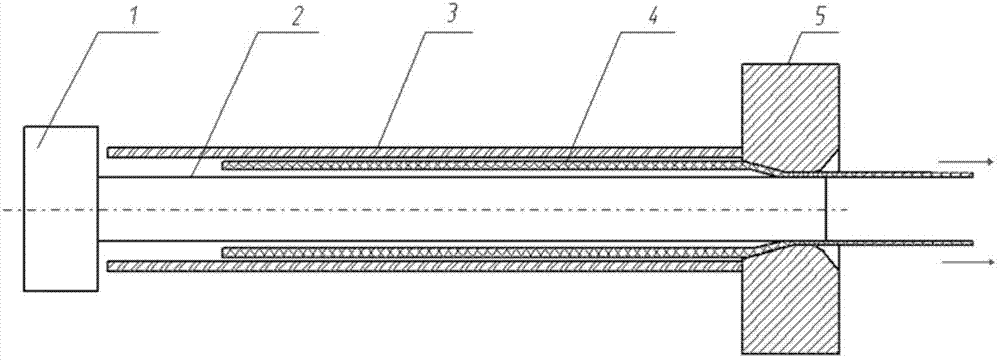

Image

Examples

Embodiment 1

[0028] This embodiment relates to a precision machining method for a capillary for a biodegradable magnesium alloy intravascular stent, the method comprising the following steps:

[0029] Step 1: Under the condition of argon gas atmosphere in a tube vacuum furnace at a temperature of 250-450°C, the extruded Mg-Nd-Zn-Zr magnesium alloy rod is subjected to stress-relief annealing for 30-90 minutes to obtain a φ20×6.5mm the tube blank;

[0030] Step 2: Spray lubricant on the inner and outer walls of the mold and the billet, and extrude the billet into a seamless extruded pipe of φ9×1.0mm at a temperature of 300-450°C and a speed of 1-10mm / s The average grain size is measured to be about 10 μm, then washed with ethanol, dried or blown dry, and subjected to stress relief annealing at 250-450°C for 30-90 minutes;

[0031] Step 3, the annealed seamless extruded tube billet is rolled in multiple passes with a three-roll cold rolling mill, the deformation of each pass is 5-15%, and 25...

Embodiment 2

[0035] This embodiment relates to a precision machining method for a capillary for a biodegradable magnesium alloy intravascular stent, the method comprising the following steps:

[0036] Step 1: Under the condition of argon gas atmosphere in a tube vacuum furnace at a temperature of 250-450°C, the extruded Mg-Nd-Zn-Zr magnesium alloy rod is subjected to stress-relief annealing for 30-90 minutes to obtain a φ20×6.5mm the tube blank;

[0037] Step 2: Spray lubricant on the inner and outer walls of the mold and the tube blank, and extrude the tube blank into a seamless extruded tube of φ8×0.6mm at a temperature of 300-450°C and a speed of 1-10mm / s The average grain size is measured to be about 6 μm, then washed with ethanol, dried or blown dry, and subjected to stress relief annealing at 250-450°C for 30-90 minutes;

[0038] Step 3, the annealed seamless extruded tube billet is rolled in multiple passes with a three-roll cold rolling mill, the deformation of each pass is 5-15%,...

Embodiment 3

[0042] This embodiment relates to a precision machining method for a capillary for a biodegradable magnesium alloy intravascular stent, the method comprising the following steps:

[0043] Step 1: Under the condition of argon gas atmosphere in a tube vacuum furnace at a temperature of 250-450°C, the extruded Mg-Nd-Zn-Zr magnesium alloy rod is subjected to stress relief annealing for 30-90 minutes to obtain a φ20×6.5mm the tube blank;

[0044]Step 2: Spray lubricant on the inner and outer walls of the mold and the billet, and extrude the billet into a seamless extruded pipe of φ7×0.5mm at a temperature of 300-450°C and a speed of 1-10mm / s The average grain size is measured to be about 5 μm, then washed with ethanol, dried or blown dry, and subjected to stress relief annealing at 250-450°C for 30-90 minutes;

[0045] Step 3, the annealed seamless extruded tube billet is rolled in multiple passes with a three-roll cold rolling mill, the deformation of each pass is 5-15%, and 250-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com