Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Increase hardening rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

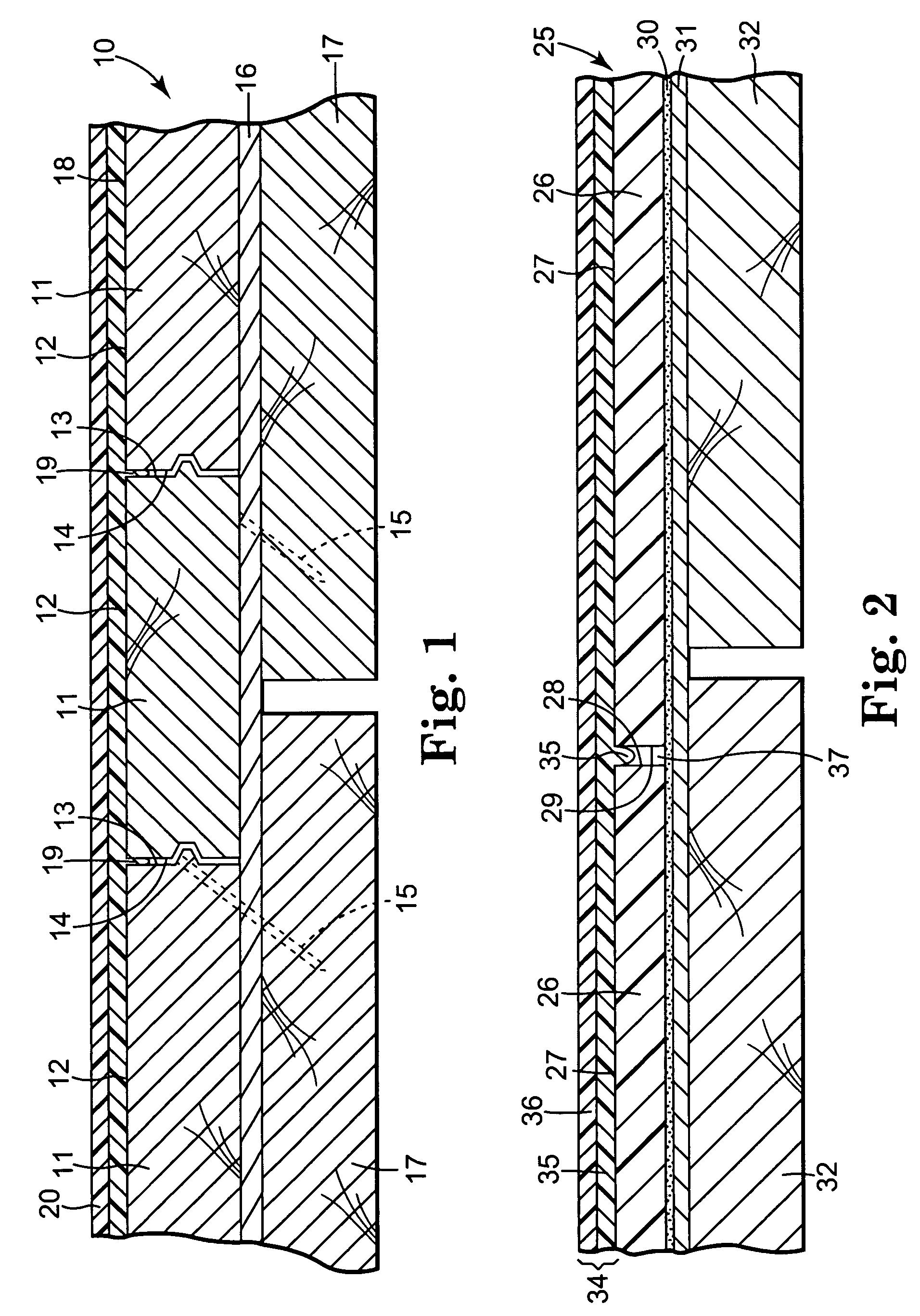

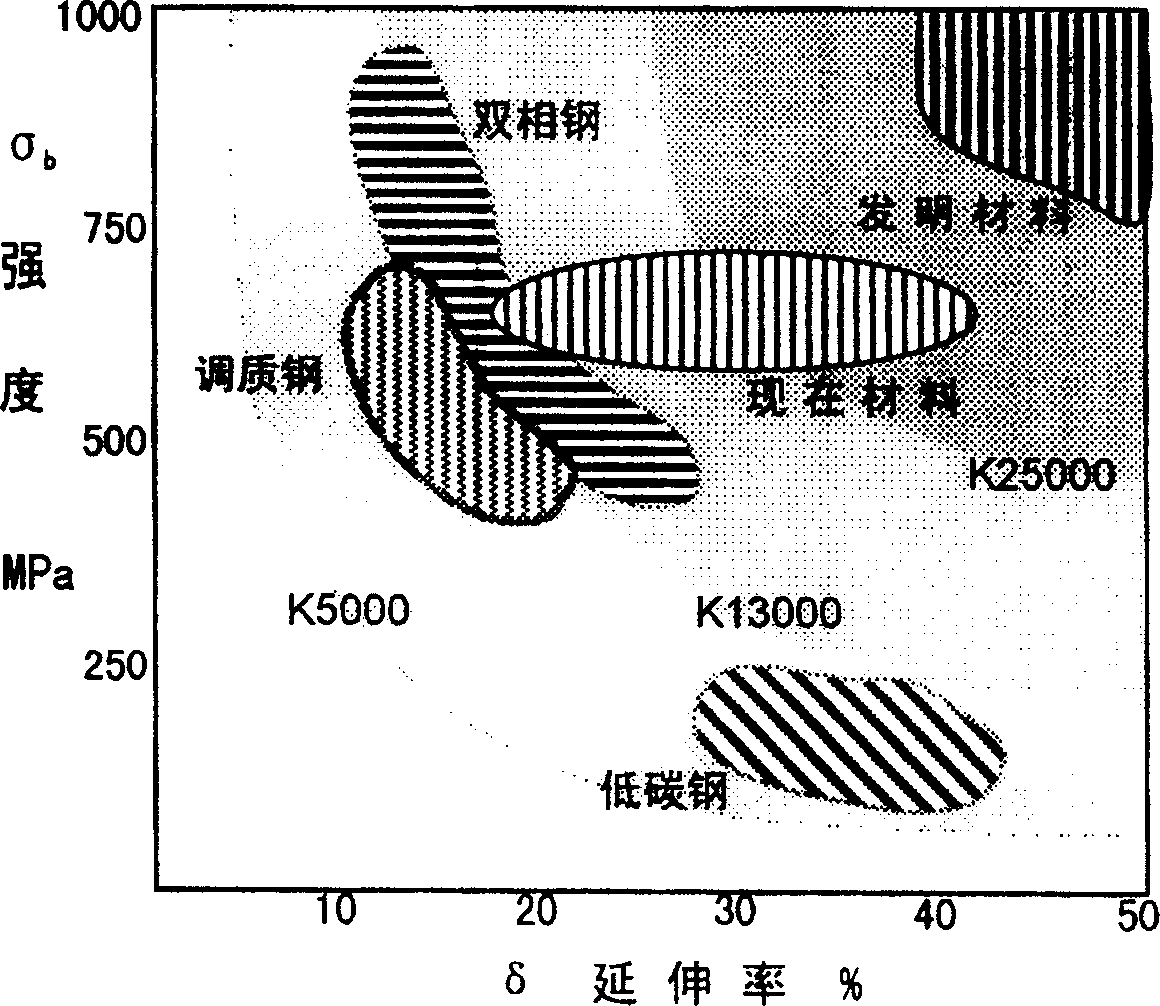

Expanding metal material and bulged tube device for petroleum oil well

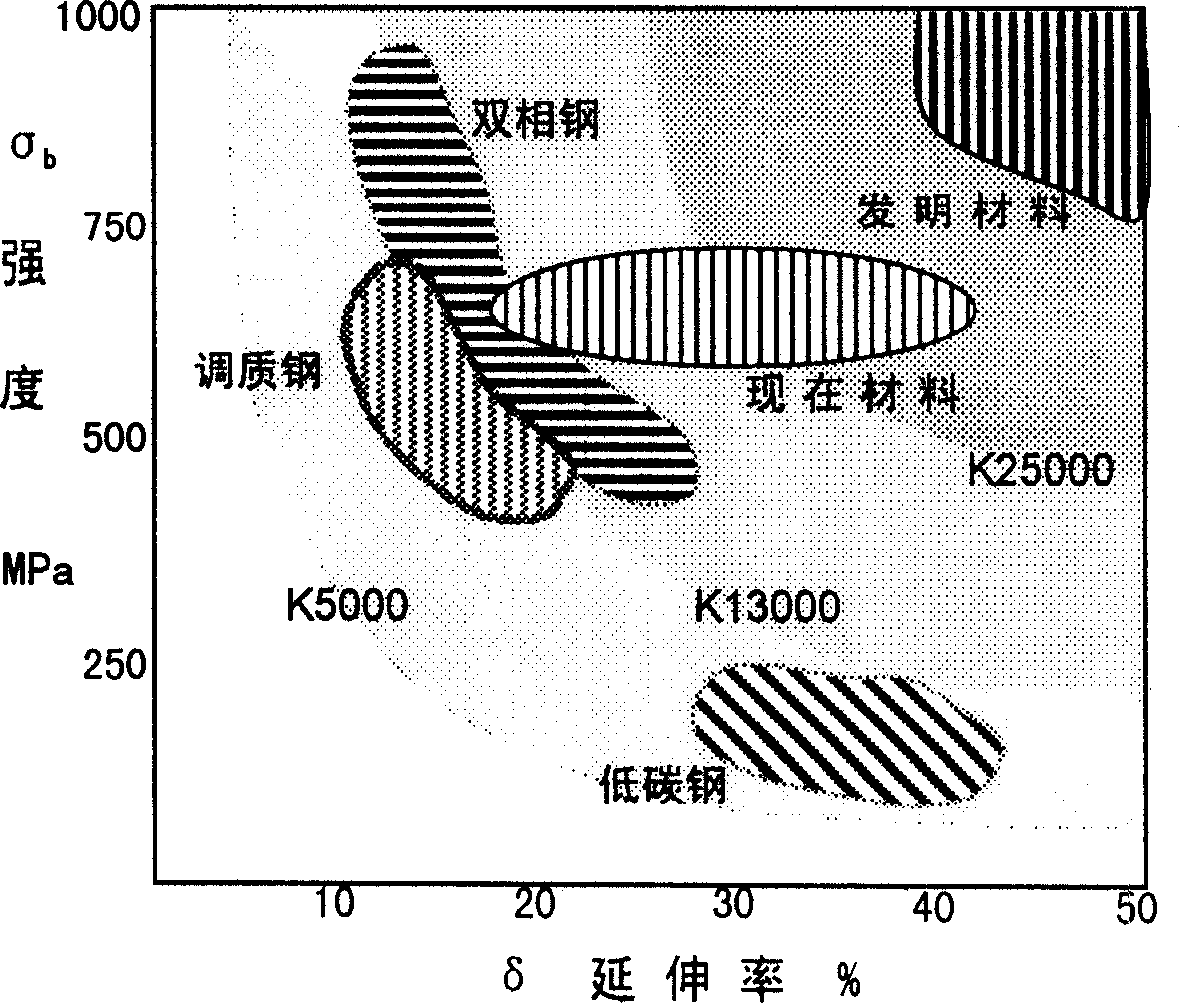

ActiveCN1594631AImprove strong plasticitySmooth expansion deformationFluid removalPipe elementsInternal pressureWell drilling

The invention relates to an expanding metal material and expansion tube device for oil well. Expanding metal material consists of :C:0.03-0.5; Si:0-6.0; Mn:0-15; Cr:0-20; Ni:0-20; N:0.02-0.08; P<=0.03; S<=0.03; mixed rare earth:0.1; Ti:0-0.8; Zr:0-1.47; surplus Fe in which carbide gross of TiC and ZrC is 0.1-1.5%. Plasticity K=sigma*delta, amount to 3800MPa%,expansion tube shape memory connector can keep good sealing state after enlarging the diameter, and internal pressure resistance of expansion tube is close to 50Mpa. Warhead piston , centralizer and hydraulic anchor fixing machine all have a simple structure, operate stably, be used easily. The invention has significance in well drilling, well completion and mending well segment, so does other duct mending.

Owner:SHANGHAI GLOBE PETRO EQUIP

Coated low-nitrogen sand and its prepn

ActiveCN101088659AReduce usageReduce nitrogen contentFoundry mouldsFoundry coresLow nitrogenTetramine

The present invention discloses one kind of coated low-nitrogen sand and its preparation process. The coated low-nitrogen sand consists of phenolic resin 1.5-4.0 wt% of the material, hexamethylene tetramine in 0-6 wt% of the phenolic resin, lubricant in 3-7 wt% of the phenolic resin, and raw sand for the rest. It has greatly lowered hexamethylene tetramine consumption, low nitrogen content and capacity of ensuring the surface quality of the casting. During its heated formation, the thermosetting phenolic resin can speed the curing, raise the hardening rate and raising the hot strength of the sand mold.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

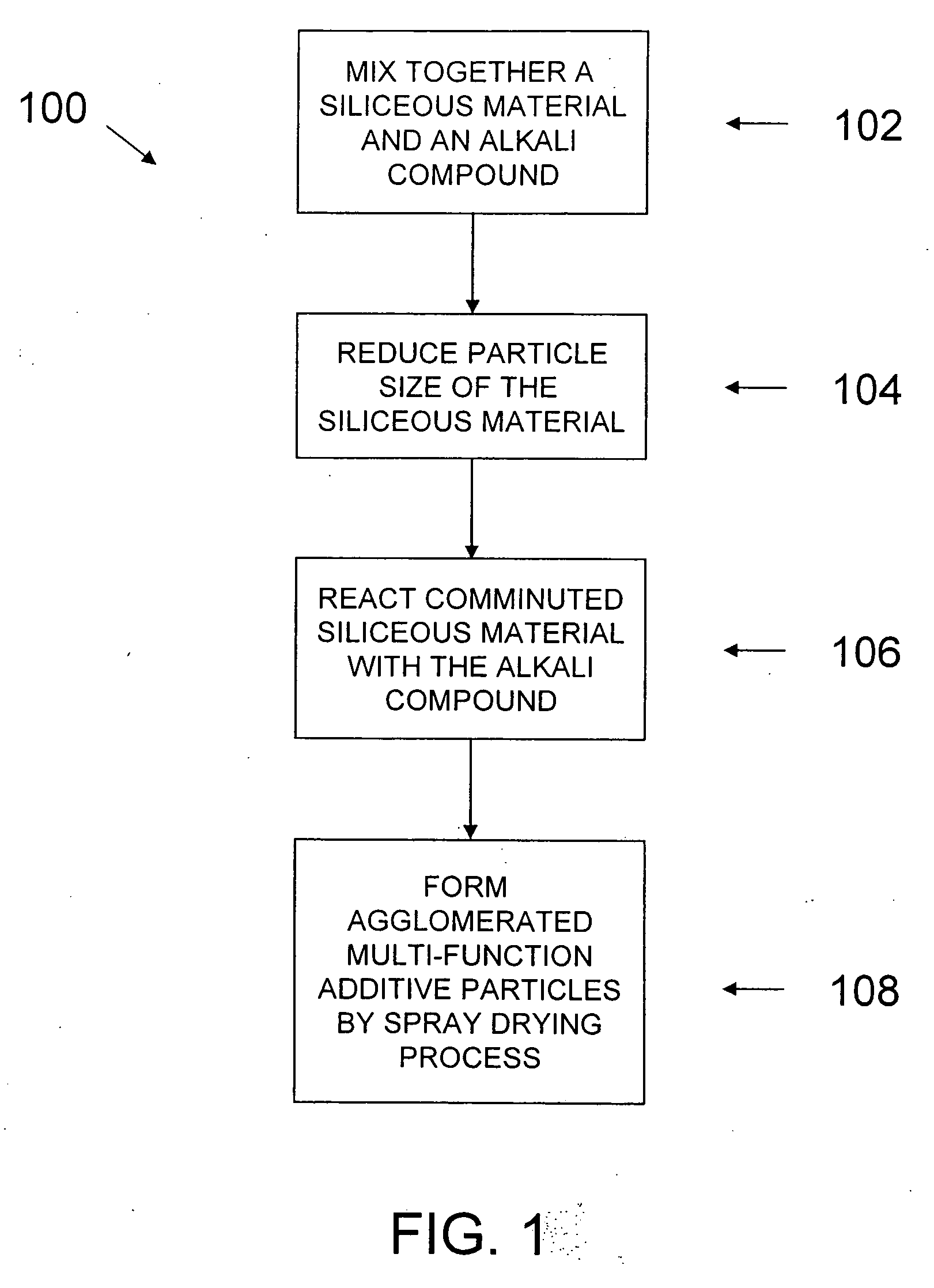

Multi-function composition for settable composite materials and methods of making the composition

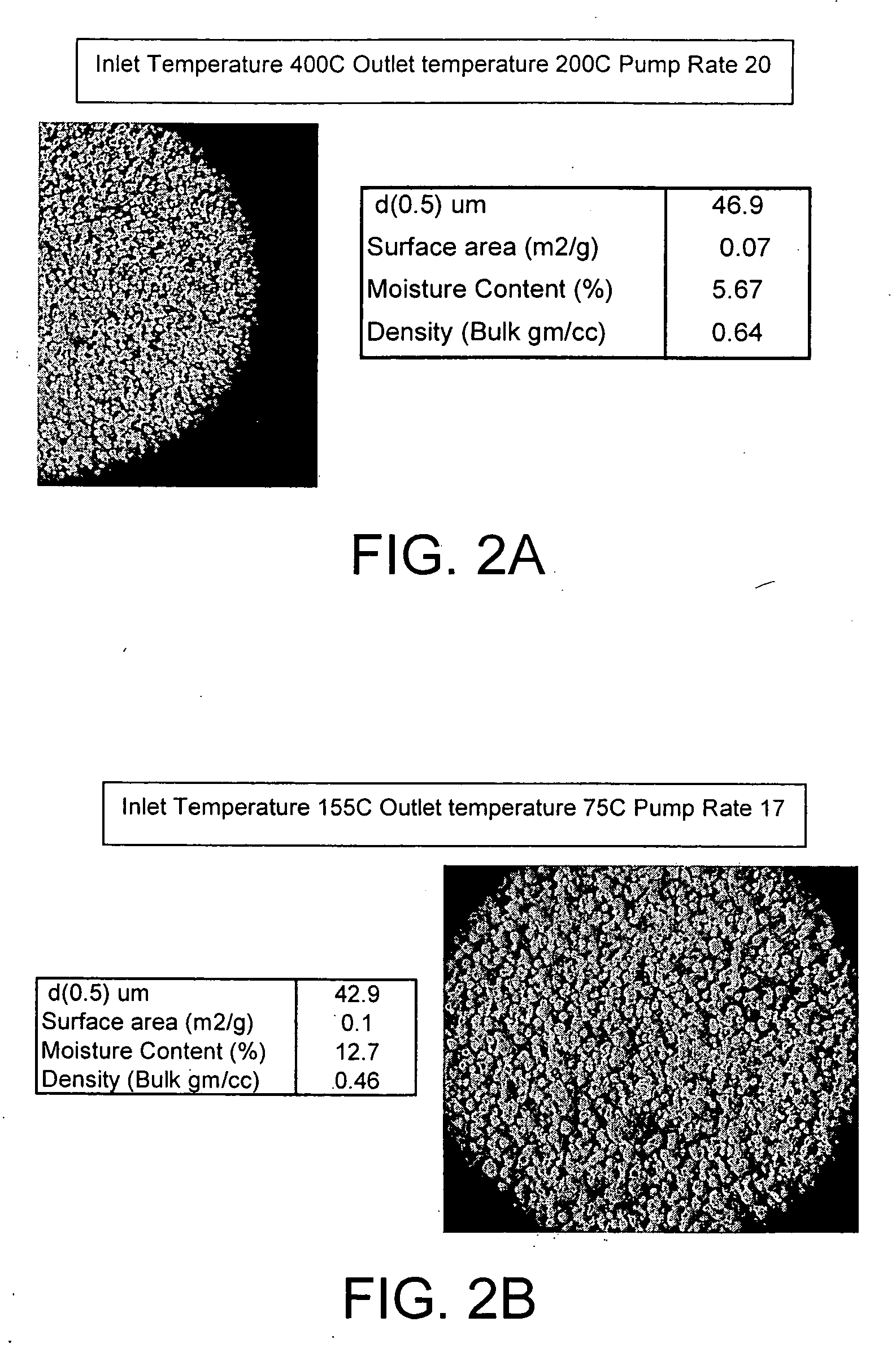

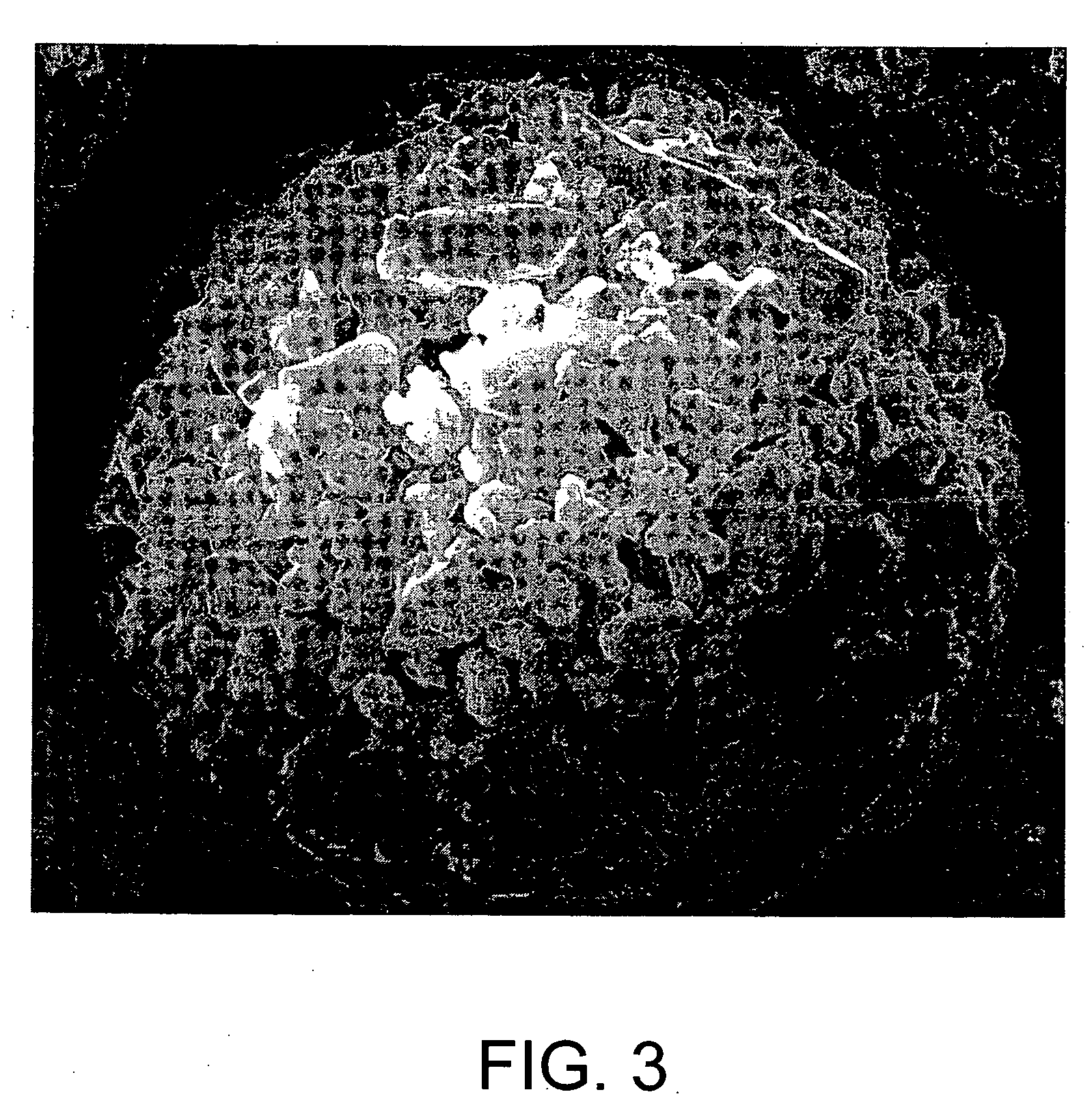

InactiveUS20070131145A1Acceleration in and hardeningSmall particle sizeAlkali metal silicate coatingsInorganic adhesivesAlkaline activationSlurry

A multi-function composition for incorporation into settable composite materials is provided. The composition is formulated as an additive to modify the density of the composite material and increase the rate of hardening or strength development of the material. The composition of the additive generally includes an alkaline activation compound such as sodium silicate and a modified low density siliceous material having at least one region morphologically altered by a chemical, such as a partially digested region. The additive can be in slurry form, in powder form, or in an agglomerated particle form. The additive can be produced using a two-stage process in which a siliceous material is reduced in particle size, combined with an alkali compound in a solution and then digested in an atmospheric or pressurized vessel. In some implementations, the solution can be spray dried to form agglomerated particles containing the alkaline activation compound and the low density siliceous particle having one or more partially digested regions.

Owner:JAMES HARDIE INT FINANCE BV

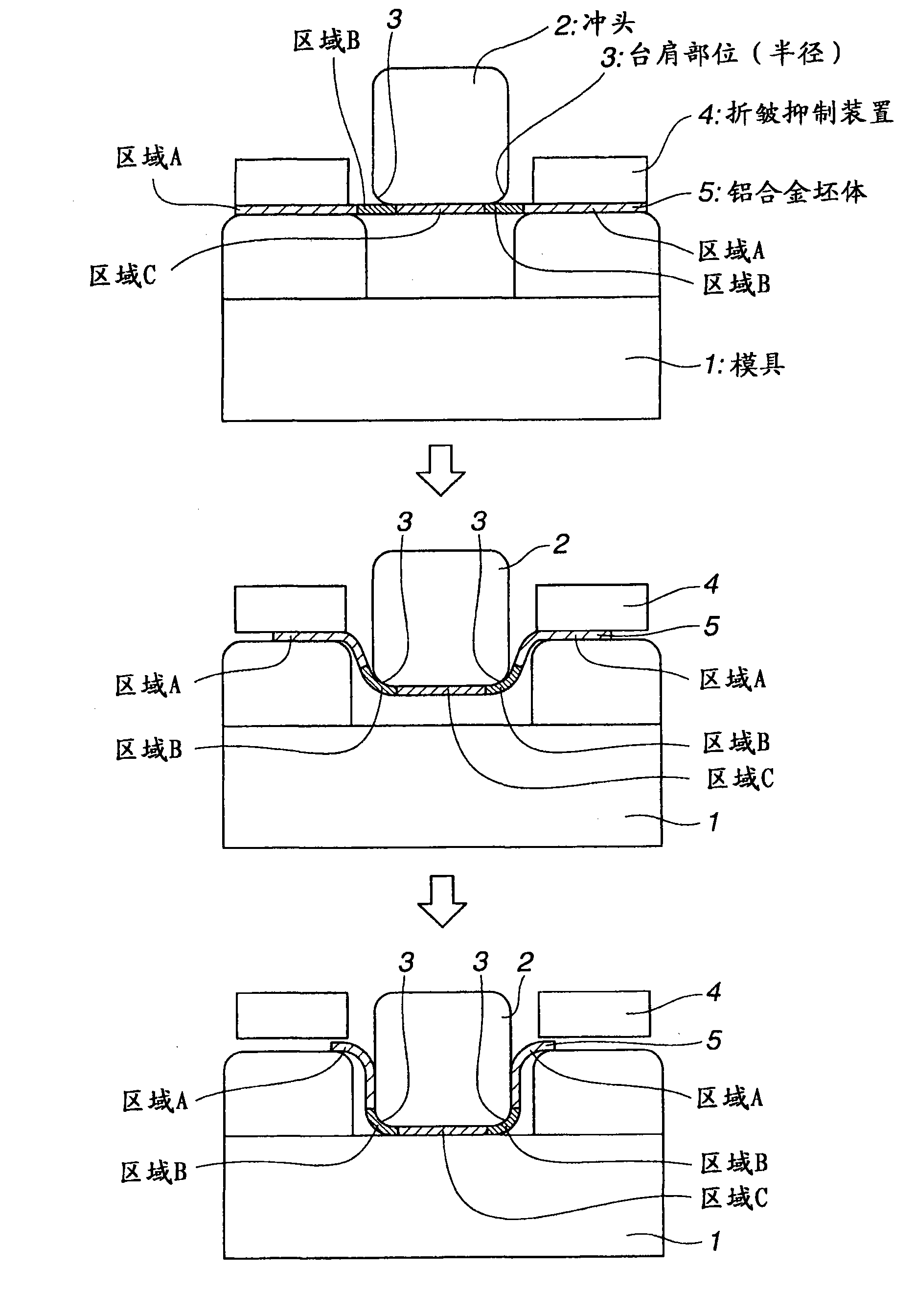

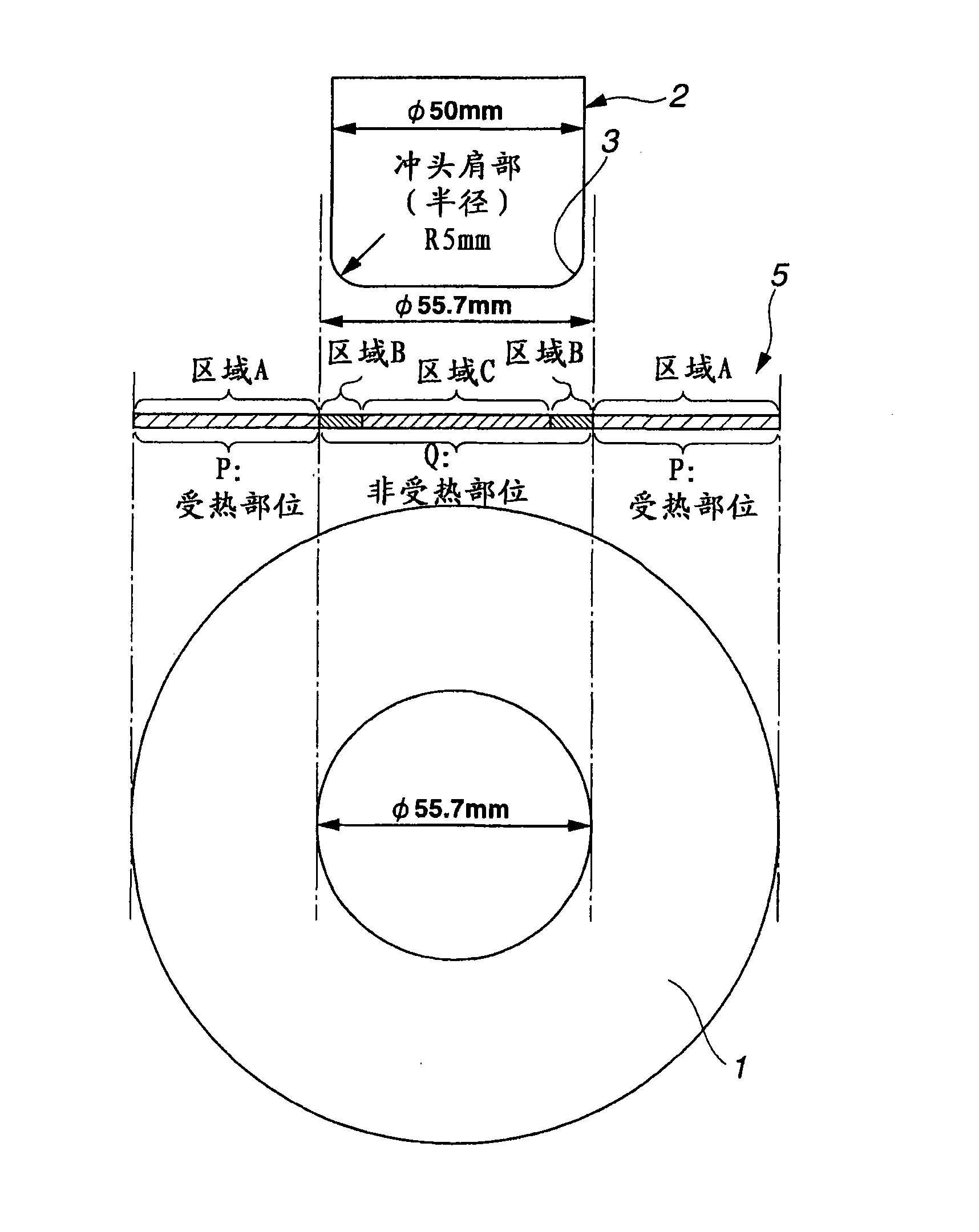

Aluminum alloy sheet for cold press forming, method of manufacturing the same, and cold press forming method for aluminum alloy sheet

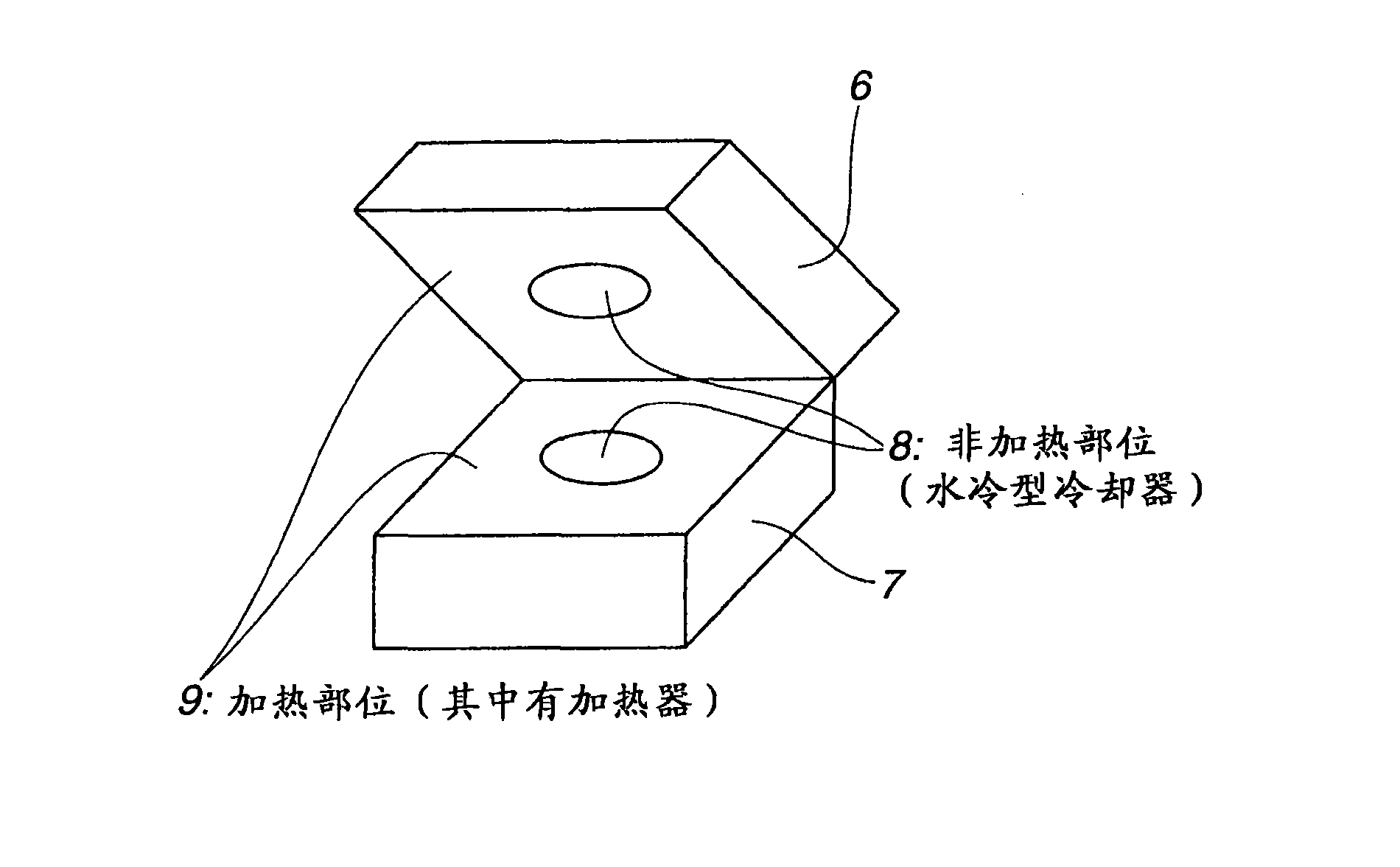

An Al-Mg-Si based aluminum alloy sheet having undergone normal-temperature aging (or being in an underage state) after a solution treatment thereof is, before press forming, subjected to a heating treatment (partial reversion heating treatment) in which the alloy sheet is partially heated to a temperature in the range of 150 to 350 DEG C for a time of not more than 5 minutes so that the difference in strength (difference in 0.2% proof stress) between the heated part and the non-heated part will be not less than 10 MPa. The alloy sheet thus treated is subjected to cold press forming in the condition where the heated part with low strength is put in contact with a wrinkle holding-down appliance of the press and the non-heated part with high strength is put in contact with the shoulder part (radius) of the punch. In the partial reversion heating treatment, the temperature rise rate and the cooling rate in cooling down to 100 DEG C or below are set to be not less than 30 DEG C / min. Further, the period for which the alloy sheet is left to stand at normal temperature after the partial reversion heating treatment until the cold press forming is set to be within 30 days.

Owner:FURUKAWA SKY ALUMINUM CORP

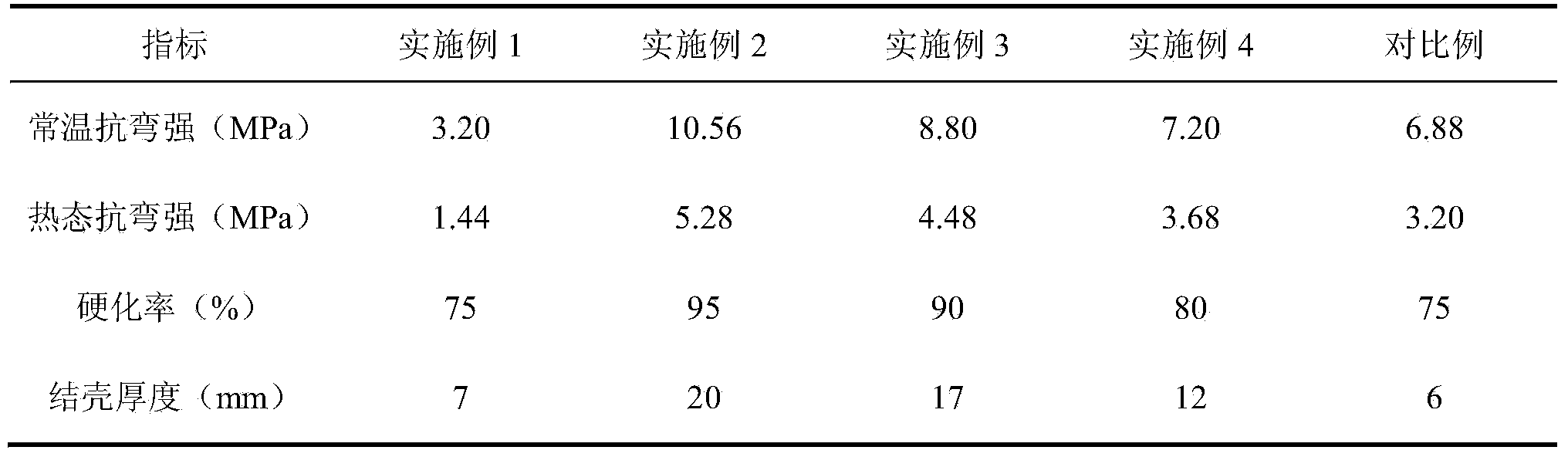

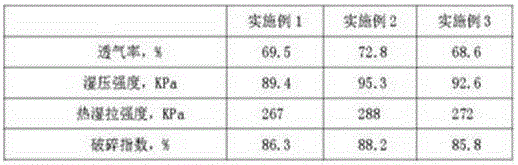

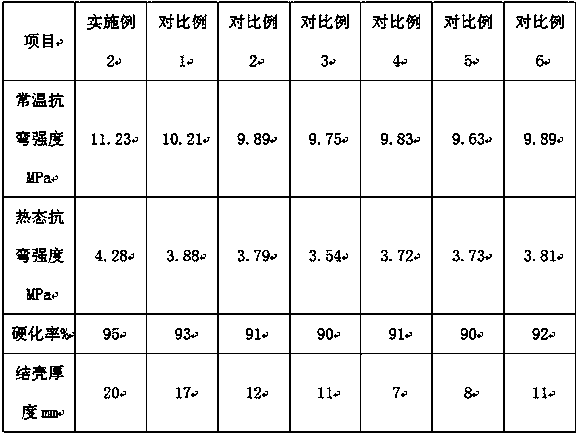

Shelling resistant pre-coated sand and preparation method thereof

ActiveCN104014718AFast curing rateIncrease hardening rateFoundry mouldsFoundry coresFirming agentUltimate tensile strength

The invention discloses shelling resistant pre-coated sand and a preparation method thereof. The shelling resistant pre-coated sand is characterized by comprising raw sand, a bonding agent the weight of which is 1-4% that of the raw sand, a curing agent the weight of which is 1-15% that of the bonding agent, 0.1-0.5% of coupling agent and 0.1-1.0% of additive. By adding the additive, the curing speed of the curing agent to the bonding agent is increased, the hardening rate of the pre-coated sand is improved and the shelling tendency is reduced; by optimizing the content of each component, the overall strength of the pre-coated sand is improved, the gas evolution amount of the pre-coated sand is greatly reduced and the defect of core piercing is alleviated; the shelling resistant pre-coated sand has strong shell resistance, is high in strength and low in gas evolution amount, is capable of remarkably alleviating or eliminating defects such as shelling and core piercing and effectively improving qualities of the inner and outer surface of a shell core, and is suitable for production of shell core sand cores.

Owner:CHENGDE BEIYAN CASTING MATERIAL

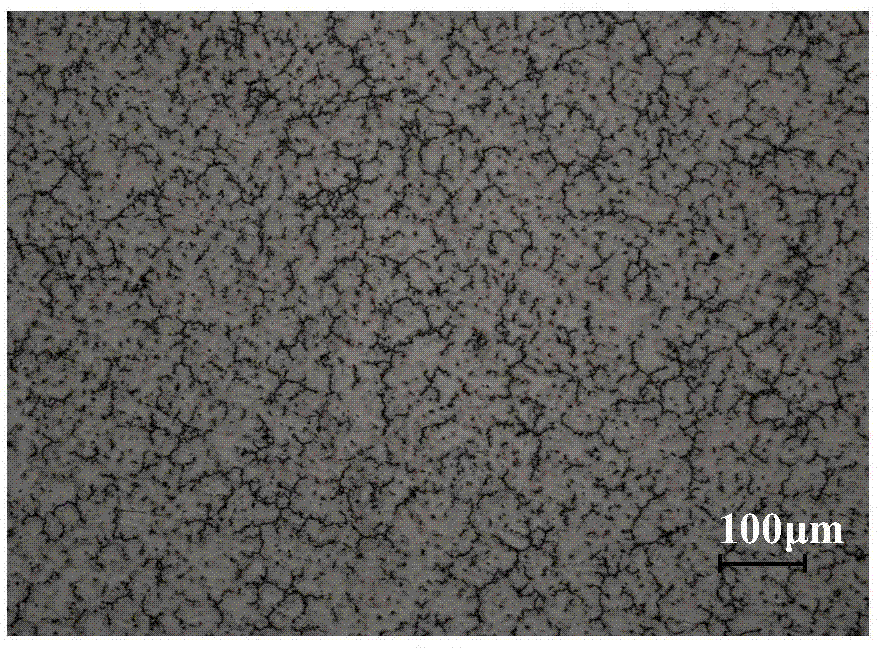

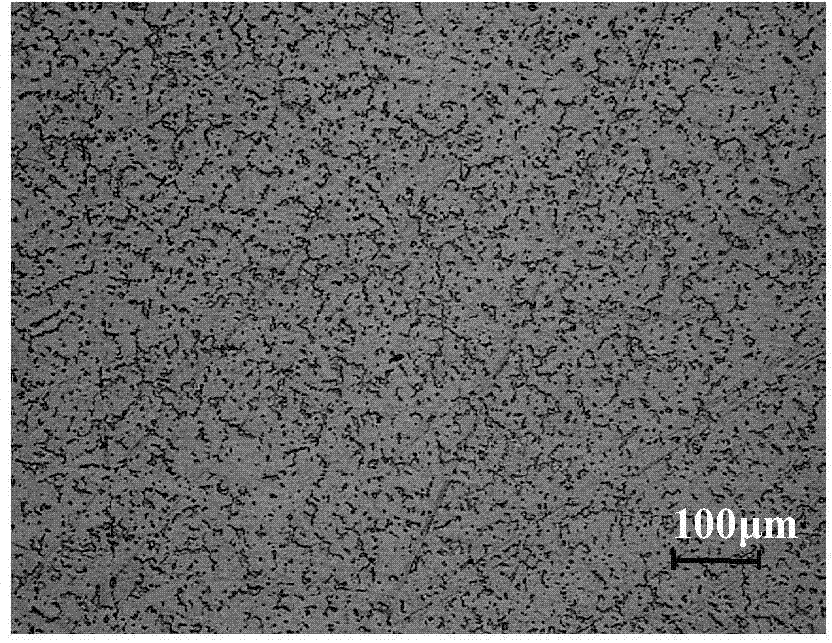

Magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and preparation method thereof

The invention discloses a magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and a preparation method thereof. Mass percent of components of the alloy is that 4 to 10% of zinc, 2 to 4% of aluminum, 0.1 to 0.5% of chromium, 0.1 to 1.0% of bismuth, 0.5 to 2.0% of calcium, the remaining is magnesium, and the total mass is 100%. The preparation method of the alloy comprises the following steps of preheating prepared alloy furnace materials, communicating a carbon dioxide and sulfur hexafluoride mixed gas to be served as a protection gas to perform smelting, performing diffusion annealing on obtained magnesium, zinc, aluminum, chromium, bismuth and calcium as-cast-condition alloy materials for 48 hours under 380 degrees, performing linear cutting to obtain aging thermal treatment samples and plate-shaped tensile samples, preserving heat of the above samples, performing water quenching and manual aging to obtain the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening. The preparation method can obtain preparation the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and relatively thin in as-cast structure and high in thermal stability and mechanical property.

Owner:NORTHEASTERN UNIV LIAONING

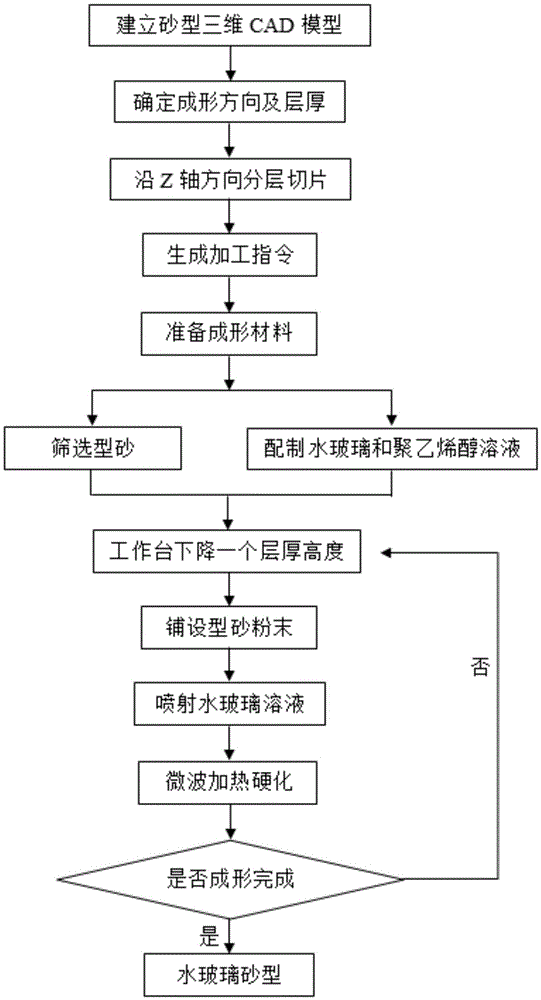

Rapid molding method of sodium silicate sand mould

ActiveCN105562623AFast bondingImprove liquidityAdditive manufacturing apparatusFoundry mouldsMicrowavePolyvinyl alcohol

The invention discloses a rapid molding method of a sodium silicate sand mould and belongs to the field of rapid casting. The rapid molding method comprises the following steps: (1), establishing a three-dimensional entity model of a sodium silicate sand mould to be molded, taking the Z axis as the molding direction, and setting molding layer thickness; (2), first, paving one layer of molding sand material, and then spraying an adhesive so as to form the current layer of outline pattern, wherein the adhesive is a mixed solution of sodium silicate and polyvinyl alcohol; (3), carrying out microwave heating on the current layer of outline pattern, and forming the current layer of sand mould outline; (4), stopping microwave heating, and lowering the work table for a height of one layer thickness along the Z axis; and (5), repeating steps (2-4) until the sodium silicate sand mould is molded. The method meets the high requirement of sodium silicate sand hardened through microwave heating on the mould, solves the problems that the surface of the sodium silicate sand mould becomes powdery due to overheating and easily absorbs moisture, and further overcomes the poor feasibility, difficult molding sand storage and difficult molding sand recycling defects of the existing micro-injection bonding sodium silicate sand rapid molding technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Jobsite-renewable multilayer floor finish with enhanced hardening rate

ActiveUS7527861B2Increase crosslink densityImprove wear resistanceSynthetic resin layered productsPretreated surfacesMetallurgyMaterials science

A jobsite-renewable multilayer floor finish system has an undercoat employing a first hardening system, an autohardenable (e.g., two-part) topcoat employing a second hardening system, and at least one initiator for the topcoat hardening system in at least the undercoat. The initiator increases the topcoat hardening rate while reducing the topcoat pot life to a lesser extent than would be the case if the initiator were included only in the topcoat. The increased topcoat hardening rate facilitates earlier application of additional topcoat layers, or earlier return of the floor to service.

Owner:ECOLAB USA INC

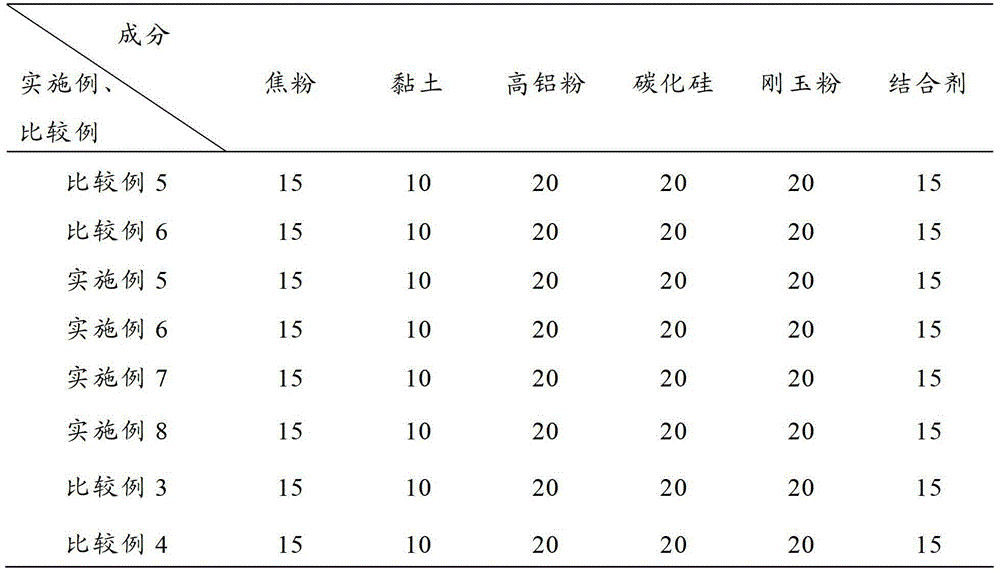

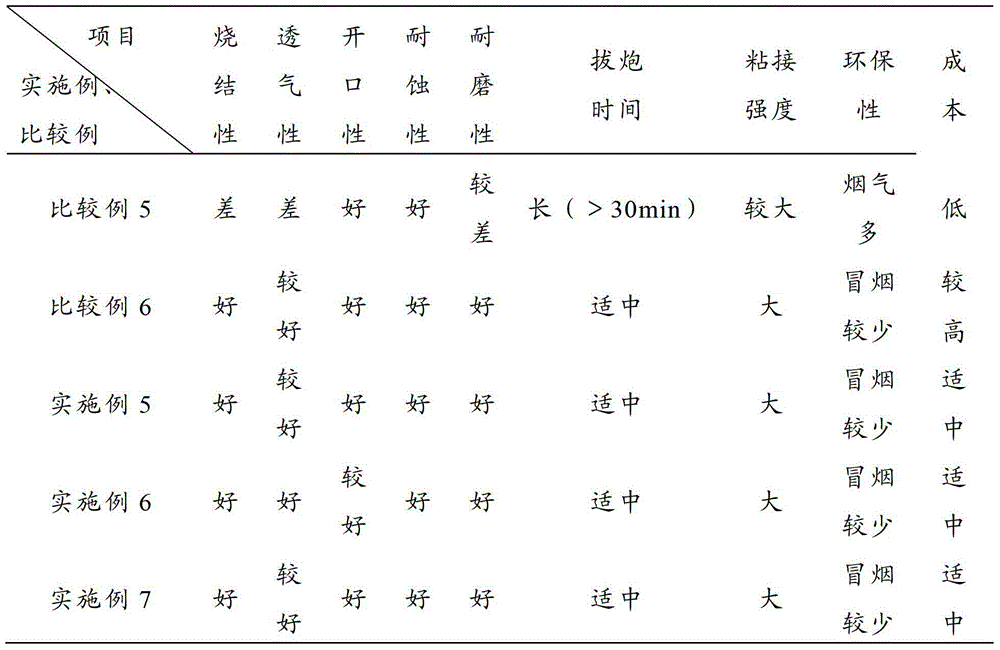

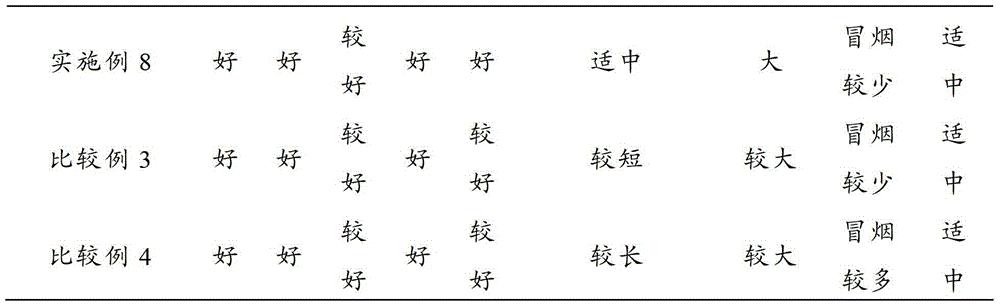

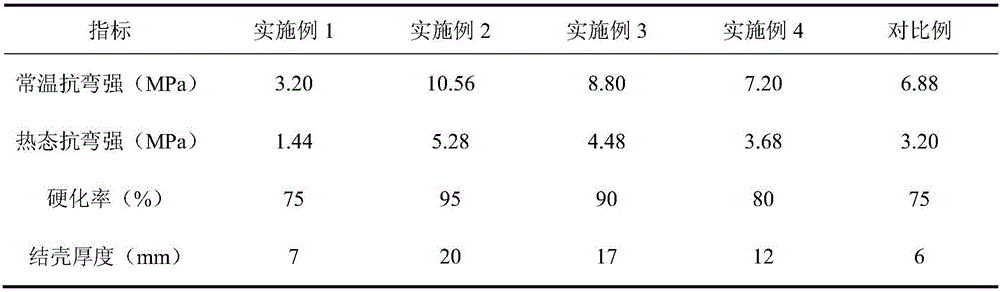

Phenolic resin composition for stemming, preparation method of composition and stemming

The invention provides a phenolic resin composition for a stemming and a preparation method of the composition. According to the method, 30-50wt% of thermosetting phenolic resin, 5-20wt% of organic solvent and the balance of a carbon-containing organic binder are mixed to obtain the phenolic resin composition for stemming. The invention further provides a stemming. The stemming comprises a refractory aggregate and a binding agent, wherein the binding agent is the phenolic resin composition provided by the invention. According to the phenolic resin composition for the stemming, the thermosetting phenolic resin and the carbon-containing organic binder are mixed and used together, and the proportions of the thermosetting phenolic resin and the carbon-containing organic binder are controlled in the specified ranges, and then an appropriate amount of the organic solvent is added, so that the stemming has a moderate curing speed. Moreover, the stemming comprising the phenolic resin composition provided by the invention has the advantages of good plasticity and cohesive property, proper porosity, small high-temperature volume shrinkage, good sintering performance, high strength, scouring resistance, erosion resistance, good opening performance and the like and hardly causes environmental pollution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Collapse-easy water glass core sand for casting train aluminum alloy castings and preparation method thereof

InactiveCN106077439AImprove casting yieldReduce casting costsFoundry mouldsFoundry coresAnodic bondingPhosphate

The invention discloses collapse-easy water glass core sand for casting train aluminum alloy castings and a preparation method thereof. The collapse-easy water glass core sand is prepared by the following raw materials in parts by weight: 140-150 of olivine sand, 30-40 of garnet sand, 20-30 of allophane, 30-35 of siltstone, 15-20 of calcined kaolin, 8-10 of asbestos leftovers, 6-8 of beryllium oxide, 12-14 of boiling slag, 8-10 of water glass, 2-4 of sodium metaaluminate, 1-2 of cooked alum stone powder and the like. The core sand, prepared by such raw materials as olivine sand, garnet sand and siltstone enables such defect rates as sand bonding, air holes, cracks and looseness in casting of the aluminum alloy castings to be below 5%, largely improves the casting yield, and reduces the casting cost; the added sodium metaaluminate and cooked alum stone powder accelerate the hardening speed of the water glass, so that the core sand is high in strength and excellent in collapsibility, and the generation of harmful gas is reduced; and the added hydroxy propyl distarch phosphate, propylene glycol alginate and the like are attached on the surface of such raw sand as olivine sand, so that the interface strength is improved, and the green compression strength and the wet-heat tensile strength of the core sand are improved.

Owner:江阴联华铸造有限公司

Chewing gum composition comprising crystalline allulose particles

InactiveUS20180271113A1Increase hardening rateSugar food ingredientsChewing gumChewing gumNuclear chemistry

The present invention pertains to a chewing gum composition comprising crystalline allulose particles and optionally an aqueous allulose syrup, and to the use of allulose for increasing the hardening rate of chewing gum compositions.

Owner:ROQUETTE FRERES SA

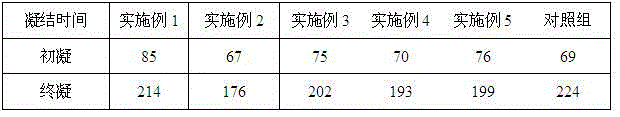

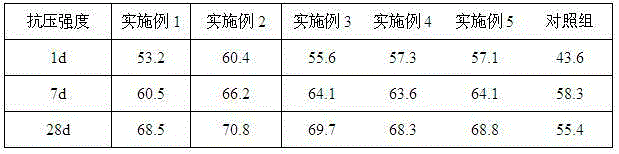

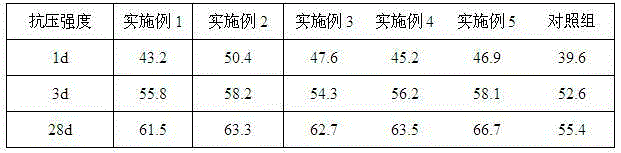

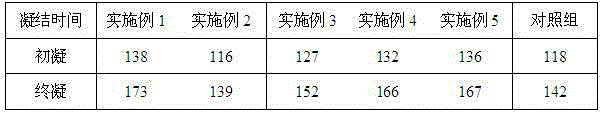

Aluminate cement and preparation method thereof

The invention discloses aluminate cement and a preparation method thereof, and relates to the field of building materials. The aluminate cement comprises the following components in percentage by mass: (1) 55.0%-75.0% of aluminate cement clinker, (2) 3.0%-10.0% of barium slag, (3) 5.0%-15.0% of garnierite tailings, (4) 5.0%-15.0% of red mud, (5) 3.0%-10.0% of steel slag, and (6) 2.5%-5.0% of gypsum, wherein the content of aluminium oxide in the aluminate cement clinker is 47.0%-65.0%. The preparation method of the aluminate cement comprises the following steps: (1) preparing materials, (2) grinding, and (3) pulverizing. The aluminate cement has the characteristics of being high in hardening rate and high in hardening strength, and besides, effectively overcomes the defect that the long-term strength of the conventional aluminate cement is relatively low, and effectively uses various industrial wastes, and is a very ideal cement material.

Owner:苏州市德莱尔建材科技有限公司

Production process of 5-series aluminum alloy profile

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a production process of a 5-series aluminum alloy profile. 5-series aluminum alloy raw materials comprise less than or equal to 0.08% of Si, less than or equal to 0.3% of Fe, less than or equal to 0.1% of Cu, less than or equal to 0.1% of Mn, 2.2-2.3% of Mg, 0.1-0.2% of Cr, 0.15-0.2% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurities, and the balance being Al. A round aluminum alloy cast ingot after casting is subjected to secondary homogenization treatment, the homogenization system comprises homogenization for 20 h at the temperature of 560 DEG C and homogenization for 8 h at the temperature of 300 DEG C, and the problem that the surface quality, the aluminum alloy tensile property and the corrosion resistance of the aluminum alloy profile cannot meet the requirements of customers at the same time when a conventional production process is adopted for producing the 5-series aluminum alloy profile is solved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

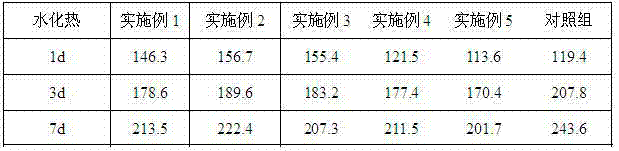

Intermediate-hydration-heat composite cement and preparation method thereof

Disclosed are intermediate-hydration-heat composite cement and a preparation method thereof, which relate to the field of a building material. The composite cement comprises the following components, by mass: (1) 40.0-55.0% of portland cement clinker, (2) 10.0-20.0% of aluminate cement clinker, (3) 2.1-8.0% of nanometer tin oxide, (4) 5.0-15.0% of glass fiber, (5) 5.0-10.0% of silica fume, (6) 5.0-10.0% of struvite, and (7) 2.5-5.0% of gypsum. The preparation method of the intermediate-hydration-heat composite cement comprises: (1) material preparation, (2) grinding, (3) pre-mixing, and (4) powder grinding. The intermediate-hydration-heat composite cement provided in the invention is prepared by utilizing both characteristics of the portland cement clinker and the aluminate cement clinker; the early strength and long-term strength of the materials are improved via a synergistic effect among each component; the hydration heat is effectively reduced; and affects of hydration heat on the molding and properties of the cement are avoided.

Owner:苏州市德莱尔建材科技有限公司

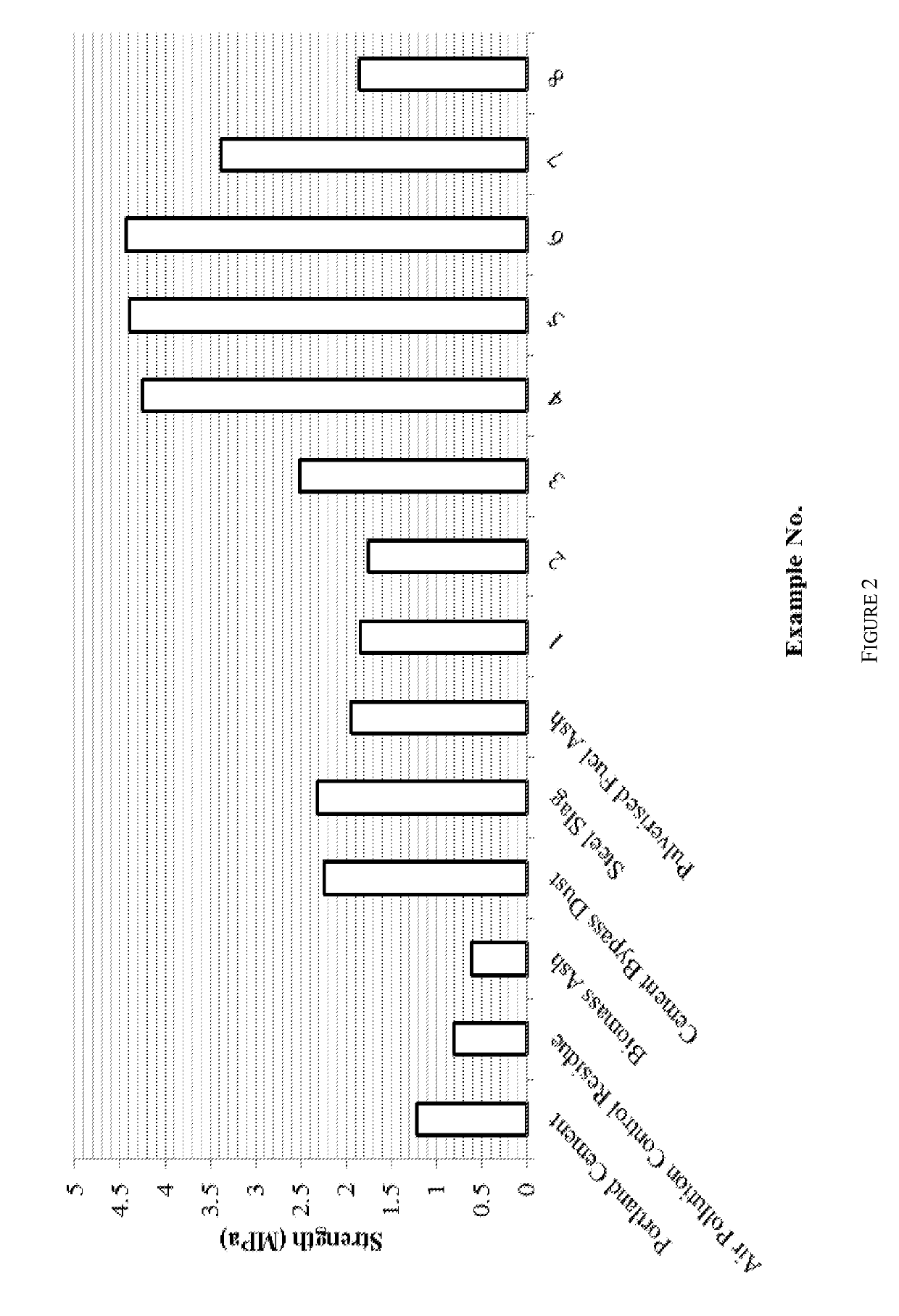

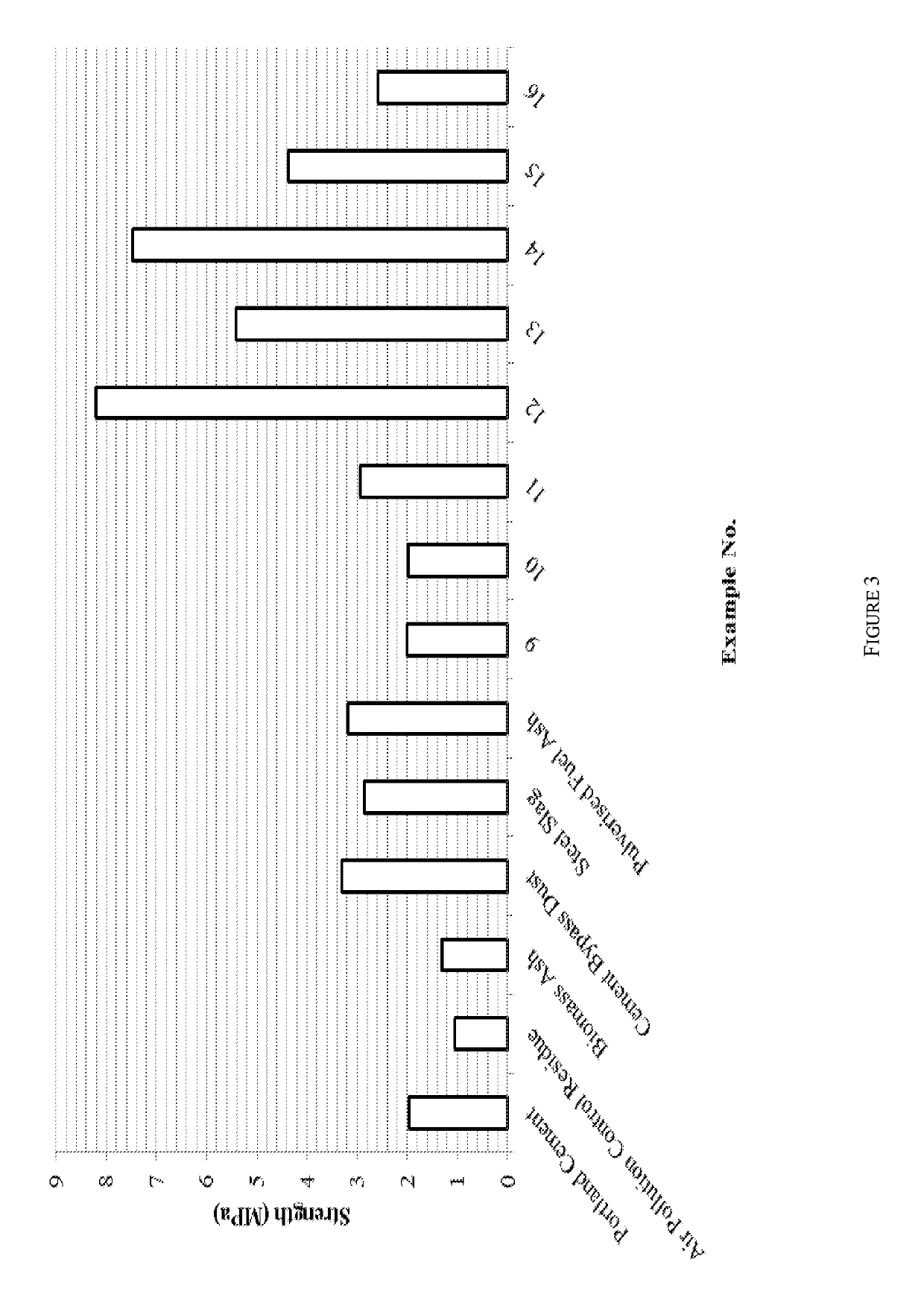

Improved production of aggregates

PendingUS20190119158A1Increase hardening rateFast formingSolid waste managementTransportation and packagingSlagCarbonation

An improved process for the preparation of aggregates for use with mixtures of various carbonatable substances, in particular mixtures comprising pulverised fuel ash and / or steel slag. The mixtures also comprise a carbonatable binder. The process comprises the steps of a. blending a combination of two carbonatable wastes, b. mixing the blended carbonatable waste with a carbonatable binder, c. mixing the blended carbonatable waste and binder with water, and d. carbonating the damp blended carbonatable waste in the presence of carbon dioxide.

Owner:CARBON8 SYST LTD

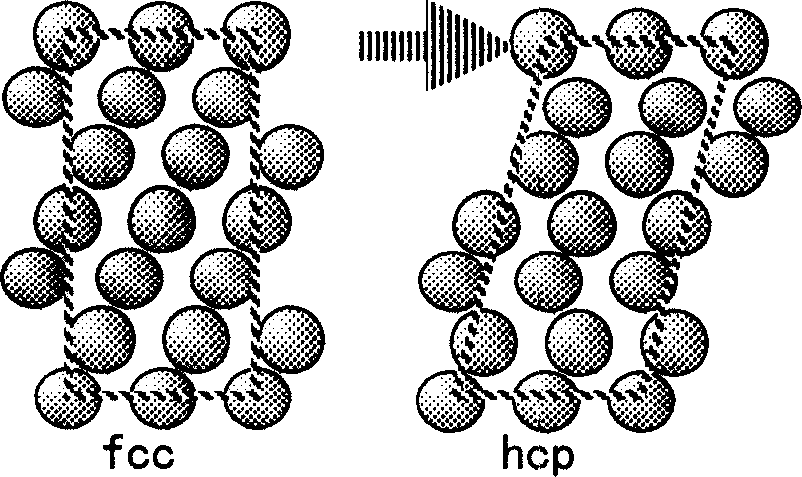

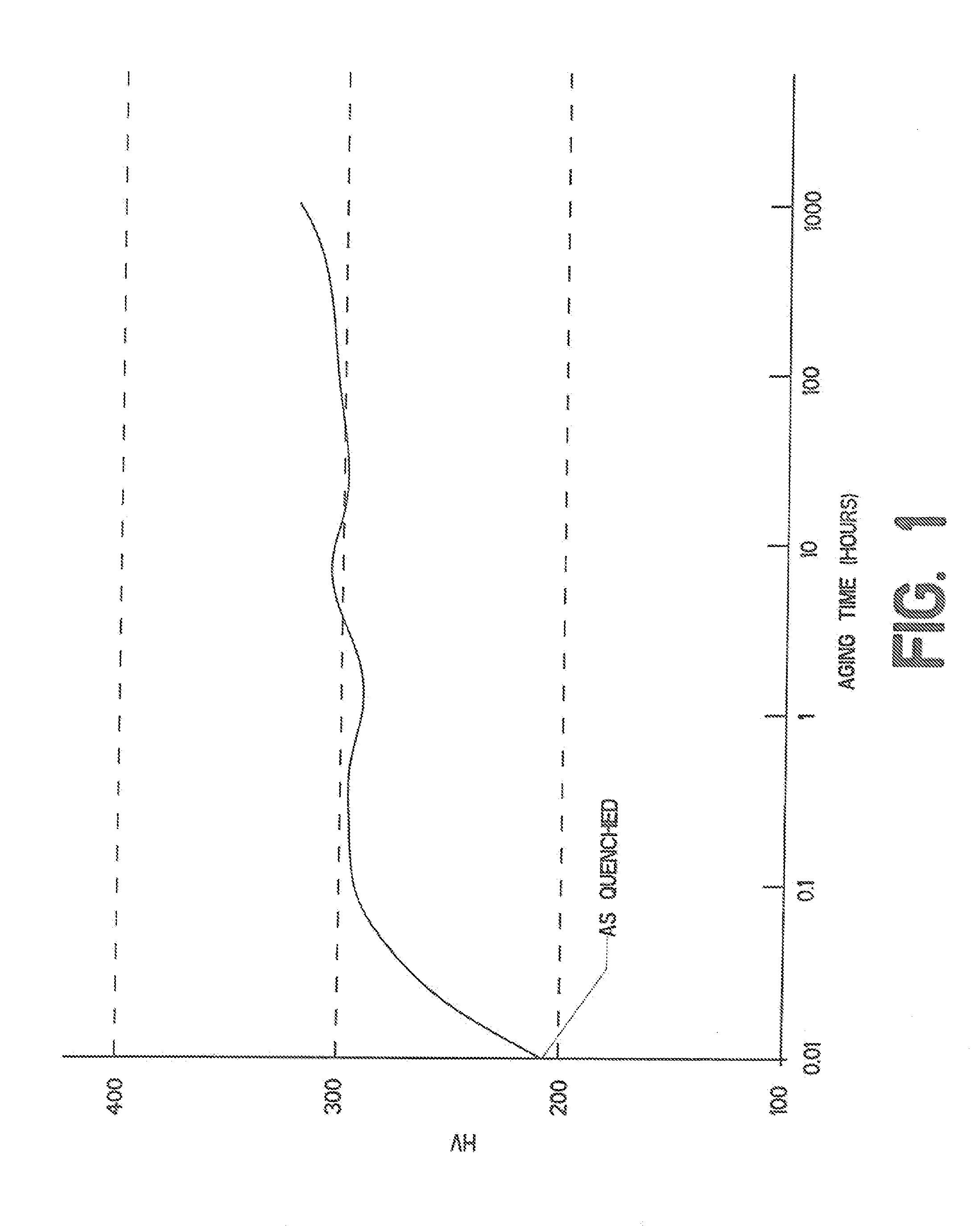

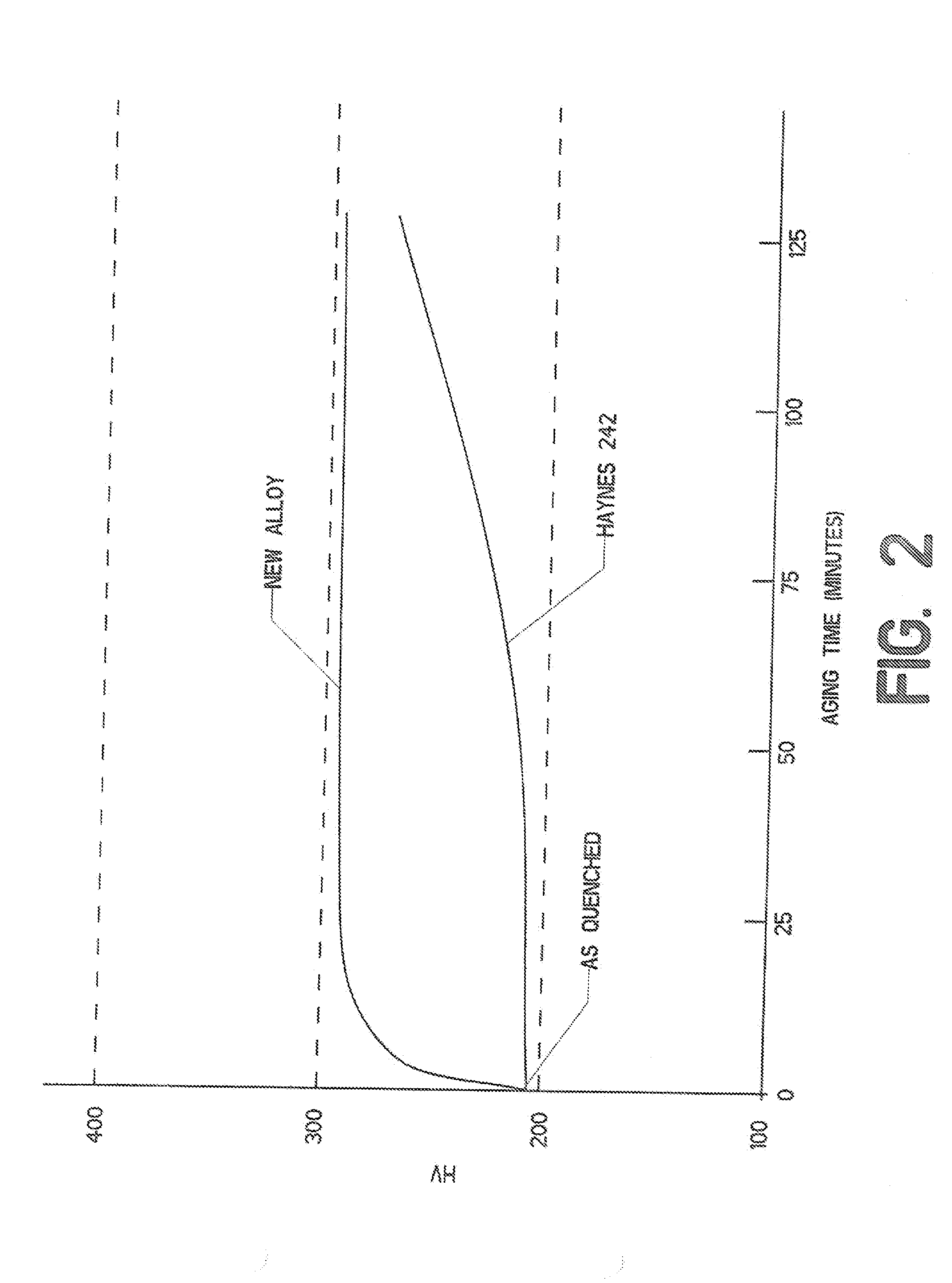

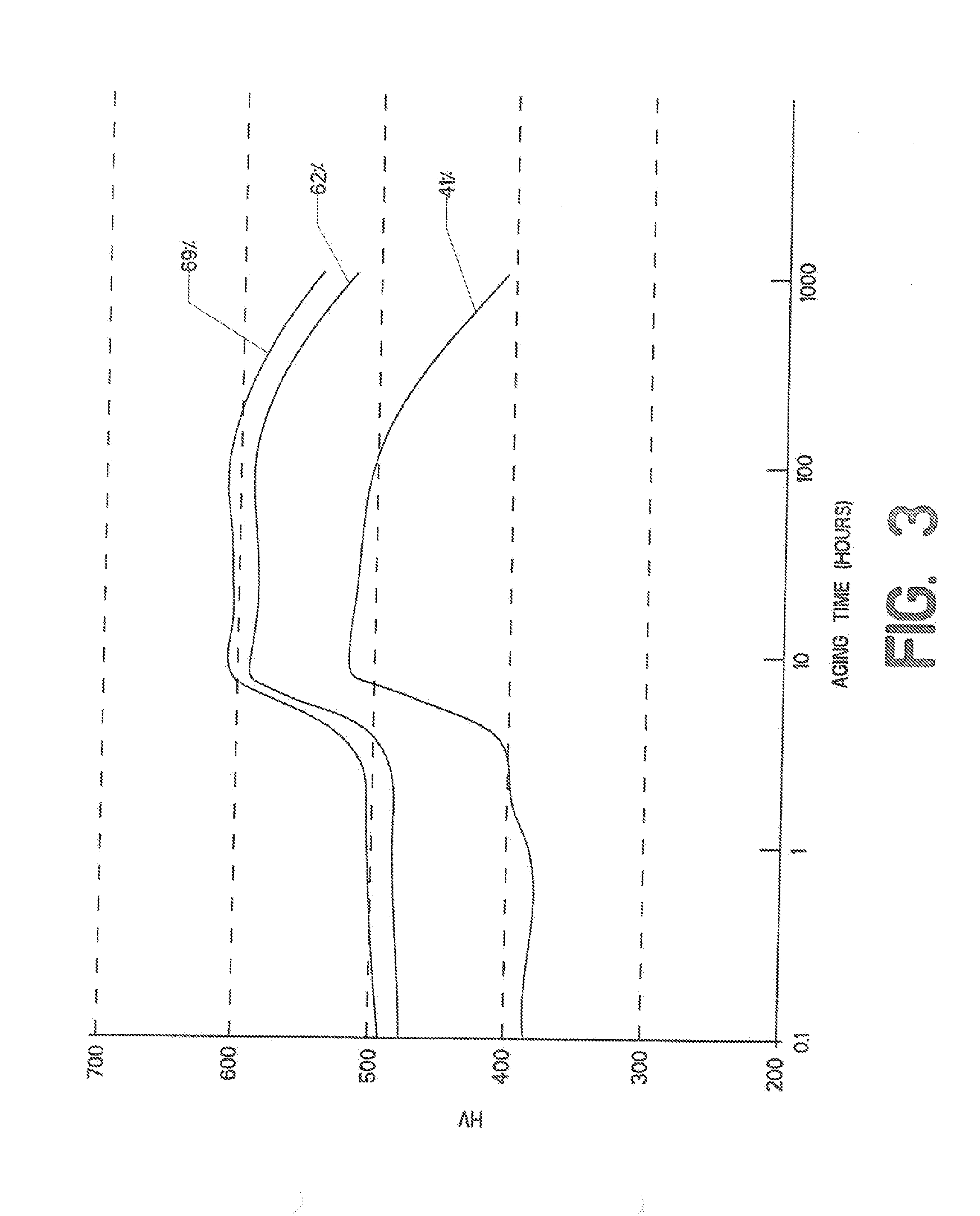

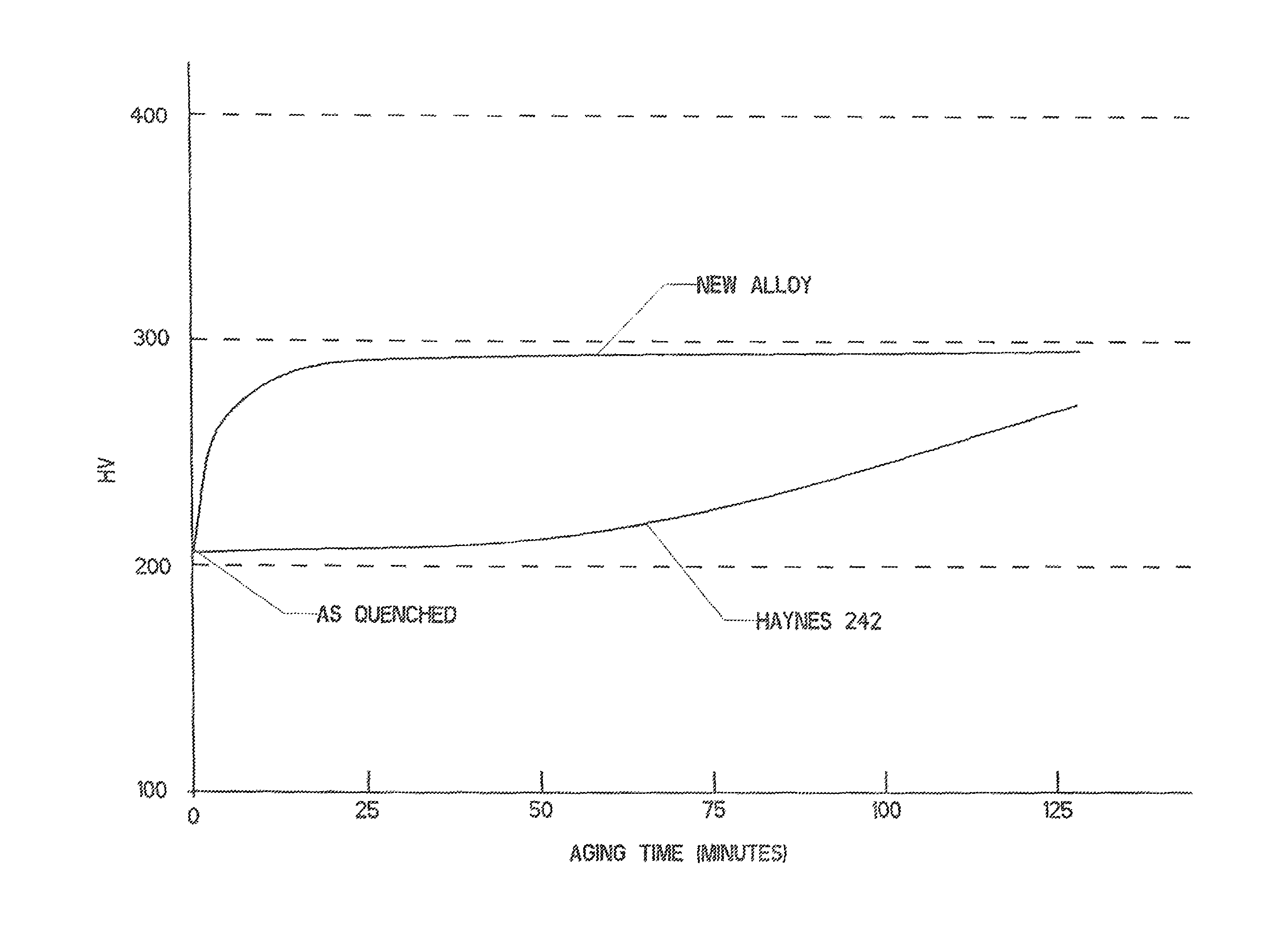

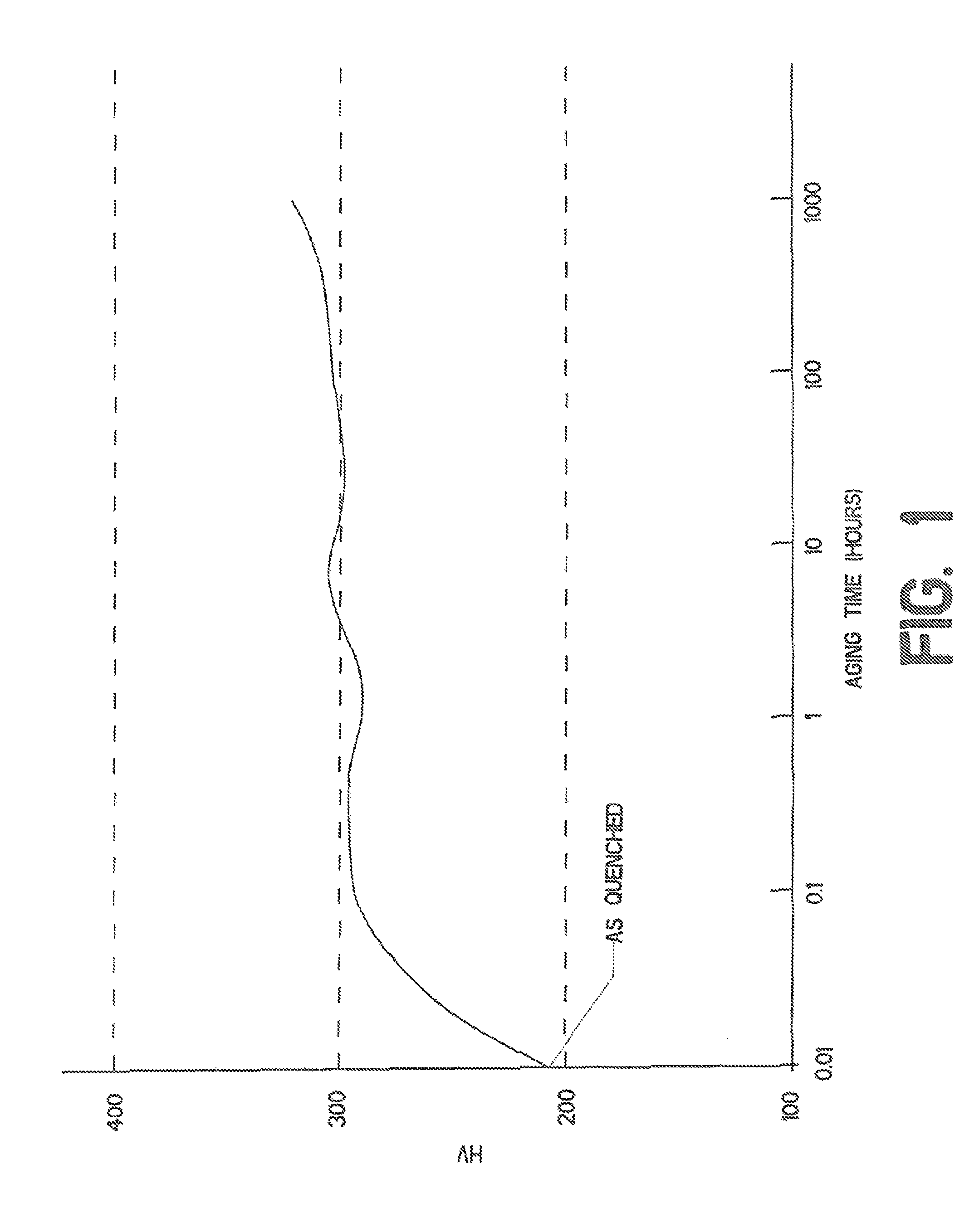

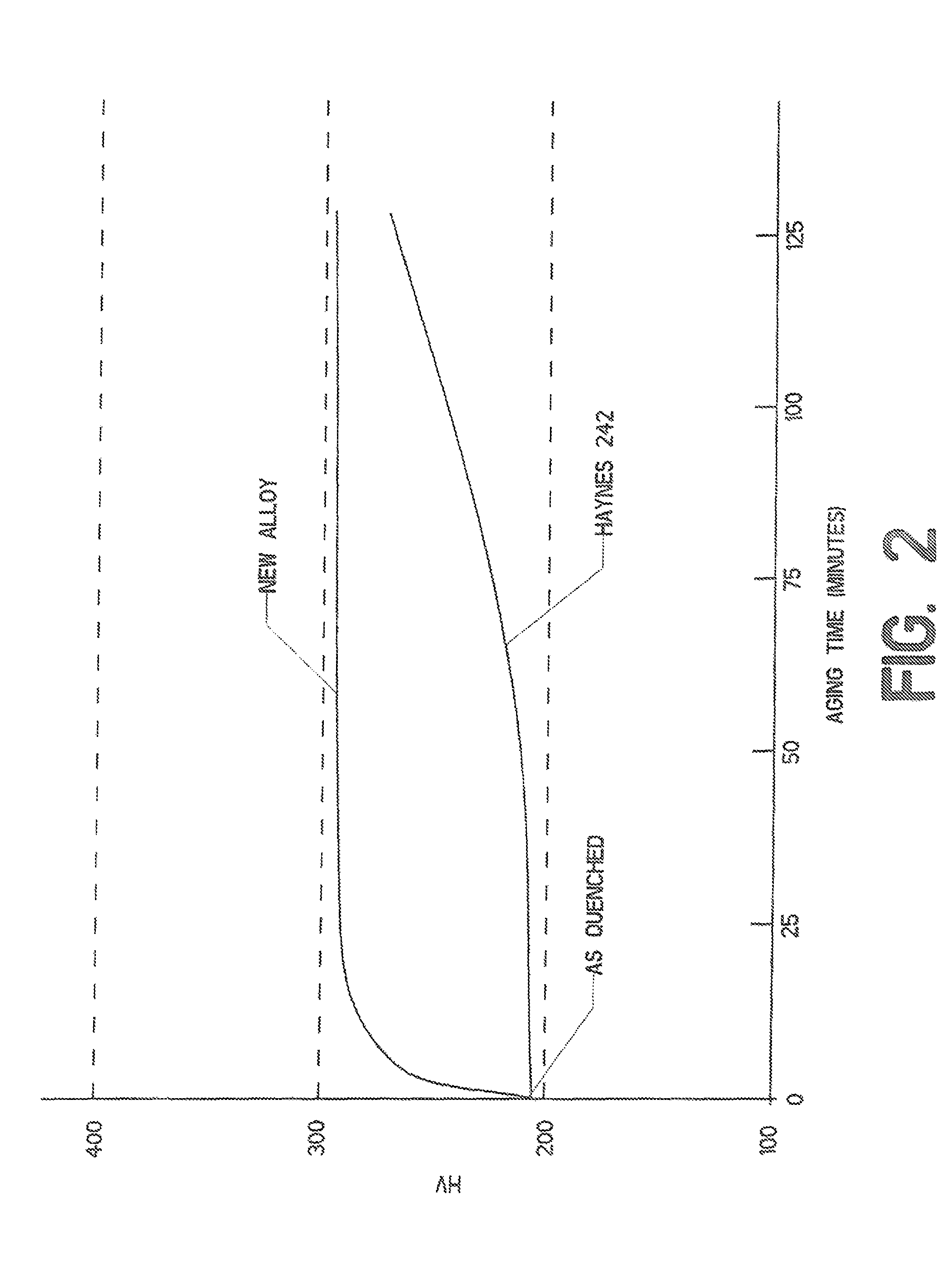

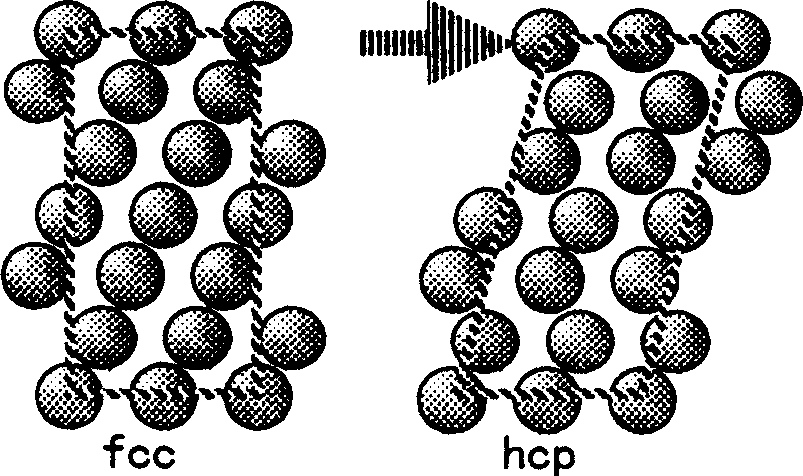

Age-Hardening Process Featuring Anomalous Aging Time

This document describes a process / strategy for age hardening nickel based alloys to create desirable properties with reduced energy expenditure. The inventive process introduces isolated atom nucleation sites to accelerate the nucleation rate by approximately 36 times, thereby permitting age hardening to occur in significantly less time and with significantly less energy expenditure.

Owner:FLORIDA STATE UNIV RES FOUND INC

Phenolic resin composition for stemming, preparation method of composition and stemming

The invention provides a phenolic resin composition for a stemming and a preparation method of the composition. According to the method, 30-50wt% of thermosetting phenolic resin, 5-20wt% of organic solvent and the balance of a carbon-containing organic binder are mixed to obtain the phenolic resin composition for stemming. The invention further provides a stemming. The stemming comprises a refractory aggregate and a binding agent, wherein the binding agent is the phenolic resin composition provided by the invention. According to the phenolic resin composition for the stemming, the thermosetting phenolic resin and the carbon-containing organic binder are mixed and used together, and the proportions of the thermosetting phenolic resin and the carbon-containing organic binder are controlled in the specified ranges, and then an appropriate amount of the organic solvent is added, so that the stemming has a moderate curing speed. Moreover, the stemming comprising the phenolic resin composition provided by the invention has the advantages of good plasticity and cohesive property, proper porosity, small high-temperature volume shrinkage, good sintering performance, high strength, scouring resistance, erosion resistance, good opening performance and the like and hardly causes environmental pollution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

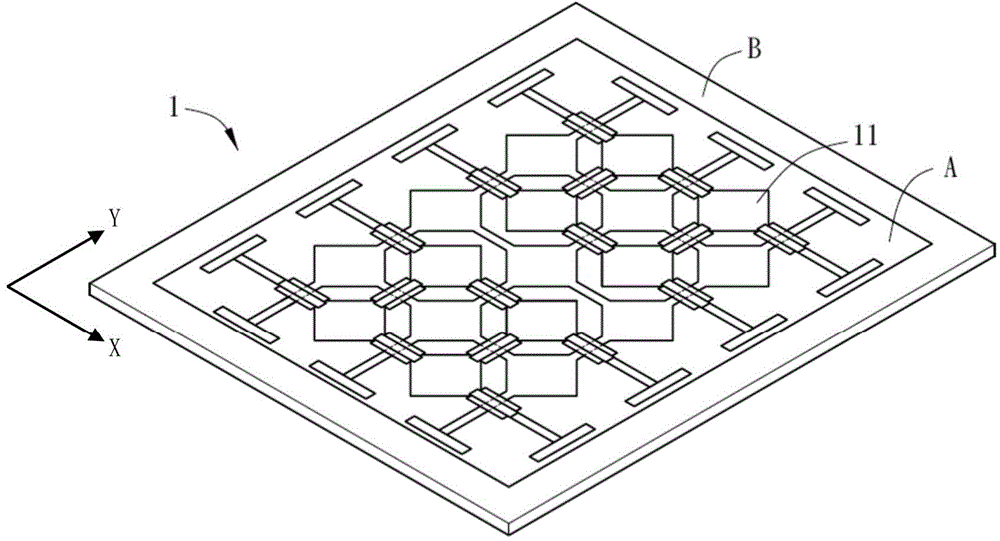

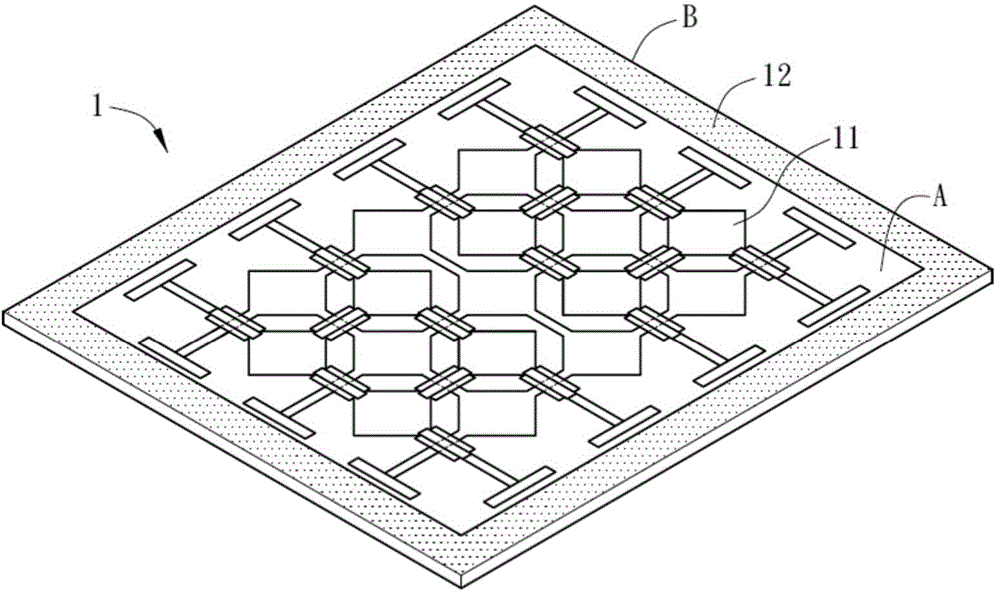

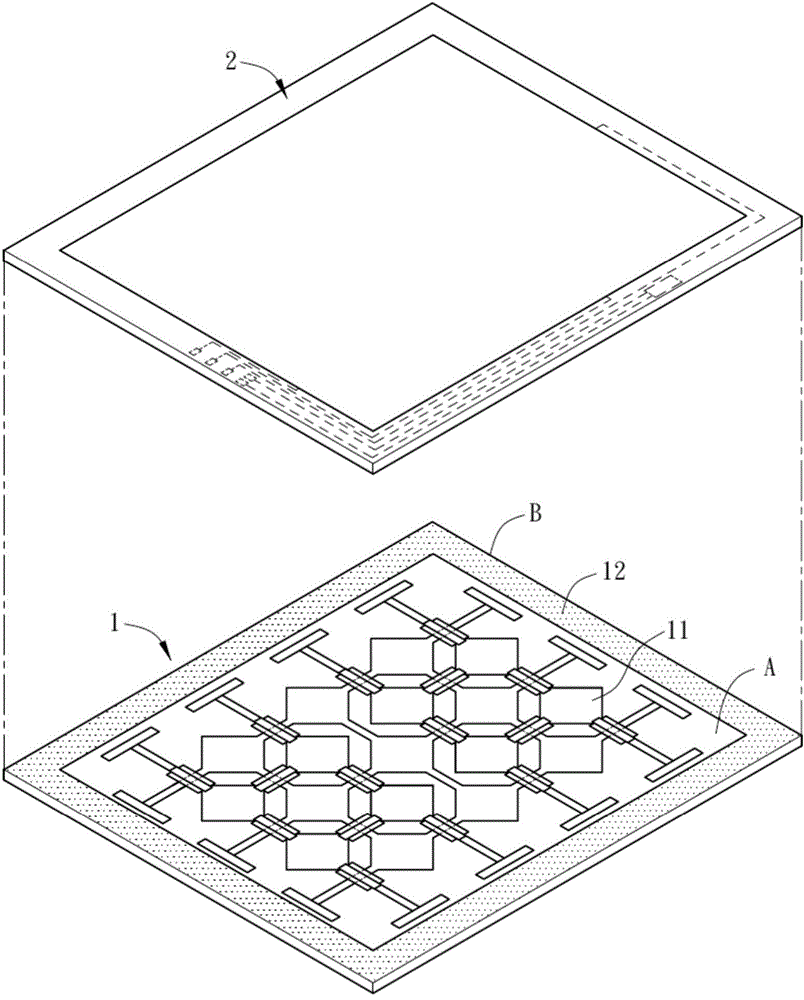

Photo-curing conductive adhesive for touch panel

InactiveCN104059558AAvoid wastingReduce the temperatureNon-macromolecular adhesive additivesEster polymer adhesivesAdhesiveMetal particle

A photo-curing conductive adhesive for a touch panel includes an adhesive in an amount within the range of 20 to 30 wt % and the metal particle composition in an amount within the range of 70 to 80 wt %.

Owner:ETURBOTOUCH TECH

Age-hardening process featuring anomalous aging time

This document describes a process / strategy for age hardening nickel based alloys to create desirable properties with reduced energy expenditure. The inventive process introduces isolated atom nucleation sites to accelerate the nucleation rate by approximately 36 times, thereby permitting age hardening to occur in significantly less time and with significantly less energy expenditure.

Owner:FLORIDA STATE UNIV RES FOUND INC

Expanding metal material and bulged tube device for petroleum oil well

ActiveCN1280443CSmooth expansion deformationIncrease hardening rateFluid removalPipe elementsMisch metalCarbide

The invention relates to an expansion alloy material and an expansion pipe device for petroleum oil wells. The composition of the expansion alloy material is: C: 0.03-0.5; Si: 0-6.0; Mn: 0-15; Cr: 0-20; Ni: 0-20; N: 0.02-0.08; P≤0.03; S≤0.03; mixed rare earth: 0.1; Ti: 0-0.8; Zr: 0-1.47; the balance is Fe. The total amount of TiC and ZrC carbides in the alloy is 0.1-1.5%. Its strong plasticity K=σ・δ can reach 3800MPa%; the shape memory connection of the expansion tube can still maintain a good sealing state after the diameter is expanded, and the internal pressure resistance of the expansion tube is close to 50MPa; the bullet piston, centralizer and hydraulic anchor fixing mechanism in the process device etc., simple in structure, stable in operation and easy to use. This invention is of great significance for oil drilling, well completion and repair of long well sections, and also has important popularization value for other pipeline repairs.

Owner:SHANGHAI GLOBE PETRO EQUIP

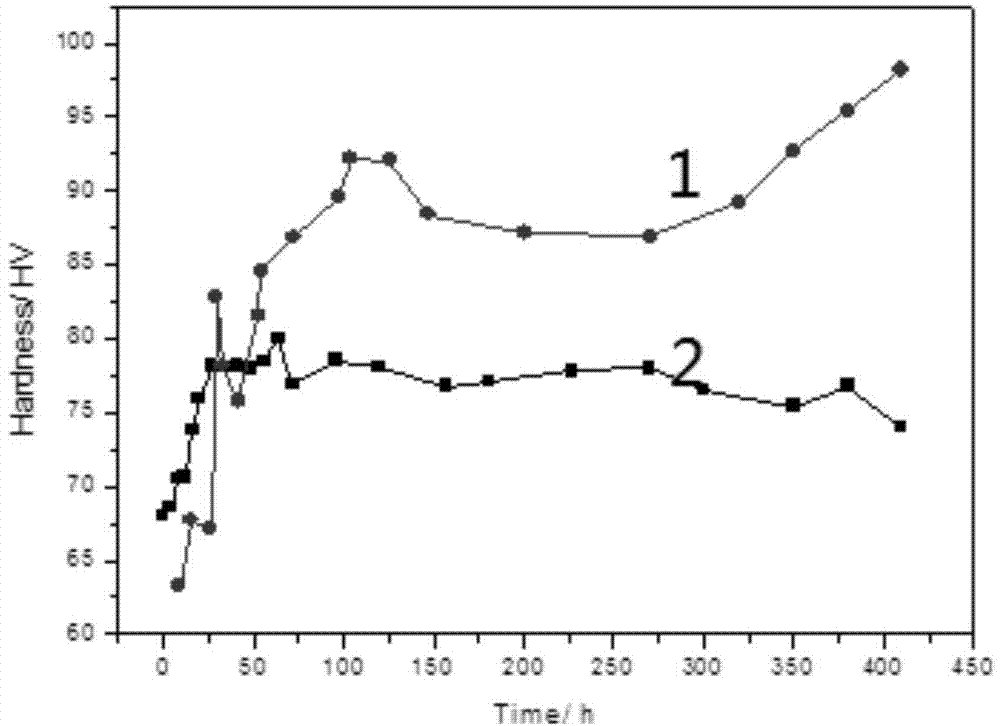

Proportioning method of aluminum-plastic composite cover

The invention discloses a proportioning method of an aluminum-plastic composite cover. The aluminum-plastic composite cover is formed by an aluminum alloy cover and a plastic piece. The proportioning method of the aluminum-plastic composite cover is characterized in that the aluminum-plastic composite cover comprises the following raw materials by weight: 0.5-0.9 parts of Si, 0.5-1.0 part of Fe, 0.05-0.2 parts of Cu, 0.10-1.5 parts of Mu, Zu being more than or equal to 0.1 parts of Zu, less than or equal to 0.08 parts of Ti, more than or equal to 0.05 parts of Ag and the balance of Al. According to the proportioning method adopted by the invention, the lower-temperature ageing rate can be lowered, the hardening rate is increased suddenly along with the prolonging of time, so that the high-temperature ageing-hardening effect can be improved, and the hardness of aluminum alloy can be enhanced.

Owner:王锦达

Anti-shelling and easy-to-fill casting sand

ActiveCN109079095AFast curing rateIncrease hardening rateFoundry mouldsFoundry coresPrepolymerZeolite

The invention discloses anti-shelling and easy-to-fill casting sand. The anti-shelling and easy-to-fill casting sand is prepared from the following raw materials: talc powder, fly ash, apatite powder,zeolite, forsterite fine powder, zinc dialkyl dithiophosphate, potassium silicon fluorate, a geopolymer prepolymer, organic bentonite, sodium tripolyphosphate, polyvinyl butyral, clay and an additiveaid. Through improvement on a formula of a system, the curing rate is increased, the hardening rate of the casting sand is increased, and the shelling tendency is reduced; through optimization of thecontent of each component, the overall strength of the casting sand can be improved, the gas generating amount of the casting sand is greatly reduced and a core defect is reduced; the casting sand disclosed by the invention has very strong anti-shelling ability, a good filling property, relatively high high-temperature strength, good rigid permeability and low gas generating amount, and can significantly reduce or eliminate shelling, the core defect and other defects, effectively improve the inner and outer surface qualities of a shell core and improve the production efficiency.

Owner:安徽江杰实业有限公司

Preparation method of health-care salted eggs for reducing blood pressure

InactiveCN107279811ANo loss of qualityShortened sensory qualityFood ingredient functionsMonosodium glutamateMaltitol

The invention discloses a preparation method of health-care salted eggs for reducing blood pressure. The preparation method comprises the following steps of S1, selecting raw materials and performing cleaning; S2, performing preserving pretreatment: putting cleaned duck eggs in organic acid, and performing soaking; S3, preparing preserving liquid: putting a traditional Chinese medicine bag in an extracting tank, adding water, performing decoction, performing filtering to obtain filtrate, adding the filtrate to a precipitation tank, performing standing, then performing centrifugation on a supernatant, performing concentration on centrifugate to obtain a material a, adding water, performing uniform mixing, performing ultrasonic extraction to obtain a material b, adding water to the material b, sorbitol, xylitol, maltitol, sodium benzoate, star aniseeds, Chinese prickly ash, cinnamon, goat bone powder, monosodium glutamate, white sugar, low sodium health-care salt and a soy sauce, performing decoction, and performing cooling to room temperature so as to obtain the preserving liquid; S4, performing preserving; and S5, performing air drying, performing sterilization and performing packing. According to the preparation method disclosed by the invention, the preparation efficiency of the salted eggs can be effectively improved, the preserving cycle of the salted eggs can be shortened, and the prepared salted eggs have the efficacy of reducing blood pressure.

Owner:SUSONG XIANGYUAN POULTRY TRADE

Preserving liquid of preserved eggs for reducing blood pressure, regulating spleen and regulating stomach

InactiveCN107232526AGood health effectSupplemental vitamin contentVitamin food ingredientsNatural extract food ingredientsPotassiumMaltitol

The invention discloses preserving liquid of preserved eggs for reducing blood pressure, regulating the spleen and regulating the stomach. The preserving liquid comprises the following raw materials in parts by weight: 2-4 parts of potassium chloride , 15-25 parts of sodium chloride , 3-9 parts of organic acid , 3-5 parts of sorbitol, 4-8 parts of xylitol, 3-6 parts of maltitol , 3-6 parts of aethylparabenum, 1-3 parts of sodium benzoate, 2-5 parts of potassium sorbate , 2-6 parts of Chinese cinnamon, 1-4 parts of star aniseeds, 3-5 parts of garlic , 3-5 parts of Chinese prickly ash, 0.5-1.5 parts of water soluble vitamins, 8-16 parts of a traditional Chinese medicine additive and 15-20 parts of water . The preserving liquid disclosed by the invention can effectively shorten the preserving period, the preserving efficiency and the quality can be improved, and the damage of high salt content can be reduced, so that the preserved eggs prepared by the preserving liquid have the health-care efficacy of reducing blood pressure, regulating the spleen and regulating the stomach.

Owner:SUSONG XIANGYUAN POULTRY TRADE

Coated low-nitrogen sand and its prepn

ActiveCN101088659BReduce usageReduce nitrogen contentFoundry mouldsFoundry coresLow nitrogenTetramine

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Processing method for one-time forming of plastic transparent outer package production

The invention provides a one-time forming processing method for producing a transparent plastic outer package, and relates to the technical field of one-time forming processing methods for producing transparent plastic outer packages. According to the one-time forming processing method for producing the transparent plastic outer package, the transparent plastic outer package takes polyethylene and polypropylene as raw materials, and the weight ratio of the polypropylene to the polyethylene is 3: (0.5-0.8). The drying machine is used for drying polyethylene and polypropylene raw materials, meanwhile, the drying efficiency of the raw materials is improved through arrangement of water-absorbent resin, the raw materials are fully dried in a high-frequency heating mode, and the product quality of transparent outer packages is effectively improved after moisture and volatile matter are fully volatilized. The raw materials are heated to a certain degree before entering the injection molding machine, the follow-up raw material melting time is shortened, the product machining time is shortened, the product quality is improved, the product efficiency is improved, and the injection molding machine is worthy of being vigorously popularized.

Owner:深圳市乙方吸塑包装有限公司

A kind of shell-resistant coated sand and preparation method thereof

ActiveCN104014718BFast curing rateIncrease hardening rateFoundry mouldsFoundry coresCouplingUltimate tensile strength

The invention discloses a peeling-resistant coated sand and a preparation method thereof. The shell-resistant coated sand is characterized in that it comprises raw sand, a binder accounting for 1 to 4% of the mass of the raw sand, 1 to 15% of a curing agent based on the mass of the binder, and 0.1 to 0.5% of Coupling agent, 0.1-1.0% additive. The additive added in the present invention can increase the curing rate of the curing agent to the binder, increase the hardening rate of the coated sand, and reduce the tendency of shelling. By optimizing the content of each component, the overall strength of the coated sand can be improved, and the gas generation of the coated sand can be greatly reduced, and core penetration defects can be reduced. The coated sand of the present invention has strong anti-shelling ability, high strength and low gas generation. It can significantly reduce or eliminate defects such as shelling and core penetration, effectively improve the quality of the inner and outer surfaces of the shell core, and is suitable for the production of shell core sand cores.

Owner:CHENGDE BEIYAN CASTING MATERIAL

Sulphate aluminium cement and preparation method thereof

The invention discloses sulphate aluminium cement and a preparation method thereof, and relates to the field of building materials. The sulphate aluminium cement comprises the following components in percentage by mass: (1) 50.0%-70.0% of sulphate aluminium cement clinker, (2) 3.0%-8.0% of alginate fiber, (3) 10.0%-25.0% of ferro-alloy slag, (4) 5.0%-15.0% of boron slag, (5) 5.0%-10.0% of pulverized fuel ash, and (6) 2.5%-5.0% of gypsum. The preparation method of the sulphate aluminium cement comprises the following steps: (1) preparing materials, (2) grinding, and (3) pulverizing. The sulphate aluminium cement has the characteristics of being high in hardening rate and high in early strength, and besides, the condition that the long-term strength of the sulphate aluminium cement is reduced greatly is avoided, and the service life of the sulphate aluminium cement is prolonged. Besides, the preparation method for the sulphate aluminium cement, provided by the invention, adopts primary grinding and mixed pulverizing processes, the granularity of the prepared sulphate aluminium cement is relatively small, the specific surface area is relatively large, and the performance is stable.

Owner:苏州市德莱尔建材科技有限公司

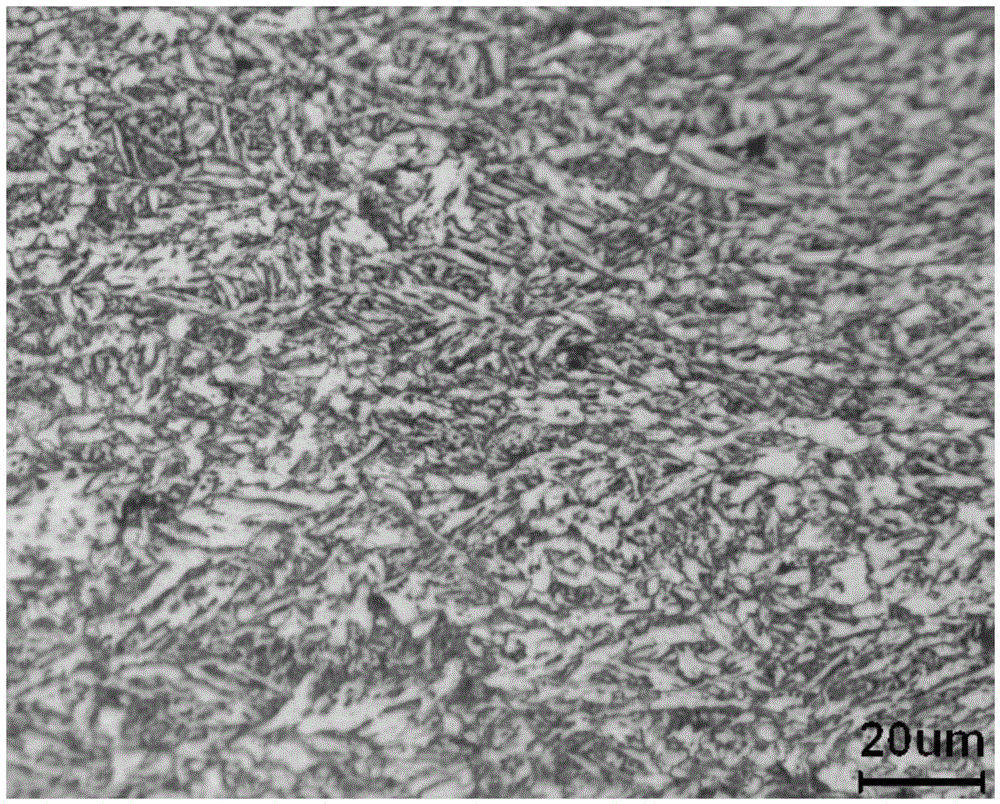

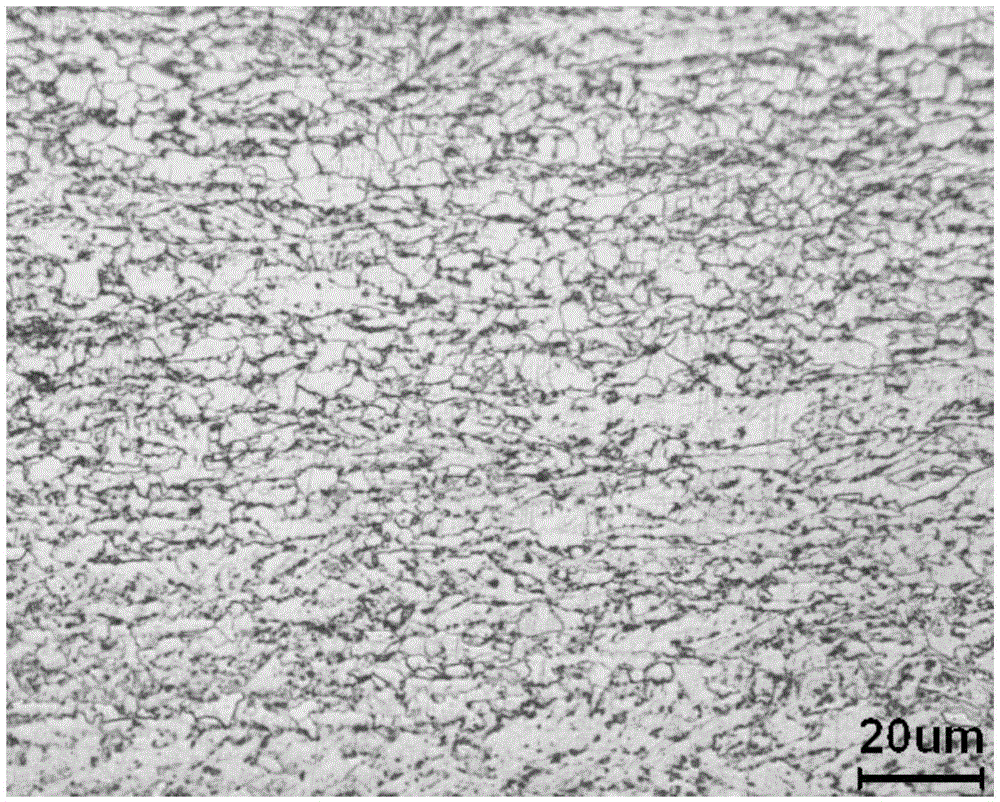

A kind of wear-resistant steel for slurry conveying welded pipe pipeline and its manufacturing method

The invention relates to wear-resistant steel for an ore slurry delivering welded pipe line and a manufacturing method thereof. The wear-resistant steel comprises the following components in percentage by weight: 0.04-0.10% of C, 1.00-1.70% of Mn, 0.20-0.60% of Cr, no more than 0.025% of Ti, no more than 0.06% of Nb, 0.02-0.06% of V, 0.10-0.40% of Si, no more than 0.05% of Al, no more than 0.008% of N, no more than 0.015% of P, no more than 0.008% of S and the balance of Fe and inevitable impurities; Pcm is no more than 0.18%, the steel plate is in a multiphase complex tissue of acicular ferrite+bainite+MA, and micro VC second-phase high-hardness particles are dispersed and precipitated in the tissue; and the transverse yield strength Rt0.5 of the steel plate is 490-705 MPa, the transverse tensile strength Rm is 570-825 MPa, and the yield ratio is Rt0.5 / Rm(0.85, hardening index n)1.10. According to the invention, the steel plate is simple in chemical composition and low in production cost, and the low carbon equivalent is beneficial to weldability; and due to the low yield ratio, the steel plate has the characteristics of easy pipe forming, high hardening index, high wear resistance and the like, and the wear resistance is almost doubled in comparison with a common line pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of preserved eggs

PendingCN112841558AShorten marinating timeReduce moisture contentFood coatingBiotechnologySulfate zinc

The invention discloses a preparation method of preserved eggs in the technical field of preserved egg processing. The preparation method comprises the steps that soaking liquid and wrapping mud are prepared, the soaking liquid is prepared from, by weight, 2-5 parts of lime, 3-9 parts of plant ash, 1-4 parts of salt, 1-2 parts of black tea powder, 0.01-0.02 part of food-grade copper sulfate, 0.02-0.04 part of food-grade zinc sulfate and 50-80 parts of water, and the wrapping mud is prepared from, by weight, 5-7 parts of medical stone powder, 20-30 parts of cavings, 5-10 parts of soluble starch and a proper amount of water; the grain size of 20%-45% of the bran coat is smaller than 50 meshes. The plant ash is used for replacing sodium carbonate, the content of the sodium carbonate is effectively reduced, when the wrapping mud is manufactured, the medical stone is added into the wrapping mud, and use of food-grade copper sulfate and food-grade zinc sulfate is reduced; meanwhile, some trace elements can be supplemented, sterilization can be achieved, and the shelf life can be prolonged.

Owner:GUIZHOU QIANBEI GRANARY METERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com