Intermediate-hydration-heat composite cement and preparation method thereof

A technology of thermal compounding and cement, which is applied in the field of building materials, can solve the problems of not being able to be used as dam cement, general strength, low heat of hydration, etc., to avoid the influence of molding and performance, improve strength performance, and reduce heat of hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

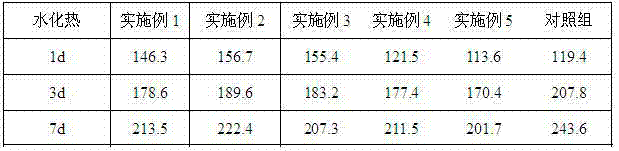

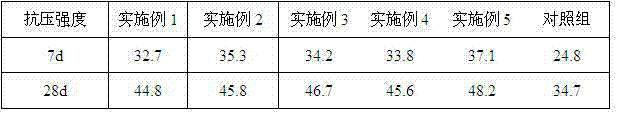

Examples

Embodiment 1

[0027] A medium-heat composite cement, comprising the following components in mass percentages:

[0028] (1) Portland cement clinker 40.0%%;

[0029] (2) Aluminate cement clinker 15.0%;

[0030] (3) Nano tin oxide 7.0%;

[0031] (4) Glass fiber 13.0%;

[0032] (5) Silicon fume 10.0%;

[0033] (6) Struvite 10.0%;

[0034] (7) Desulfurization gypsum 5.0%.

[0035] According to the preparation method provided by the invention, medium-heat composite cement is prepared, and the preparation steps are as follows:

[0036] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0037] (2) Grinding: Grinding the components with a particle size greater than 1mm until the average particle size reaches 200um;

[0038] (3) Premixing: Mix the components together and stir evenly;

[0039] (4) Grinding: Grinding the powdery material obtained in step (3) until the average particle size is 85um, that is, medium heat composite cement i...

Embodiment 2

[0041] A medium-heat composite cement, comprising the following components in mass percentages:

[0042] (1) Portland cement clinker 55.0%;

[0043] (2) Aluminate cement clinker 15.0%;

[0044] (3) Nano tin oxide 5.0%;

[0045] (4) Glass fiber 5.0%;

[0046] (5) Silicon fume 5.0%;

[0047] (6) Struvite 10.0%;

[0048] (7) Desulfurization gypsum 5.0%.

[0049] According to the preparation method provided by the invention, medium-heat composite cement is prepared, and the preparation steps are as follows:

[0050] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0051] (2) Grinding: Grinding the components with a particle size greater than 1mm until the average particle size reaches 200um;

[0052] (3) Premixing: Mix the components together and stir evenly;

[0053] (4) Grinding: Grinding the powdery material obtained in step (3) until the average particle size is 85um, that is, medium heat composite cement is o...

Embodiment 3

[0055] A medium-heat composite cement, comprising the following components in mass percentages:

[0056] (1) Portland cement clinker 45.0%;

[0057] (2) Aluminate cement clinker 15.0%;

[0058] (3) Nano tin oxide 8.0%;

[0059] (4) Glass fiber 10.0%;

[0060] (5) Silicon fume 10.0%;

[0061] (6) Struvite 7.0%;

[0062] (7) Desulfurization gypsum 5.0%.

[0063] According to the preparation method provided by the invention, medium-heat composite cement is prepared, and the preparation steps are as follows:

[0064] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0065] (2) Grinding: Grinding the components with a particle size larger than 1mm until the average particle size reaches 100-200um;

[0066] (3) Premixing: Mix the components together and stir evenly;

[0067] (4) Grinding: Grinding the powdery material obtained in step (3) until the average particle size is 30-85um, that is, medium heat composite ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com