Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "High normal sclerosis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

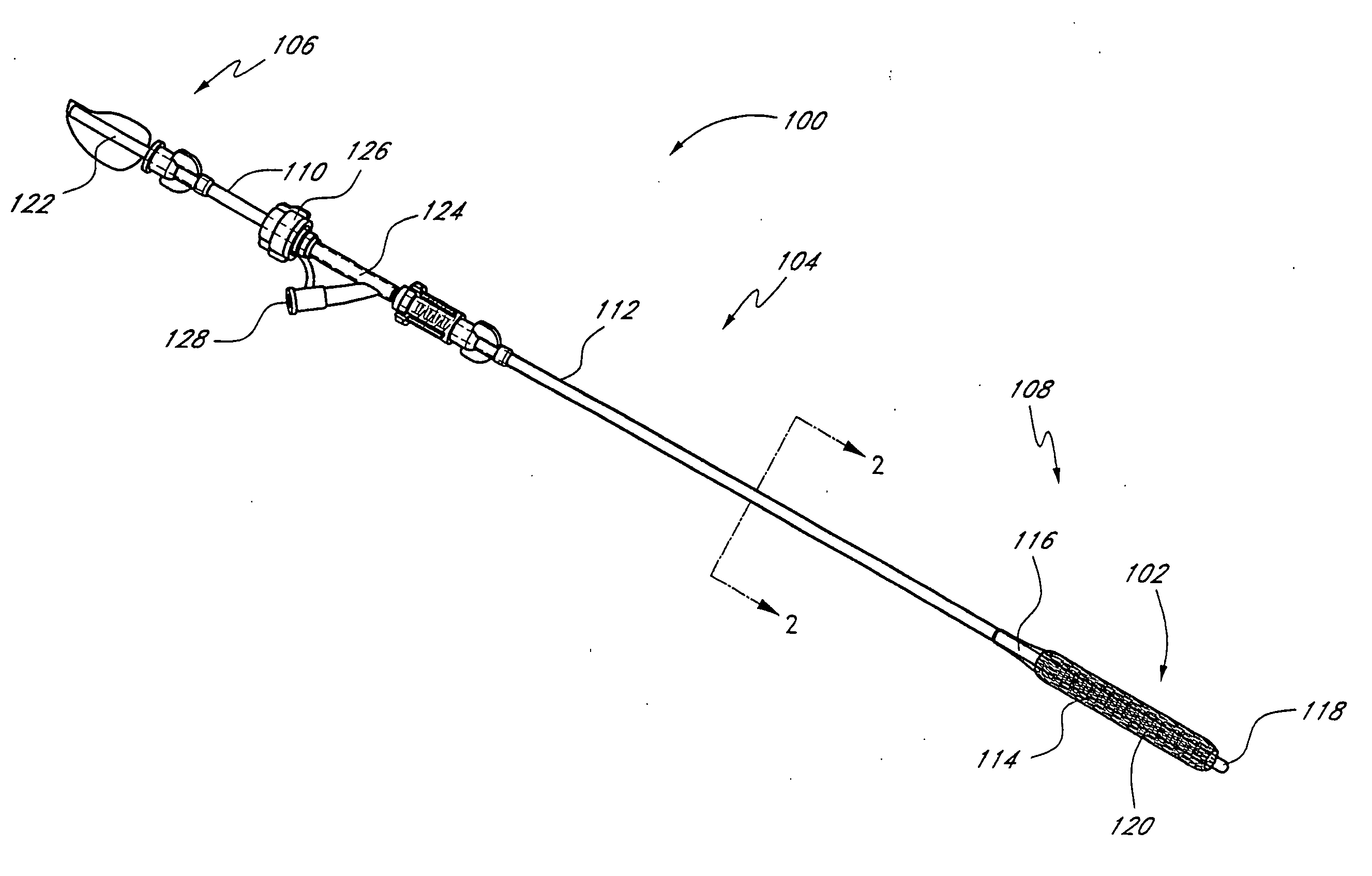

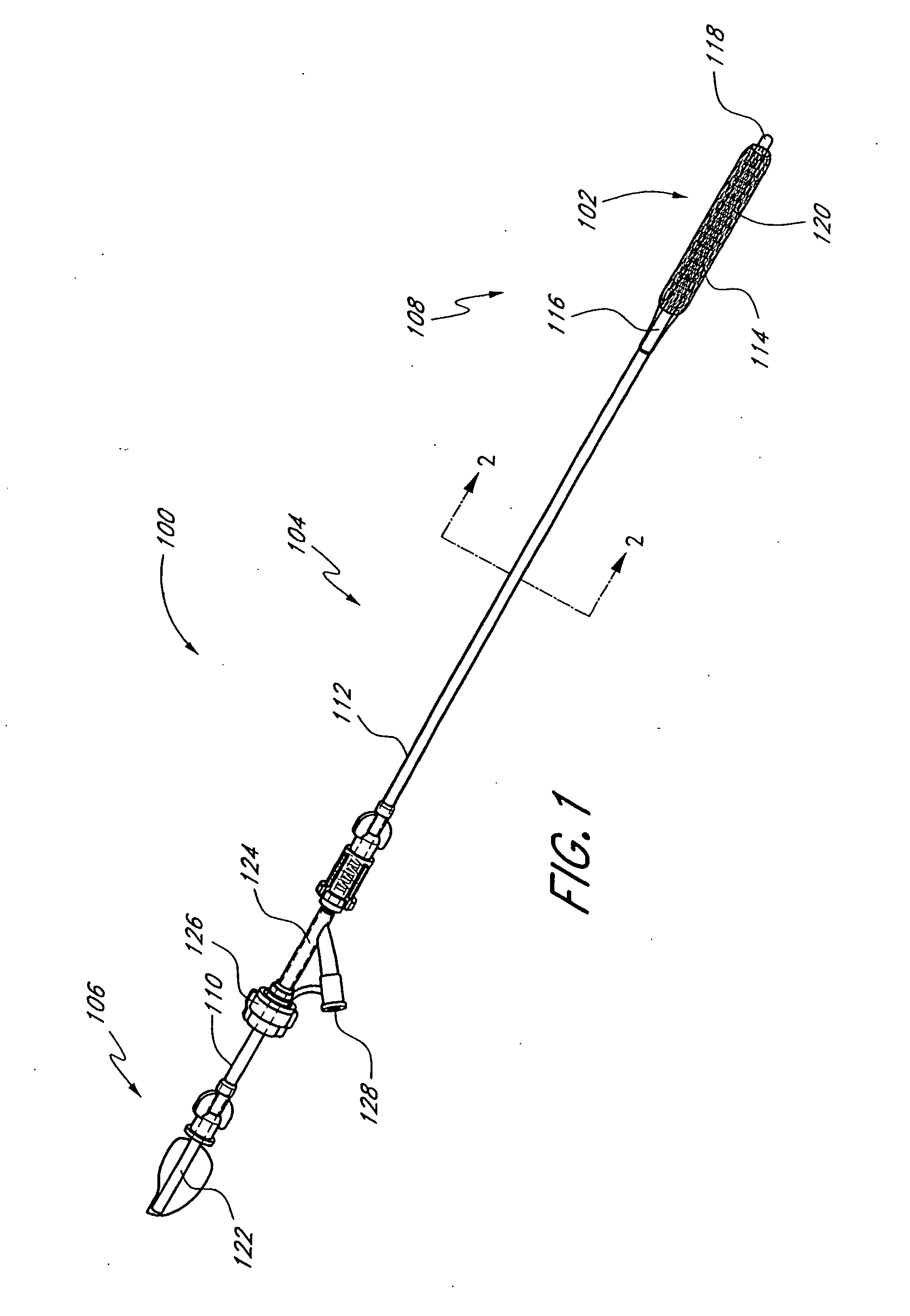

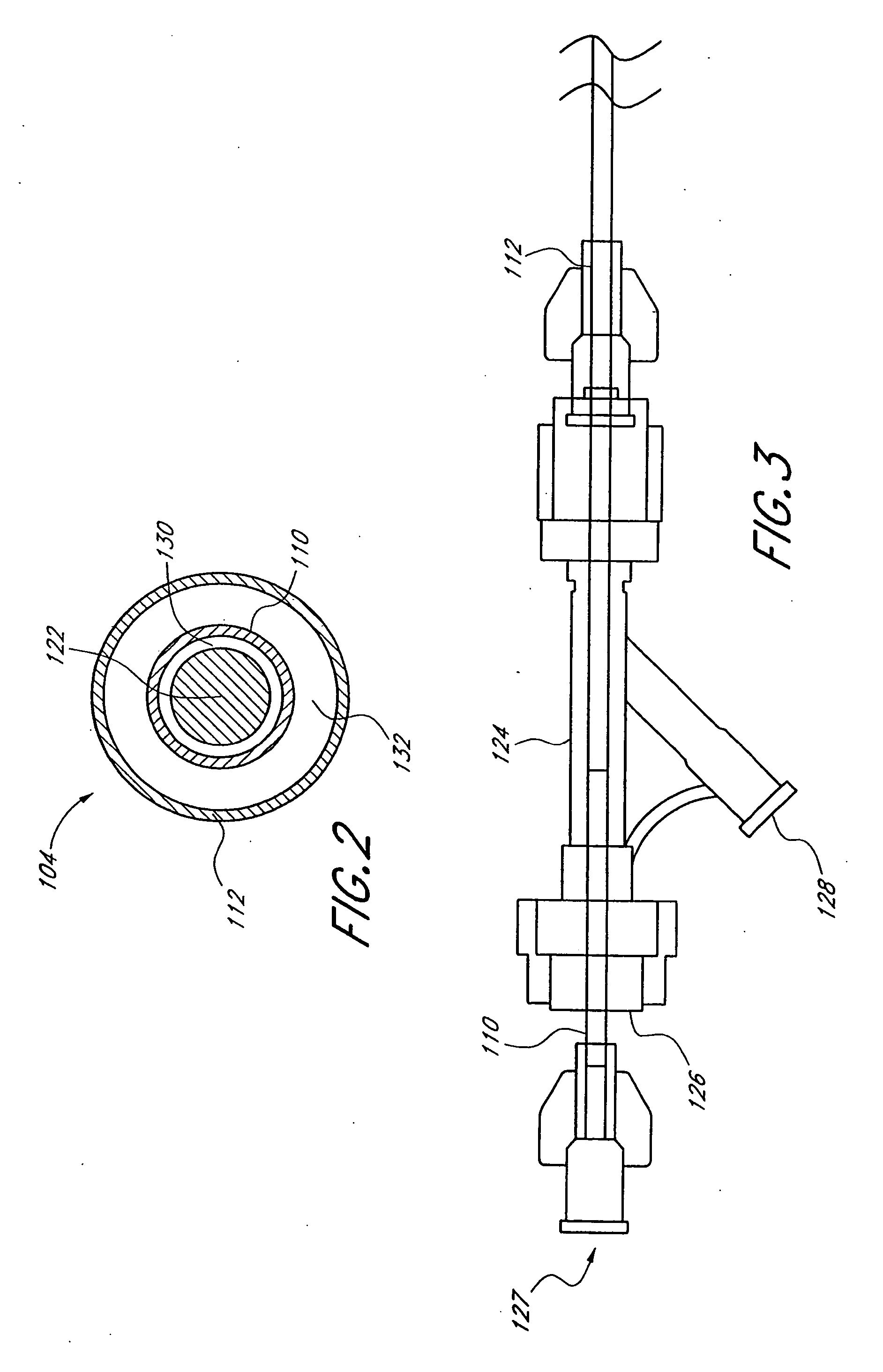

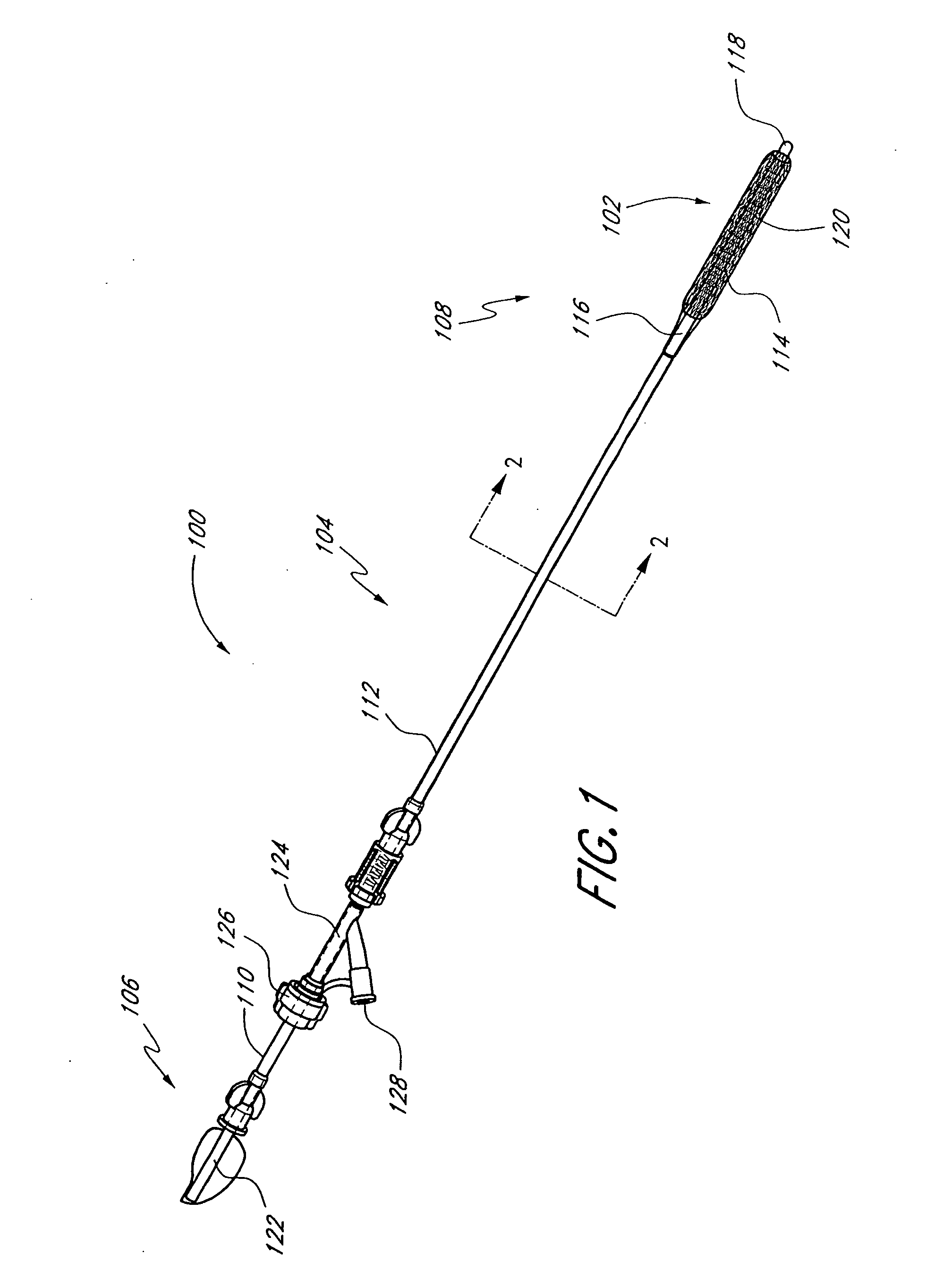

Formed in place fixation system with thermal acceleration

InactiveUS20050234453A1High normal sclerosisInternal osteosythesisDilatorsOrthopedic fixation devicesThermal acceleration

A subcutaneously formed in place orthopedic fixation device is provided, such as for fixation of the spine or other bone or bones. The device comprises an inflatable member, such as a tubular balloon. A heat source is provided in thermal communication with the interior of the balloon. The balloon is positioned at a treatment site while in a flexible, low crossing profile configuration. The balloon is thereafter inflated with a hardenable media, and heated to accelerate hardening of the media. Methods and delivery structures are also disclosed.

Owner:WARSAW ORTHOPEDIC INC

Formed in place fixation system with thermal acceleration

InactiveUS20050251140A1High normal sclerosisSuture equipmentsInternal osteosythesisOrthopedic fixation devicesThermal acceleration

Owner:WARSAW ORTHOPEDIC INC

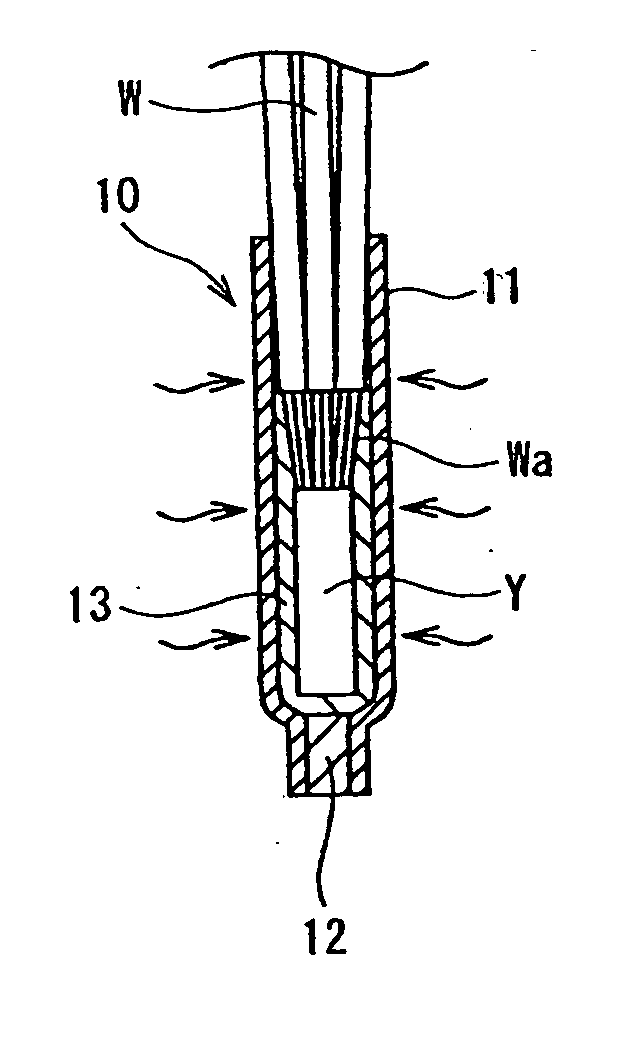

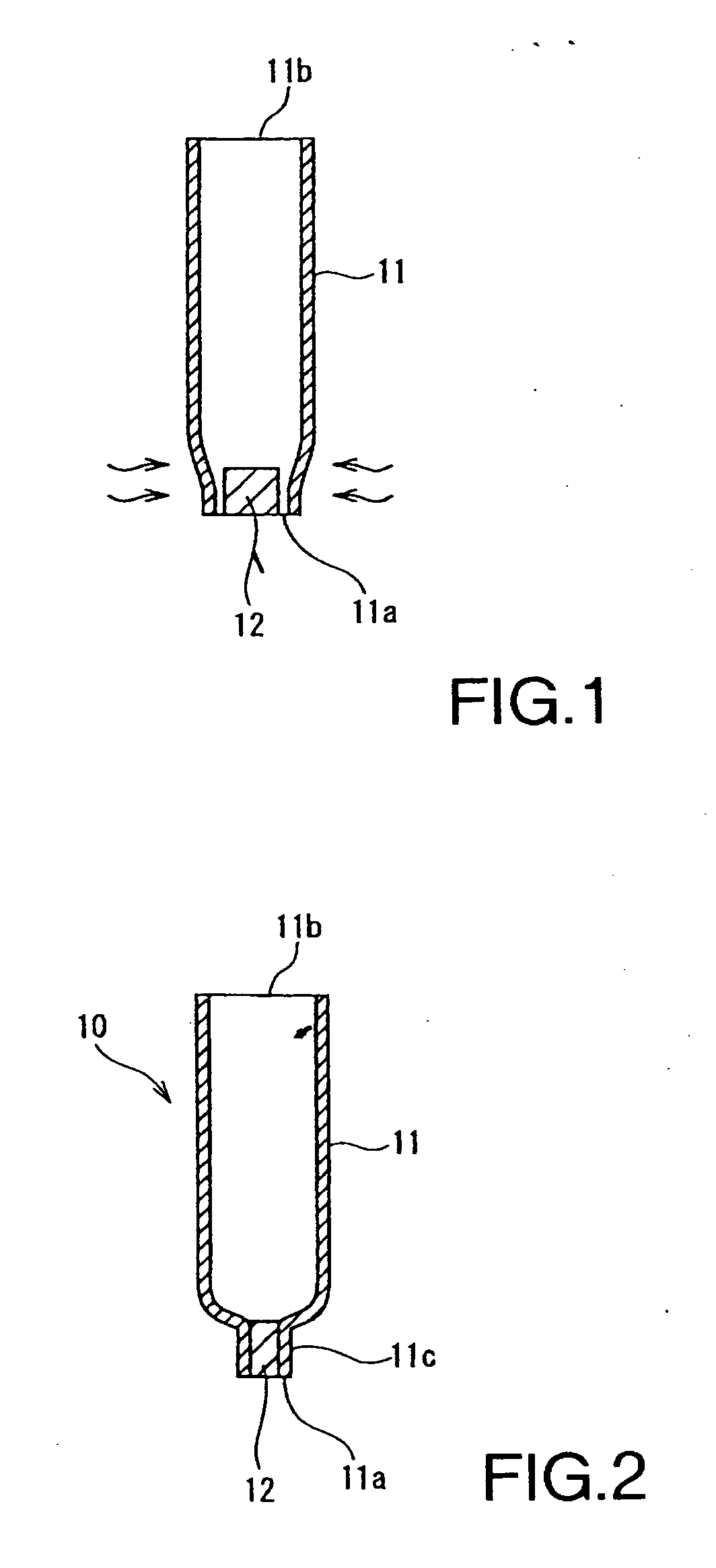

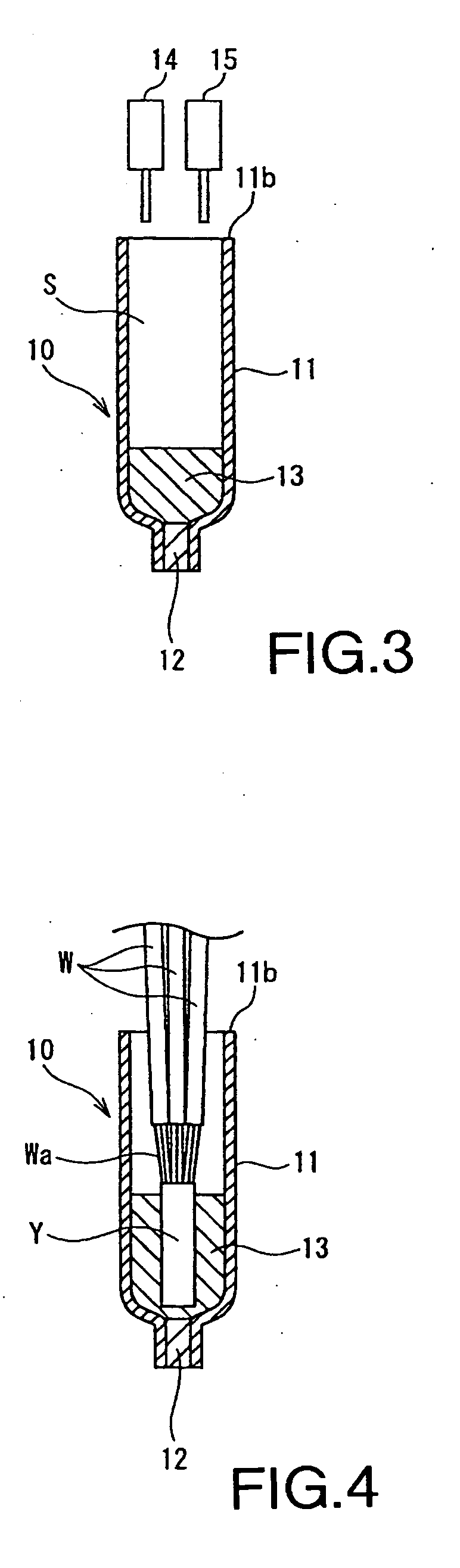

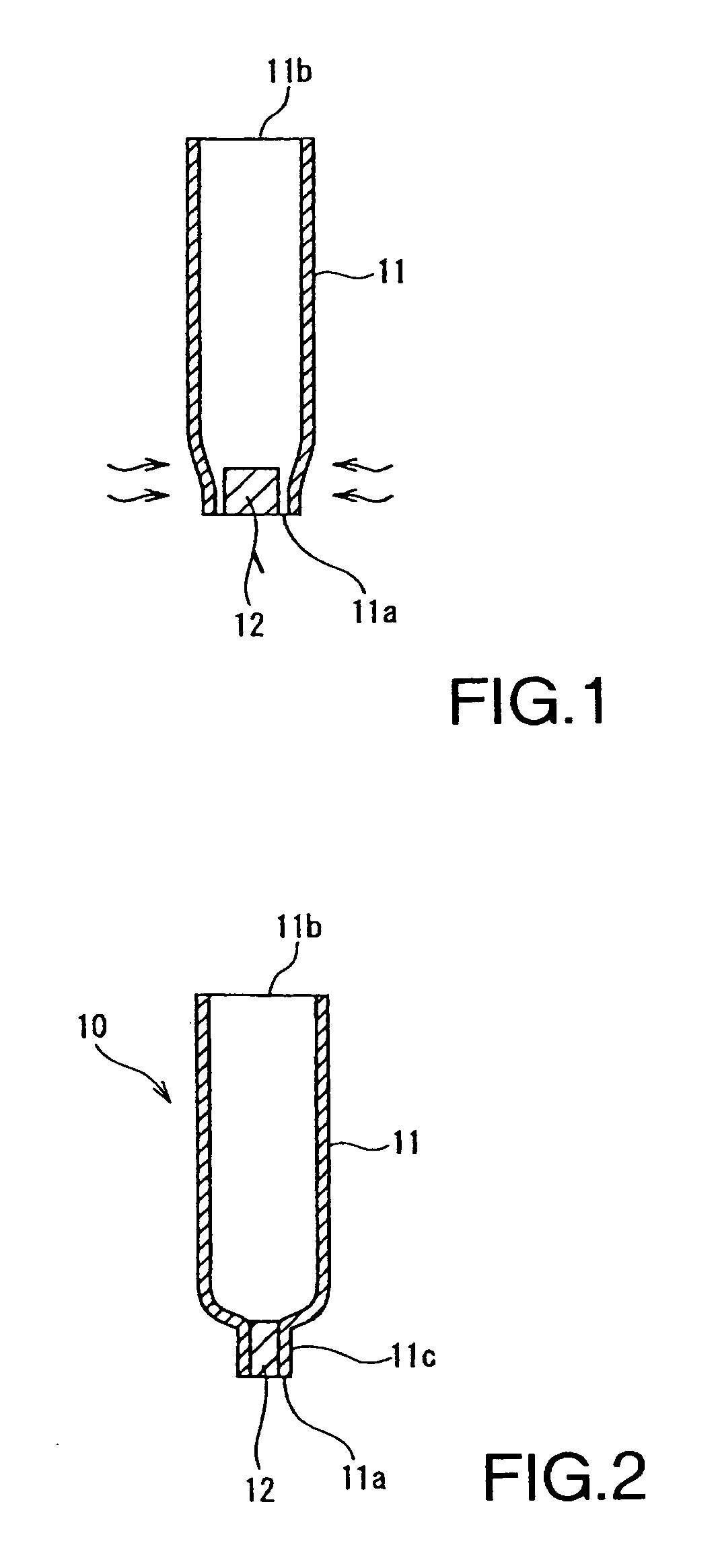

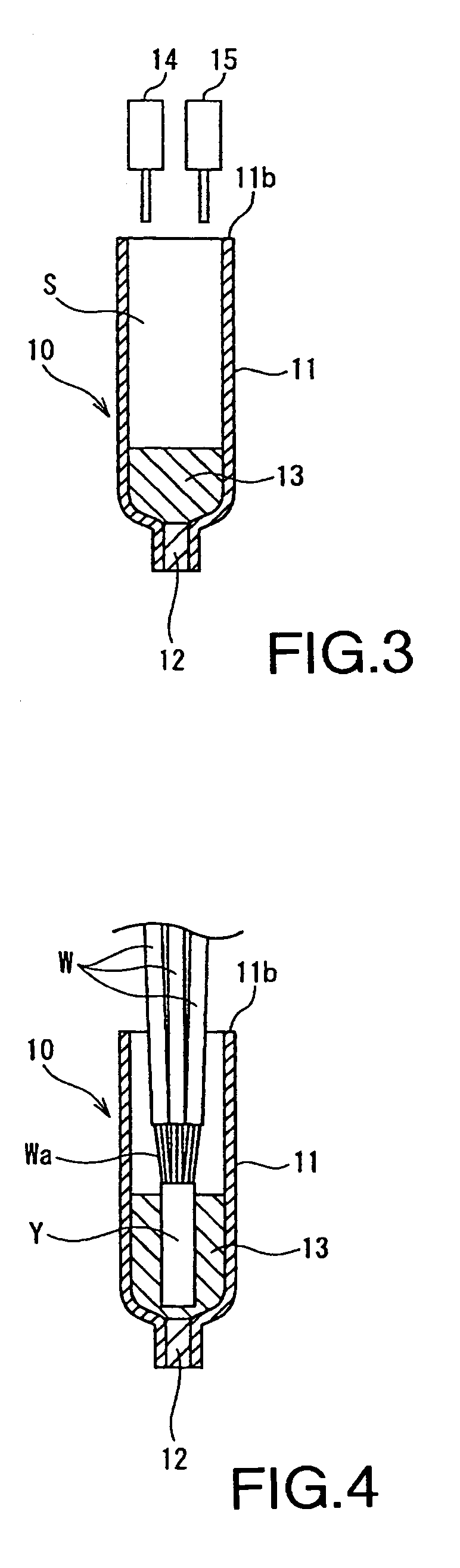

Method and structure for waterproofing a terminal splice

ActiveUS20060048965A1Reduce the overall diameterImprove performanceDustproof/splashproof/drip-proof/waterproof/flameproof connectionCouplings bases/casesHeat-shrink tubing

To decrease cap diameter covering a terminal splice and improve workability and waterproof performance, a stopper is inserted in one opening of a heat shrinkable tube. The heat shrinkable tube is heat-shrunk in this state, then a cap having end an closure is formed. A fluid thermosetting waterproofing agent is injected into the cap from a second opening. A thermal splice, which is formed from welded strands stripped from a plurality of wire terminals, is inserted and immersed in the thermosetting waterproofing agent. Then, the entire cap is heated and heat-shrunk at a predetermined temperature and the thermosetting waterproofing agent is heat-hardened.

Owner:SUMITOMO WIRING SYST LTD

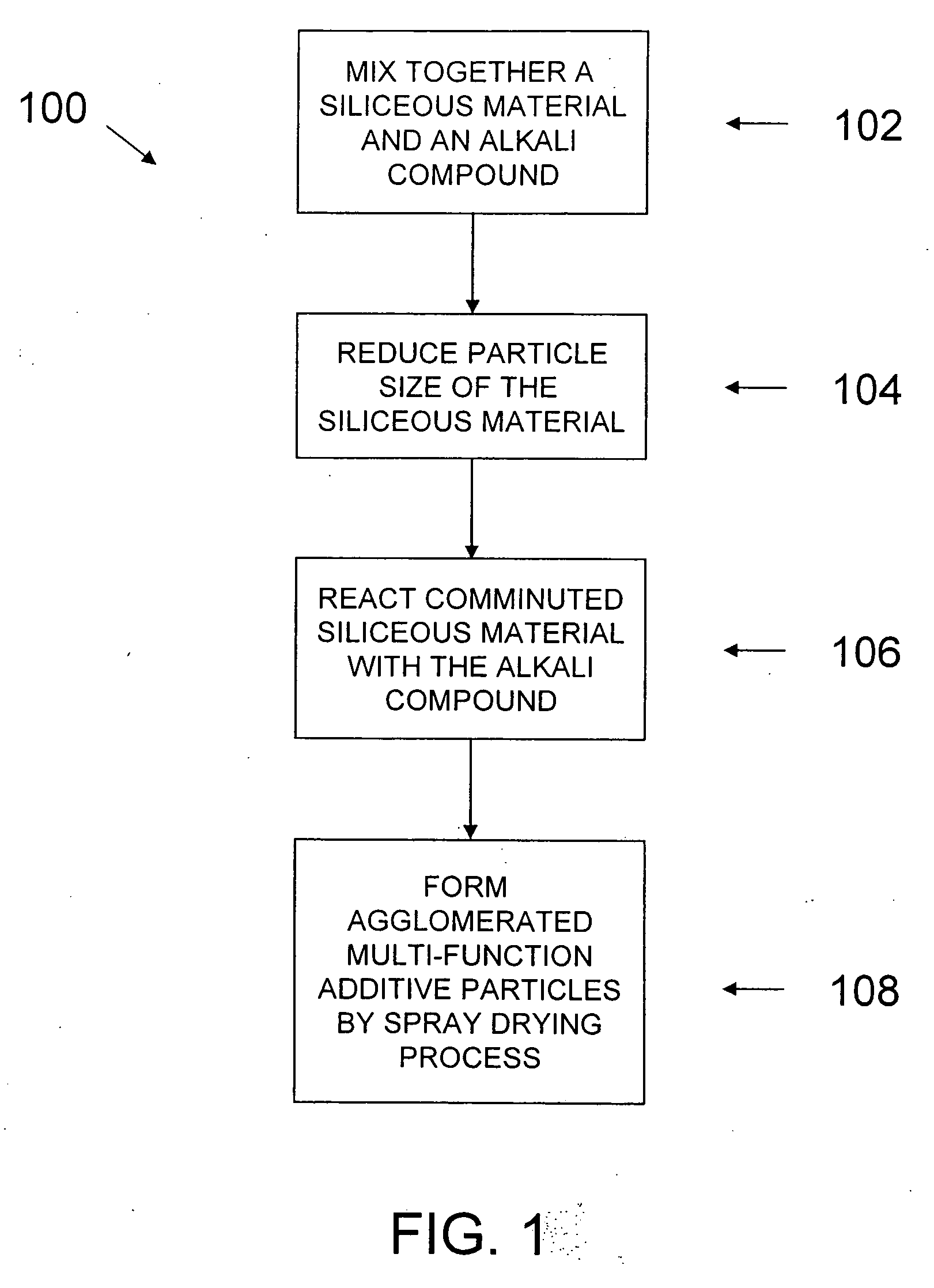

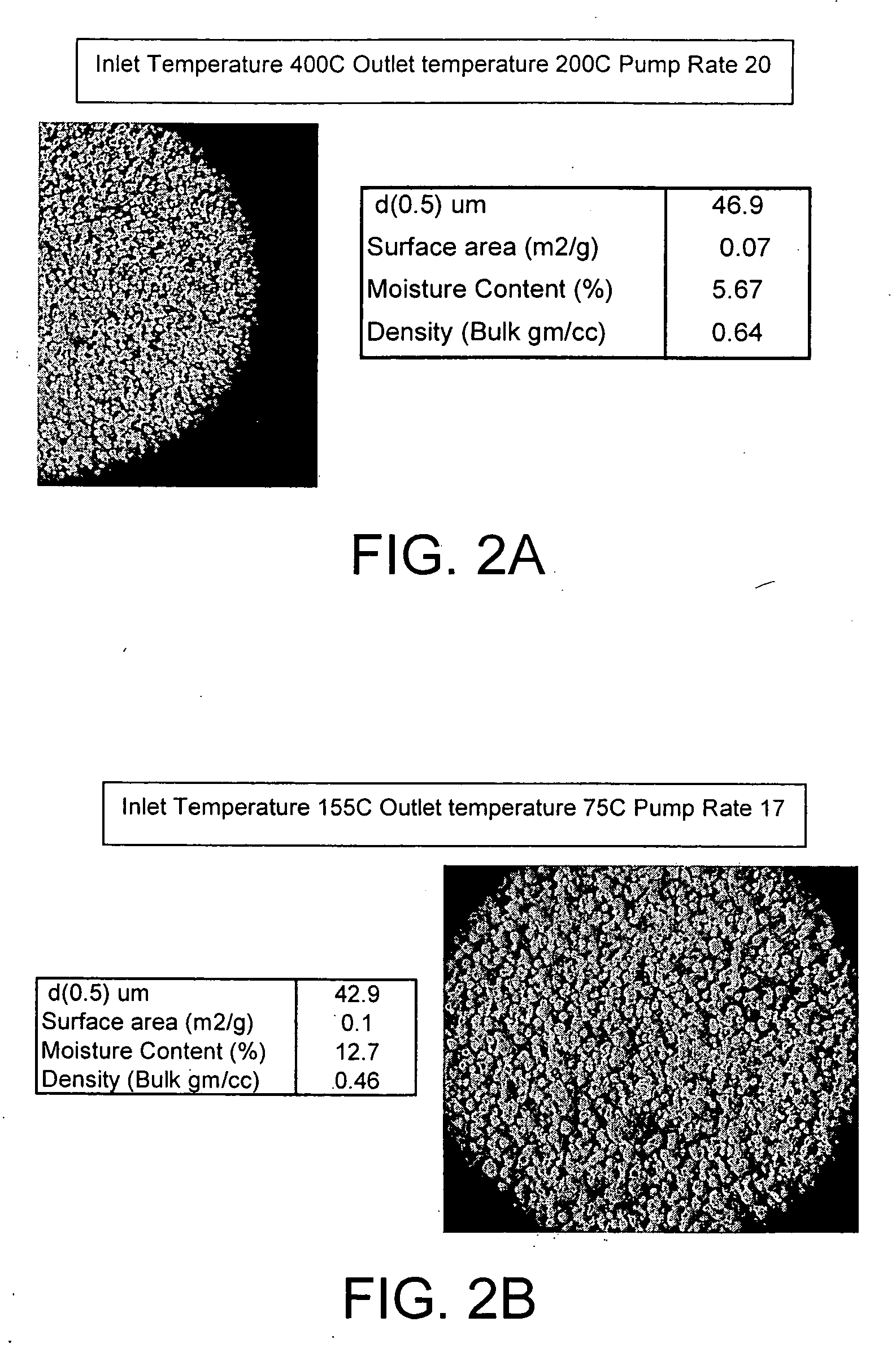

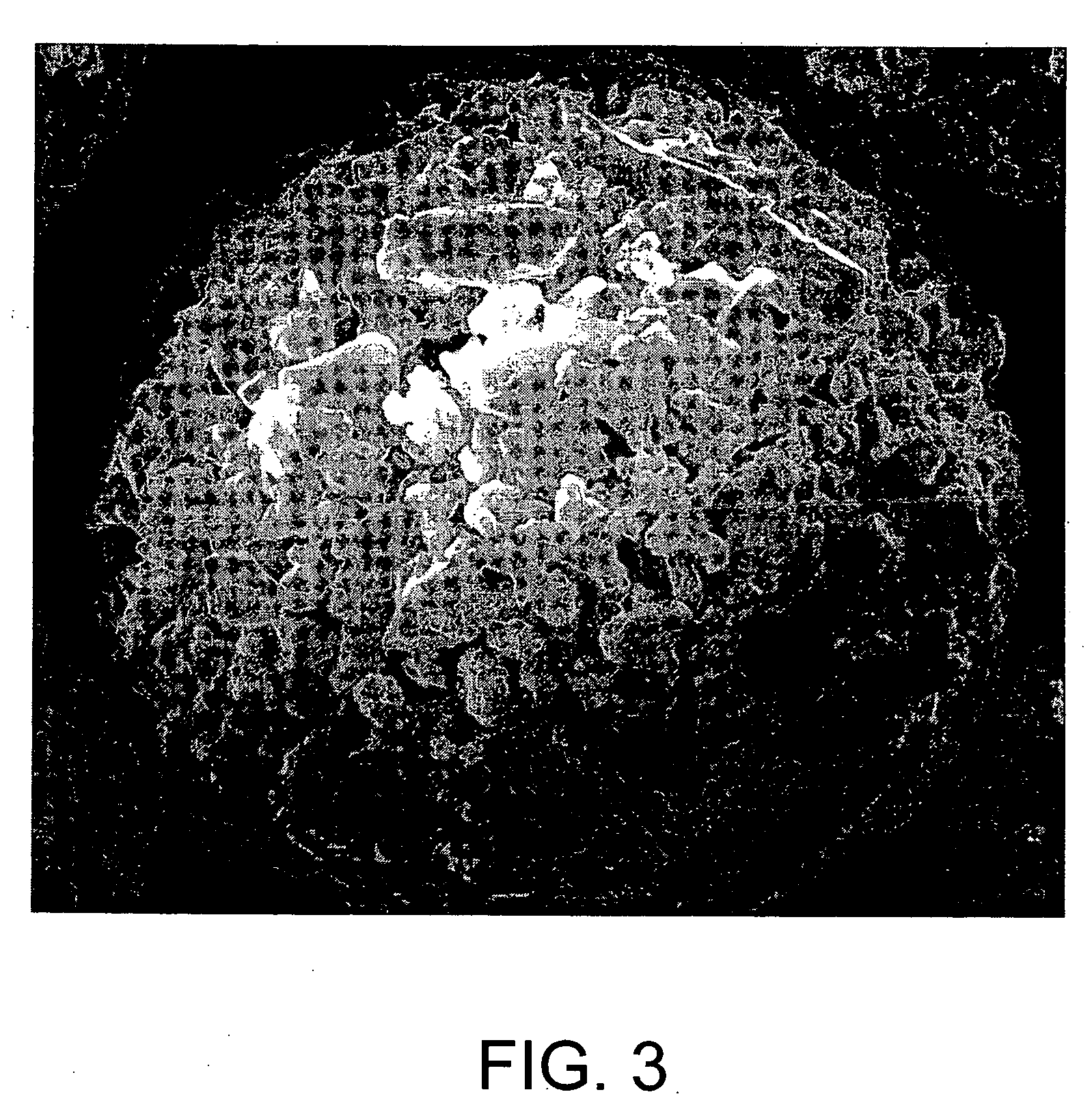

Multi-function composition for settable composite materials and methods of making the composition

InactiveUS20070131145A1Acceleration in and hardeningSmall particle sizeAlkali metal silicate coatingsInorganic adhesivesAlkaline activationSlurry

A multi-function composition for incorporation into settable composite materials is provided. The composition is formulated as an additive to modify the density of the composite material and increase the rate of hardening or strength development of the material. The composition of the additive generally includes an alkaline activation compound such as sodium silicate and a modified low density siliceous material having at least one region morphologically altered by a chemical, such as a partially digested region. The additive can be in slurry form, in powder form, or in an agglomerated particle form. The additive can be produced using a two-stage process in which a siliceous material is reduced in particle size, combined with an alkali compound in a solution and then digested in an atmospheric or pressurized vessel. In some implementations, the solution can be spray dried to form agglomerated particles containing the alkaline activation compound and the low density siliceous particle having one or more partially digested regions.

Owner:JAMES HARDIE INT FINANCE BV

Method and structure for waterproofing a terminal splice

ActiveUS7834268B2Reduce the overall diameterImprove performanceDustproof/splashproof/drip-proof/waterproof/flameproof connectionCouplings bases/casesEngineeringMechanical engineering

A method of waterproofing a terminal that includes a stopper inserted in one opening of a heat shrinkable tube. The heat shrinkable tube is heat-shrunk in this state to form a cap having a end closure. A fluid thermosetting waterproofing agent is injected into the cap from a second opening. A thermal splice, which is formed from welded strands stripped from a plurality of wire terminals, is inserted and immersed in the thermosetting waterproofing agent. Then, the entire cap is heated and heat-shrunk at a predetermined temperature and the thermosetting waterproofing agent is heat-hardened.

Owner:SUMITOMO WIRING SYST LTD

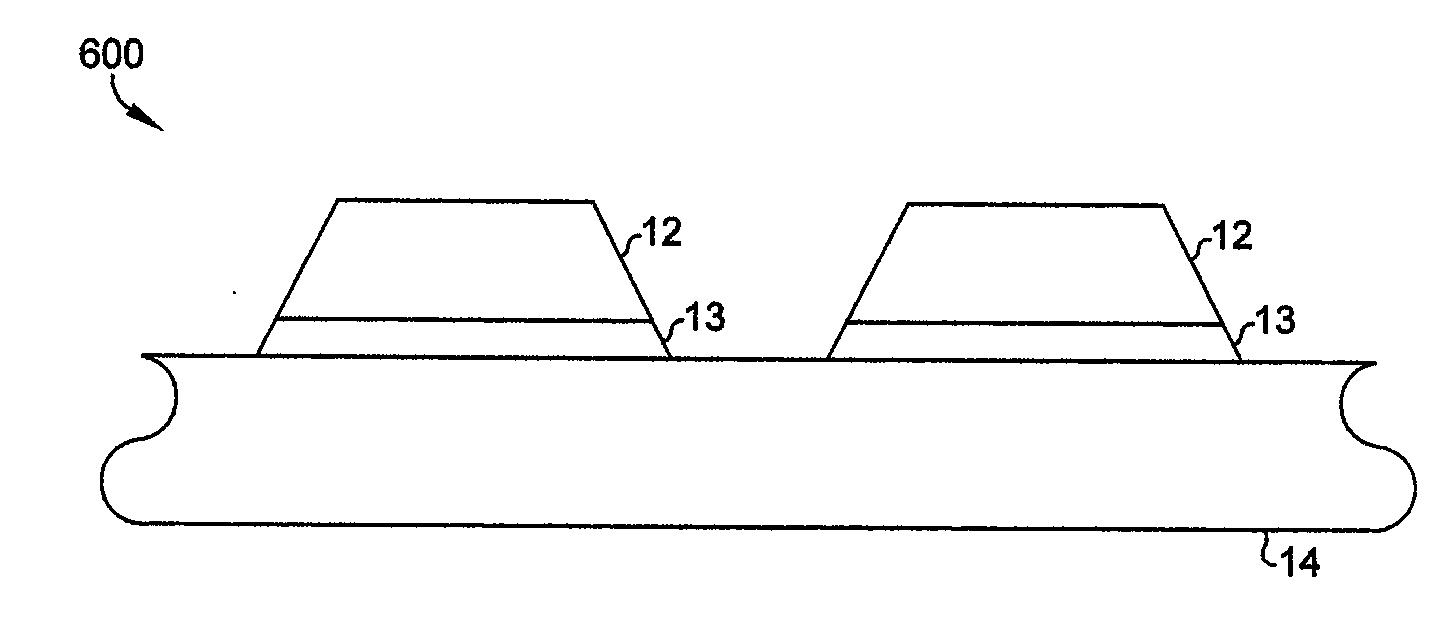

Composite panel based on cementitious mortar with properties of transparency

InactiveUS20130084424A1Improve cohesionImprove toughnessConstruction materialMouldsGlass fiberCement mortar

The present invention relates to a composite panel (10) based on cementitious mortar, passed through its entire thickness by a plurality of through openings (11), each of which is filled with a material transparent to light in the form of a preformed plate (12) housed in said opening (11), or formed in said opening, wherein said cement-based mortar contains at least 30 kg / m 3 of fibres selected from one or more of the following types: metallic fibres, steel fibres, glass fibres, polymeric resin fibres. The invention also relates to methods of production of said panel.

Owner:ITALCEMENTI

Agglomerated zeolitic adsorbents, their method of preparation and their uses

ActiveUS20100113854A1High mechanical strengthImproved kineticsAluminium compoundsMolecular sieve catalystsMean diameterSorbent

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / AL<1.5, consisting of crystals with a mean diameter of 1.7 mm or less and of an inert binder, at least 90% of the exchangeable cationic sites of the zeolite X being occupied by barium ions. They may be obtained by agglomerating a zeolite X powder having a mean diameter of 1.7 mm or less with a binder, followed by zeolitization of the binder, exchange of the zeolite ions with barium (and potassium) ions and activation of the adsorbents thus exchanged. These adsorbents exhibit, simultaneously, excellent selectivity, reduced mass transfer resistance and excellent mechanical strength and are particularly suitable for the adsorption of the paraxylene contained in C8 aromatic hydrocarbon fractions in liquid phase in processes of the simulated moving bed type and especially for the separation of paraxylene of C8 aromatic hydrocarbon fractions by adsorption, but also for the separation of sugars, polyhydric alcohols, cresols, and substituted toluene isomers.

Owner:ARKEMA FRANCE SA

Agglomerated zeolitic adsorbents, their method of preparation and their uses

ActiveUS8530367B2Loss of mechanical strengthMaintain good propertiesAluminium compoundsMolecular sieve catalystsAlcoholCresol

Owner:ARKEMA FRANCE SA

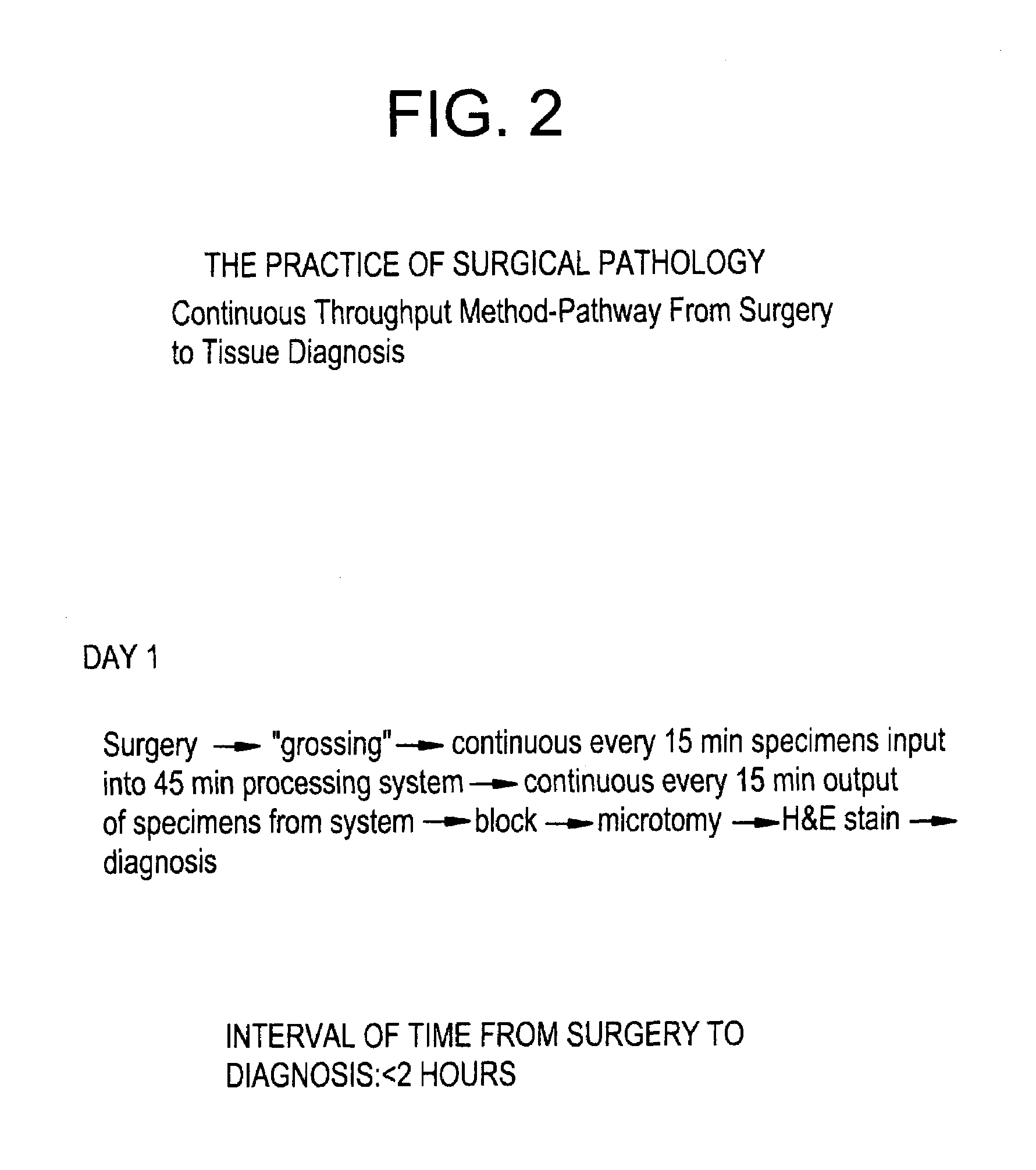

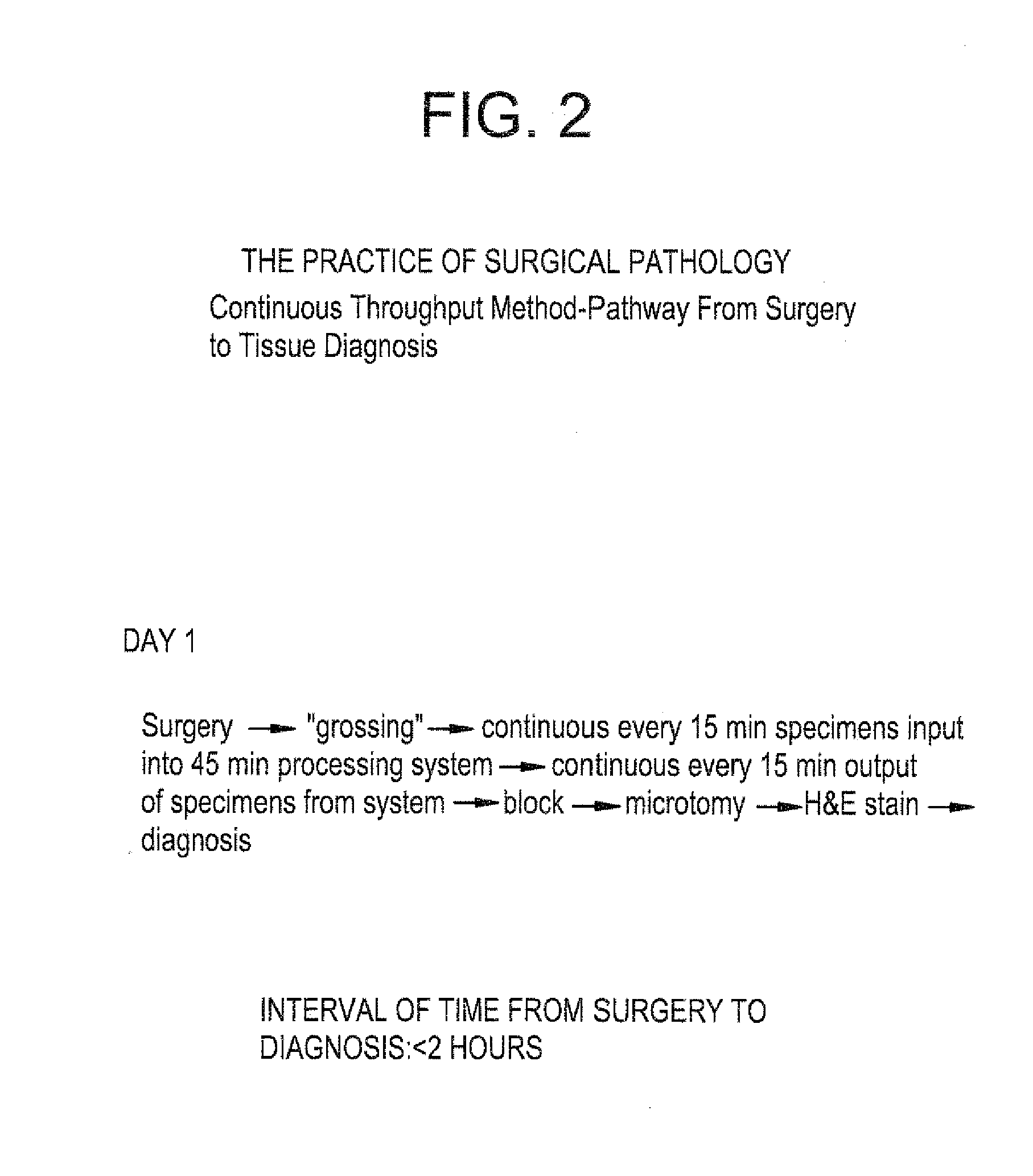

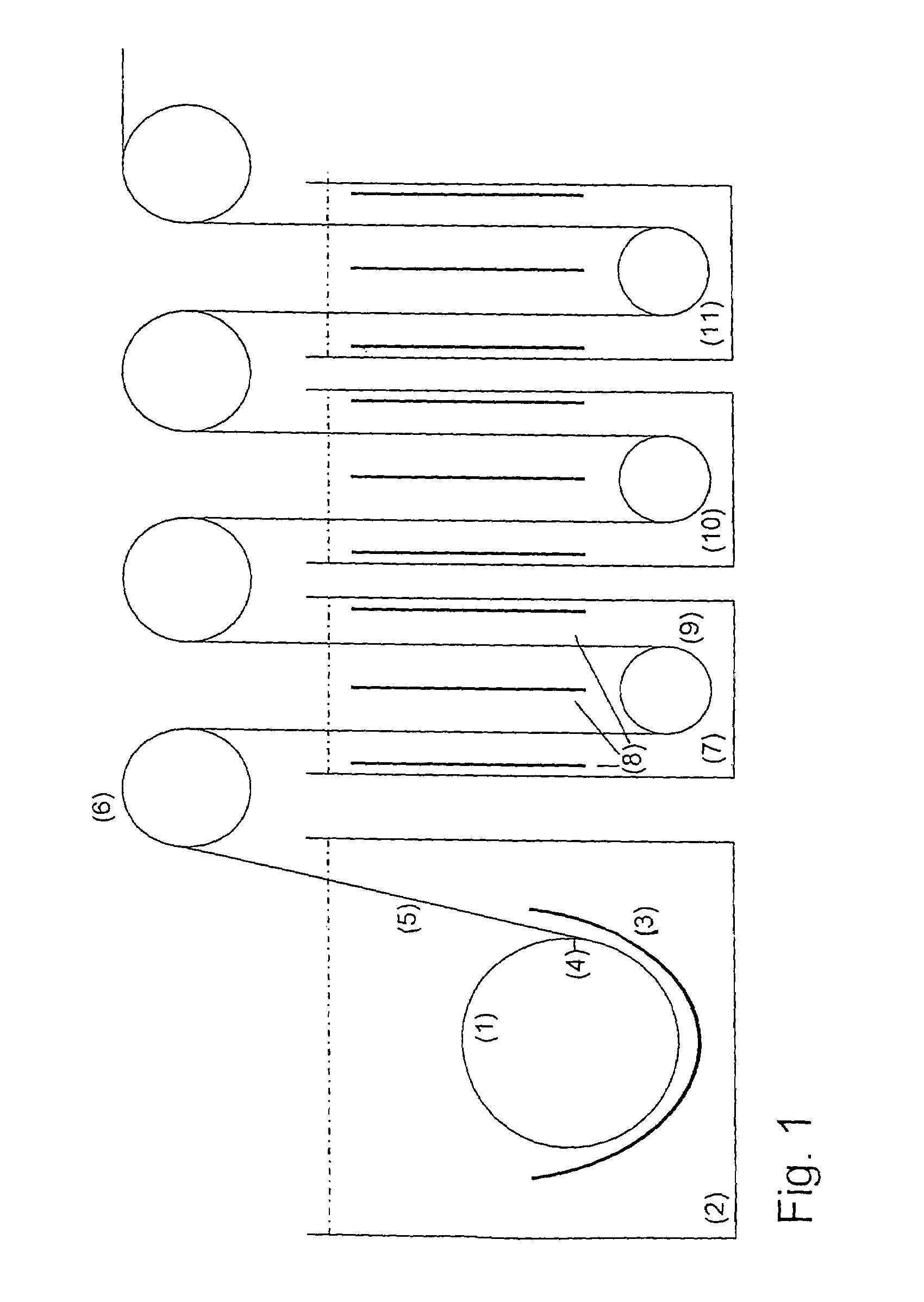

High quality, continuous throughput, tissue processing

InactiveUS7547538B2Shorten the timeLow costWithdrawing sample devicesPreparing sample for investigationSurgical operationPoint of care

A process and apparatus for rapid, continuous flow histological processing of tissues is disclosed. The steps of fixation, dehydration, clearing and impregnation are performed in less than one hour; this allows a pathologist to evaluate samples shortly after receipt, perhaps while the patient is still in the operating room. Rapid and continuous processing is accomplished by decreasing the thickness of tissue sections, use of nonaqueous solutions composed of admixtures of solutions, solution exchange at elevated temperature and with agitation, and impregnation under vacuum pressure. The patient in surgery is thus provided with point-of-care surgical pathology.

Owner:UNIV OF MIAMI

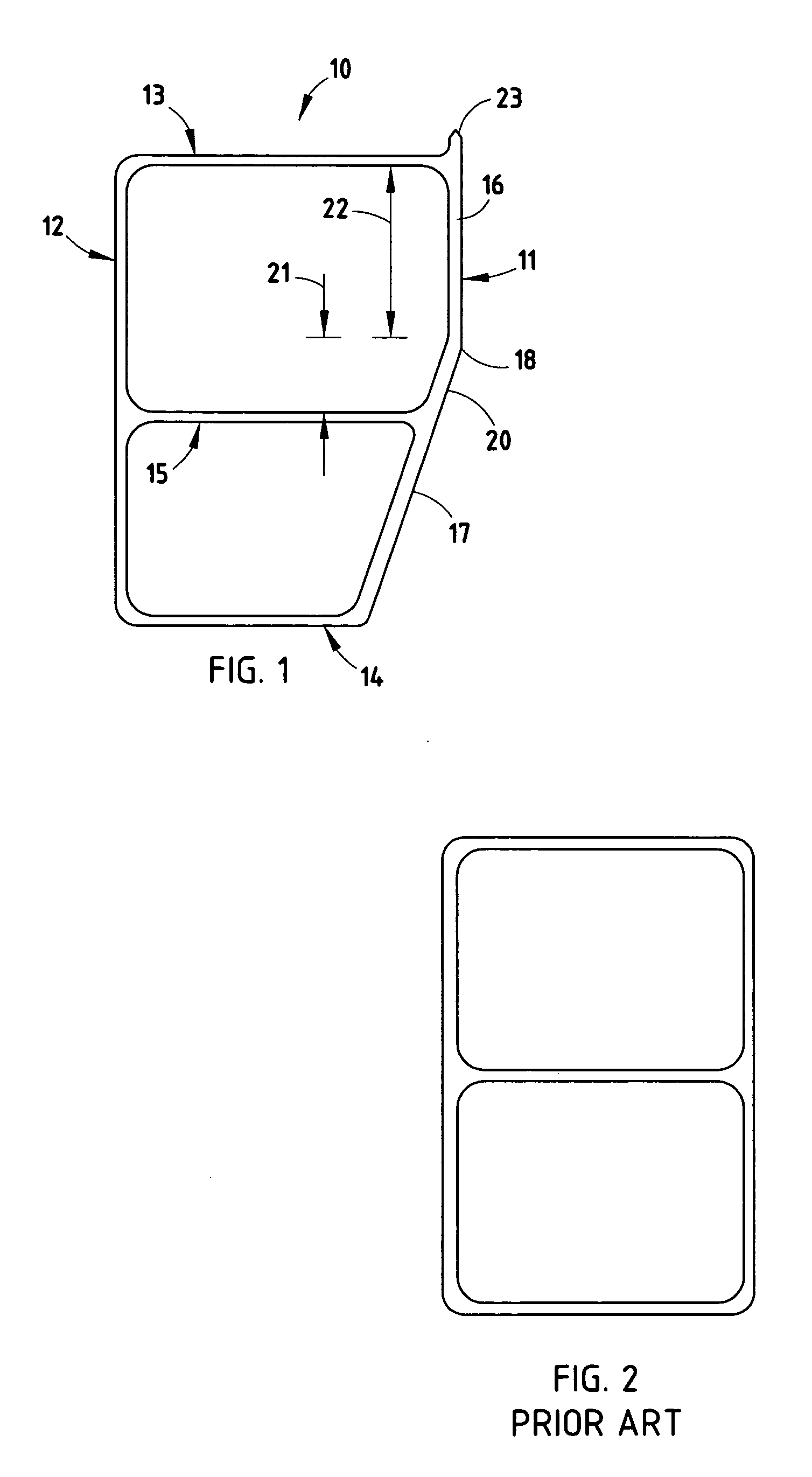

Bumper beam having face with supported angled wall

InactiveUS7017960B2Predictable and desired energy absorption upon impactHigh normal sclerosisBumpersEnergy absorptionEngineering

Owner:SHAPE CORP

Halogen-resistant, anodized aluminum for use in semiconductor processing apparatus

InactiveUS7048814B2Excellent abrasion resistanceHigh densityAnodisationVacuum evaporation coatingParticulatesHalogen

We have discovered that the formation of particulate inclusions at the surface of an aluminum alloy article, which inclusions interfere with a smooth transition from the alloy surface to an overlying aluminum oxide protective film can be controlled by maintaining the content of mobile impurities within a specific range and controlling the particulate size and distribution of the mobile impurities and compounds thereof; by heat-treating the aluminum alloy at a temperature less than about 330° C.; and by creating the aluminum oxide protective film by employing a particular electrolytic process. When these factors are taken into consideration, an improved aluminum oxide protective film is obtained.

Owner:APPLIED MATERIALS INC

Dry mixture for manufacturing cellular fibro concrete and method thereof

InactiveUS20120041087A1Good physical and mechanical propertiesHigh strengthSolid waste managementCeramicwareCombustionSlag

A dry raw mixture for manufacturing cellular fibro-concrete comprises components preferably in the following ratio: Portland cement 20-75%, mineralogical additives 70-20%, microsilica 2-10%', super-plastifier 0.6-3%, polypropylene fiber 0.08-0.15%, pore former 0.002-0.65%, and modifying ceolite additive 2-10%. The mineralogical additives can be represented by: fly ashes from coal combustion, ashes and slag, silica sand, limestone, and any combination thereof. The pore former can be represented by aluminum powder. The structure of modifying ceolite additive includes tetrahedrons SiO2 and AlO4. The raw mixture is further subjected to -intermingling and grinding in a conventional thin-powder grinder / mechanical activator, -bringing the mixture to a construction site, and -adding water to the mixture, thereby obtaining cellular fibro concrete. The method allows: -obtaining uniform mixtures, accelerating the hardening phase, -reducing costs due to avoiding the use of autoclave, steaming, and thermal curing equipment, -deploying inexpensive equipment for mixing concrete.

Owner:YASTREMSKIY EVGENIY NIKOLAEVICH +1

Monomer-polymer systems with a controllable pot life

InactiveUS20060293451A1High normal sclerosisMinimizing undesirable odorOrganic non-macromolecular adhesiveCoatingsEmulsionEmulsion polymerization

The invention relates to a dual component system with a controllable pot life. Said system can be hardened by a redox initiator system and comprises an emulsion polymer or a plurality of emulsion polymers and an ethylenically unsaturated monomer or a monomer mixture made from ethylenically unsaturated monomers. The emulsion polymer as well as the monomer or the monomer mixture can contain one of the components of a redox initiator system. Pot life is controlled by absorption of the redox initiator system on the polymer (A and B).

Owner:ROEHM GMBH & CO KG

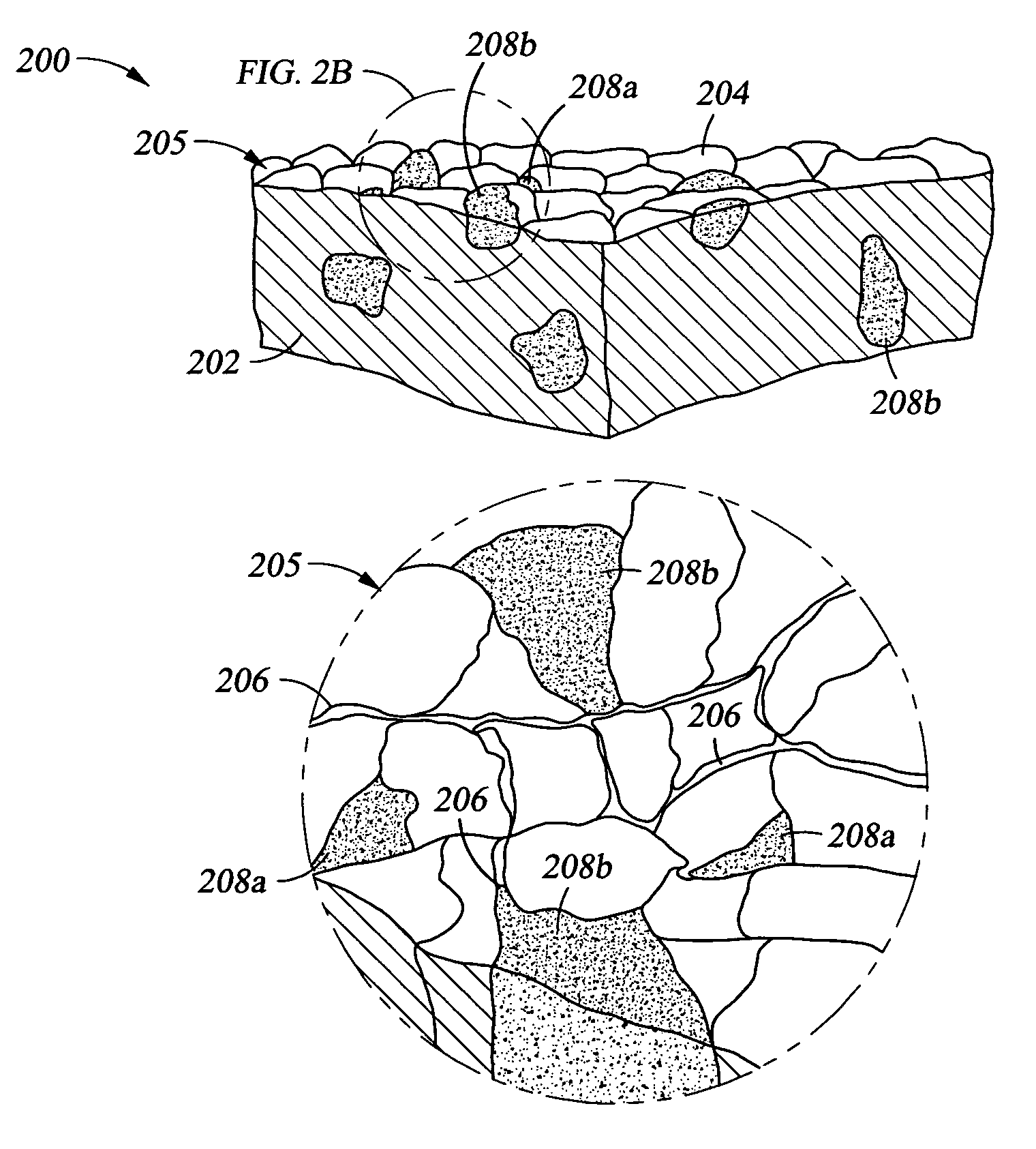

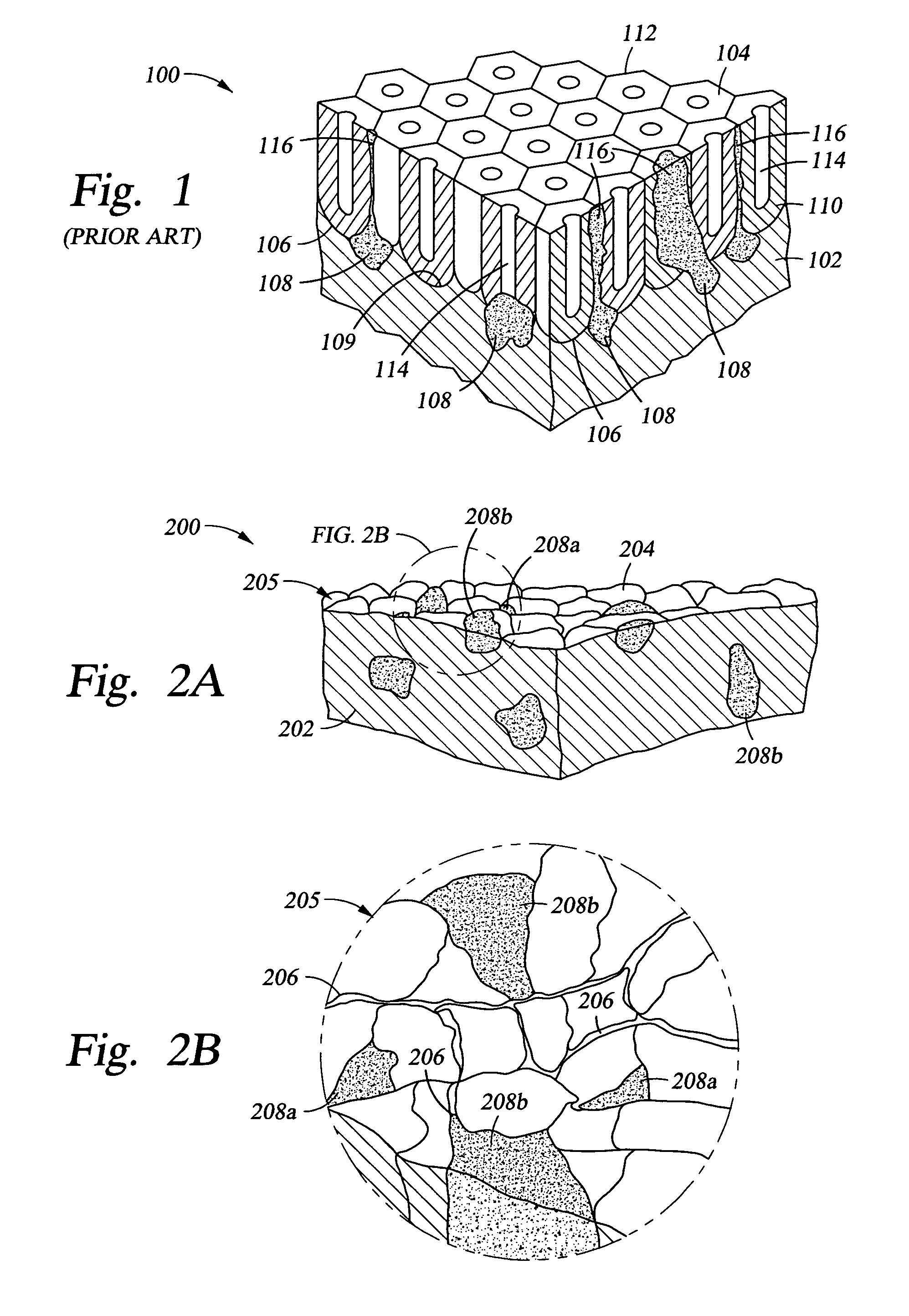

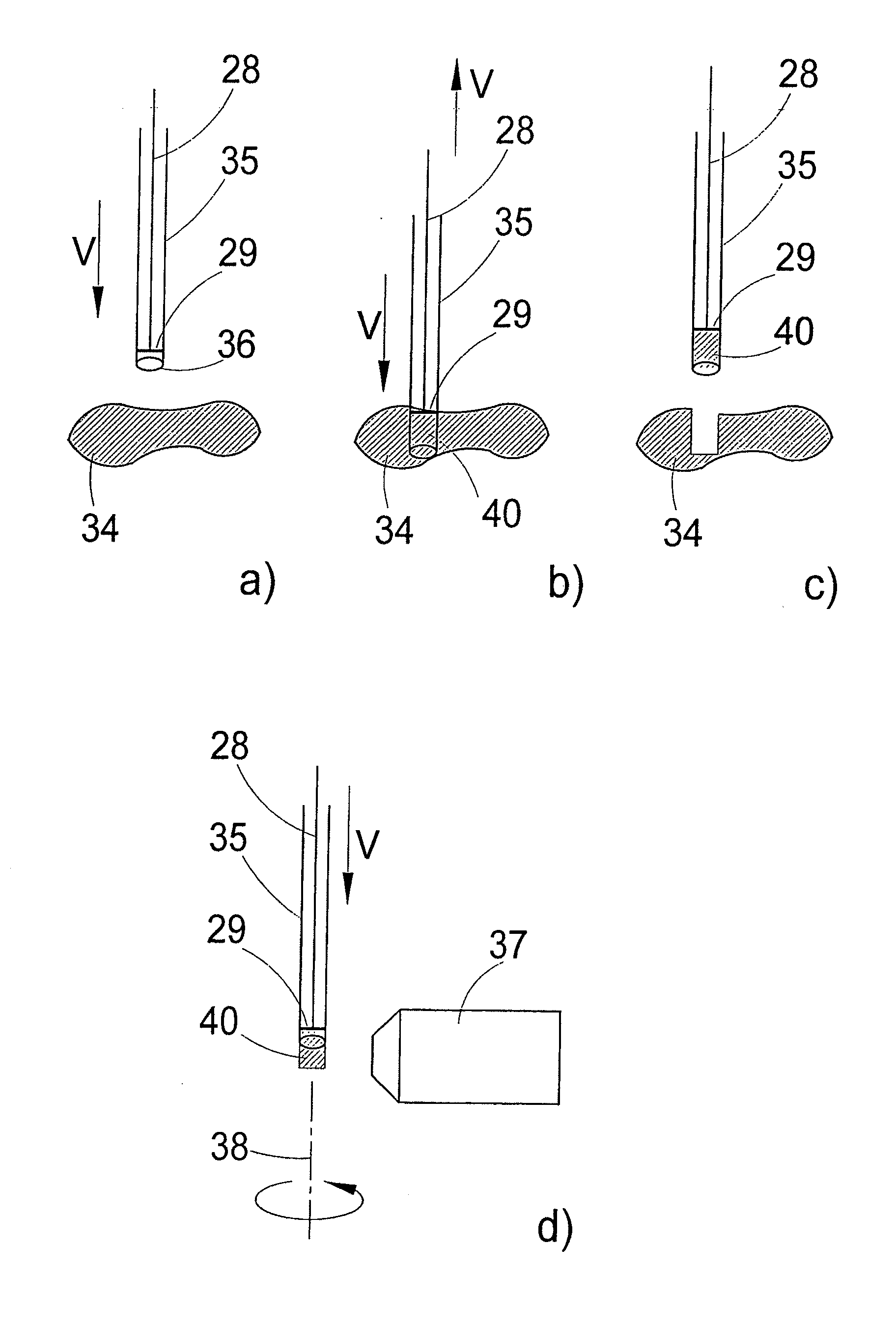

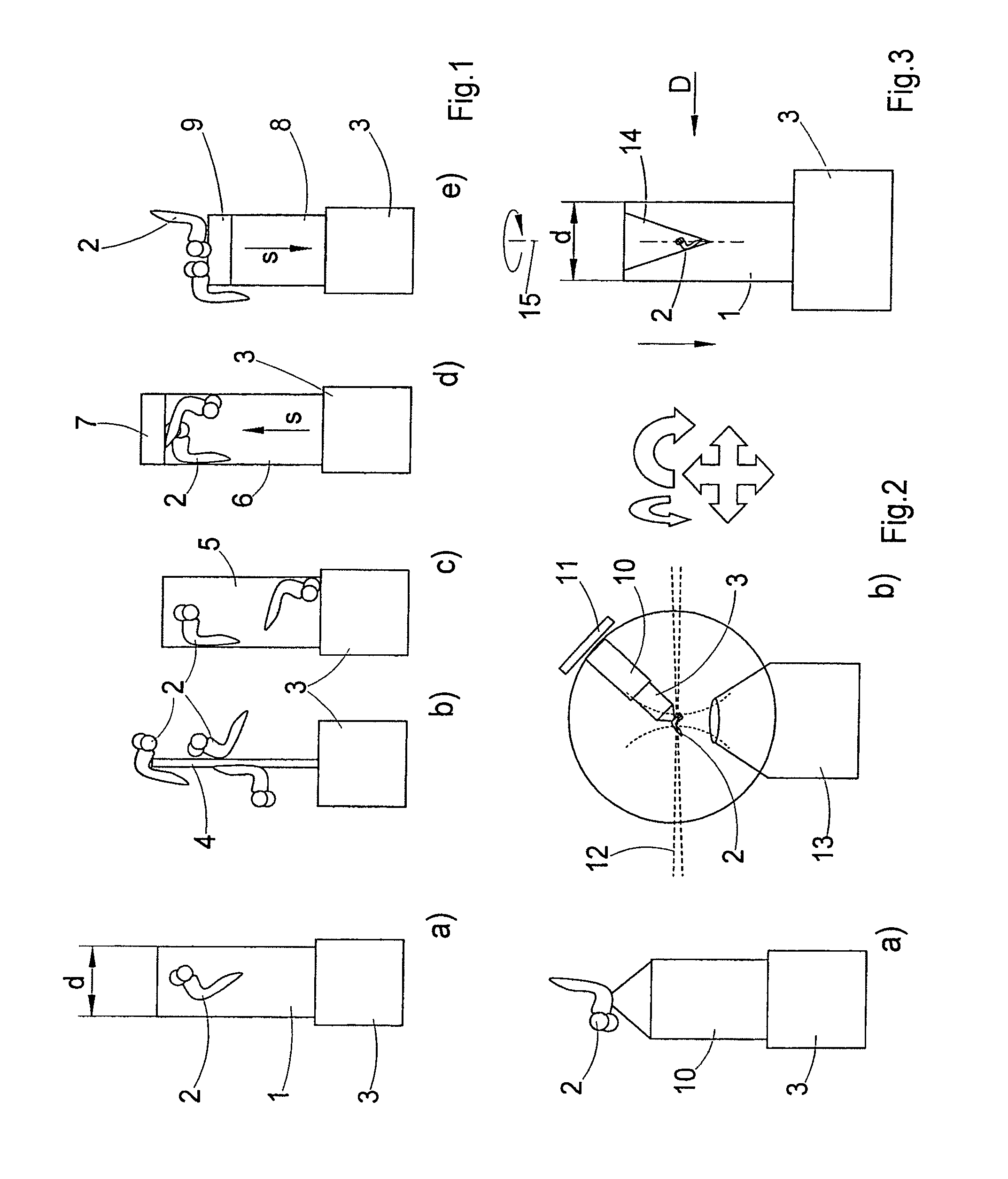

Method for positioning biological samples in a microscopic arrangement

ActiveUS20100239138A1Improve efficiencyFreedom of movementWithdrawing sample devicesMaterial analysis by optical meansOptical axisEngineering

The invention relates to methods for positioning at least one preferably biological specimen in the specimen space of a microscope arrangement, and to devices for carrying out these methods. Methods and devices are proposed, wherein the specimen's orientation relative to a detection objective's optical axis can be repeatedly changed and, in doing so, the specimen is held so that a substantially unobstructed view of the specimen is ensured from every detection direction. In different constructional variants, the specimen is held at a supporting device by adhesive forces or by a flowing medium, the specimen is held at a capillary opening by capillary action, or at least one specimen is embedded in a body of transparent gel, and the gel body is fixed in the specimen space by means of a rotatable holding device, and the detection direction is changed by rotating the holding device by a given angle of rotation.

Owner:CARL ZEISS MICROSCOPY GMBH

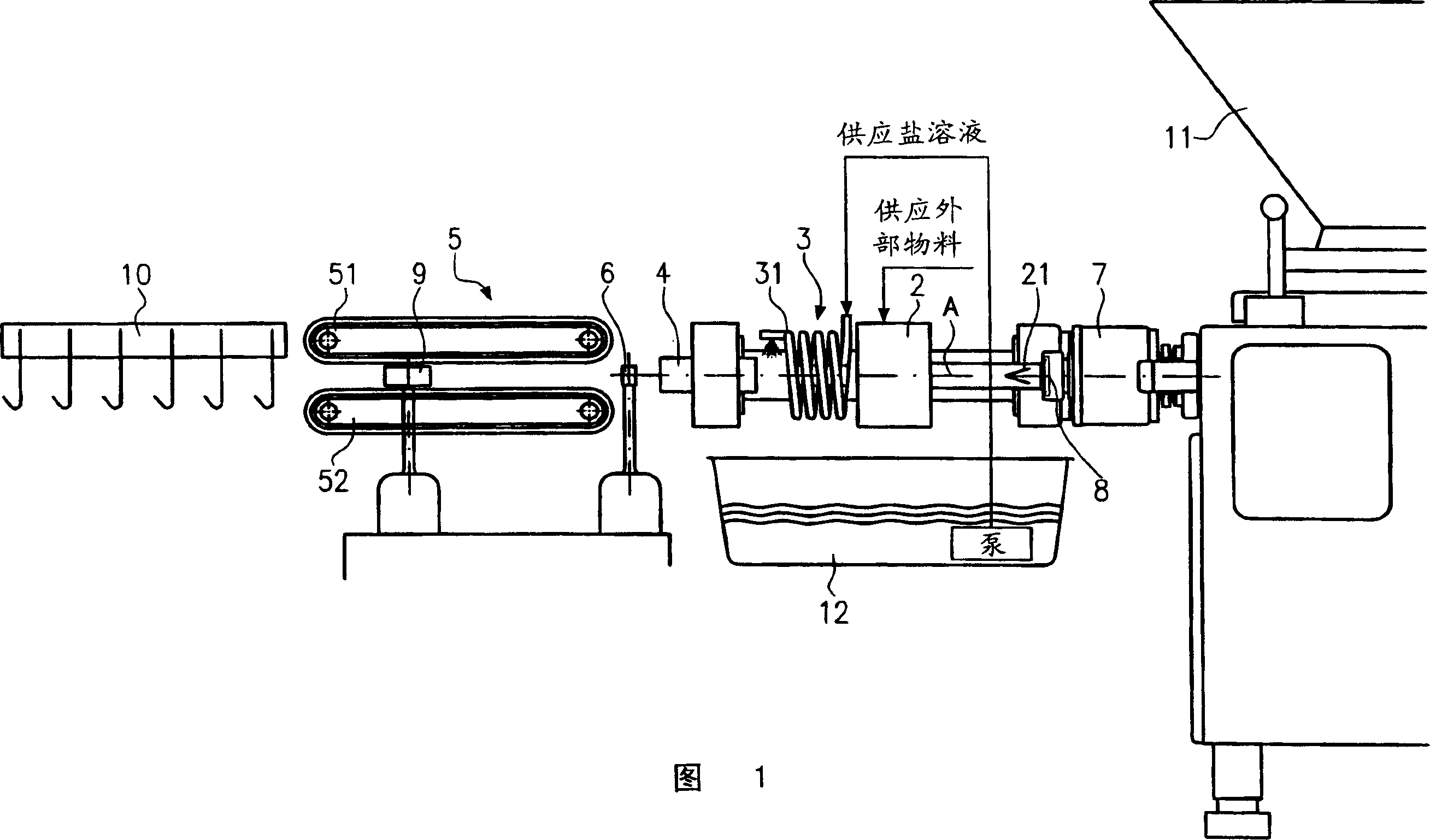

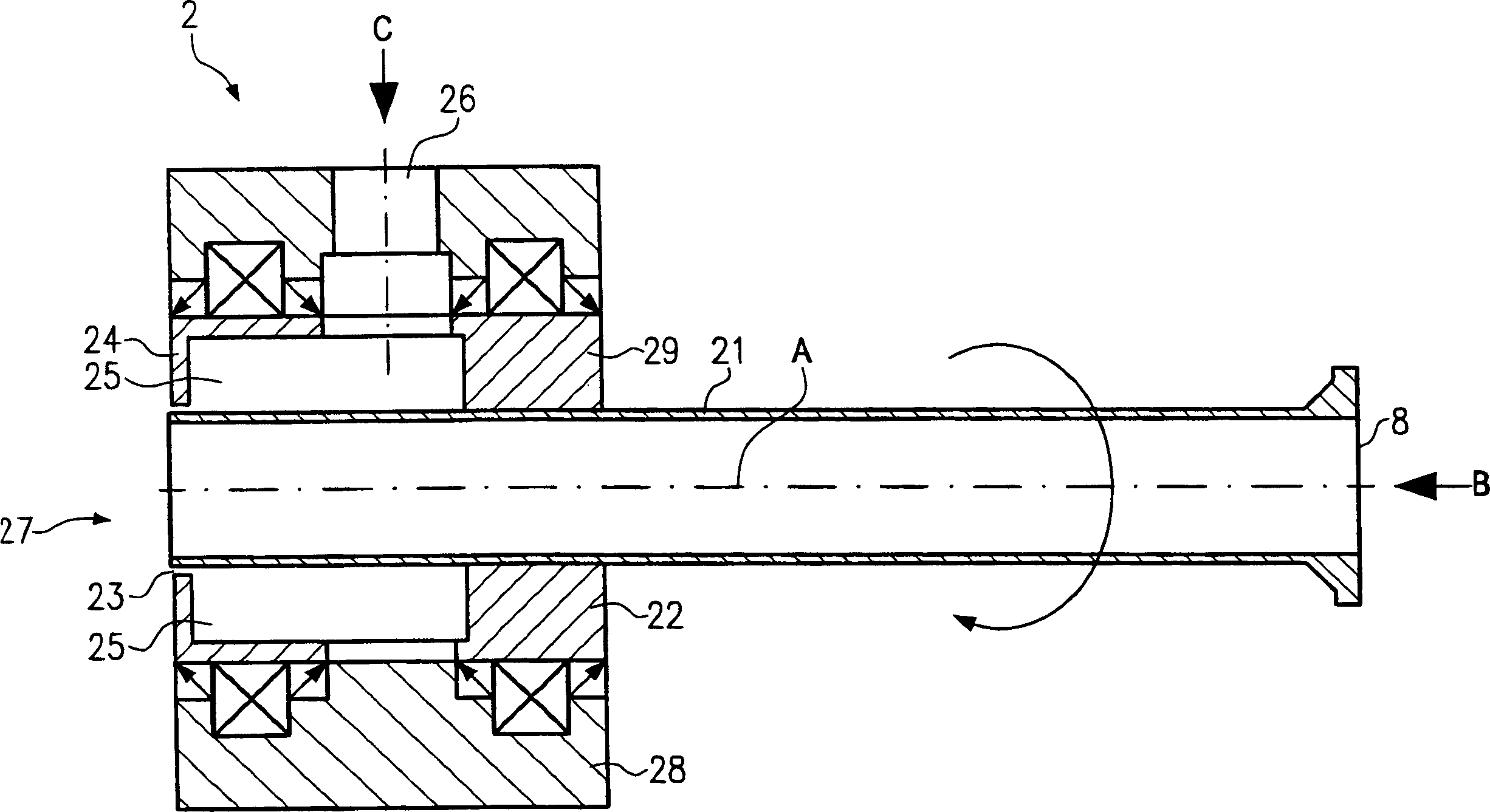

Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

InactiveCN1468540AHigh normal sclerosisIncrease distanceSausage skin tying apparatusSausage casing manufactureMechanical engineeringExtrusion

Owner:ALBERT HANDTMANN MASCHFABRICK

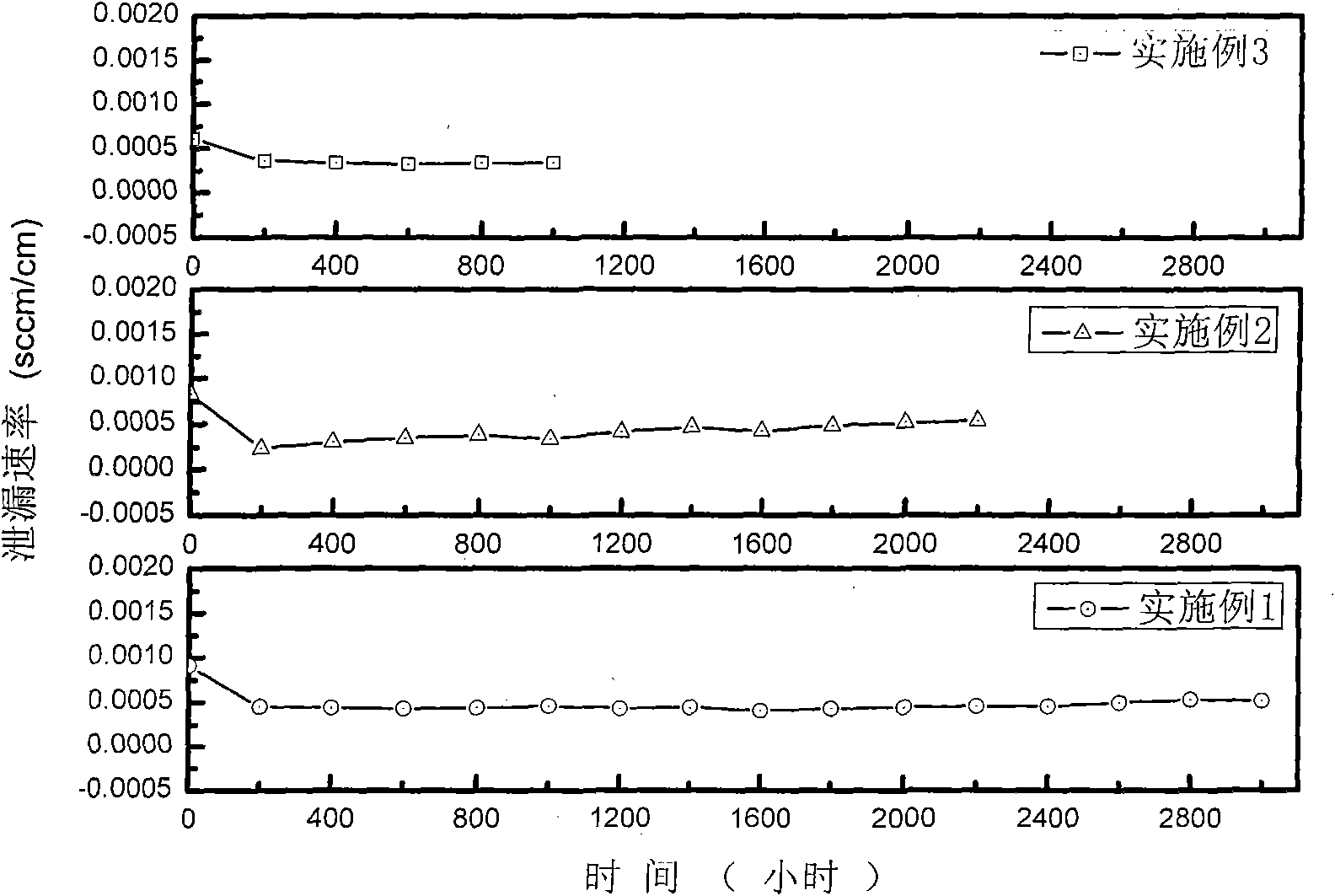

Sealing glass powder, sealing glass ceramic powder and application

The invention provides sealing glass powder, which is prepared from glass containing 20 to 40 mol percent of SiO2, 10 to 30 mol percent of B2O3, 10 to 40 mol percent of BaO, 2 to 15 mol percent of MgO, 0.1 to 5 mol percent of La2O3, 2 to 10 mol percent of Y2O3, 1 to 5 mol percent of ZrO, 0 to 15 mol percent of SrO and 0 to 30 mol percent of CaO. The invention also provides a method for forming sealing glass by sintering the glass powder. In addition, the invention provides glass ceramic powder and the method for forming the sealing glass ceramic by sintering the powder. Furthermore, the invention provides the application of the sealing glass and the sealing glass ceramic. The glass powder and the glass ceramic powder in the invention are simple in adopted raw materials and manufacturing process, low in cost and good in wetting quality and compatibility with connected parts and have the advantages of adjustable thermal expansion coefficient and good thermal stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for positioning biological samples in a microscopic arrangement

ActiveUS8228499B2Improve efficiencyFreedom of movementWithdrawing sample devicesMaterial analysis by optical meansOptical axisEngineering

The invention relates to methods for positioning at least one preferably biological specimen in the specimen space of a microscope arrangement, and to devices for carrying out these methods. Methods and devices are proposed, wherein the specimen's orientation relative to a detection objective's optical axis can be repeatedly changed and, in doing so, the specimen is held so that a substantially unobstructed view of the specimen is ensured from every detection direction. In different constructional variants, the specimen is held at a supporting device by adhesive forces or by a flowing medium, the specimen is held at a capillary opening by capillary action, or at least one specimen is embedded in a body of transparent gel, and the gel body is fixed in the specimen space by means of a rotatable holding device, and the detection direction is changed by rotating the holding device by a given angle of rotation.

Owner:CARL ZEISS MICROSCOPY GMBH

High quality, continuous throughput, tissue processing

InactiveUS20080153127A1Shorten the timeLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careIon exchange

A process and apparatus for rapid, continuous flow histological processing of tissues is disclosed. The steps of fixation, dehydration, clearing and impregnation are performed in less than one hour; this allows a pathologist to evaluate samples shortly after receipt, perhaps while the patient is still in the operating room. Rapid and continuous processing is accomplished by decreasing the thickness of tissue sections, use of non-aqueous solutions composed of admixtures of solutions, solution exchange at elevated temperature and with agitation, and impregnation under vacuum pressure. The patient in surgery is thus provided with point-of-care surgical pathology.

Owner:UNIV OF MIAMI

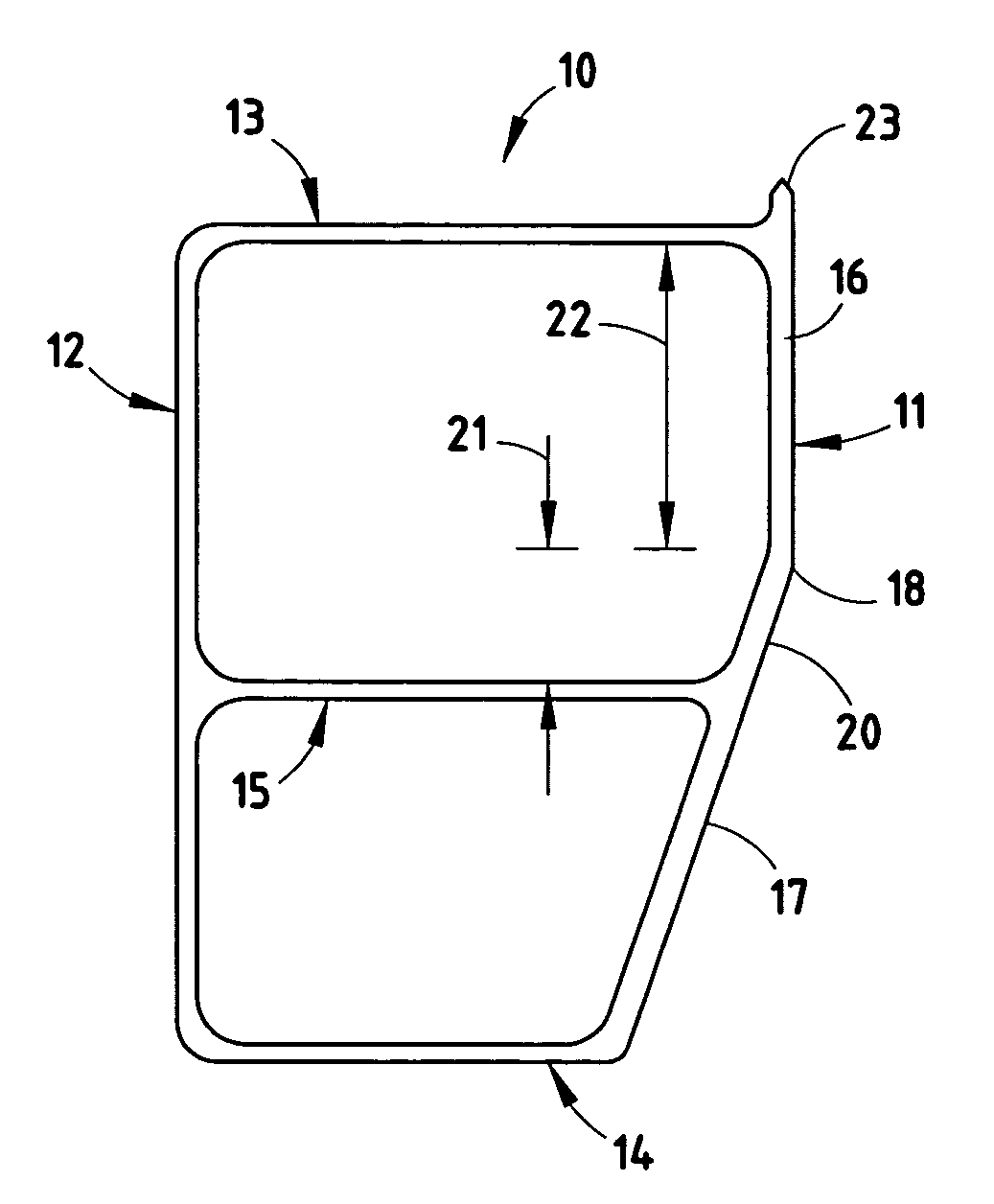

Bumper beam having face with supported angled wall

InactiveUS20050082850A1Predictable and desired energy absorption upon impactHigh normal sclerosisBumpersEnergy absorptionVertical Dimensions

A vehicle bumper beam includes front, rear, top and bottom walls and a reinforcement wall that define upper and lower tubes. The front wall includes a vertical section, an angled section, and a bent section. The reinforcement wall supports the angled section below the bent section to provide predictable and desired energy absorption. The angled section preferably includes an angled portion defining a first vertical dimension in the first tube and the vertical section defining a second vertical dimension, with a ratio of the first and second being about 1:3. Also preferably, the front wall is at least about 3 mm and the remaining walls are less than about 2.0 mm thickness, or more preferably the exterior ones of the remaining walls are less than about 1.7 mm. In one embodiment, the upper and lower tubes are spaced apart.

Owner:SHAPE CORP

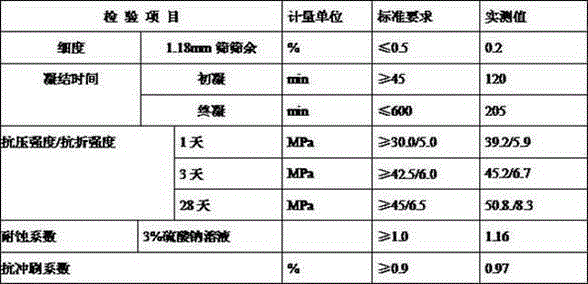

Seashore building cement resisting strong wind and big waves

The invention discloses seashore building cement resisting strong wind and big waves. The seashore building cement is prepared from the following raw materials in parts by weight: 60-80 parts of slag, 1-30 parts of sulphoaluminate cement clinker, 5-10 parts of silicon powder, 0.03-0.05 part of composite activating agent, 2-4 parts of early strength agent, 1-3 parts of water reducer, 0.005-0.007 part of air entraining agent, and 0.3-0.5 part of retarder. The production method comprises the steps of: respectively crushing, milling and homogenizing the slag, sulphoaluminate cement clinker, silicon powder, composite activating agent, and early strength agent, then batching, mixing and homogenizing according to the ratio, then adding the water reducer, air entraining agent, and retarder, and mixing and homogenizing to obtain a product. The green and ecological cement resisting strong wind and big waves also has good characteristics of high strength, seawater erosion resistance, seawater rushing resistance and the like besides of the performance of common cement, and is especially suitable for the engineering of ports and docks resisting wind and big wave impact and other erosion medium corrosion.

Owner:广西云燕特种水泥建材有限公司

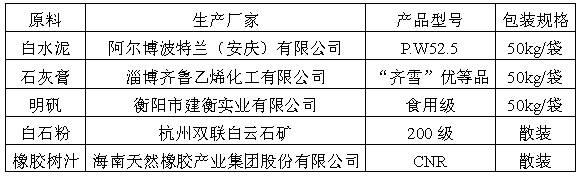

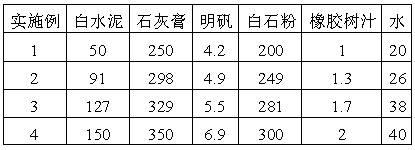

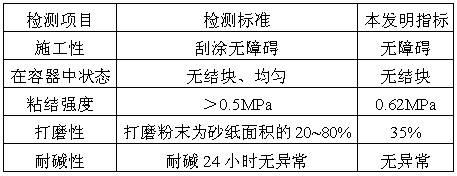

All-natural putty for interior walls of constructions

All-natural putty for interior walls of constructions comprises, by weight, 50-150 parts of white cement, 250-350 parts of lime putty, 4.2-6.9 parts of alum, 200-300 parts of white stone powder, 1-2 parts of rubber tree tapping and 20-40 parts of water. The preparation steps of the all-natural putty include: (1) crushing the white stone powder and the alum; (2) mixing white cement with lime putty, feeding the mixture into a mixer, sequentially feeding the crushed white stone powder and the crushed alum into the mixer, and then adding the rubber tree tapping to be uniformly stirred; and (3) adding water into mixed dry solids which are discharged through stirring to obtain the all-natural putty finished product for the interior walls of the constructions. The all-natural putty for the interior walls of the constructions is good in technical performance and low in cost, resources can be saved and the environment can be protected as used raw materials are natural, non-toxic and non-hazardous, and the all-natural putty can be widely applied to treatment of batches of embedded layers of interior wall finishing processes of various constructions.

Owner:无锡市康顺节能材料科技有限公司

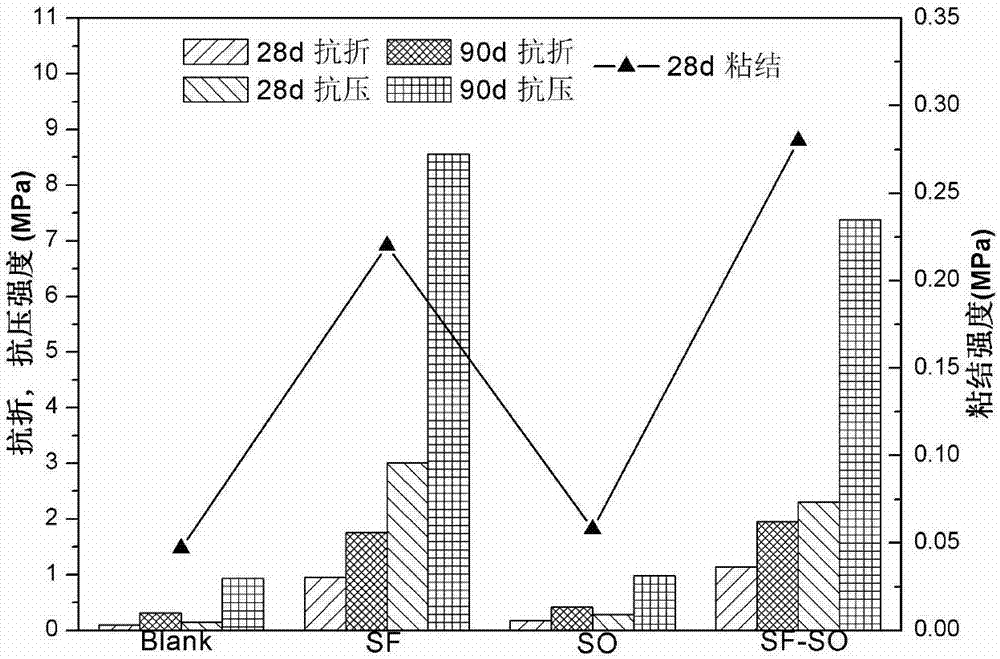

High-performance durable natural hydraulic lime mortar for reinforcing and repairing rock and soil buildings and preparation method thereof

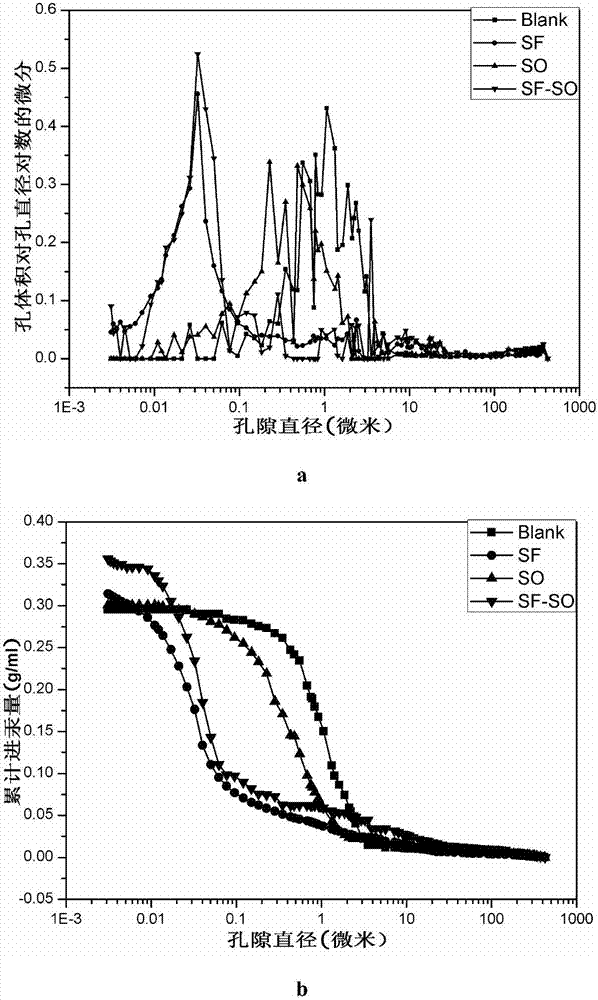

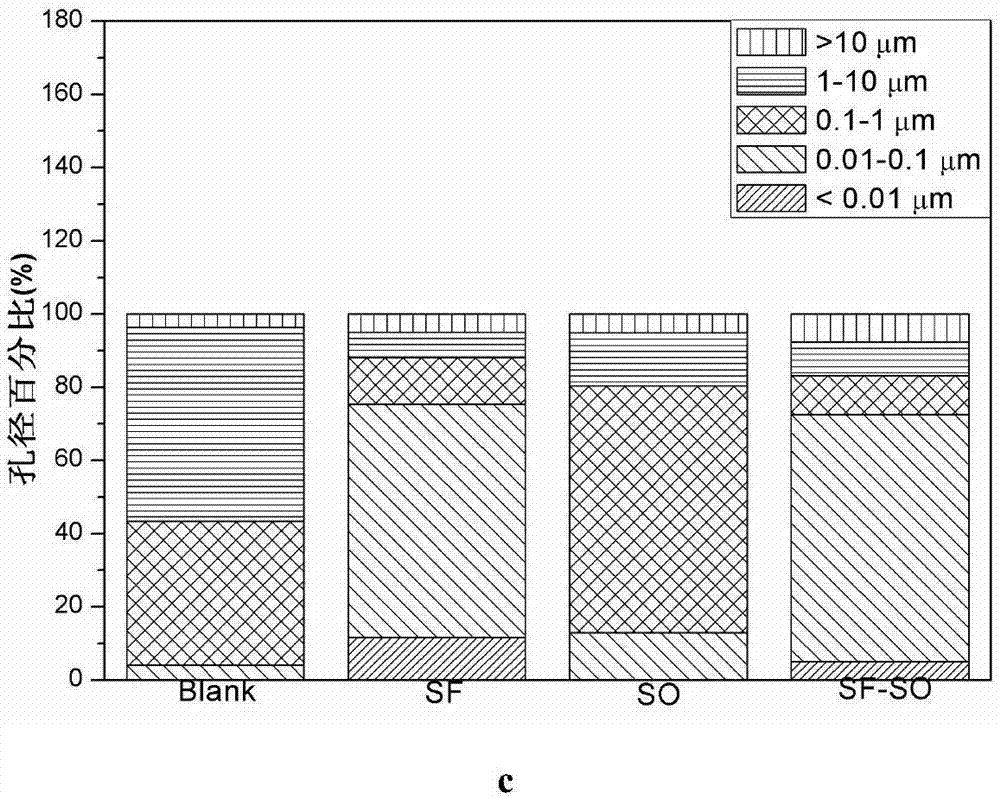

The invention relates to high-performance durable natural hydraulic lime mortar for reinforcing and repairing rock and soil buildings and a preparation method thereof and belongs to the field of modified research of building materials and preservation materials of cultural relics. The mortar is prepared by partially replacing a main body cementing material natural hydraulic lime (NHL2) by silica fume and adding a certain amount of isobutyl triethoxy silane. The mortar prepared by the method has the characteristic of being light. The total amount of raw materials required for preparing the mortar in same volume, in particular the dosage of the natural hydraulic lime, is reduced. Both the water absorption and volume shrinkage of the modified mortar are reduced, and the service performance of the mortar is improved. The inner porous structure of the mortar is refined, and the mechanical strength is improved. The mortar can be applied to repairing buildings with higher strength designs. The preparation method improves the freeze-thaw resistance, acid corrosion resistance and salt expansion resistance of the mortar to a great extent, so that the mortar can better exert reinforcing and repairing effects.

Owner:BEIJING UNIV OF CHEM TECH

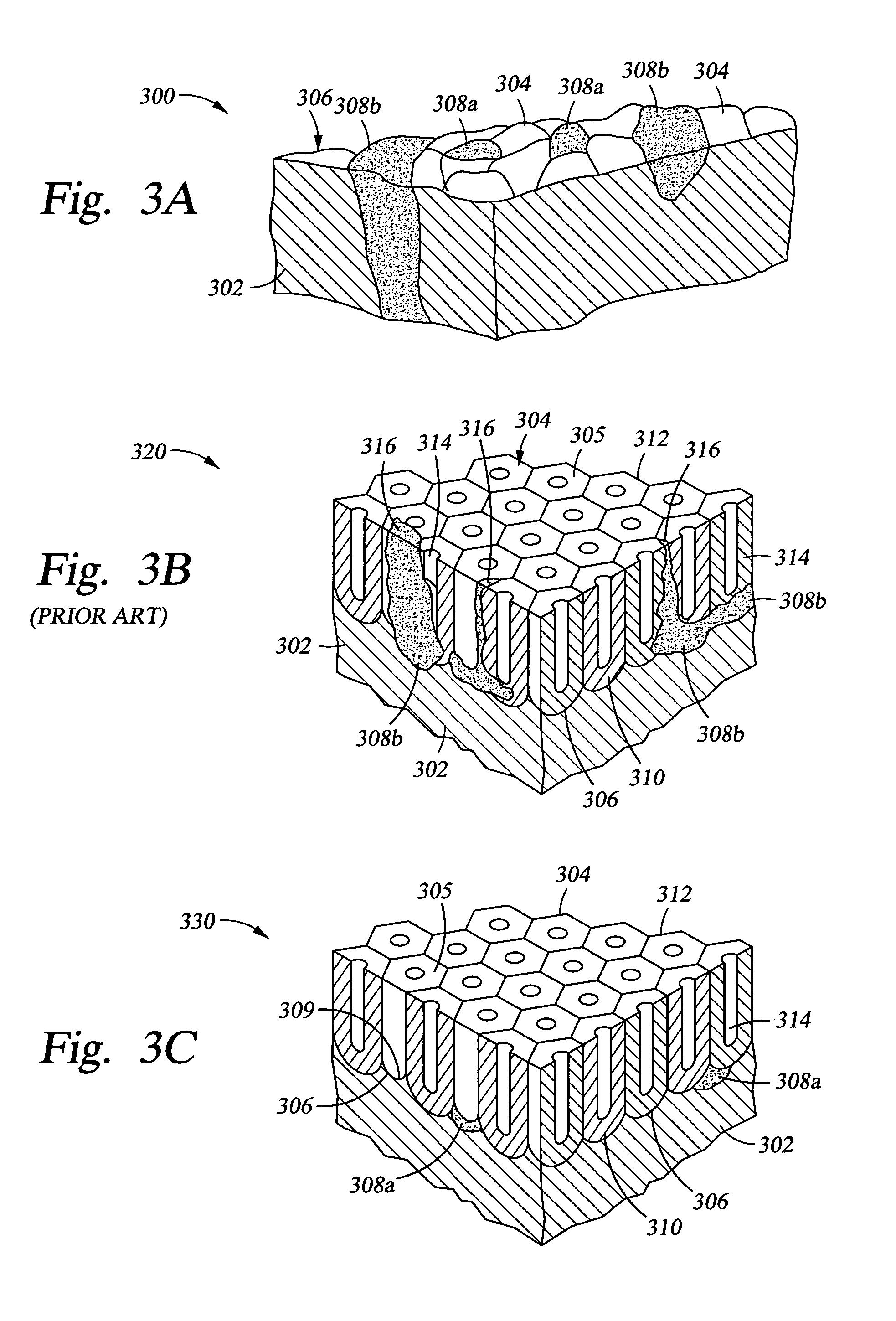

Continuous electroforming process to form a strip for battery electrodes and a mandrel to be used in said electroforming process

InactiveUS7097754B2High productivity and flexibilitySatisfies economical and technical demandElectrochemical processing of electrodesElectrolysis componentsHigh rateCorrosion

A continuous electroforming process to form a strip for battery electrodes, comprising the steps of providing a mandrel having on its surface a reusable pattern subdivided into conductive and non-conductive areas; moving said mandrel through an electroforming bath to deposit a metal layer on said mandrel while it moves through the electroforming bath until the metal layer has assumed the shape of the conductive pattern and a thickness at least sufficient to provide strength for the layer to be removed from said mandrel; and separating said layer from said mandrel; is characterised by moving said strip through at least one subsequent bath in which electrodeposition of metal takes place on both sides of said strip while it is moved through said subsequent bath, applying a current density of at least 10 A / dm2 and up to 300 A / dm2 to the conductive surface of the moving mandrel and to the metal surface of the strip in each of the subsequent baths; and directing a forced flow of electrolyte onto the surface of the layer and said strip, wherein the reusable conductive pattern of the surface of the mandrel takes the form of at least one battery electrode and the electrolyte contains additives providing increased hardness, increased corrosion resistance and being suited specifically to permit combining a high rate of deposition with controlled surface roughness and controlled composition of the deposit.

Owner:DSL DRESDEN MATERIAL INNOVATION

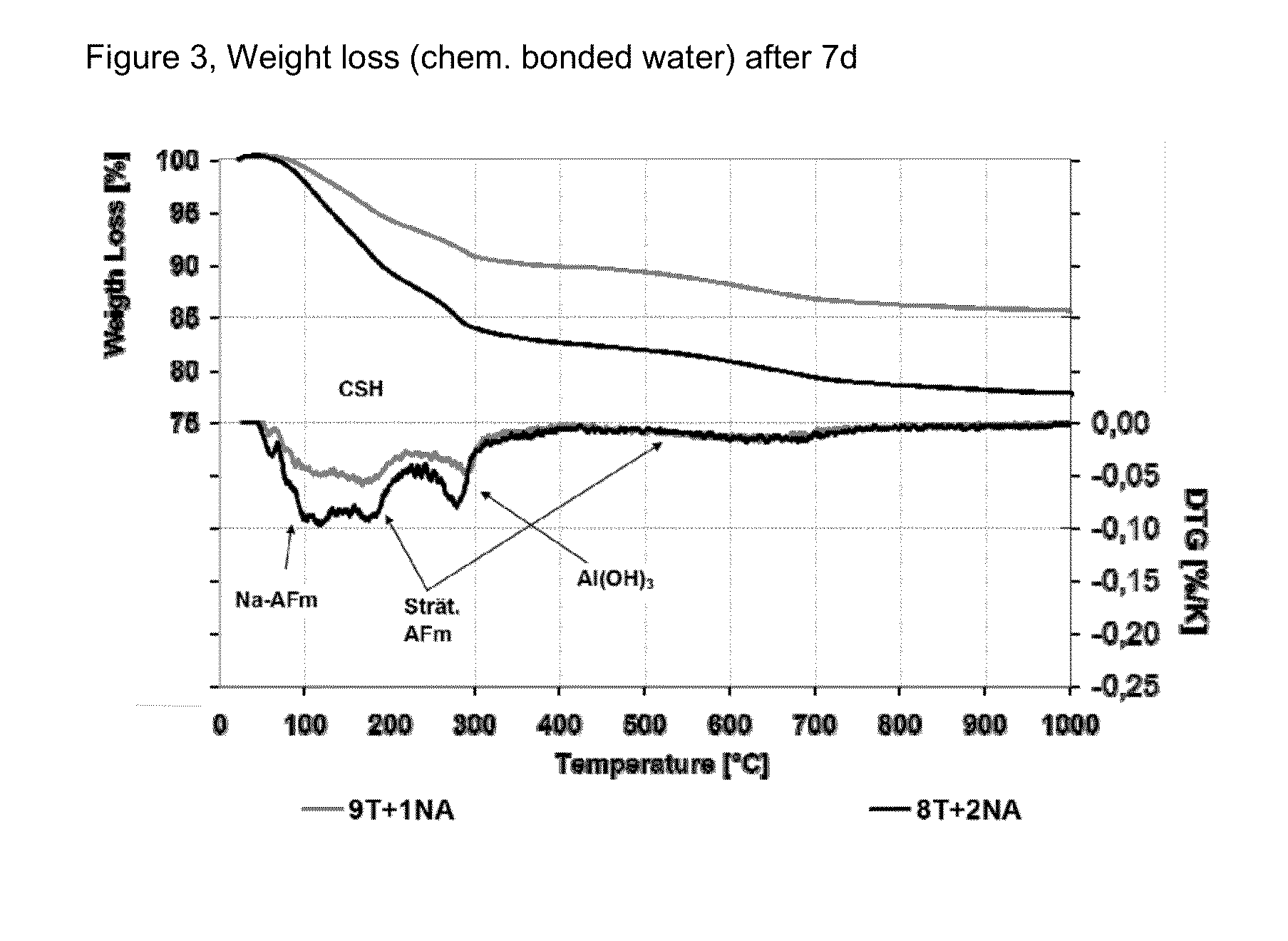

Method and additive for increasing early strength

ActiveUS20140238274A1High normal sclerosisHigh strengthSolid waste managementCement productionUltimate tensile strengthAluminium

Owner:HCONNECT 2 GMBH

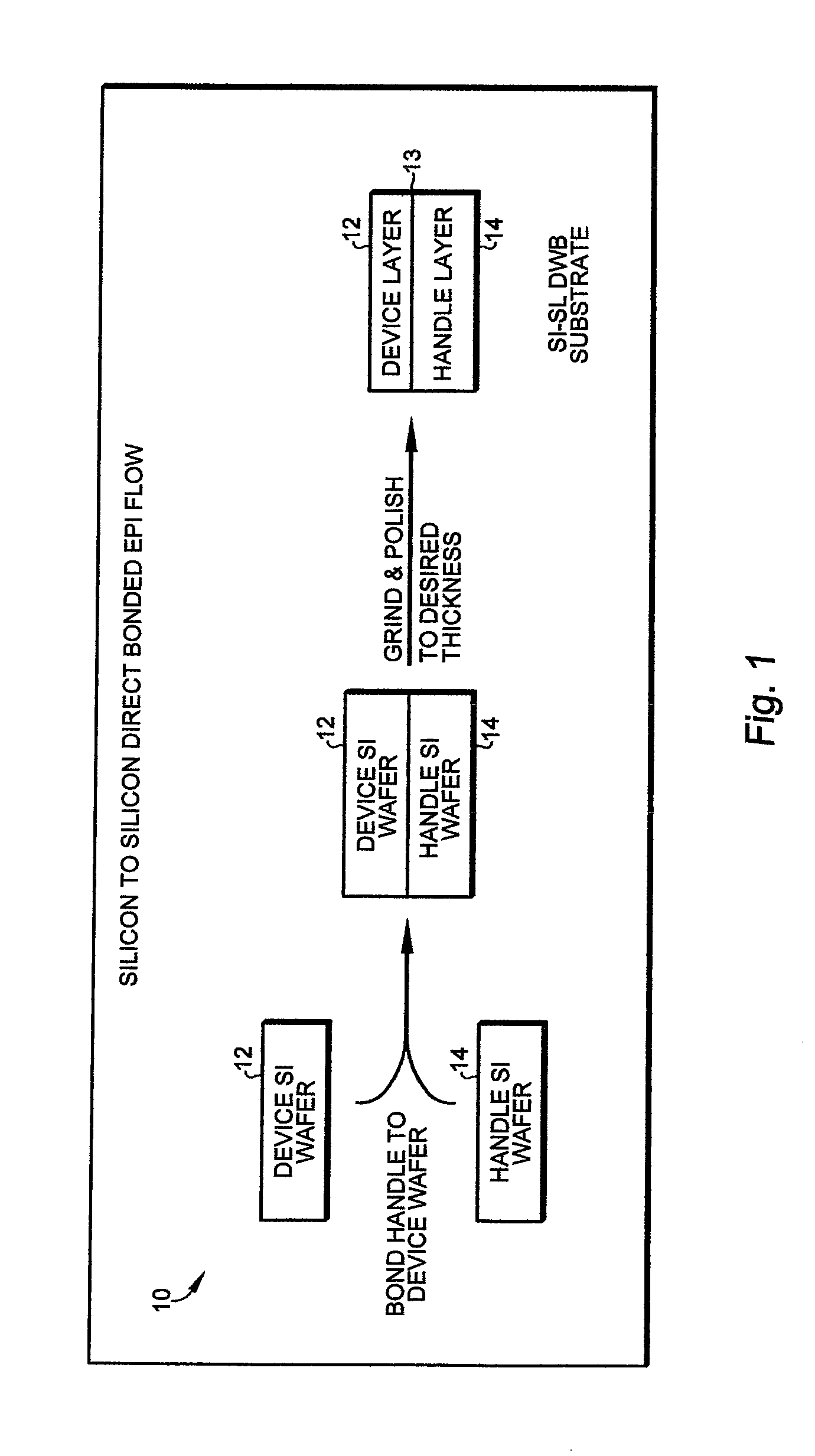

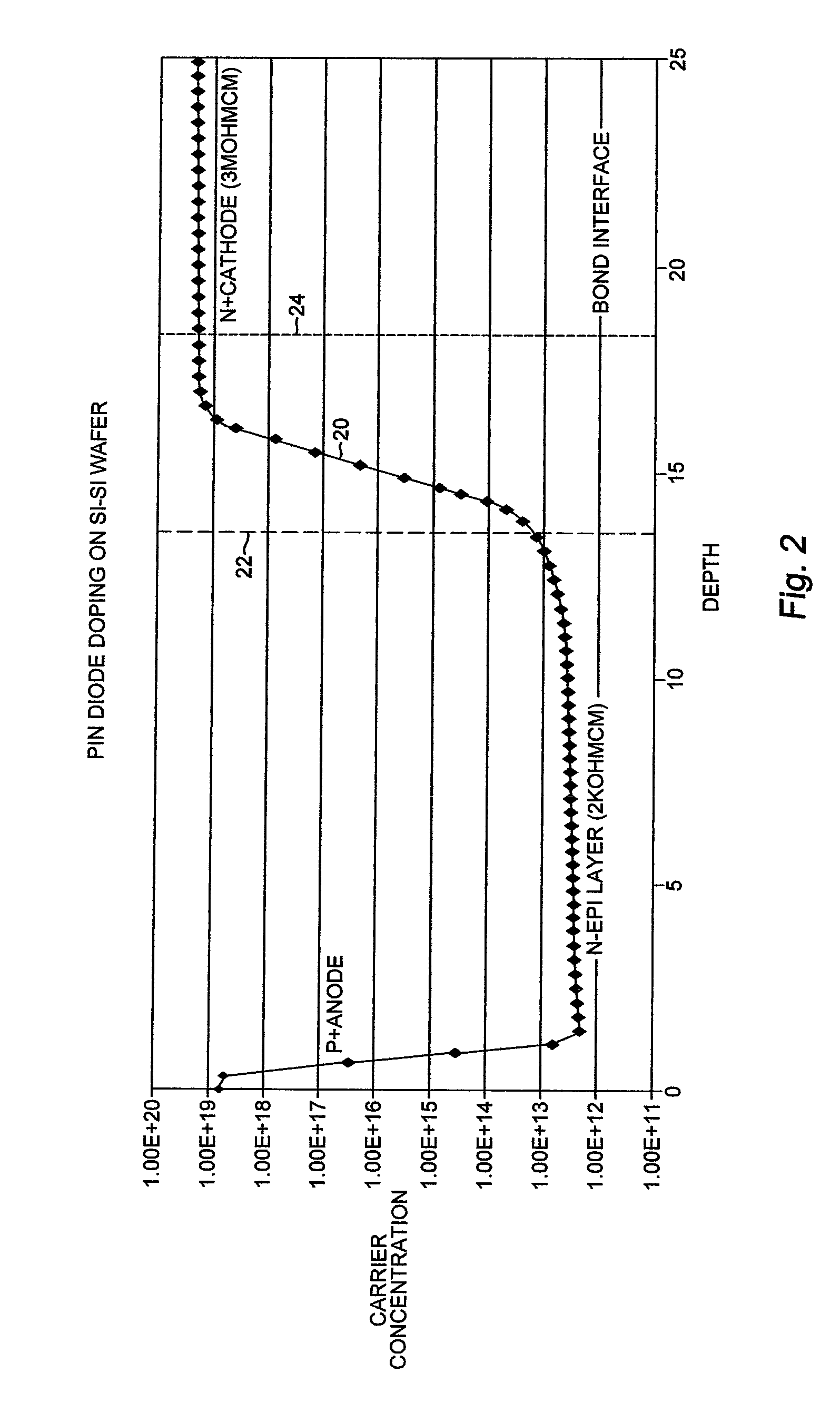

Wafer structure for electronic integrated circuit manufacturing

ActiveUS20130049173A1Increase doseImprove the substrateSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuit manufacturingEngineering

A bonded wafer structure having a handle wafer, a device wafer, and an interface region with an abrupt transition between the conductivity profile of the device wafer and the handle wafer is used for making semiconductor devices. The improved doping profile of the bonded wafer structure is well suited for use in the manufacture of integrated circuits. The bonded wafer structure is especially suited for making radiation-hardened integrated circuits.

Owner:CAES COLORADO SPRINGS LLC

Acrylic plaster coating composition

The present invention provides a translucent, acrylic based plaster composition, particularly for coating wall surfaces. The composition provides a mottled surface effect.

Owner:VARIANCE ACRYLIC FINISHES

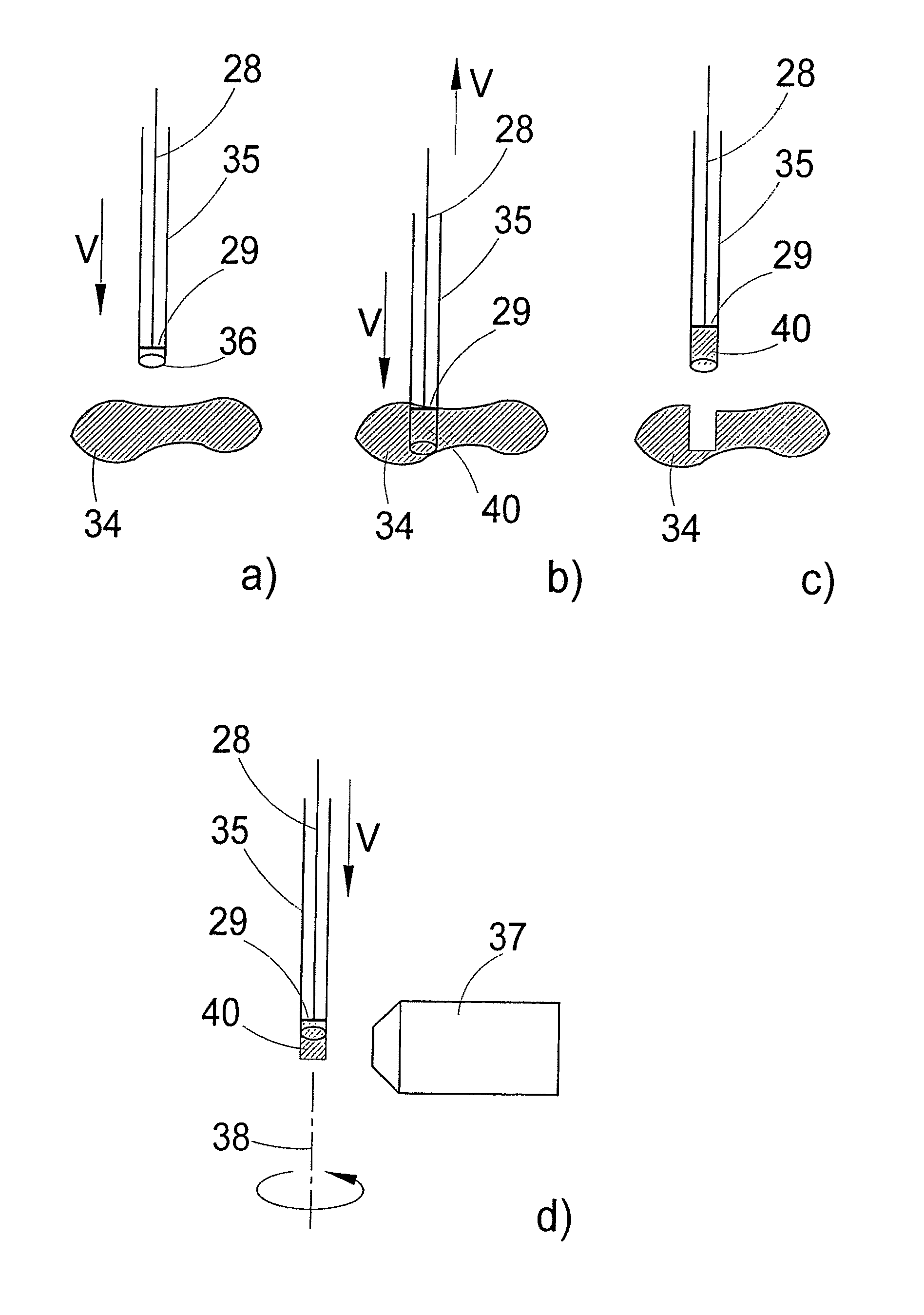

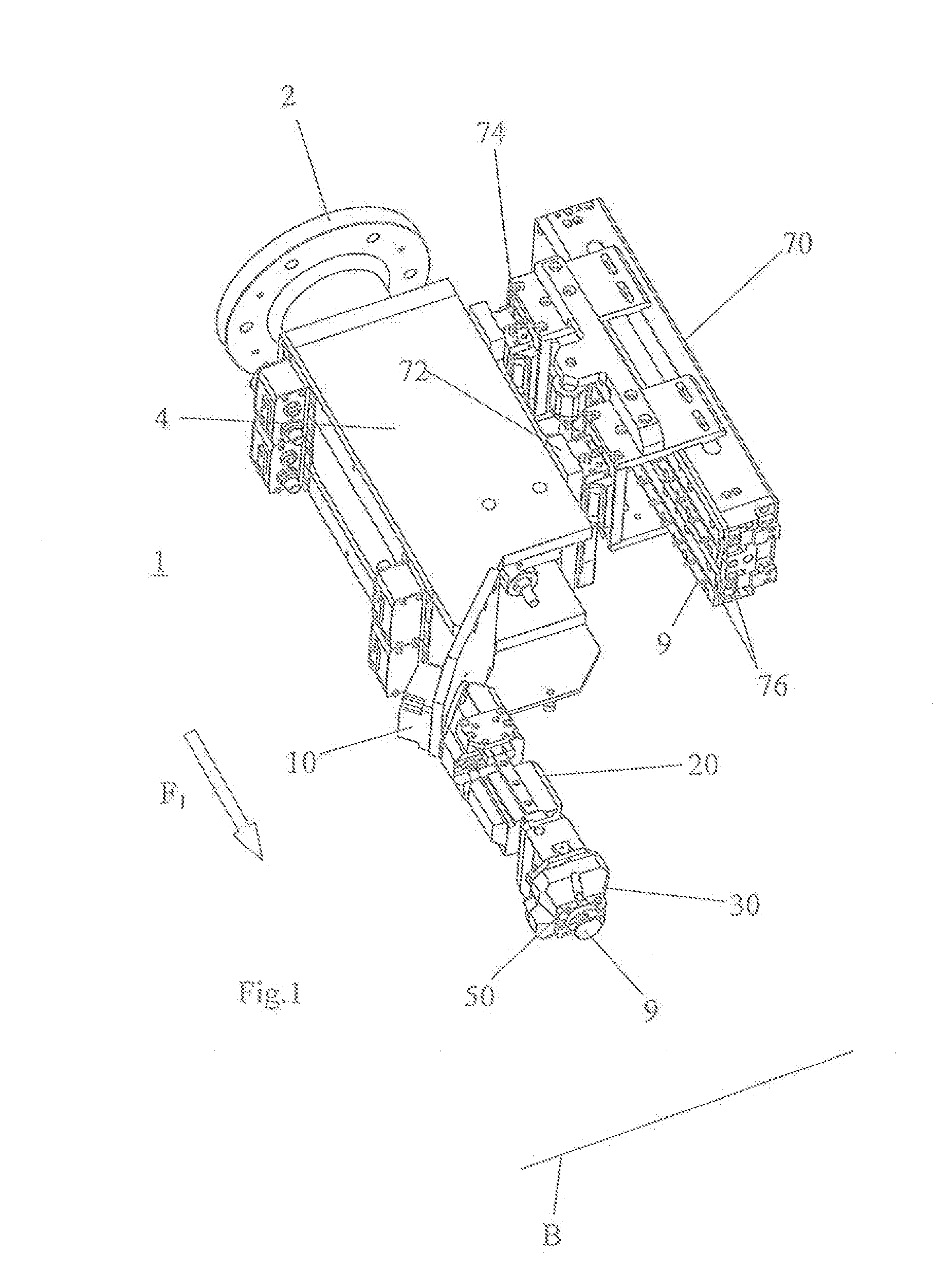

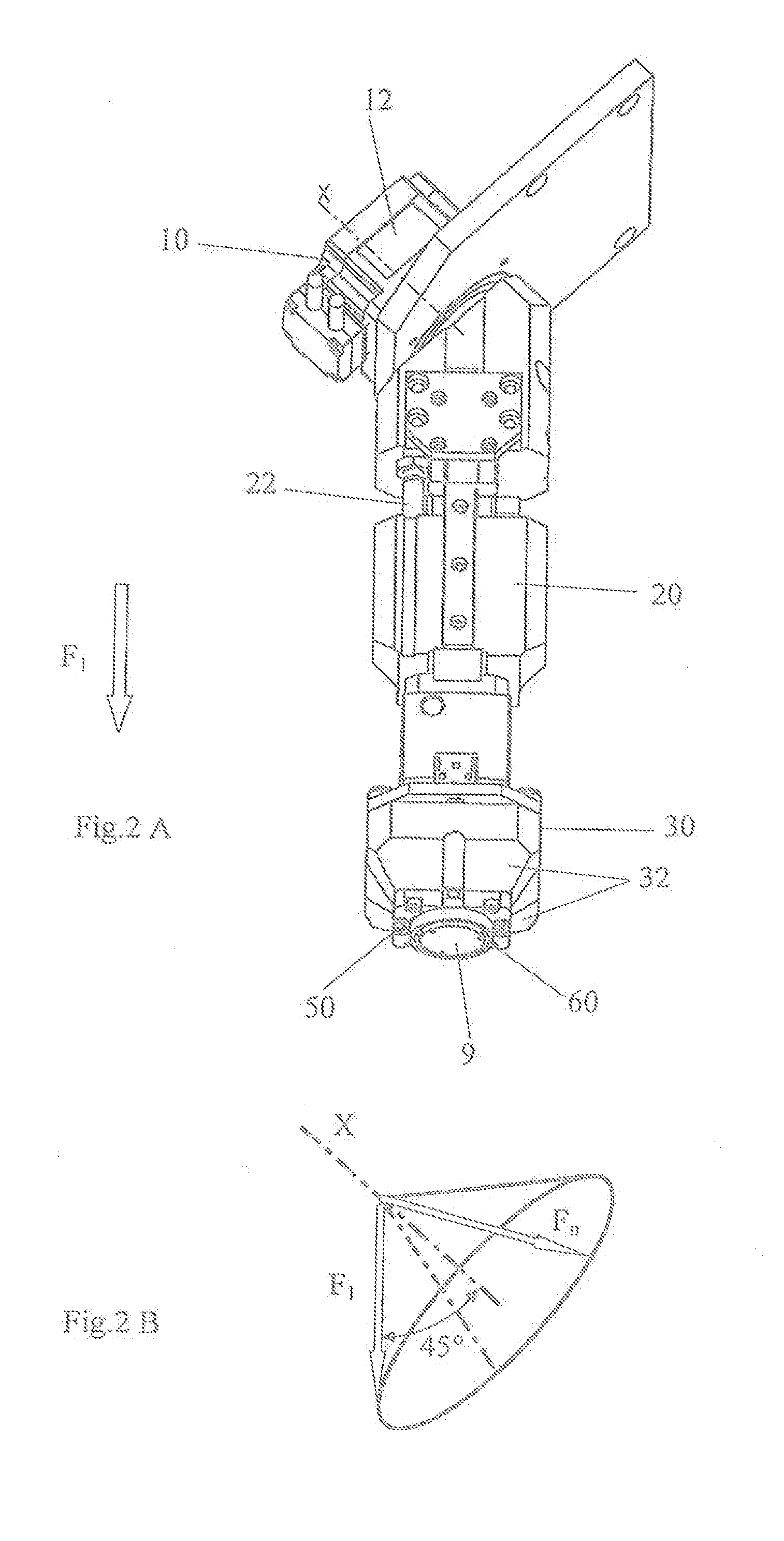

Jointing head for fastening element, and a fastening method

InactiveUS20140020814A1Dampens mechanicalLess vulnerableMechanical working/deformationSlide fastenersMechanical engineeringLight source

The present invention comprises a jointing head 1, a robot with this jointing head 1, and a fastening method for affixing fastening elements 9 to a component surface B. The jointing head 1 comprises a gripper 30 that removes fastening elements 9 from a removal position E of a cartridge 70 by means of a pivoting movement. In addition, the jointing head 1 comprises a compensation mechanism 40 of the gripper 30 so that, when the fastening element 9 is mounted on a component surface B, the fastening element 9 is optimally arranged adjacent to a hardening source 60 such as a light source.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Method for producing high-salinity maritime work cement through mineral waste residue waste materials

The invention discloses a method for producing high-salinity maritime work cement through mineral waste residue waste materials. The high-salinity maritime work cement is prepared from, by weight, 30-40 parts of mineral waste residues, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of composite activating agents, 2-4 parts of early strength agents, 0.3-0.5 part of water reducing agents, 0.005-0.007 part of air entraining agents and 0.3-0.5 part of retarder. The method for producing the high-salinity maritime work cement comprises the steps that the mineral waste residue waste materials, the sulphate aluminum clinker, the composite activating agents and the early strength agents are smashed, ground into powder and homogenized respectively and then dosed, mixed and homogenized according to proportions, then the water reducing agents, the air entraining agents and the retarder are added, mixed and homogenized, and the product is obtained. The high-salinity maritime work cement has the performance of common cement, further has the excellent characters of early-stage hardness resisting, long-term corrosion resistance, retardation progressive increasing and the like, and is especially suitable for ports, wharfs and other engineering which are corroded by corrosive media.

Owner:广西云燕特种水泥建材有限公司

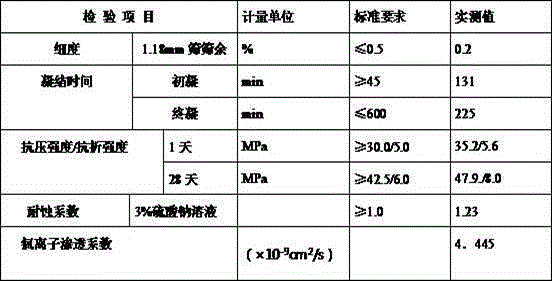

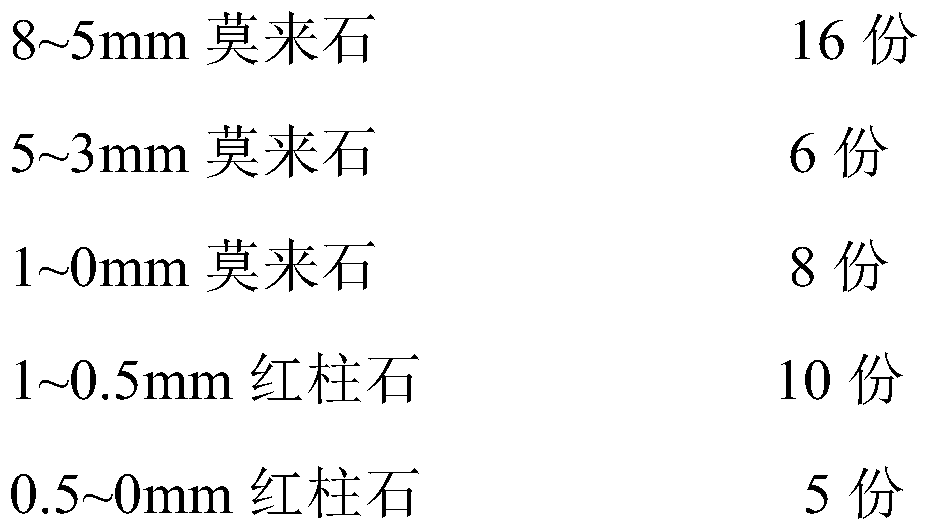

Anti-skinning spray coating for cement kiln preheater

ActiveCN111018506ALow thermal conductivityRapid build-up of strengthClinker productionCarbide siliconLithium chloride

The invention relates to an anti-skinning spray coating for a cement kiln preheater. The spray coating comprises, by weight, 30-45 parts of mullite, 15-20 parts of andalusite, 10-15 parts of zirconitemicro-powder, 10-14 parts of silicon carbide micro-powder, 10-12 parts of Suzhou clay, 8-12 parts of calcium aluminate cement, 4-8 parts of aluminum oxide micro-powder, 1-3 parts of silicon micro-powder, 1-2 parts of lithium chloride and 0.01-0.03 part of sodium tripolyphosphate. The formula is adopted, so the thermal shock stability of the spray coating can be improved, the service life of the spray coating can be prolonged, and an energy-saving effect is achieved.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

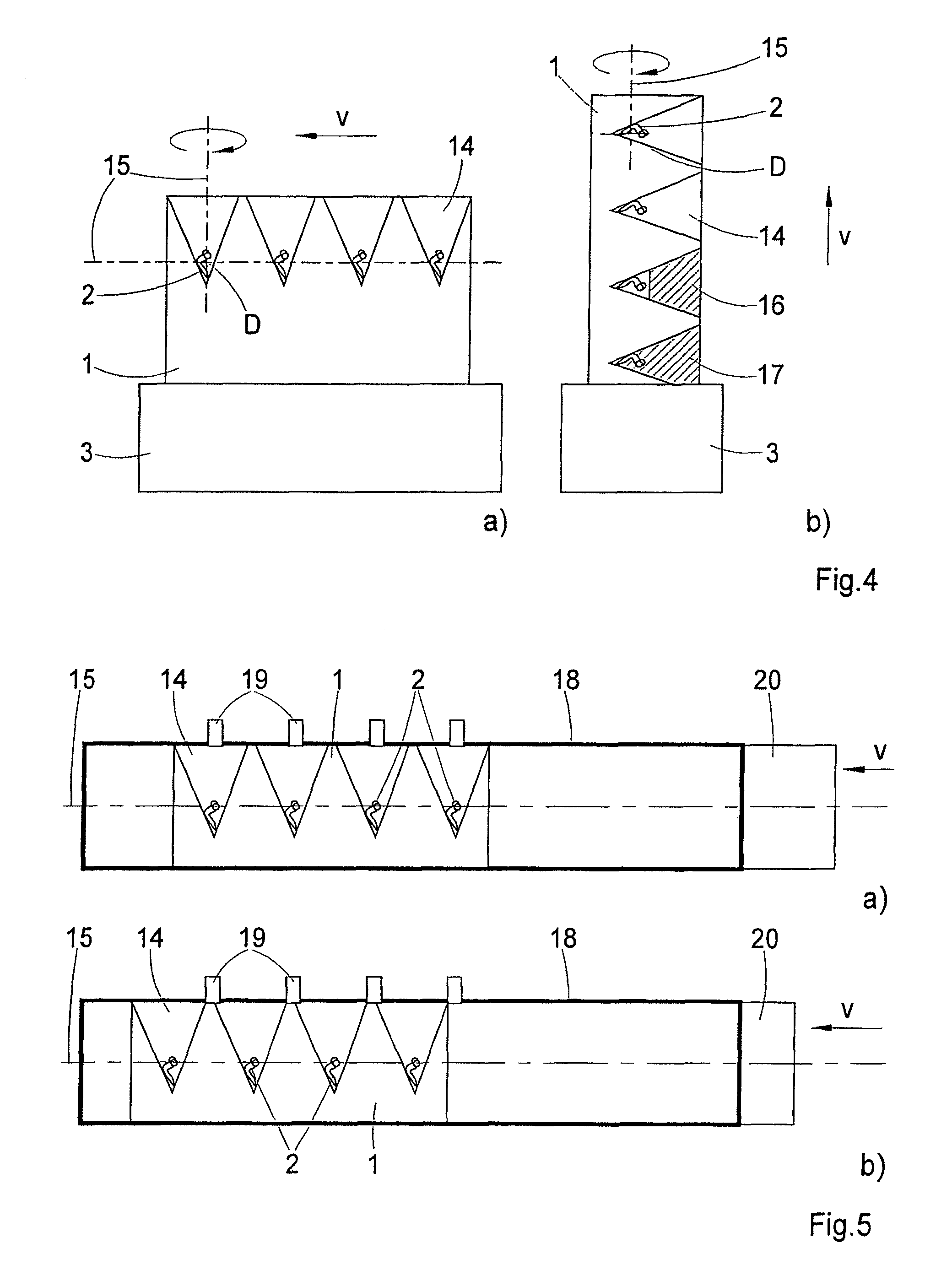

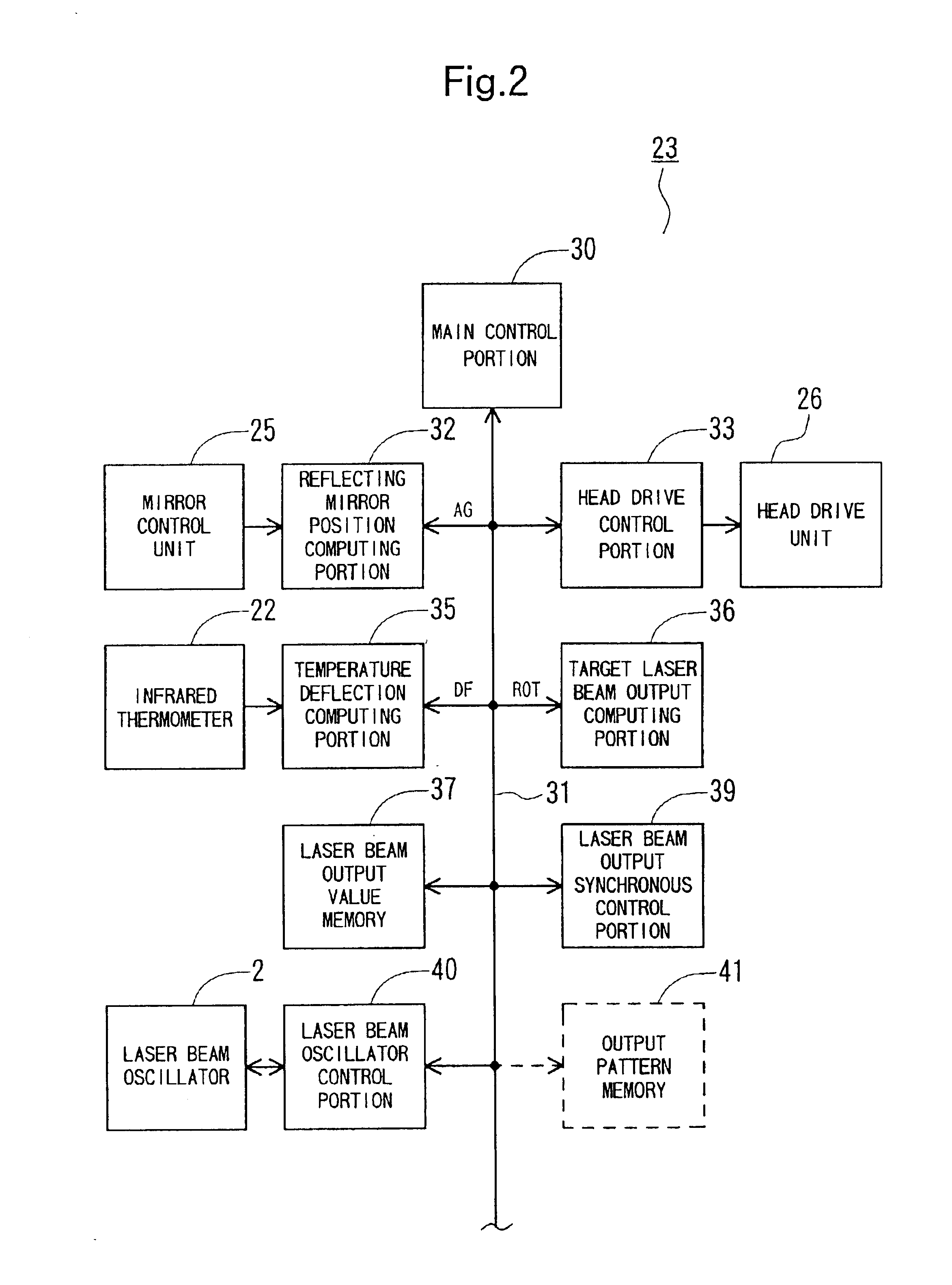

Method of controlling hardening with laser beam and laser beam hardening device

InactiveUS6922420B2Uniform energy densityHighly effectiveLaser detailsHeat treatment process controlOptical pathPower level

A workpiece is irradiated by a laser beam scanned in an oscillating track as the workpiece is advanced along a feed path in a hardening process. Sinusoidal variations in scan velocity are offset by decreasing the laser beam power level at phases in the scanning cycles corresponding to high and low scan displacement peaks, where the scan velocity is least. The beam power is increased near the scanning center line where the scan velocity is highest. The beam energy applied per unit of area is thus equalized over the scanning cycle. The workpiece temperature can be sampled at regular phases by a non-contact temperature sensor in the optical path, and used to control beam power versus phase in a subsequent scanning cycle. Alternatively or in addition, a sinusoidal beam power pattern can be stored and used to offset scan velocity variations as a function of phase.

Owner:YAMAZAKI MAZAK KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com