Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Hydraulic lime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

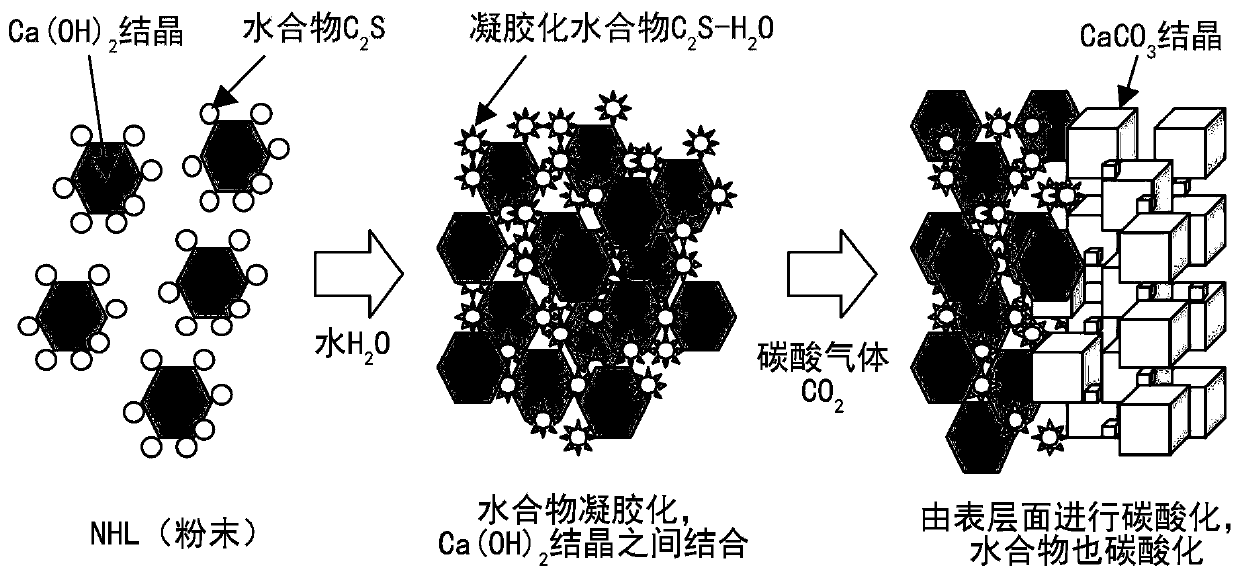

Hydraulic lime (HL) is a general term for varieties of lime (calcium oxide), or slaked lime (calcium hydroxide), used to make lime mortar which set through hydration. These contrast with varieties of air lime, the other common types of lime mortar, which set through carbonation (re-absorbing carbon dioxide (CO₂) from the air).

Infusion and binding material composition

InactiveCN101811853AGood physical and chemical affinityModerate intensityCeramic shaping apparatusWeather resistanceBrick

The invention relates to an infusion and binding material composition containing the following components in proportion by weight: 20%-60% of natural hydraulic lime, 35%-78% of aggregates, 0-2% of polymer latex powder, 0.01%-2% of water reducers and 0.01%-2% of water-retention thickeners. 20%-50% of water is added in per 100 kg of materials mixed by the formula for uniformly stirring, and then the material composition can be used. The invention can satisfy the special requirements for infusing, binding and reinforcing brick and stone materials in historical buildings, positions infused and bound by adopting the infusion and binding material composition have similar performance to bricks and stones in the constructed positions, and the infusion and binding material composition has the advantages of environmental protection, safe solidified material, excellent binding force, good weather resistance and self-cure performance.

Owner:中国文化遗产研究院 +1

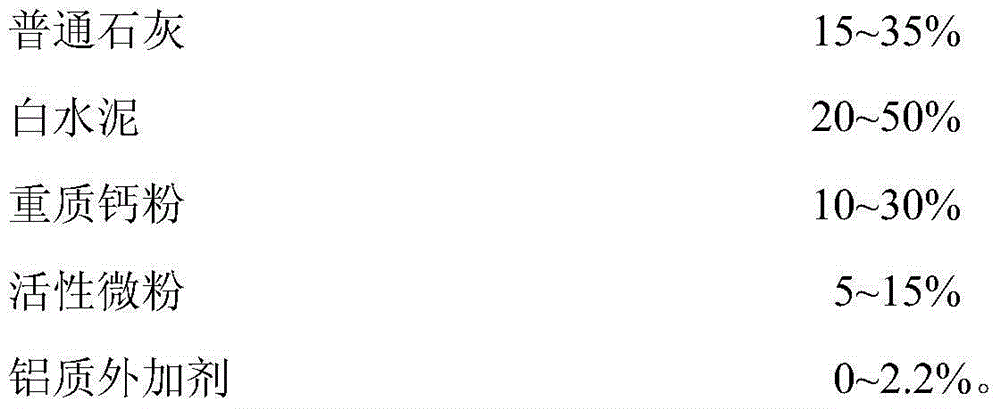

Protection brick and stone ancient building repair lime bonding material

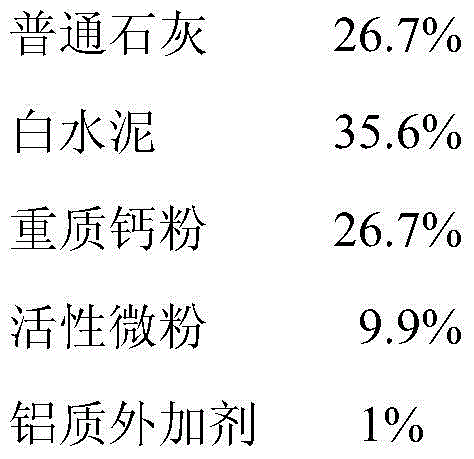

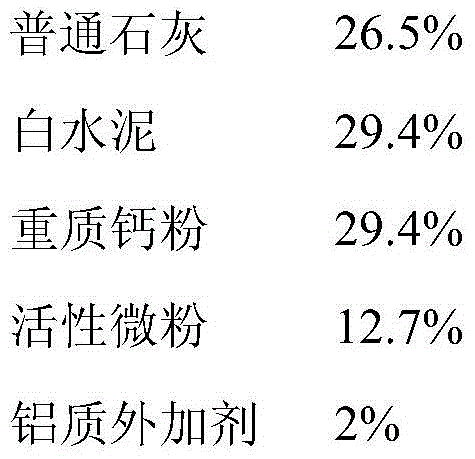

The invention discloses a protection brick and stone ancient building repair lime bonding material, the hydraulic lime material comprises the following components by mass: 15-35% of lime, 20-50% of white cement, 10-30% of heavy calcium powder, 5-15% of active micro powder, and 0-2.2% of an aluminium additive, and the chemical composition, mineral composition and physical and mechanical properties of the hydraulic lime material are similar to that of ancient brick / stone building lime slurry in China, the hydraulic lime material solves the key problems of mismatching strength of cement mortar or polymer mortar in the prior art and ancient brick / stone, poor chemical compatibility and low longterm durability and the like, and overcomes the shortcomings of slow hardening, low strength, too large shrinkage, and the poor water resistance of the ordinary lime, and a new type inorganic cementing material is provided for protection brick and stone ancient building repair.

Owner:SOUTHEAST UNIV

Method for preparing natural hydraulic lime by using limestone and quartz powder

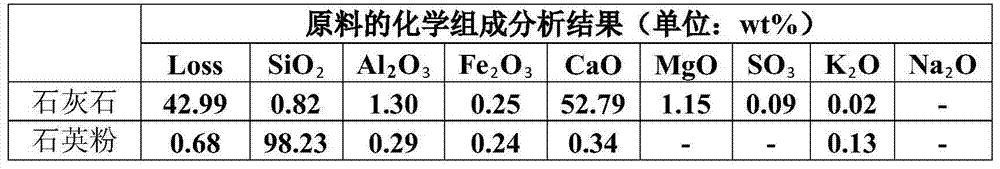

The invention relates to a method for preparing natural hydraulic lime by using limestone and quartz powder, and belongs to a building material. The method is implemented by taking limestone as a main raw material through the steps of adding high-purity quartz powder to adjust the ratio of calcium oxide and silicon oxide, controlling the content of alumina, carrying out mixed material co-grinding for 6-10 hours by using a ball mill, adding water with a mass accounting for 8% of the mass of a mixed raw material, fully stirring, putting the obtained object into a sealing bag to place for 6-7 hours, pressing the obtained object into a cylinder, drying the cylinder by using a drying oven, putting the cylinder into a muffle furnace to calcinate for 3 hours at a temperature of 1100-1200 DEG C, cooling the calcinated material to room temperature in the air by air cooling, determining the free calcium oxide content of the calcinated product, adding a certain amount of water for slaking into the calcinated product, and after the slaking process is completed, obtaining desirable natural hydraulic lime.

Owner:新疆荣高鸿骏新材料技术有限公司

Hydraulic oyster ash for repairing and protecting stone ruins

InactiveCN103880303ASolve the strength problemSolve the durability problemChemical compositionWeather resistance

The invention relates to a material for reinforcing and repairing stone ruins, and in particular to hydraulic oyster ash for repairing and protecting stone ruins. The hydraulic oyster ash for repairing and protecting stone ruins is obtained by roasting clam shells in a roasting furnace at 1000-1100 DEG C, discharging, then naturally cooling to an environmental temperature, and then crushing to 150 meshes. The hydraulic oyster ash for repairing and protecting stone ruins disclosed by the invention is mainly used for a cementing material for repairing brick stone ruins; the cementing material is obtained by uniformly mixing 150-mesh hydraulic oyster ash for repairing and protecting stone ruins with 100-mesh quartz sand in a mass ratio of 1:1; during use, a slurry material is prepared by uniformly proportioning and stirring the cementing material with water in a mass ratio of 100:50. The chemical composition, mineral constituents and physical mechanical properties of the hydraulic oyster ash for repairing and protecting stone ruins disclosed by the invention are basically similar to those of hydraulic lime NHL-2 for repairing stone ruins, which is introduced in the field of historical relics of China from Germany in recent years, can be used for solving the problems of strength, durability and weather resistance of the reinforced brick stone ruins, and a novel material which is firmly combined with brick stone is provided for repairing damaged brick stone relics.

Owner:李黎

High-performance durable natural hydraulic lime mortar for reinforcing and repairing rock and soil buildings and preparation method thereof

The invention relates to high-performance durable natural hydraulic lime mortar for reinforcing and repairing rock and soil buildings and a preparation method thereof and belongs to the field of modified research of building materials and preservation materials of cultural relics. The mortar is prepared by partially replacing a main body cementing material natural hydraulic lime (NHL2) by silica fume and adding a certain amount of isobutyl triethoxy silane. The mortar prepared by the method has the characteristic of being light. The total amount of raw materials required for preparing the mortar in same volume, in particular the dosage of the natural hydraulic lime, is reduced. Both the water absorption and volume shrinkage of the modified mortar are reduced, and the service performance of the mortar is improved. The inner porous structure of the mortar is refined, and the mechanical strength is improved. The mortar can be applied to repairing buildings with higher strength designs. The preparation method improves the freeze-thaw resistance, acid corrosion resistance and salt expansion resistance of the mortar to a great extent, so that the mortar can better exert reinforcing and repairing effects.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing natural hydraulic lime with lead and zinc mine tailings

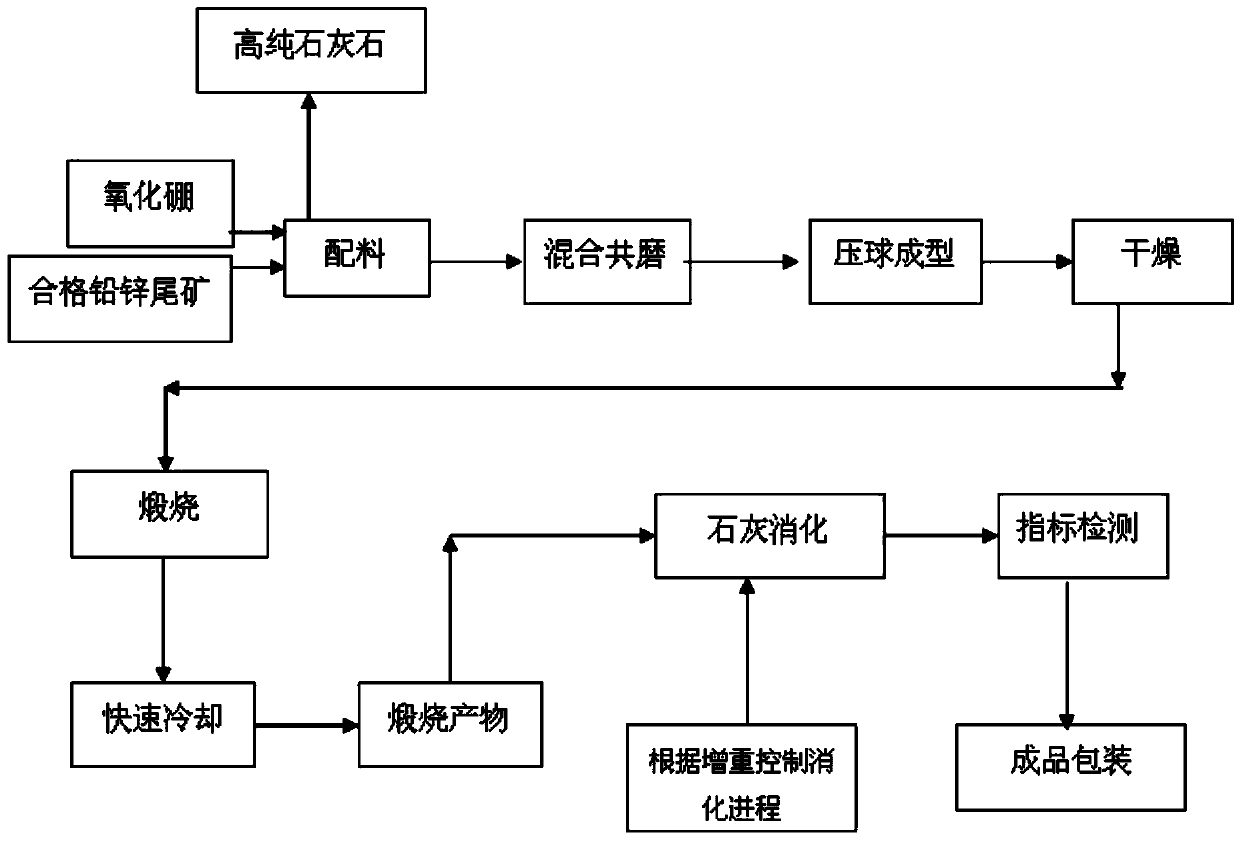

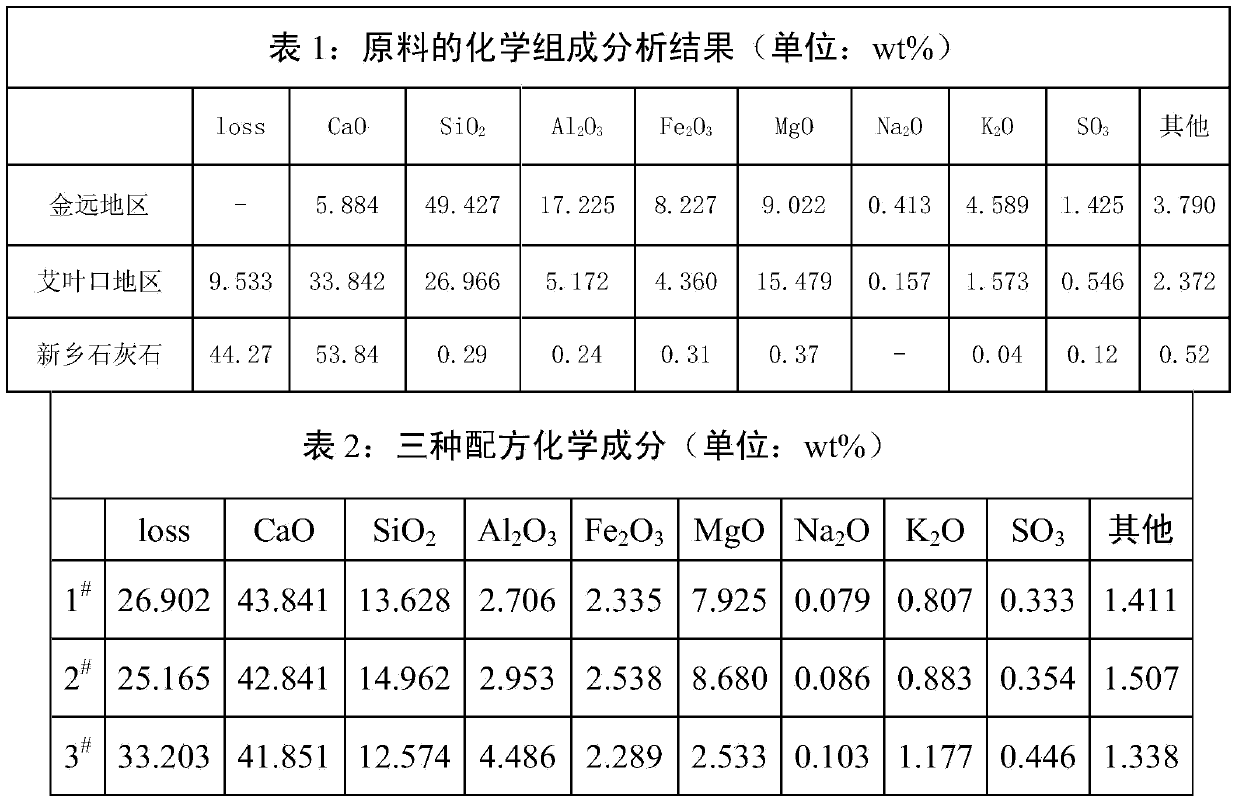

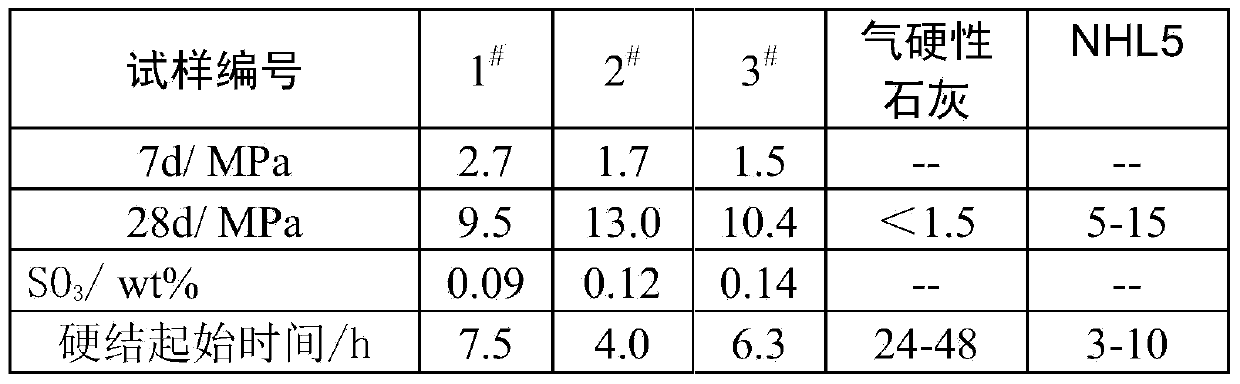

The invention discloses a method for preparing natural hydraulic lime with lead and zinc mine tailings. The method comprises the steps of taking the lead and zinc mine tailings as a major raw material, adding boron oxide, wherein the boron oxide and impurities, such as sodium oxide and potassium oxide, in the lead and zinc mine tailings form a glass phase with low hydration activity and a low hydration heat value, improving later strength, adjusting a ratio of calcium oxide to silicon oxide by adding high-purity limestone, controlling an aluminum oxide content, mixing and grinding ingredients for 6-10h with a ball mill, adding a temporary binding agent to press into a ball or a cylinder, drying, putting in a furnace for roasting for 3h at 1000-1050 DEG C, blowing and quenching the roasted material in air to the room temperature, measuring a free calcium oxide content in a roasted product, putting the roasted product in an environment with the humidity of 50-80% for digestion, recording weights of the product before and after the digestion, calculating digestibility of free calcium oxide according to a measured weight gain of the product after the digestion, finishing the digestion procedure when the digestibility of free calcium oxide reaches 98%, and obtaining the satisfactory hydraulic lime.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Modified hydraulic lime based material and preparation method thereof

The invention discloses a modified hydraulic lime based material and a preparation method thereof and belongs to the technical field of building materials. The modified hydraulic lime based material comprises components of raw materials in percentage by weight as follows: 40%-80% of hydraulic lime, 5%-50% of ground mineral powder (S95level), 1%-5% of calcium nitrite, 1%-3% of lithium carbonate, 0.5%-2% of sodium gluconate, 0.5%-2% of a viscous resisting agent, 0.5%-2% of an adhesion resisting agent, 1%-3% of a thixotropy resisting agent, 1%-3% of an anti-crack resisting agent and 0.5%-1.5% of a water reducer, wherein the water reducer is an ShiJiXingYuan XY-4 type Qingdao naphthalene water reducer. The preparation method comprises steps as follows: the components are uniformly mixed in proportion and put in a grinding machine to be ground, and a mixture is obtained. The raw materials are easy to obtain, a preparation process is simple, and the modified hydraulic lime based material is simple to cure; compared with ordinary hydraulic lime, the hydraulic lime has higher crush resistance, fracture resistance and adhesion strength, has good water resistance, acid resistance, alkali resistance and ultraviolet resistance and can be well used for repairing work of antiques.

Owner:BEIJING GUOWENYAN CULTURAL HERITAGE CONSERVATION CENT LTD

Hydraulic lime composition

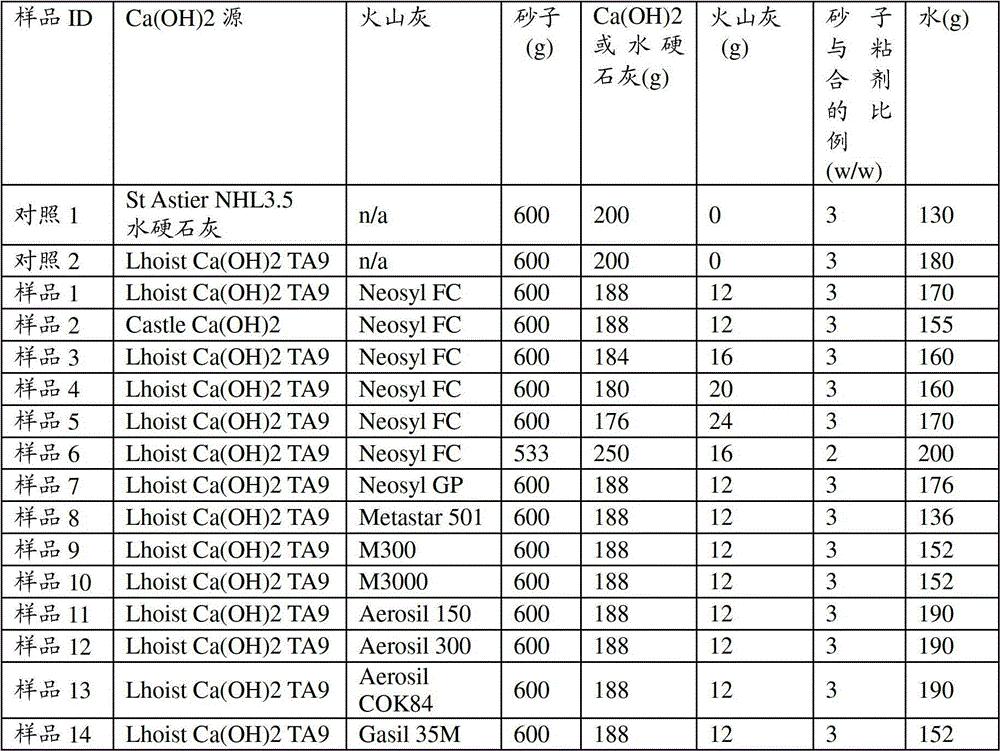

According to the invention there is provided A hydraulic lime composition including between 1 and 20% by weight of a Pozzolanic material which has a surface area of between 2 and 1000 m2g-1 when measured by BET N2 porosimetry, and an average particle size in the range 0.1 to 1000 [mu]m.

Owner:LIMECO LTD

Preparation method for high-strength water-resistant rock-soil repairing material used for ancient buildings

PendingCN110436865AGood gloss and color retentionGood water and chemical resistanceWater resistantHigh adhesion

The invention relates to a preparation method for a high-strength water-resistant rock-soil repairing material used for ancient buildings, belonging to the technical field of repairing materials for buildings. According to the invention, the high-strength water-resistant rock-soil repairing material used for ancient buildings is prepared by using carboxymethyl styrene-butadiene latex and acrylic resin modified natural hydraulic lime as raw materials, zeolite as aggregate, glass fibers as a reinforcing agent, carboxymethyl cellulose as a thickener and maleic anhydride grafted starch as a compatibilizer; the addition of maleic anhydride grafted starch improves the structural compactness of the material to improve the water resistance, frost resistance and impermeability of the material and enhances the compatibility between the material and a matrix; carboxylic butadiene-styrene latex is an environmentally-friendly product with high adhesion and conjunctival strength, good mechanical andchemical stability, good fluidity, good storage stability, large filling capacity and the like; and acrylic resin has the characteristics of good gloss and color retention performance, water and chemical resistance, fast drying and so on, so the modified natural hydraulic lime has good strength and water resistance.

Owner:涂民强

Lime-based micro-contraction grouting material composition and preparation method thereof

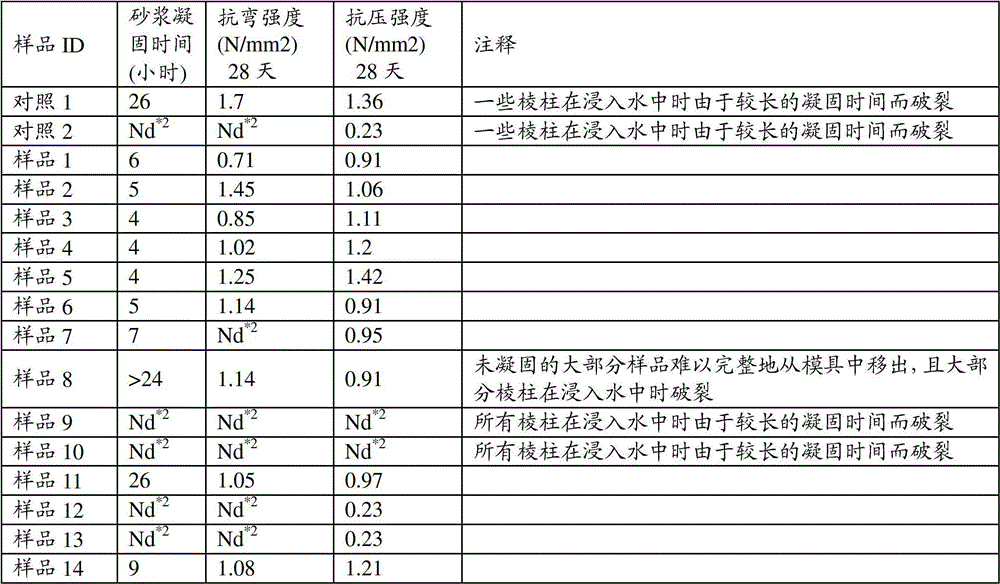

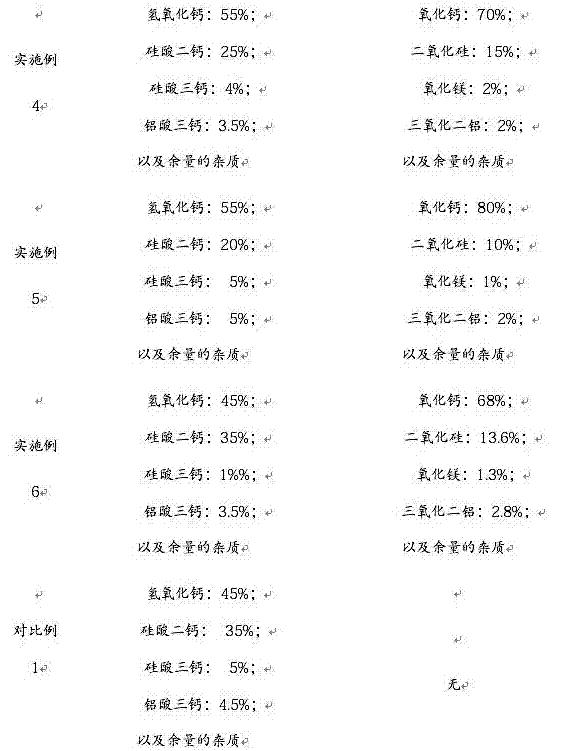

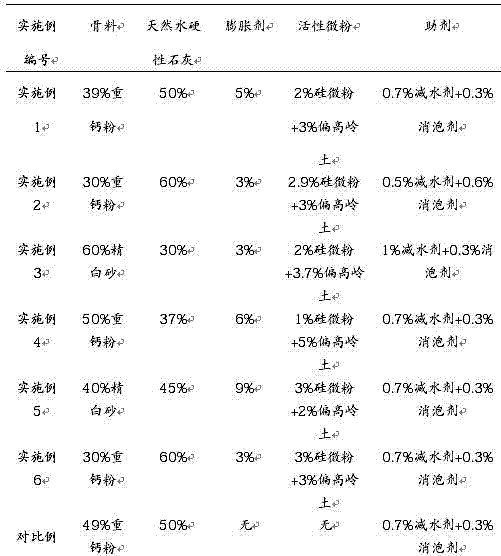

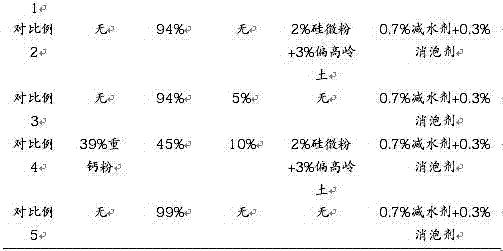

The invention discloses lime-based micro-contraction grouting material composition and relates to the technical field of materials for brick and stone historical relic protection. The composition is prepared from components in percentage by weight as follows: 30%-60% of aggregate, 30%-60% of natural hydraulic lime, 3%-9% of an expanding agent, 3%-8% of active micropowder and 0.8%-1.6% of an auxiliary. The micro-contraction grouting material has good compatibility with traditional brick and stone materials in physical and chemical property as well as relatively high strength, besides, micro volume expansion can be produced after the grouting material is poured into gaps due to reasonable introduction of the expanding agent, so that the grouting material can be closely combined with bricks and stone serving as a base material, and more compact grouting is realized.

Owner:浙江德赛堡建筑材料科技有限公司

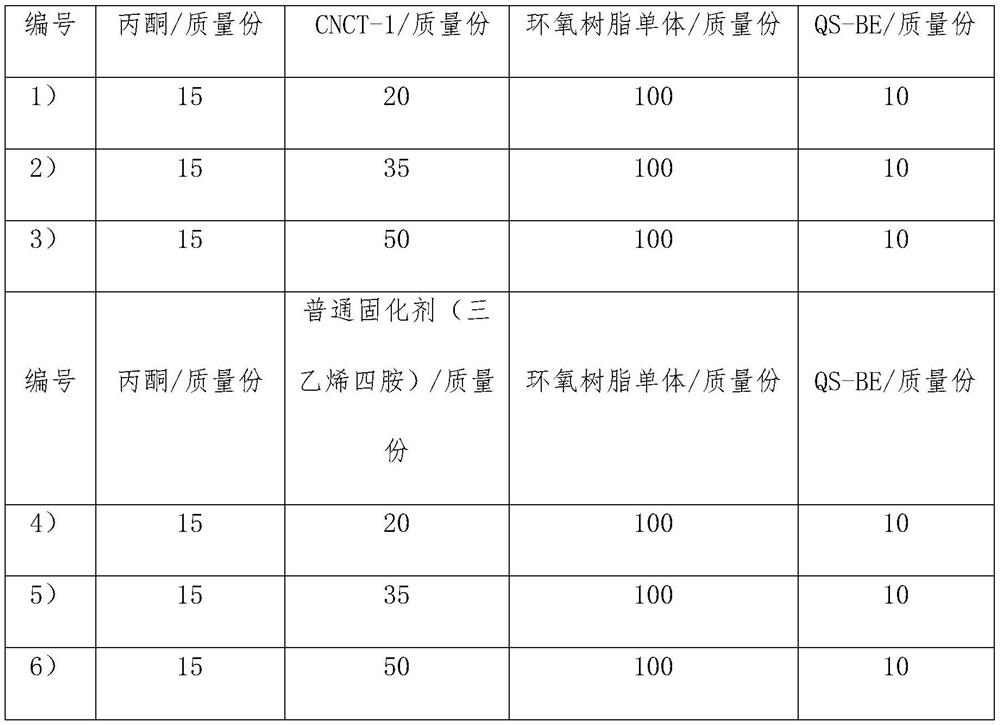

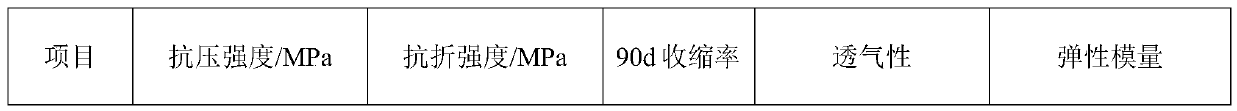

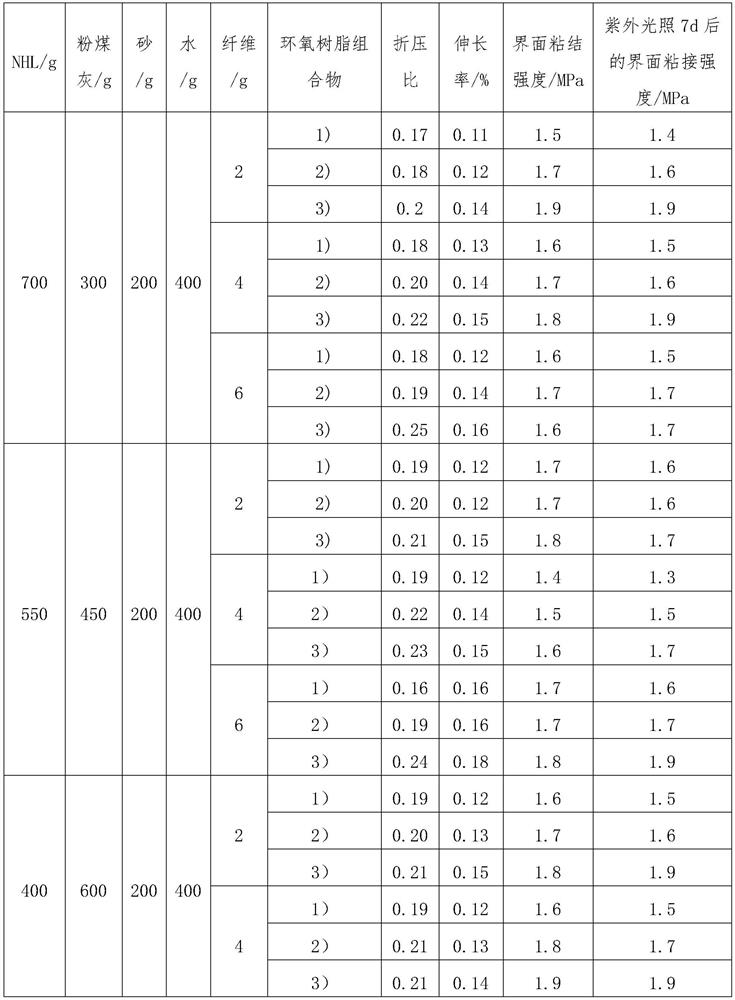

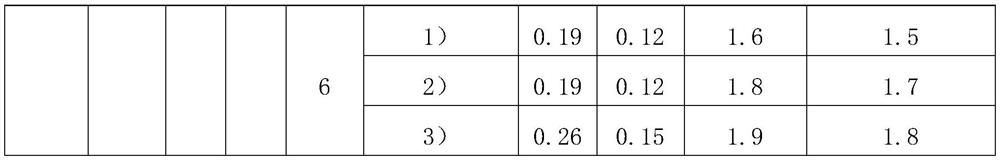

Mortar composite material for repairing masonry ancient building, and preparation method thereof

The invention relates to the technical field of building materials, in particular to a mortar composite material for repairing masonry ancient buildings, and a preparation method of the mortar composite material. According to the invention, an epoxy resin is combined with natural hydraulic lime, wherein the brittle fracture resistance of the prepared mortar is improved by utilizing the high-toughness effect of the epoxy resin, the characteristic of poor durability of the epoxy resin is made up by high durability of the natural hydraulic lime, and the problem of insufficient adhesion of the natural hydraulic lime is made up by high adhesion of the epoxy resin, so that the advantages of the two parties are complementary, the adhesion and toughness of the mortar are improved, after the mortar is subjected to high temperature, water soaking and long-time illumination, the bonding strength of an interface is still higher than 1.5 MPa; and by adding a modified amine curing agent, an organic material (epoxy resin) and an inorganic material (natural hydraulic lime) are better compatible to solve the problem of interface layering, so that the overall performance of the mortar composite material is improved.

Owner:BEIJING GUOWENYAN CULTURAL HERITAGE CONSERVATION CENT LTD

Lime-metakaolin modified soil and application thereof

The invention discloses lime-metakaolin modified soil and application thereof, and relates to the technical field of soil architecture site restoration. The lime-metakaolin modified soil provided by the invention is prepared from the following components in percentage by mass: 8-12% of quicklime powder, 4-12% of metakaolin, and the balance of a soil material. The lime-metakaolin modified soil provided by the invention is a natural inorganic material, the good compatibility of traditional lime mortar is retained, the hydraulicity of hydraulic lime is achieved, after curing for 28 days, a compressive strength value of the lime-metakaolin modified soil can meet the compressive strength class requirements for natural hydraulic lime NHL5, the color change is not obvious, the cost is low, the economical efficiency and environmental protection are achieved, and the significant advantages are achieved in application of restoration and reinforcement of soil architecture sites.

Owner:ZHONGYUAN ENGINEERING COLLEGE

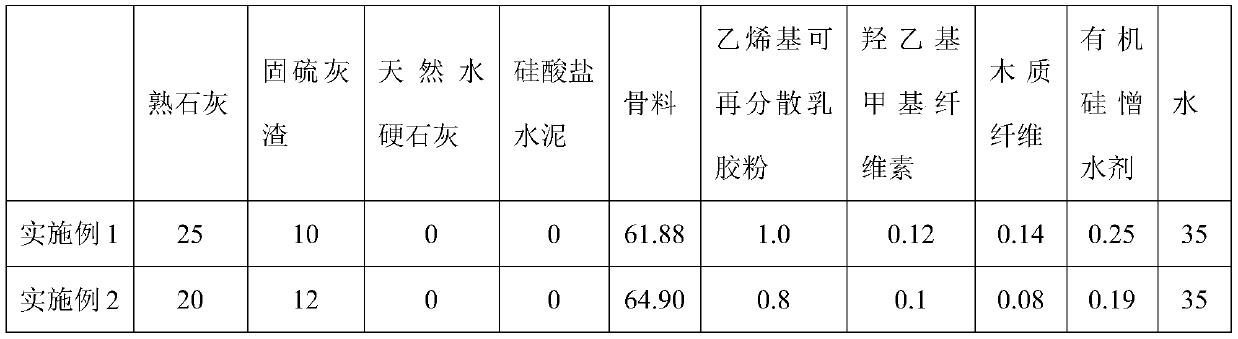

Slag adjusting hydraulic lime mortar for reinforcing and repairing earth construction, and preparation method thereof

The invention discloses slag adjusting hydraulic lime mortar for reinforcing and repairing earth construction, and a preparation method thereof, and belongs to the field of building materials, whereinthe raw materials comprise: 15-25 parts of slaked lime, 10-20 parts of slag, 45-65 parts of aggregate, 0.4-1.2 parts of polymer latex powder, 0.03-0.15 part of cellulose ether, and 0.05-0.2 part of the fiber. The preparation method comprises: adding vinyl redispersible latex powder, hydroxyethyl methyl cellulose ether and fiber to a high speed mixer, uniformly stirring, adjusting the rotation speed, adding slaked lime, slag and aggregate, and uniformly mixing to obtain the product. Compared with the cement-based mortar, the obtained slag adjusting hydraulic lime mortar of the present invention can significantly reduce the high energy consumption produced by the utilization of cement, and has excellent compatibility with earth construction matrixes. Compared with the natural hydraulic lime-based mortar, the obtained slag adjusting hydraulic lime mortar of the present invention has the significantly reduced cost, can promote the resource utilization of solid waste, has significant economic benefits and environmental value, and is suitable for large-scale promotion application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

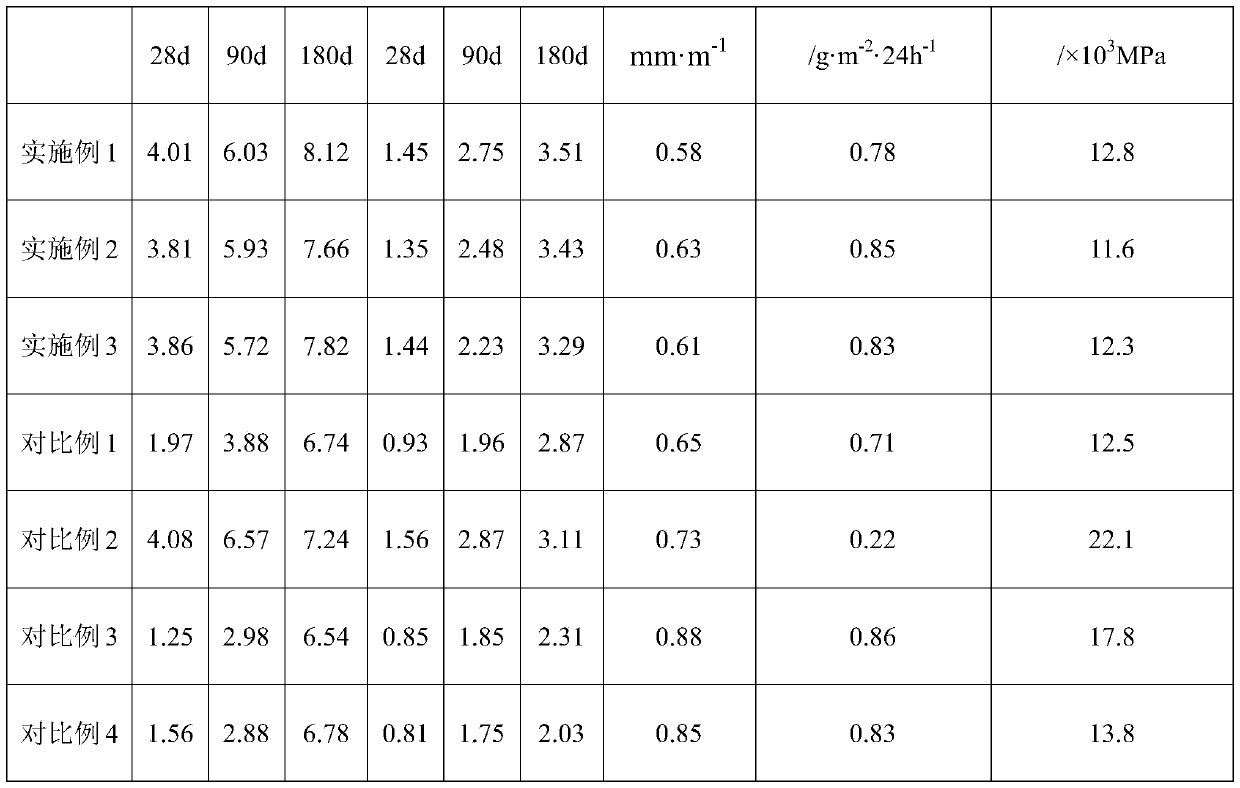

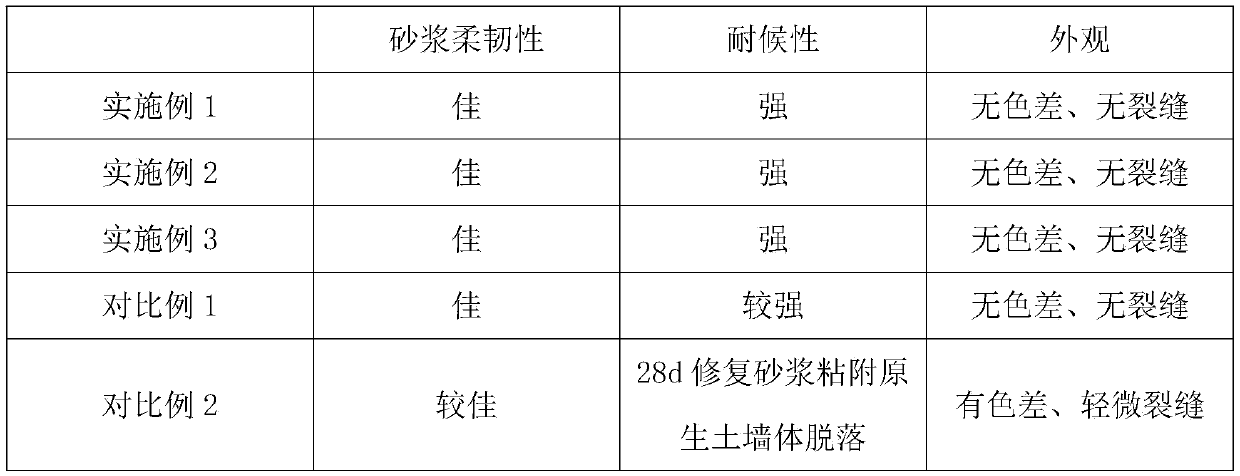

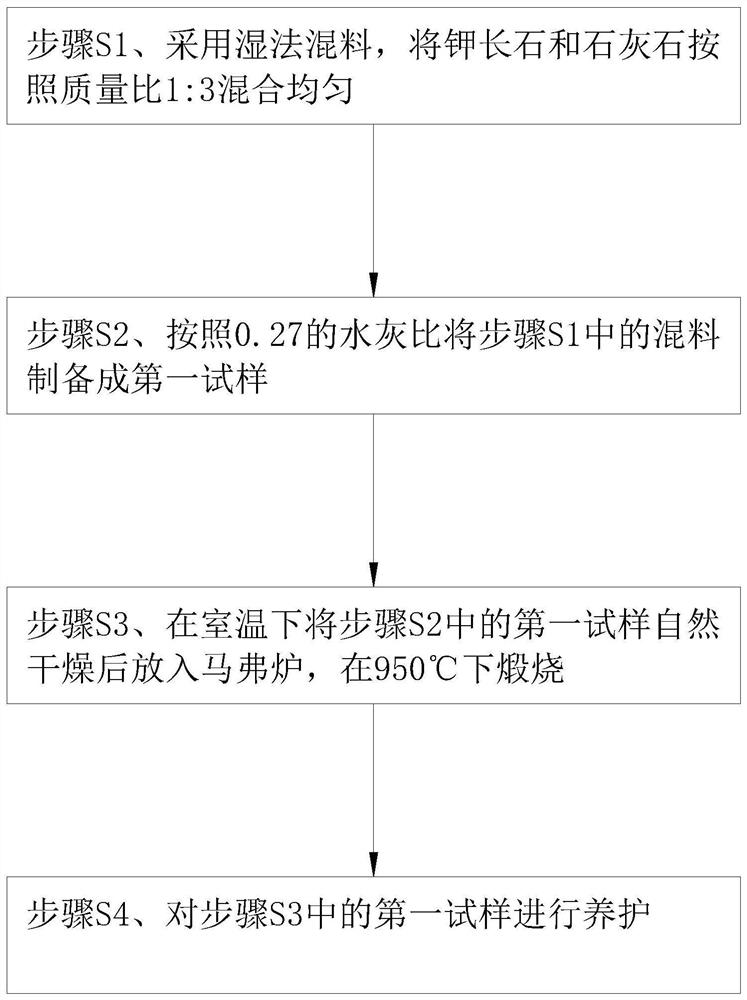

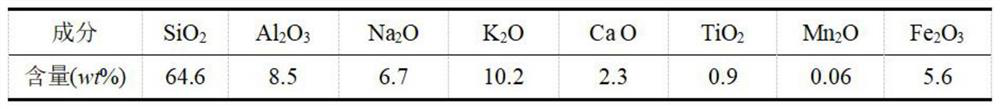

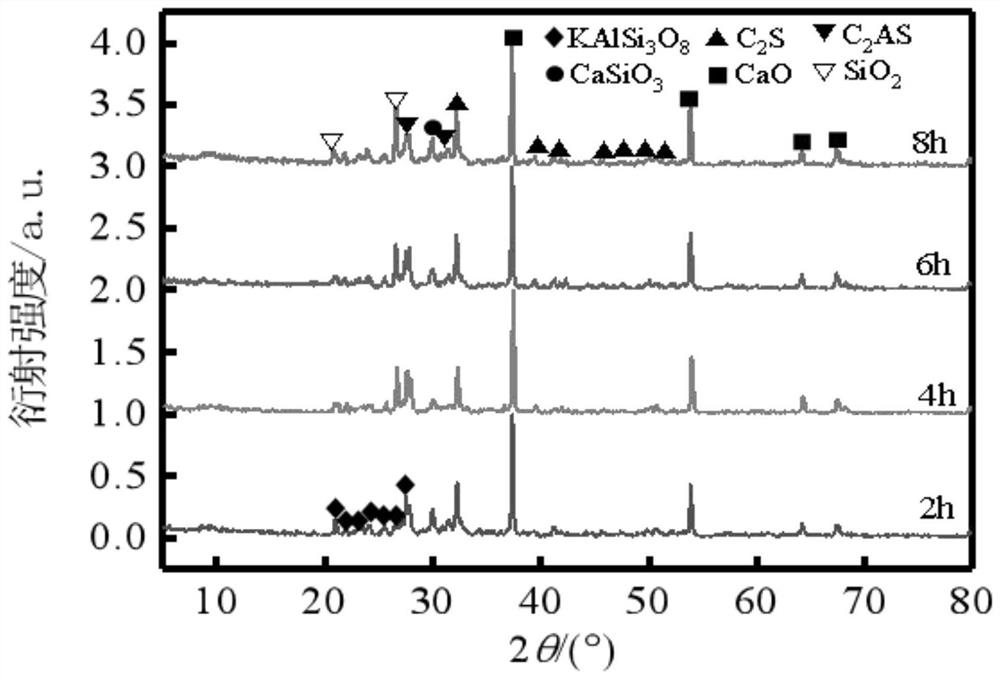

Method for preparing natural hydraulic lime from potassium feldspar and limestone

PendingCN113185158AImprove mechanical propertiesUniform deformation distributionPhysical chemistryMixed materials

The invention belongs to the field of preparation of natural hydraulic lime, and discloses a method for preparing natural hydraulic lime from potassium feldspar and limestone. The method comprises the following steps of: step S1, uniformly mixing potassium feldspar and limestone according to a mass ratio of 1: 3 by wet mixing; S2, preparing the mixed material in the step S1 into a first sample according to a water-cement ratio of 0.27; S3, naturally drying the first sample in the step S2 at room temperature, putting the first sample into a muffle furnace, and calcining the first sample at 950 DEG C; and S4, curing the first sample in the step S3. According to the method, the potassium feldspar and limestone are used as raw materials and calcined at 950 DEG C for 6 hours, the content of CaO, 2CaO. SiO2 and 2CaO. Al2O3.SiO2 in a product is similar to that of the components of European hydraulic lime NHL3.5, and the blank about preparation of NHL3.5 hydraulic lime in China is filled.

Owner:白雨鑫

Grouting proppant for repairing grotto cracks, and preparing and using method thereof

The invention relates to a grouting proppant for repairing grotto cracks, and a preparing and using method thereof. The preparing and using method comprises the following steps: washing a cultural relic matrix material with water, and uniformly mixing the cultural relic matrix material, natural hydraulic lime, kaolin, potassium silicate and a water reducing agent to obtain a mixed dry material; adding water into the mixed dry material, and stirring until uniformity to obtain a slurry; taking and ball-milling kaolin and natural hydraulic lime, fully drying the slurry after ball-milling is finished, crushing and sieving the dried slurry to obtain a raw material, and adding water or drying the raw material to control the water content of the raw material to be 25-30% so as to prepare raw material balls; firing the raw material balls to form ceramsites which comprise large ceramsite and small ceramsite; and filling the cracks with the large ceramsite firstly to play a supporting role, thenfilling the small cracks with the small ceramsite, pouring the slurry to fill remaining cracks, and solidifying the slurry to complete crack repairing. The cracks filled with the grouting proppant isnot prone to cracking, and has a long repair validity period; and the prepared ceramsite and the slurry have good compatibility with cultural relics, and are suitable for repairing grotto cultural relics.

Owner:SHAANXI UNIV OF SCI & TECH

Cementless salt storage mortar composition and preparation method thereof

InactiveCN108017359AExcellent water absorption and breathability balanceWon't breakPorosityHydraulic lime

The invention discloses a cementless salt storage mortar composition and a preparation method thereof. The composition is prepared from, by weight, 50-65% of aggregates, 10-20% of lightweight aggregates, 20-35% of natural hydraulic lime and 1-2% of assistant. The invention further discloses the preparation method of the cementless salt storage mortar composition. According to the cementless salt storage mortar composition, the composition is high in porosity and excellent in water absorption and permeability balance, so that salt in a wall body can be absorbed to the interior of a material toprevent a decoration layer of the wall body from being destructed by the salt, weathering acceleration of the facade of the wall body caused by the fact that the salt residual on the facade of the wall body is prevented, attractive appearances of historical buildings and industrial heritage buildings are guaranteed, more comprehensive protection is provided for the historical buildings and the industrial heritage buildings, and the cementless salt storage mortar composition has significant market and social value.

Owner:浙江德赛堡建筑材料科技有限公司

Hydraulic lime and preparation method thereof

Owner:SOUTHWEAT UNIV OF SCI & TECH

Continuous method for manufacturing material which contains hydraulic binder and which is lightened by expansion

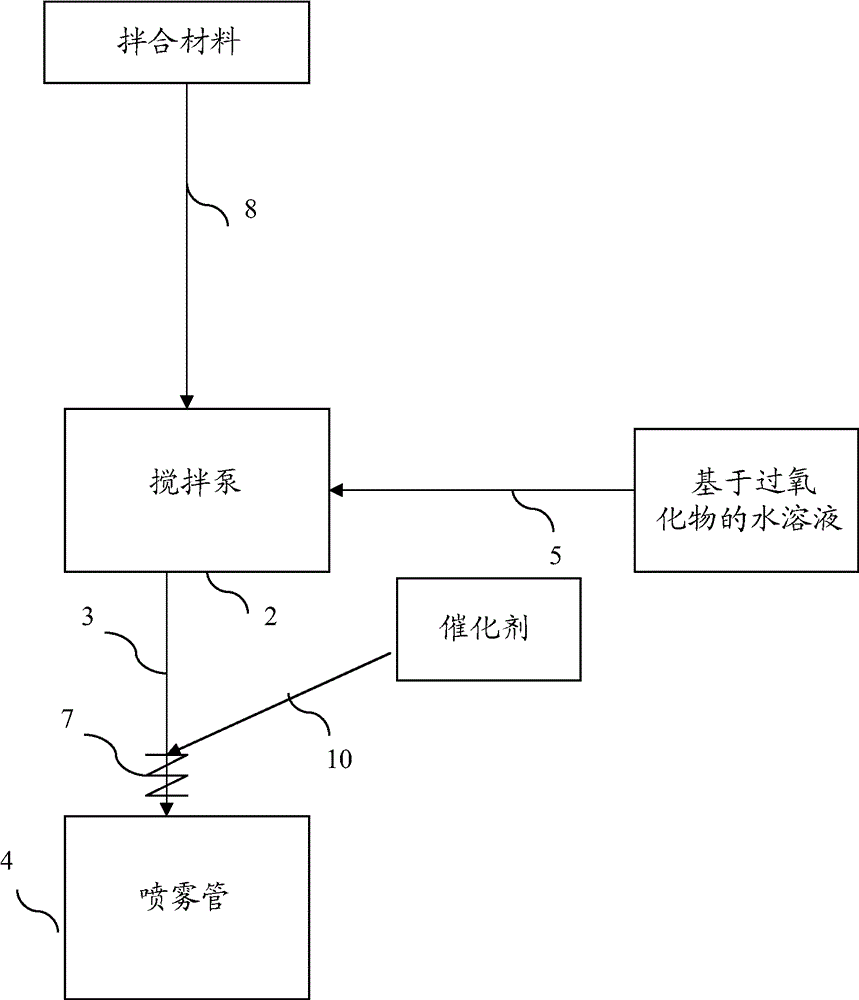

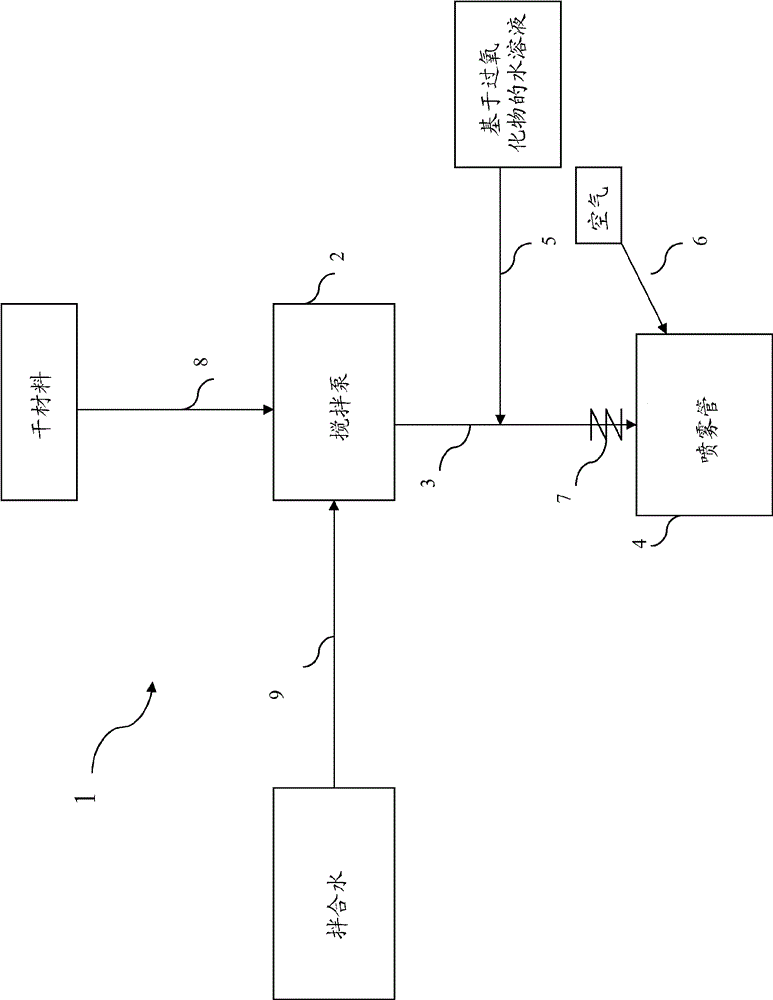

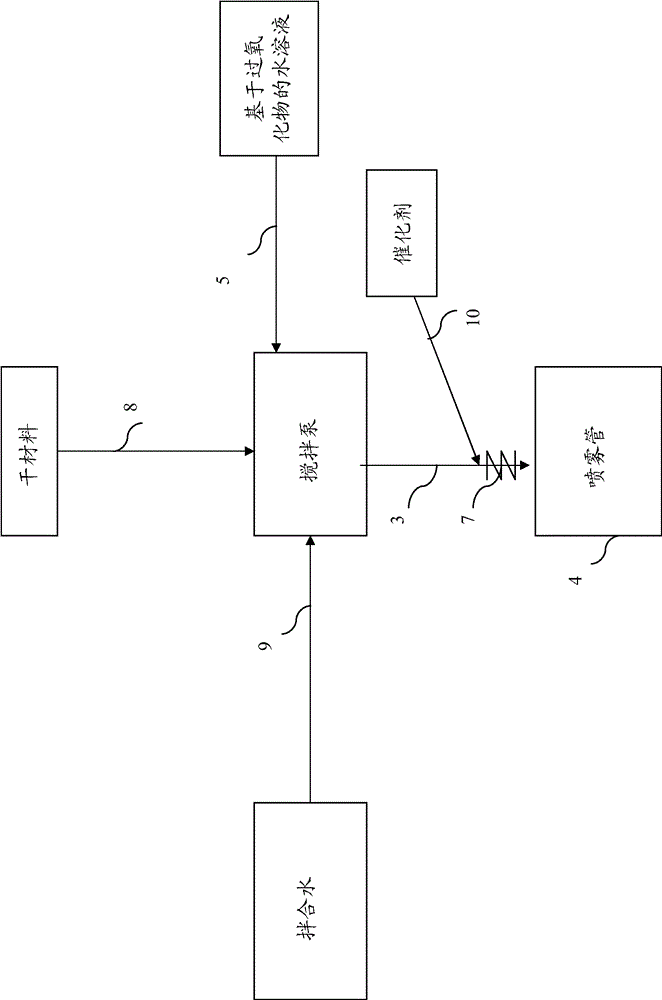

The present invention relates to a method for applying, onto a substrate, mortar which contains a hydraulic binder and which is lightened by expansion, said method implementing a pump spray device including a mixing pump, an outlet pipe for said pump, and a spray nozzle attached to the outlet pipe, and including the following steps implemented continuously in the device: a) mixing an aqueous solution, containing a peroxide pore-forming agent, with a composition including at least one hydraulic binder, in the presence of a catalyst for the breakdown of the pore-forming agent, said binder being selected from among, or being a combination of: cement(s), in particular Portland cement; a pozzolan cement mixture optionally including fly ash, blast-furnace slag, silica fumes, and / or natural or calcined or synthetic pozzolans; aluminous cement; sulfoaluminous cement; belite cement; as well as the mixtures thereof, and / or hydraulic lime; and, immediately after, b) continuously spraying the resulting lightened mixture.

Owner:SAINT GOBAIN WEBER GMBH

Production method of ready injection material comprising NANO hydraulic lime

The present invention is the production method of ready injection material which aims to develop natural hydraulic lime in nano size by using a single raw material.

Owner:YILDIZ TEKNIK UNIVSI

Wall humidifying material based on wool and jute and preparation method thereof

InactiveCN103896526AImprove tensile propertiesStrong shrinkage resistanceSolid waste managementPulverized fuel ashHydraulic lime

The invention discloses a wall humidifying material and a preparation method thereof. The wall humidifying material comprises the following components in parts by weight: 1-5 parts of wool fiber, 2-5 parts of jute fiber, 50-54 parts of sand, 15-19 parts of standard cement, 1-185 parts of pulverized fuel ash, 1-5 parts of hydraulic lime, 1-13 parts of additive and water, the parts by weight of which are 0.99-1.2 times of the total parts by weight of the wool fiber, the jute fiber, the sand, the standard cement, the pulverized fuel ash, the hydraulic lime and the additive. The preparation method comprises the following steps: uniformly mixing the wool fiber, the jute fiber, the sand, the standard cement, the pulverized fuel ash, the hydraulic lime and the additive, then adding water, and uniformly stirring so as to obtain the wall humidifying material. The wall humidifying material has high hygroscopic capacity, tensile performance and shrinkage resistance. When being applied to the inner surfaces of buildings, the wall humidifying material is capable of preventing wall cracking, adjusting indoor humid environments and reducing the energy consumption of air conditioner systems.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

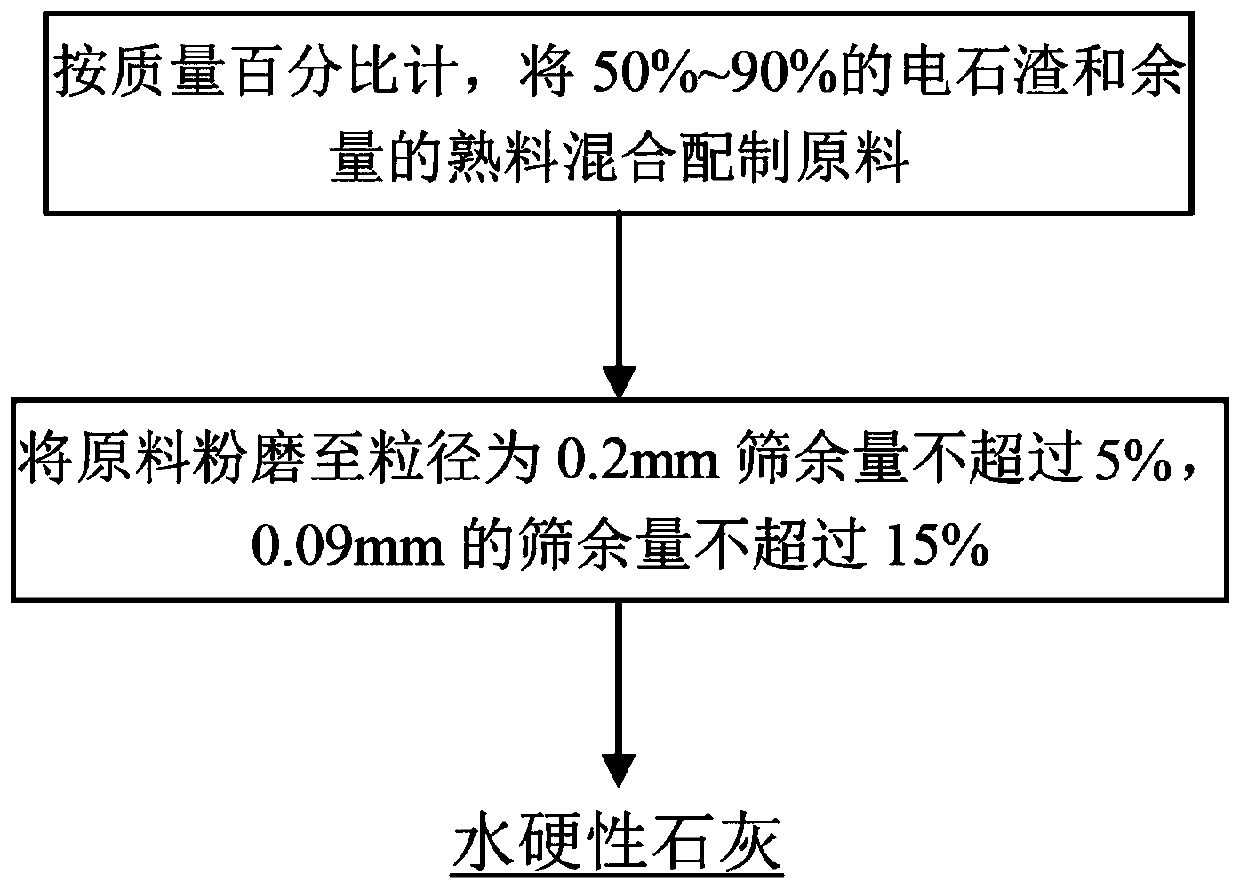

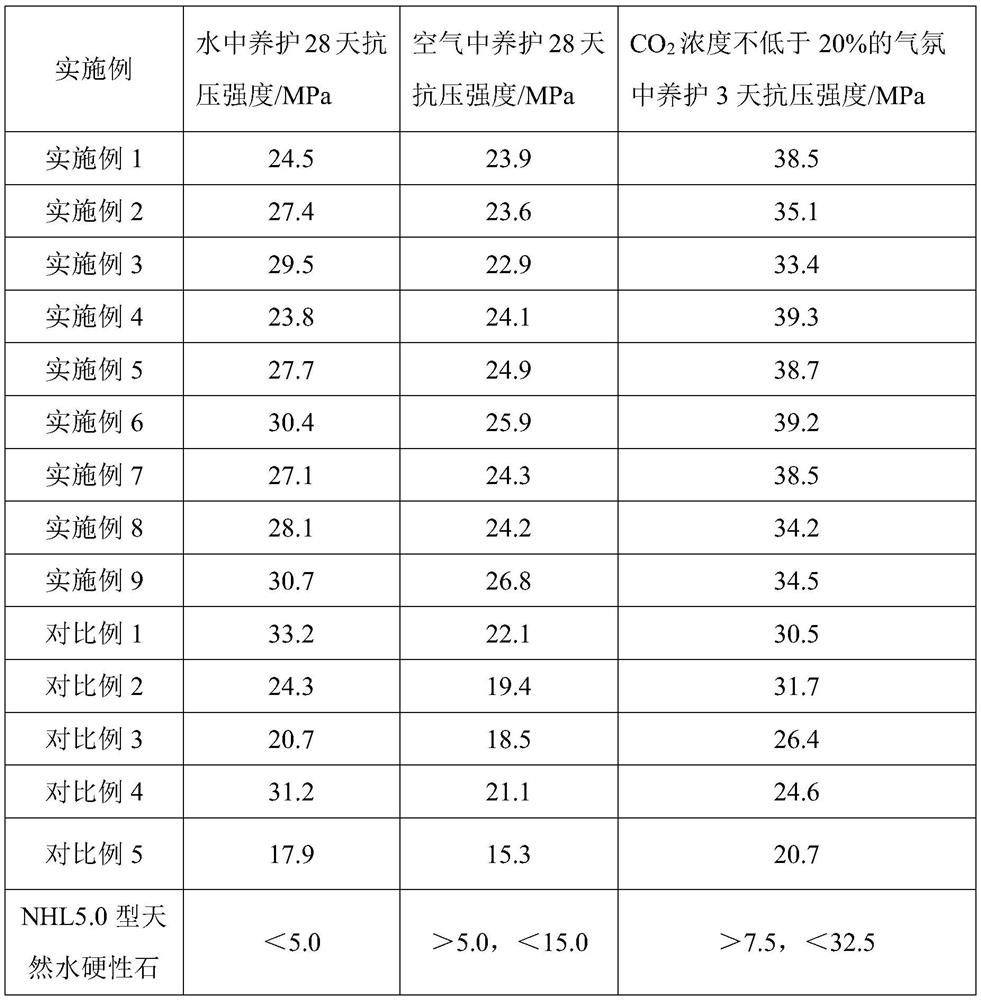

Hydrated and carbonized composite hardened cementing material based on steel slag and preparation method of hydrated and carbonized composite hardened cementing material

The invention discloses a hydrated and carbonized composite hardened cementing material based on steel slag and a preparation method thereof, belongs to the technical field of building materials, and solves the problems of high consumption, high energy consumption, large CO2 emission, low carbonized and hardened body strength and narrow application range in production of natural ore from hydraulic lime / natural hydraulic lime. The hydrated and carbonized composite hardened cementing material based on steel slag comprises the following raw materials: 25-30% of cement clinker, 20-25% of pretreated carbide slag, 1.5-2.0% of industrial byproduct gypsum, 3-5% of bentonite, 0.5-1.0% of a hydrated and carbonized accelerant and the balance of steel slag. The method comprises the following steps: preparing materials, selecting iron, and grinding into powder. The hydration and carbonization composite hardening cementing material based on the steel slag has good hydration hardening performance and carbonization hardening performance, a hardened body shows good mechanical performance in water, air and CO2 atmosphere, and the application field is widened.

Owner:JIAHUA SPECIAL CEMENT +1

A hydraulic oyster ash for restoration and protection of stone cultural relics

The invention relates to a material for reinforcing and repairing stone ruins, and in particular to hydraulic oyster ash for repairing and protecting stone ruins. The hydraulic oyster ash for repairing and protecting stone ruins is obtained by roasting clam shells in a roasting furnace at 1000-1100 DEG C, discharging, then naturally cooling to an environmental temperature, and then crushing to 150 meshes. The hydraulic oyster ash for repairing and protecting stone ruins disclosed by the invention is mainly used for a cementing material for repairing brick stone ruins; the cementing material is obtained by uniformly mixing 150-mesh hydraulic oyster ash for repairing and protecting stone ruins with 100-mesh quartz sand in a mass ratio of 1:1; during use, a slurry material is prepared by uniformly proportioning and stirring the cementing material with water in a mass ratio of 100:50. The chemical composition, mineral constituents and physical mechanical properties of the hydraulic oyster ash for repairing and protecting stone ruins disclosed by the invention are basically similar to those of hydraulic lime NHL-2 for repairing stone ruins, which is introduced in the field of historical relics of China from Germany in recent years, can be used for solving the problems of strength, durability and weather resistance of the reinforced brick stone ruins, and a novel material which is firmly combined with brick stone is provided for repairing damaged brick stone relics.

Owner:李黎

Sound deadener melt pad composition

The present invention relates to a sound deadener melt pad composition, wherein the composition includes an asphalt, EVA H2020, a oil palm fibre, a hydraulic lime and an oil palm olein.

Owner:MALASIAN PALM OIL BOARD

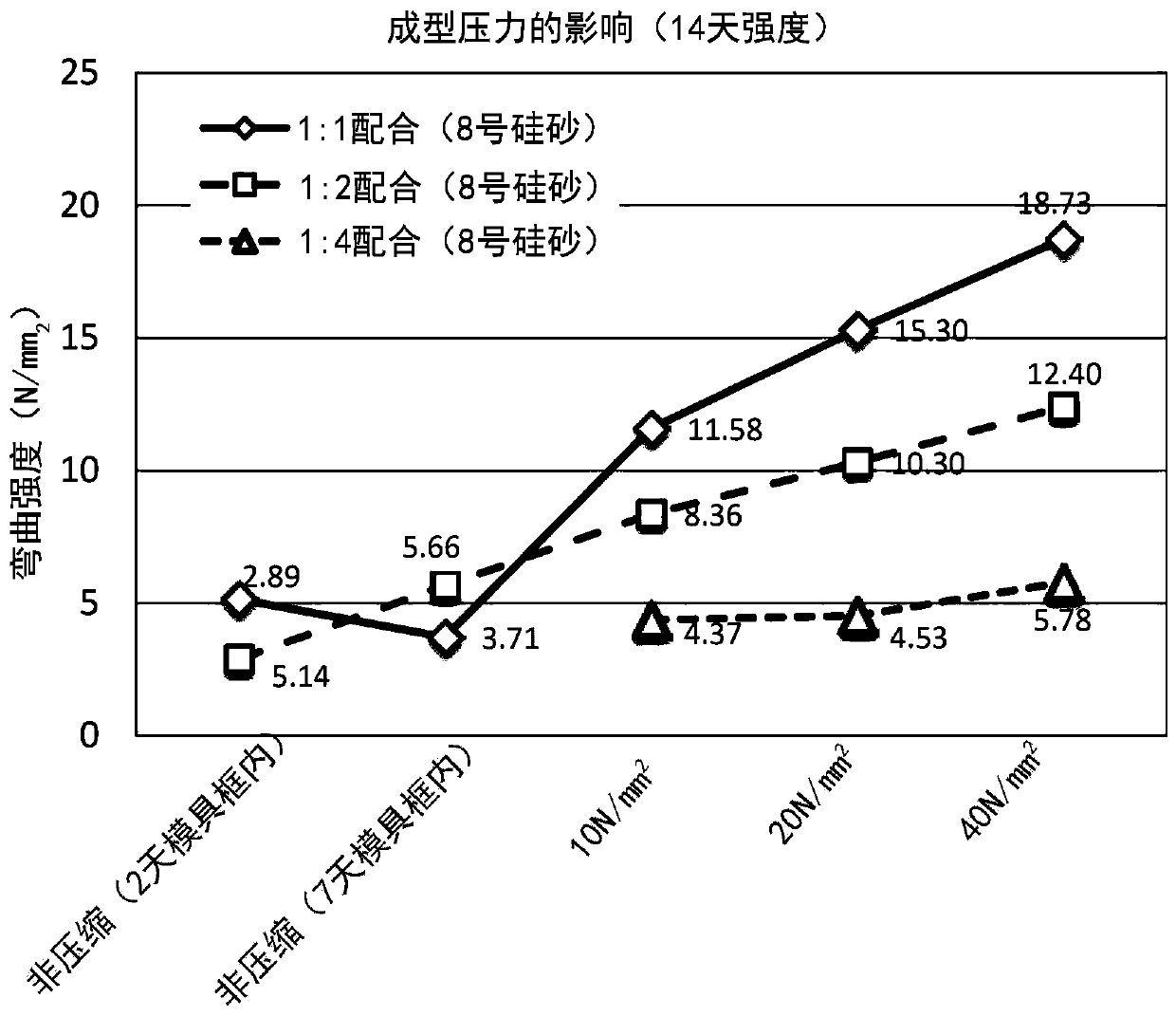

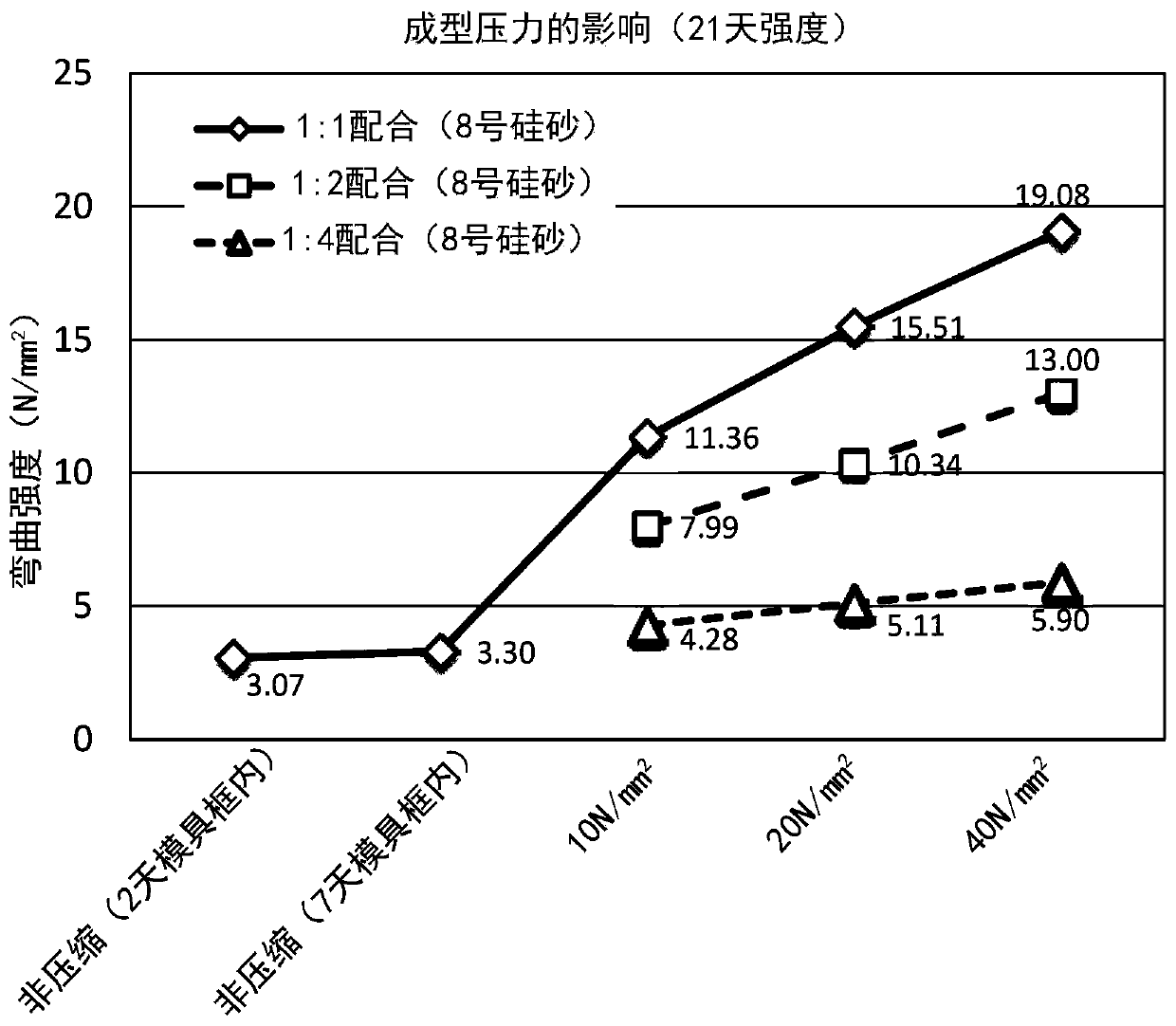

Molded article using hydraulic lime and method for producing same

Owner:KUSUNOKI SEKKAI CO LTD

Fluidized bed combustion ash mixed hydraulic lime mortar for reinforcement repairing of masonry ancient buildings and preparation method of mortar

The invention discloses fluidized bed combustion ash mixed hydraulic lime mortar for reinforcement and repairing of masonry ancient buildings and a preparation method of the mortar, and belongs to the technical field of building materials. The mortar comprises the following raw materials, in parts by weight: 10-25 parts of slaked lime, 5-15 parts of fluidized bed combustion ashes, 45-68 parts of aggregate, and 0.5-2 parts of an additive. The fluidized bed combustion ash mixed hydraulic lime mortar for reinforcement repairing of the masonry ancient buildings provided by the invention has moderate strength development, small shrinkage, and excellent compatibility and matching with the masonry ancient buildings, can be applied to reinforcement repairing projects of various masonry ancient buildings, and utilizes a large amount of industrial solid waste, thereby having lower economic cost and good environmentally-friendly energy-saving waste-utilization effects.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

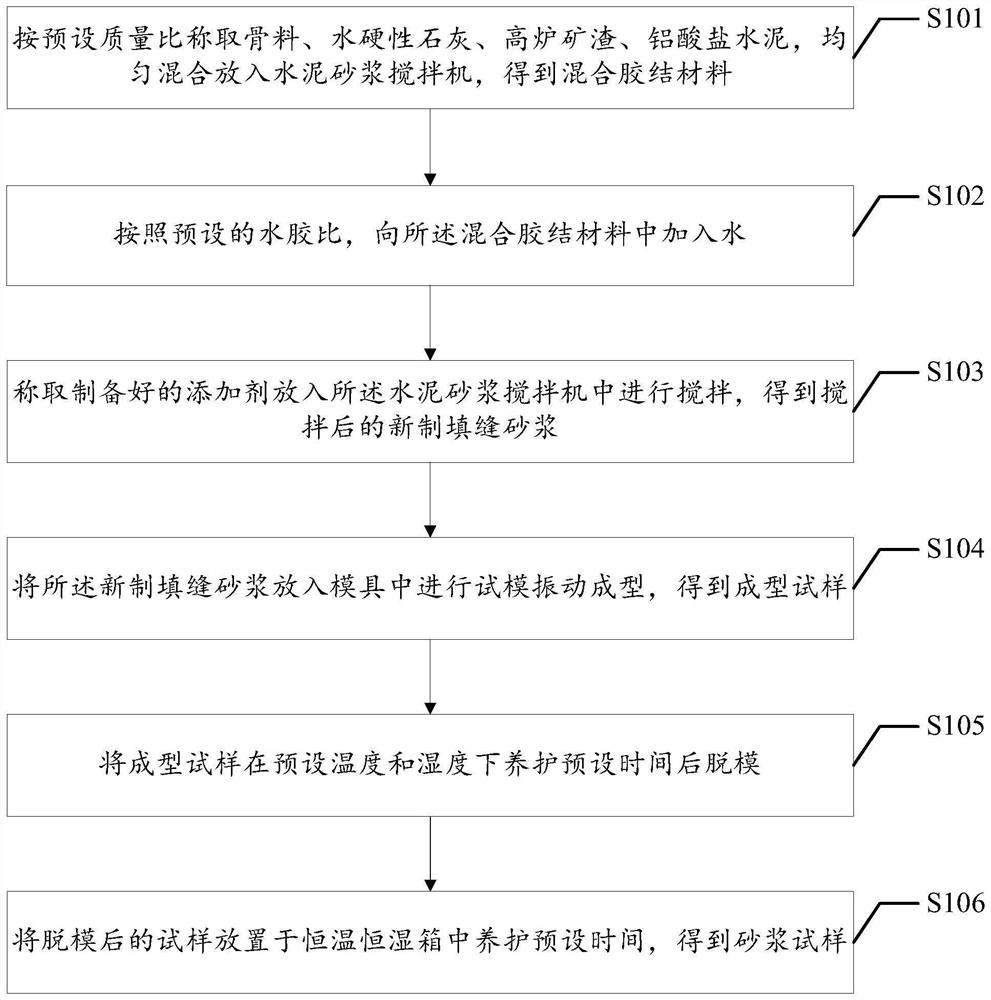

Lime mortar for joint filling of dry-hanging masonry wall and preparation method of lime mortar

The invention discloses lime mortar for dry-hanging masonry wall joint filling and a preparation method thereof.The lime mortar is prepared from hydraulic lime, blast furnace slag, aluminate cement, aggregate, an additive and water, the hydraulic lime mortar serves as a dry-hanging masonry wall joint filling material, the elastic property and durability of the material are improved, and the dry-hanging masonry wall joint filling material is suitable for being used as a dry-hanging masonry wall joint filling material. The resource and environment problems caused by the blast furnace slag are alleviated to a certain extent; the expanded aluminate cement is slightly expanded in volume and is adaptive to structural deformation, and the additive improves the breaking strength and compressive strength of the mortar, so that the mortar can better play a role in caulking.

Owner:科幕(广东)科技有限公司

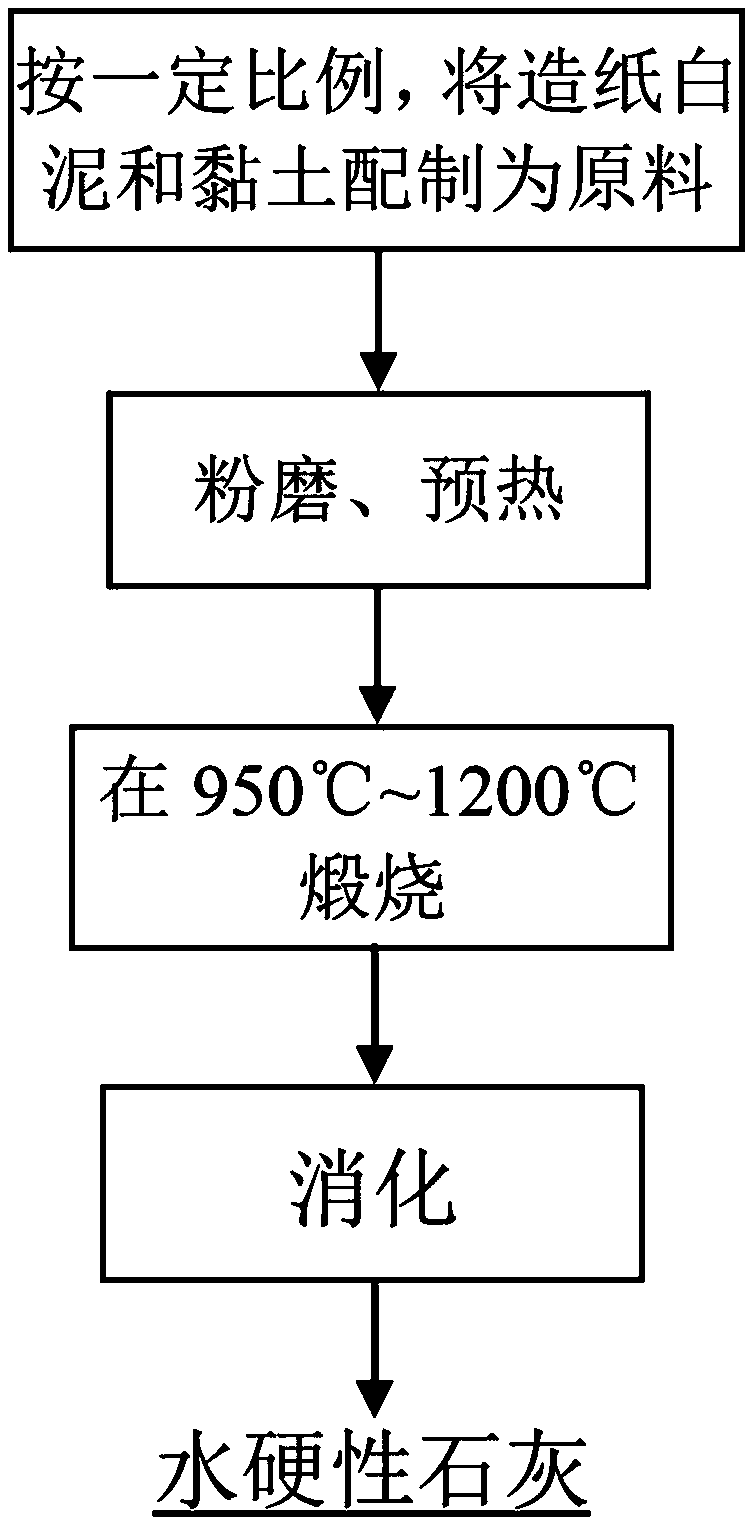

Hydraulic lime and production method thereof

The invention provides hydraulic lime and a production method thereof. The method comprises the following steps of: mixing papermaking white mud and clay to prepare a raw material, wherein the mass ratio of calcium oxide to silicon oxide in the raw material is controlled to be 0.89-10.41, and the raw material comprises the following chemical components in percentage by mass: 32.45%-50.27% of calcium oxide, 4.83%-36.55% of silicon oxide and no more than 4.5% of aluminum oxide; and grinding the raw material, preheating, calcining at 950-1200 DEG C, cooling, digesting, drying, and grinding to obtain the hydraulic lime. According to the method, the papermaking white mud is used as a main raw material, and can be turned into wealth, so that reasonable utilization of resources is achieved, and the method is environmentally friendly, short in technological process and low in production cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Grease lime and preparation method thereof

InactiveCN105695049ALow experience requirementEasy to operateLubricant compositionLiquid stateHydraulic lime

The invention discloses grease lime and its preparation method. The grease lime is composed of lime and No.3 industrial grease, and the ratio of lime to No.3 industrial grease is 10: 1.2-1.5. The preparation method comprises the following steps: blending hydraulic lime and No.3 industrial grease in proportion, fully and uniformly stirring in a stirrer for 15-20 min to obtain a liquid state without oil balls, diluting with water to proper viscosity, and stirring for about 10 min. The preparation method is simple to operate, and has low requirement on experience of operators. In addition, quality of the product is high.

Owner:CHONGQING YIMAN ENVIRONMENTAL PROTECTION EQUIP

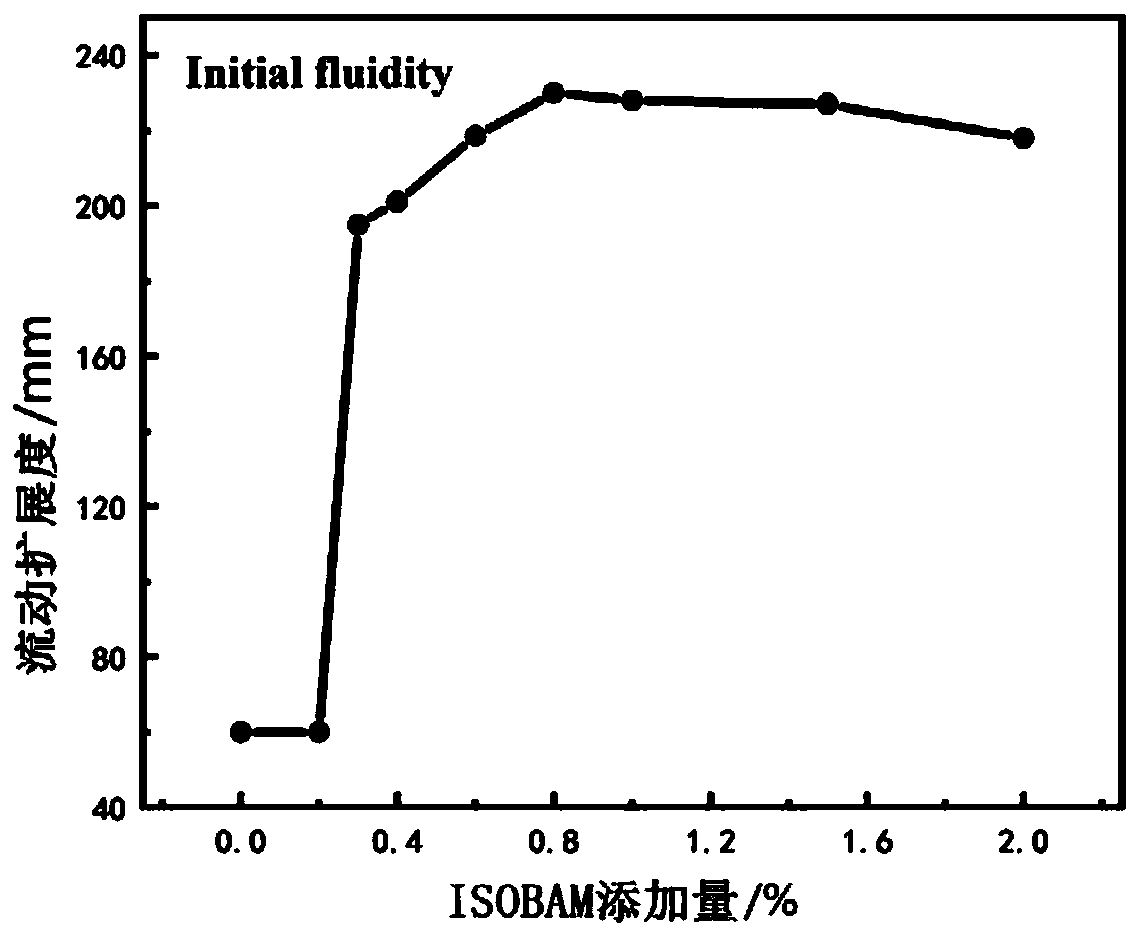

Early-strength multi-scene applicable natural hydraulic lime slurry and modification preparation method thereof

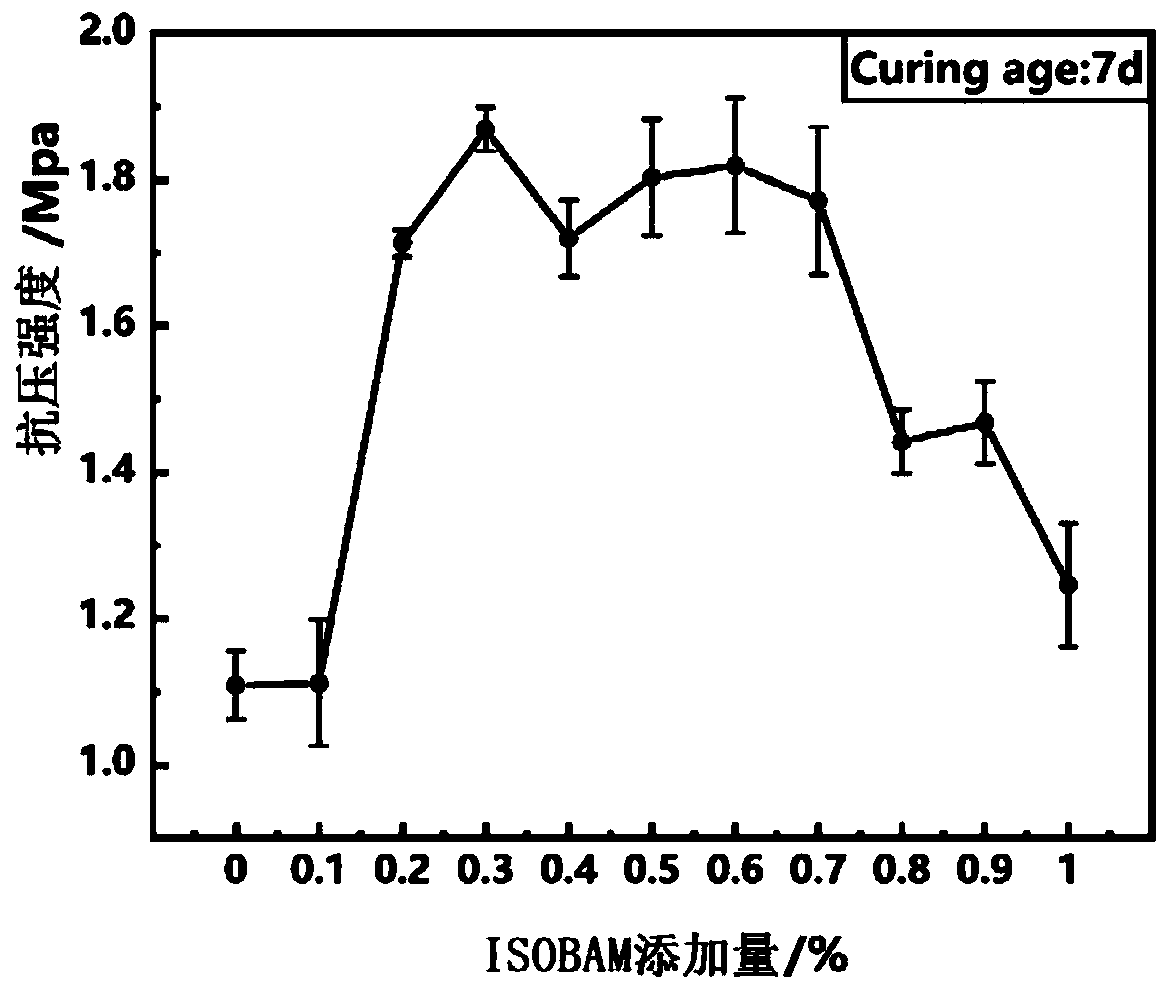

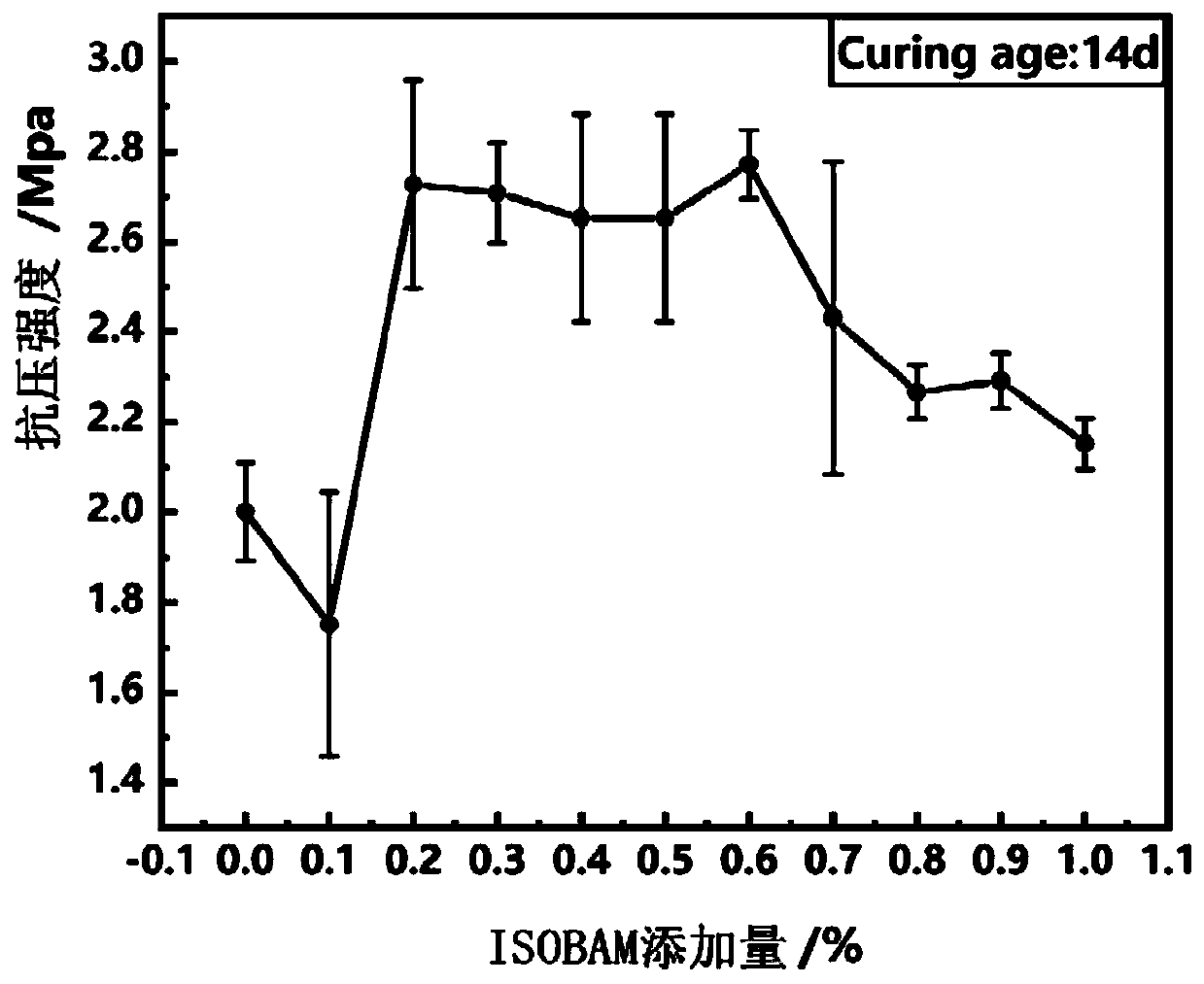

The invention relates to early-strength multi-scene applicable natural hydraulic lime slurry, which comprises the following components in percentage by mass: and water, the water cement ratio is 30%-60%, and the ash comprises the following components in percentage by mass: 94%-99.9% of natural hydraulic lime and 0.1%-6% of an isobutylene-maleic anhydride copolymer. The preparation method comprisesthe following steps: dissolving the isobutylene-maleic anhydride copolymer in water, and uniformly mixing an isobutylene-maleic anhydride copolymer aqueous solution with natural hydraulic lime. According to the prepared slurry, the early strength and fluidity of natural hydraulic lime are improved, the service life of the natural hydraulic lime is prolonged, and the application scene of the natural hydraulic lime is expanded.

Owner:SHAANXI UNIV OF SCI & TECH

Mortar composite material for repairing historic building, and preparation method thereof

The invention relates to the technical field of building materials, in particular to a mortar composite material for repairing ancient buildings and a preparation method of the mortar composite material. The mortar composite material is characterized in that an epoxy resin composition is added into an inorganic cementing material composition containing natural hydraulic lime, wherein the epoxy resin as an organic material for buildings has many excellent characteristics such as high adhesion and high toughness in the repair work of ancient buildings; the organic material and the inorganic material are combined, so that the brittle fracture resistance of the prepared mortar is improved by utilizing the high toughness effect of the epoxy resin; and the characteristic of poor durability of the epoxy resin is made up by high durability of the natural hydraulic lime, and the problem of insufficient adhesion of the natural hydraulic lime is made up by high adhesion of the epoxy resin, so that the advantages of the two materials are complementary, the adhesion and toughness of the mortar are improved, and after the mortar is subjected to high temperature, water soaking and long-time illumination, the bonding strength of the interface is still higher than 1.5 MPa.

Owner:CE CENT FOR ENG RES TEST & APPRAISAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com