Method for preparing natural hydraulic lime with lead and zinc mine tailings

A technology of natural water and tailings, applied in the field of preparing natural hydraulic lime, can solve the problem that the research and development of natural hydraulic lime is still blank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

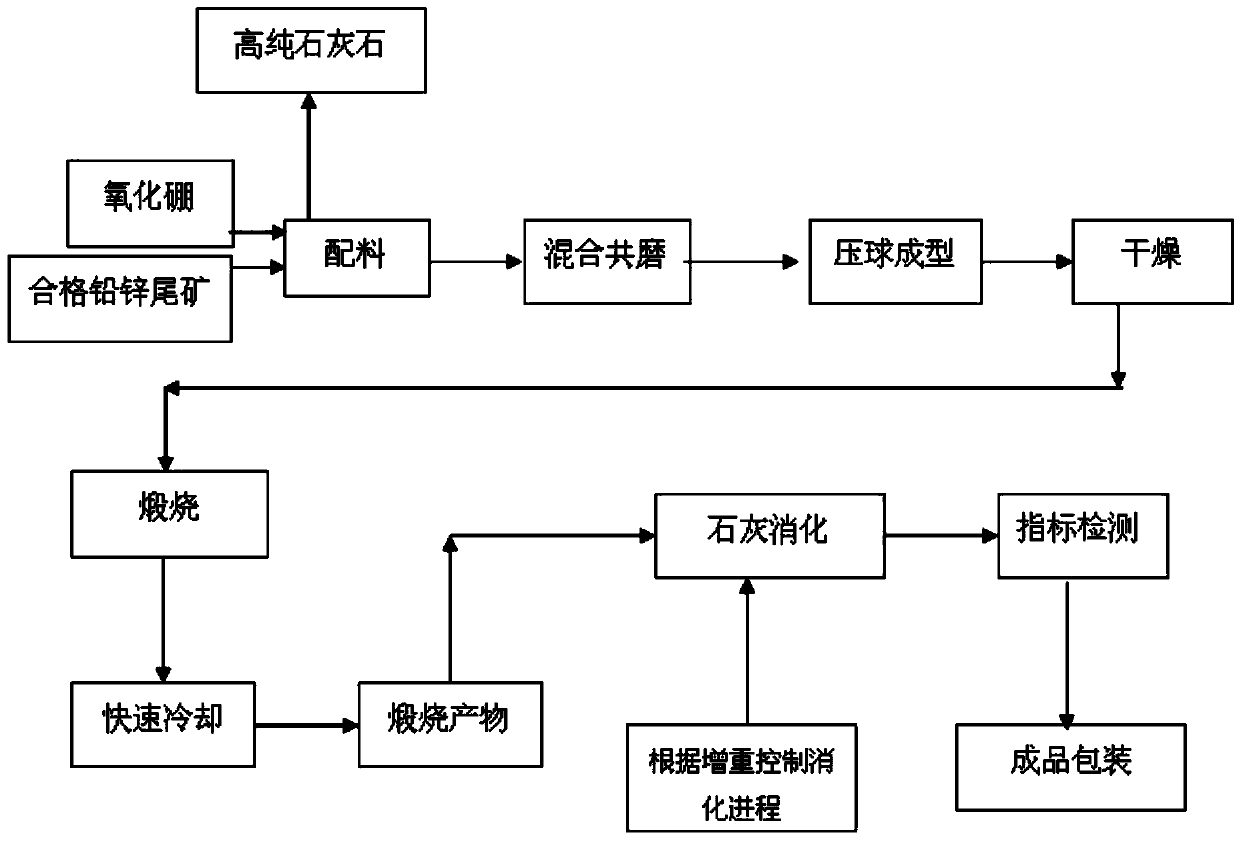

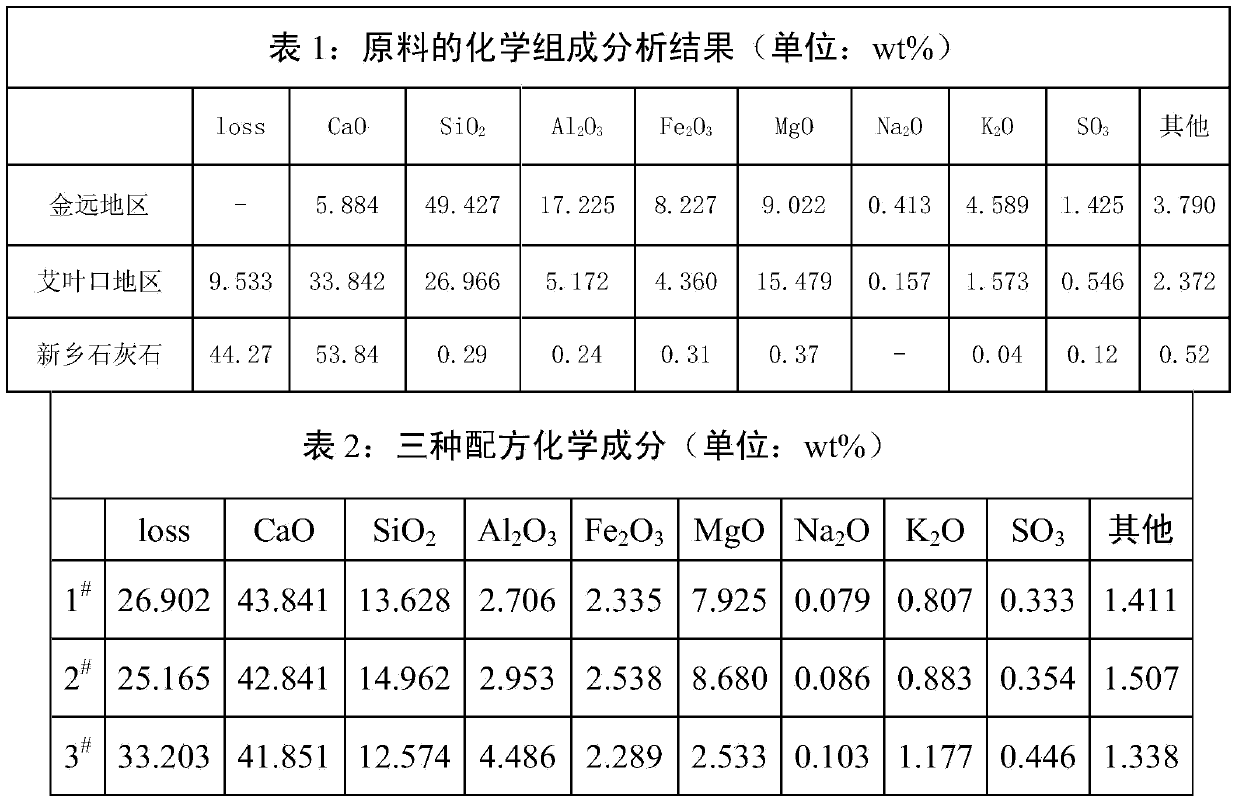

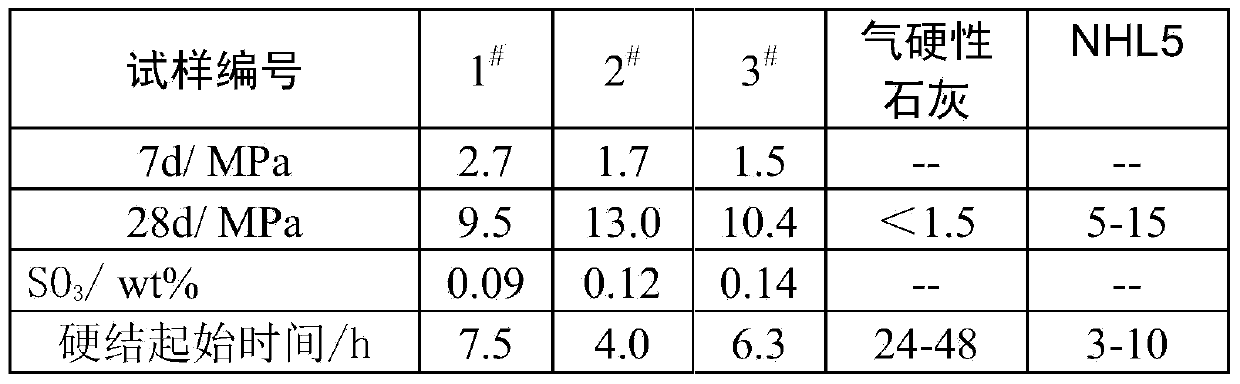

[0020] see figure 1 Shown, according to the technical scheme of the present invention, a kind of method that utilizes lead-zinc tailings to prepare natural hydraulic lime, the lead-zinc tailings that meet the requirement is main raw material, and the silicon dioxide in this lead-zinc tailings must dissolve into Calcium oxide with fine particles and uniform distribution; use high-purity limestone to adjust the ratio of calcium oxide and silicon oxide in lead-zinc tailings (CaO / SiO 2 =2.86-3.33), the alumina content does not exceed 4.5%, in order to control the content of hydraulic products in the product, add 0.5-0.8% of the total amount of lead-zinc tailings boron oxide, and lead-zinc tailings in sodium oxide, Potassium oxide and other impurities form a glass phase with low hydration activity and low hydration heat value, which improves the strength in the later stage and reduces the "frosting" of soluble salts.

[0021] Lead-zinc tailings are fully co-ground with high-purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com