Protection brick and stone ancient building repair lime bonding material

A technology of bonding materials and ancient buildings, applied in the field of building materials manufacturing, can solve problems such as unsatisfactory bonding reinforcement and protection effects, incompatibility, slow hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

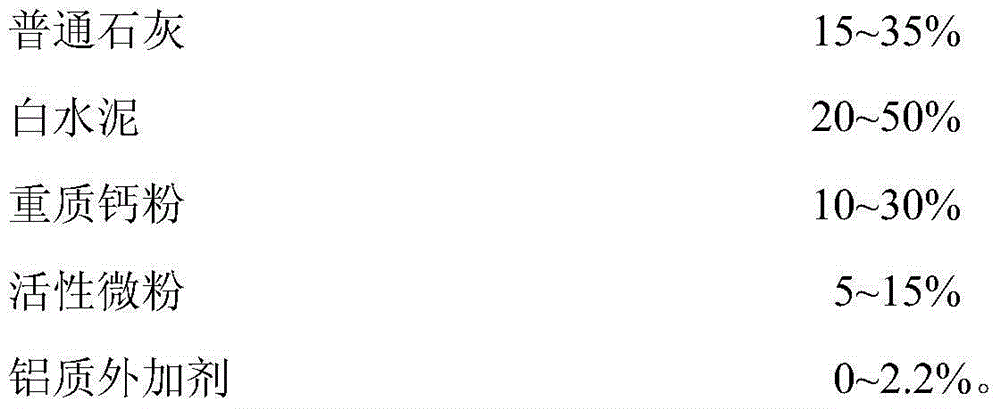

[0017] Embodiment 1: the mass percent of each component of the lime binding material of repair protection brick / stone class ancient building of the present invention is:

[0018]

[0019] The active micropowder is ground slag, and the aluminum admixture is aluminum sulfate.

[0020] According to European standards, the water-cement ratio of the lime bonded mortar is 0.55, and the mortar-sand ratio is 1:3. After mixing and forming, the fluidity of the mortar is tested, and the mold is naturally cured to the specified age. After taking it out, it is demoulded to test the resistance. compressive strength. In this example, the fluidity of the mortar reaches 185mm, the initial setting time is 159min, the final setting time is 375min, the 28-day compressive strength reaches 8.73MPa, and the softening coefficient is 0.69, which meets the requirements for the repair and reinforcement of brick / stone ancient buildings.

Embodiment 2

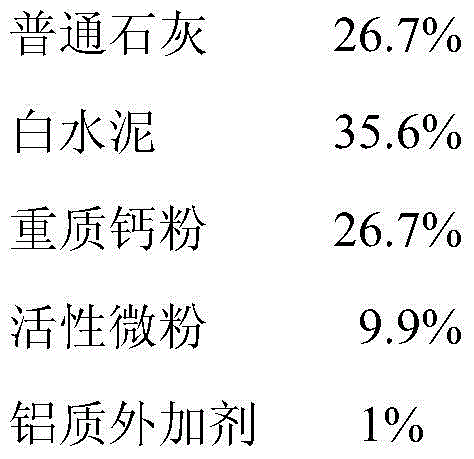

[0021] Embodiment 2: the mass percent of each component of the lime binding material of repair protection brick / stone class ancient building of the present invention is:

[0022]

[0023] Wherein the active micropowder is metakaolin, and the aluminum additive is aluminum sulfate.

[0024] According to European standards, the water-cement ratio of the hydraulic lime mortar is 0.55, and the cement-sand ratio is 1:3. After mixing and forming, the fluidity of the mortar is tested, and the mold is naturally cured to the specified age. After taking it out, it is demolded to test the compression resistance. strength. In this example, the fluidity of the mortar reaches 180mm, the initial setting time is 175min, the final setting time is 390min, the 28-day compressive strength reaches 9.68MPa, and the softening coefficient is 0.73, which meets the requirements for the repair and reinforcement of brick / stone ancient buildings.

Embodiment 3

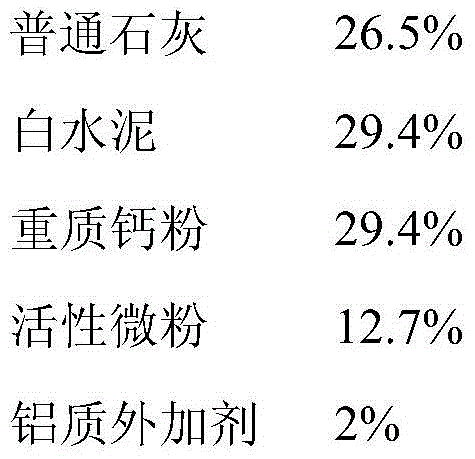

[0025] Embodiment 3: the mass percent of each component of the lime binding material of repair protection brick / stone class ancient building of the present invention is:

[0026]

[0027] The active micropowder is ground slag, and the aluminum additive is alunite.

[0028] According to the European standard, the water-cement ratio of the hydraulic lime mortar is 0.55, and the cement-sand ratio is 1:3. After mixing and forming, test the fluidity of the mortar, and put it into the mold and naturally maintain it to the specified age. After taking it out, it will be demoulded to test the compression resistance. strength. In this example, the fluidity of the mortar reaches 190mm, the initial setting time is 138min, the final setting time is 365min, the 28-day compressive strength reaches 10.17MPa, and the softening coefficient is 0.66, which meets the requirements for the repair and reinforcement of brick / stone ancient buildings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com