Continuous method for manufacturing material which contains hydraulic binder and which is lightened by expansion

A hydraulic binder, peroxide technology, used in mixing methods, chemical instruments and methods, ceramic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A dry mortar composition comprising the following components was mixed with a peroxide decomposition catalyst precursor.

[0086] 88.75% Portland cement CEM 52.5 R (Heidelberg Cement, Schelklingen)

[0087] 10% glass microspheres (Q-CEL 7014, Potter Industries LLC)

[0088] 1% manganese sulfate monohydrate (catalyst precursor)

[0089] 0.2% cellulose ether (DOW 267)

[0090] 0.05% surfactant (Hostapur OSB).

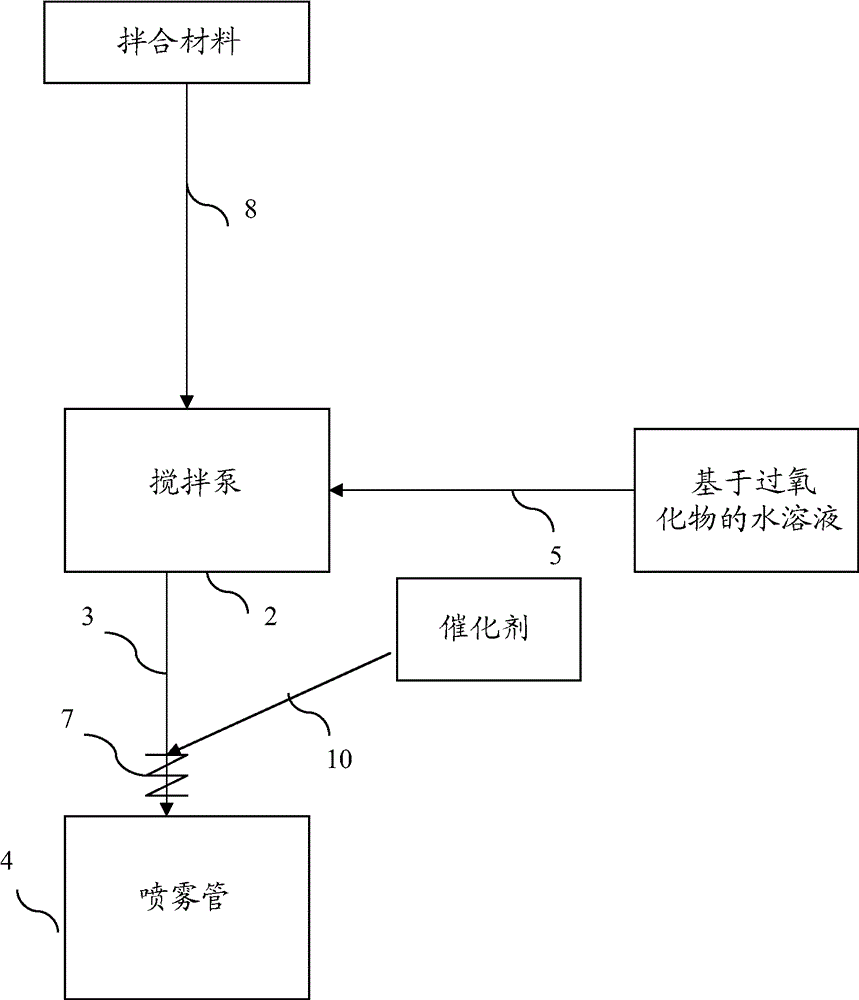

[0091] according to Figure 1A Carry out the method. The dry mortar composition and catalyst precursor mixture ( 12 ) and mixing water are each fed into a mixing pump ( 11 ) of the M-Tec M100 type at a flow rate of 100 kg / h. The resulting blended composition was pumped continuously at a pumping flow rate of 200 kg / h.

[0092] The fresh mortar leaving the spray nozzle had a density of 920 g / l without the addition of the peroxide-based solution.

[0093] The line containing 8.5% aqueous hydrogen peroxide solution was opened and introduced continuously at the e...

Embodiment 2

[0096] A dry mortar composition comprising the following components was mixed with a peroxide decomposition catalyst precursor.

[0097] 84% white cement (CPA CEM1 52.5N Calcia)

[0098] 15% Perlite 0 / 1

[0099] 0.7% manganese acetate (catalyst precursor)

[0100] 0.25% cellulose ether (Tylose MH100000P6)

[0101] 0.05% surfactant (Ufapore TP808).

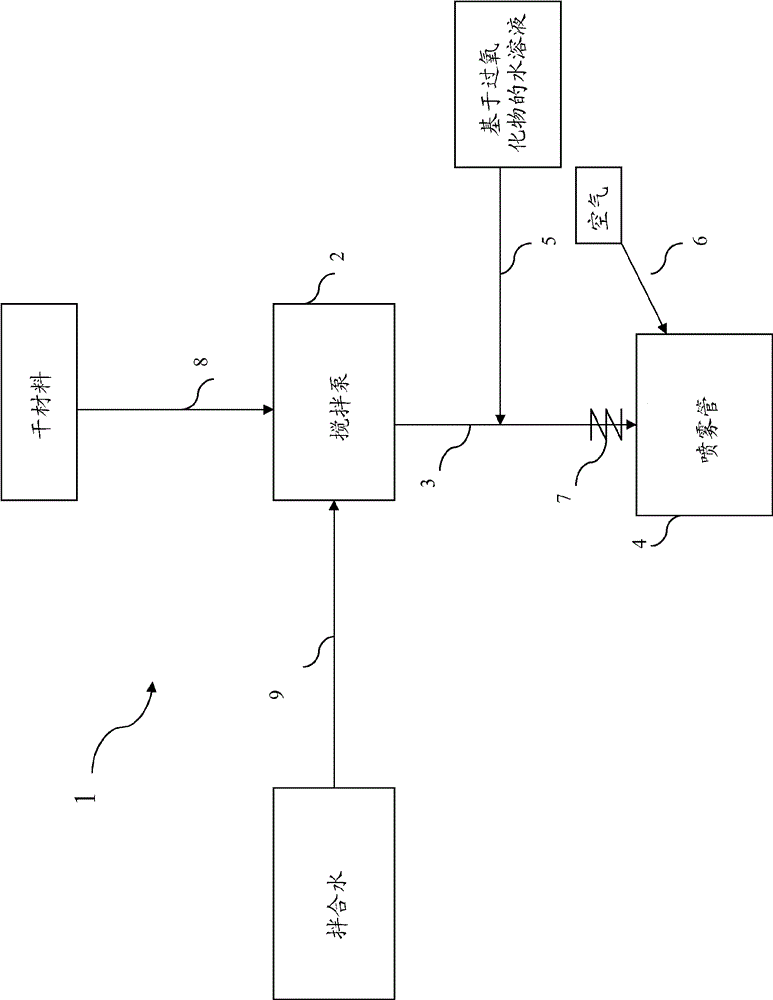

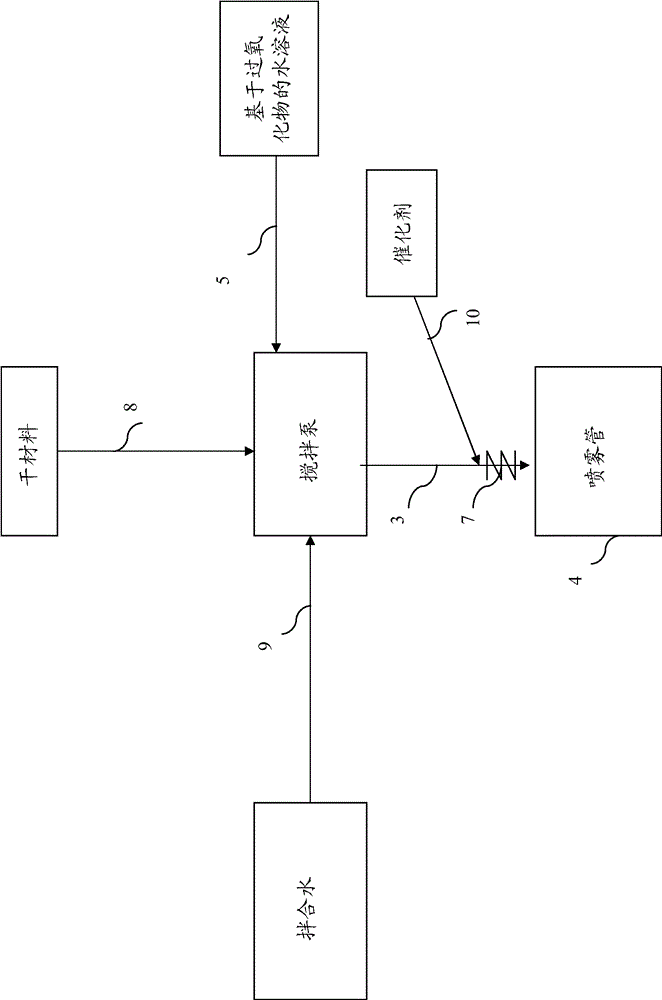

[0102] according to Figure 2ACarry out the method. The dry mortar composition (21 kg of dry mortar and 30 kg of water) to which the catalyst precursor had been added was mixed in a batch mixer (M-Tec CM) separate from the spraying apparatus. The paste thus obtained was fed into a M-Tec P20 pump and pumped at a flow rate of 540 kg / h.

[0103] The fresh mortar leaving the spray nozzle had a density of 815 g / l without the addition of the peroxide-based solution.

[0104] The line containing 17% aqueous hydrogen peroxide solution was opened and introduced continuously at the end of the nozzle at the level of the static mixer at...

Embodiment 3

[0107] Lightweight dry mortar compositions containing expanded polystyrene (Weber.Aislone) and a mixture of Portland cement with slaked lime as hydraulic binder are mixed in a continuous mixing pump of the MTec Duo-mix type with a quantity of water for mixing .

[0108] Prepare a solution containing 50% of water, 5% of manganese acetate, 5% of sulfuric acid and 40% of 35% hydrogen peroxide solution (pH is maintained at 4).

[0109] according to Figure 1A Carry out the method. The pump has a pumping capacity of 22 liters / minute.

[0110] The fresh mortar leaving the spray nozzle had a density of 560 g / l without the addition of the peroxide-based solution.

[0111] When the line containing the aqueous hydrogen peroxide solution was opened and introduced into the outlet line of the mixing pump at a flow rate of 20 kg / h, the density of the mortar extracted from the nozzle decreased to 400 g / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com