Slag adjusting hydraulic lime mortar for reinforcing and repairing earth construction, and preparation method thereof

A technology of hydraulic lime and slag, which is applied in the field of mixing hydraulic lime mortar with slag for reinforcement and repair of raw soil buildings and its preparation, which can solve the problem that natural hydraulic lime fails to realize commercial production, restricts the application and development of hydraulic lime, etc. problems, to achieve good ecological environmental benefits and social benefits, great historical and cultural protection value, high adhesion and crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0025] The raw materials and properties used are as follows:

[0026] Slaked lime: commercially available slaked lime powder with a purity greater than 98%.

[0027] Slag: The specific surface area is 463m 2 / kg S95 grade granulated blast furnace slag.

[0028] Natural hydraulic lime: Natural hydraulic lime imported from Europe with a strength level of NHL2.

[0029] Cement: Portland cement of strength class 42.5.

[0030] Additives: vinyl redispersible latex powder, hydroxyethyl methyl cellulose ether with a viscosity of 30000mPa·s, wood fiber with a diameter of 0.5-3mm.

[0031] Aggregate: waste clay brick powder.

[0032] Water: tap water.

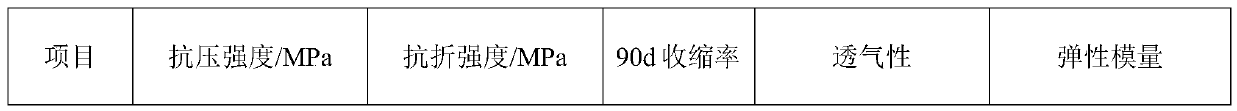

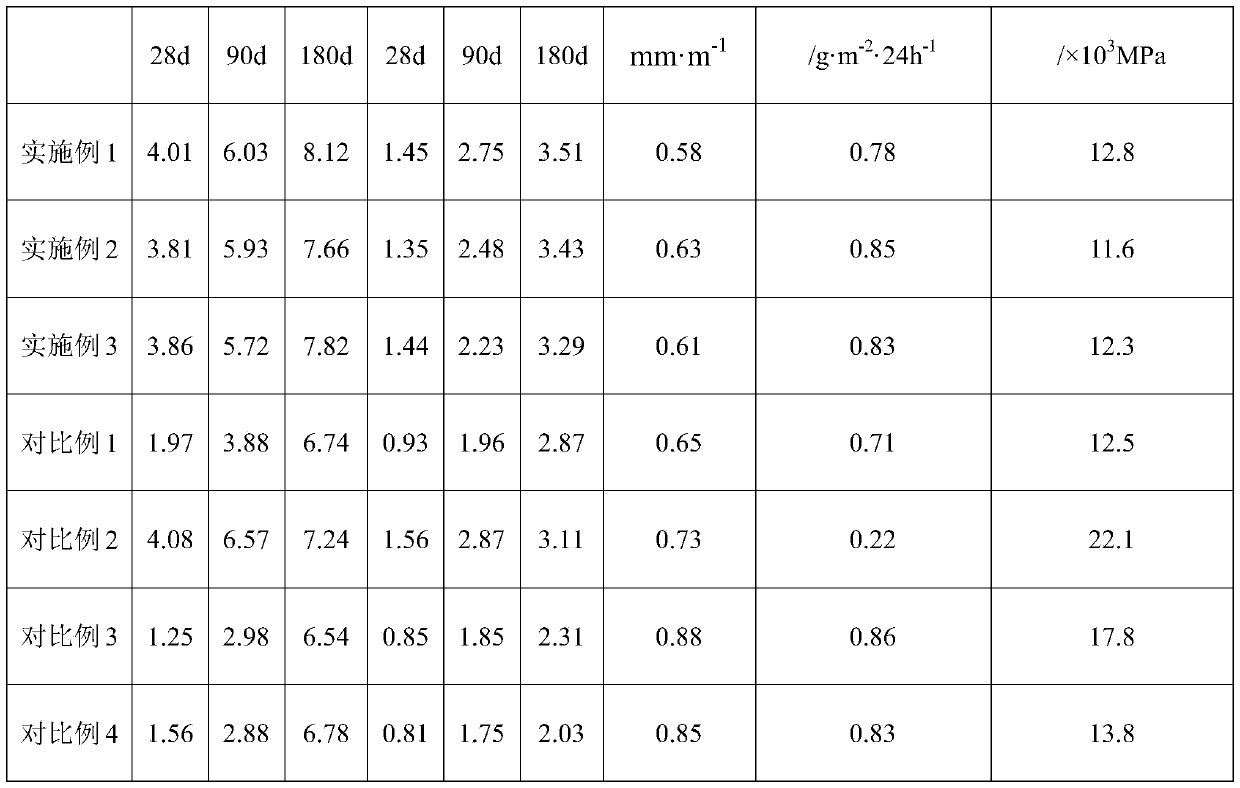

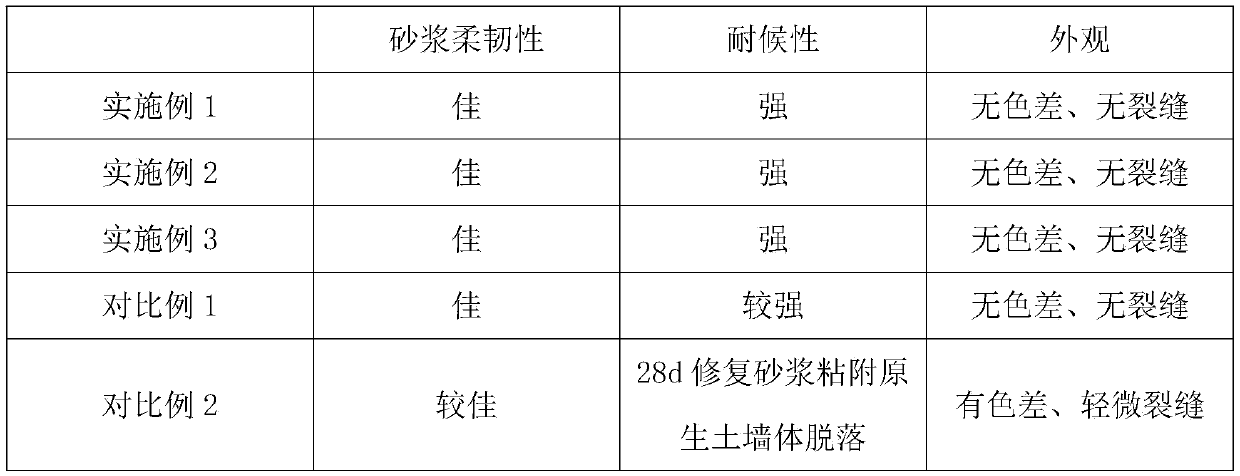

[0033] The mix ratio of slag and hydraulic lime mortar is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com