Hydraulic lime and preparation method thereof

A technology of hydraulic lime and carbide slag, which is applied in the field of building materials to achieve the effects of rational use of resources, low energy consumption, and good self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

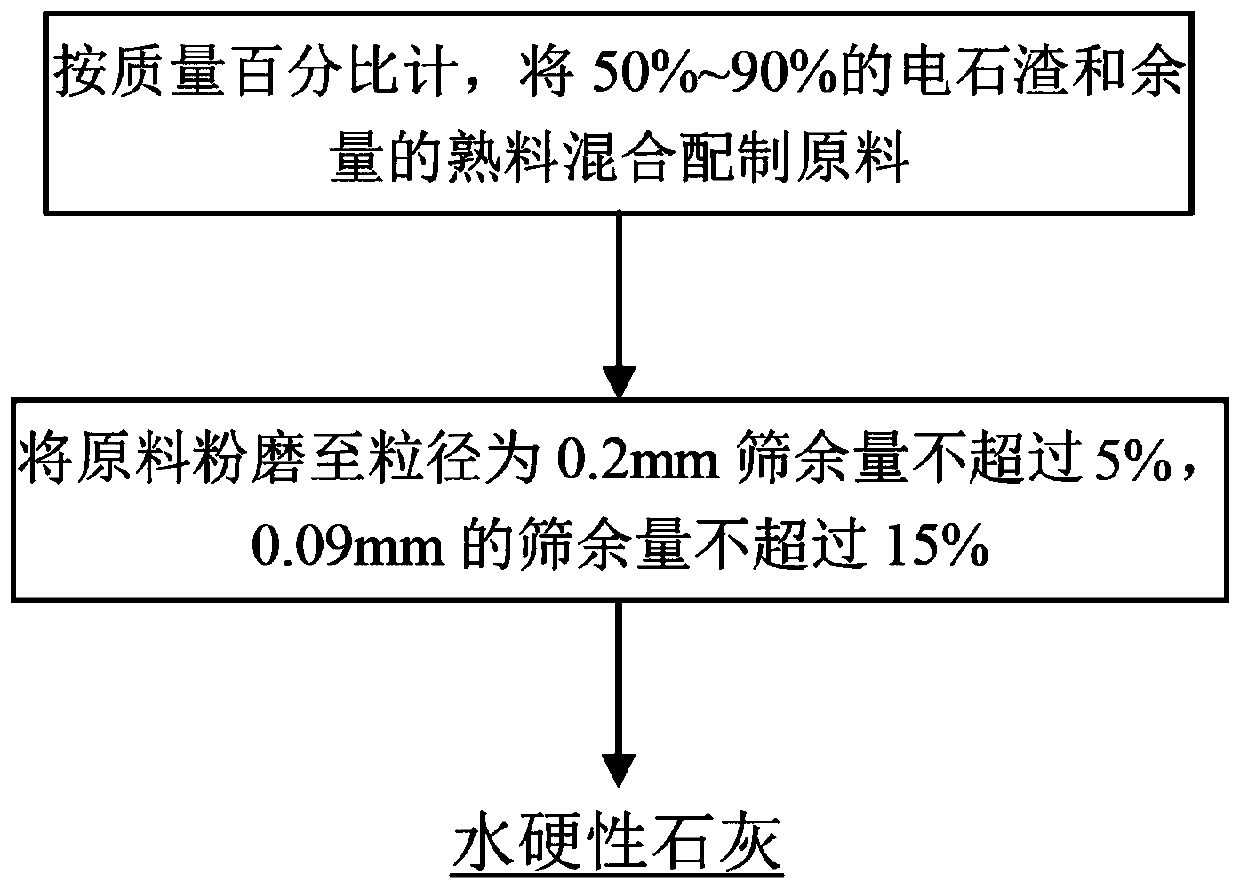

[0018] One aspect of the present invention provides a method for preparing hydraulic lime, in an exemplary embodiment of the method for preparing hydraulic lime of the present invention, as figure 1 As shown, the preparation method may include:

[0019] Step S01, preparing raw materials.

[0020] The preparation of raw materials includes calcium carbide slag as the main raw material, and clinker is added according to a certain mass ratio. In order to make hydraulic lime meet its own performance requirements, such as strength, adhesion, water resistance, repairability, etc., the composition of the raw materials must meet the corresponding requirements. Therefore, the preparation of raw materials is particularly important to the preparation of products. The present invention adopts calcium carbide slag as the main raw material and is combined with clinker, which can well meet the composition requirements of hydraulic lime, saves the calcining process, and has a simple producti...

example 1

[0037] Configure hydraulic lime according to 50% of carbide slag and 50% of white cement clinker, and its preparation method includes:

[0038] 1) Carbide slag is dried;

[0039] 2) According to the mass ratio of 50% calcium carbide slag and 50% white cement clinker, batching is carried out;

[0040] 3) After grinding the raw materials for 2 hours, when the 0.2mm sieve residue does not exceed 5%, and the 0.09mm sieve residue does not exceed 15%, hydraulic lime is obtained.

example 2

[0042] Configure hydraulic lime with 75% calcium carbide slag and 25% white cement clinker. The preparation method includes:

[0043] 1) Carbide slag is dried;

[0044] 2) According to the mass ratio of 75% calcium carbide slag and 25% white cement clinker, batching is carried out;

[0045] 3) After grinding the raw materials for 2 hours, when the 0.2mm sieve residue does not exceed 5%, and the 0.09mm sieve residue does not exceed 15%, hydraulic lime is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com