Method for preparing natural hydraulic lime by using limestone and quartz powder

A technology of quartz powder and limestone, applied in the field of preparing natural hydraulic lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

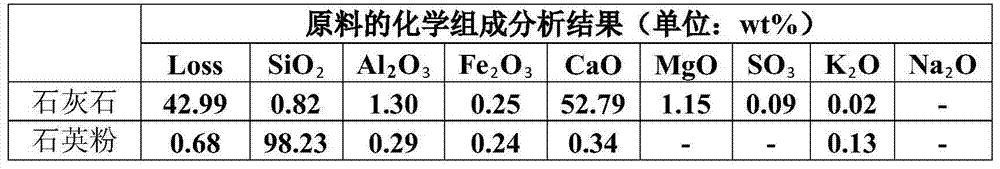

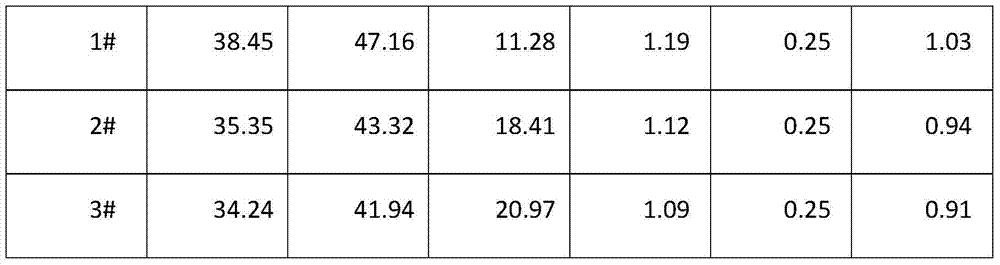

[0011] Limestone is used as the main raw material, and high-purity quartz powder with a purity of more than 98% is added to adjust the molar ratio of calcium oxide and silicon oxide, that is, CaO / SiO 2 =2.14—4.48, the content of alumina does not exceed 4.5% of the total mass of raw materials, so as to control the content of hydraulic products in the product; limestone and quartz powder with adjusted components are mixed and ground by a ball mill for 6 hours to 10 hours; 180 mesh sieve The amount is not more than 3% of the total mass of the sieved material; the mixed raw material is added to 8% of the mixed raw material mass of water, then fully mixed and stirred, sealed and stored for about 6-7 hours and then pressed into a cylinder, and then It is dried; the dried cylinder is placed in a furnace for calcination, the calcination temperature is 1100°C-1200°C, and the time is 3 hours; the calcined material is quenched to room temperature in the air; the free For calcium oxide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com