Method for preparing natural hydraulic lime from potassium feldspar and limestone

A technology of limestone and potassium feldspar, applied in the field of preparation of natural hydraulic lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

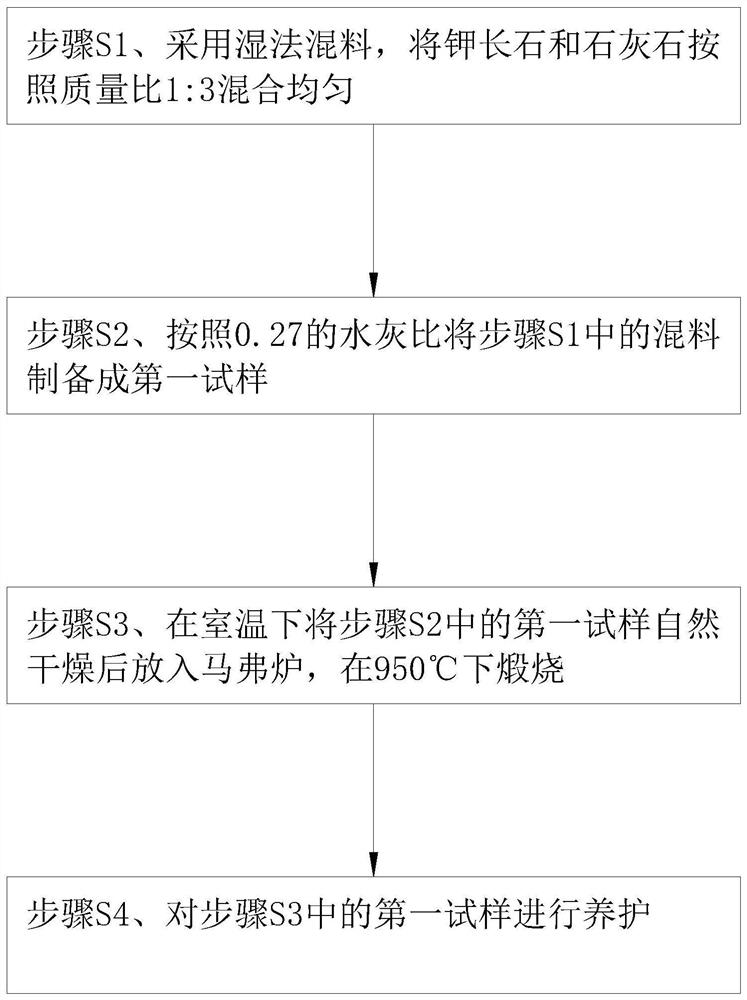

[0033] Please refer to figure 1 , a method for utilizing potassium feldspar and limestone to prepare natural hydraulic lime, comprising the following steps:

[0034] Step S1, adopt wet method mixing, mix potassium feldspar and limestone according to mass ratio 1:3;

[0035] Step S2, preparing the mixture in step S1 into a first sample according to a water-cement ratio of 0.27, specifically, the first sample is a sample of 80×40×10 mm;

[0036] In step S3, the first sample in step S2 is naturally dried at room temperature and then placed in a muffle furnace, and calcined at 950°C;

[0037] Step S4, curing the first sample in step S3.

Embodiment 2

[0039] A method of utilizing potassium feldspar and limestone to prepare natural hydraulic lime, comprising the following steps:

[0040] Step S1, adopt wet method mixing, mix potassium feldspar and limestone according to mass ratio 1:3;

[0041] Step S2, preparing the mixture in step S1 into a first sample according to a water-cement ratio of 0.27, specifically, the first sample is a sample of 80×40×10 mm;

[0042] In step S3, the first sample in step S2 is naturally dried at room temperature and then placed in a muffle furnace, and calcined at 950°C;

[0043] Step S4, curing the first sample in step S3.

[0044] Further, in the step S4, the first sample in the step S3 is uniformly mixed with the quartz sand at a mass ratio of 1:1, the mortar is uniformly mixed at a water-cement ratio of 0.42, the mortar is poured into the mold, and the vibration is formed. , after 24 h demoulding, the second sample made was cured at room temperature.

[0045] Preferably, the particle size...

Embodiment 3

[0049] A method of utilizing potassium feldspar and limestone to prepare natural hydraulic lime, comprising the following steps:

[0050] Step S1, adopt wet method mixing, mix potassium feldspar and limestone according to mass ratio 1:3;

[0051] Step S2, preparing the mixture in step S1 into a first sample according to a water-cement ratio of 0.27, specifically, the first sample is a sample of 80×40×10 mm;

[0052] In step S3, the first sample in step S2 is naturally dried at room temperature and then placed in a muffle furnace, and calcined at 950°C;

[0053] In step S4, the first sample in step S3 is maintained. Specifically, the first sample in step S3 is mixed with quartz sand in a mass ratio of 1:1, and the particle size of the quartz sand is less than 420 μm. The ratio of 0.42, the mortar was mixed evenly, the mortar was poured into the mold, and the vibration was formed. After 24 hours of demoulding, the second sample made was cured at room temperature.

[0054] Prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com