Fluidized bed combustion ash mixed hydraulic lime mortar for reinforcement repairing of masonry ancient buildings and preparation method of mortar

A technology of sulfur-fixing ash and hydraulic lime, which is applied in the field of building materials, can solve the problems that the strength and durability of air-hard lime cannot meet the protection requirements, the antique mortar process is complicated, and the physical and chemical properties are not compatible, etc., and achieve significant economic benefits , high cohesion, and moderate strength development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

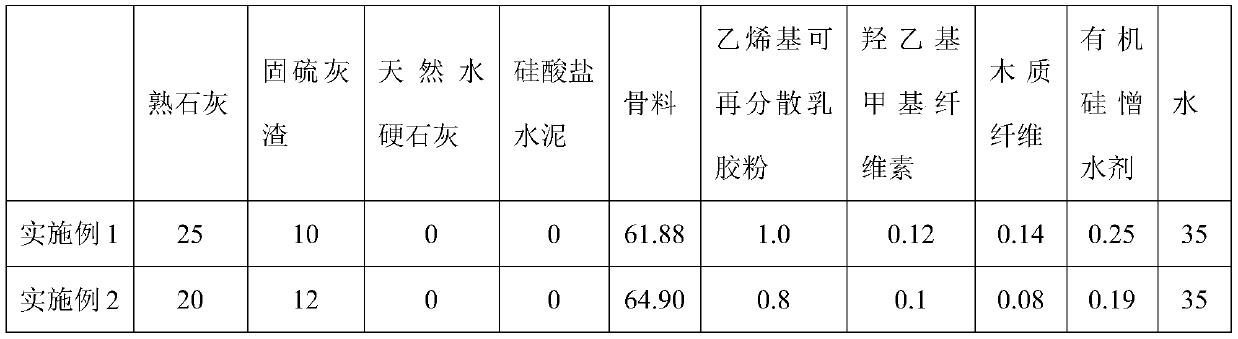

[0035] In Examples 1-5, the sulfur-fixing ash and hydraulic lime mortar for the reinforcement and repair of masonry ancient buildings, in parts by weight, its raw materials include the following components: 10-25 parts of slaked lime, sulfur-fixing ash 5-15 parts, 45-68 parts of aggregate, 0.5-2 parts of additives.

[0036] In this embodiment, the additives include, in parts by weight: 0.4-1.2 parts of vinyl redispersible latex powder, 0.03-0.15 parts of hydroxyethyl methylcellulose with a viscosity of 10000-45000 mPa·s, organosilicone 0.08-0.4 parts of water agent, 0.05-0.2 parts of wood fiber with a diameter of 0.5-3mm.

[0037] See Table 1 for the proportioning of each raw material in Examples 1-5.

[0038] The method for preparing the sulfur-fixed ash and hydraulic lime mortar for the reinforcement and restoration of the above-mentioned masonry ancient buildings comprises the following steps:

[0039] (1) Add vinyl redispersible latex powder, hydroxyethyl methylcellulose...

Embodiment 1

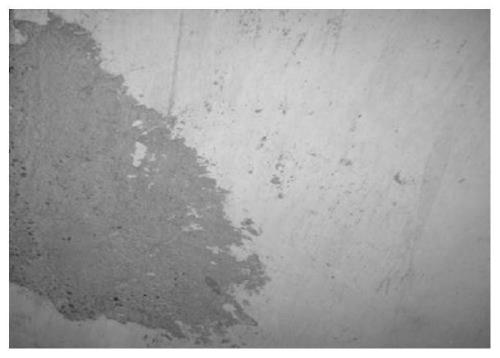

[0051] Example 1 The effect of sulfur-fixing ash slag reconciling hydraulic lime mortar and comparative example 2 Portland cement mortar repairing the wall surface of ancient buildings is as follows Figure 1~2 shown.

[0052]The results show that the appearance of the sulfur-fixed ash blended hydraulic lime mortar proposed by the invention is consistent with that of traditional calcareous cementitious materials, and meets the requirement of "repairing the old as old" as an ancient building restoration material. The sulfur-fixed ash blended hydraulic lime mortar also has similar or even higher compressive strength, flexural strength and air permeability than natural hydraulic lime mortar, and can achieve lower shrinkage, soluble salt content and elastic modulus ; What's more, its cost is much lower than that of natural hydraulic lime mortar. Compared with Portland cement mortar, the early strength of sulfur-fixed ash and hydraulic lime mortar is lower, but the strength at 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com