Hydraulic lime and production method thereof

A technology of hydraulic lime and production method, which is applied in the field of building materials, can solve the problems of high cost of hydraulic lime, and achieve the effects of good frost resistance, low production cost, and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

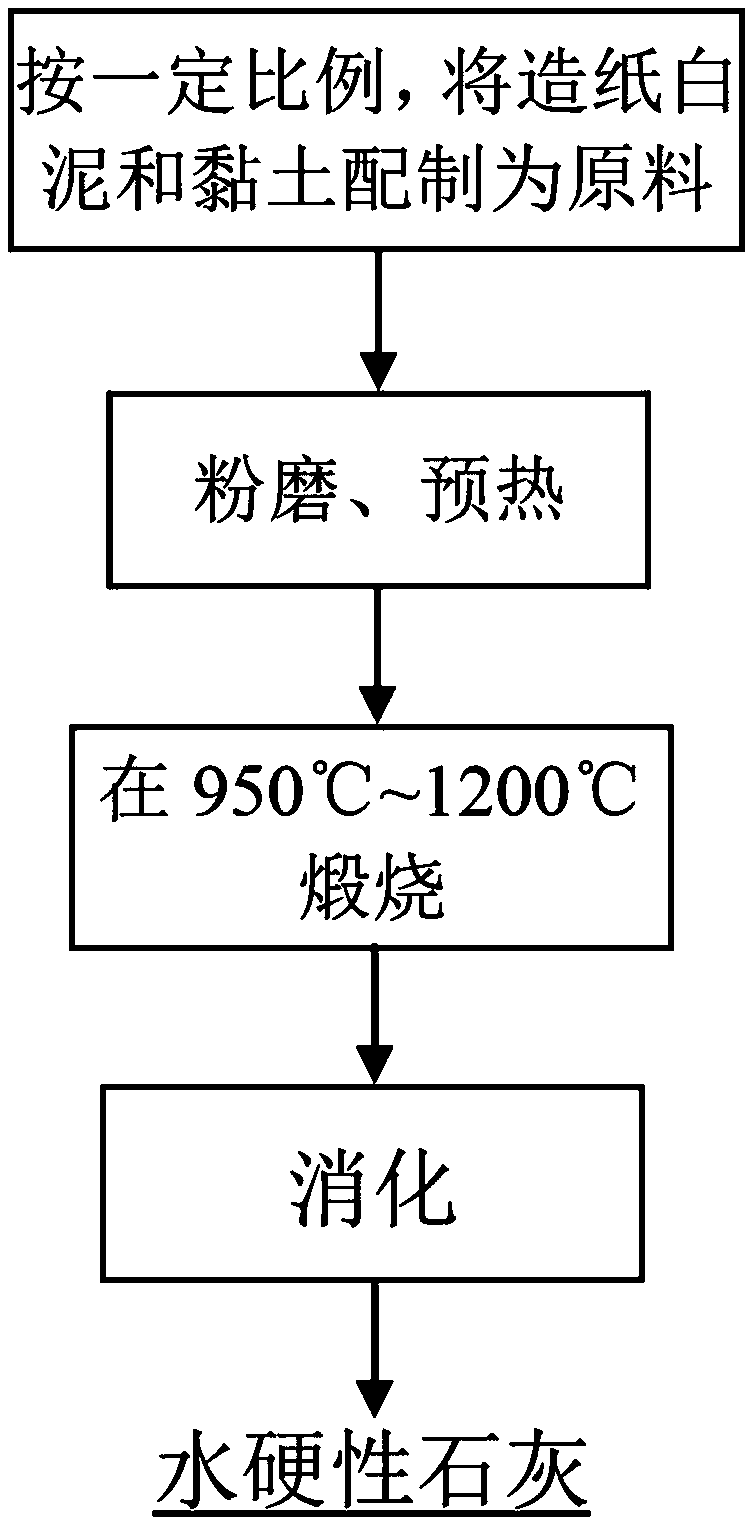

Method used

Image

Examples

example 1

[0040] 1) According to the required mass ratio of calcium oxide and silicon oxide of 0.89, papermaking lime mud and clay are mixed;

[0041] 2) The raw material is ground for 1.5 hours, and the residue to 180 mesh sieve is 2%;

[0042] 3) Preheating and decomposing the raw meal in a high-temperature furnace at 900°C for 0.5 hours;

[0043] 4) After preheating and decomposing, calcining at 1050°C for 0.5 hours; after calcination, naturally cool to room temperature and measure the free calcium oxide content;

[0044] 5) Digest in an environment with a humidity of 65%, record the weight change of the product before and after digestion, and when the digestibility of free calcium oxide in the product reaches 98%, the digestion ends;

[0045] 6) After digestion and drying, grind for 2.3 hours, when the 0.2mm sieve residue does not exceed 2%, and the 0.09mm sieve residue does not exceed 15%, the hydraulic lime is obtained.

example 2

[0047] 1) According to the required mass ratio of calcium oxide and silicon oxide of 1.0, papermaking lime mud and clay are mixed;

[0048] 2) The raw material is ground for 1.5 hours, and the residue to 180 mesh sieve is 2%;

[0049] 3) Preheating and decomposing the raw meal in a high-temperature furnace at 900°C for 0.5 hours;

[0050] 4) After preheating and decomposing, calcining at 1050°C for 0.5 hours; after calcination, naturally cool to room temperature and measure the free calcium oxide content;

[0051] 5) Digest in an environment with a humidity of 65%, record the weight change of the product before and after digestion, and when the digestibility of free calcium oxide in the product reaches 98%, the digestion ends;

[0052] 6) After digestion and drying, grind for 2.3 hours, when the 0.2mm sieve residue does not exceed 2%, and the 0.09mm sieve residue does not exceed 15%, the hydraulic lime is obtained

example 3

[0054] 1) According to the required mass ratio of calcium oxide and silicon oxide of 1.20, papermaking lime mud and clay are mixed;

[0055] 2) The raw material is ground for 1.5 hours, and the residue to 180 mesh sieve is 2%;

[0056] 3) Preheating and decomposing the raw meal in a high-temperature furnace at 850°C for 0.5 hours;

[0057] 4) After preheating and decomposing, calcining at 1050°C for 0.5 hours; after calcination, naturally cool to room temperature and measure the free calcium oxide content;

[0058] 5) Digest in an environment with a humidity of 65%, record the weight change of the product before and after digestion, and when the digestibility of free calcium oxide in the product reaches 98%, the digestion ends;

[0059] 6) After digestion and drying, grind for 2.3 hours, when the 0.2mm sieve residue does not exceed 2%, and the 0.09mm sieve residue does not exceed 15%, the hydraulic lime is obtained

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com