Lime-based micro-contraction grouting material composition and preparation method thereof

A technology of grouting material and lime, which is applied in the field of lime-based micro-shrinkage grouting material composition and its preparation, can solve problems such as low strength, impossibility, and slow setting speed, and achieve high strength, good compatibility, and dense grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

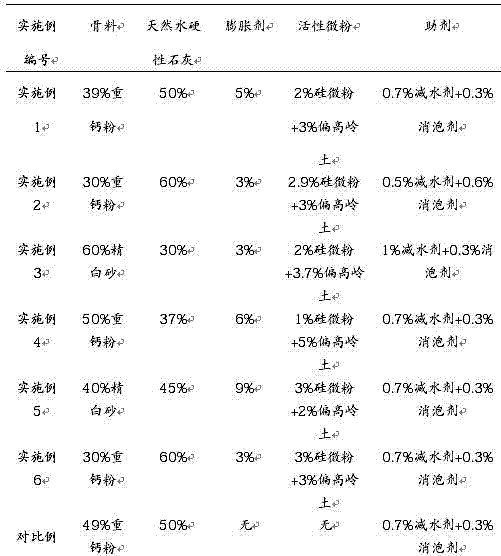

Examples

Embodiment 7

[0080] Embodiment 7: a kind of preparation method of lime-based micro-shrinkage grouting material composition, comprises the steps:

[0081] ①Dry mixing: Put each component into a vertical cone dry powder mixer and stir for 40 minutes to make it evenly mixed;

[0082] ②Adding water: Mix the uniformly mixed dry material with clear water to form a mixed material, and the mass of water added accounts for 25% of the total mass of each component;

[0083] ③Initial dispersion: adjust the speed of the disperser to 500 rpm, take part of the material that accounts for 25% of the total mass of the mixed material, and add it to the disperser at a uniform speed within a time period of 3 minutes;

[0084] ④ Two-stage dispersion: adjust the speed of the disperser to 800 rpm, take part of the material that accounts for 25% of the total mass of the mixed material, and add it to the disperser at a uniform speed within a time period of 3 minutes;

[0085] ⑤ Three-stage dispersion: adjust the s...

Embodiment 8

[0087] Embodiment 8: a kind of preparation method of lime-based micro-shrinkage grouting material composition, comprises the steps:

[0088] ①Dry mixing: Put each component into a vertical cone dry powder mixer and stir for 60 minutes to make it evenly mixed;

[0089] ② Adding water: Mix the uniformly mixed dry material with clear water to form a mixed material, and the mass of water added accounts for 35% of the total mass of each component;

[0090] ③Initial dispersion: adjust the speed of the disperser to 600 rpm, take part of the material that accounts for 35% of the total mass of the mixed material, and add it to the disperser at a uniform speed within a time period of 6 minutes;

[0091] ④ Two-stage dispersion: adjust the speed of the disperser to 1000 rpm, take part of the material that accounts for 35% of the total mass of the mixed material, and add it to the disperser at a uniform speed within a time period of 6 minutes;

[0092] ⑤ Three-stage dispersion: adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com