Lime mortar for joint filling of dry-hanging masonry wall and preparation method of lime mortar

A technology of lime mortar and masonry, which is applied in the field of lime mortar for dry-hanging masonry wall joint filling and its preparation, and can solve the problems of low strength, durability and cooperative deformation of dry-hanging masonry walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

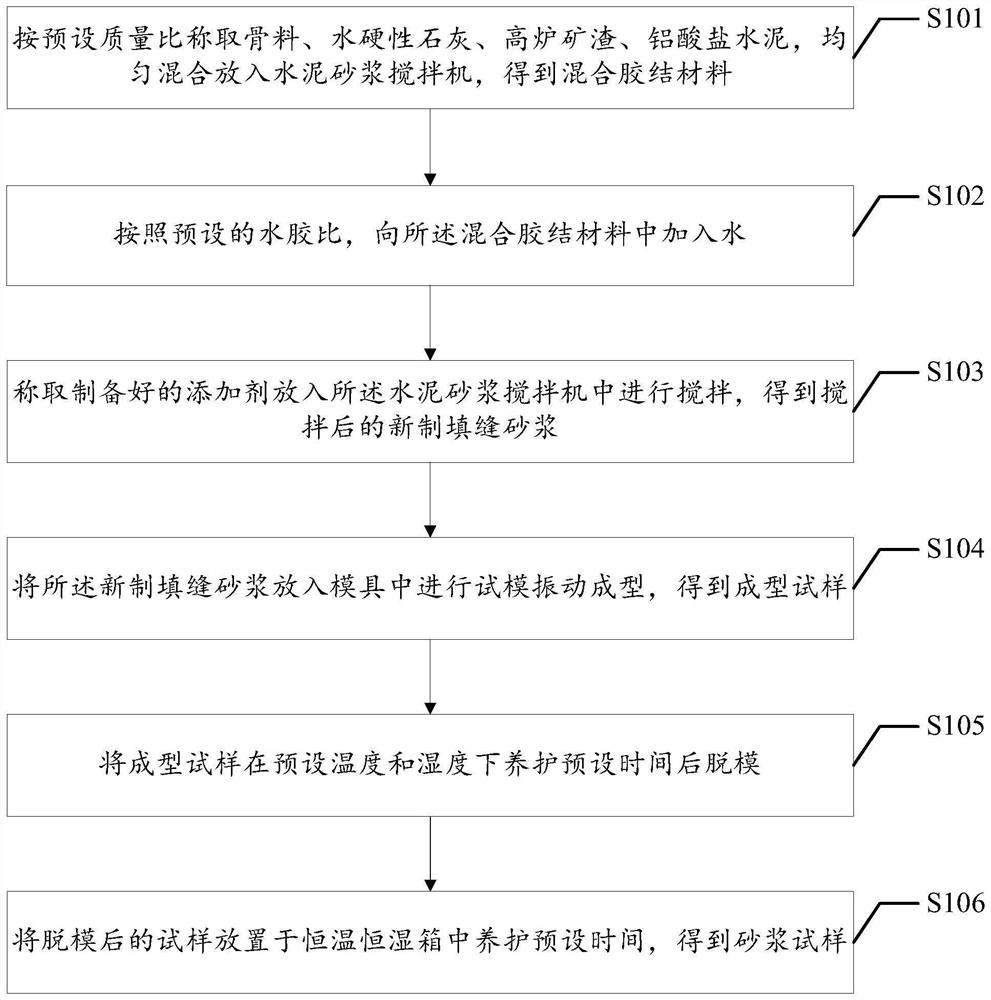

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0027] The main solution of the embodiment of the present invention is: the lime mortar is prepared from hydraulic lime, blast furnace slag, aluminate cement, aggregate, additives and water, and the hydraulic lime mortar is used as a dry-hanging masonry wall joint filling material, Improve the elastic properties and durability of materials, and reduce the resource and environmental problems caused by blast furnace slag to a certain extent. Specifically, S75 grade granulated blast furnace slag can be stimulated by natural hydraulic lime, which has hydraulic gel properties, accelerates the development of early strength of mortar, refines the internal void structure of mortar, improves the strength of mortar, and reduces the natural water volume of the same volume. The amount of hard lime reduces environmental poll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com