Silicon-aluminum gelatinized material produced by pulverized fuel ash and application method thereof

An application method and technology of silica-alumina glue, applied in cement production and other directions, can solve the problems of atmospheric environment groundwater pollution, ineffective utilization, low pozzolanic activity, etc., and achieve rapid strength development, sufficient supply of raw materials, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

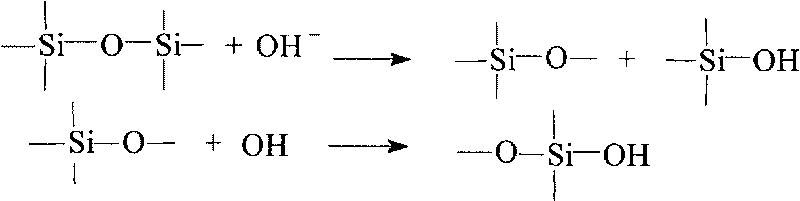

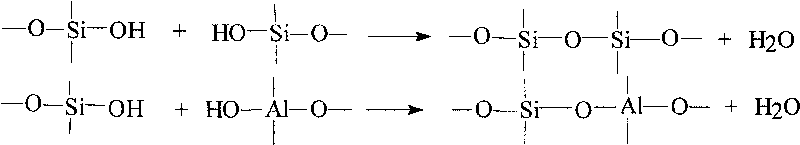

Method used

Image

Examples

Embodiment

[0042] Example: KOH, calcium lignosulfonate and sodium silicate were uniformly mixed in a ratio of 5:0.1:0.5 to prepare an admixture. The coal gangue is crushed by a jaw crusher and pulverized by a ball mill to obtain coal gangue powder, which is calcined at 650° C. for 2 hours to obtain calcined kaolin. Mix fly ash, calcined kaolin and quicklime according to the ratio (mass ratio) of 7:1:2 and ball mill for 1.5 hours, and the specific surface area of the obtained powder material is 600m 2 / kg. The admixture is fully dissolved in water to prepare an admixture solution, and the ratio of the silica-alumina gel material, the amount of the admixture and the amount of water is 100:8:45, and the mortar experiment is carried out. After mixing various raw materials and stirring evenly, the silica-alumina cementitious material product is obtained. For specific methods, see GB / T17671-1999. It has been determined that the compressive strength of 3d mortar is 14MPa, and the compressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com