Early-strength multi-scene applicable natural hydraulic lime slurry and modification preparation method thereof

A natural water, multi-scenario technology, applied in the direction of solid waste management, etc., can solve the problems of insufficient strength and slurry fluidity, water absorption and mortar porosity reduction, etc., to achieve good application prospects, high early curing strength, and repeatability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The modification preparation method of early-strength and multi-scenario application type natural hydraulic lime slurry comprises the following steps:

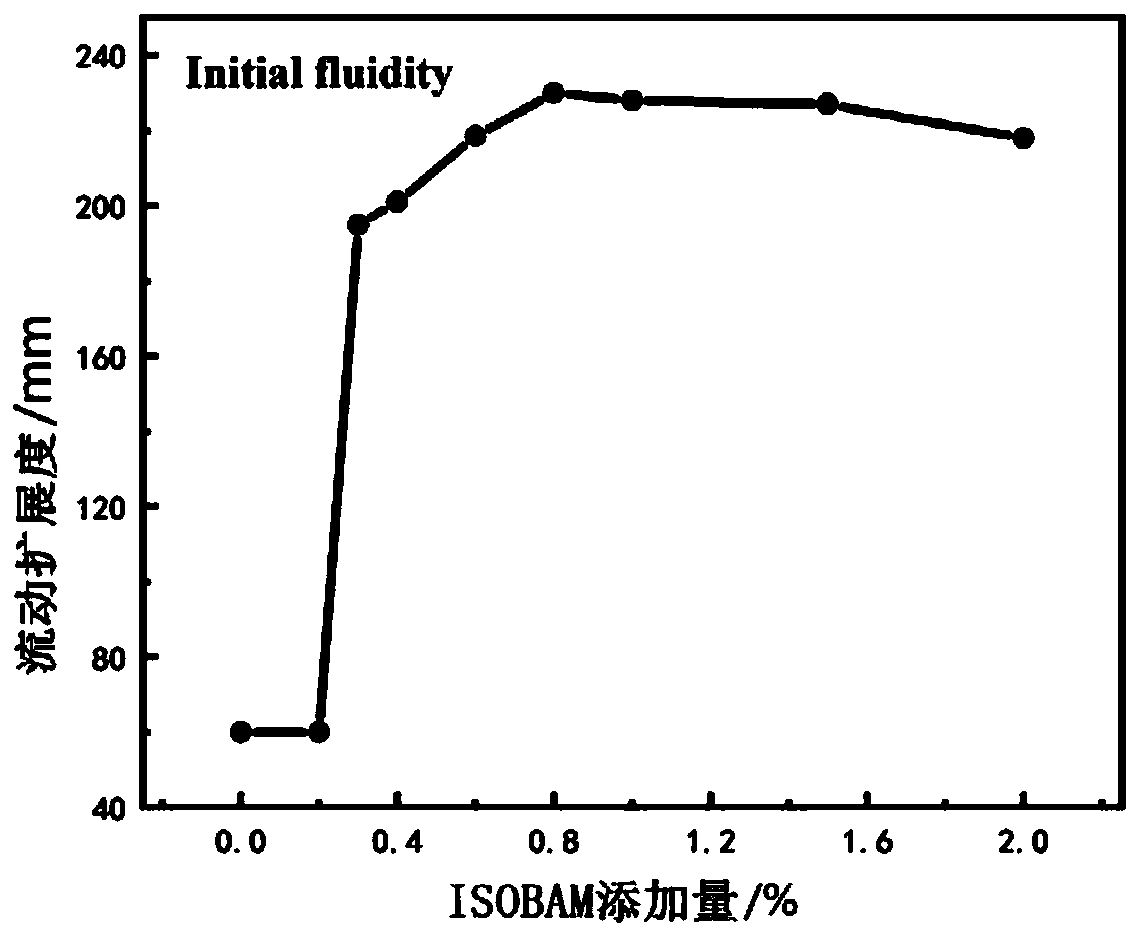

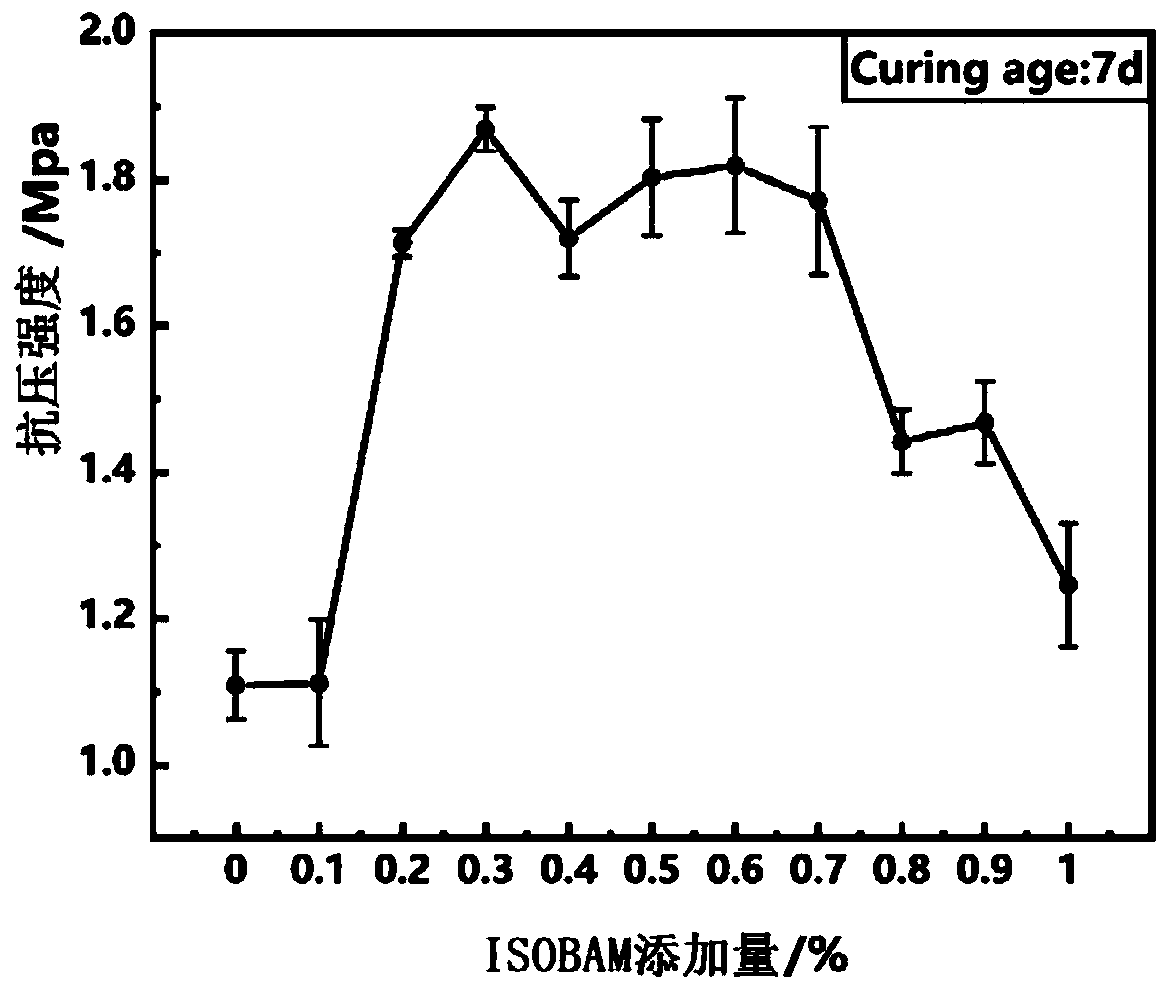

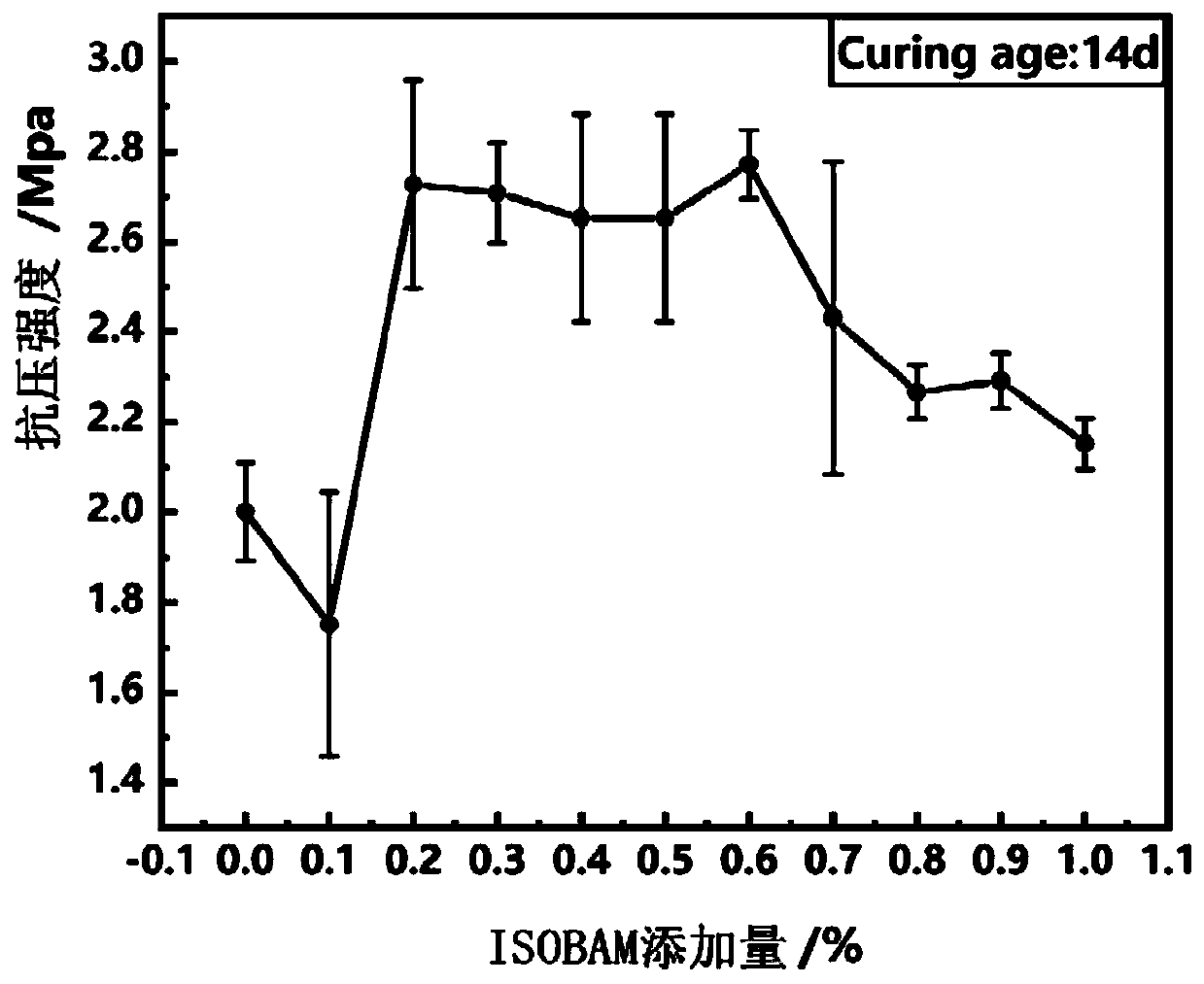

[0021] 1), with hydraulic lime 94%-99.9%, the ratio of isobutylene-maleic anhydride copolymer 0.1%-6%, take required hydraulic lime and isobutylene-maleic anhydride copolymer respectively; 0.3 to 0.6, according to the total mass of natural hydraulic lime and isobutylene-maleic anhydride copolymer weighed, measure the required water, the above are all in mass percentage; the ash in the water-cement ratio refers to the natural Hydraulic lime and isobutylene-maleic anhydride copolymer;

[0022] 2): adding the weighed isobutylene-maleic anhydride copolymer into water, heating in a water bath to obtain an aqueous solution of isobutylene-maleic anhydride copolymer, the temperature of the water bath is 35-55°C;

[0023] 3): adding the aqueous solution of isobutylene-maleic anhydride copolymer obtained in step 2) to the weighe...

Embodiment 1

[0027] 1) Weigh 188g of natural hydraulic lime and 12g of isobutylene-maleic anhydride copolymer; then weigh 60g of water.

[0028] 2) Add isobutylene-maleic anhydride copolymer to the weighed water, then heat in a water bath, the temperature of the water bath is 55°C; fully stir for 5 minutes, so that the isobutylene-maleic anhydride copolymer is fully dissolved in water, and the desired isobutylene-maleic anhydride copolymer is obtained. Aqueous solution of acid anhydride copolymer;

[0029] 3), transfer the natural hydraulic lime taken in step 1) into a standard cement mortar mixer for stirring, the stirring mode is automatic (the automatic mode is first slow, then pause for a period of time, and then stir quickly), in the stirring state Add the aqueous solution of isobutylene-maleic anhydride copolymer obtained in step 2), and mix the natural hydraulic lime and the aqueous solution of isobutylene-maleic anhydride copolymer to obtain the desired modified natural hydraulic l...

Embodiment 2

[0032] 1) Weigh 192g of natural hydraulic lime and 8g of isobutylene-maleic anhydride copolymer; then weigh 90g of water.

[0033] 2) Add isobutylene-maleic anhydride copolymer to the weighed water, then heat in a water bath, the temperature of the water bath is 45°C; fully stir for 5 minutes, so that the isobutylene-maleic anhydride copolymer is fully dissolved in water, and the desired isobutylene-maleic anhydride copolymer is obtained. Aqueous solution of acid anhydride copolymer;

[0034]3), the natural hydraulic lime taken by step 1) is transferred into a standard cement mortar mixer and stirred, the stirring mode is automatic, and in the stirring state, add the isobutylene-maleic anhydride copolymer aqueous solution obtained in step 2 to make the natural water The hard lime is mixed with the aqueous solution of isobutylene-maleic anhydride copolymer to obtain the desired modified natural hydraulic lime slurry.

[0035] 4), the modified natural hydraulic lime slurry prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com