Molded article using hydraulic lime and method for producing same

A technology of hydraulic lime and a manufacturing method, which is applied in manufacturing tools, ceramic molding machines, cement production, etc., can solve the problems of difficult rusting of steel bars and poor compressive strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

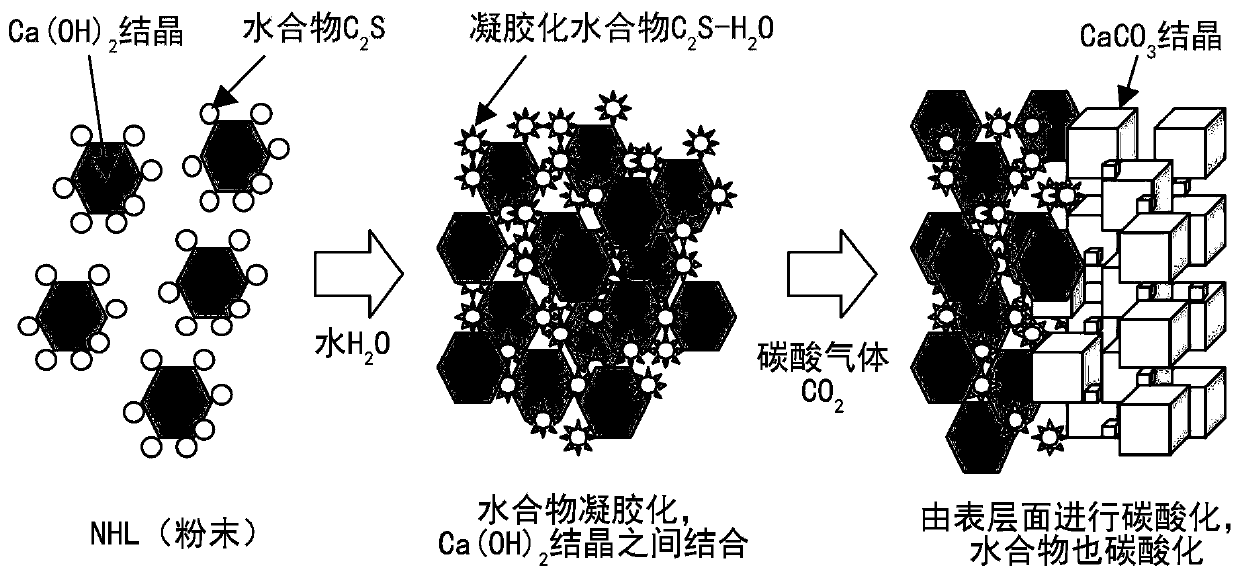

Method used

Image

Examples

Embodiment 1

[0098] 1. Fabrication of Test Body

[0099] 1.1. Materials

[0100] (natural hydraulic lime)

[0101] The hydraulic lime used in the preparation of the test body was NHL2 from the A producing area (Eastern France), and these chemical components are shown in Table 1.

[0102] (aggregate)

[0103] In the preparation of the test body, No. 5 silica sand (Mikawa silica sand), No. 6 silica sand (Mikawa silica sand), and No. 8 silica sand (Mikawa silica sand) with different particle size distributions were used as aggregates, and the maximum diameter was 250 μm or less, and the peak value of the particle size distribution was Calcium carbonate (hitachi gravel) of 40-100 μm.

[0104] 1.2. Compounding amount of each component of the test body

[0105] Table 2 shows the parameters of the manufactured test bodies.

[0106] (moisture content)

[0107] According to the provisions of European Standard EN459-2, when 55 mass% of water was added to the hydraulic lime and press-molded, no...

Embodiment 2

[0141] 1. Fabrication of Test Body

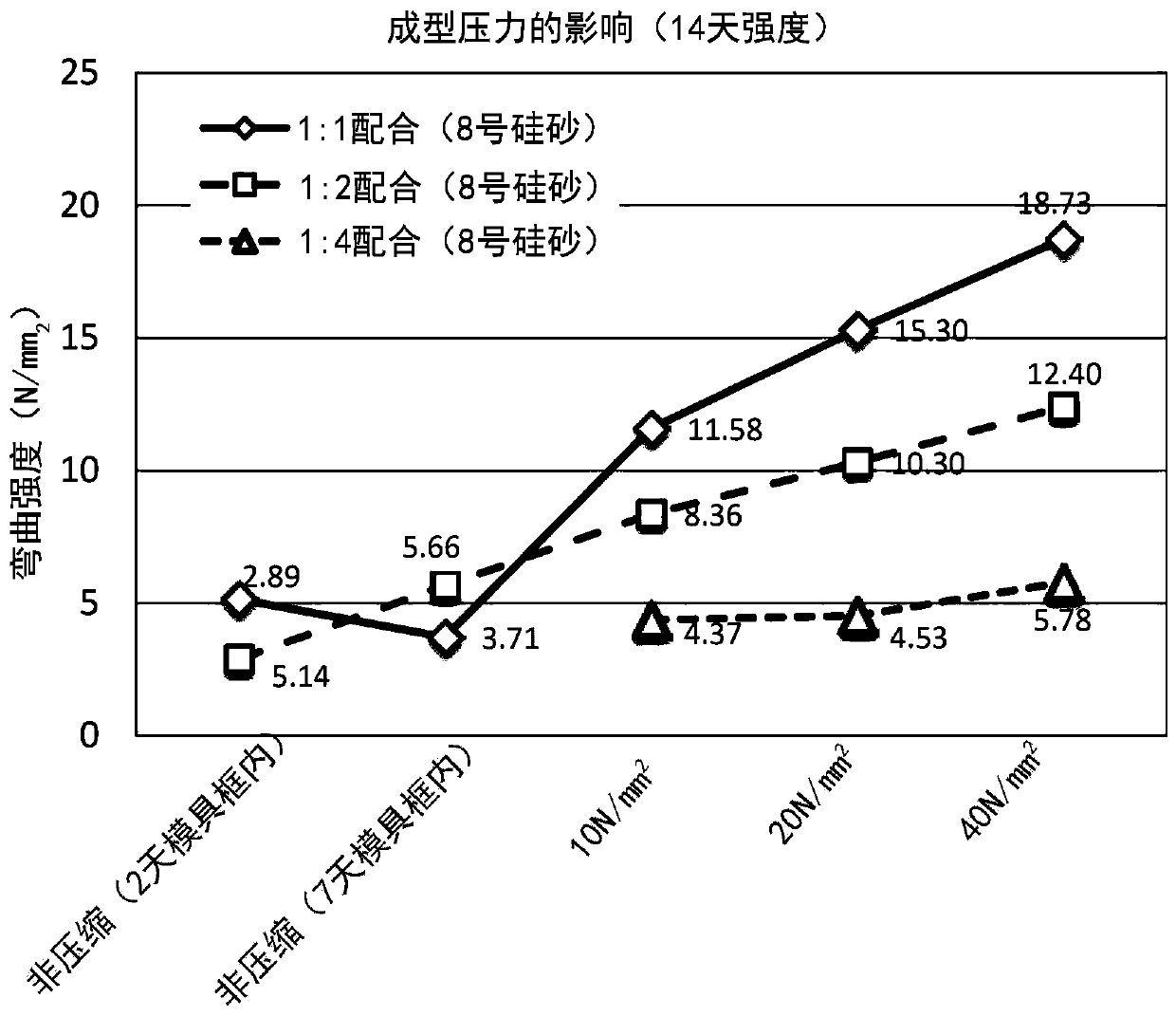

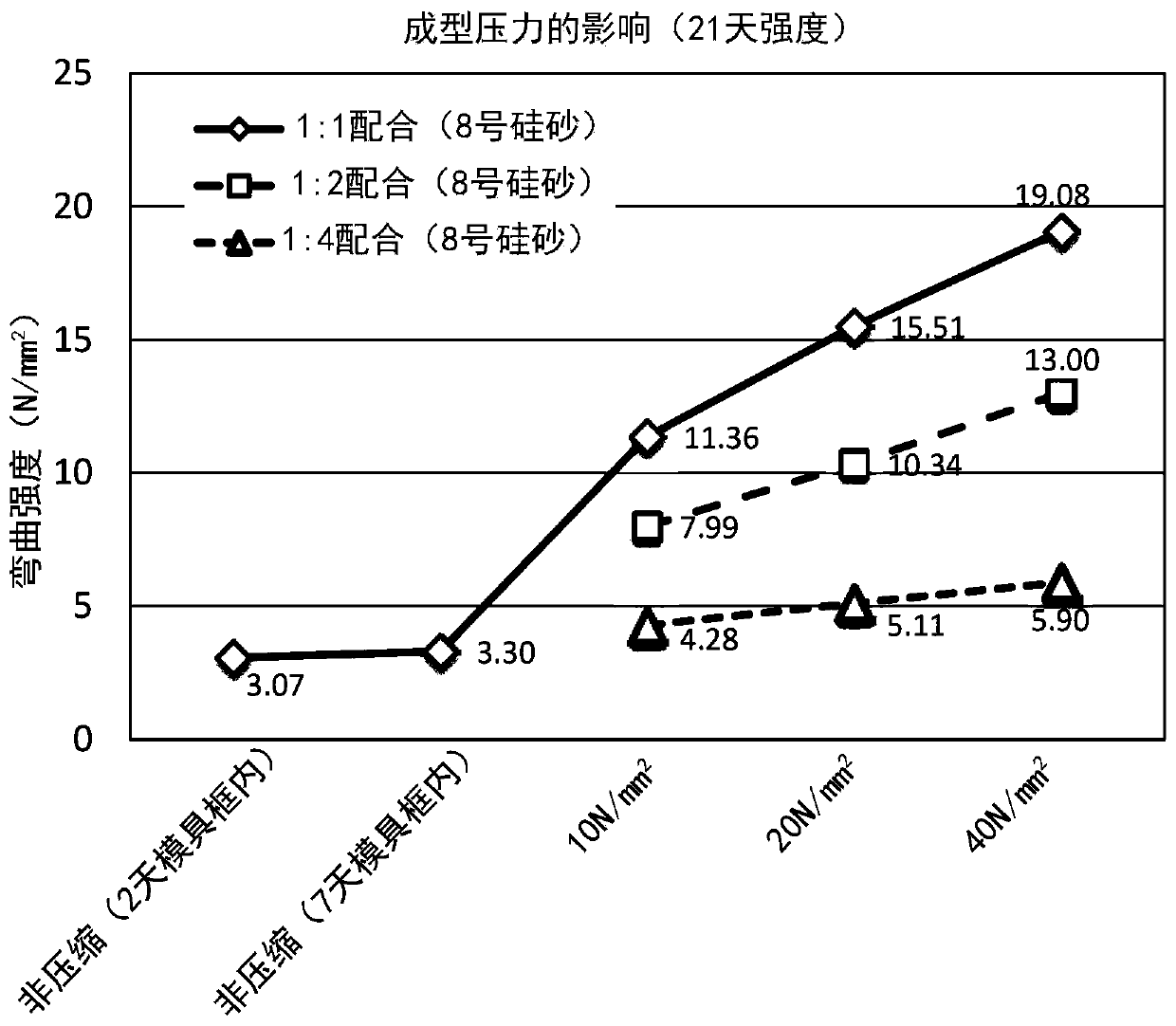

[0142] Using the materials used in Example 1, adjust the water content appropriately to manufacture a test body of the same size as Example 1. In order to make up for the influence of the molding pressure, the solidification concentration of carbon dioxide gas, and the presence or absence of aggregate mixed with hydraulic lime, Perform the bending test again. Table 3 shows parameters of the manufactured test bodies.

[0143] Compared to the 10-40N / mm given in Example 1 2The molding pressure, lower limit is 5N / mm in embodiment 2 2 , the upper limit is 60N / mm 2 , to study the effect of molding pressure.

[0144] As the curing conditions, it was also implemented at a carbonic acid concentration of 1%. However, for a concentration of 1%, it is only carried out when the curing period is 2 days. Regarding the curing period, in Example 1, since no significant increase was seen over 14 days, the maximum number of days during the curing period...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com