Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about "Sausage skin tying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

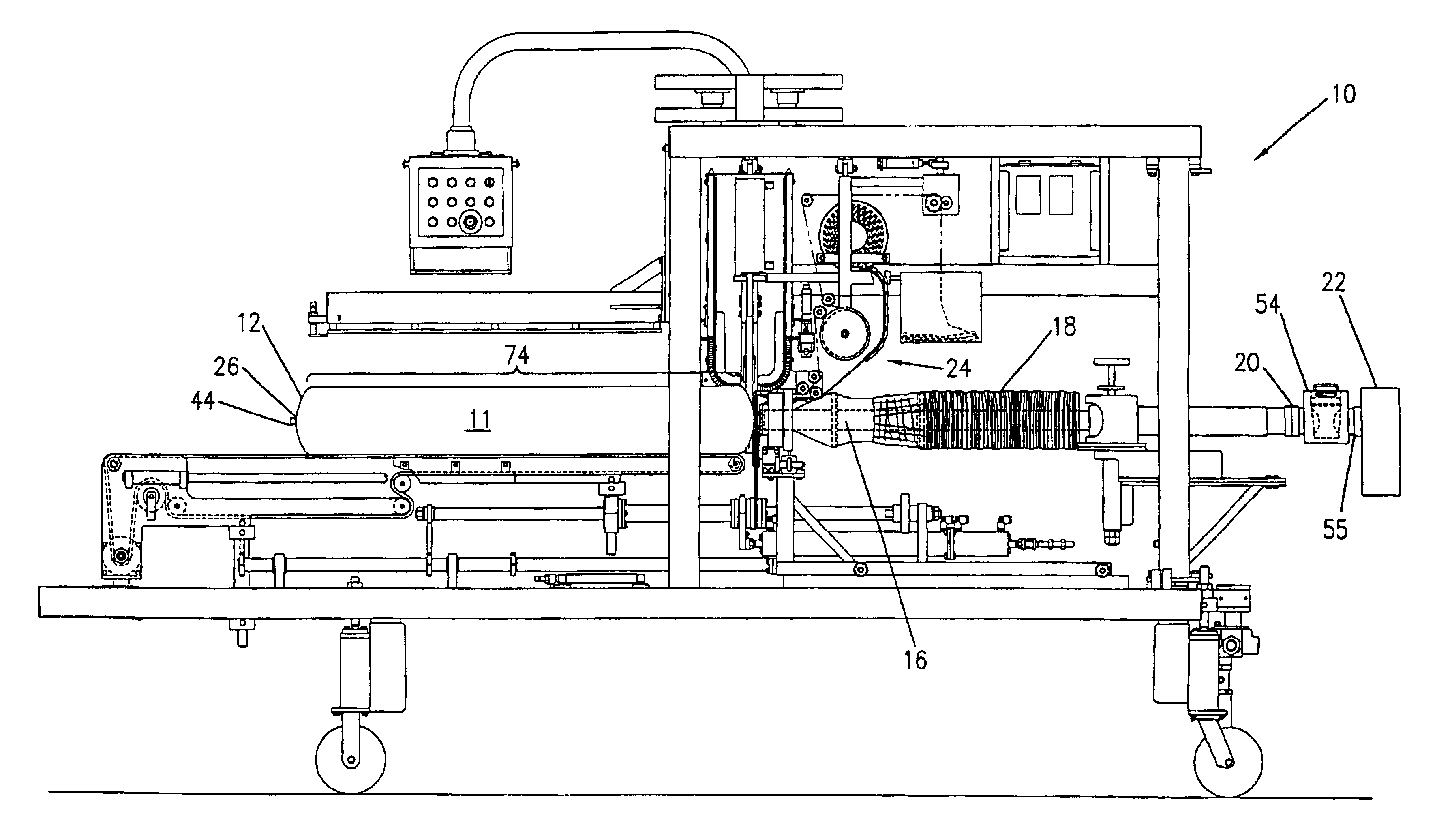

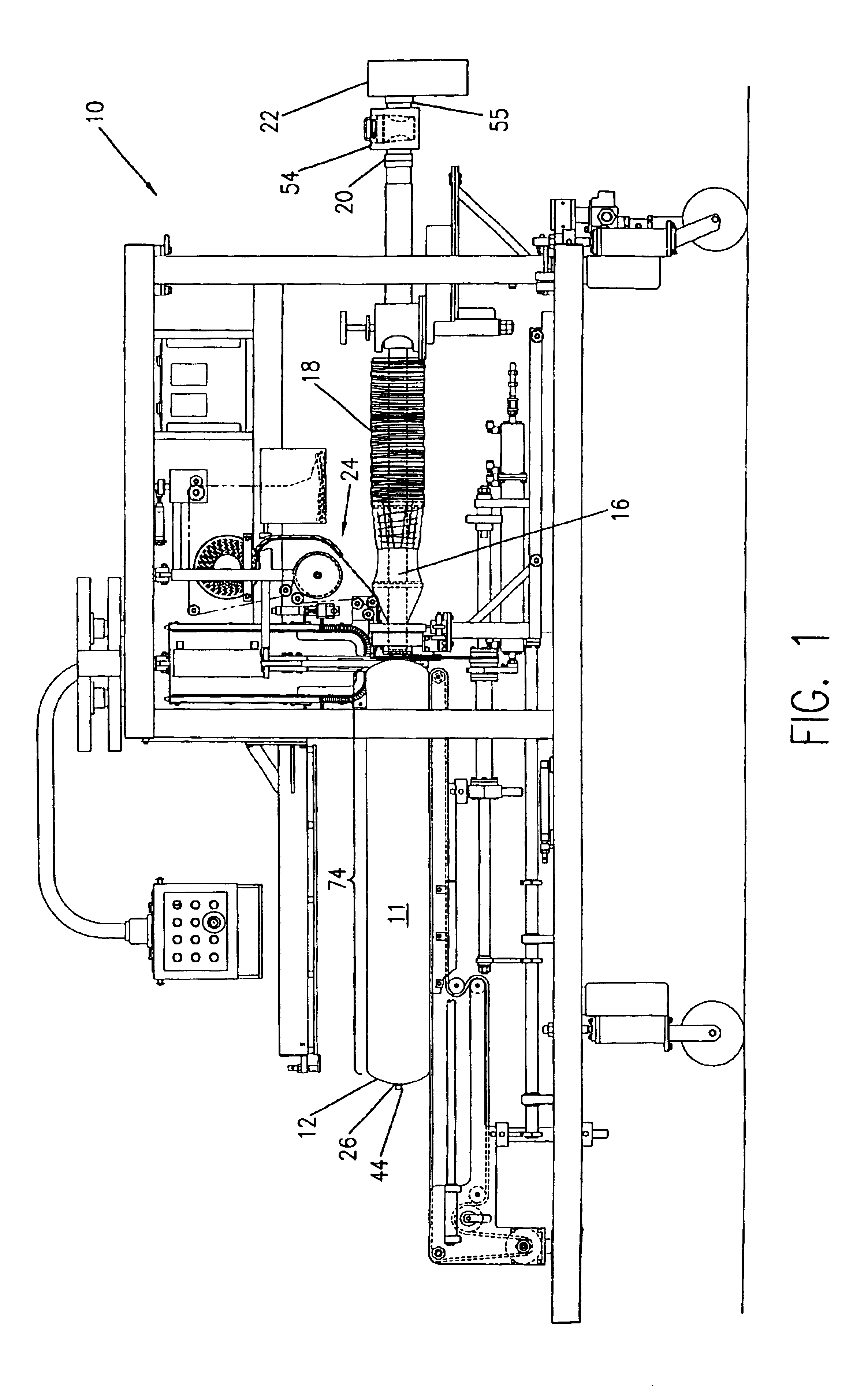

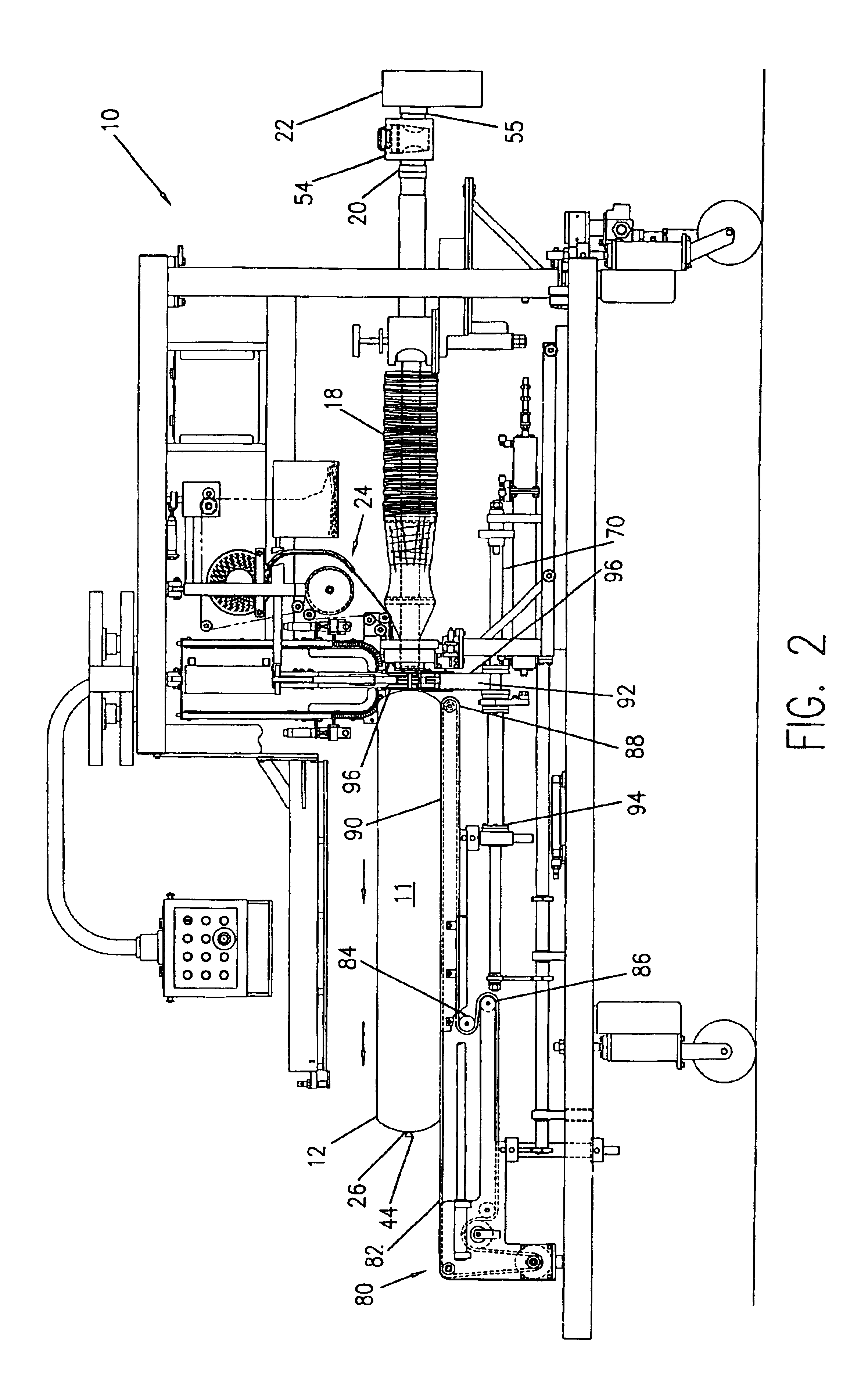

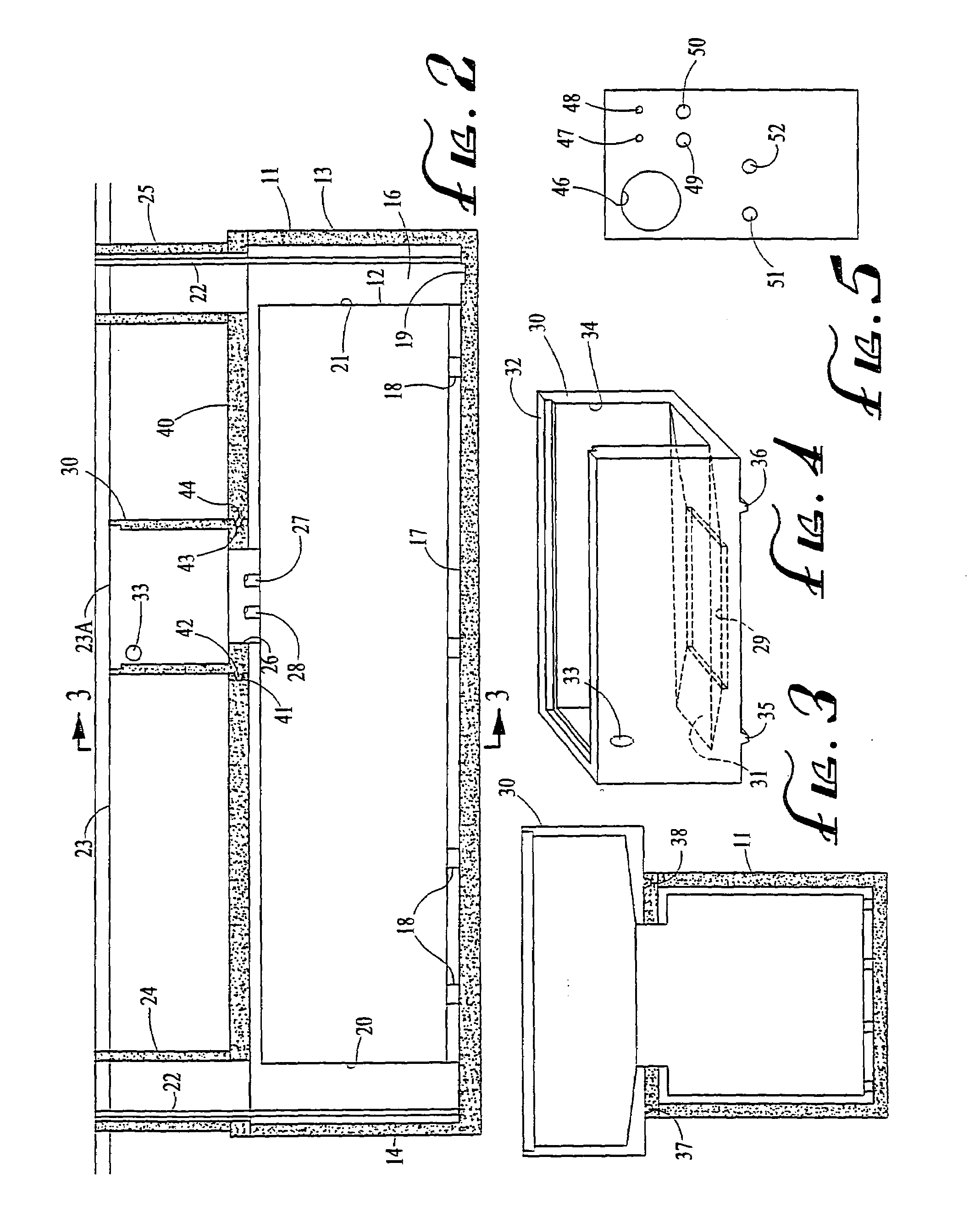

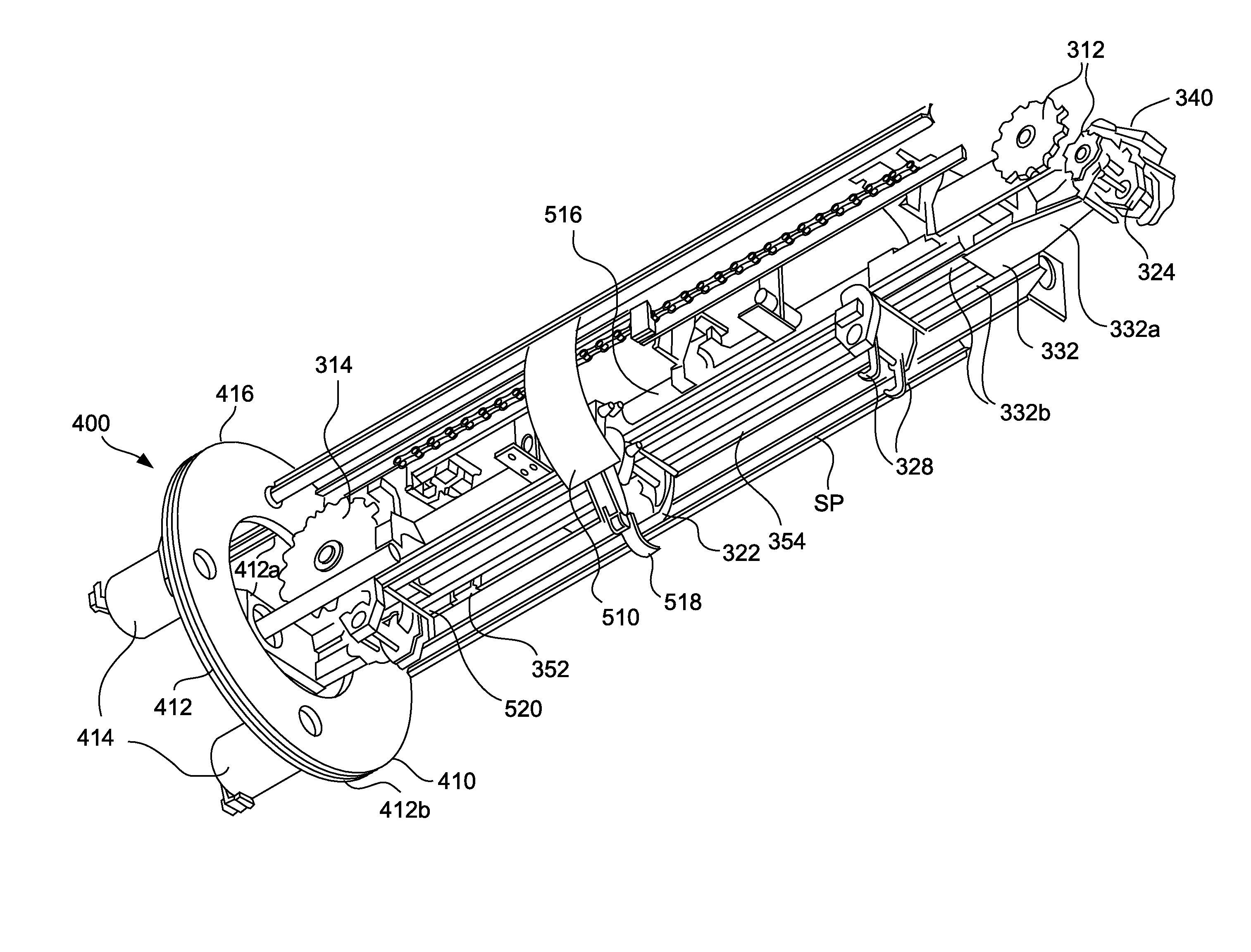

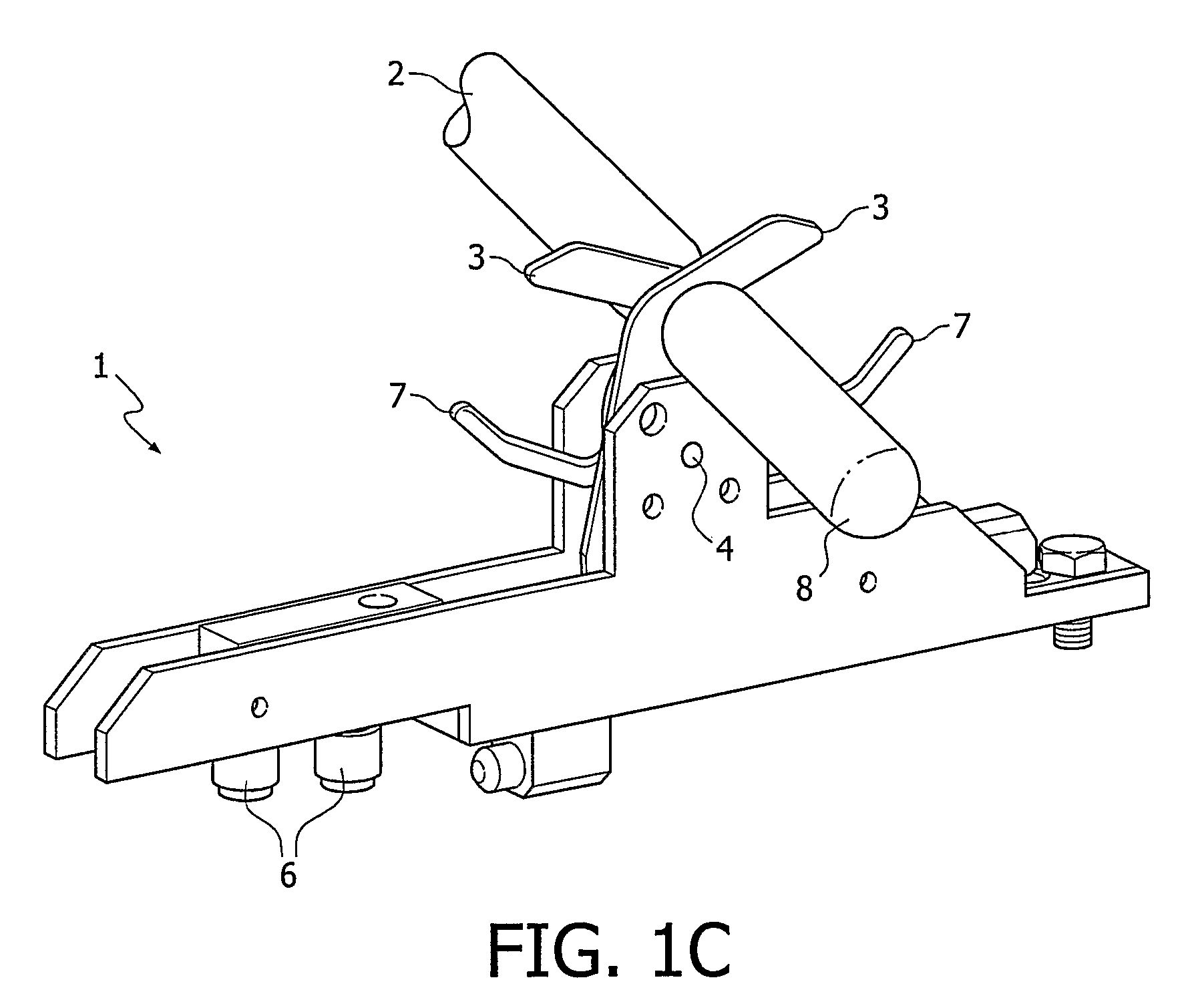

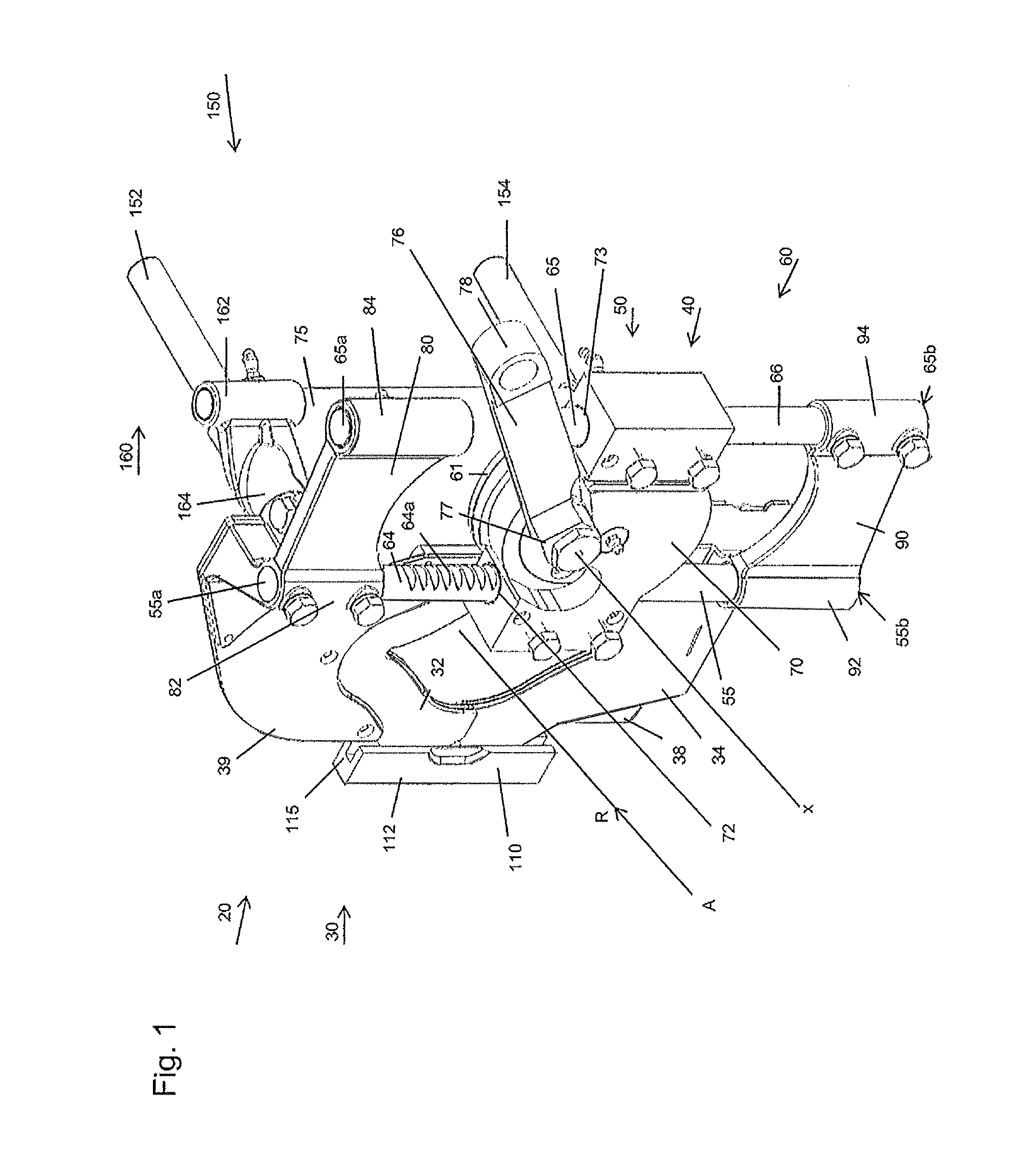

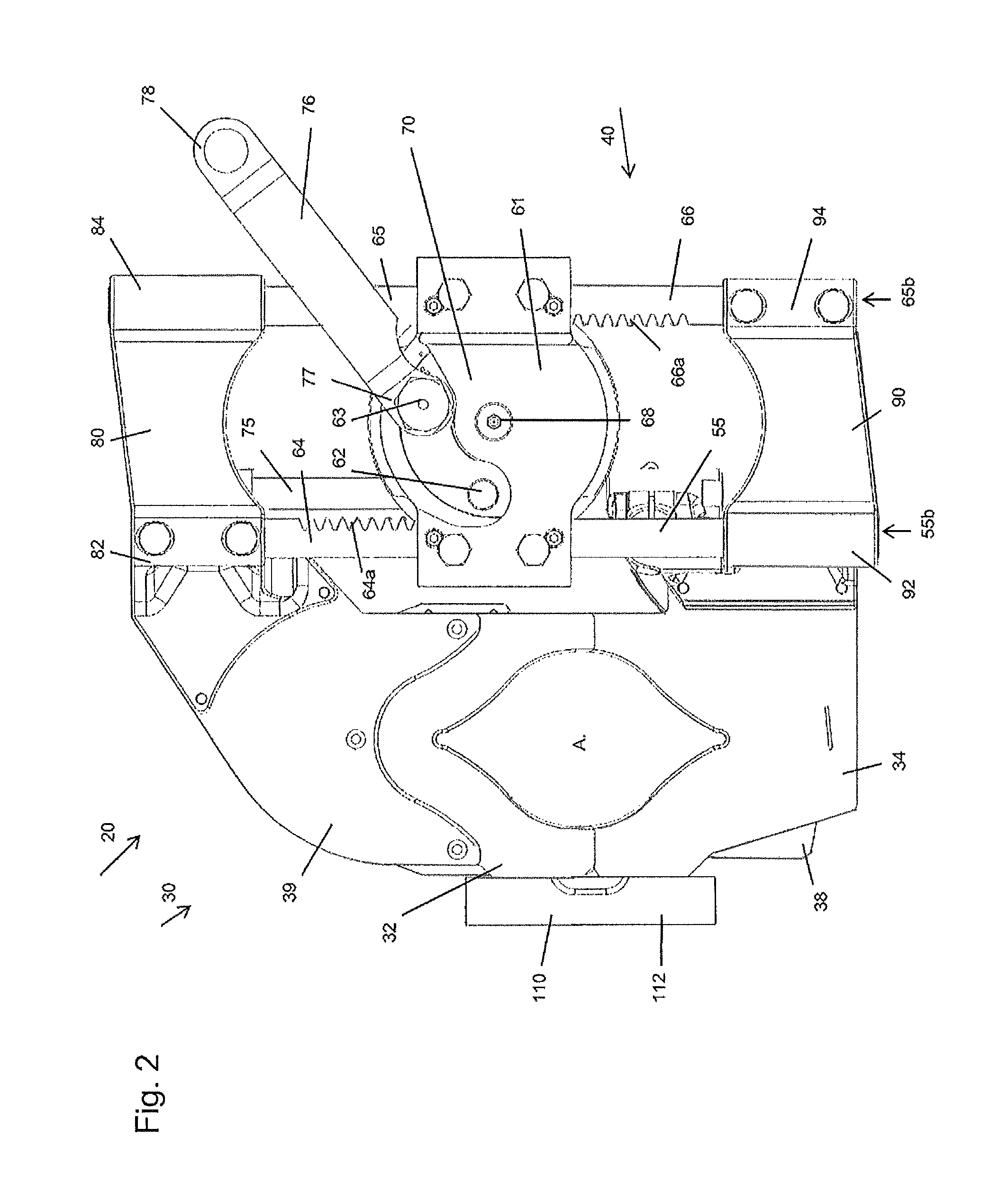

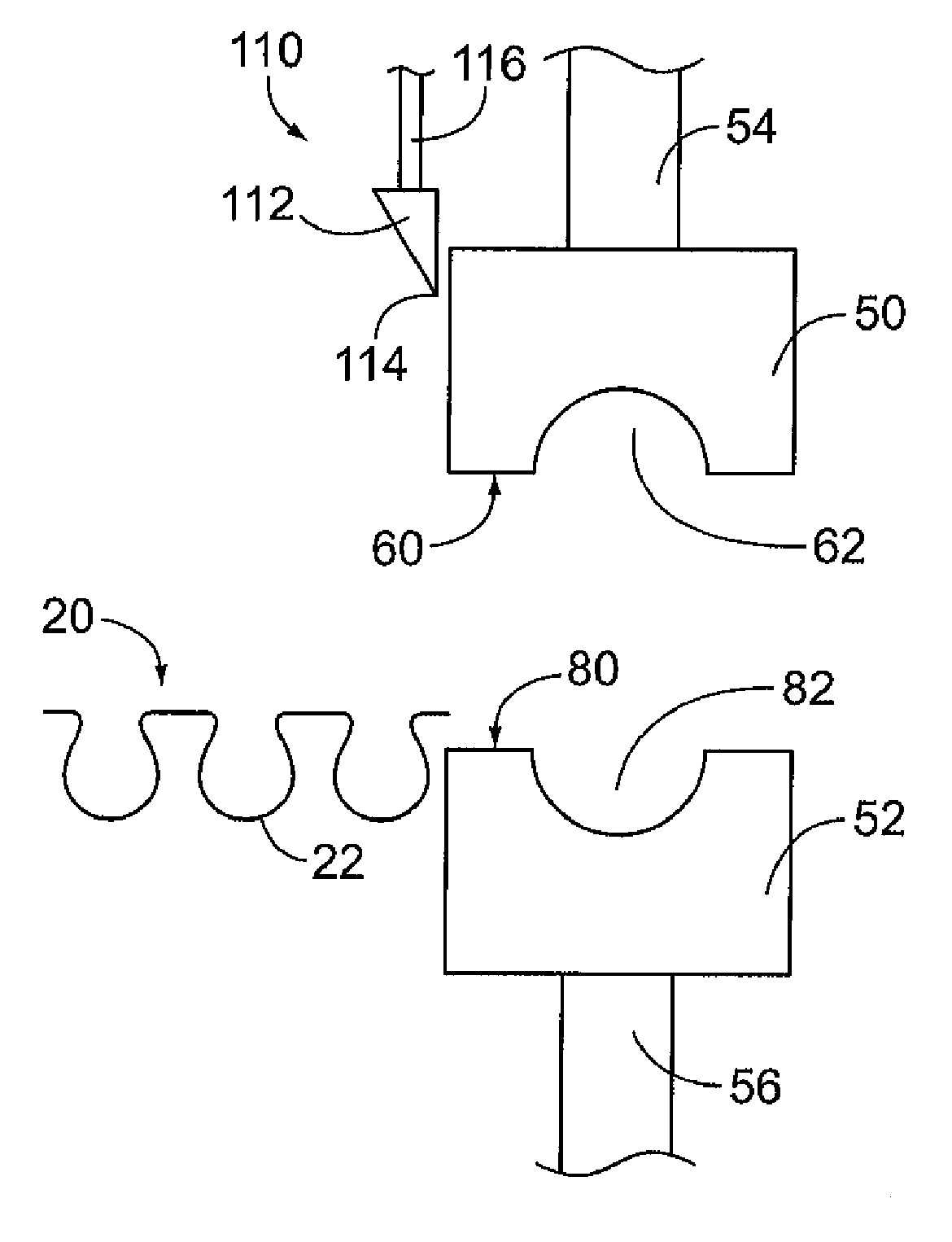

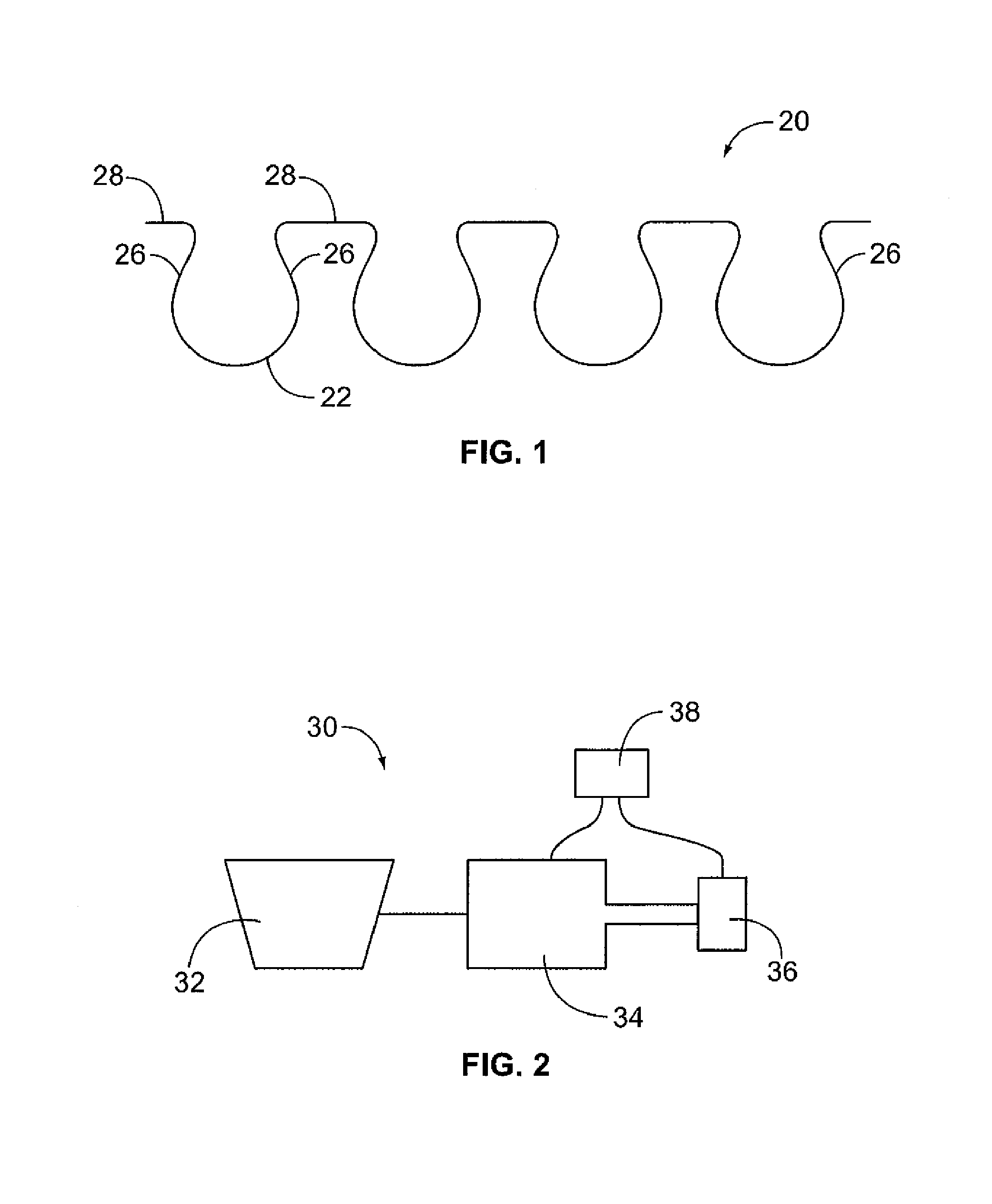

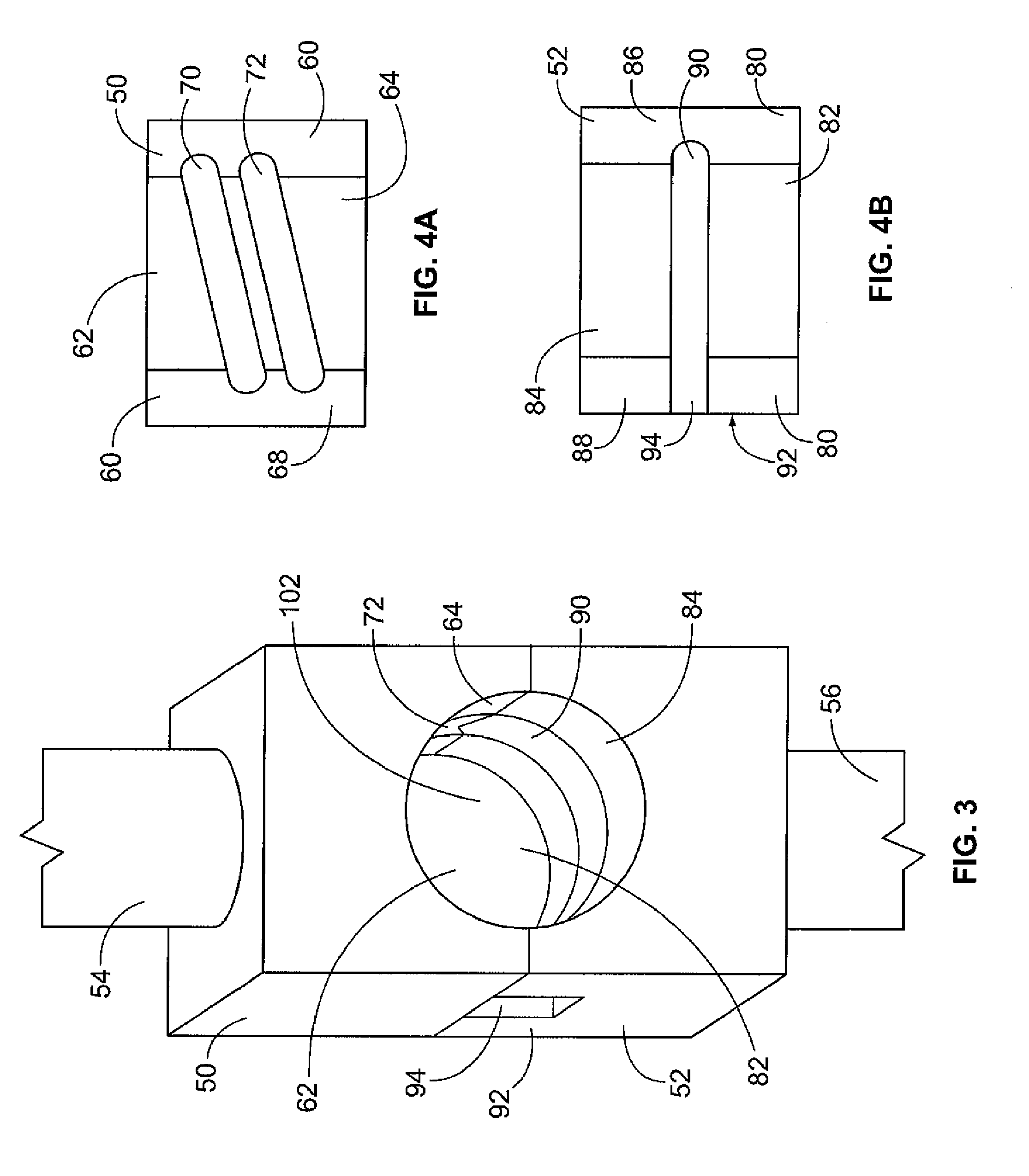

Apparatus for automatically stuffing food casing

InactiveUS6932688B2LengthReduce spacingSausage skin tying apparatusSausage filling/stuffing machinesBand shapeEngineering

A clipping device is provided for closing stuffed food casing with a clip and an apparatus is provided for causing a taped, holding string loops, to be directed toward the clipping device for closing an end of the food casing so that a string loop is transferred directly from the tape into an entry into a channel in the clipping device. The clip draws the loop to the casing and holds the loop to the food casing. The stuffing apparatus preferably also includes a novel readily cleanable food flow cut-off valve. A punch and clip anvil is provided to apply clips bent around the casing in essentially mirror image helixes. An extending and retracting conveyor is provided to remove stuffed food product from the vicinity of the clipping device after stuffed food casing is closed.

Owner:HARRIS TRUST & SAVINGS BANK

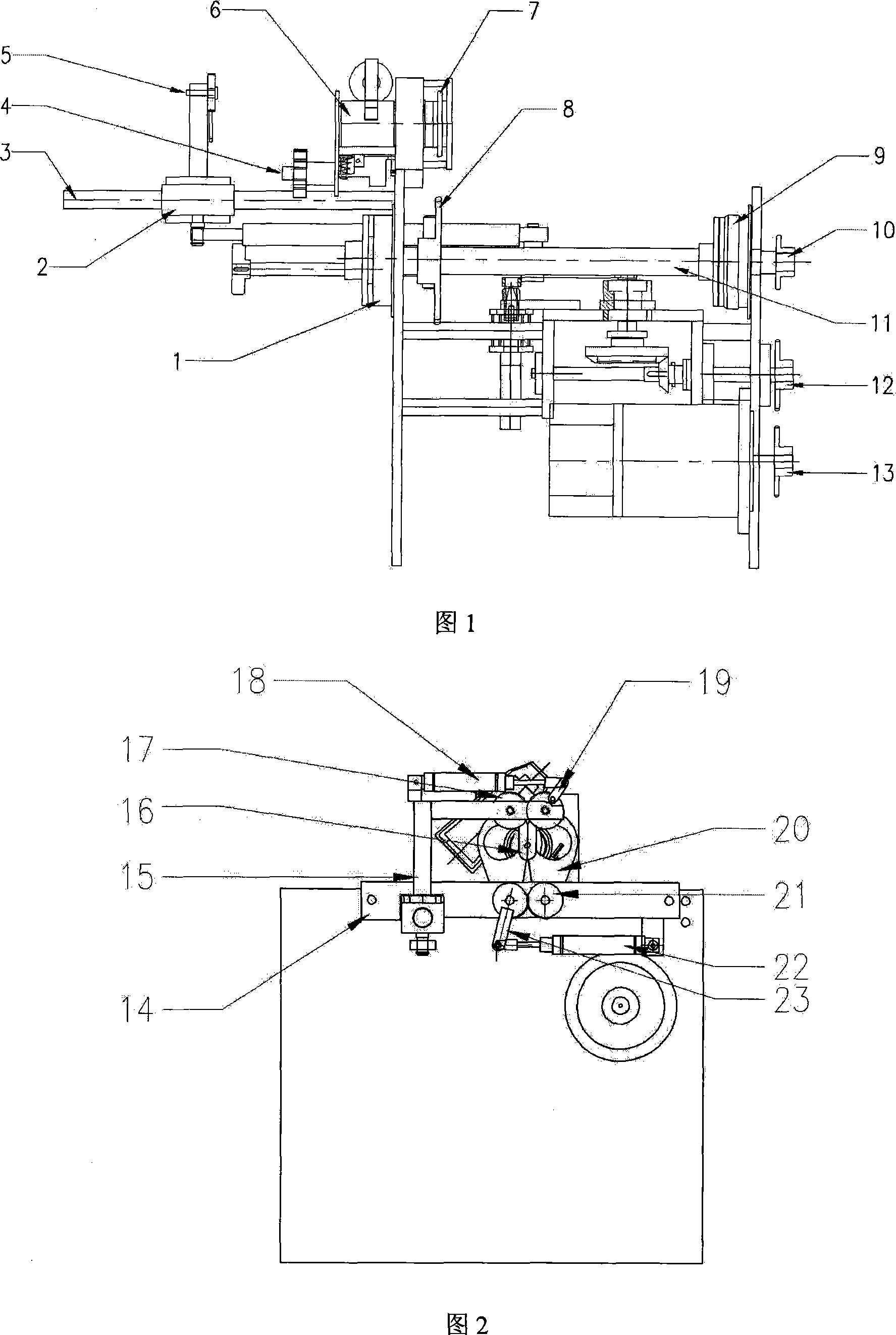

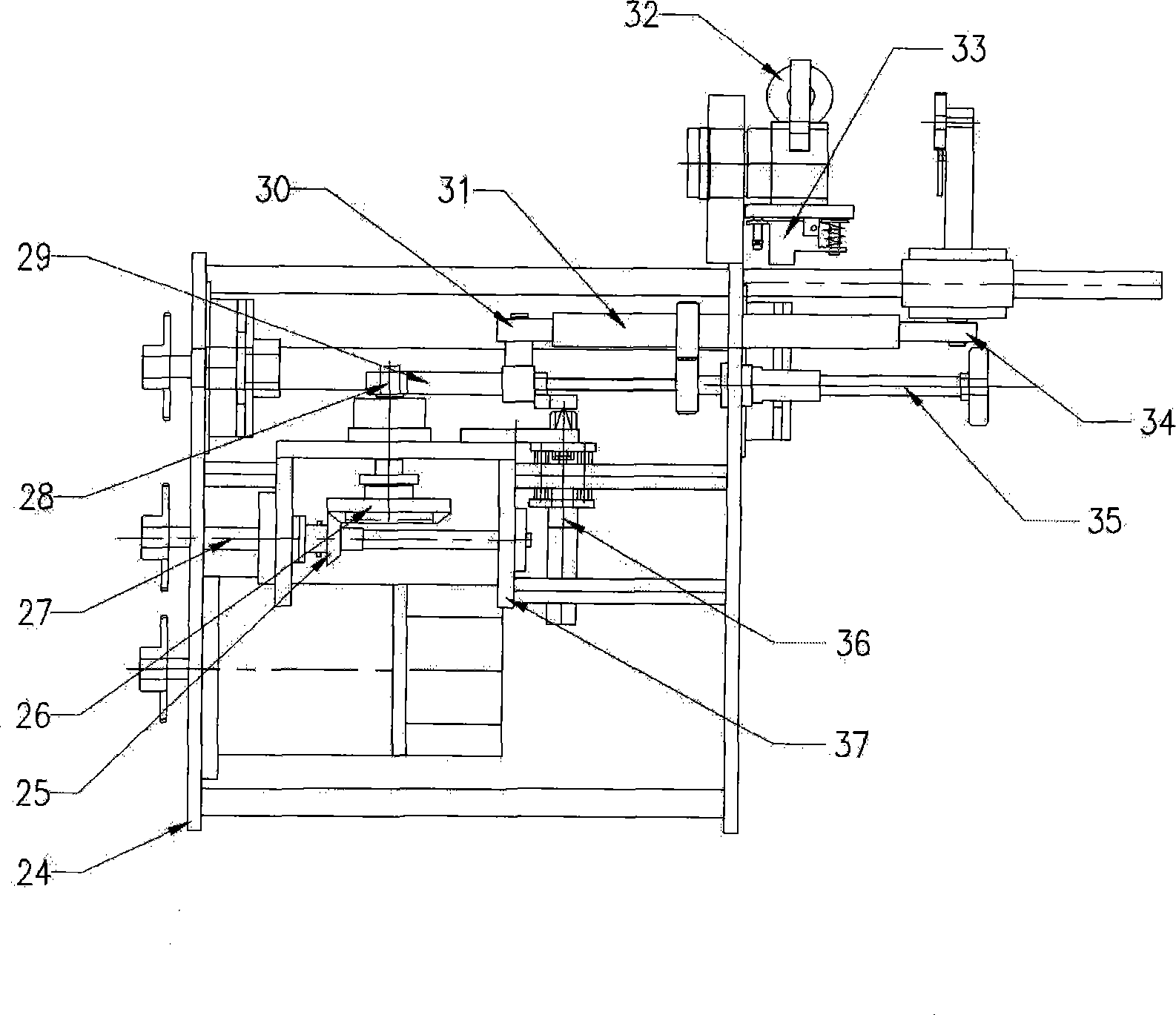

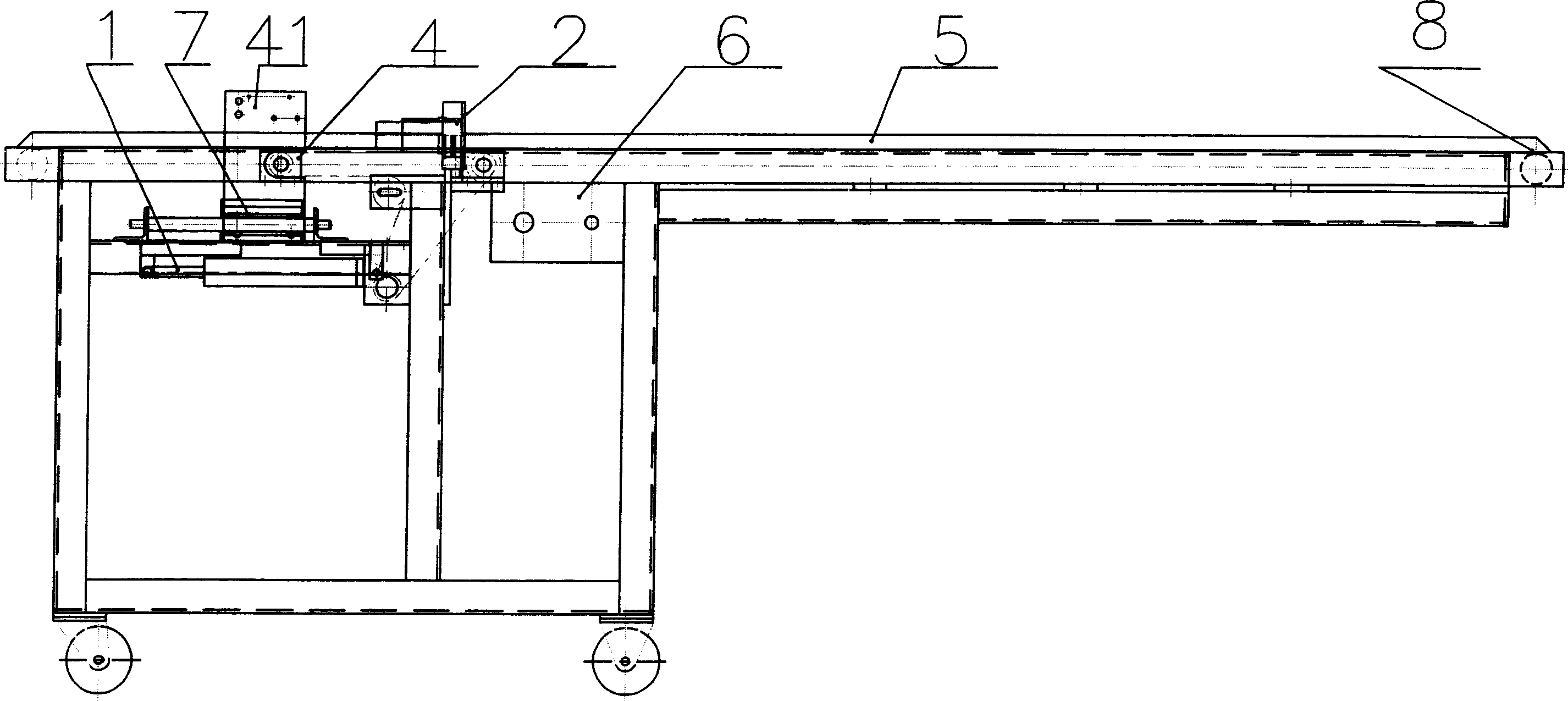

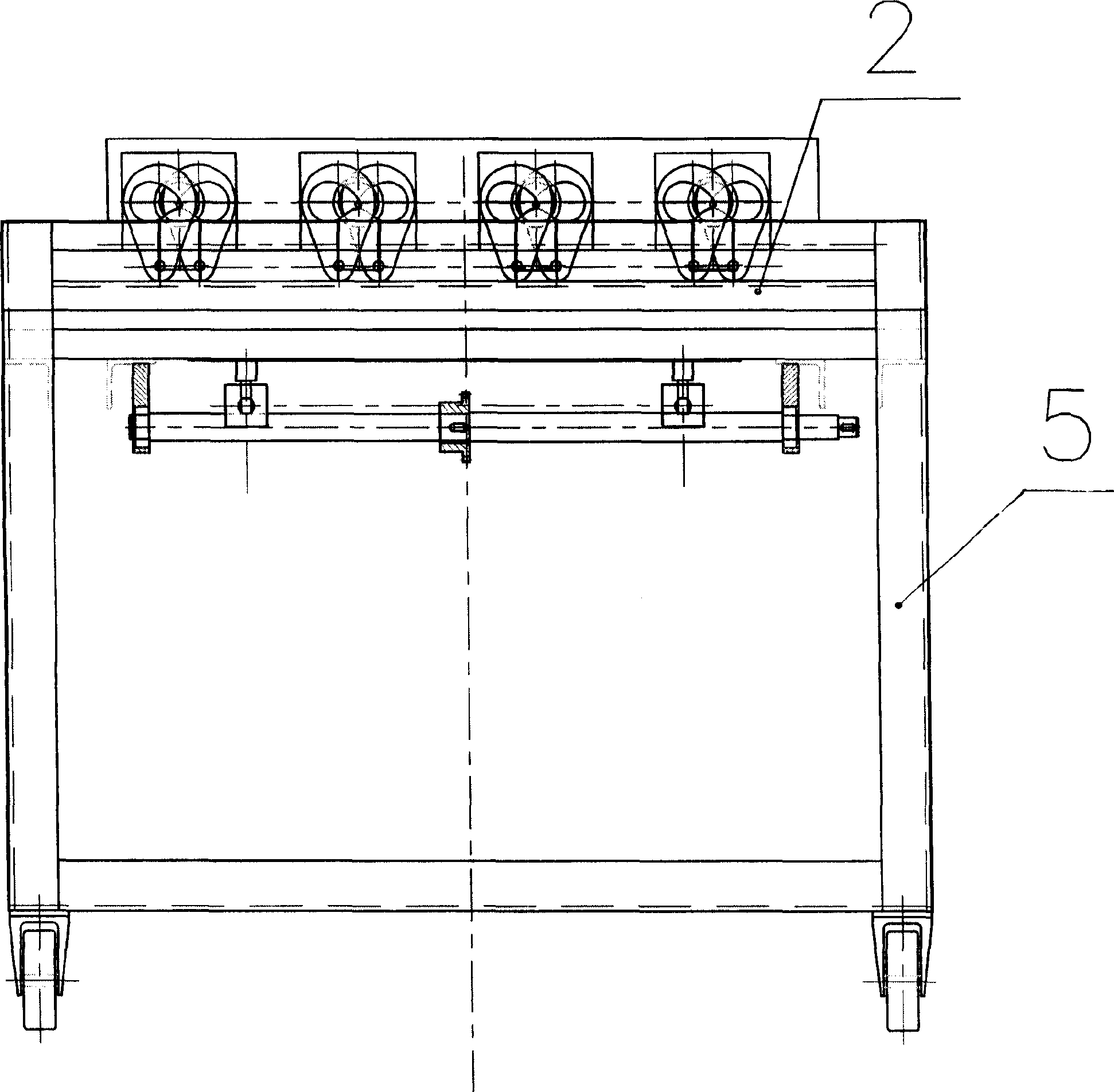

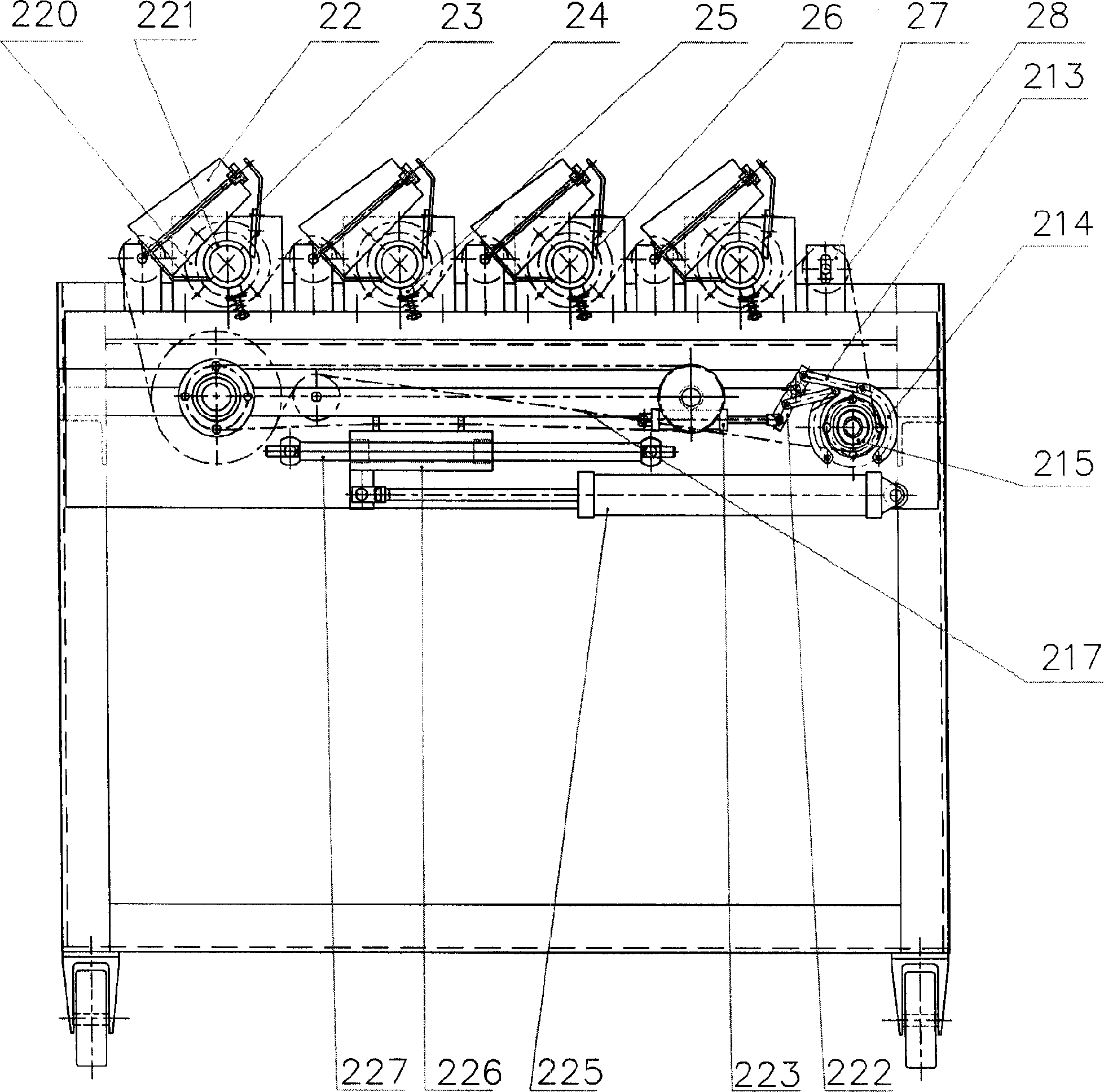

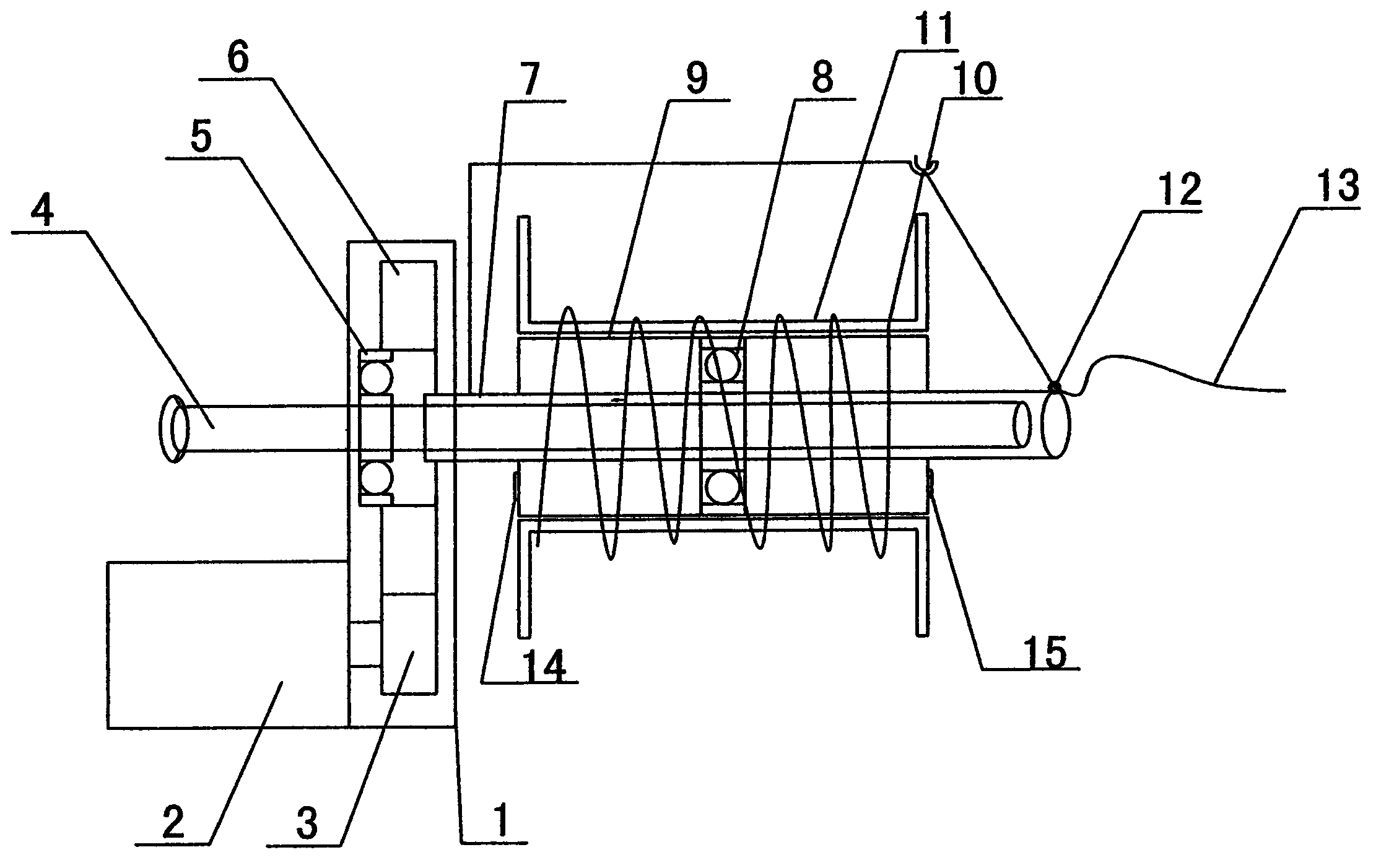

High-speed binding machine

InactiveCN101164416AReasonable structureCompact structureSausage skin tying apparatusGear wheelEngineering

The present invention relates to a high-speed wire-binding machine. It mainly is composed of machine frame, holding mechanism, reducing mechanism and one-way synchronous regulation mechanism. The described one-way synchronous regulation mechanism is formed from curved bar, transmission-retaining screw rod, regulation transmission screw rod, double-pitch two-head screw rod and hand wheel regulation component. The described holding mechanism includes the following several portions: holding jaw supporting frame, holding jaw rotating shaft core, holding jaw intermittent gear, holding jaw driving lug and holding jaw cylinder.

Owner:嘉兴市瑞胜食品有限公司

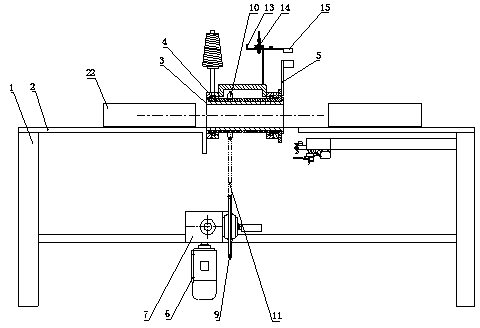

Automatic knotting and wire breaking device for producing sausages

ActiveCN103719224AFully automatedReduce labor intensitySausage skin tying apparatusControl systemRotary encoder

The invention relates to an automatic knotting and wire breaking device for producing sausages. The innovation points are that a sausage guiding sleeve, a wire supplying assembly and a length fixing transmission mechanism are mounted on a working platen; a pneumatic wire clamping assembly and a wire breaking assembly are arranged below the working platen; a shaft sleeve of a wire winding assembly is sleeved with the sausage guiding sleeve, and is driven to rotate through a wire winding driving mechanism; a winder is mounted in the shaft sleeve and at one end near the discharging side. The automatic knotting and wire breaking device has the advantages that the wire winding assembly works together with the pneumatic wire clamping assembly and the wire breaking assembly to bundle the sausages, during the bundling process, the coordination of a control system with rotary encoders and a material sensor is utilized to perform cooperation control, so that actions of bundling and wire breaking are enabled to be performed smoothly without mutual noninterference, manual bundling and wire breaking are not needed, the labor intensity of the operating personnel is reduced, the qualified rate of the bundling and wire breaking is high, the coordination of the length fixing transmission mechanism with the material sensor, the rotary encoders and the like is utilized to convey the sausages in rated length, the distance of each section of bundling wire is ensured to be consistent, and the product specification is enabled to meet the requirement.

Owner:JIANGSU CHANGSHOU GRP CO LTD

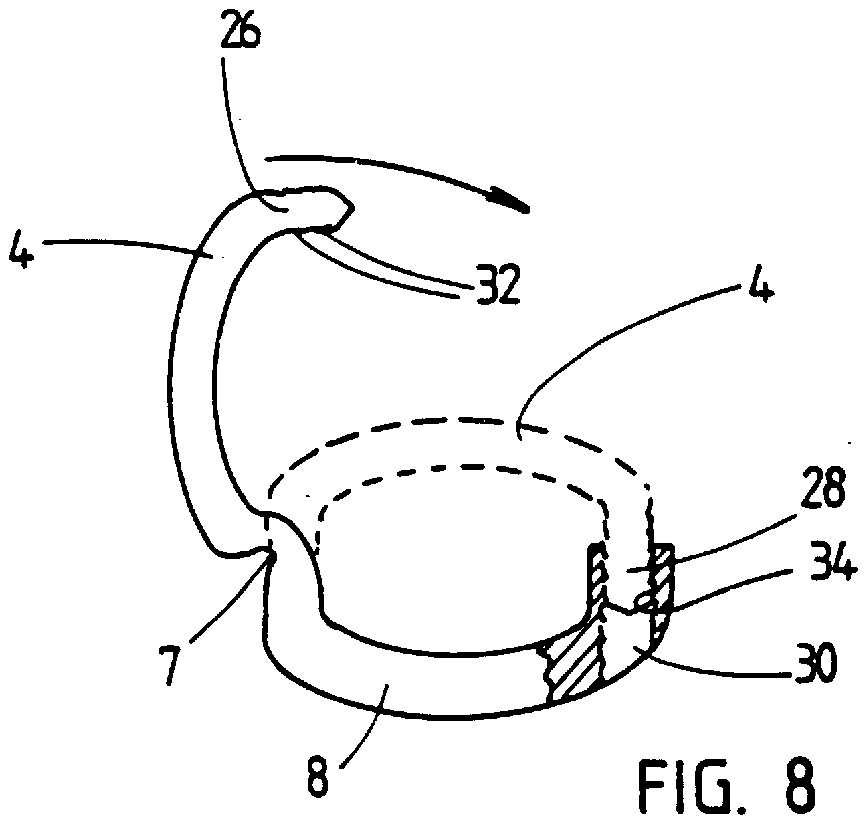

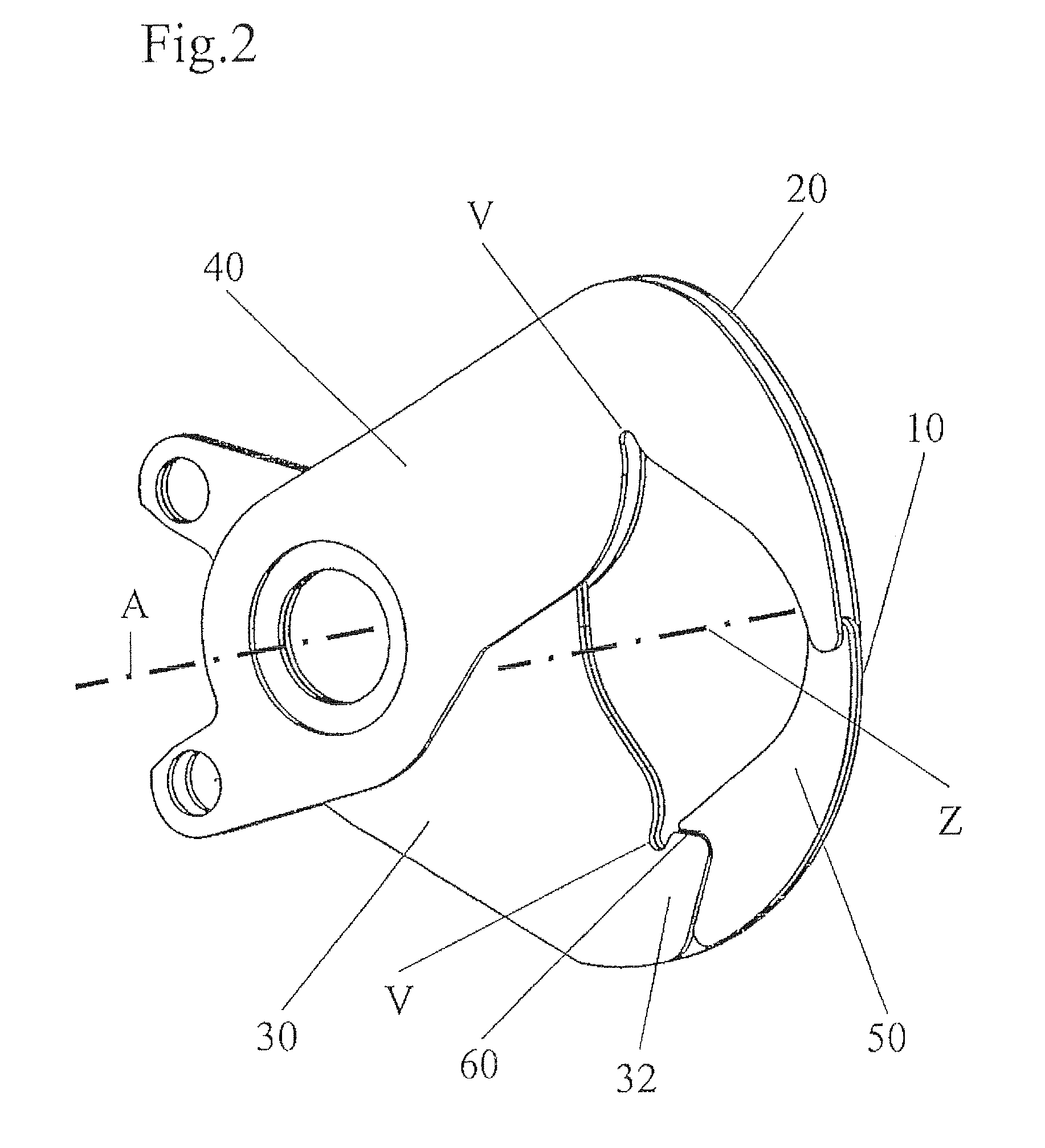

End closure for an edible collagen casing and a method for obtaining thereof

InactiveUS20180084792A1Facilitate expulsionIncrease the number ofSausage skin tying apparatusSausage casing manufactureMoisturePolymer chemistry

The invention relates to an edible tubular collagen film which has a closure at either of their ends. The closure is formed by an edible solid ring-like element which tightens the end portion of casing and seals the outlet of the same, in order to stop the filling mass upon beginning of a sausage stuffing process, whereby in such a process one can rescue the initial filled sausage for its further processing, whereafter the ring disappears. This edible closing element is characterized by being of an edible, and thermoplastic composition, which is preferably based on collagen or gelatine. The solid composition has a low melting temperature and becomes adhesive at fluid state onto the surface of a collagen film which contains a certain level of moisture. The strong cohesiveness of the material of said composition in the fluid state as well as the so narrow difference between its melting temperature and the temperature of solidification, makes that a welding of said material to be set very quickly. The closure can be made before or after the shirring of the collagen casing and the present invention provides also a process to perform such a closure by heat welding the closing element on the casing material.

Owner:VISCOFAN TECH SUZHOU

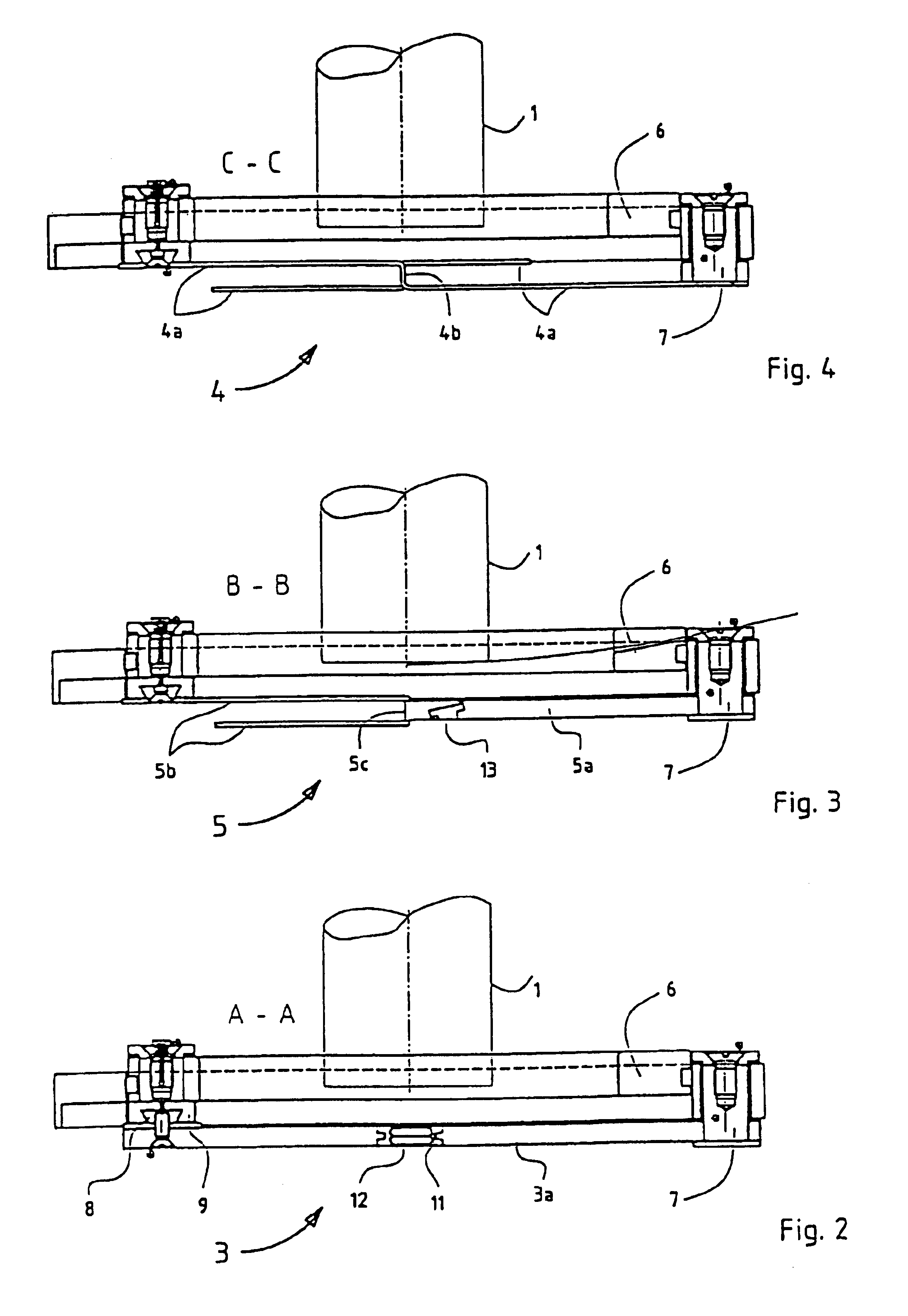

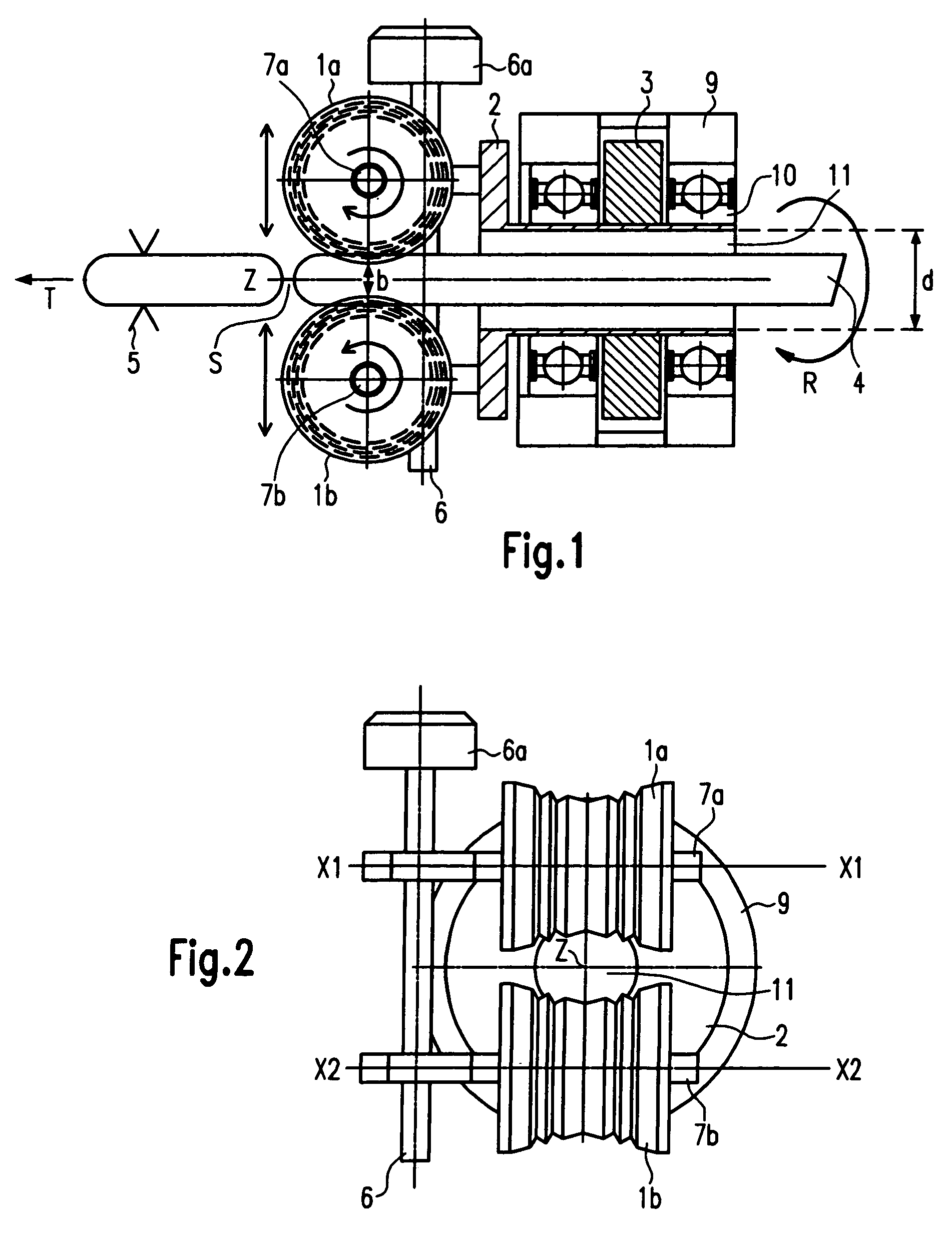

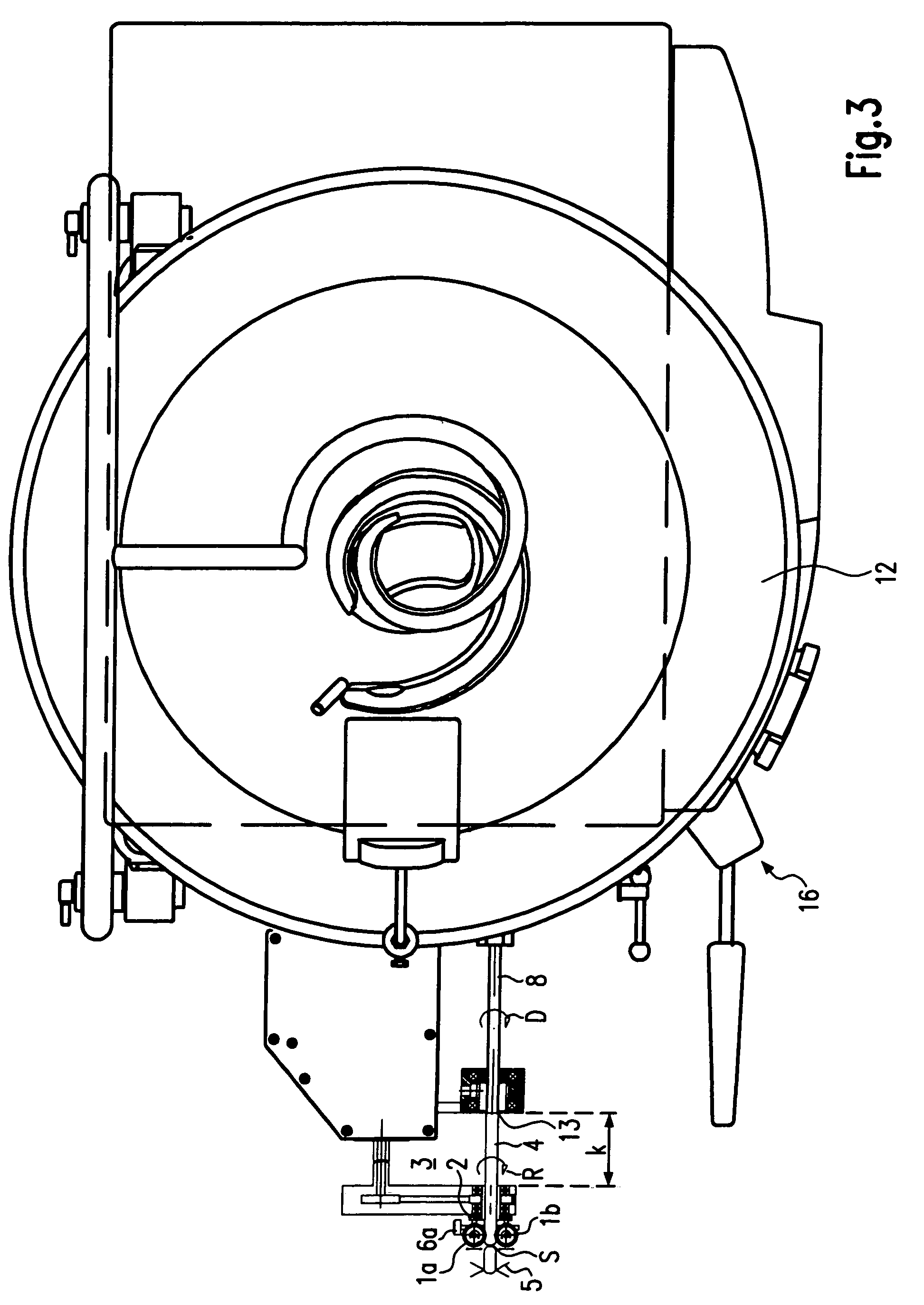

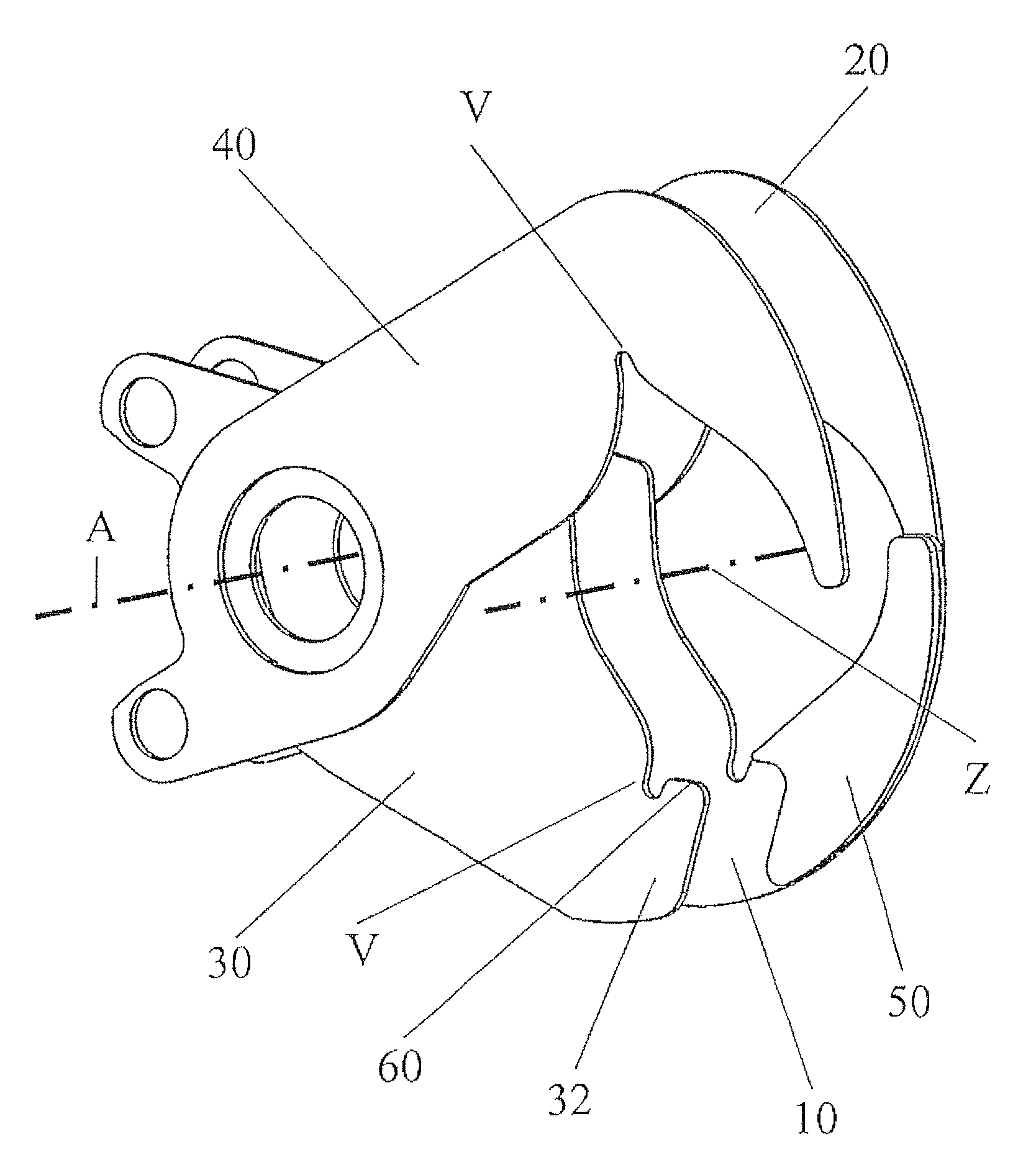

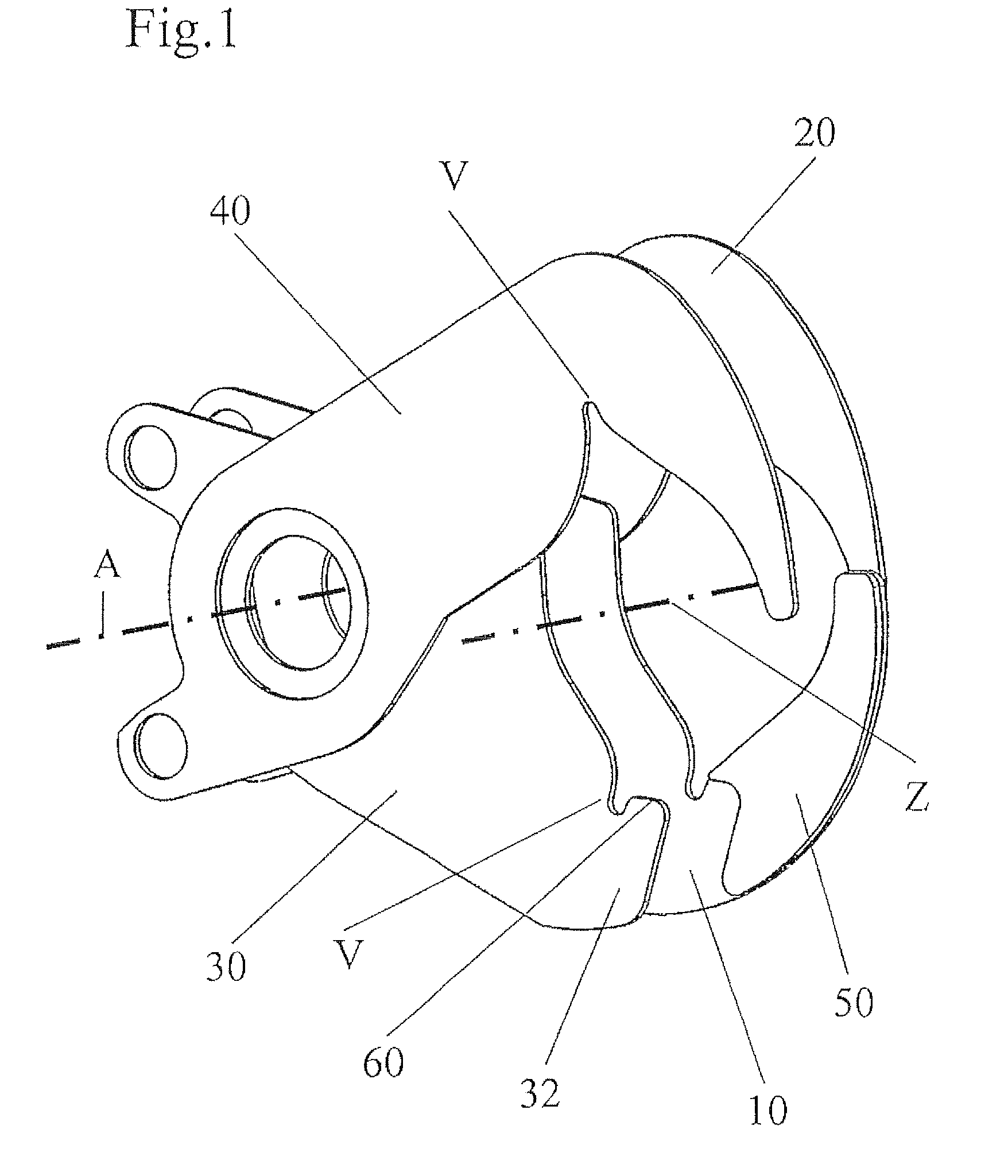

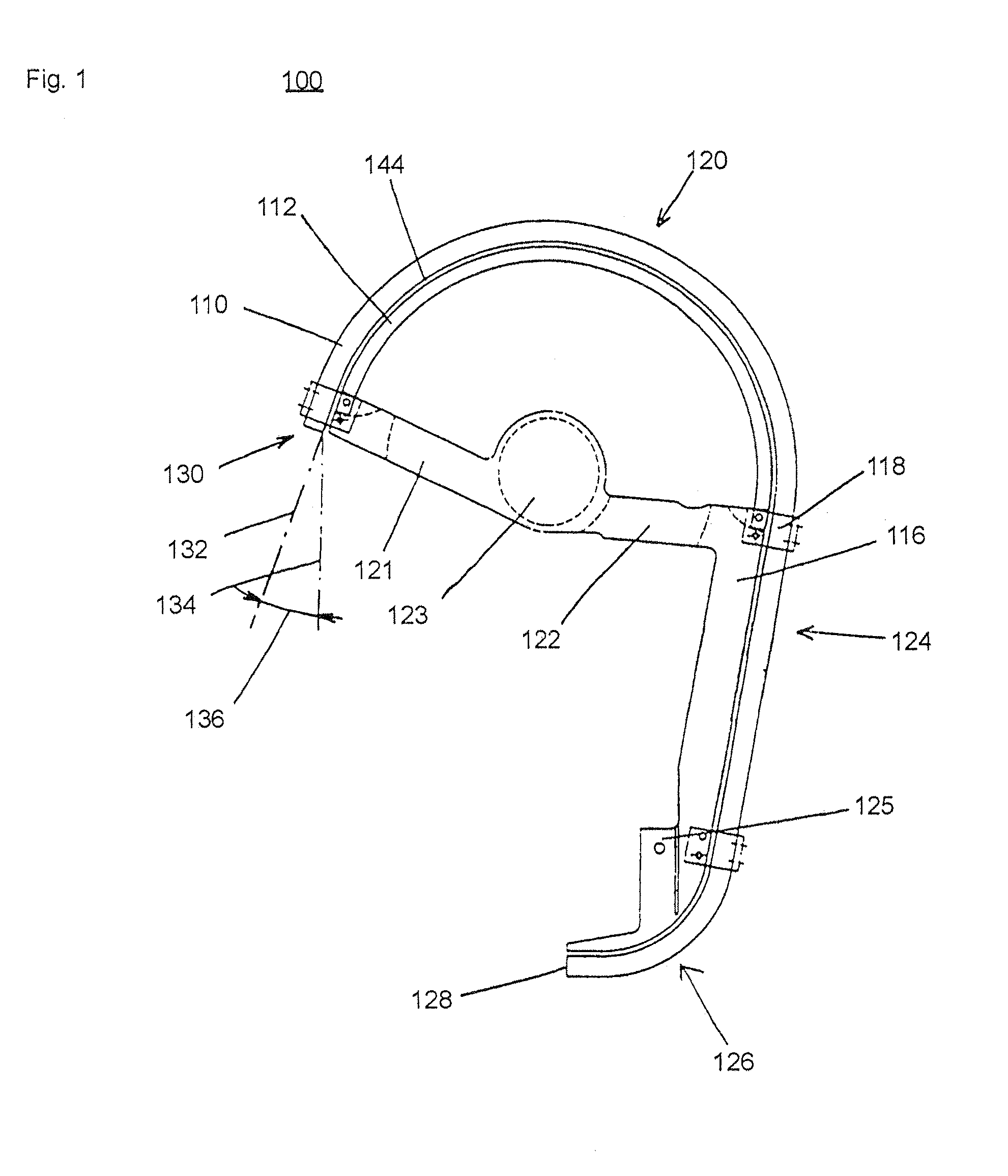

Shaping device and shaping method for forming rounded tips on the ends of sausages

ActiveUS7762874B2Facilitates the tying off and/or partingUniform formatSausage skin tying apparatusSausage filling/stuffing machinesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

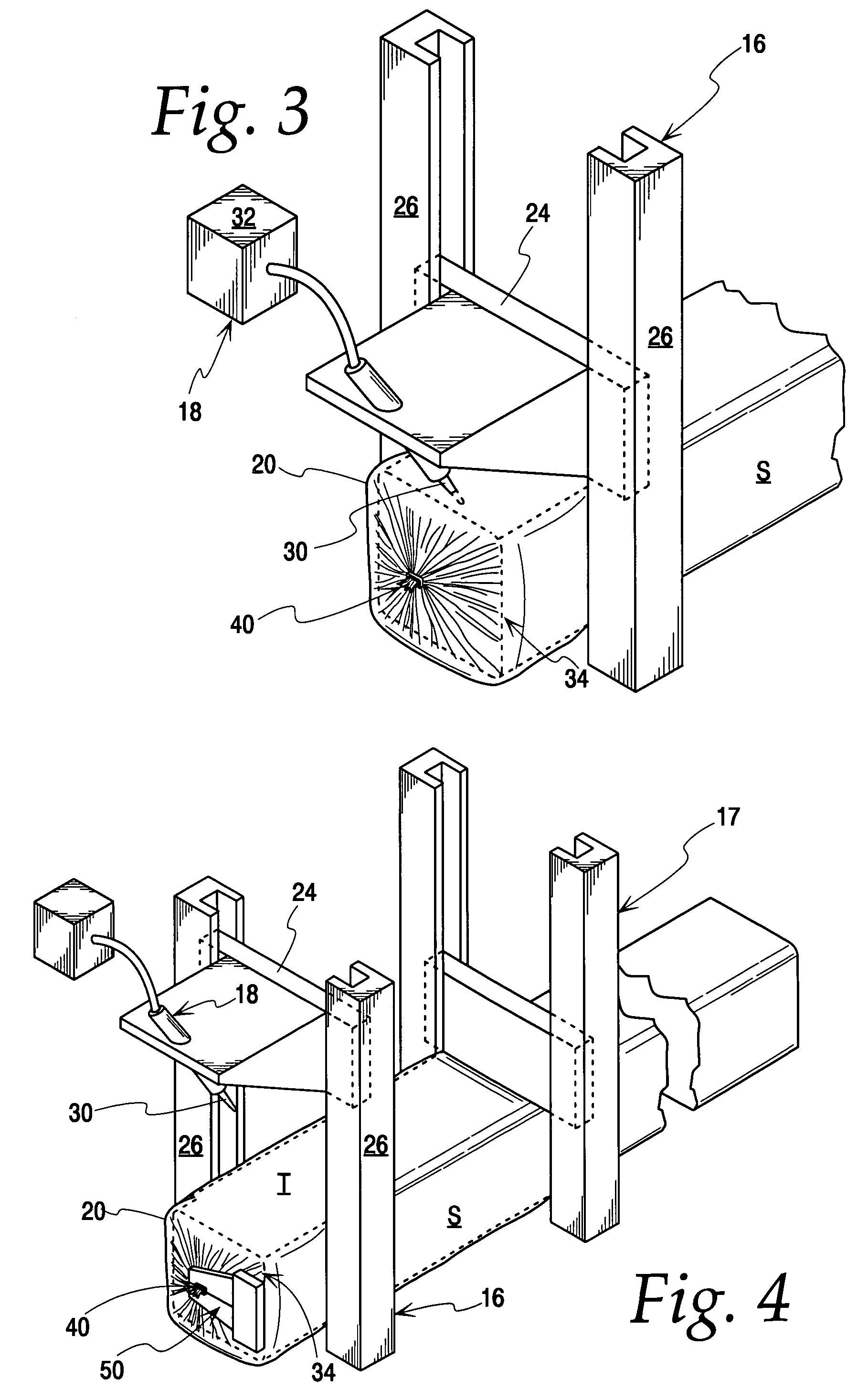

Fuel dispensing and containment assembly

A modular fuel dispensing and containment assembly for storing fuel in at least one fuel tank and for pumping the fuel to a group of fuel dispensers. The assembly has a reinforced concrete vault located underground which contains a fuel tank within its interior. The fuel tank is separated from the interior walls of the vault. The fuel tank has a turbine corridor on its lid, which corridor has an interior volume which leads from the fuel tank to a series of piping corridors. The turbine corridor and the piping corridors are all underground and the piping corridors lead to dispensing modules which are located under the dispensers or gas pumps. The dispenser modules and piping corridors are all sufficiently large to permit the entry of service personnel to their interiors. The interiors of the various corridors and modules form a single interconnected air volume. The result is a fuel dispensing and containment assembly wherein the vault and corridors and dispensing modules act as a secondary containment against any contaminant leaking from the primary piping or tanks. It also permits complete visual inspection of the primary containment and physical access to all its parts at any time.

Owner:GROPP STEVEN M

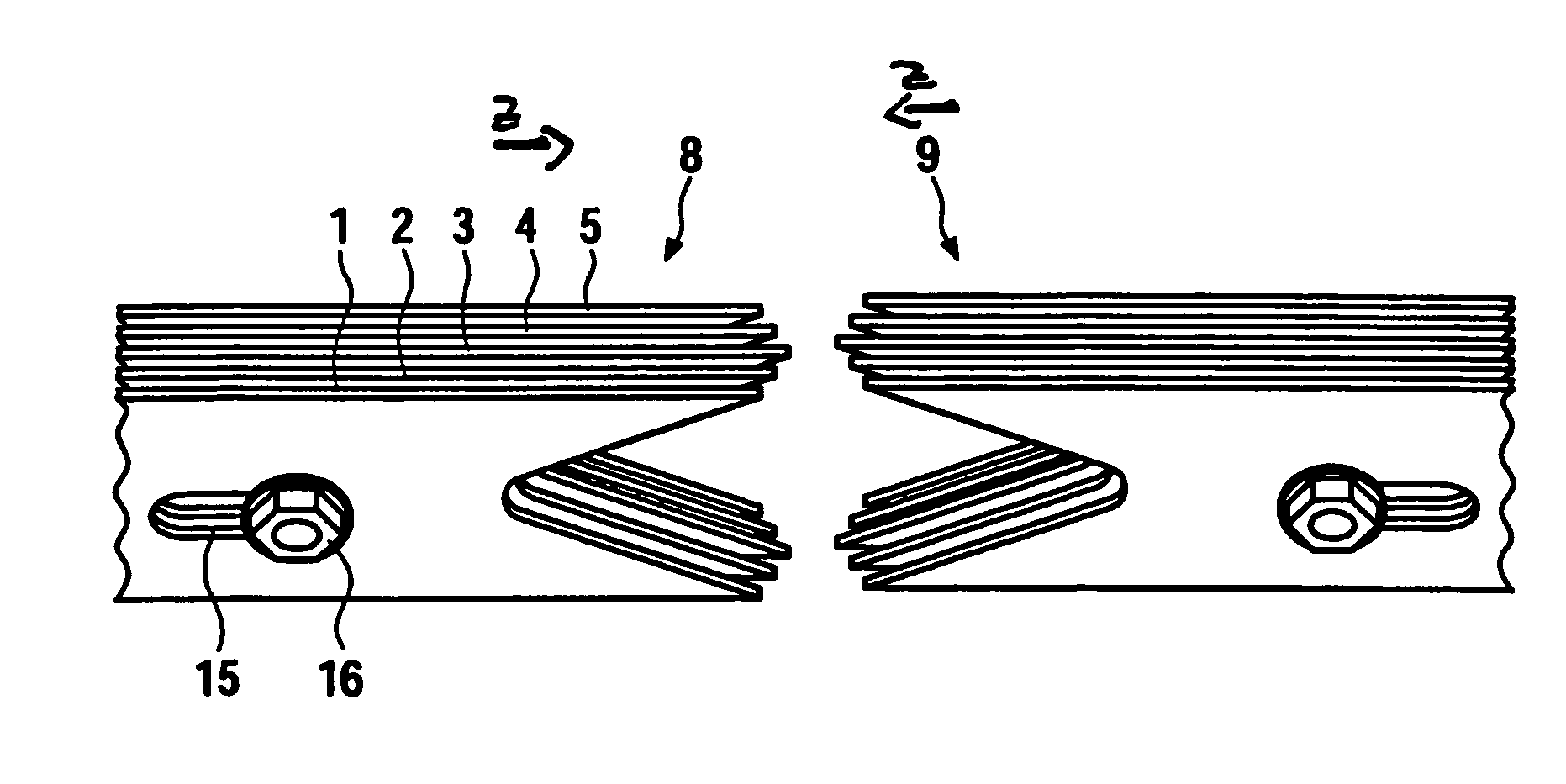

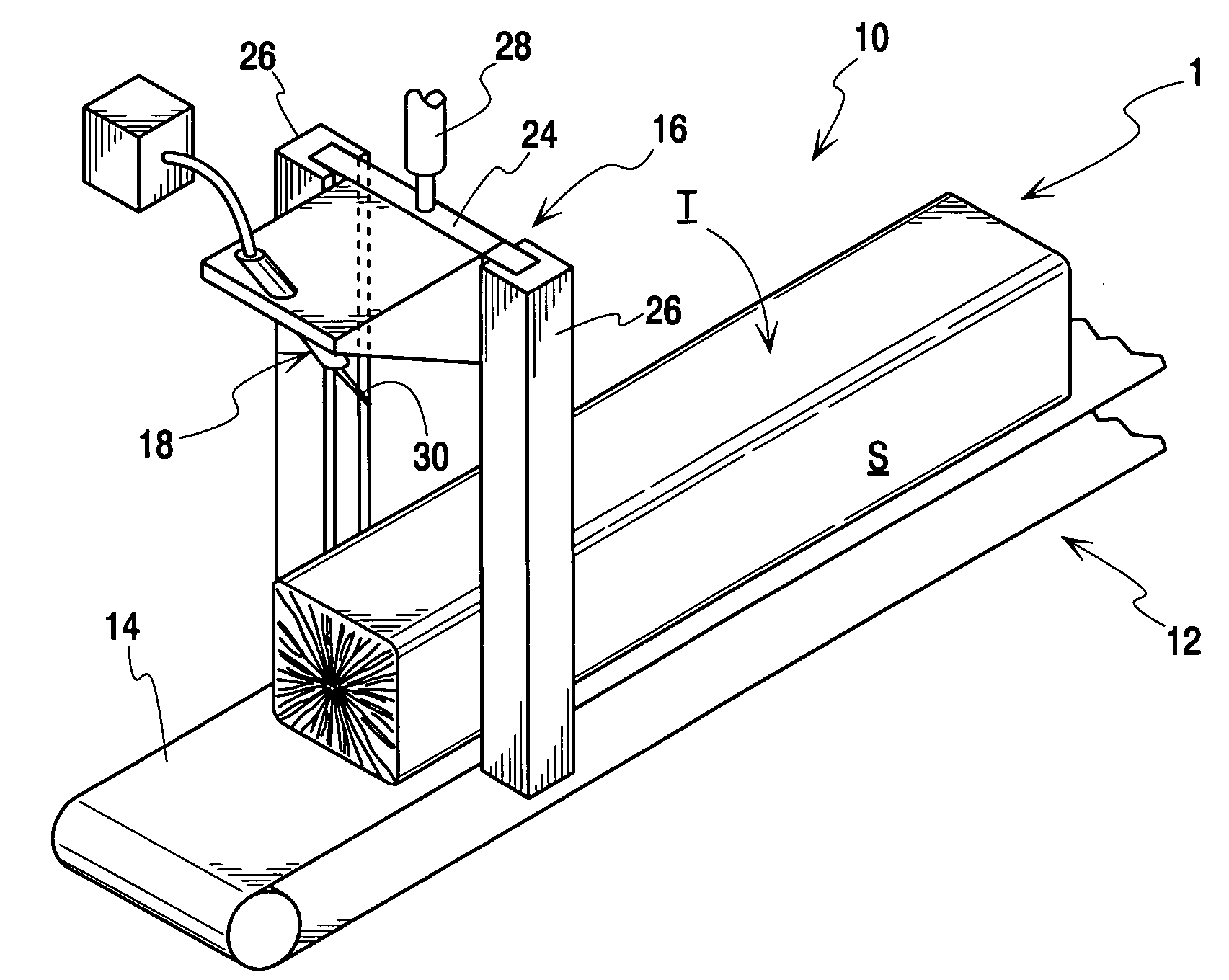

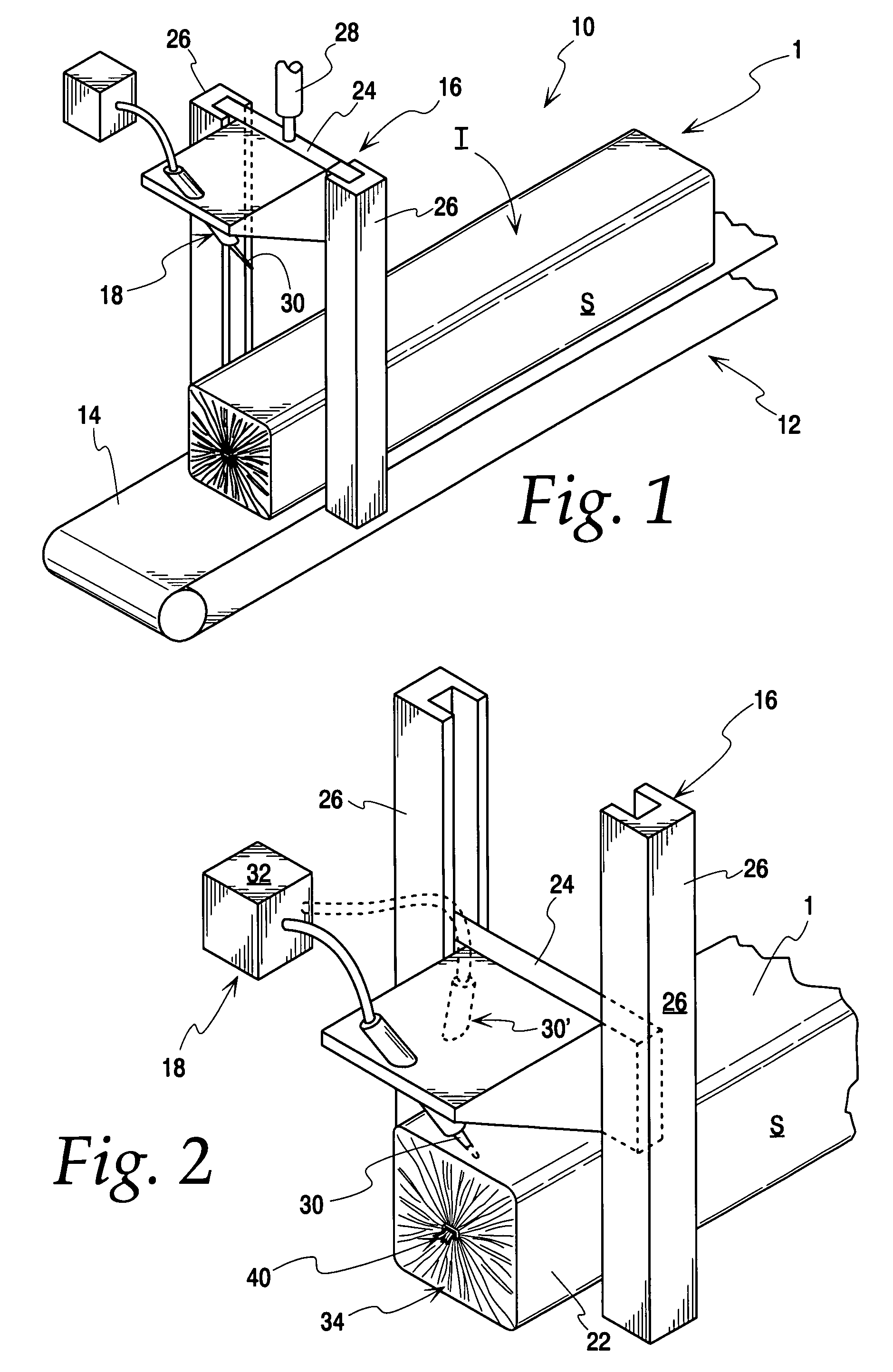

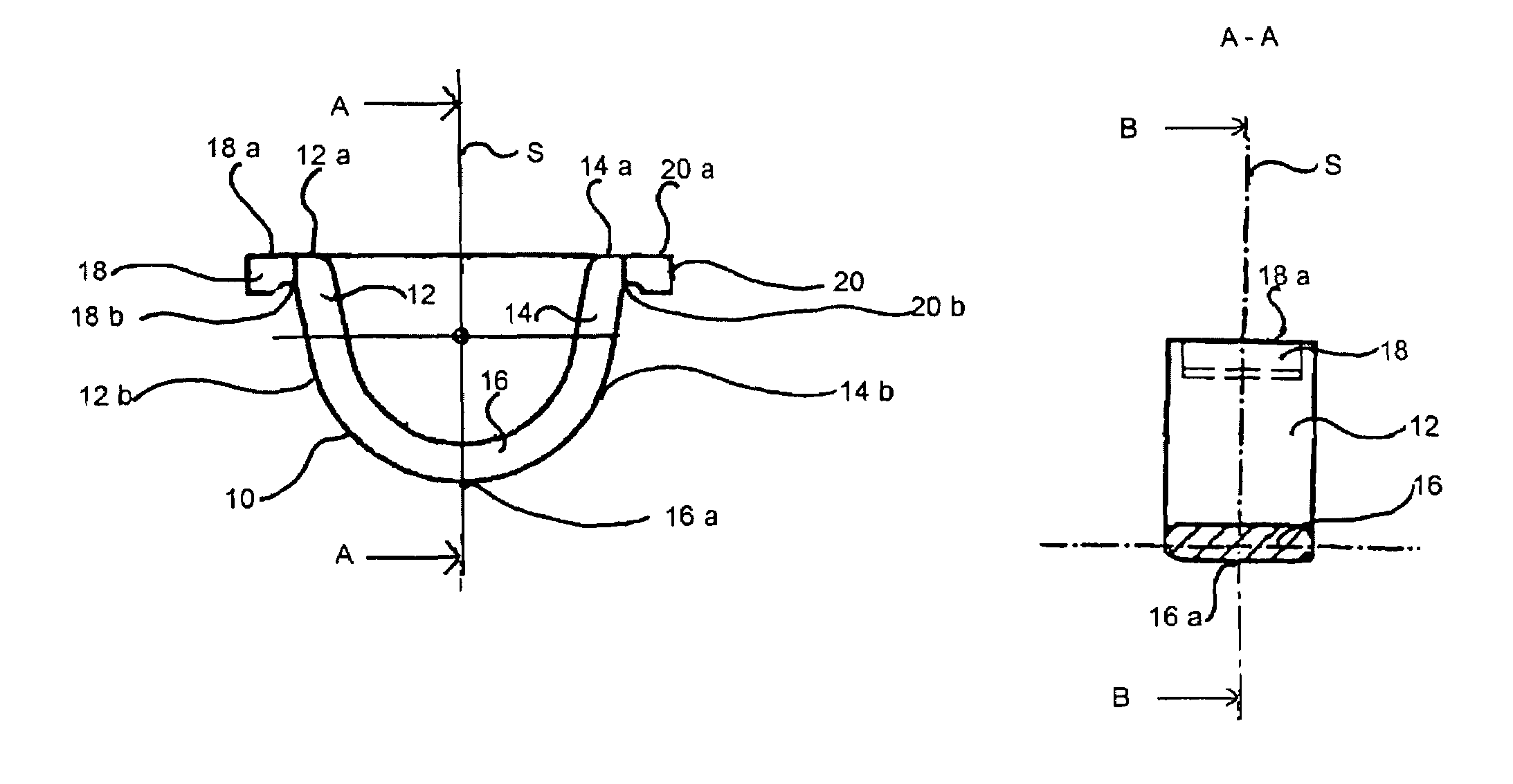

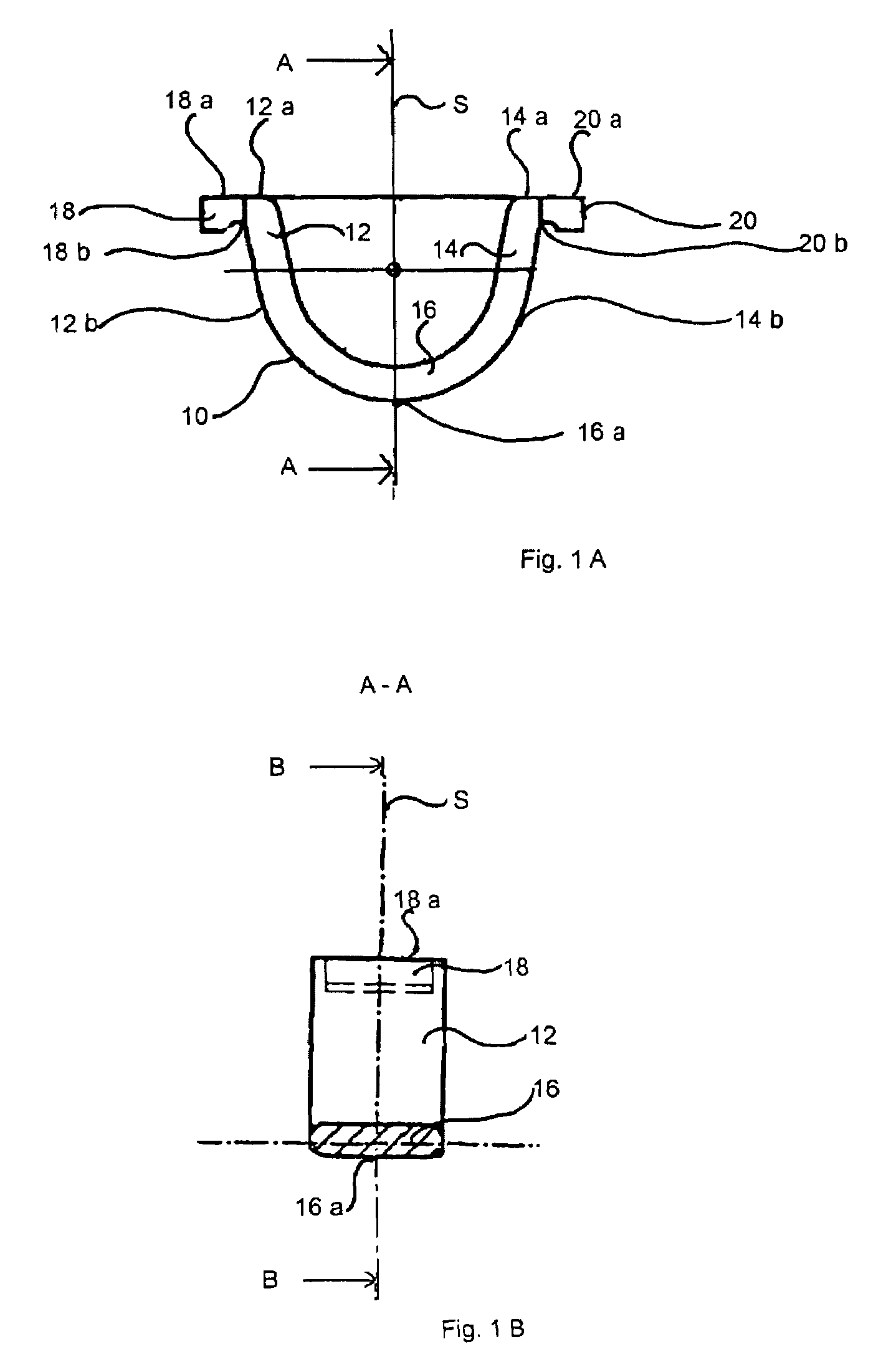

Method, a binder and a binding machine for closing hose or bag shaped packings, primarily tubular foodstuff packings

The closing of tubular casings containing foodstuffs by mounting a binder on a constriction of the casing involves the traditional problem of a high waste percentage due to the binders either damaging the casing material or sliding off the constriction. A method and a binder are proposed which makes it possible to obtain a very strong clamping of the binder without damaging the casing material, and, in connection with tight plastic casings, it is even possible to provide a "super tight" closure, by ranging the constriction with an oblong cross section between opposed straight clamping beams, which are forced together so as to produce a controlled deformation flowing of the casing material.

Owner:TAMAMCO PAC

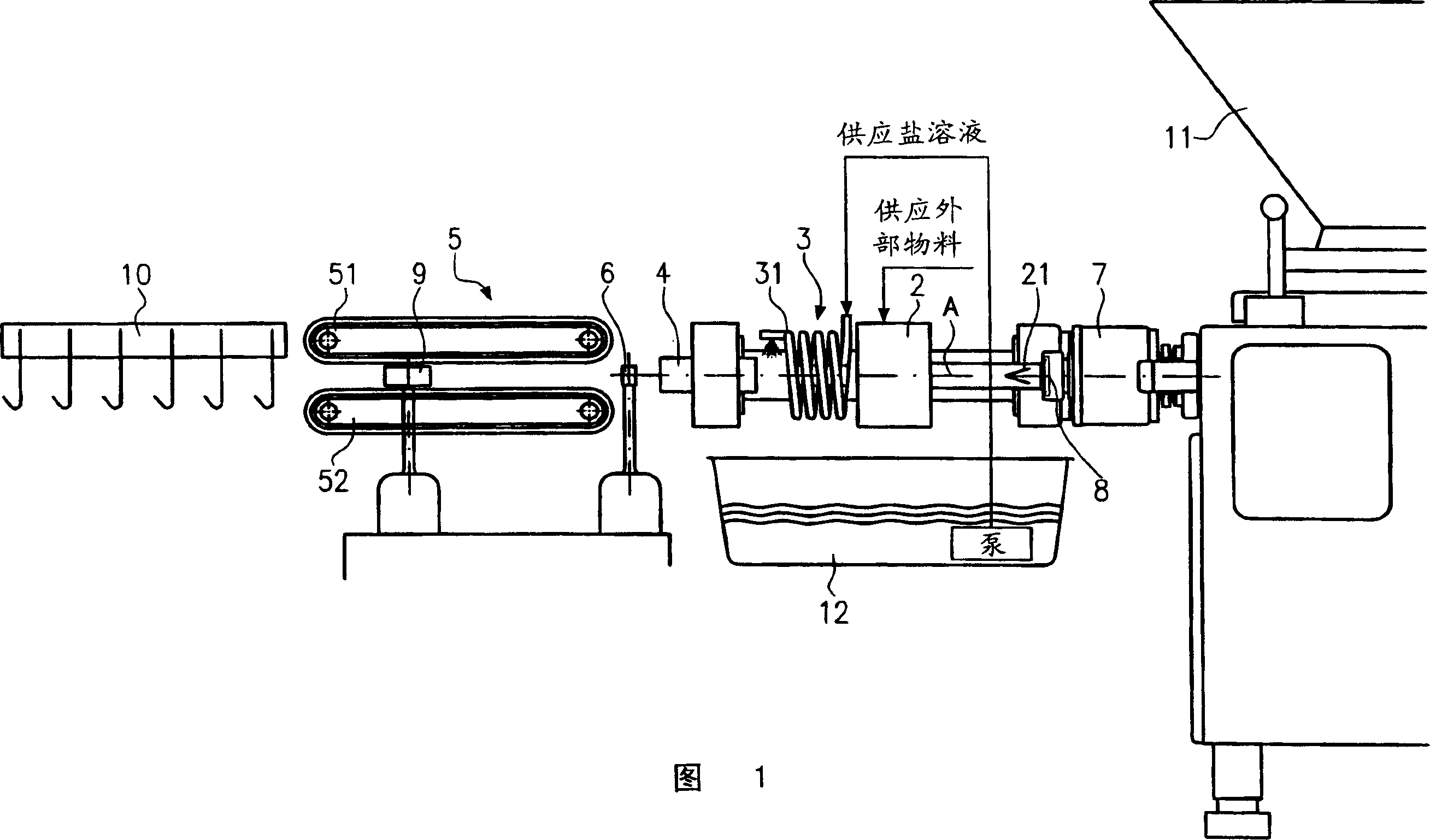

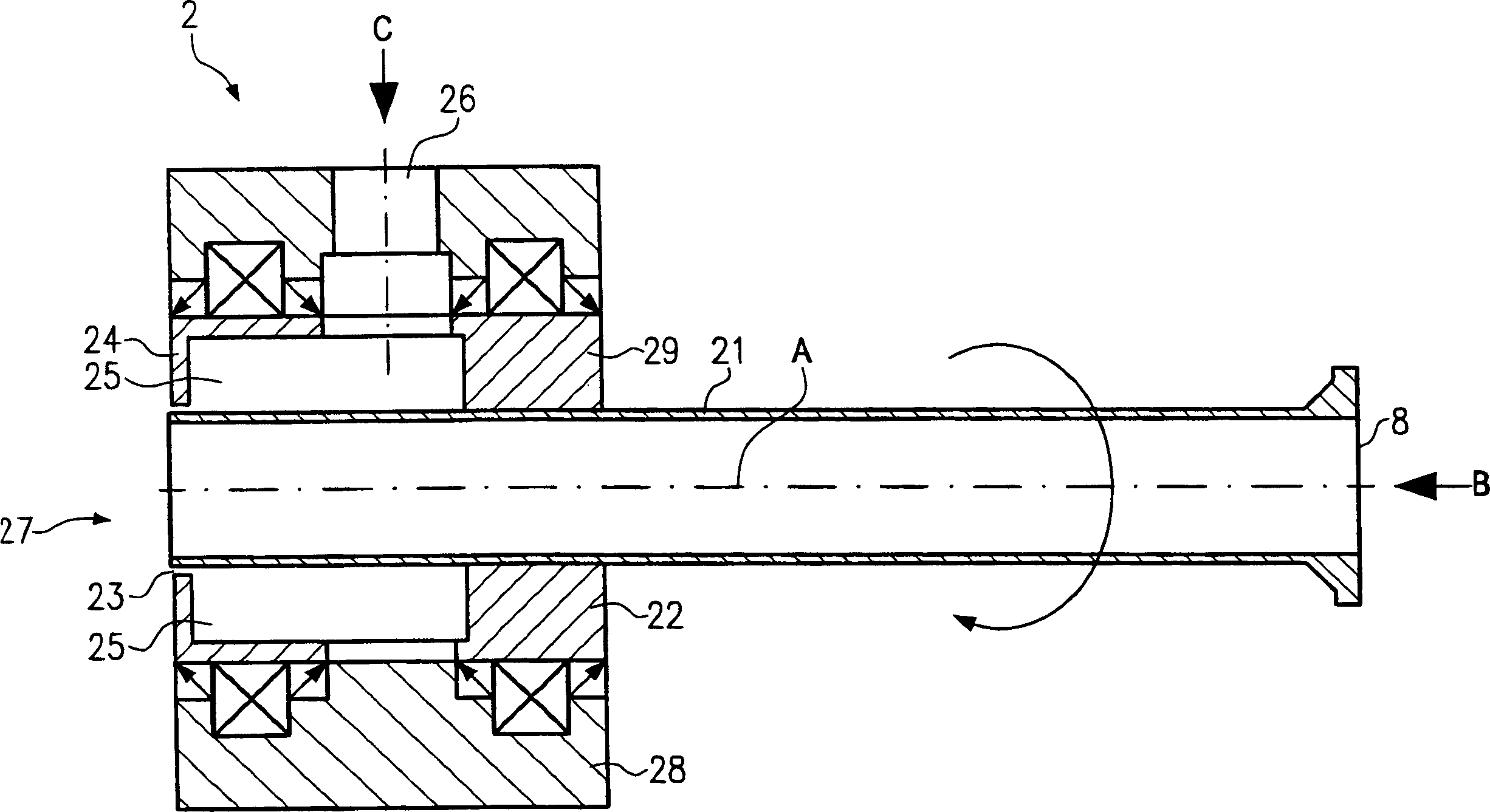

Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

InactiveCN1468540AHigh normal sclerosisIncrease distanceSausage skin tying apparatusSausage casing manufactureMechanical engineeringExtrusion

Owner:ALBERT HANDTMANN MASCHFABRICK

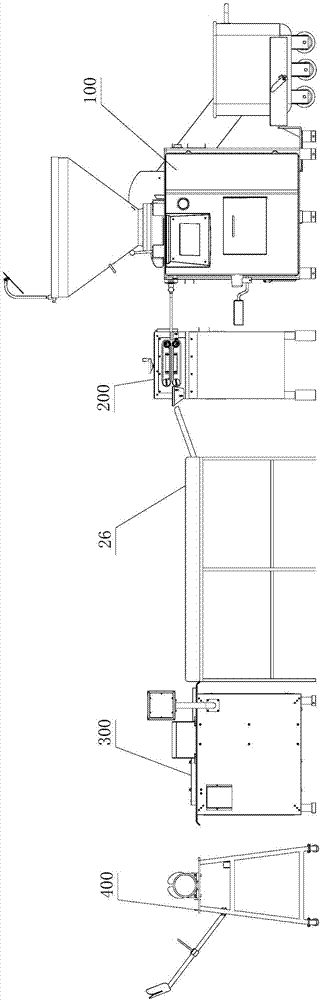

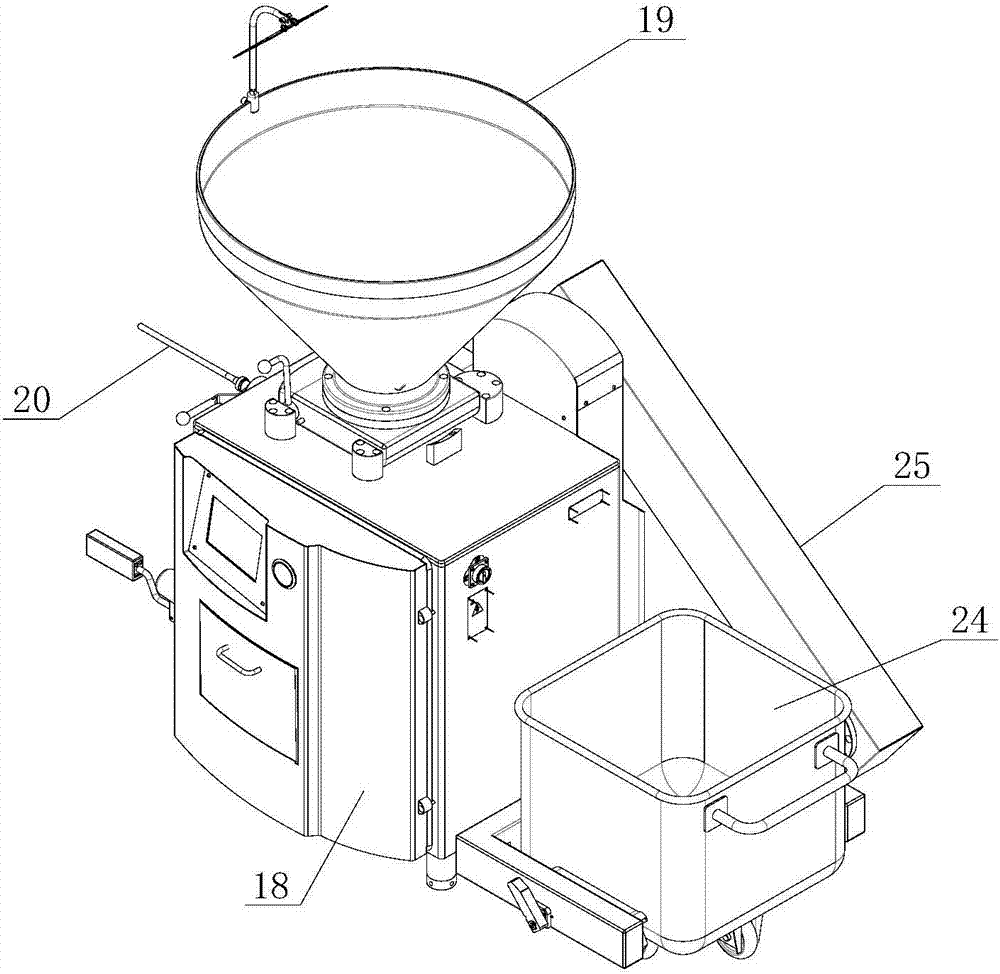

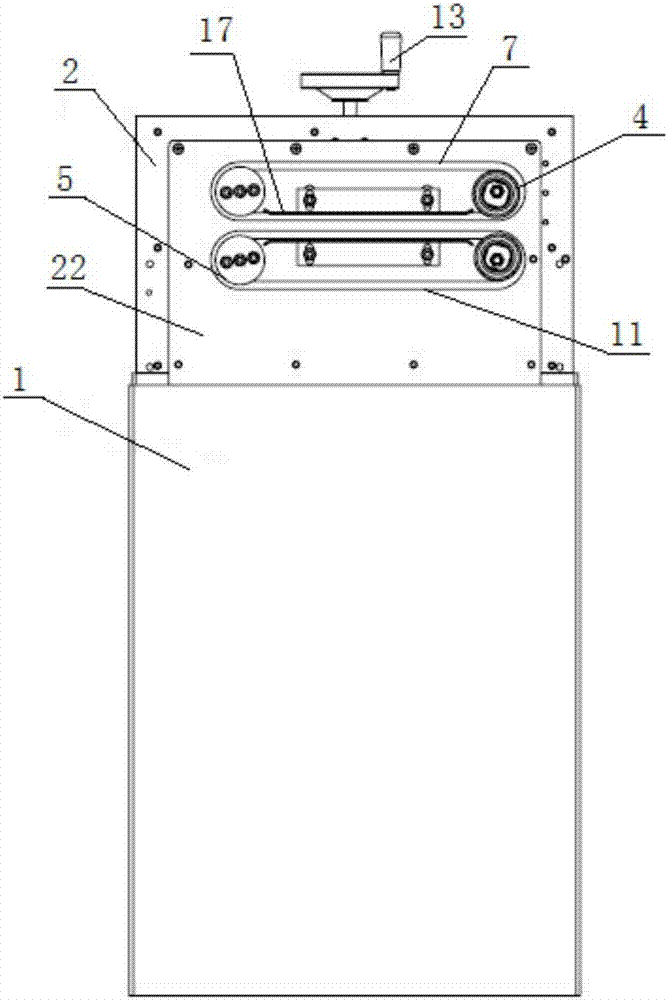

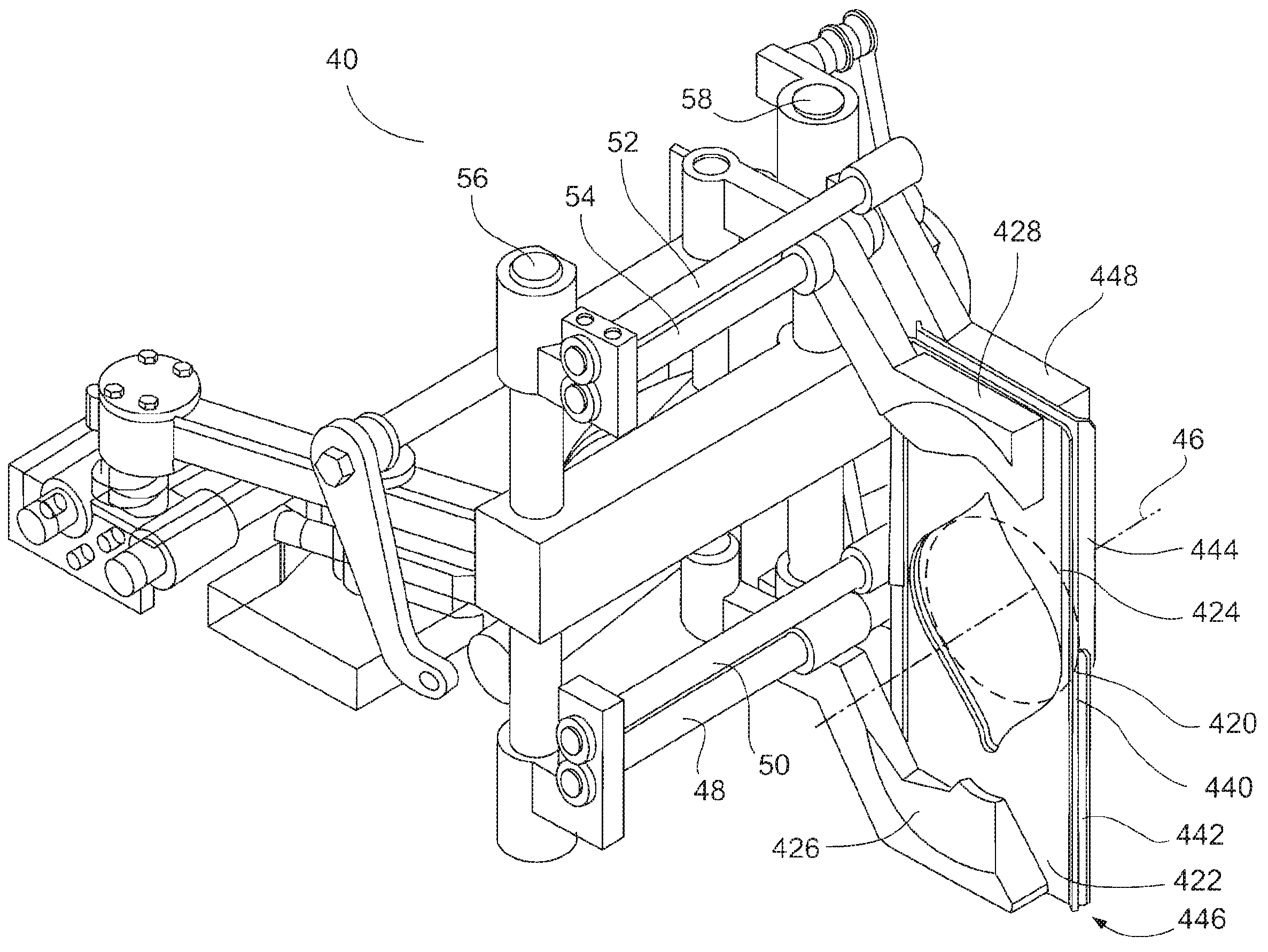

Production line for producing sausage product

ActiveCN107041413AReduce manufacturing costSmall footprintSausage skin tying apparatusSausage filling/stuffing machinesProduction lineEngineering

The invention relates to the field of sausage product processing, and discloses a production line for producing a sausage product. The production line comprises a filling device, a drawing device, a working table, a thread binding device and a thread removing device, wherein the filling device is used for automatically filling a casing; the drawing device is used for guiding and transmitting forwards the casing filled with sauce; the working table is used for temporarily storing a sausage product to be subjected to thread binding; the thread binding device is used for carrying out length determination, segmentation and thread binding on the sausage product; the thread removing device is used for removing cotton threads on segments of the fumigated or cooked sausage product subjected to thread binding; the thread binding device comprises a segment clamping mechanism for carrying out pre-constriction on the sausage product, a thread binding mechanism for winding and binding the sausage product at constricted positions by adopting the cotton threads so as to segment the sausage product, and a fixed-length drawing mechanism for drawing an initial position of the sausage product at a set drawing distance so as to enable the sausage product to be segmented at a fixed length. The integral production line for producing the sausage product, which is disclosed by the invention, is small occupied space, simple operation, convenience in maintenance, low production cost, high production efficiency, uniformness of the filled sausage product and high quality.

Owner:佛山市奥楷机械科技有限公司

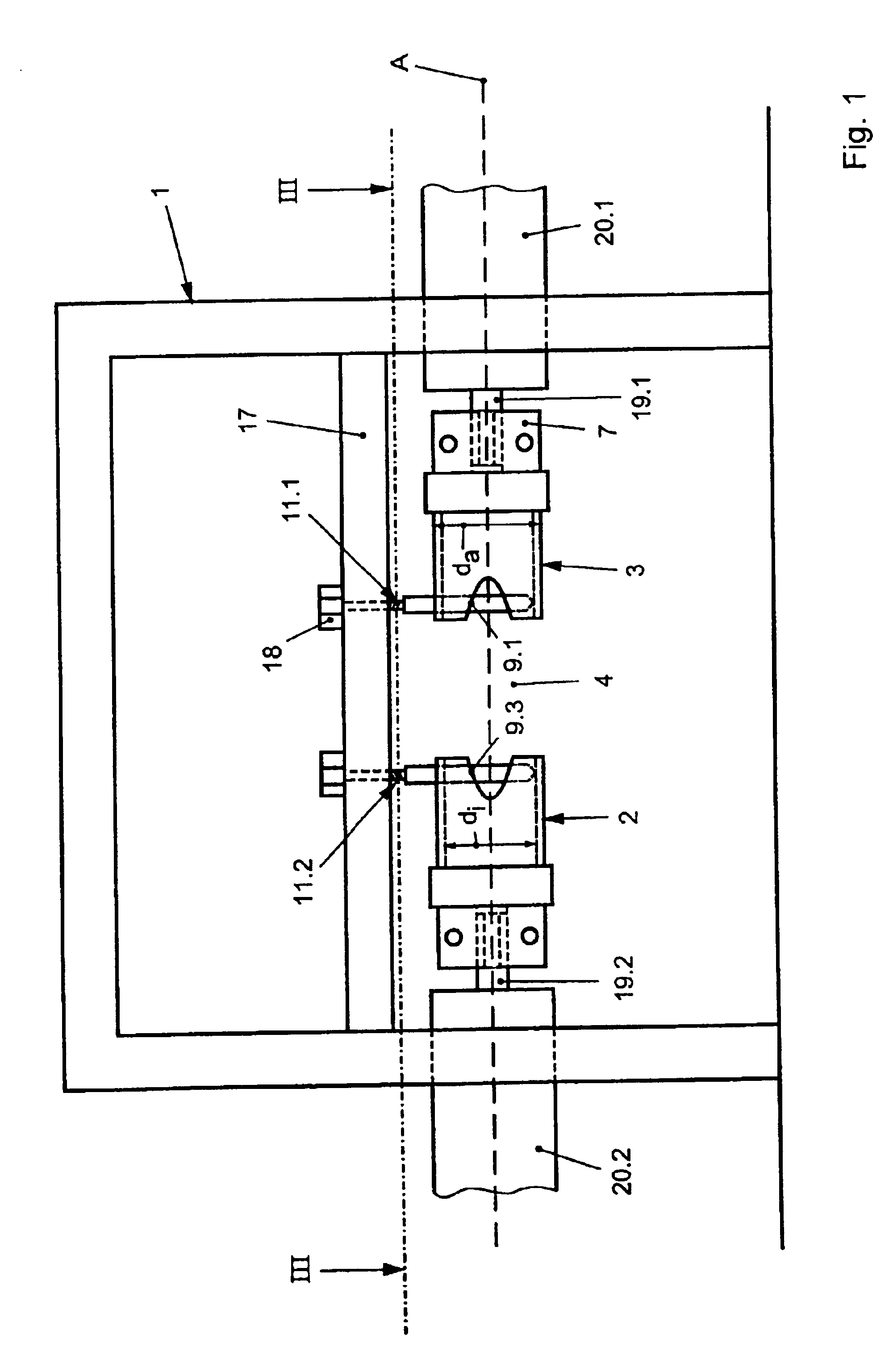

Clip machine

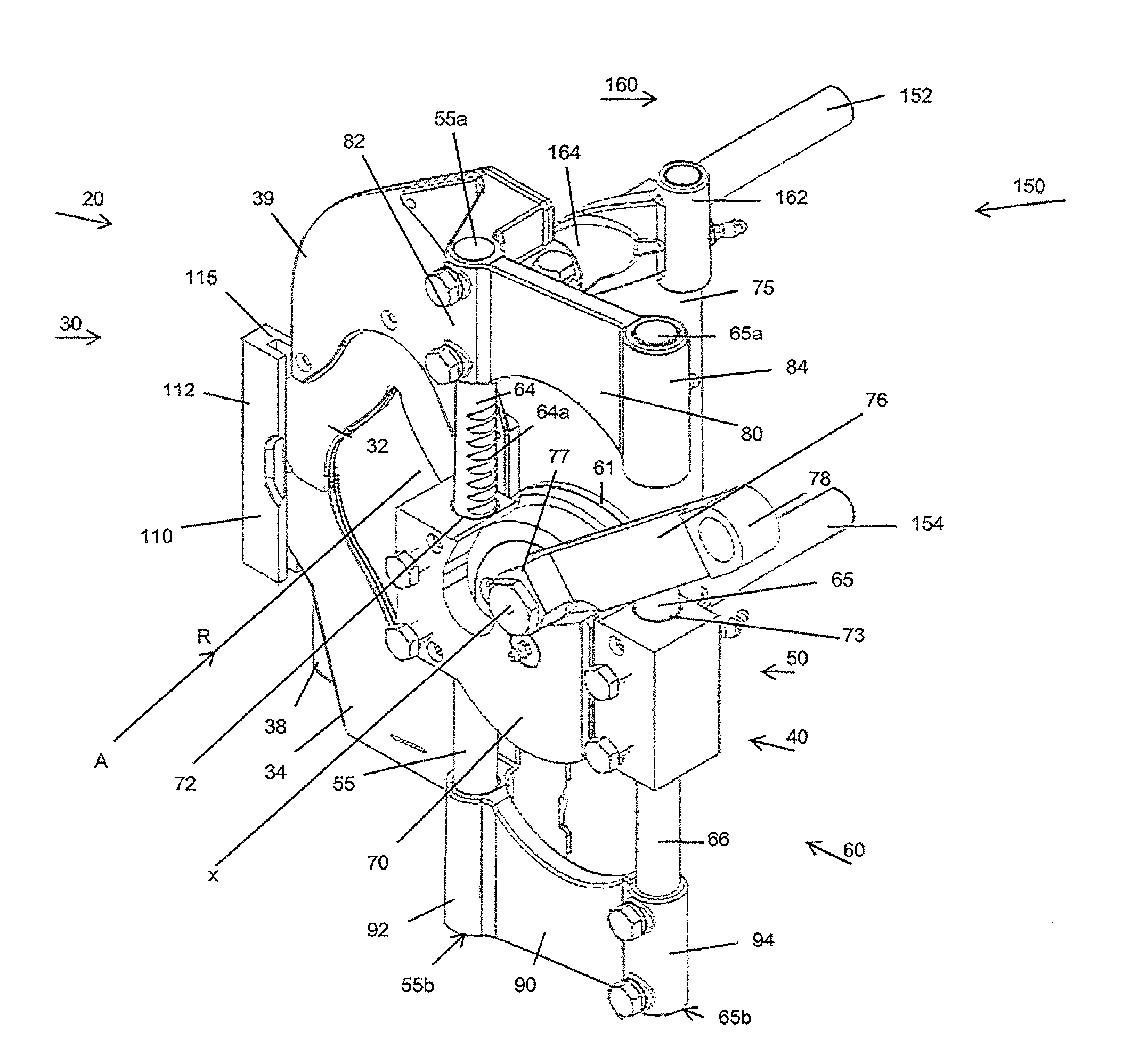

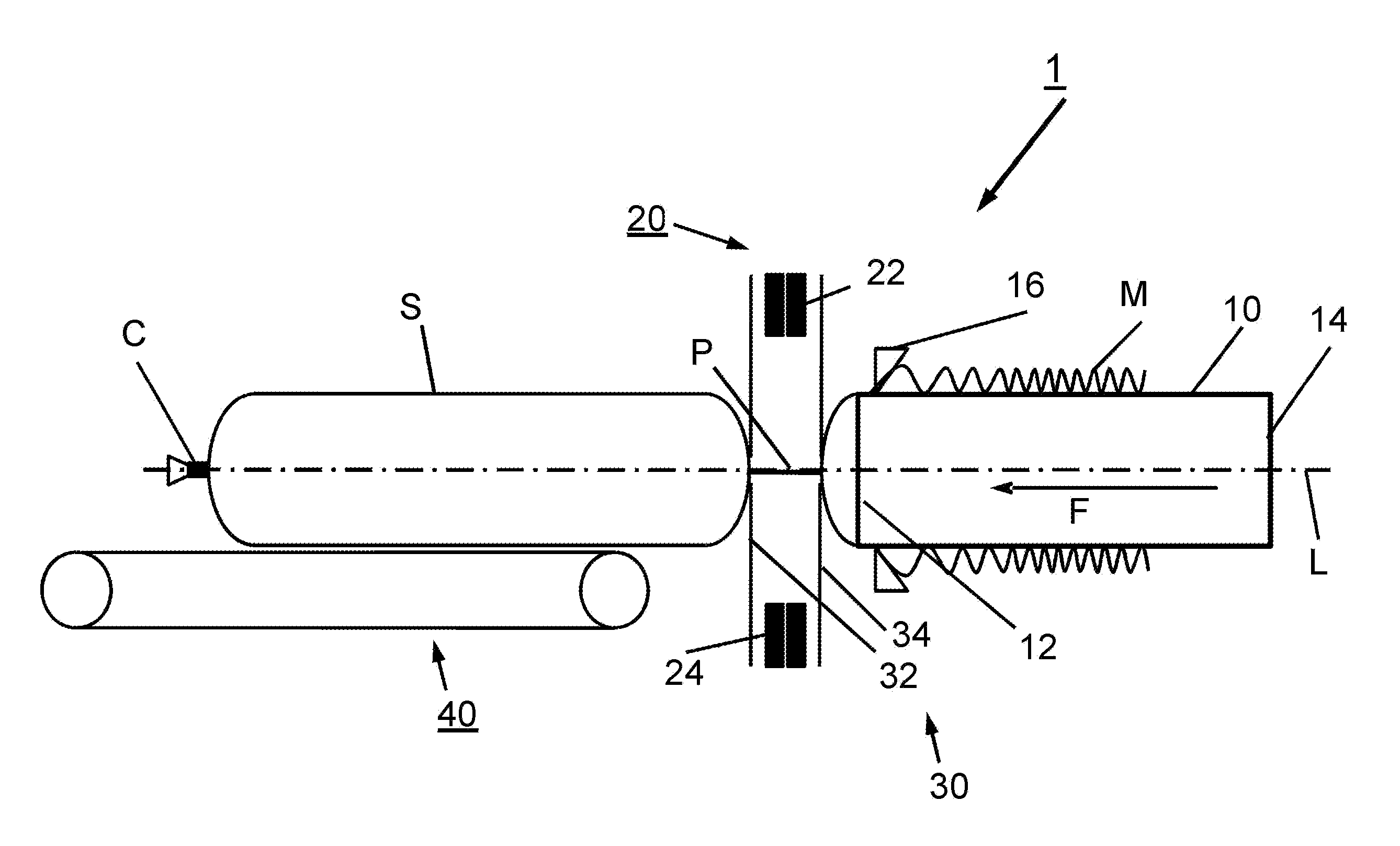

ActiveUS20080085668A1Reliable workmanshipSimple designSausage skin tying apparatusSausage filling/stuffing machinesRadial compressionEngineering

A clip machine for dividing and sealing tubular-shaped packaging filled with stuffing having at least two axially spaced pairs of radially opposed displacement elements, relating to the axis of the packaging tube, which are linked to and equipped with a linear guide, to be compressed radially towards one another and then separated axially in pairs, for the local constriction of the filled packaging and the formation of a tubular braid radially-linearly, and a pivotably arranged first sealing tool and a second sealing tool, with the first and second sealing tools being equipped to set and close at least one clamp fastener around the formed tubular braid, to be compressed radially between the axially separated displacement element pairs, the radial movement direction of displacement element pairs coincides with the radial movement direction of sealing tools.

Owner:POLY CLIP SYST

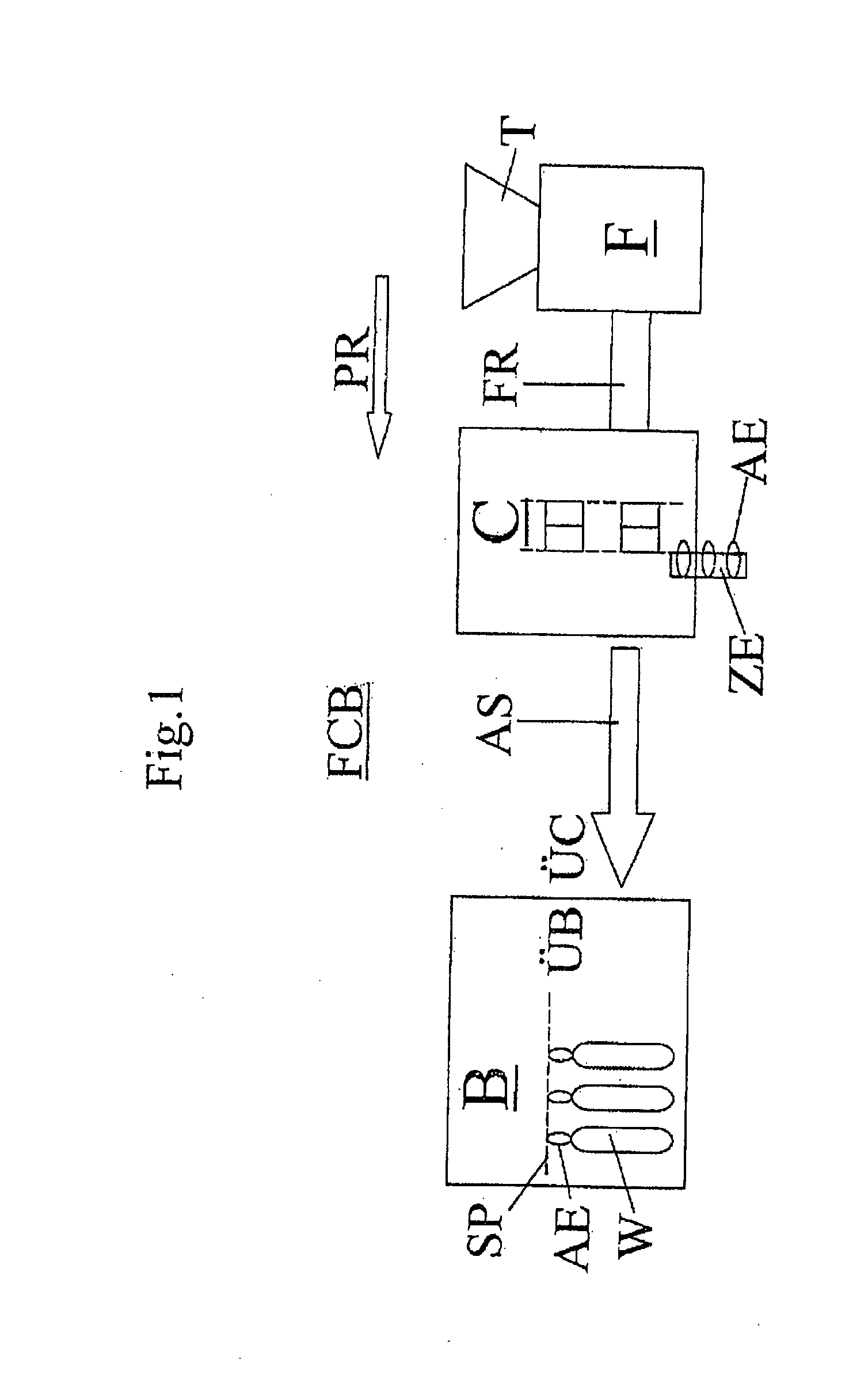

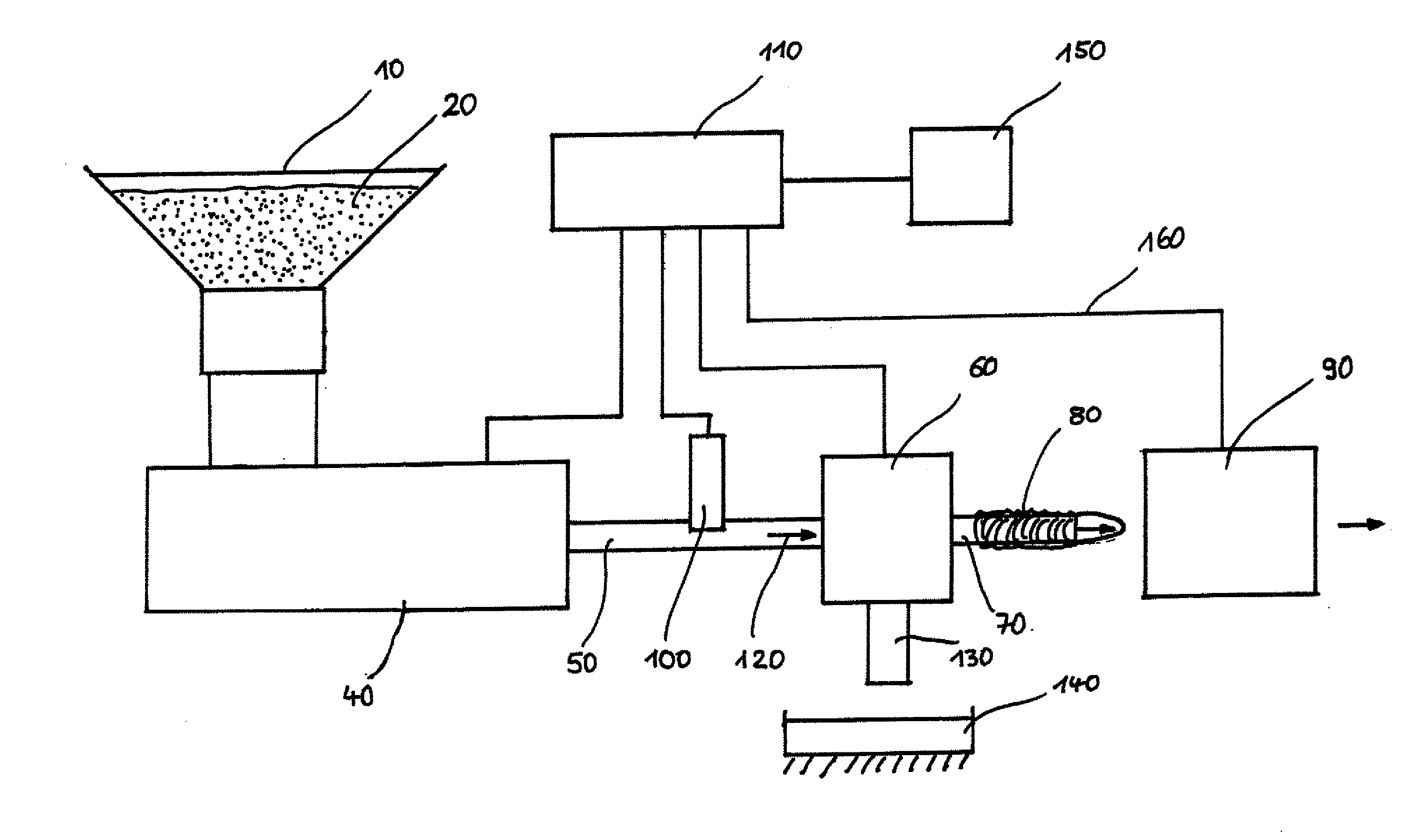

Production Line for the Manufacture of Sausage-Shaped Products

InactiveUS20080064313A1Continuous loadingMeat/sausage hanging-upConveyorsProduction lineManufacturing engineering

A method for controlling a production line for manufacturing sausage-shaped products, a production line provided for this as well as a clip machine and a feeding machine for the manufacture of sausage-shaped products, with a flowable filling material such as sausage meat, a sealing material, granulate and the like being received in a tubular wrapper material and with the production line having at least: a clip machine, in which the wrapper material filled with filling material is divided into portions into individual sausage-shaped products by placing closing clips and is separated from the supply of the remaining wrapper material; with at least one flexible suspension element being applied to the sausage-shaped product during the placing of the closing clips, which is fed in a timed manner into the clip machine; and a feeding machine, which supplies the storage rods individually for further processing of the sausage-shaped products and which has conveyor elements, circulating continuously along a transport path, which is used to supply the storage rods with sausage-shaped products and which takes the sausage-shaped products proceeding out of the clip machine into a takeover area provided between the clip machine, and the feeding machine. In addition, at least the circulation rate of the conveyor elements of the feeding machine.

Owner:POLY CLIP SYST

Clip machine

ActiveUS7654889B2Reliable workmanshipSimple designSausage skin tying apparatusSausage filling/stuffing machinesRadial compressionPackaging Tube

A clip machine for dividing and sealing tubular-shaped packaging filled with stuffing having at least two axially spaced pairs of radially opposed displacement elements, relating to the axis of the packaging tube, which are linked to and equipped with a linear guide, to be compressed radially towards one another and then separated axially in pairs, for the local constriction of the filled packaging and the formation of a tubular braid radially-linearly, and a pivotably arranged first sealing tool and a second sealing tool, with the first and second sealing tools being equipped to set and close at least one clamp fastener around the formed tubular braid, to be compressed radially between the axially separated displacement element pairs, the radial movement direction of displacement element pairs coincides with the radial movement direction of sealing tools.

Owner:POLY CLIP SYST

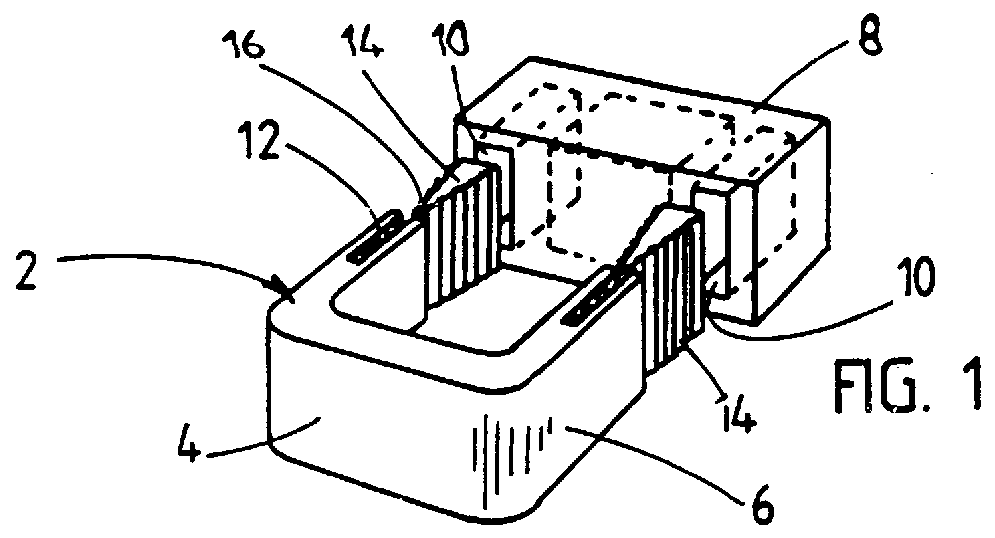

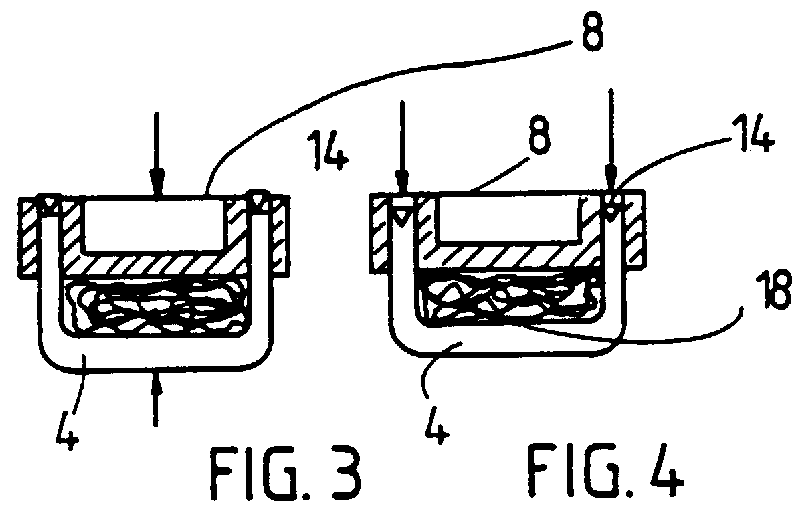

Closing device for flexible tubular packaging

InactiveUS6846235B2Reduce consumptionLittle wearSausage skin tying apparatusPackagingEngineeringMechanical engineering

Owner:POLY CLIP SYST

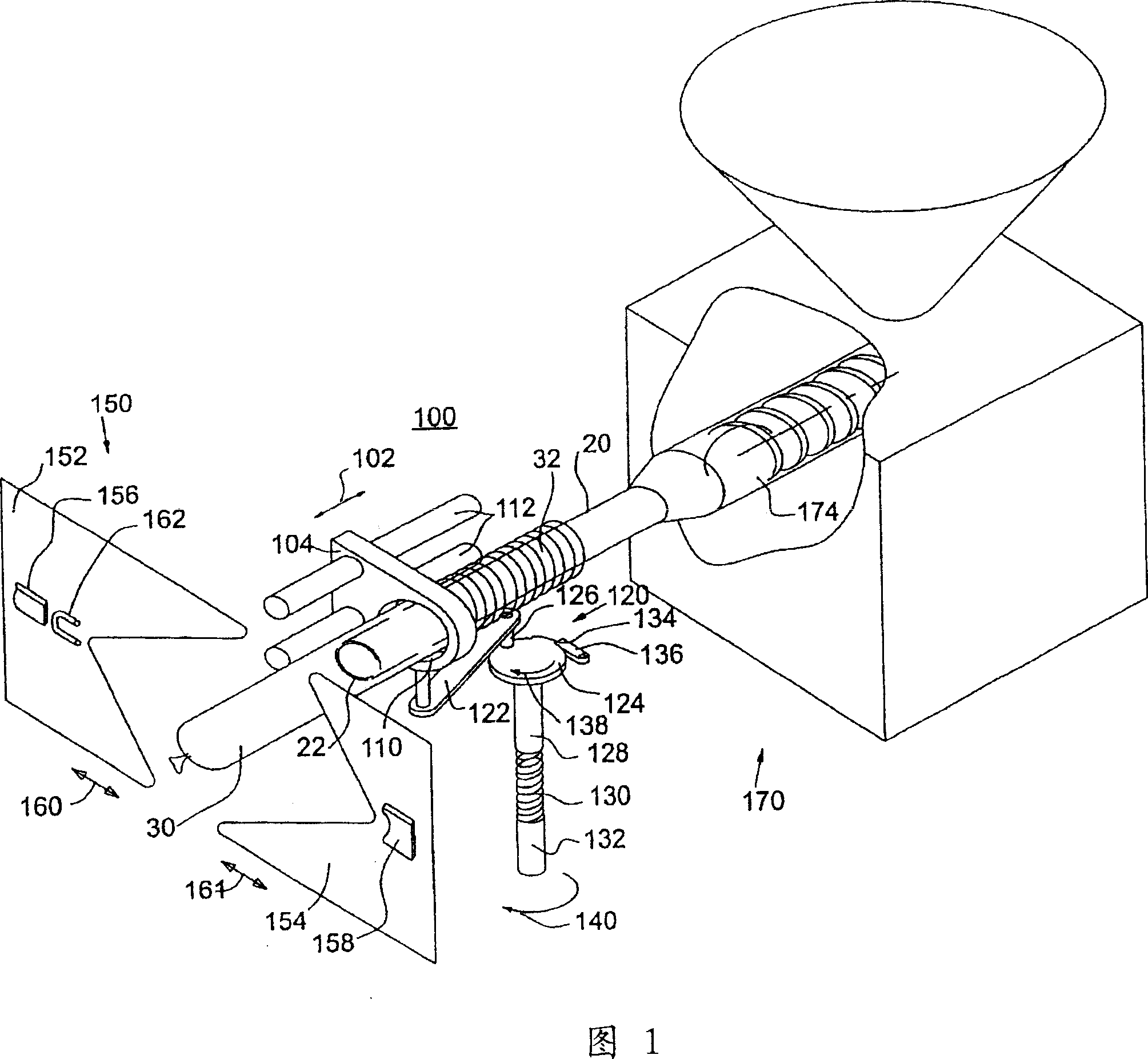

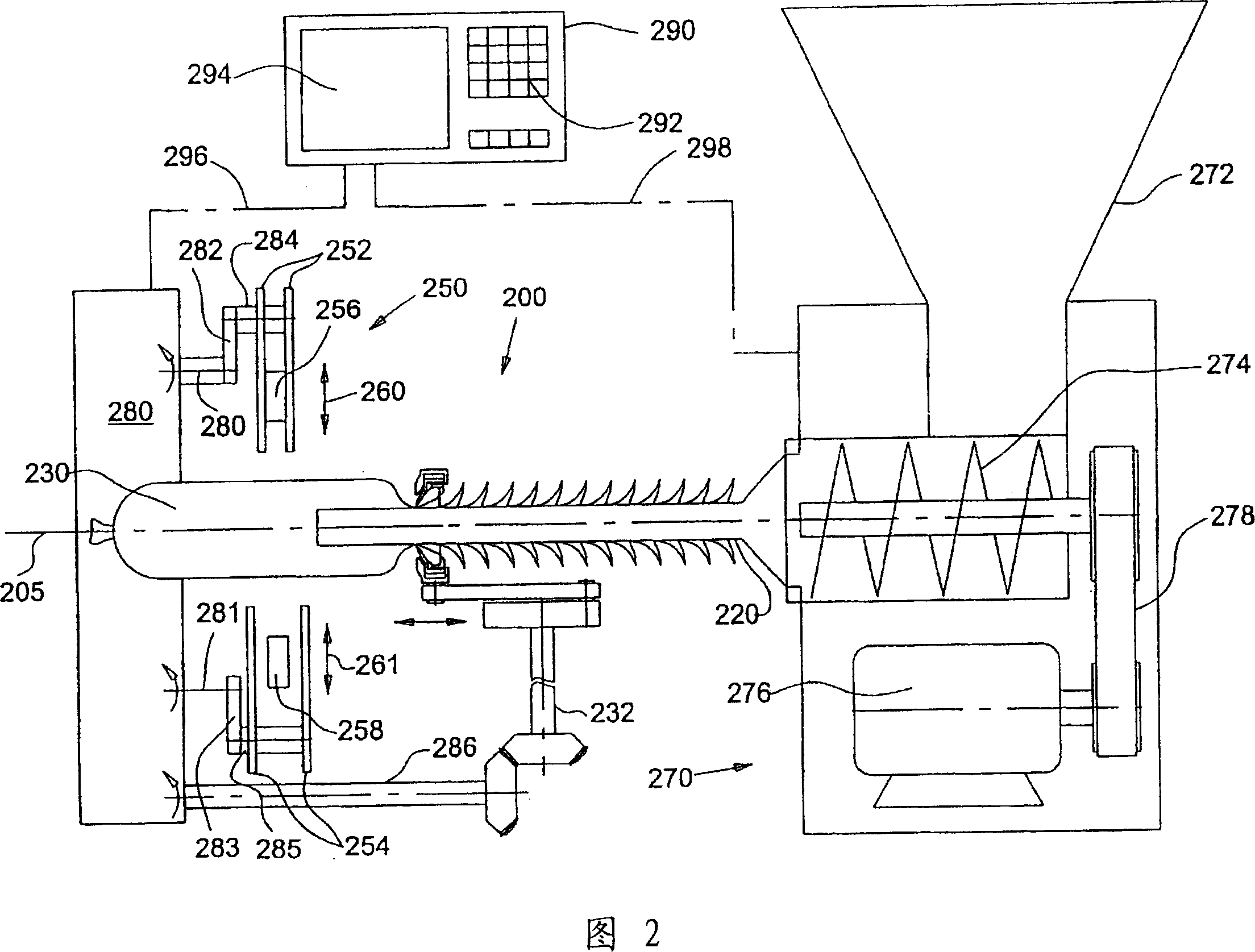

Device and method for portioning and packaging

InactiveCN1934961ASimplified actuationAllows for increased efficiencySausage skin tying apparatusSausage filling/stuffing machinesPortion sizeFilling materials

Portioning and packaging device comprises a conveying device (170, 270) for filling material that has a pump for generating a continuous volume and is connected to a filling pipe (20, 220) supplying a reservoir of a tube-shaped packing sleeve (30, 230) so that this can be removed with filling material from the filling tube, and a sealing device (150, 250) that ties the end of the filled tube and seals it with a sealing element(162). The sealing device has a control device (290) that generates a control signal during the tying and sealing step based on a selected portion size and the continuous volume flow and sends it to a drive of the sealing device. An independent claim is also included for a portioning and packaging process.

Owner:POLY CLIP SYST

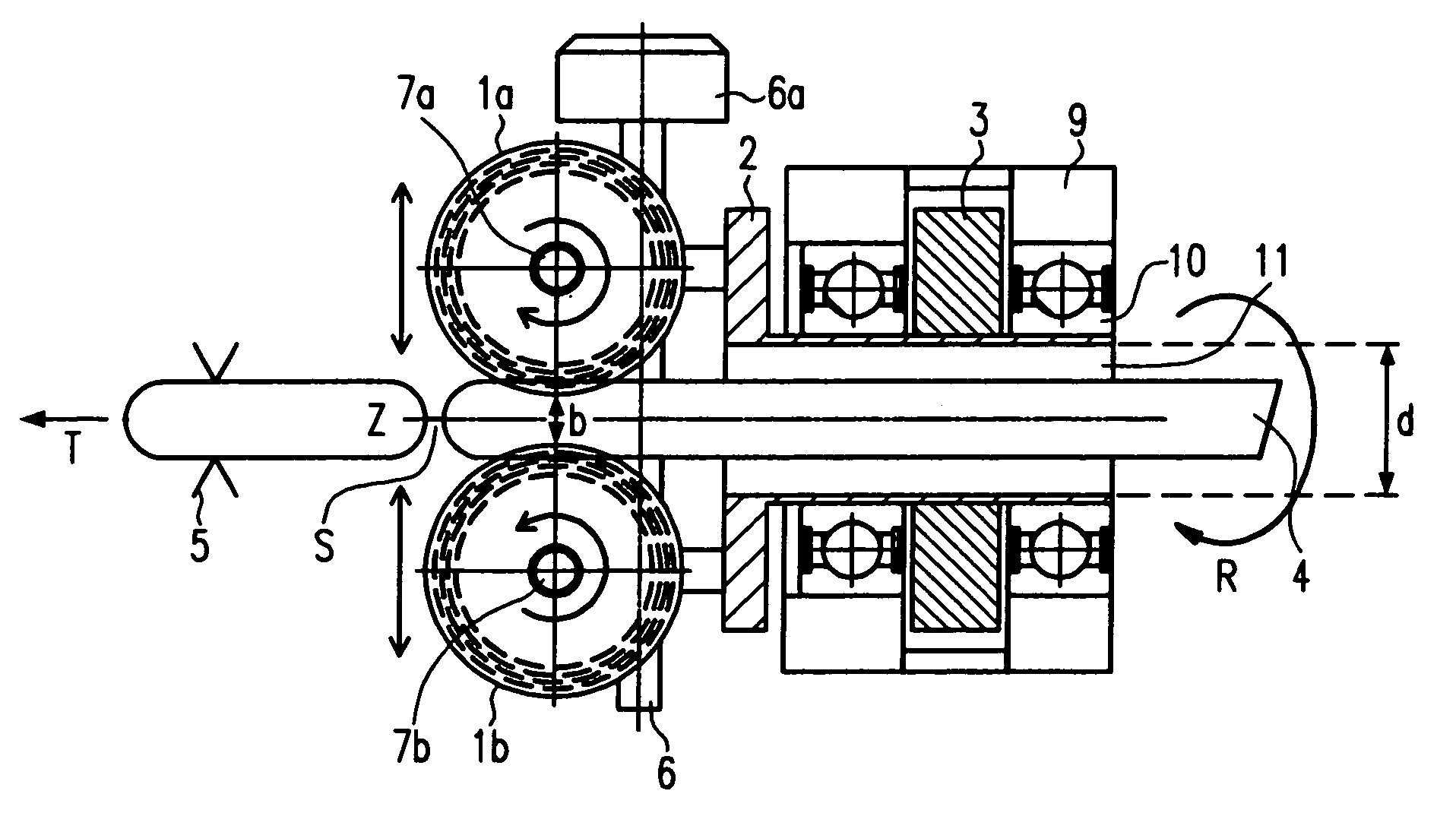

Apparatus and method for dividing a sausage strand

InactiveUS7140958B2Easy to modifyEasy to transformSausage skin tying apparatusSausage filling/stuffing machinesFirst FillEngineering

An apparatus for dividing a sausage strand includes at least two opposite spaced-apart guide elements having a distance which can be adapted to a sausage caliber such that the filled sausage strand can be moved between and through the guide elements in the transportation direction along a first axis and rotated by the guide elements about the first axis, and a means for jointly rotating the guide elements about the first axis. The sausage strand is first filled with a filling tube of a filling unit, and then guided in the transportation direction through the at least two opposite spaced-apart guide elements whose distance can be adapted to the sausage caliber, and the guide elements are rotated about a first axis extending along the transportation direction, wherein the filled sausage strand is also rotated about the first axis, the filled sausage strand being simultaneously supported at a place in the transportation direction behind the guide elements.

Owner:ALBERT HANDTMANN MASCHFABRICK

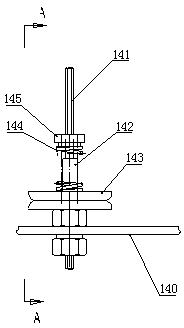

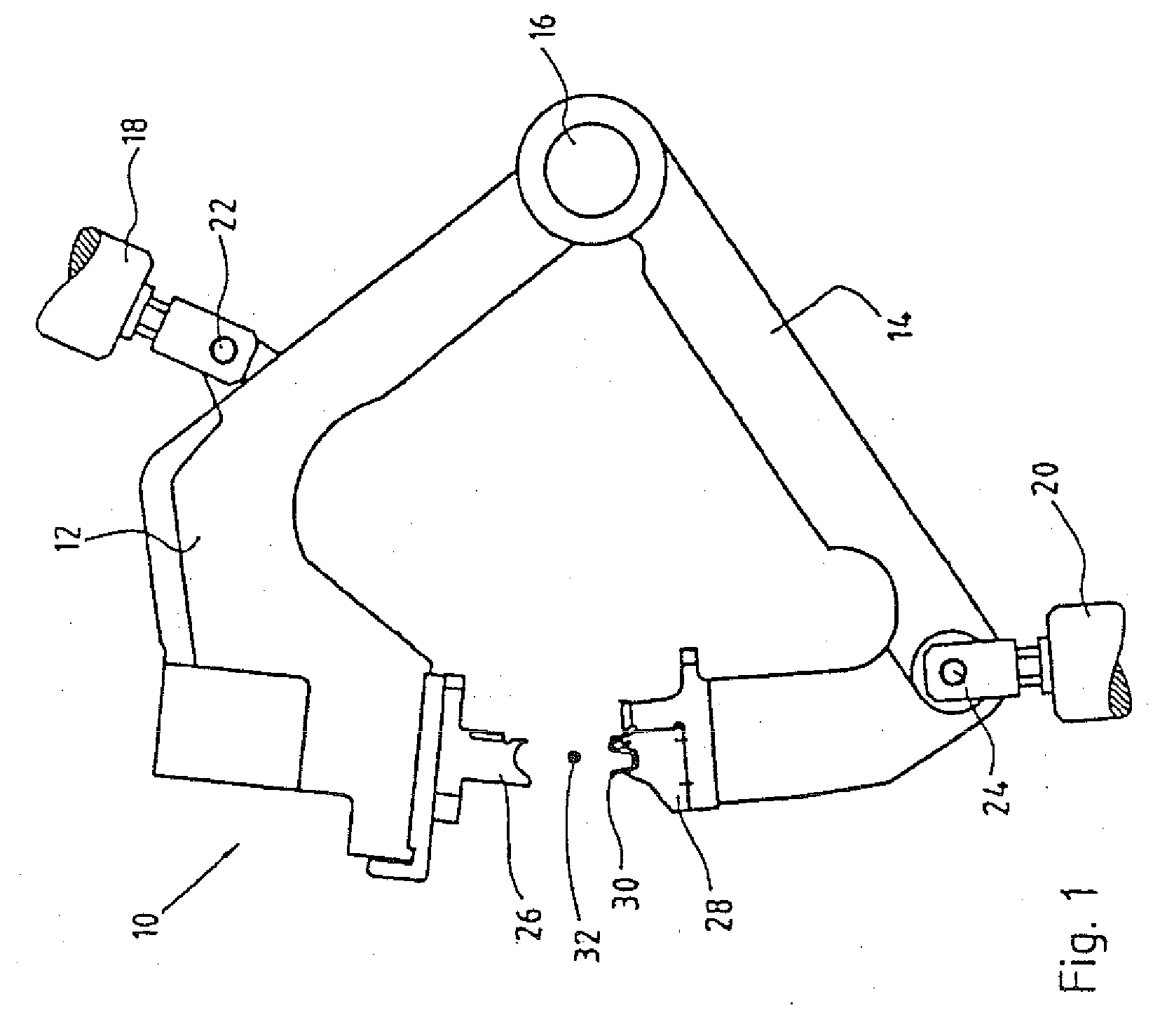

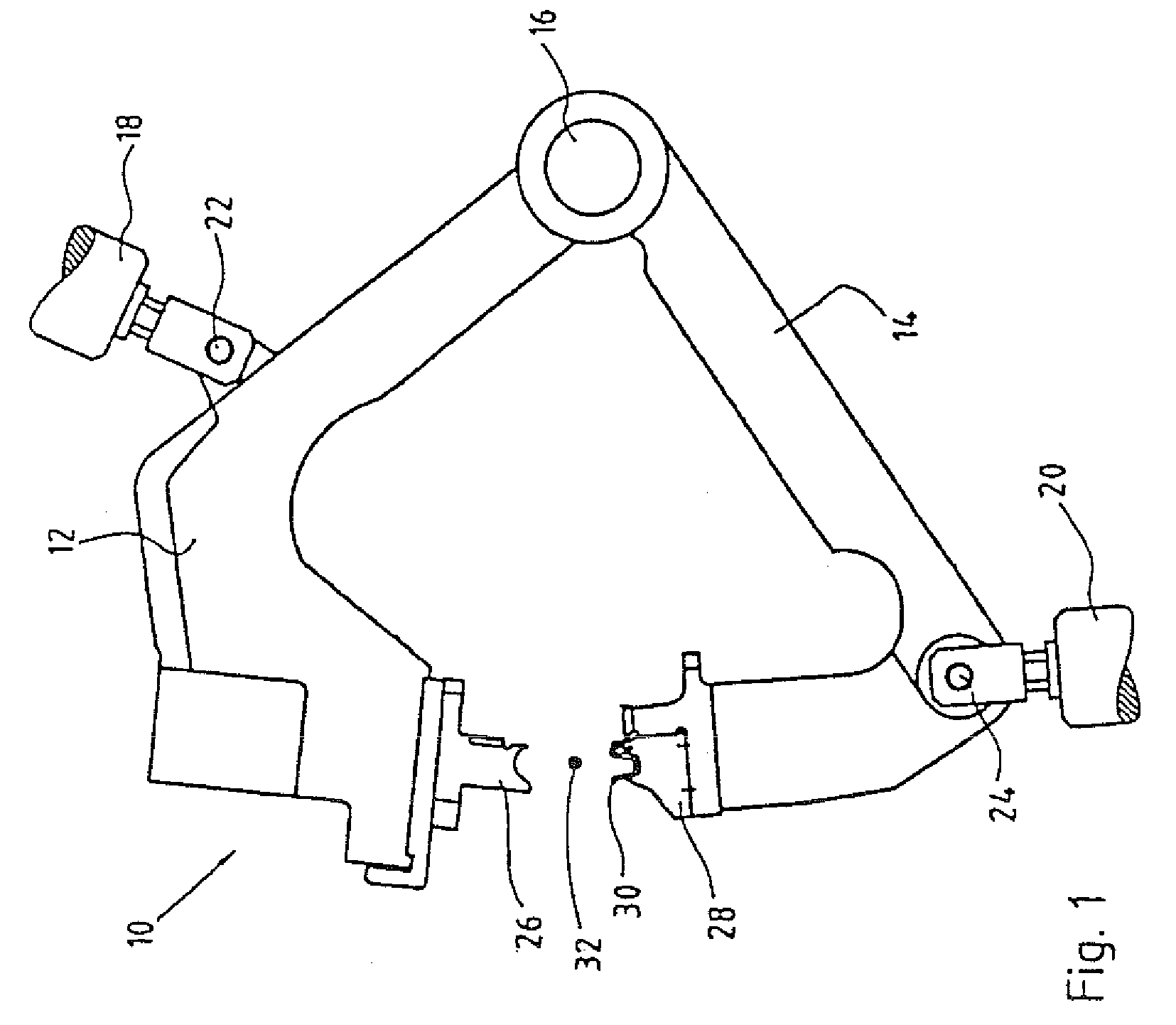

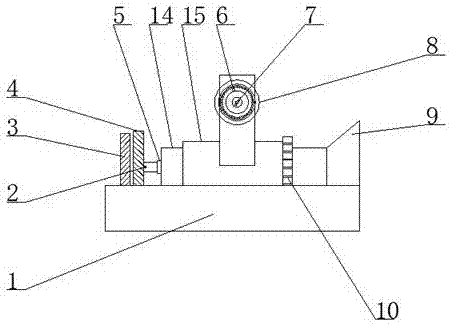

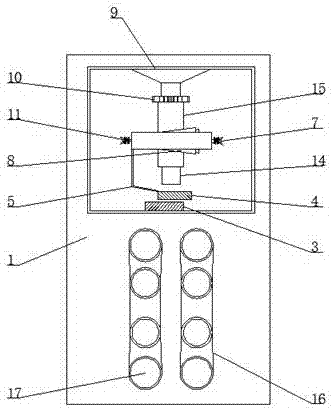

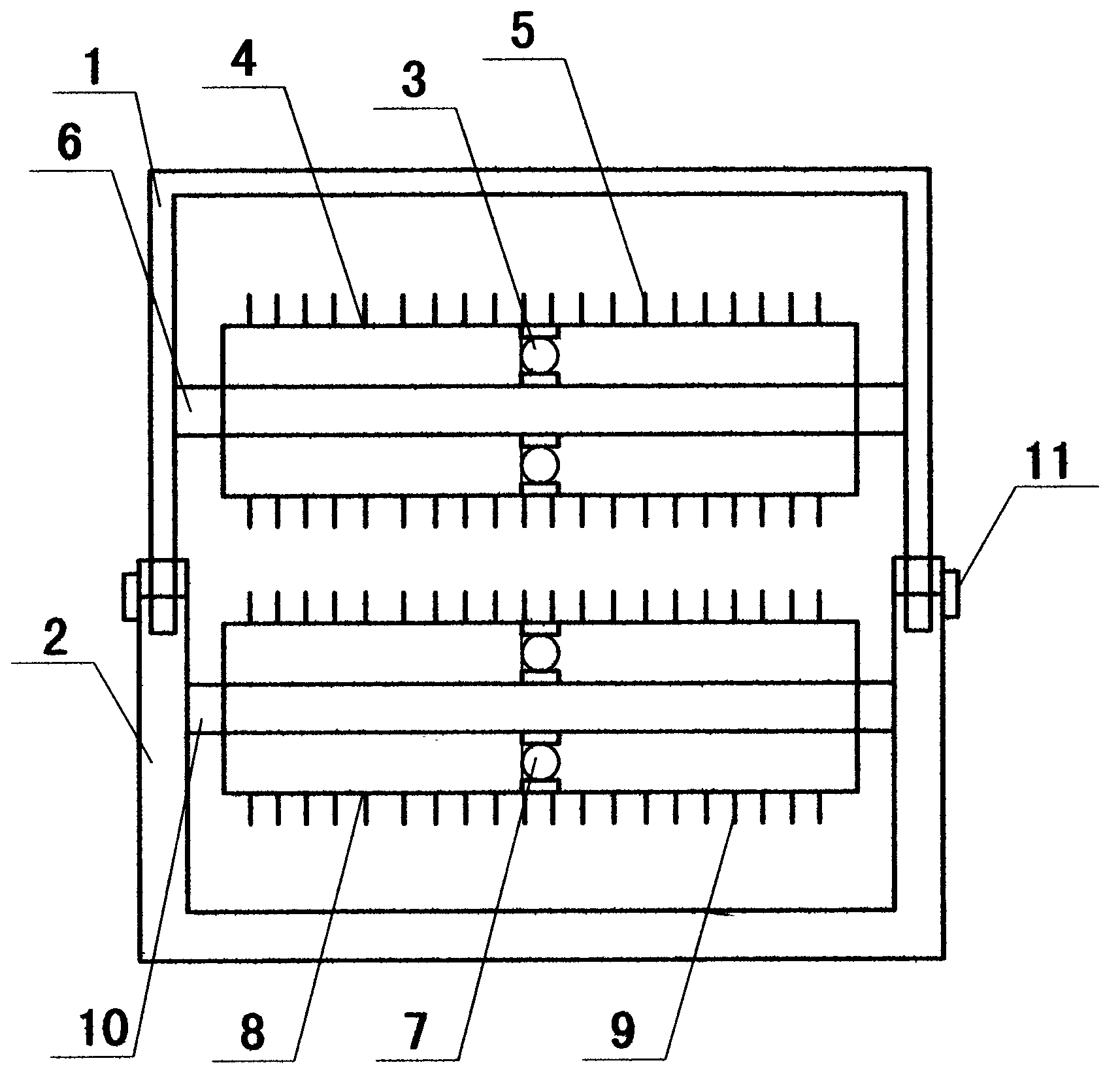

Sectional ham sausage binding device

ActiveCN104186629AFast and efficient production processEasy to useSausage skin tying apparatusBiochemical engineeringPortal frame

The invention provides a sectional ham sausage binding device which comprises a base and a bracket on the base, wherein the bracket forms a portal frame by encircling a left vertical upright rod, a right vertical upright rod and a top transverse beam. The sectional ham sausage binding device is characterized in that a pressing and binding mechanism is arranged on the bracket; an extrusion mechanism is arranged at a position, which is positioned below the pressing and binding mechanism, on the base; and one side or each of two sides of the extrusion mechanism is provided with a binding nail conveying mechanism. According to the sectional ham sausage binding device provided by the invention, ham sausages can be conveniently arranged in through holes or straight slots in the middles of front and rear fixing plates of the extrusion mechanism and are extruded in a sectional mode through the extrusion mechanism, binding nails are conveyed to the sectional extrusion positions through the binding nail conveying mechanisms, and binding of the ham sausages at the sectional extrusion positions is synchronously finished by the pressing and binding mechanism, so that the whole ham sausage manufacturing process is rapid and high-efficiency. In addition, the sectional ham sausage binding device is simple in structure and convenient to use, can realize mechanical operation without excessive investment and is convenient for later repair and maintenance.

Owner:日照鑫博机械设备有限公司

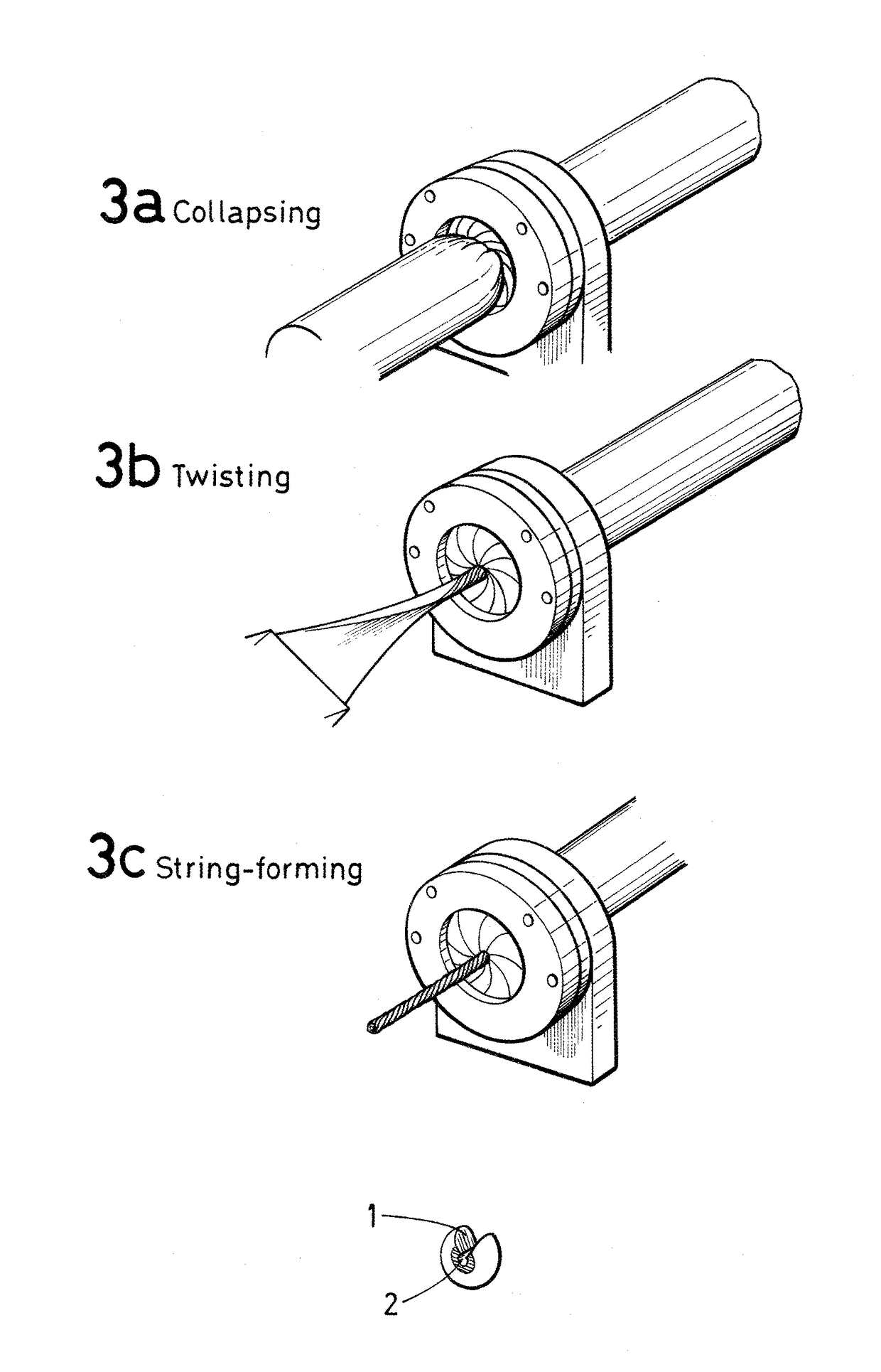

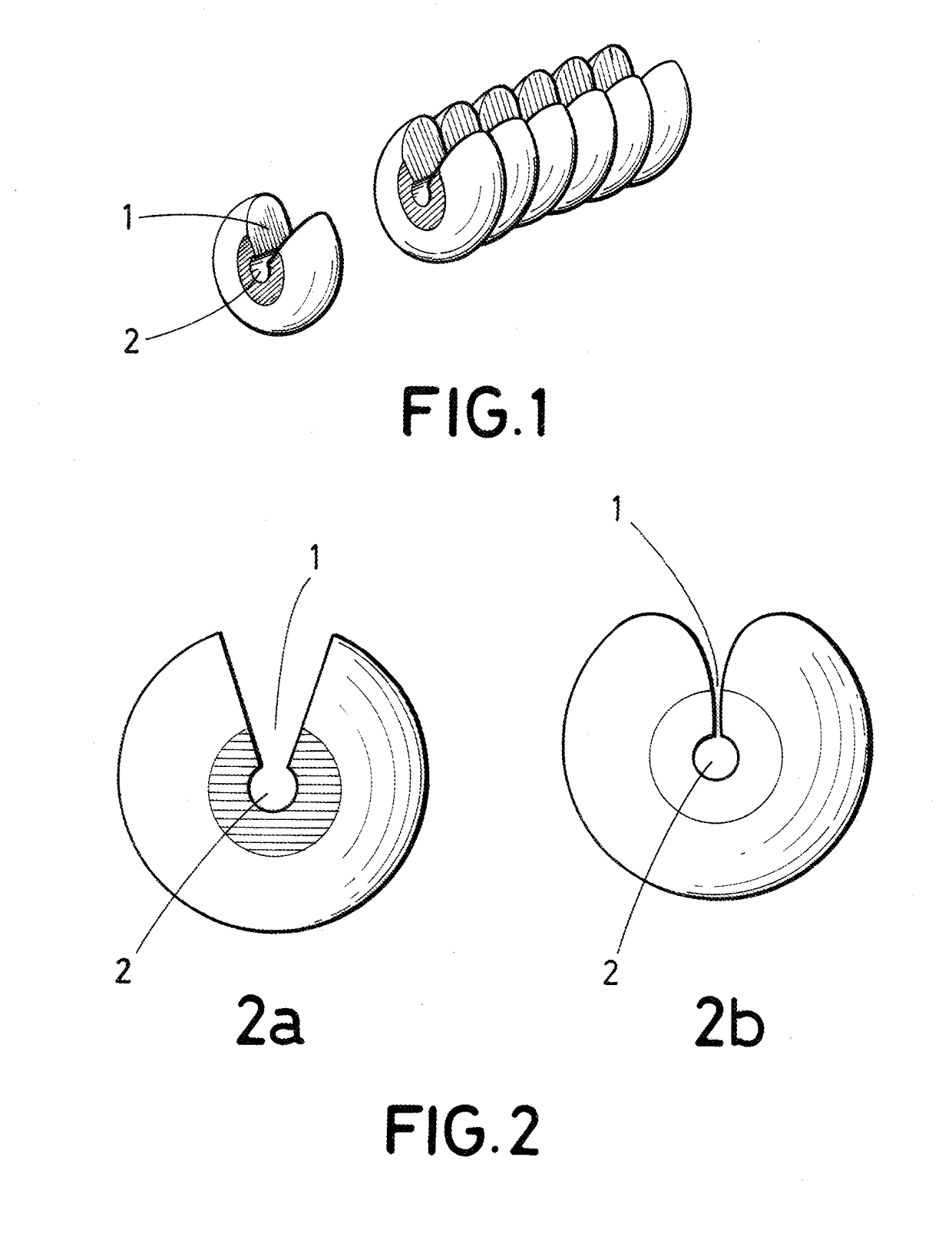

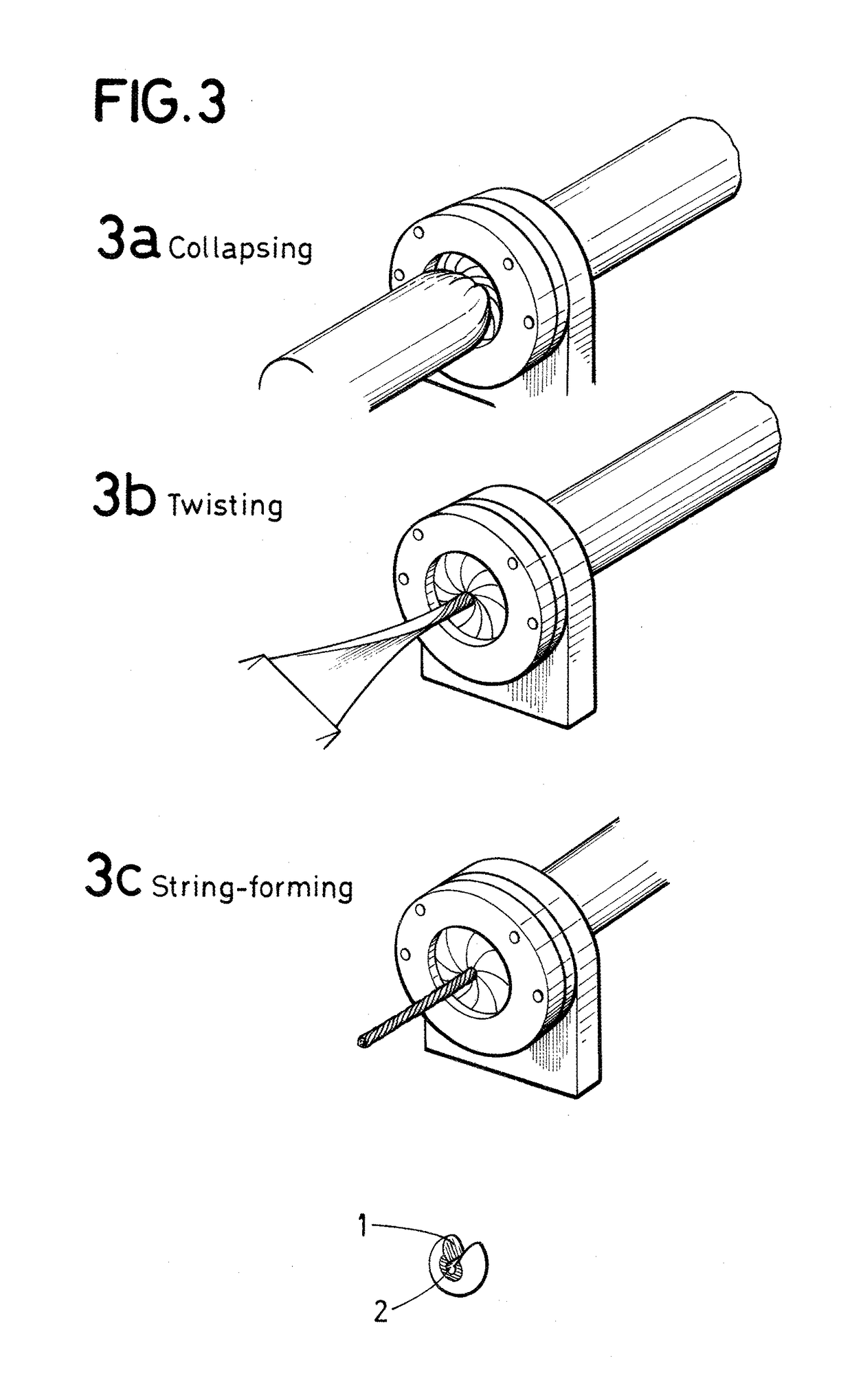

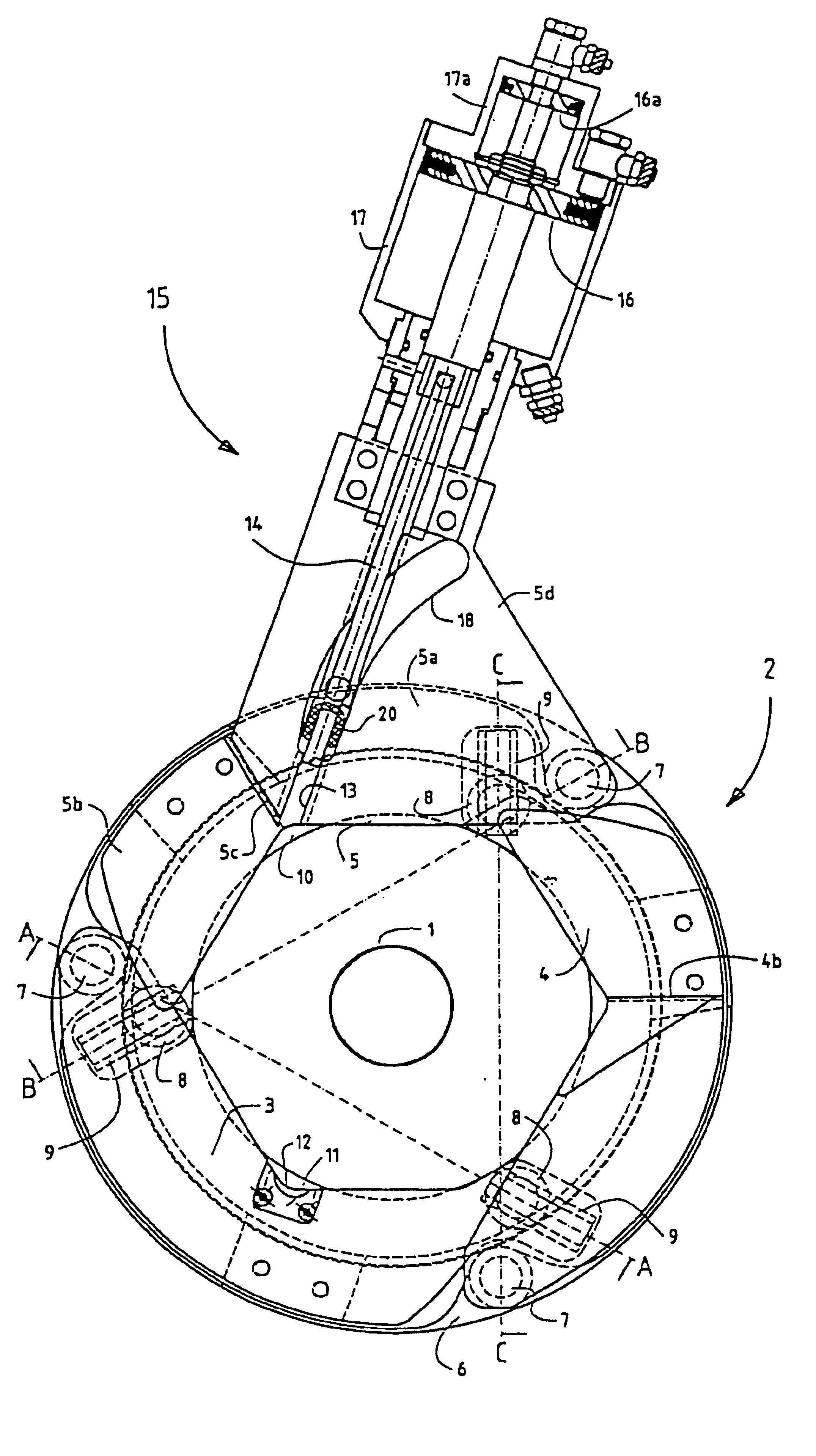

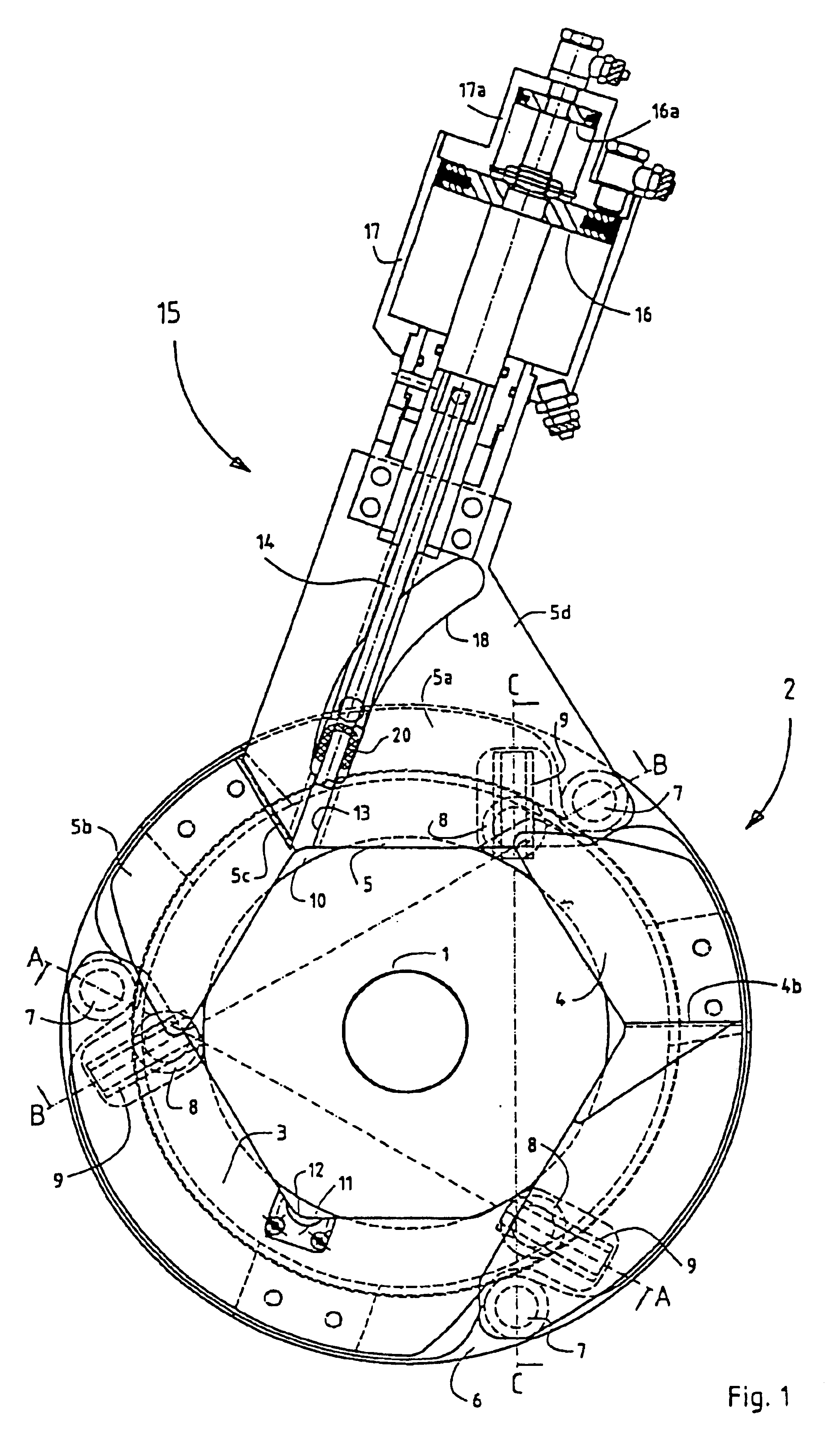

Method for phased separation of a sausage strand, separating element and assembly of separating elements

ActiveUS7625266B2Sufficient separating capacitySimple and inexpensive drivingLinked sausage separationSausage skin tying apparatusEngineeringControl manner

A method for phased separation of a sausage strand, a separating element for phased separation of a sausage strand, and an assembly of a plurality of such separating elements. In the production of sausages it frequently occurs that a sausage strand must be divided into smaller segments, and the result of this division is achieved in controlled manner by the present invention.

Owner:STORK TOWNSEND BV

Apparatus for severing the link between two sausages

InactiveUS6932689B2Improve guidanceLinked sausage separationSausage skin tying apparatusEngineeringMechanical engineering

In an apparatus for severing a link between two sausages, in particular for cutting out a clip at a twisting point by means of a cutting device which has a cutting edge, comprises at least two cutting edges lying opposite one another and movable toward one another when the twisting point is located between them.

Owner:STIMPFL & GIESELER SONDERMASCHEN F LEBENSMITTELIND

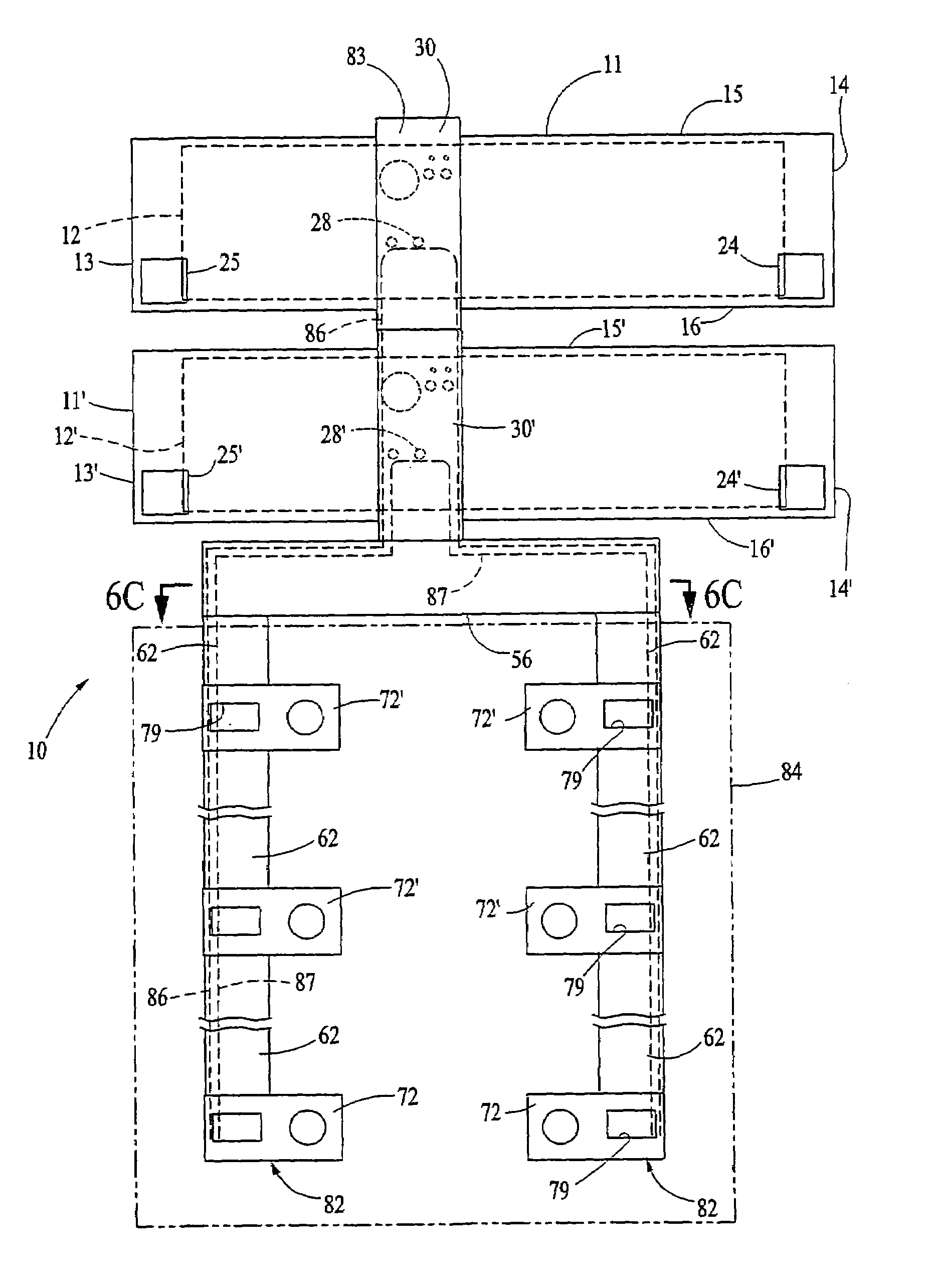

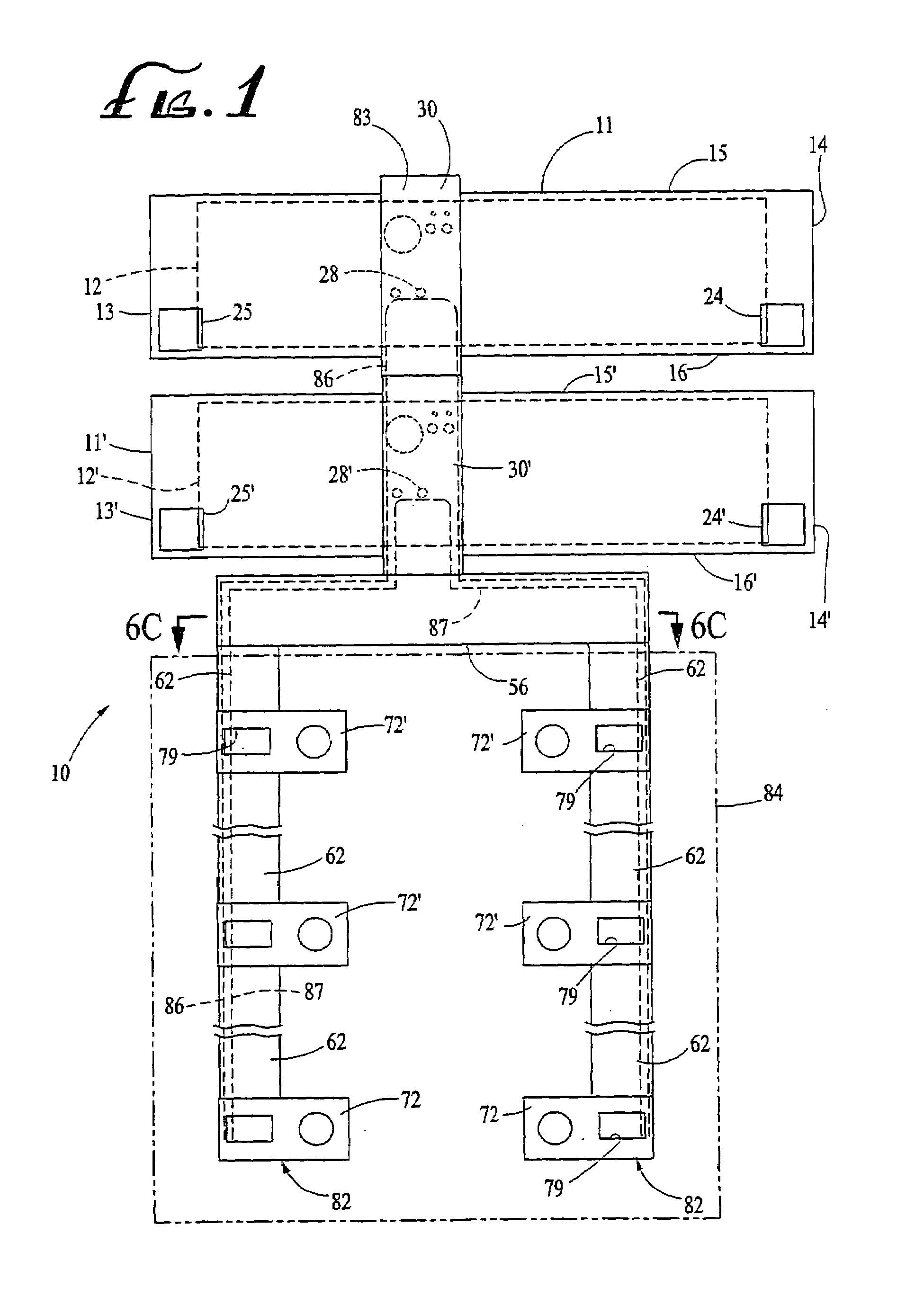

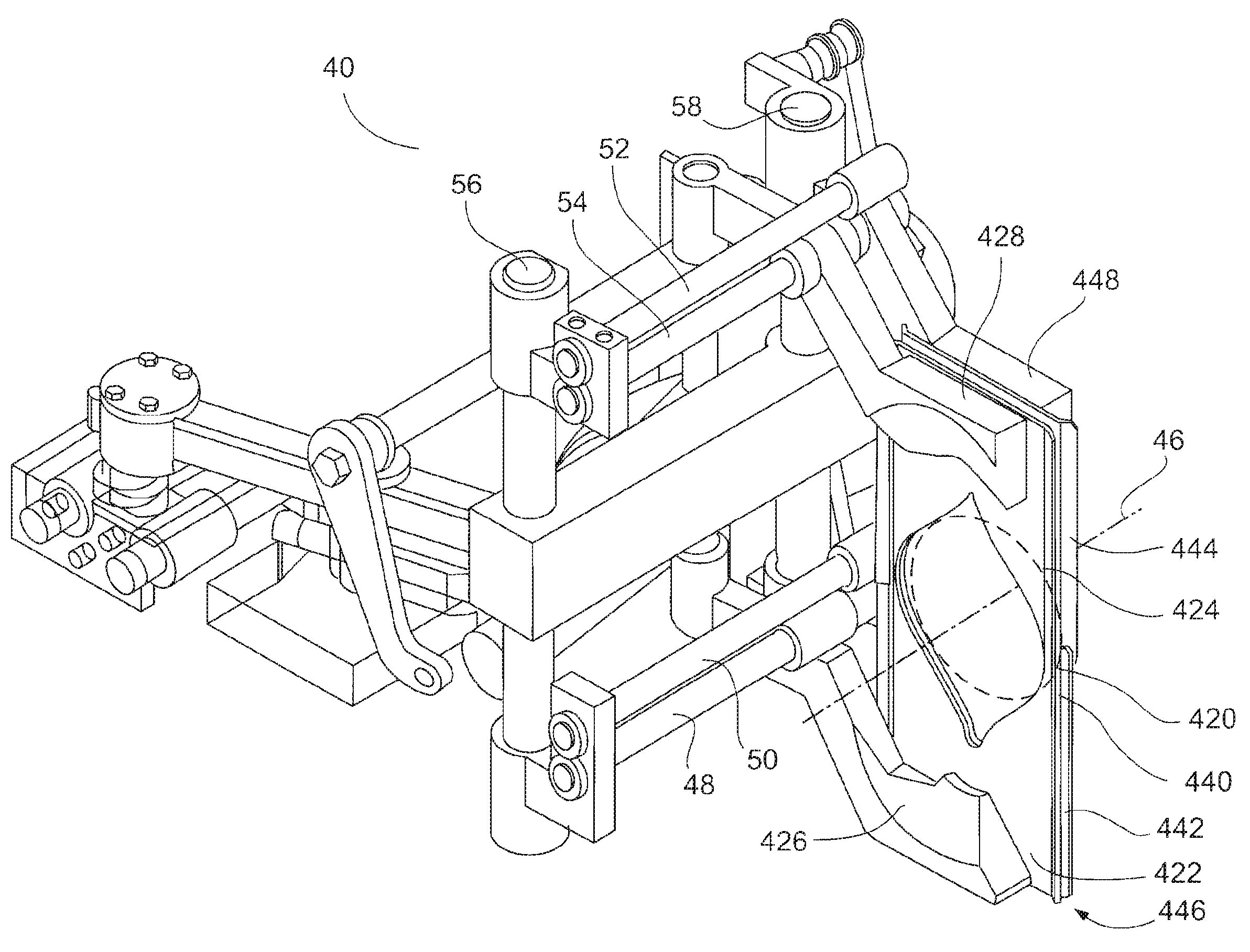

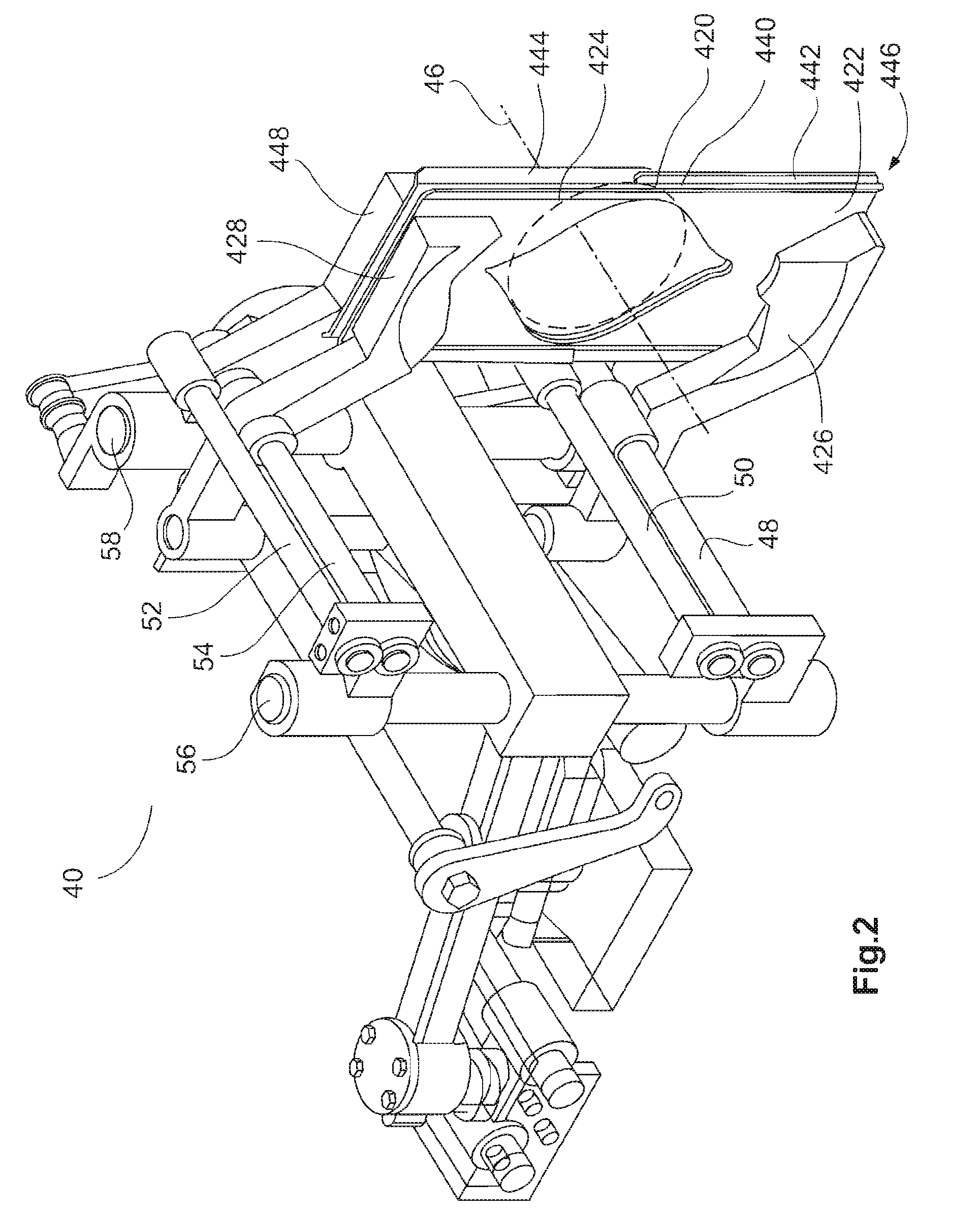

Displacement elements for a clip machine

ActiveUS8113925B2Avoid damageShorten the lengthSausage skin tying apparatusSausage filling/stuffing machinesFilling materialsEngineering

A displacer assembly for a clip machine, in particular a sausage clip machine, including at least a first pair of displacer shears and a second pair of displacer shears arranged parallel thereto. The displacer shears are arranged pivotably about a common axis and are reversibly movable towards each other for constriction of the filled packaging casing for forming a filling material-free plaited portion. In that respect the first pair of displacer shears comprises two displacer shears which are at least approximately identical in minor image relationship and the second pair of displacer shears has a second displacer shear which is at least approximately identical to the displacer shears of the first pair of displacer shears, as well as a first, shorter displacer shear. The first displacer shear of the first pair of displacer shears has a reinforcement which at least approximately reproduces the contour of the part, which is cut off for shortening purposes, of the first displacer shear of the second pair of displacer shears.

Owner:POLY CLIP SYST

Casing wire tying machine for stable wire tying

ActiveCN106982909ASmooth rotationReduce laborFood processingSausage skin tying apparatusRatchetWire rod

The invention discloses a casing wire tying machine for stable wire tying. The casing wire tying machine comprises a rack and a wire rod shaft, a middle position at the upper side of the rack is equipped with a casing duct, a wire tying stand shaft is mounted at a middle position on the outer surface of the casing duct, a wire tying stand is disposed close to a middle position on the outer surface of the wire tying stand shaft, a wire guide hole is arranged close to a middle position on the left side of the wire tying stand, and a tie wire is mounted close to a middle position on the upper side of the wire tying stand. The casing wire tying machine provided by the invention is scientific and reasonable, and is convenient for use, the inner wall of a tie wire rod is connected to a ratchet wheel, so that during work, the tie wire and the tie wire rod can rotate more stably, the wire route is clearer, work suspension and manual disassembly repair caused by wire winding during wire tying can be avoided, thus alleviating labor consumption of operators, and making wire tying more stable and line production more smooth. The casing wire tying machine can cooperate rapid production under high degree of automation to increase output and improve efficiency.

Owner:南通天龙畜产品有限公司

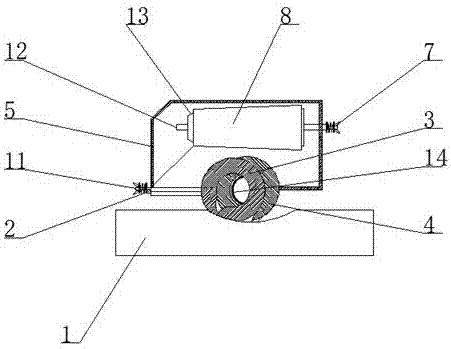

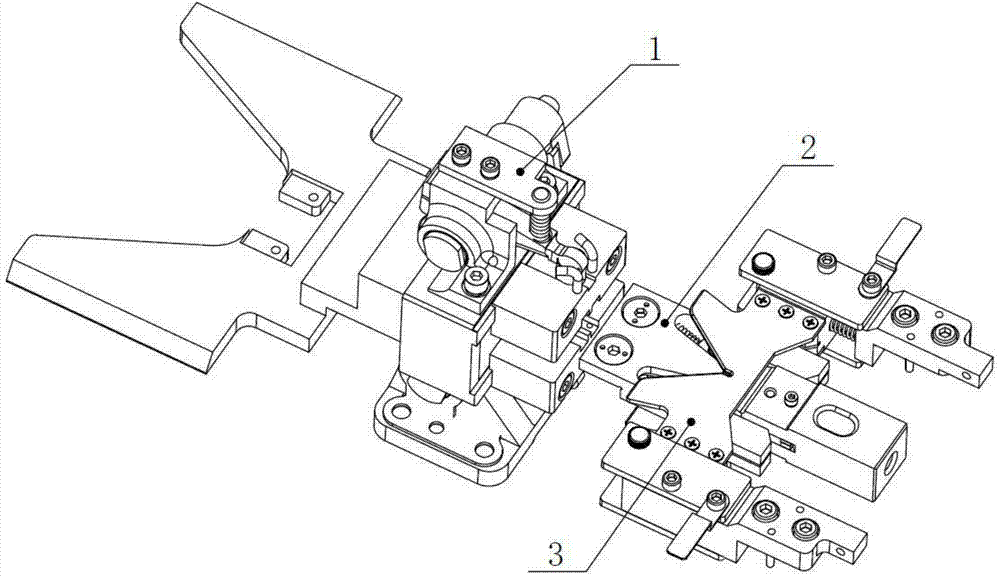

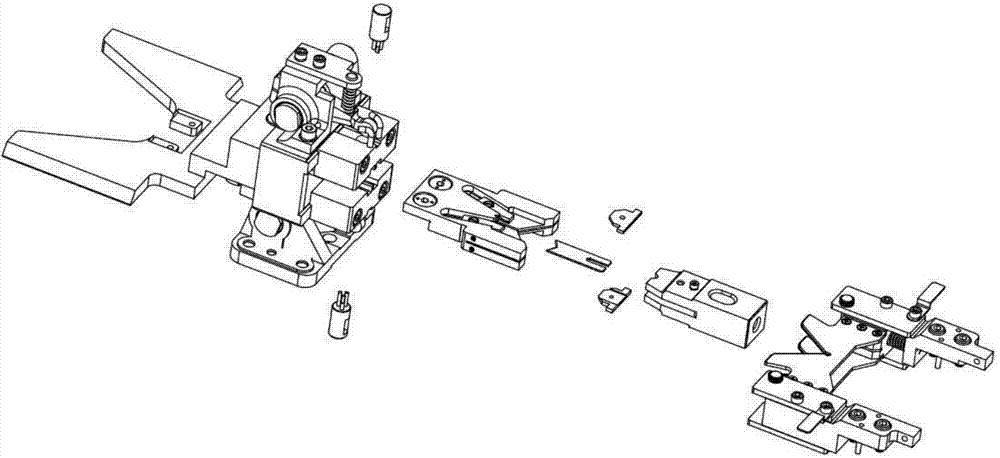

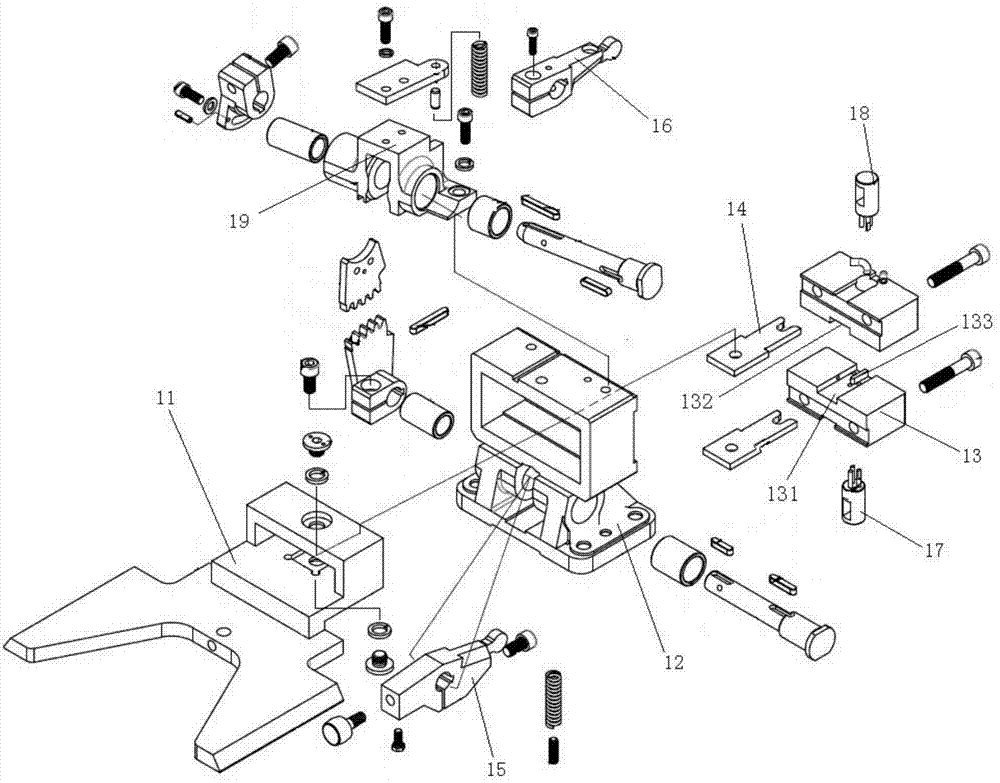

Pork sausage tying and cutting device

ActiveCN104719418AIncrease productivityBuckle distance shortenedSausage skin tying apparatusMetal working apparatusEngineeringAluminium

The invention provides a pork sausage tying and cutting device which comprises a once-forming upper / lower mold mechanism 1, a secondary-forming upper / lower mold mechanism 2 and a bundle collecting plate mechanism 3, wherein the once-forming upper / lower mold mechanism 1 and the secondary-forming upper / lower mold mechanism 2 are matched with each other; the once-forming upper / lower mold mechanism 1 comprises a once-forming upper mold and a once-forming lower mold; the secondary-forming upper / lower mold mechanism 2 comprises a secondary-forming upper mold and a secondary-forming lower mold; the once-forming upper mold and the once-forming lower mold cooperate with each other to make an aluminum wire which penetrates through the once-forming upper mold into a U-shaped buckle, and press the U-shaped buckle into the secondary-forming lower mold; and the secondary-forming upper mold and the secondary-forming lower mold cooperate with each other to extrude the U-shaped buckle pressed in the secondary-forming lower mold into a heart shape, and cut off a sausage casing membrane which penetrates through from top to bottom. By adopting the pork sausage tying and cutting device provided by the invention, the operation of tying and cutting can be simultaneously achieved, the sausage casing membrane for each piece of sausage can be reduced by 5mm, the production efficiency can be improved, and the cost can be reduced.

Owner:北京东航精密机械制造有限公司

Displacer FCA Y

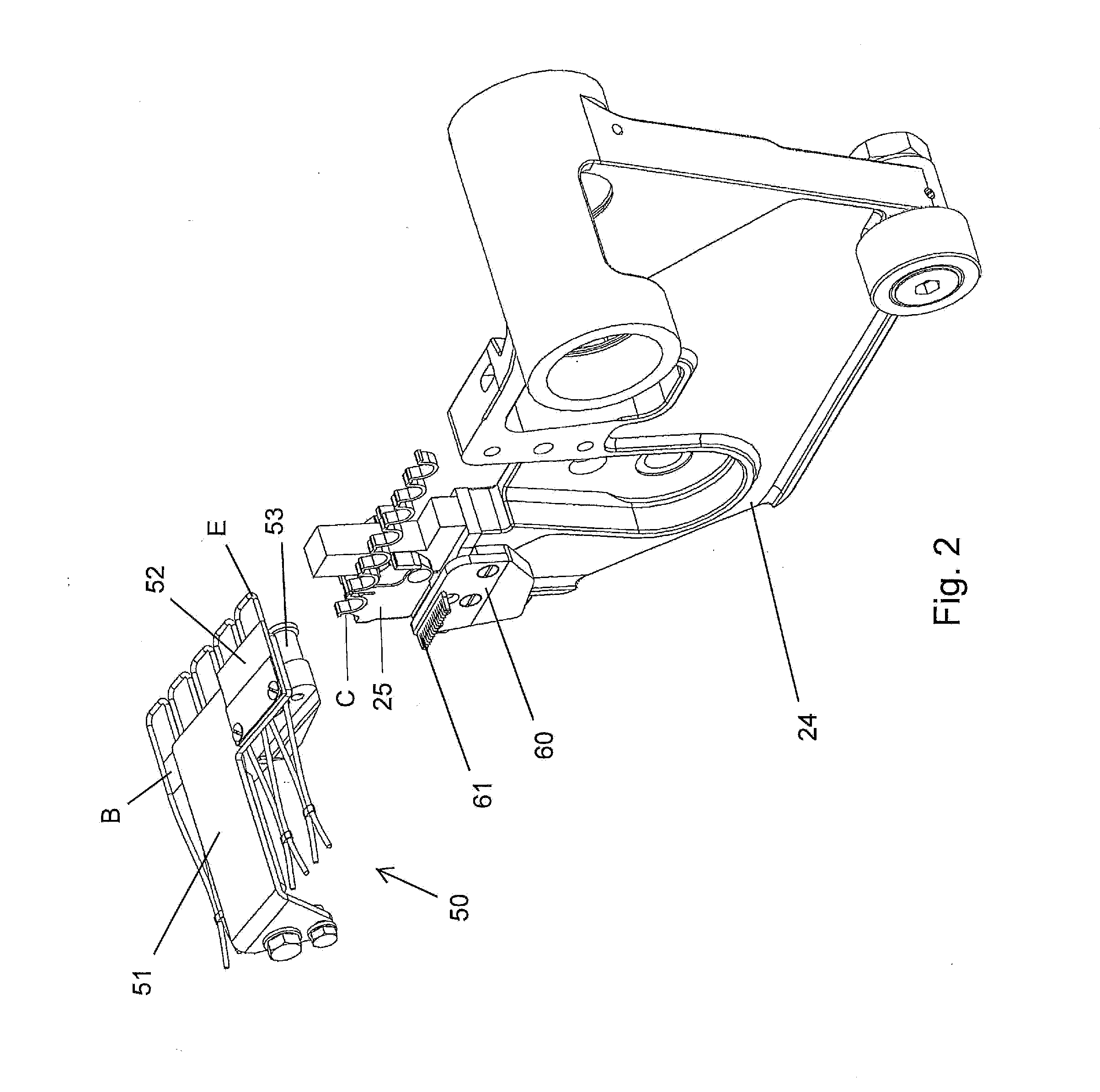

ActiveUS8579682B2Reduce extra spaceMore compact clipping machineSausage skin tying apparatusFilling materialsPlane parallel

The invention relates to a clipping machine for partitioning and closing a tubular packaging casing accommodating a filing material, and in particular sausage meat. The clipping machine comprises at least a first and second displacer element pair which in relation to an axis of the tubular packaging casing are arranged axially one after the other, and, which comprise each an upper displacer element and a lower displacer element. Each pair of the displacer elements are linearly reversibly movable in a first and second plane from an open position to a closed position. A first linear guidance comprises a first and second guiding rod for guiding the two pairs of the displacer elements. The first and second guiding rods are positioned in a plane parallel to the first and second plane of the first and second pairs of the displacer elements.

Owner:POLY CLIP SYST

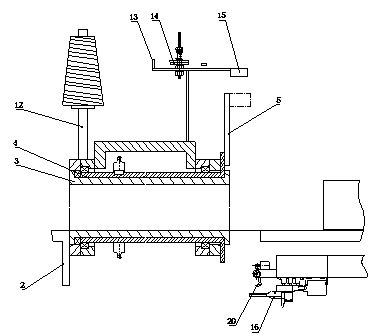

Full automatic sausage segment binding machine

InactiveCN1823597AEasy to wrap and tie knotsConsistent knot lengthSausage skin tying apparatusMechanical engineeringPiston

A full-automatic sausage binding machine is composed of a machine frame, a feeding mechanism consisting of a conveying belt and a clamping jaw unit comprising a pair of clamping jaws and the baseplate of clamping jaws, a diameter reducing unit, and a thread winding unit. Said clamping jaws are fixed to the fixing block and respectively pivoted to pressing plate and synchronous connecting rod linked to the piston of cylinder via a three-connecting-rod mechanism. Said diameter reducing unit has a pair of peach-Shaped clamps. Said thread winding unit has a ratchet mechanism.

Owner:刘金生

Plastic wire clipper/stuffer

Owner:POLY CLIP SYST

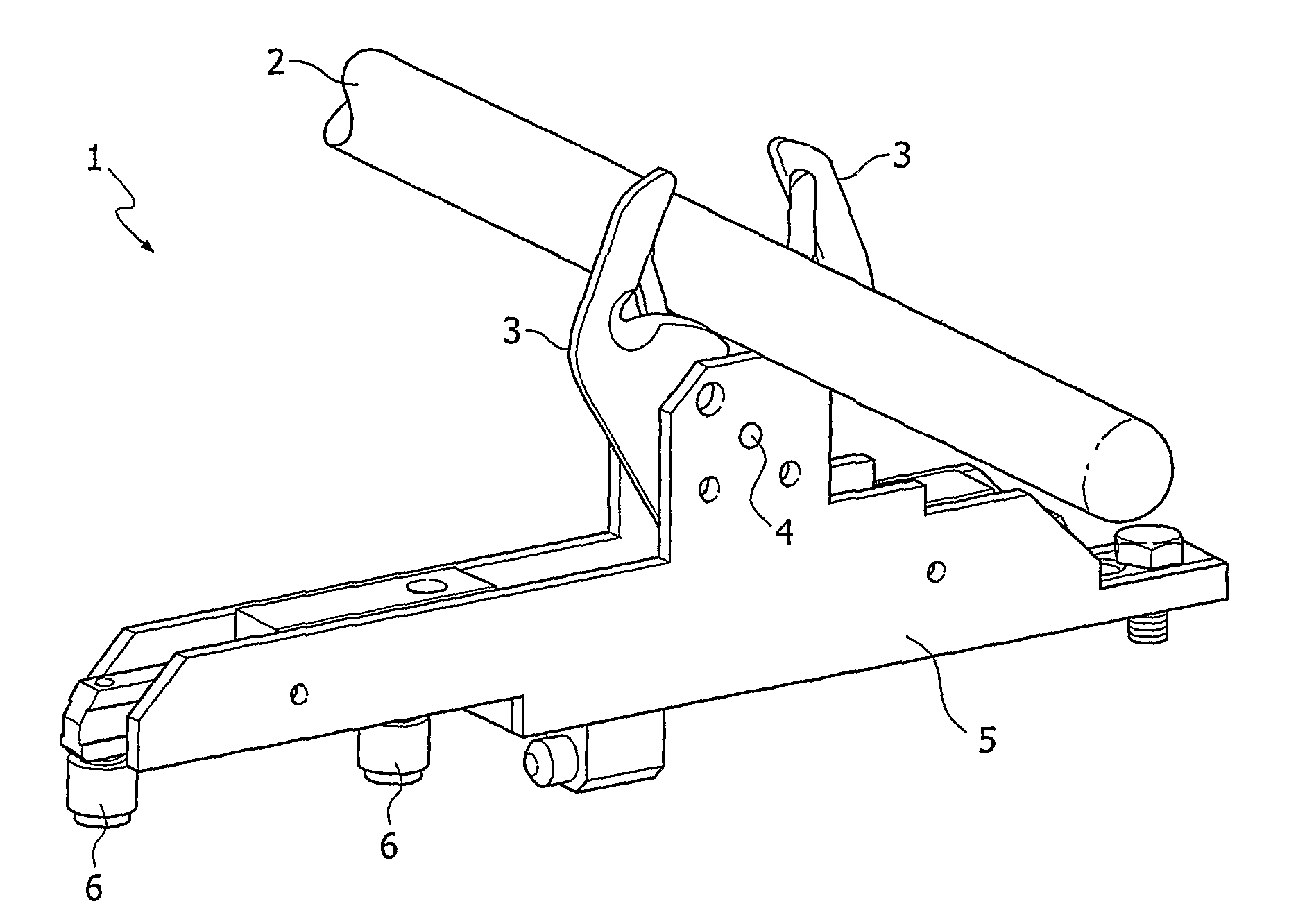

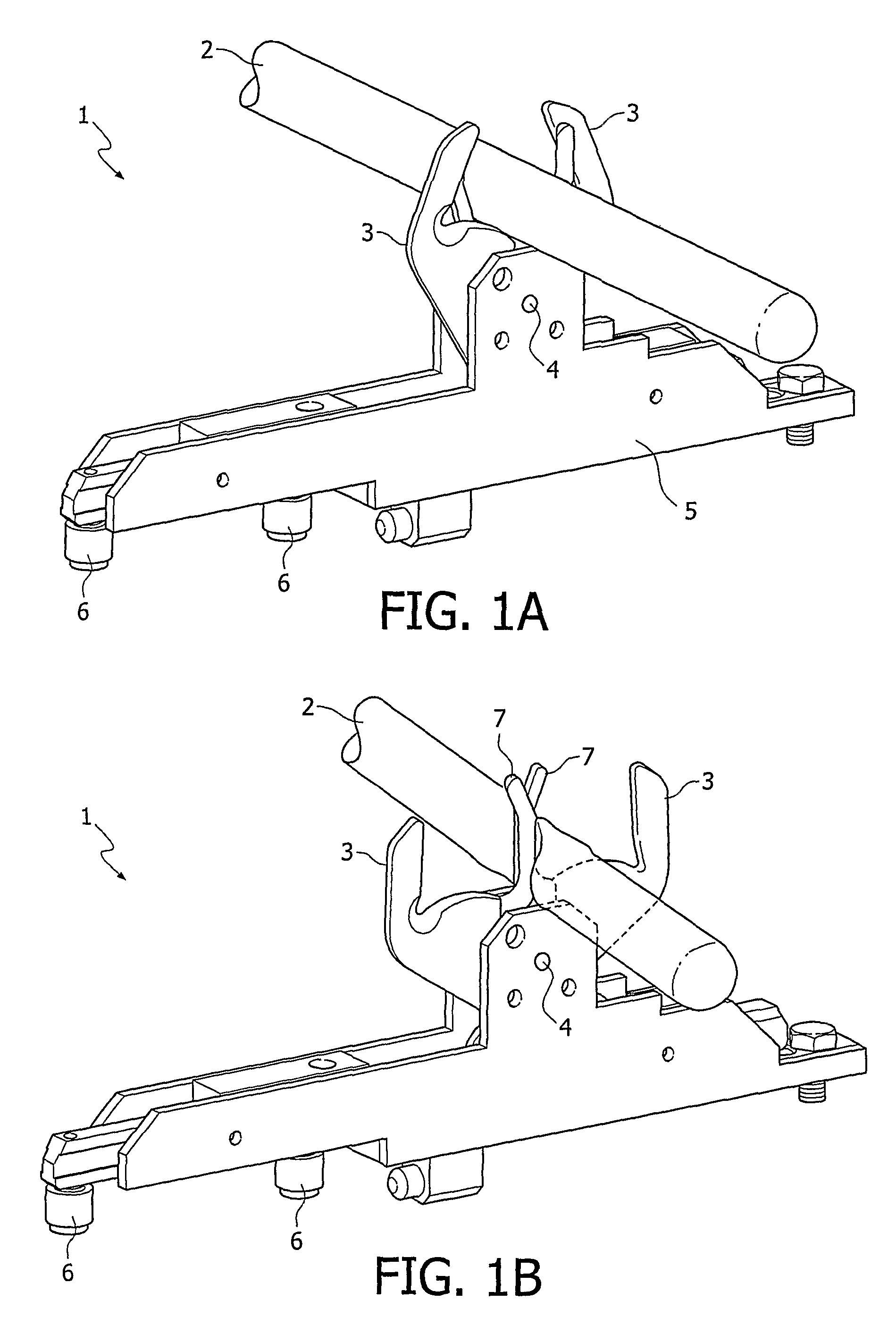

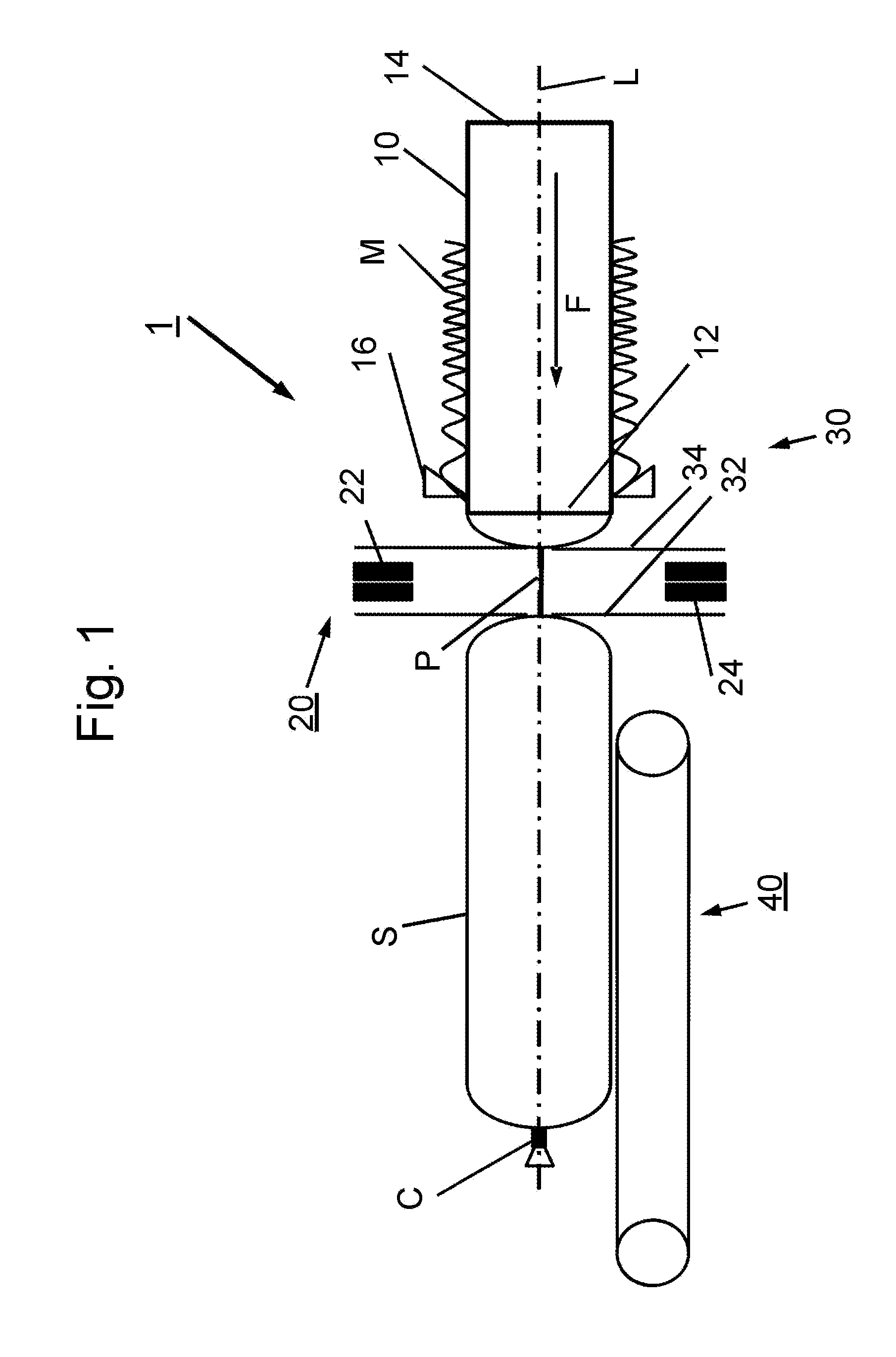

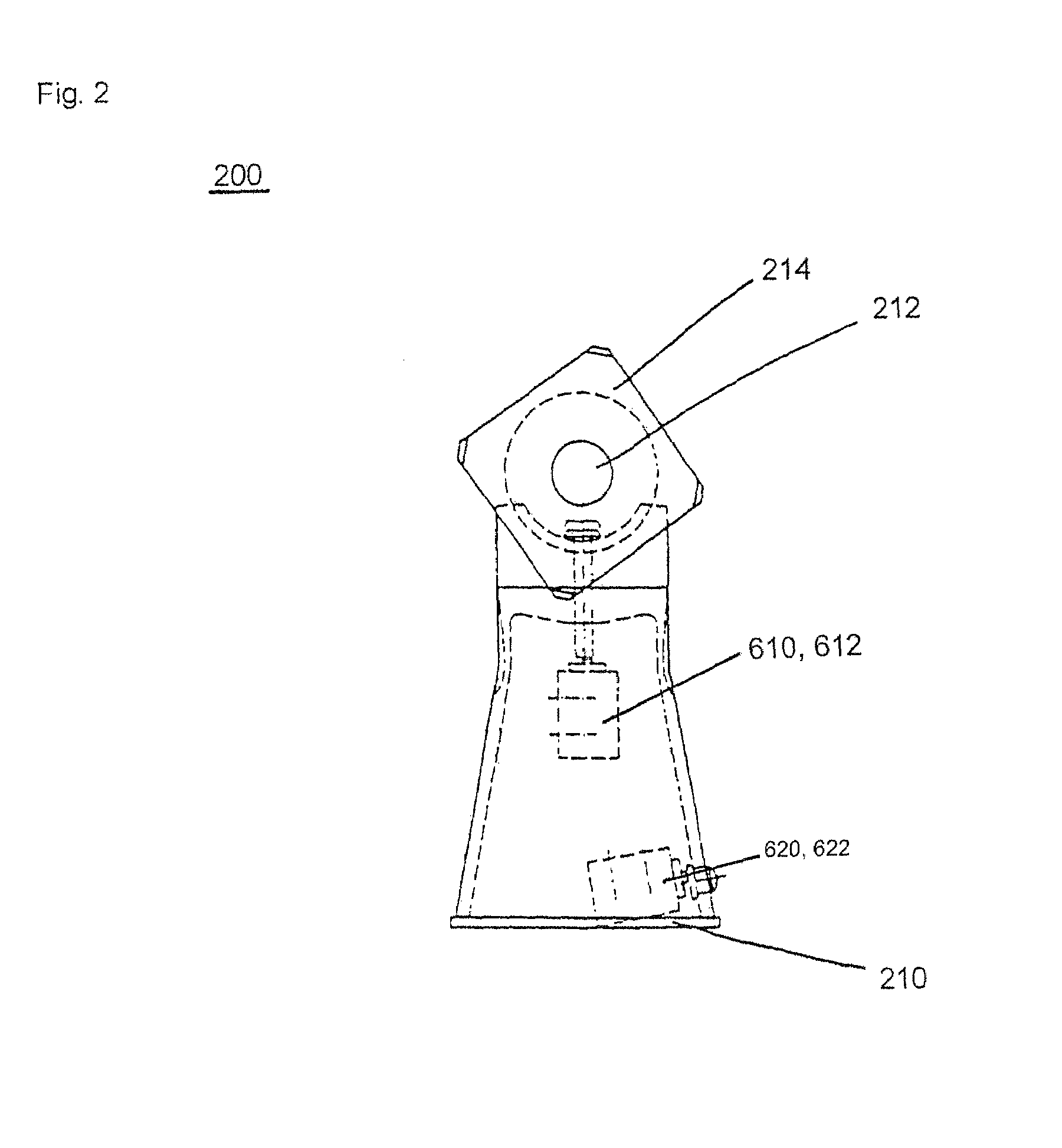

Clipping machine with improved handling of suspension elements

ActiveUS20150223478A1Improve accuracyImprove reliabilityMeat/sausage hanging-upSausage skin tying apparatusFilling materialsEngineering

A clipping machine for producing sausage-shaped products (S), like sausages, by filing a flowable filling material into a tubular or bag-shaped packaging casing (M) and closing said packaging casing (M) by a closure means, like a closure clip (C). The clipping machine (1) comprises a feeding device (50) for suspension elements configured to feed suspension elements (E) attached to a carrier strip (B) to a delivery position and to place a first section of a suspension element (E) within the closure means (C) positioned on the die (25) of the second closing tool (24). The feeding device (50) further comprises a guiding device (51) configured to hold down the suspension element (E) close to the carrier strip (B) while the suspension element (E) is pulled off and detached from the carrier strip (B) by a relative movement between the second clipping tool (24) and the feeding device (50). A holding device (60) attached to the second clipping tool (24) is configured to releasably receive and hold a second section of the suspension element (E) when detached from the carrier strip (B).

Owner:POLY CLIP SYST

Clip feed arrangement

InactiveUS7331155B2High outputIncrease productivityStapling toolsWrapper twisting/gatheringEngineeringDriven element

A clip feed arrangement including a magazine bar for guiding a line of clips from a clip supply to a separating device of a closure apparatus, and a clip drive arranged in the region of the magazine bar. The clip drive has two drive elements which can be successively brought into engagement with the line of clips and which separately produce the advance.

Owner:POLY CLIP SYST

Automated extraction of casing clips from cooked meat products

A method apparatus for removing a casing, particularly a casing with a clip end embedded in the product, is disclosed where the clipped end is clamped and gas is injected into this end to blow out the clip and casing end while the clamped portion prevents the entire casing from being inflated. The air or gas, such as HEPA filtered air, is injected into the product with a needle, for instance, to balloon out the casing in the clamped area to free the previously embedded clip. The clip is then gripped, certain cuts are made in the casing, and the casing is pulled from the product. An injector such as a needle is inserted into the end portion of the product and pressurized gas, such as HEPA filtered air, is injected into the end portion. The injection of the gas causes the casing to balloon out from the product thereby freeing the previously embedded clip. The freed clip is then gripped while the casing is then cut for removal. The casing may be cut in a Y-shape with two cuts beginning approximately at two corners of one side of the square end and angled towards each other along a side of the product. The two cuts meet, and a third cut is made longitudinally along the length of the product beginning at the meeting point of the two angled cuts. The gripped clip and casing are pulled causing the casing to separate from the product along the cut lines.

Owner:KRAFT FOODS GRP BRANDS LLC

Closure clip with round bottom

A closure clip for products in bag or sausage form, the packaging cover material of which is formed from at least one packaging film, wherein the closure clip has a clip bottom and two straight clip legs which adjoin the clip bottom in the same direction and which diverge away from each other away from the clip bottom and the central longitudinal axes of which and the central longitudinal axis of the clip bottom lie in a common plane. It is further provided that the clip bottom has a rounding in the form of part of a circular arc.

Owner:POLY CLIP SYST

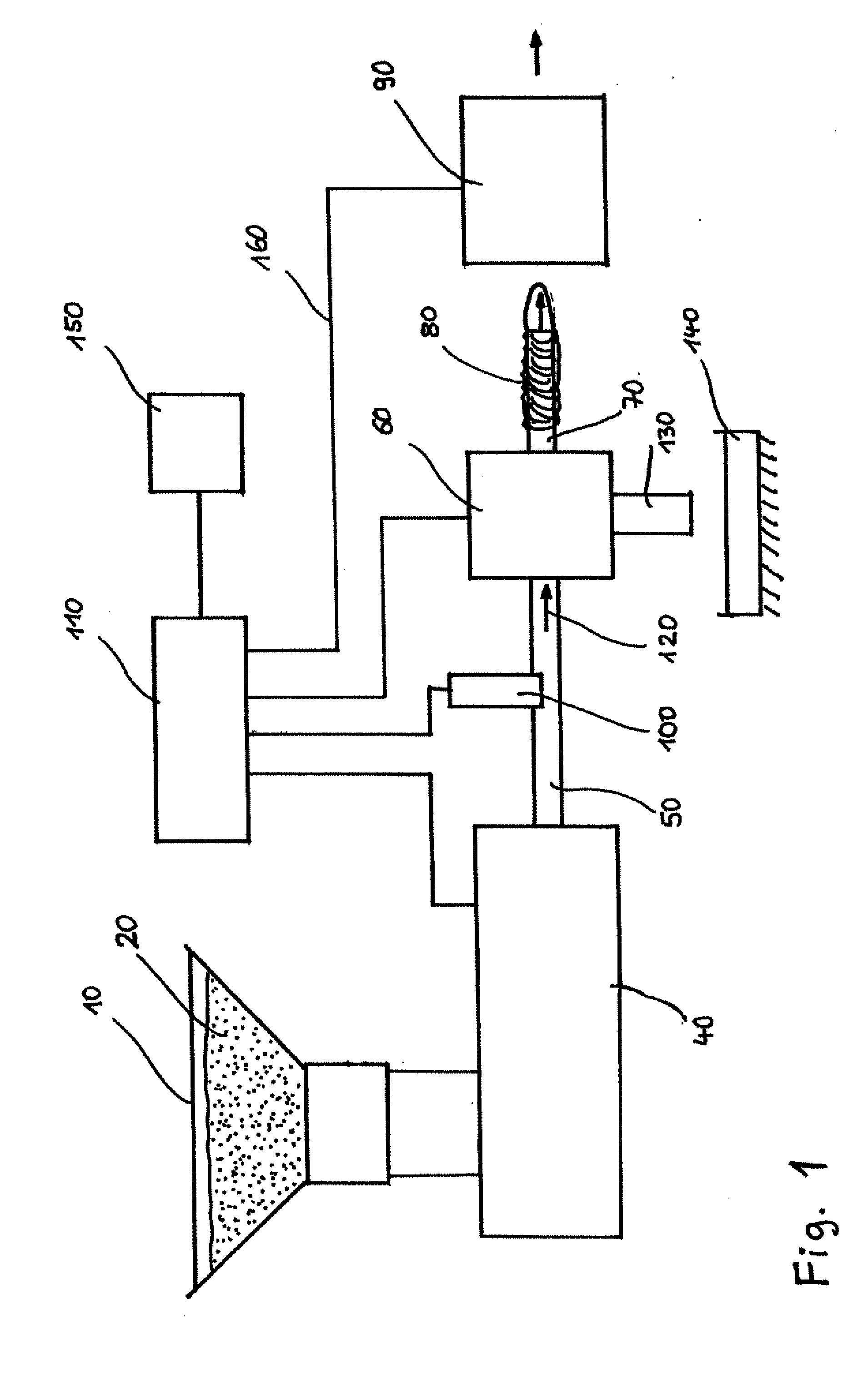

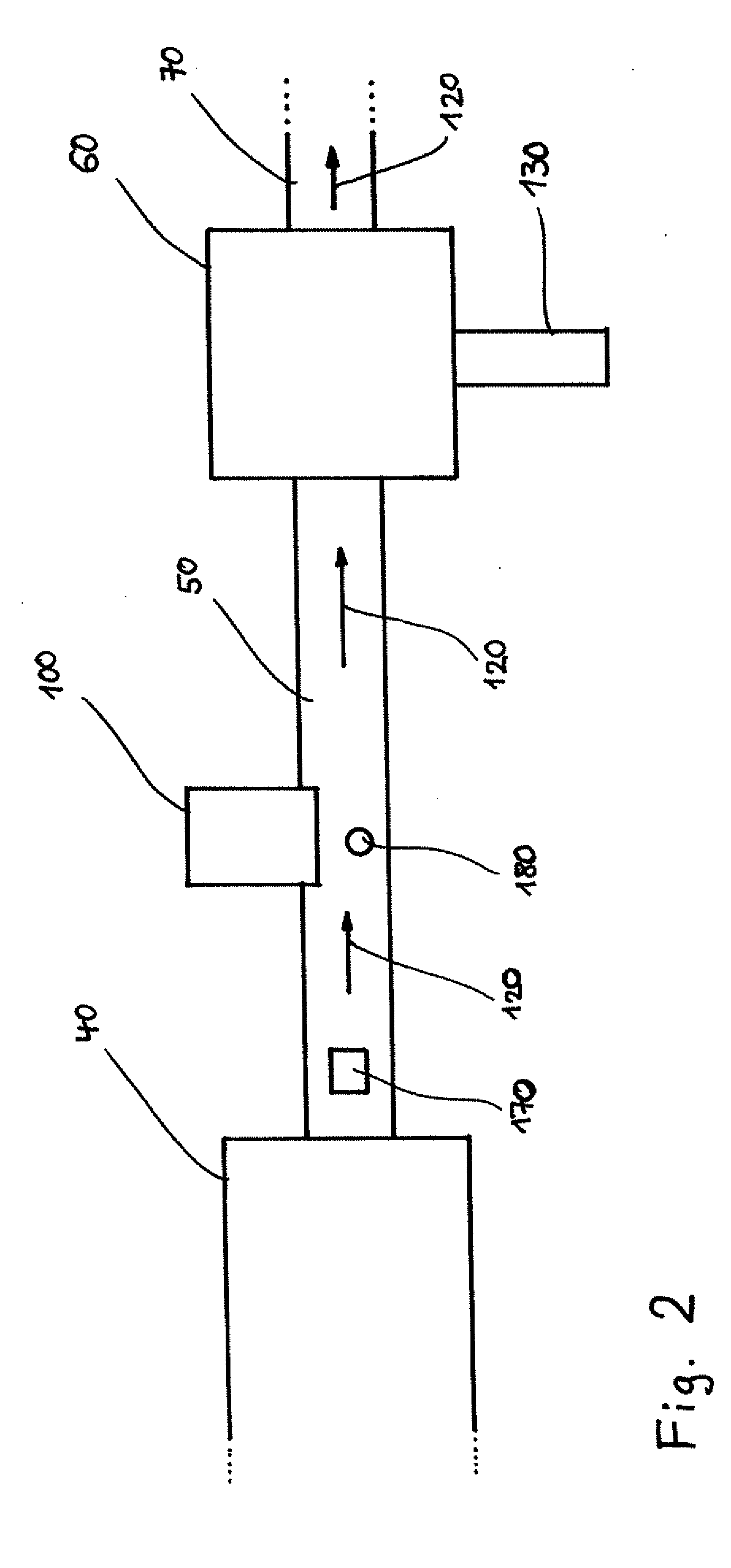

Packaging equipment and process for controlling of the packaging equipment

ActiveUS20100112922A1Reliable detectionIncrease probabilityWrapper twisting/gatheringPackaging automatic controlFilling materialsEngineering

A packaging device including a filling unit for transporting a filling material, a filling tube connected to said filling unit, for introducing the filling material supplied by the filling unit into a tubular casing and for ejecting the filling material located in the casing, a clipping unit disposed in the direction of transport of the filling unit, for constricting the casing at a predetermined position and for closing the casing with at least one closure element, a sensor unit disposed between the filling unit and the filling tube, for detecting impurities in the filling material and for emitting a detection signal to a control unit, wherein the control unit has a control connection to the clipping unit. The invention also relates to a method for controlling a packaging device.

Owner:POLY CLIP SYST

Winding-tying type Chinese sausage tying and pricking machine

InactiveCN104068095ASimple structureEasy to operateSausage skin tying apparatusGear wheelEngineering

The invention relates to a winding-tying type Chinese sausage tying and pricking machine. A pinion is fixed on a motor shaft. A first bearing is fixed on a Chinese sausage passage pipe. A bull gear is fixed on the first bearing. A second bearing is fixed on a shaft sleeve pipe which is fixed on the bull gear. A hanging wire hook is fixed on the shaft sleeve pipe. A wire barrel is fixed on the second bearing. A wiring barrel sleeves the wire barrel. A wire threading hole is fixed in the shaft sleeve pipe. A wire is hung on the hanging wire hook and is threaded in the wire threading hole. A spring clamp is fixed on the wire barrel. A piece of friction leather is fixed on the wiring barrel. A motor is fixed on a casing. The Chinese sausage passage pipe is fixed on the casing to be combined with a pricking device. The pricking device has a structure that an upper bearing is fixed on an upper needle tubing, upper steel needles are fixed on the upper needle tubing, an upper shaft is fixed on an upper bracket, a lower bearing is fixed on a lower needle tubing, lower steel needles are fixed on the lower needle tubing, a lower shaft is fixed on a lower bracket, and regulating screws are fixed on the lower bracket. The tying and pricking machine has a connecting relationship with a sausage work table.

Owner:姚广勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com