Automatic knotting and wire breaking device for producing sausages

An automatic knotting and sausage technology, which is applied to the equipment for ligating sausage casings, etc., can solve problems such as low work efficiency, low efficiency, and troublesome adjustments, and achieve the effects of reducing labor intensity, realizing automation, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

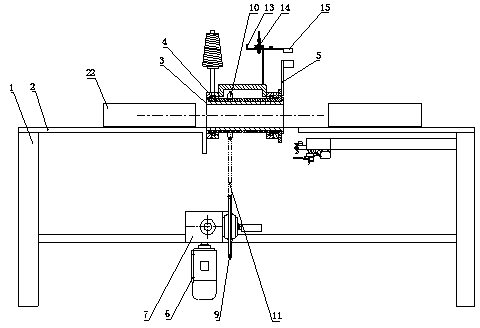

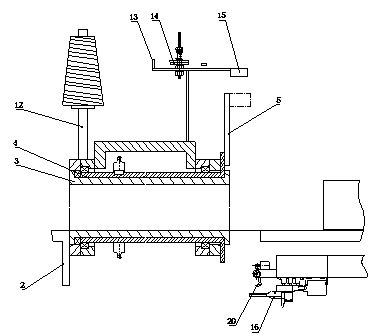

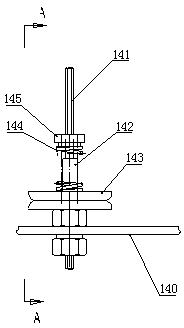

[0026] Such as figure 1 , 2 As shown, it includes frame 1, worktable 2, catheter sleeve 3, winding assembly, wire supply assembly, pneumatic clamp assembly, disconnection assembly, and fixed-length transmission mechanism;

[0027] The upper surface of the frame 1 is provided with a working table 2, one end of the working table 2 is the feeding side, and the other end is the discharging side;

[0028] A bowel guide sleeve 3 installed on the workbench 2, the bowel guide sleeve 3 is a stainless steel pipe body horizontally arranged on the workbench, and the lower edge of the inner tube of the stainless steel pipe body is flush with the upper surface of the workbench 2 flat; the discharge side of the sausage guide sleeve 3 is provided with a material sensor.

[0029] A winding assembly, including a shaft sleeve 4, a wire winder 5 and a winding driving mechanism, the shaft sleeve 4 is set in the catheter sleeve 3, and is driven to rotate by the winding driving mechanism, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com