Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

558 results about "Case material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Case material is a good measure of quality, if most of the case is made out of cheap plastic and thin metal, usually steel, since its stronger then aluminium. its generally going to be a POS, if the design is largly metal the quality is usually high.

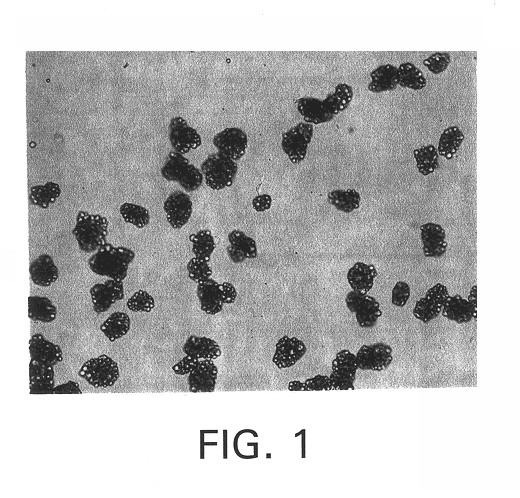

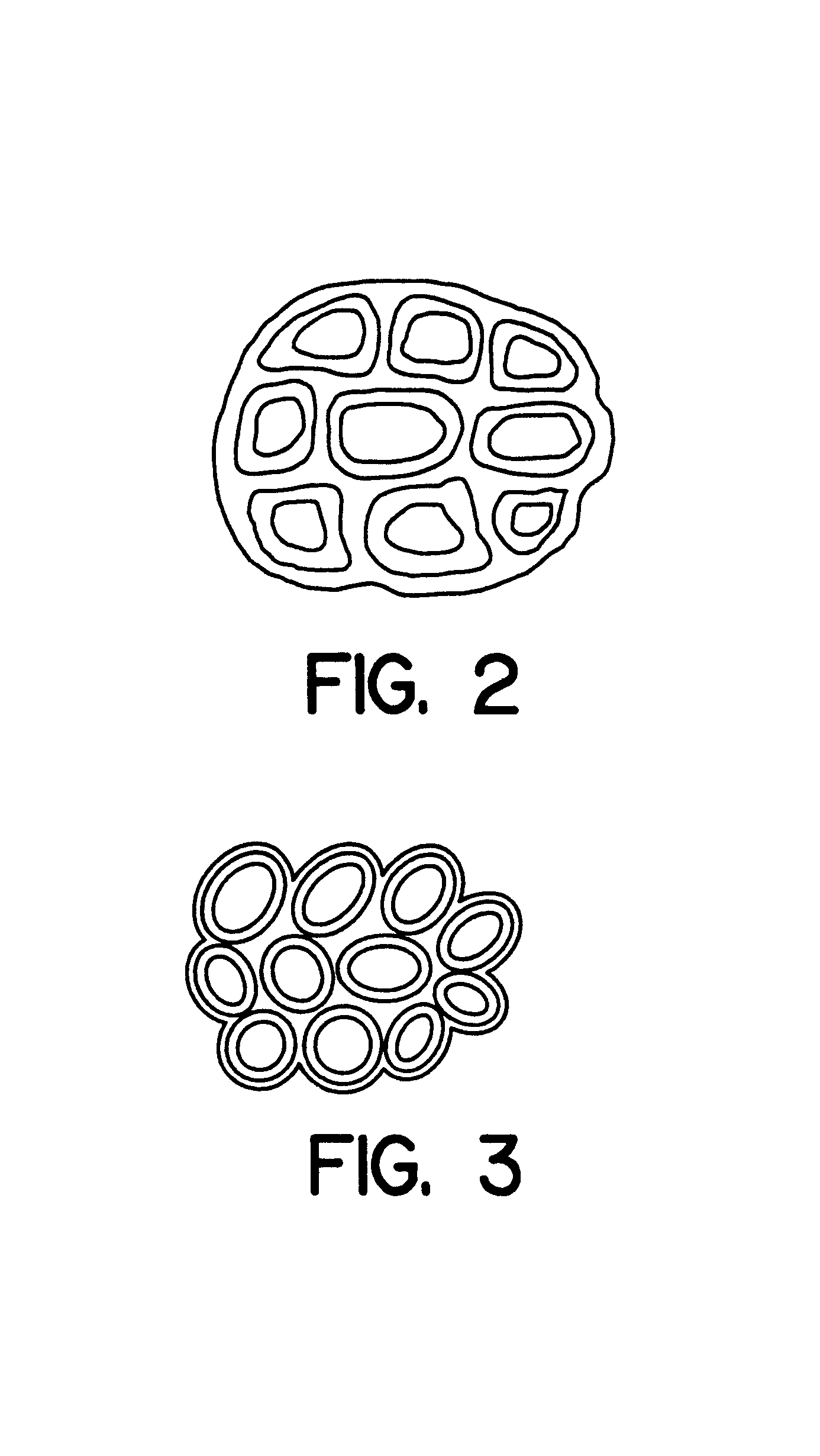

Microcapsules having improved printing and efficiency

InactiveUS6544926B1Efficient use ofSharpness of image printing qualitiesPretreated surfacesGlass/slag layered productsChromogenicColloid

Dual shell microcapsule aggregate particles and copy materials coated therewith, such aggregate particles having inner shells surrounding chromogenic nucleus material, and outer shells encompassing multiple such inner shells to form aggregate particles thereof. The inner shells are derived from polar pre-polymer compositions. The outer shells are derived from complex colloids such as gelatin and gelatin derivatives. The outer shell material causes agglomeration of the inner shells into aggregate particles, thus increasing the sizes of the particles without increasing the sizes of the respective inner-shell microcapsules which contain the chromogenic material.

Owner:ENCAPSYS LLC

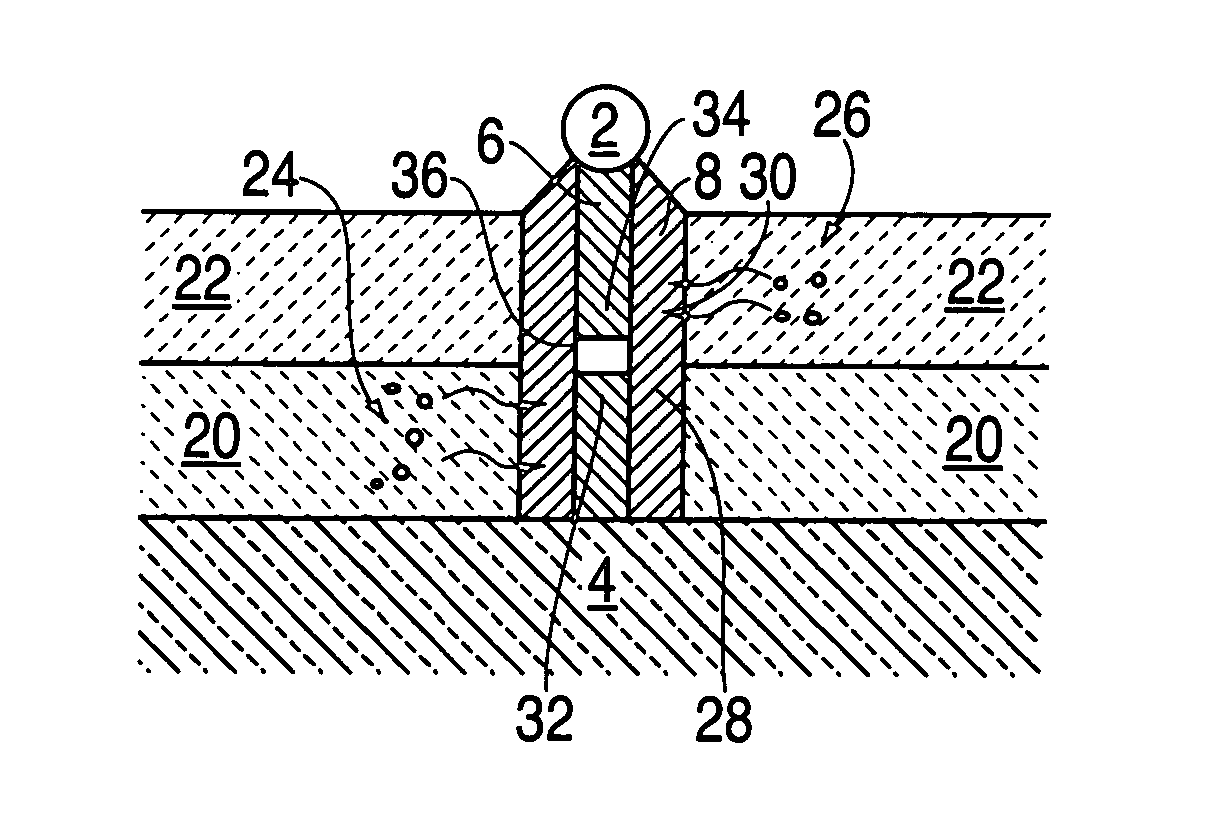

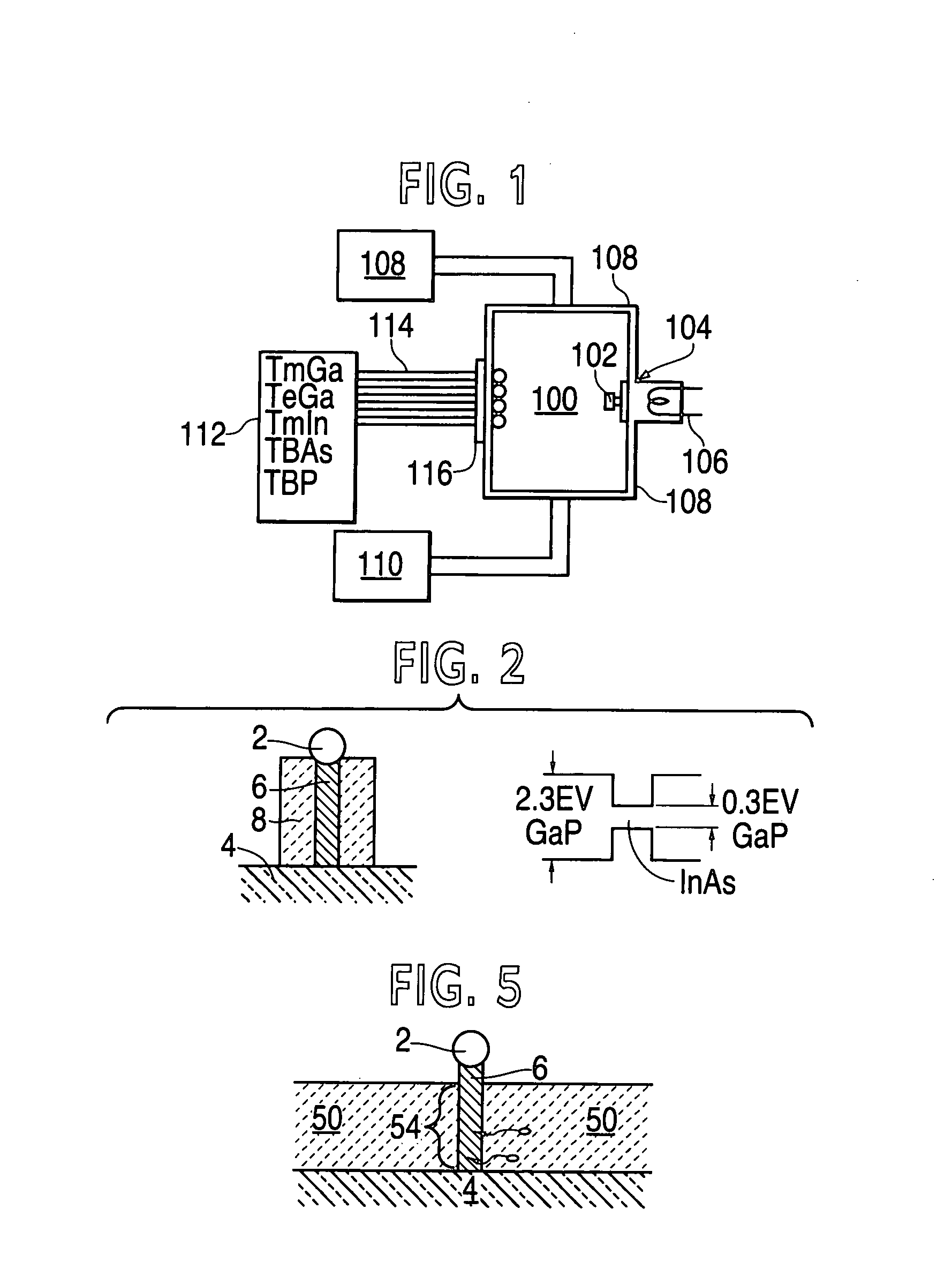

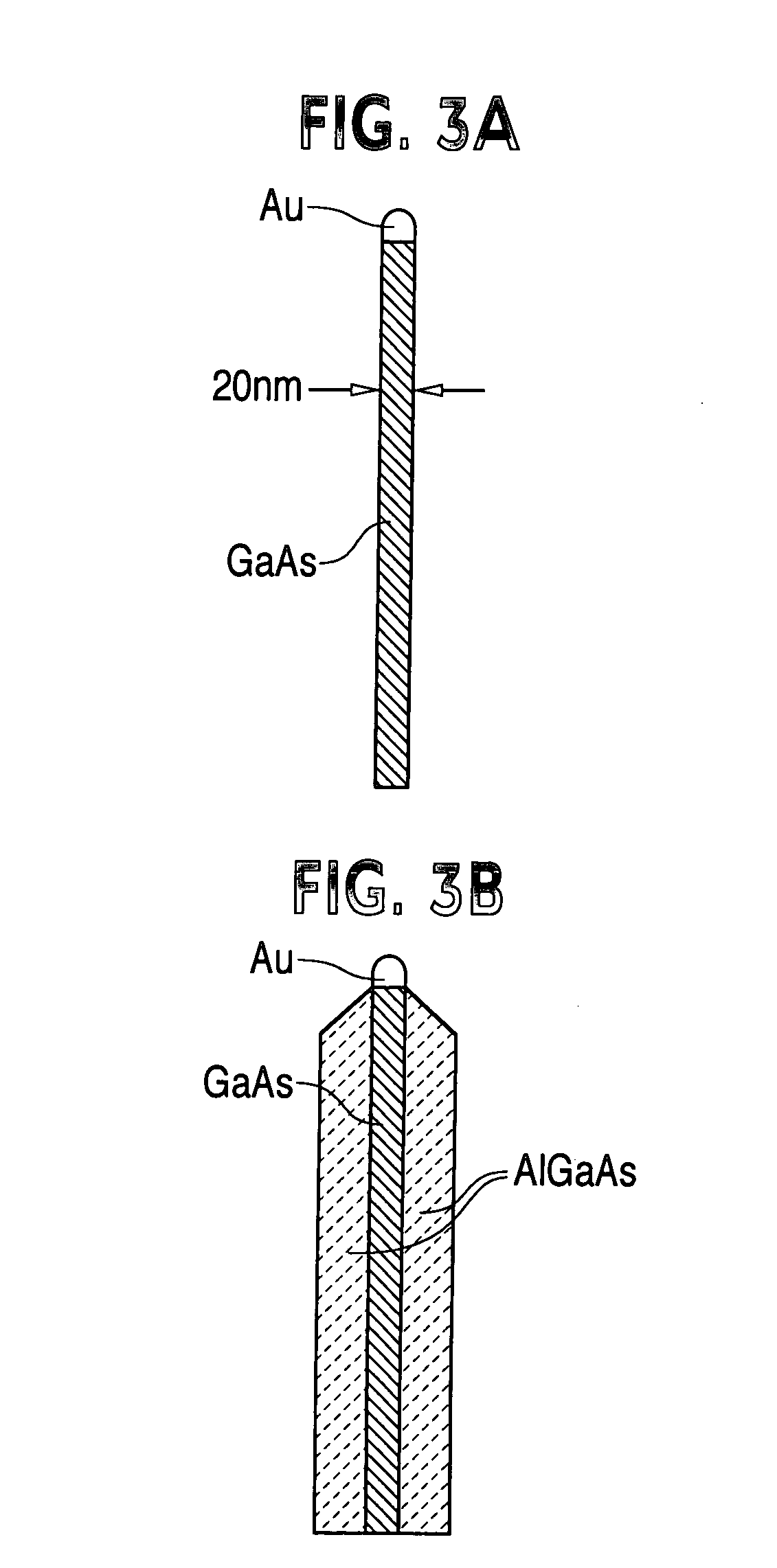

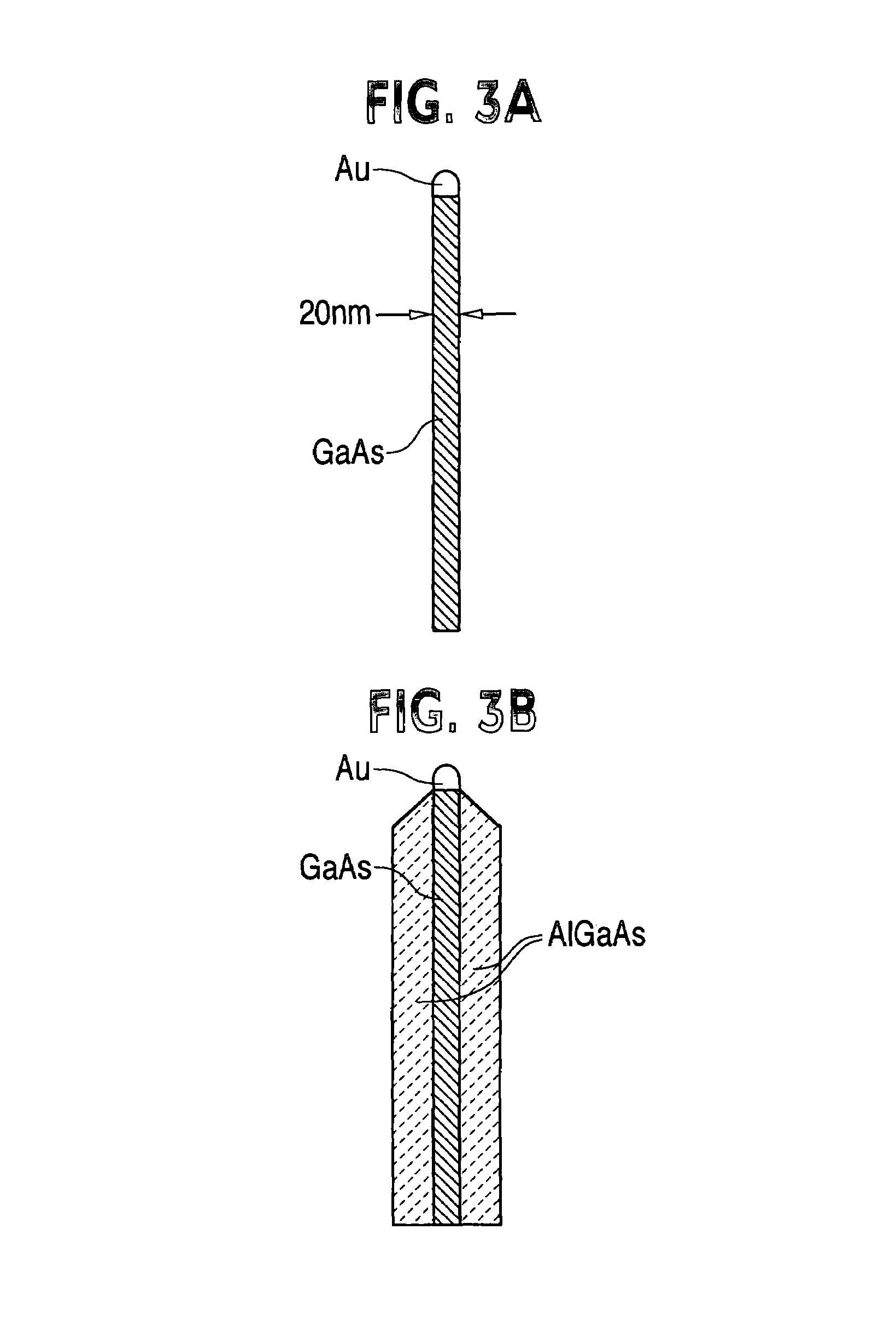

Nanowhiskers with PN junctions, doped nanowhiskers, and methods for preparing them

InactiveUS20050006673A1Good electrical conductivityPermitted diffusionPolycrystalline material growthNanoinformaticsHeterojunctionP–n junction

Nano-engineered structures are disclosed, incorporating nanowhiskers of high mobility conductivity and incorporating pn junctions. In one embodiment, a nanowhisker of a first semiconducting material has a first band gap, and an enclosure comprising at least one second material with a second band gap encloses said nanoelement along at least part of its length, the second material being doped to provide opposite conductivity type charge carriers in respective first and second regions along the length of the of the nanowhisker, whereby to create in the nanowhisker by transfer of charge carriers into the nanowhisker, corresponding first and second regions of opposite conductivity type charge carriers with a region depleted of free carriers therebetween. The doping of the enclosure material may be degenerate so as to create within the nanowhisker adjacent segments having very heavy modulation doping of opposite conductivity type analogous to the heavily doped regions of an Esaki diode. In another embodiment, a nanowhisker is surrounded by polymer material containing dopant material. A step of rapid thermal annealing causes the dopant material to diffuse into the nanowhisker. In a further embodiment, a nanowhisker has a heterojunction between two different intrinsic materials, and Fermi level pinning creates a pn junction at the interface without doping.

Owner:QUNANO

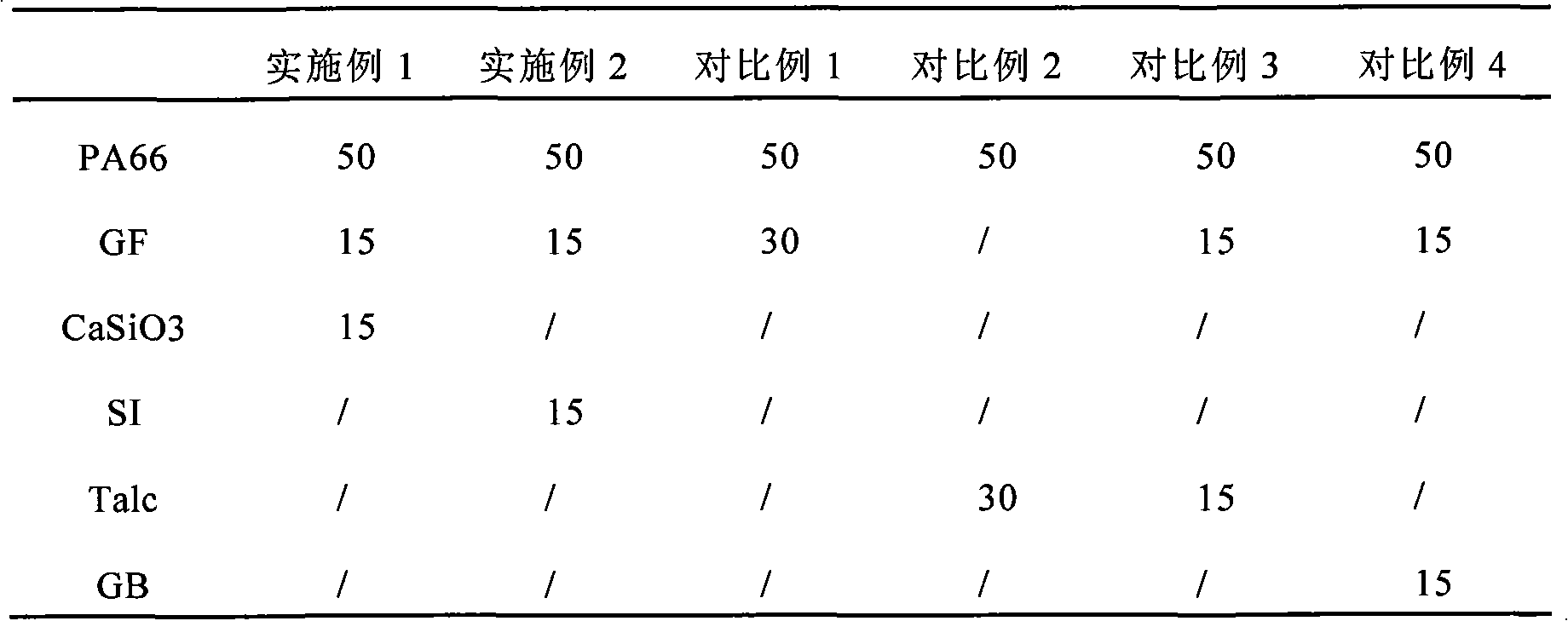

Plastic case material for breaker and preparation method thereof

ActiveCN102108204ASolve the problem of exposureHigh strengthProtective switch detailsBreaking strengthGlass fiber

The invention relates to a plastic case material for a breaker and a preparation method thereof. The material comprises the following components in parts by weight: 22-80 parts of nylon, 5-25 parts of glass fiber, 5-25 parts of needle-like filling material, 8-20 parts of fire retardant, 2-6 parts of auxiliary fire retardant and 0.1-2 parts of other auxiliaries. The preparation method comprises the following steps: evenly mixing the raw materials with a high-speed mixer at a high speed; and then bracing and pelleting the mixed materials with a screw extruder at the temperature of 220 DEG C-290DEG C to obtain the plastic case material. Compared with the prior art, the plastic case material has high breaking strength and elastic modulus, the strength of a compound material is barely influenced by a proper addition of the raw materials, and the obtained product has the advantages of no glass fiber rich surface, no buckling deformation, high strength and good heat resistance.

Owner:HEFEI GENIUS NEW MATERIALS

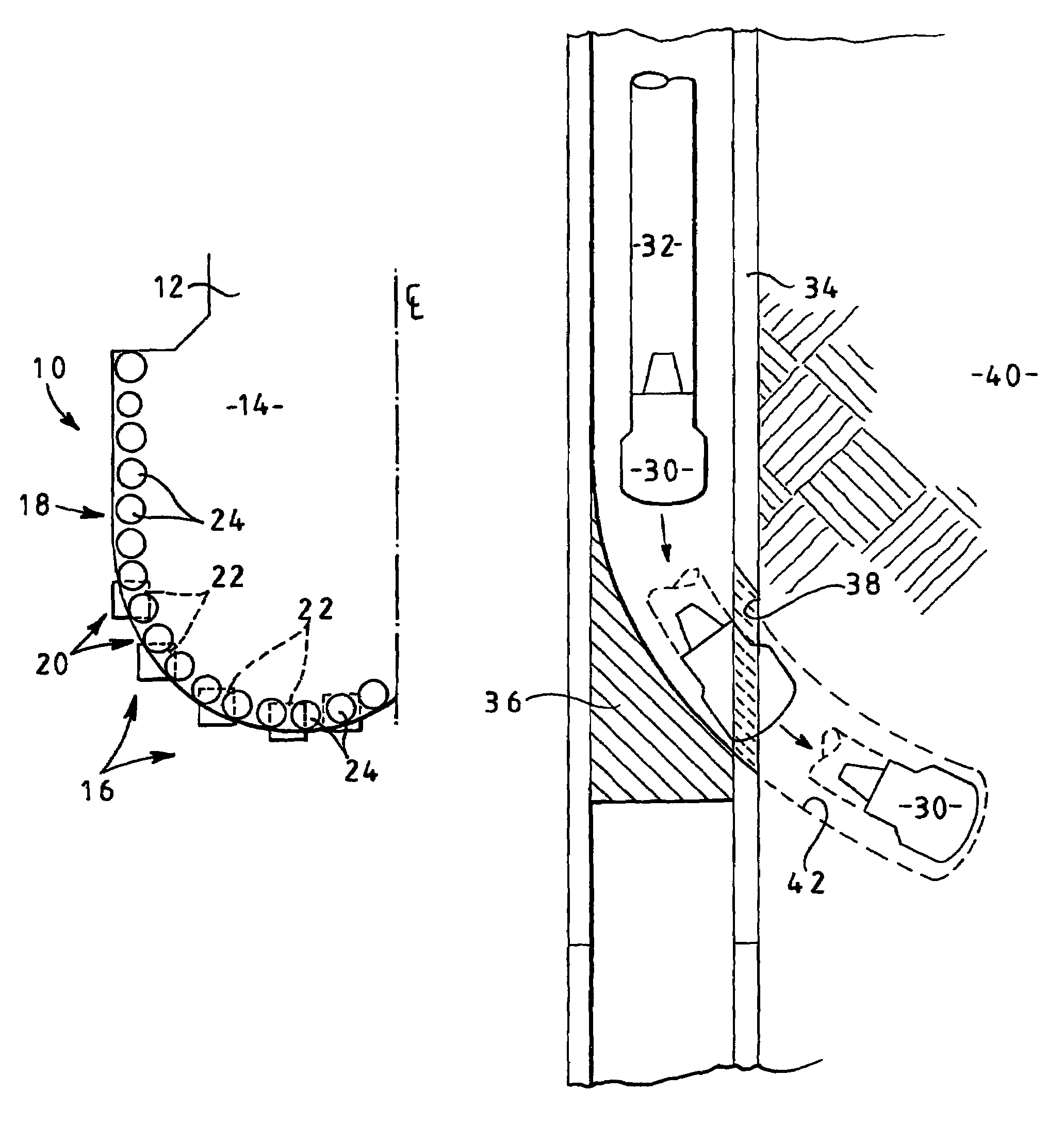

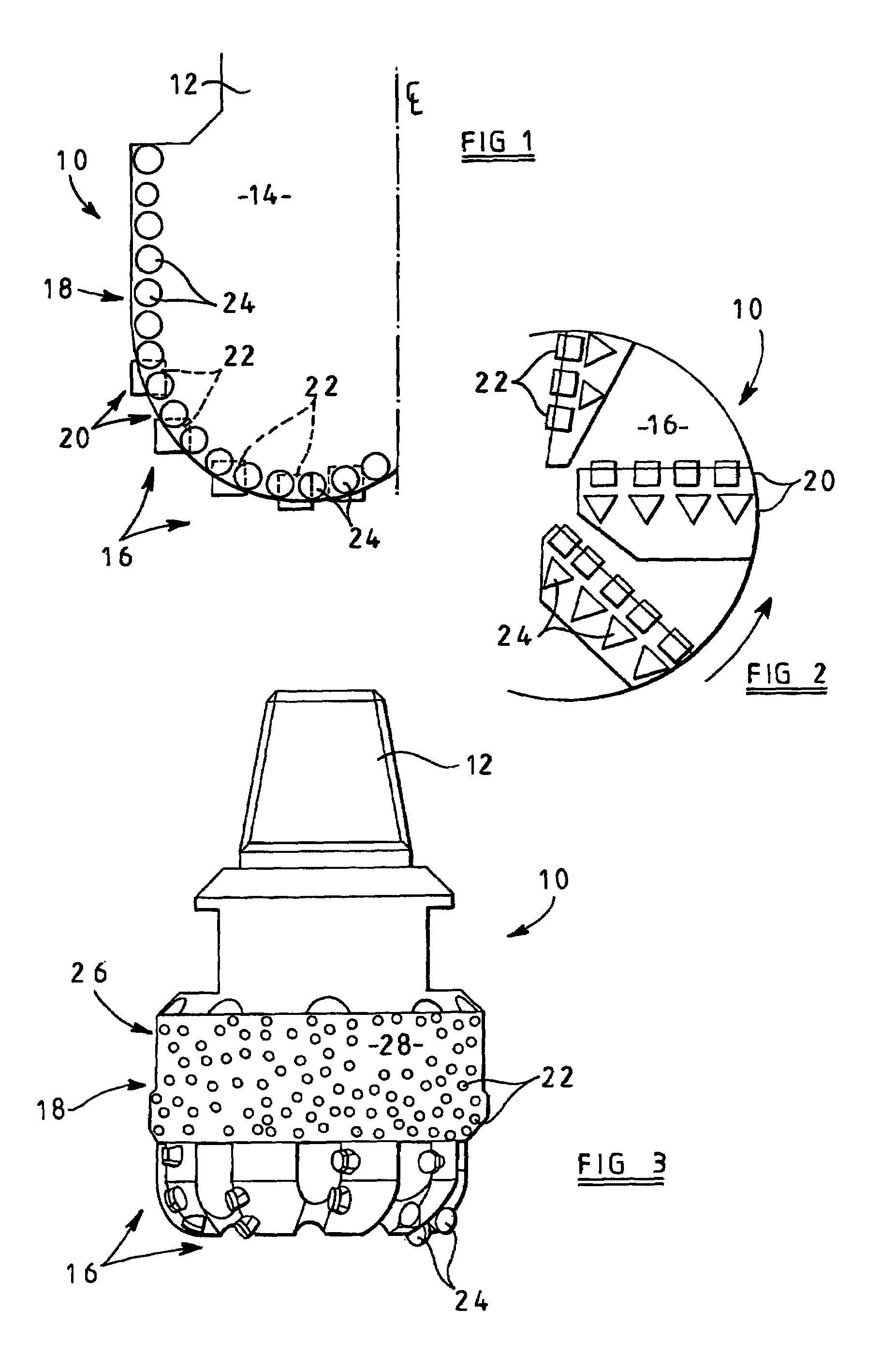

Rotary drill bit for casting milling and formation drilling

A rotary drill bit is used both for milling a casing window and drilling a lateral borehole into subterranean earthen materials, without the prior need of having separate drill bits for milling of the casing and for drilling of the borehole. The rotary drill bit is lowered into a casing set within a borehole; and the drill bit is rotated to engage an inner surface of the casing. A first set of cutting elements on the drill bit remove casing material to mill a casing window. The drill bit is then moved through the casing window so that a second set of cutting elements on the drill bit create a lateral wellbore in subterranean earthen material.

Owner:WEATHERFORD TECH HLDG LLC

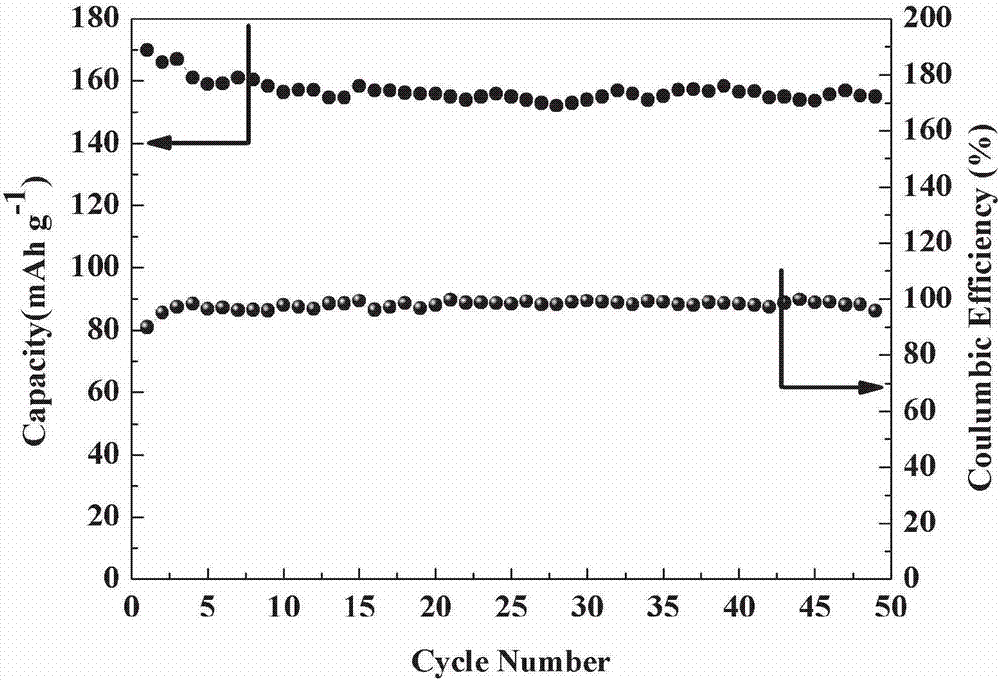

Lithium ion battery gradient core shell cathode material and synthetic method thereof

ActiveCN103236537AGuaranteed cycle performanceGuaranteed rate performanceCell electrodesNickel compoundsElectrical batteryPhysical chemistry

The invention provides a lithium ion battery gradient core shell cathode material and synthetic method thereof, and relates to a lithium ion battery cathode material and synthetic method thereof. The lithium ion battery gradient core shell cathode material provided by the present invention may have two kinds of core shell structures as follows: a two-layer structure: a ternary material is used as a core material, and a binary material or a unitary material is casing material, and the ternary material external layer is covered by the binary material or the unitary material; three-layer structure: the ternary material is used as a core material, and the binary material and the unitary material are casing materials, and the ternary material external layer is covered with the binary material, and the binary material is covered with the unitary material. The synthetic method includes: employing a coprecipitation method for obtaining a precursor, and then adding lithium source, calcining and coating to obtain the ternary gradient core shell material. Under the prerequisite that the structure stability of the material is kept, the cost is reduced, and the gram capacity of the material is improved, and the material circulating performance and rate capability of the material are improved, and the safety performance and low temperature performance of the ternary cathode material are increased, and the preparation technology is optimized and improved.

Owner:HARBIN INST OF TECH

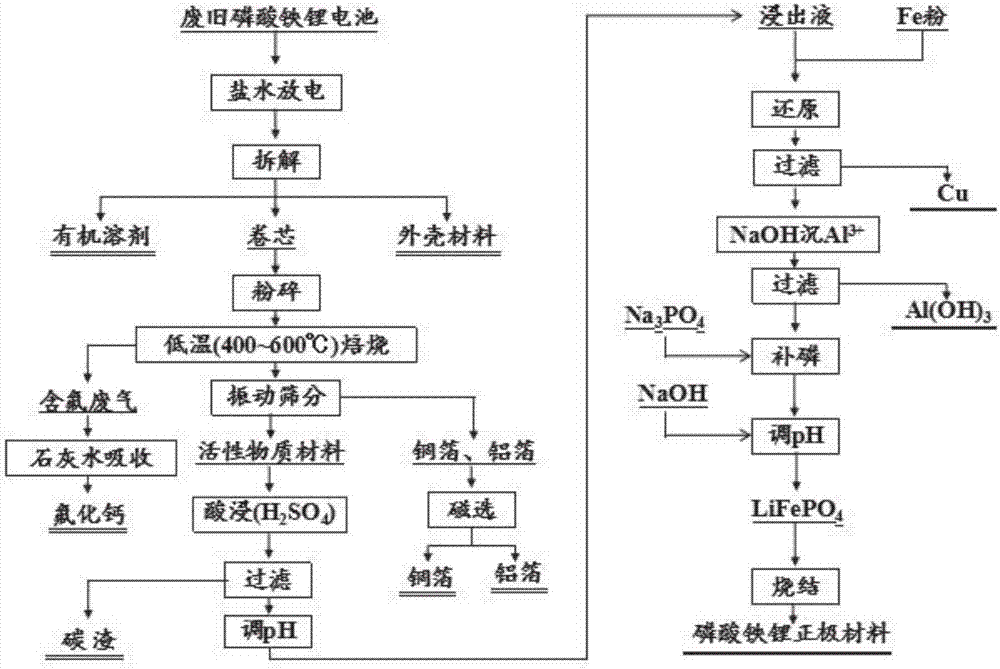

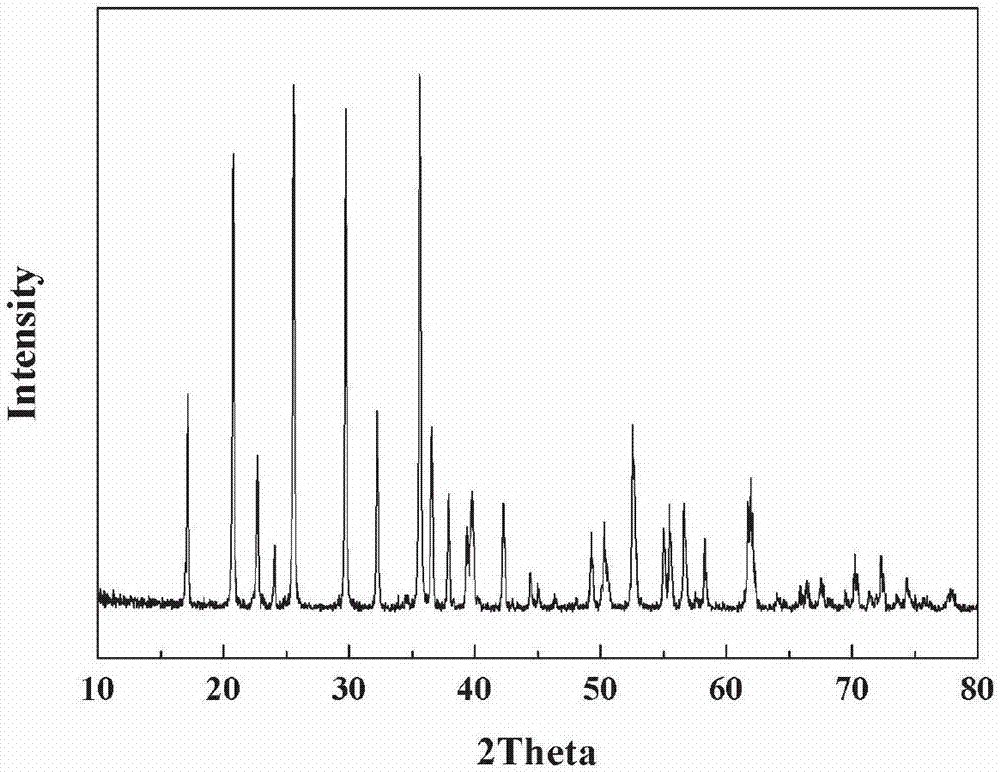

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

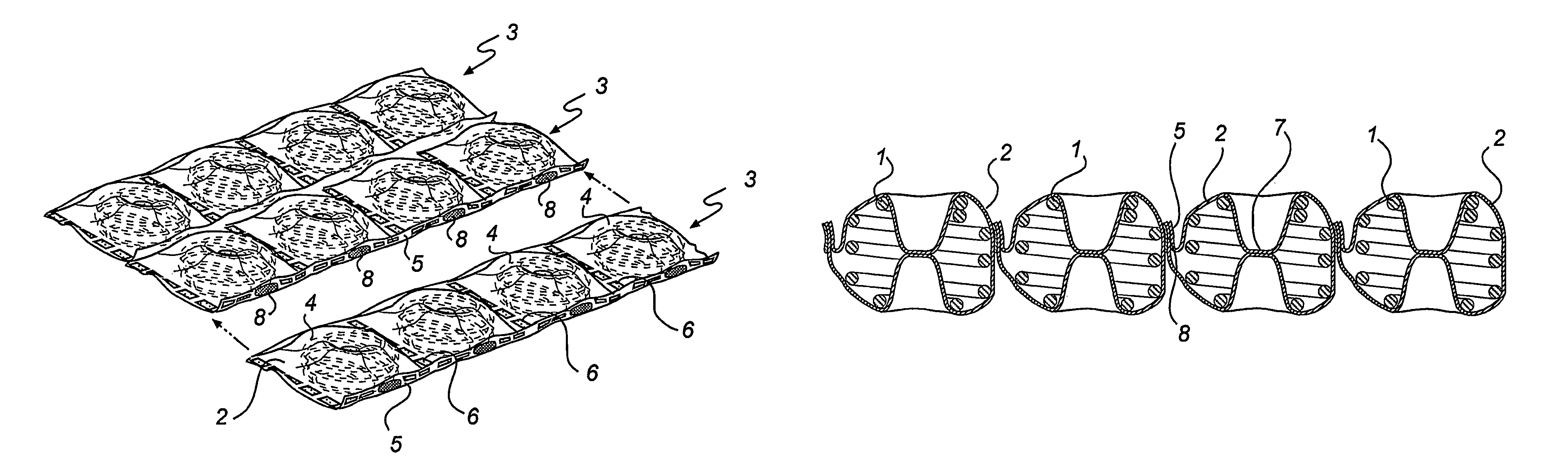

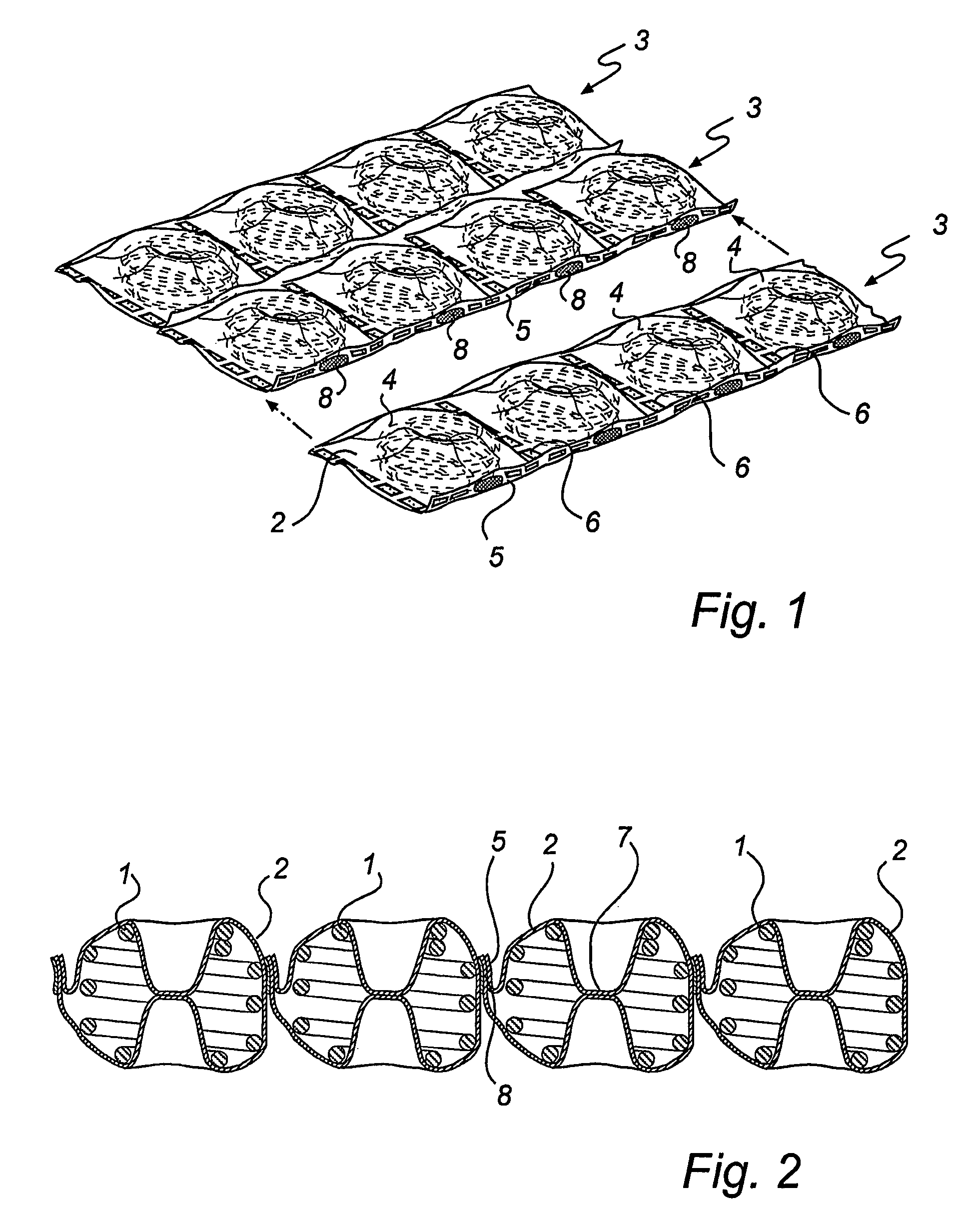

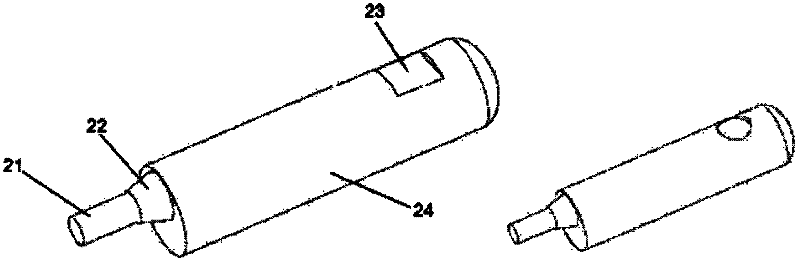

Thin pocket mattress, and method and device for its manufacturing

ActiveUS8087114B2Cost-effective manufacturingReduce the amount requiredStuffed mattressesMultiple spring combinationsCoil springEngineering

Owner:STJERNFJADRAR

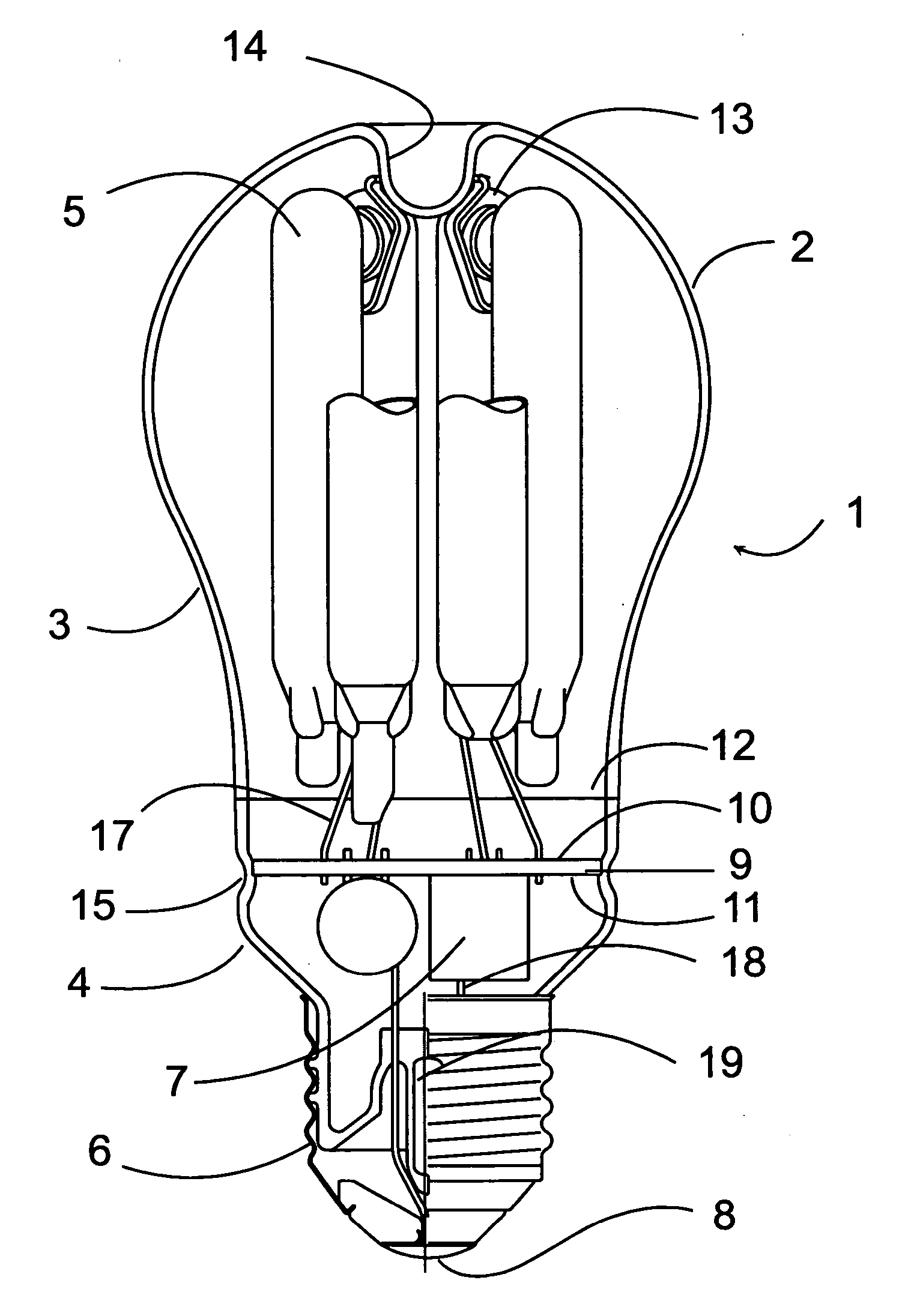

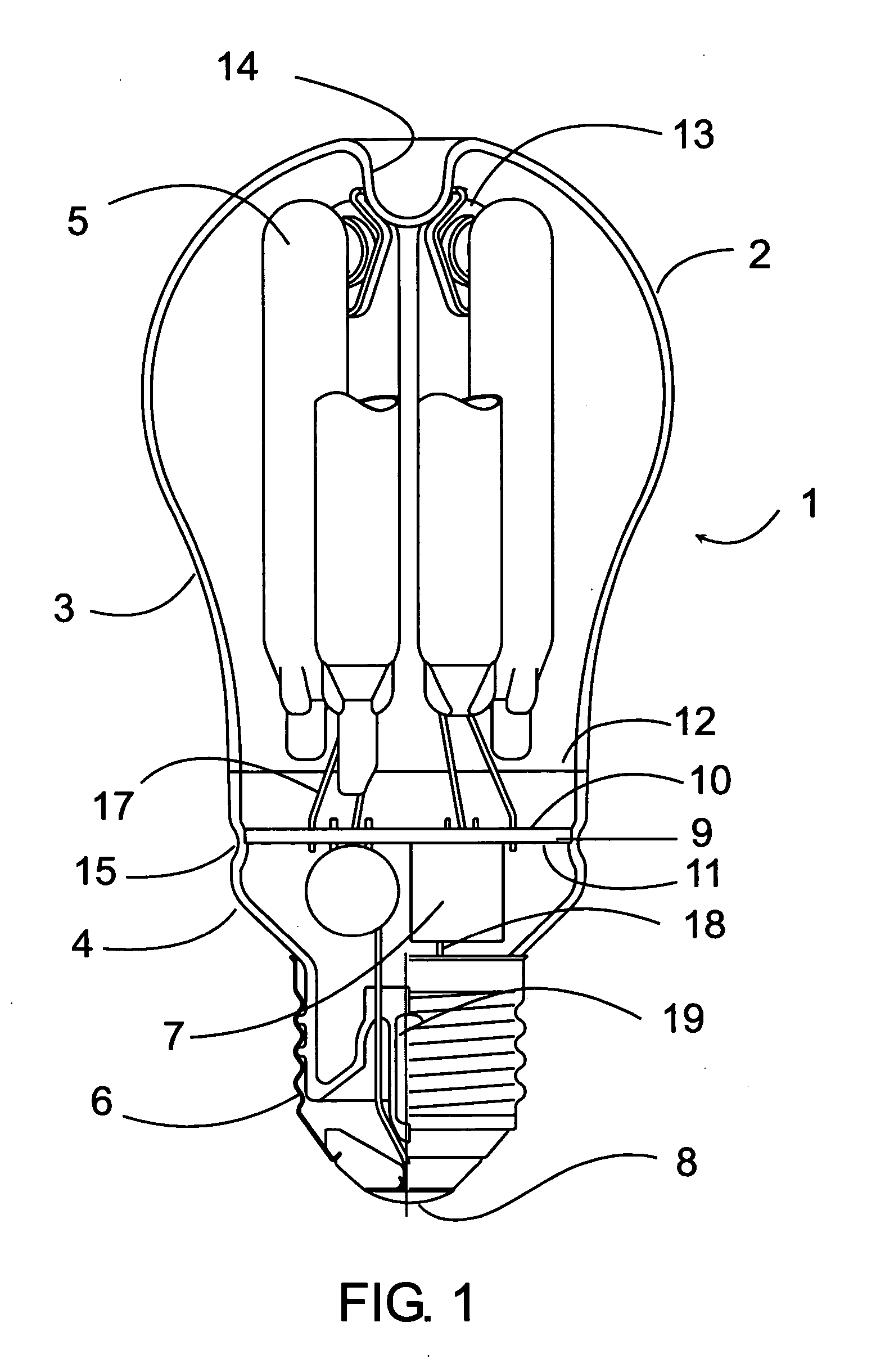

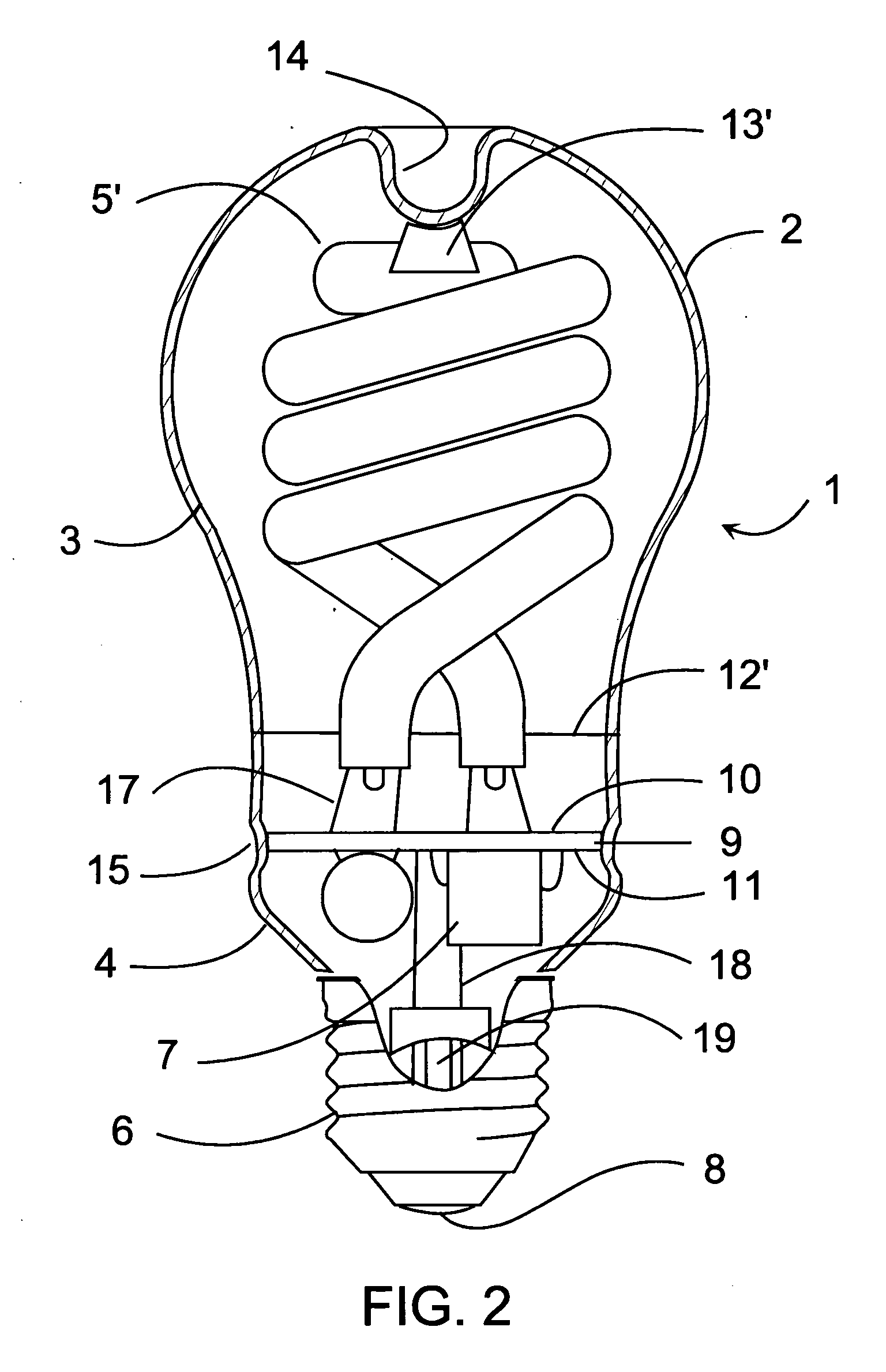

Compact fluorescent lamp and method for manufacturing

InactiveUS20070063656A1More to mechanical vibrationSimplify manufacturing stepsGas discharge lamp usageSolid cathode detailsElectrical ballastFluorescence

This compact fluorescent lamp comprises a discharge tube arrangement with at least one discharge tube. The tube is formed of glass, encloses a discharge volume filled with a discharge gas and has a fluorescent phosphor coating disposed on the inner surface of the tube. The tube forms a continuous arc path and the tube is provided with electrodes disposed at each end of the arc path. The lamp also comprises a ballast circuit connected to the electrodes for controlling the current in the tube and a lamp base for connecting said lamp to a power supply through a socket. The lamp is enclosed in an outer envelope comprising a substantially spherical portion enclosing the tube arrangement and an elongated end portion enclosing the ballast circuit. The end portion of the outer envelope is closed and sealed by a sealing means of the same material as the material of the outer envelope. The sealing means is connected to the envelope in a hermetically sealing way. A method for manufacturing a compact fluorescent lamp as described above is also disclosed. In the method, an outer envelope with an open end on the base side is provided. The open end of the envelope is closed and sealed with a sealing means to provide a hermetic seal. The envelope is separated by cutting along a circumferential line into an upper part and a lower part. The ballast circuit is introduced into the lower part and respective connection points of the ballast circuit are connected to power supply lead-out wires. The discharge tube arrangement is connected to respective connection points of the ballast circuit by lead-in wires. The lead-in wires and the lead-out wires are short and need not be insulated. The ballast circuit and the discharge tube arrangement are held and supported in the outer envelope by the connecting wires and fixing means.

Owner:GENERAL ELECTRIC CO

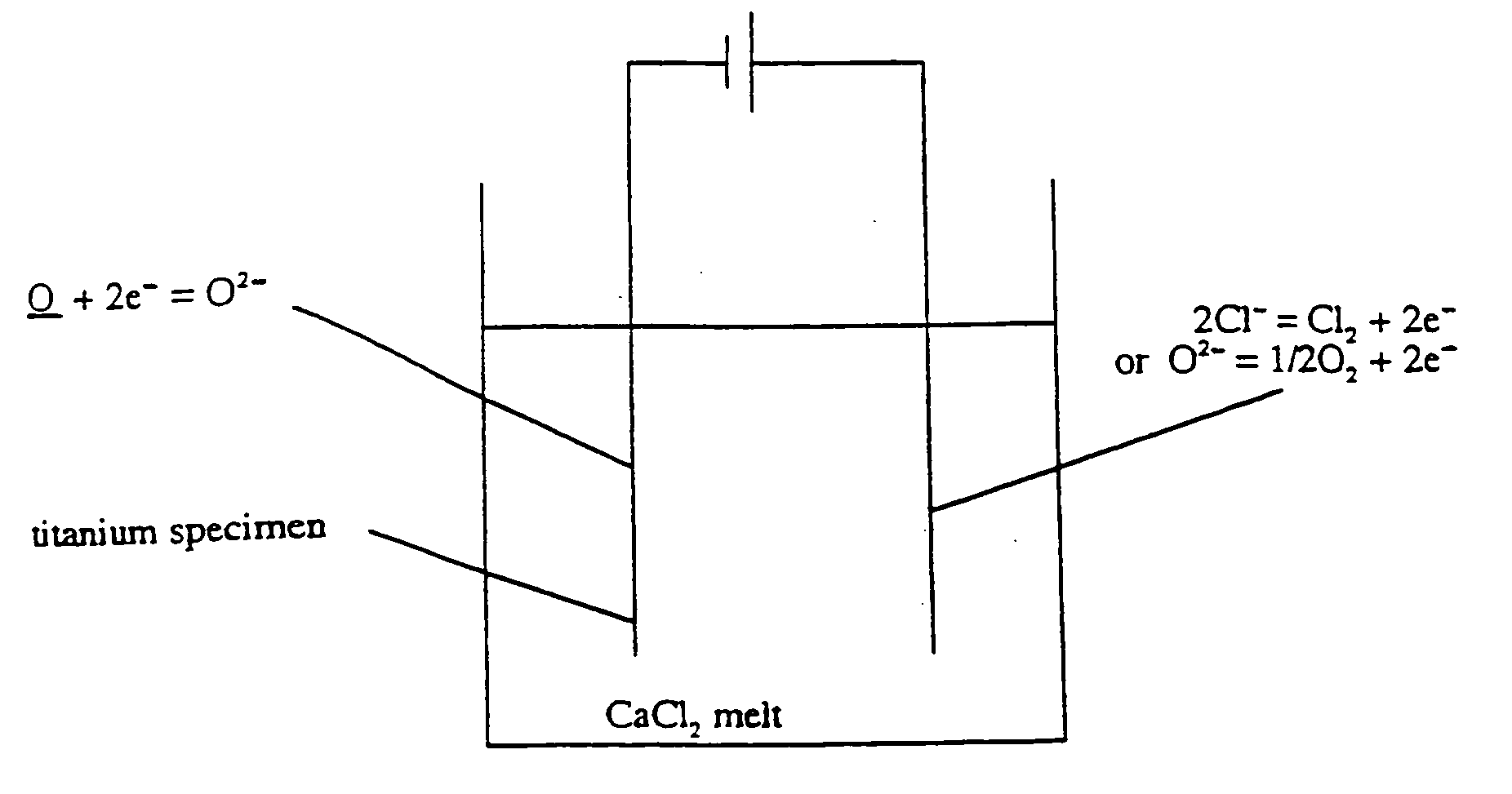

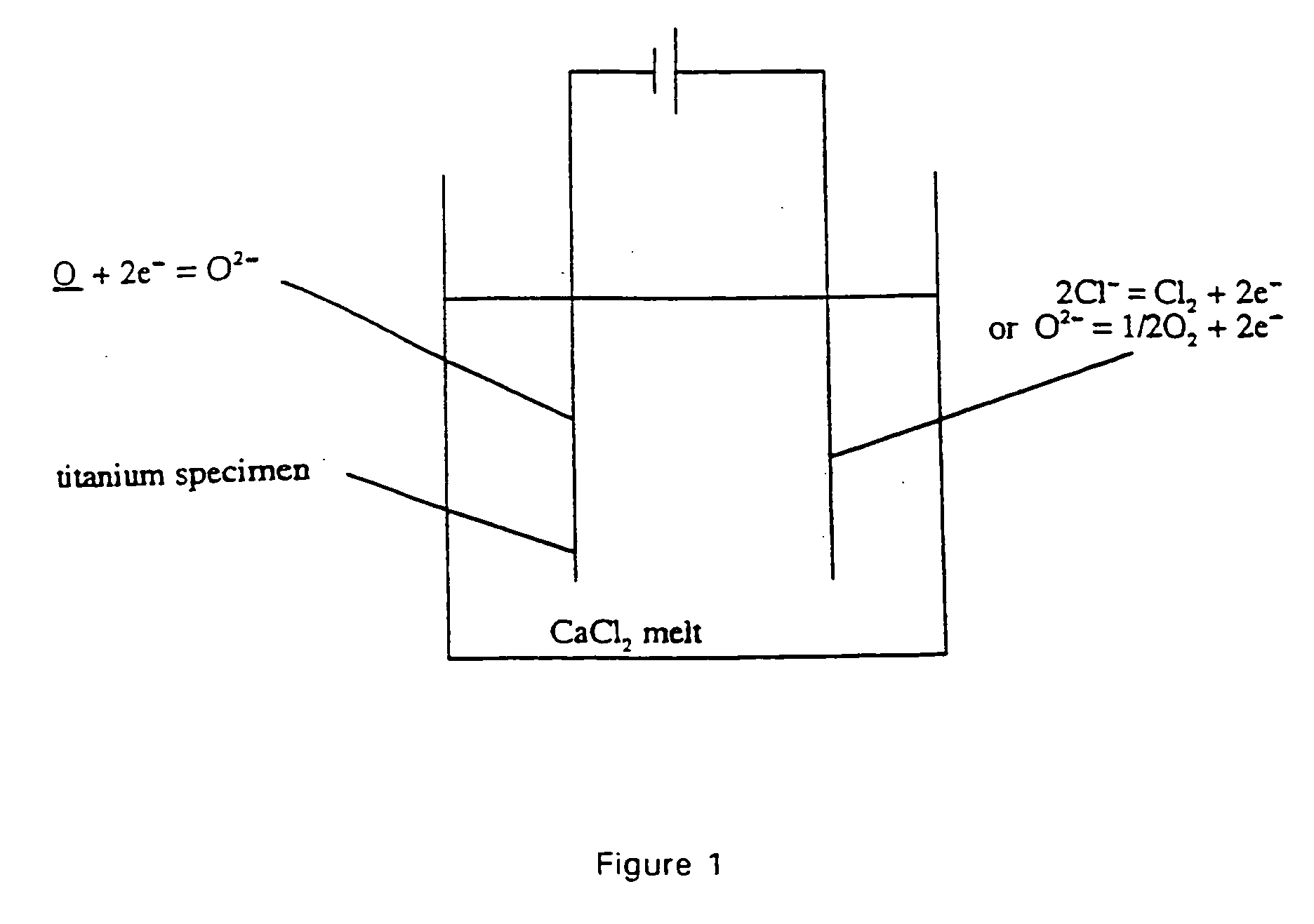

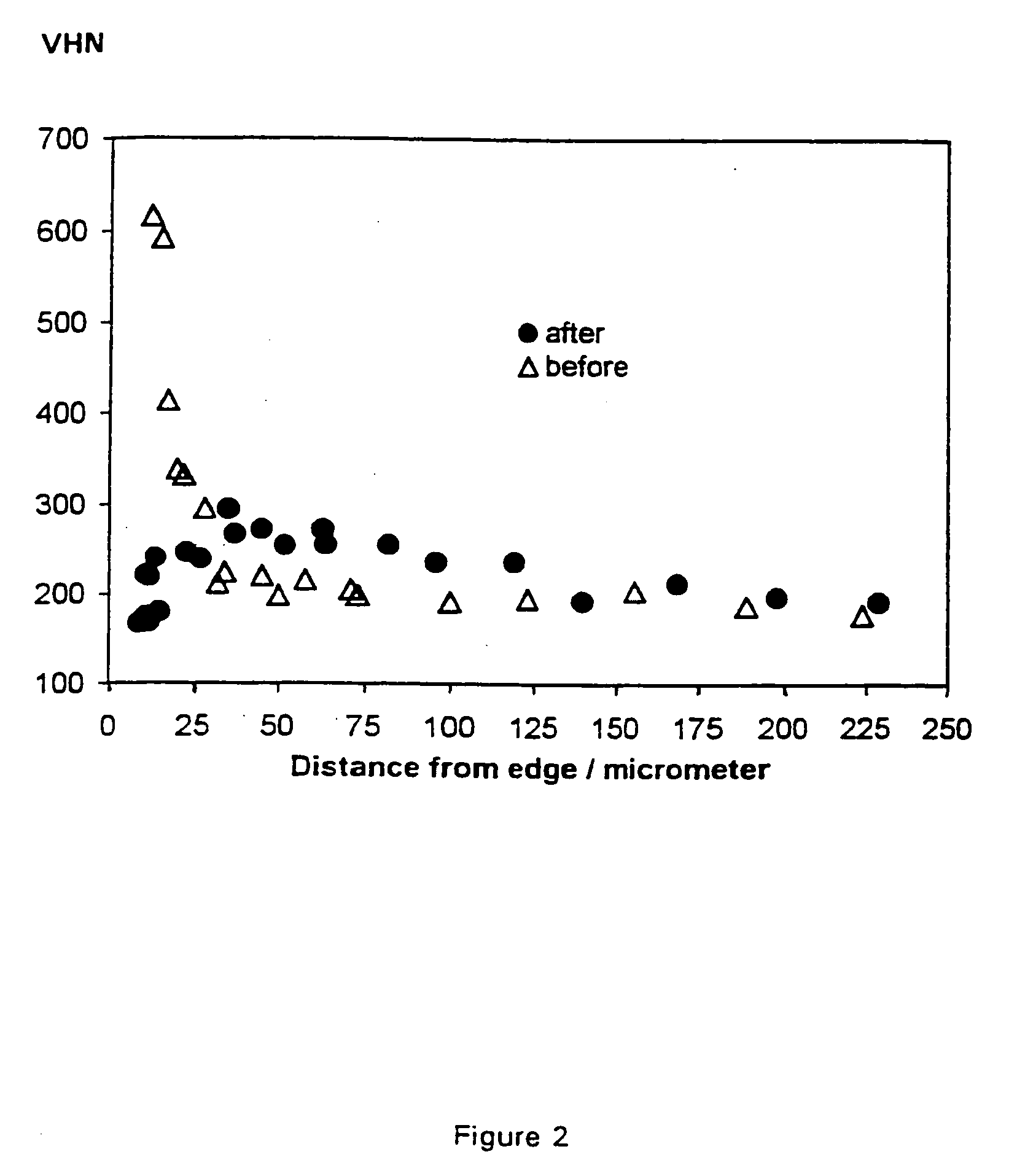

Removal of substances from metal and semi-metal compounds

InactiveUS6712952B1Polycrystalline material growthFrom normal temperature solutionsMelting temperatureMetal

The present invention pertains to a method for removing a substance (X) from a solid metal or semi-metal compound (M<1>X) by electrolysis in a melt of M<2>Y, which comprises conducting the electrolysis under conditions such that reaction of X rather than M<2 >deposition occurs at a electrode surface, and that X dissolves in the electrolyte M<2>Y. The substance X is either removed from the surface (i.e., M<1>X) or by means of diffusion extracted from the case material. The temperature of the fused salt is chosen below the melting temperature of the metal M<1>. The potential is chosen below the decomposition potential of the electrolyte.

Owner:METALYSIS

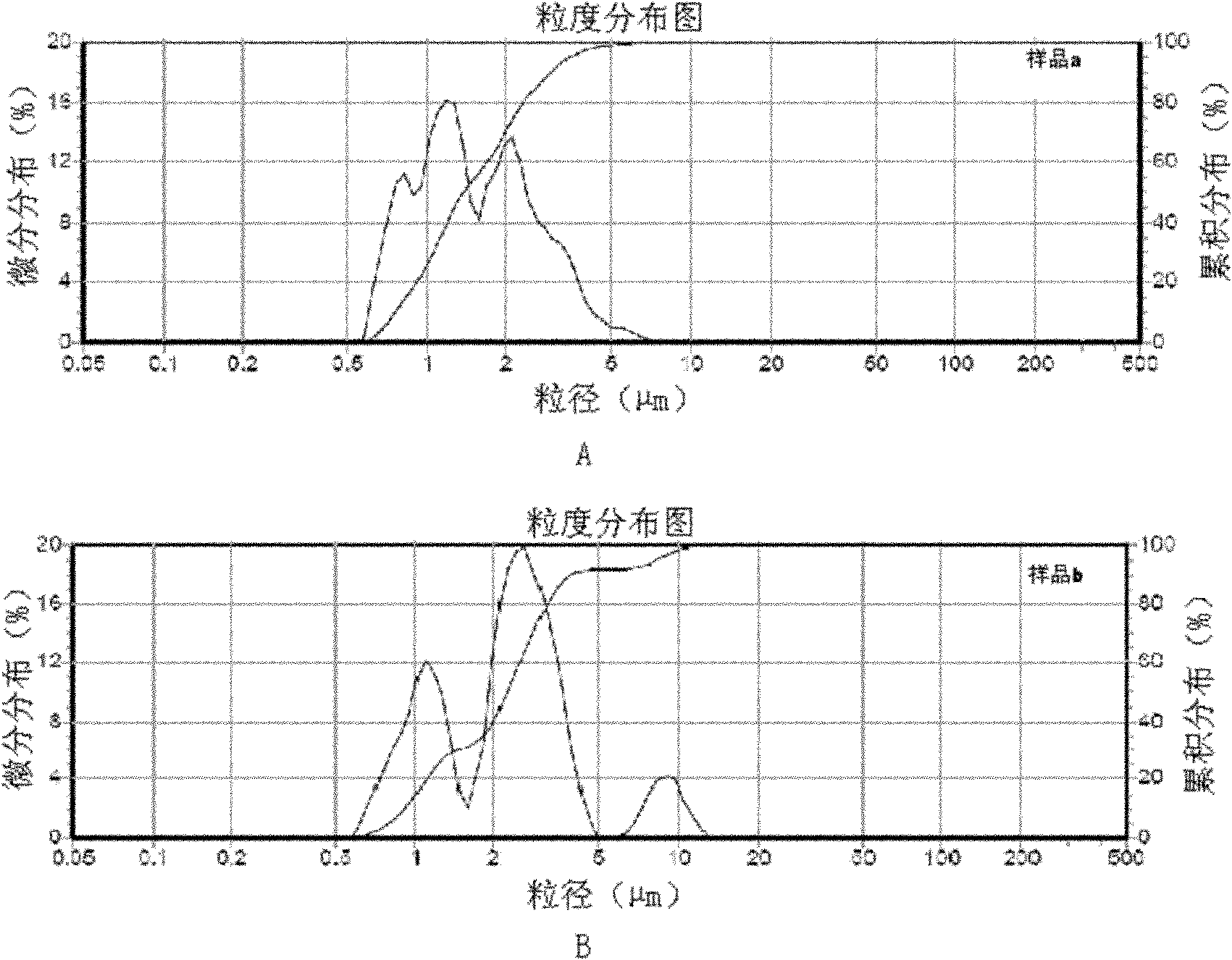

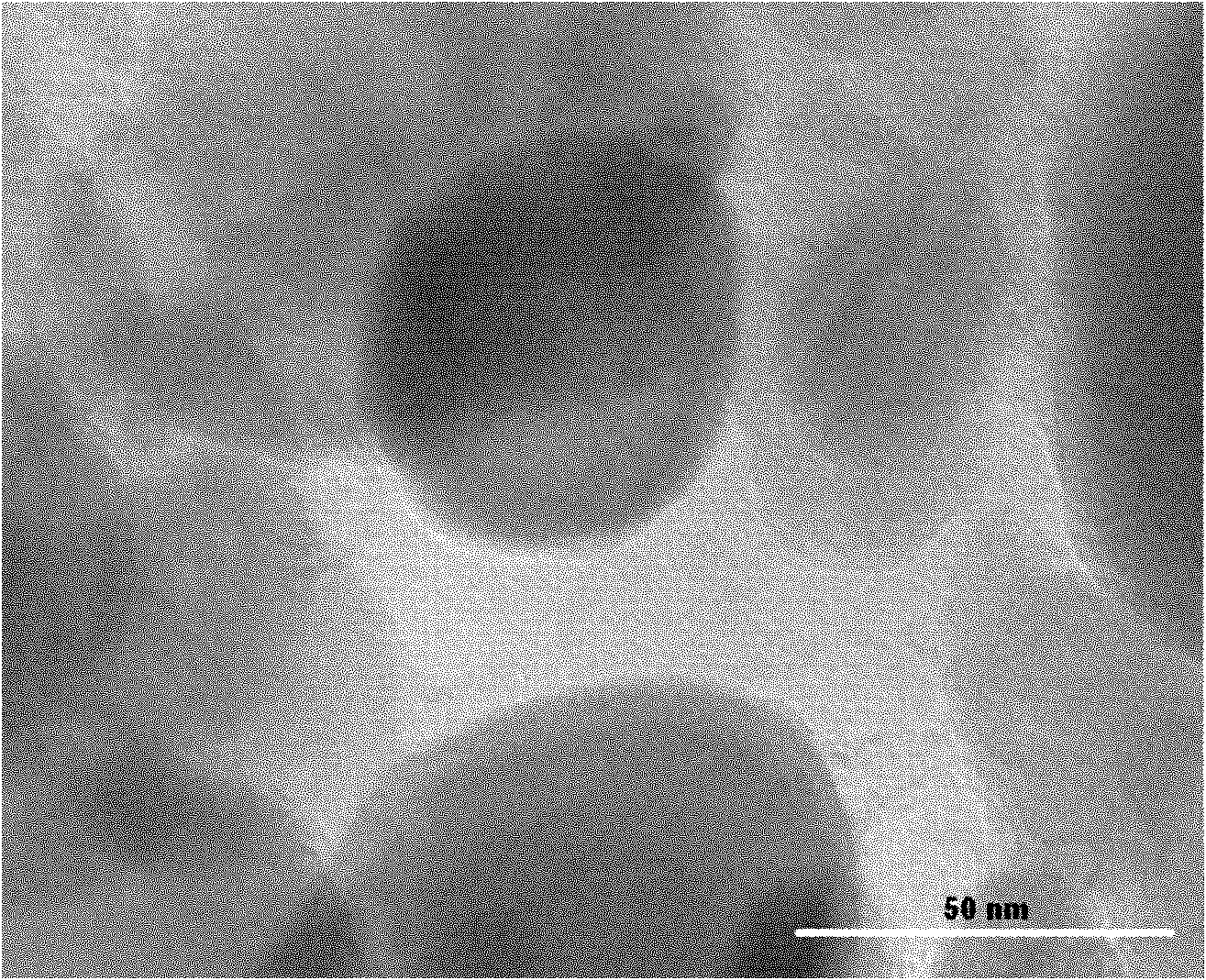

Lithium ion phosphate positive electrode material of nanometer core shell structure and preparation method thereof

InactiveCN102420324AShape is easy to controlControllable granularityCell electrodesPhosphateMixed materials

The invention discloses a lithium ion phosphate positive electrode material of a nanometer core shell structure. The positive electrode material is provided with an inner core active material and a conductive outer shell structure; a conductive agent is an outer shell material; the active material is of an inner core structure; and the structure formula of the inner core active material is LiFe[1-x]MxP[1-y]AyO4, wherein x is greater than or equal to 0, y is less than or equal to 0.1, M is a transition metal element, and A is silicon. Additionally, the invention also discloses a preparation method of the lithium ion phosphate positive electrode material. According to the preparation method in the invention, a porous material is adopted as a synthesis microreactor, and a lithium ion phosphate precursor is loaded and filled in holes, namely, the inner core active precursor reversely wraps a porous precursor so as to form a special nanometer core shell structure, thus the topography granularity of primary granule is controlled; and the lithium ion phosphate positive electrode material of the nanometer core shell structure is prepared by adopting a liquid phase mixed material and solid phase sintering technology. According to the invention, on the premise that the electrical performance of the positive electrode material is not influenced, a nanometer core shell structured active substance with uniform and controllable topography and granularity is synthesized; and the preparation method disclosed by the invention has lower technology, devices and control costs, which is beneficial to large-scale production.

Owner:SHANGHAI PYLON TECH CO LTD

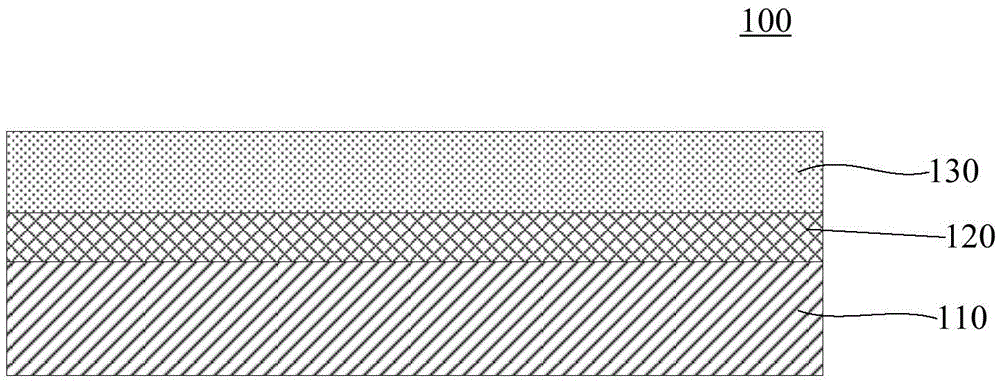

Packaging material for electronic-part case, and others

InactiveUS20040142190A1Less directionalitySuperior to heat sealing propertyBattery isolationSynthetic resin layered productsElectronic componentAluminum foil

The present invention provides a casing material for an electronic component which has a good adhesion with an aluminum foil and a resin layer, impermeability of steam, heat seal property, and corrosion resistance for an electrolyte. The present invention also provides a casing for an electronic component using the casing material. The present invention also provides an electronic component including the casing. The casing material comprises a heat resistant resin drawn film layer as an outer layer, a thermoplastic resin not-drawn film as an inner layer, and an aluminum foil layer provided between the layers. In particular, an acrylic polymer layer is provided between the aluminum foil layer and the not-drawn film layer.

Owner:SHOWA DENKO PACKAGING CO LTD +1

Scratch-Resistant Flameproof Thermoplastic Resin Composition

ActiveUS20090118402A1Improve scratch resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsDyeing processPolyethylene terephthalate glycolPolyethylene terephthalate

Disclosed herein is a flame retardant thermoplastic resin composition that has superior scratch resistance and mechanical properties, satisfying requirements for the appearance of housing materials resulting from a recent increase in volume of electrical and electronic products, and that contains a phosphorus-based flame-retarding agent, satisfying requirements for fire safety and prevention of environmental problems. The resin composition with scratch resistance comprises a base resin comprising (A) about 30 to about 90 parts by weight of a polycarbonate resin, (B) about 15 to about 50 parts by weight of a polymethylmethacrylate resin and (C) about 5 to about 50 parts by weight of a polyethylene terephthalate-based resin, and (D) about 5 to about 30 parts by weight of a phosphorus-based flame-retarding agent based on 100 parts by weight of the base resin. The composition may further comprise about 1 to about 30 parts by weight of an impact modifier based on 100 parts by weight of the base resin.

Owner:LOTTE ADVANCED MATERIALS CO LTD

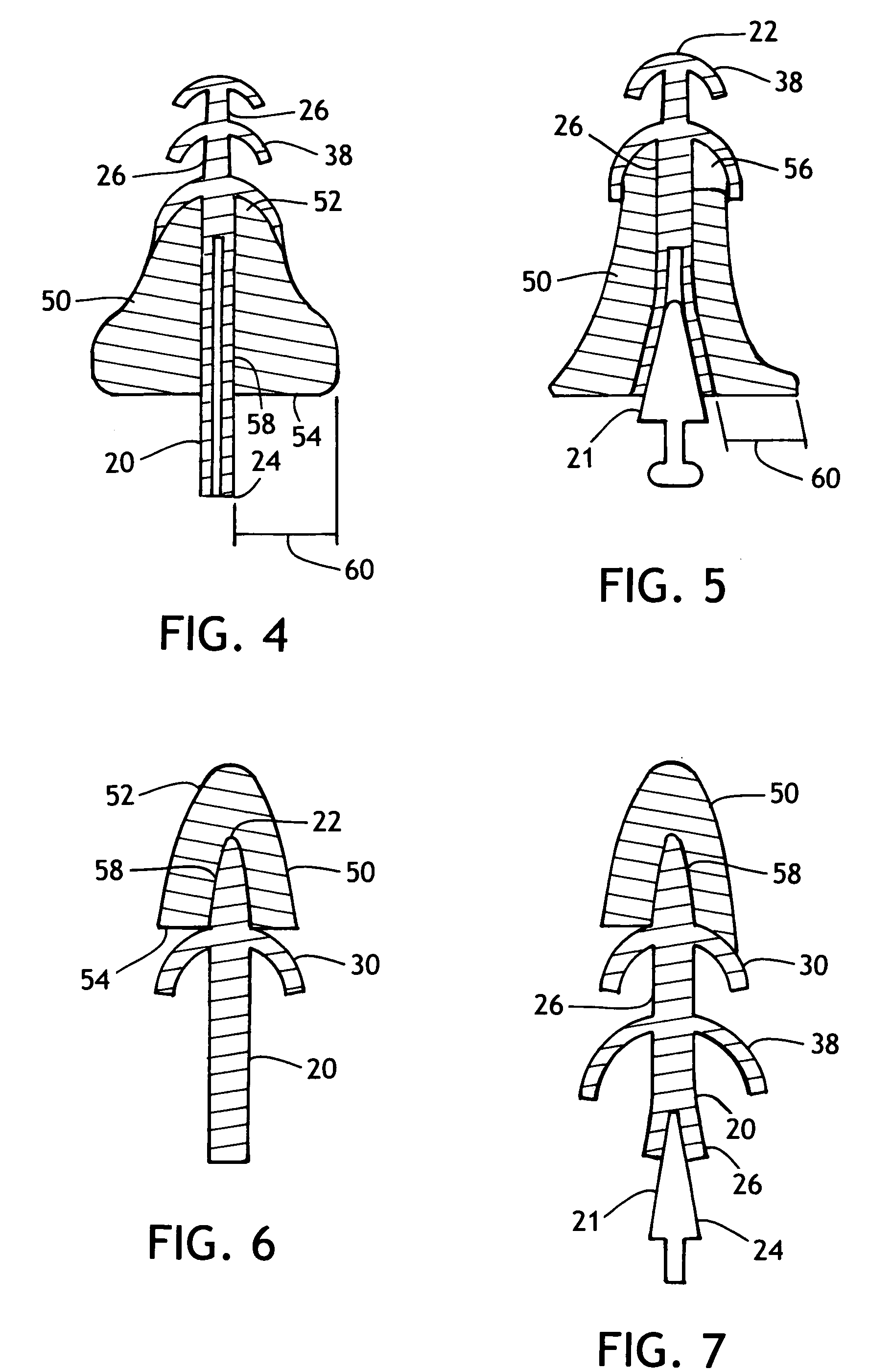

Self-conforming sound attenuation earplug

A self-conforming sound attenuation earplug for location in an ear canal. The earplug includes a stem. At least one support is joined with the stem and located between the stem ear end and the stem user end, and extends radially outward from the stem. A shell is made of a deformable-resilient shell material and has a tapered exterior that increases in circumference when moving from the stem ear end to the stem user end. The shell engages at least a portion of the support and engages at least a portion of the stem located between the stem ear end and the stem user end. At least a portion of the support is free from contact with the shell and the support material is a different type of material than the shell material.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Electronic product case and manufacturing method thereof

The invention relates to an electronic product case and a manufacturing method thereof. The electronic product case comprises a metal or alloy body layer and a flashing effect layer arranged on the metal or alloy body layer. The flashing effect layer is a coating layer doped with flashing particles, or the flashing effect layer is an overlaying structure formed by a flashing particle layer and the coating layer that is outside, or the flashing effect layer is a mixed layer overlaid by the coating layer doped with flashing particles and the overlaying structure. The electronic product case has a flashing effect, can make the product more fashionable, and improves the user experience. According to the manufacturing method, the coating layer is sprayed and prepared on the metal or alloy case material, so that the appearance of the product is effectively protected and is less likely to wear.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

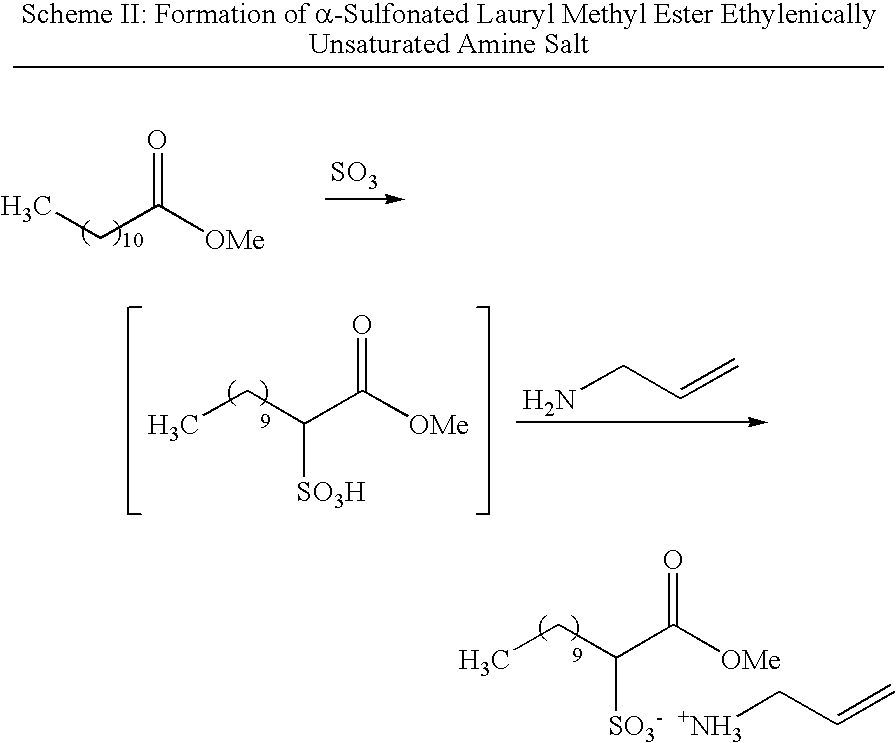

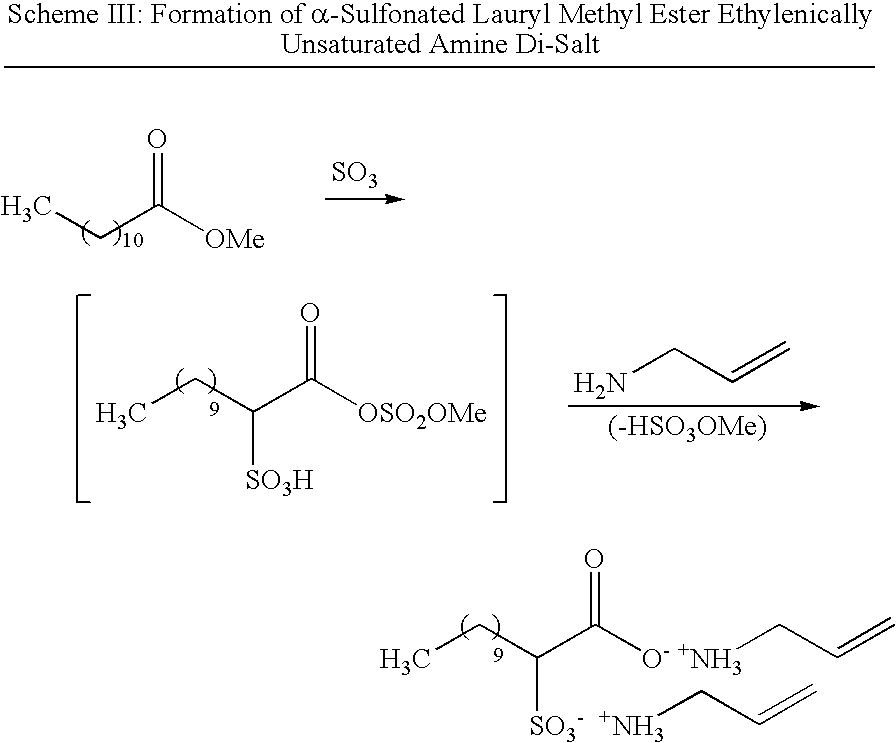

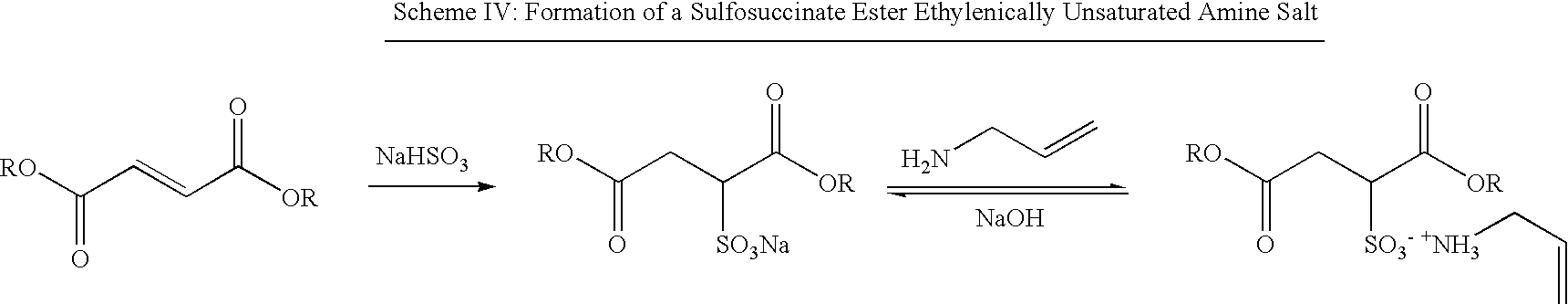

Antimicrobial polymer latexes derived from unsaturated quaternary ammonium compounds and antimicrobial coatings, sealants, adhesives and elastomers produced from such latexes

InactiveUS6900265B2Improve propertiesImprove water sensitivitySpecial tyresCoatingsElastomerPolymer science

An improved method of making CASE materials is provided, wherein the method utilizes a polymer latex derived from at least one ethylenically unsaturated monomer and at least one polymerizable surface active agent. The polymerizable surface active agent is capable of co-polymerization with traditional monomers and is preferably substantially completely consumed during the course of the polymerization. Latex polymers produced by the method of the present invention are well suited for use in coatings, adhesives, sealants, elastomers. Additionally, the present invention relates to improved coating, adhesive, sealant and elastomer (CASE) materials utilizing polymer latexes derived from various monomers and ethylenically unsaturated amine salts of sulfonic, phosphoric and / or carboxylic acids.

Owner:STEPAN COMPANY

Thermoplastic resin composite material for laptop shells and manufacturing method thereof

The invention relates to a thermoplastic resin composite material for laptop shells and a manufacturing method thereof. The composite material comprises the following components in percentage by weight: 40 to 60 parts of thermoplastic resin, 10 to 20 parts of organic fibers, 0 to 20 parts of inorganic fibers, 0 to 10 parts of other aids, and 20 to 40 parts of halogen-free flame-retarding master batch. The manufacturing method comprises: melting thermoplastic resin to obtain melt, immersing fibers into the melt of the thermoplastic resin, adding other aids into the melt, cooling the melt, and making fiber reinforced thermoplastic resin granules; and mixing the granules and the halogen-free flame-retarding master batch in batch to obtain the composite material. Compared with the prior art, the composite material manufactured by the method has high toughness, high strength and high rigidity, and has the characteristics of environment-friendliness, flame retardance, high thermostability, and low-temperature toughness. The thermoplastic resin composite material is an ideal novel laptop shell material.

Owner:HEFEI GENIUS NEW MATERIALS

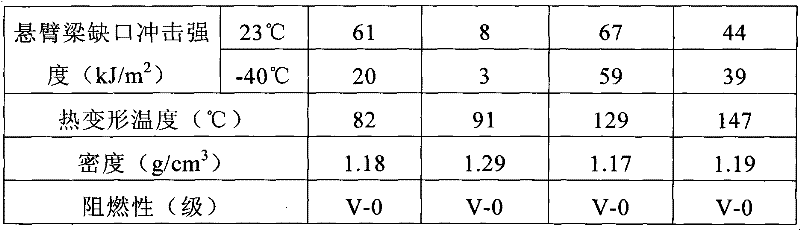

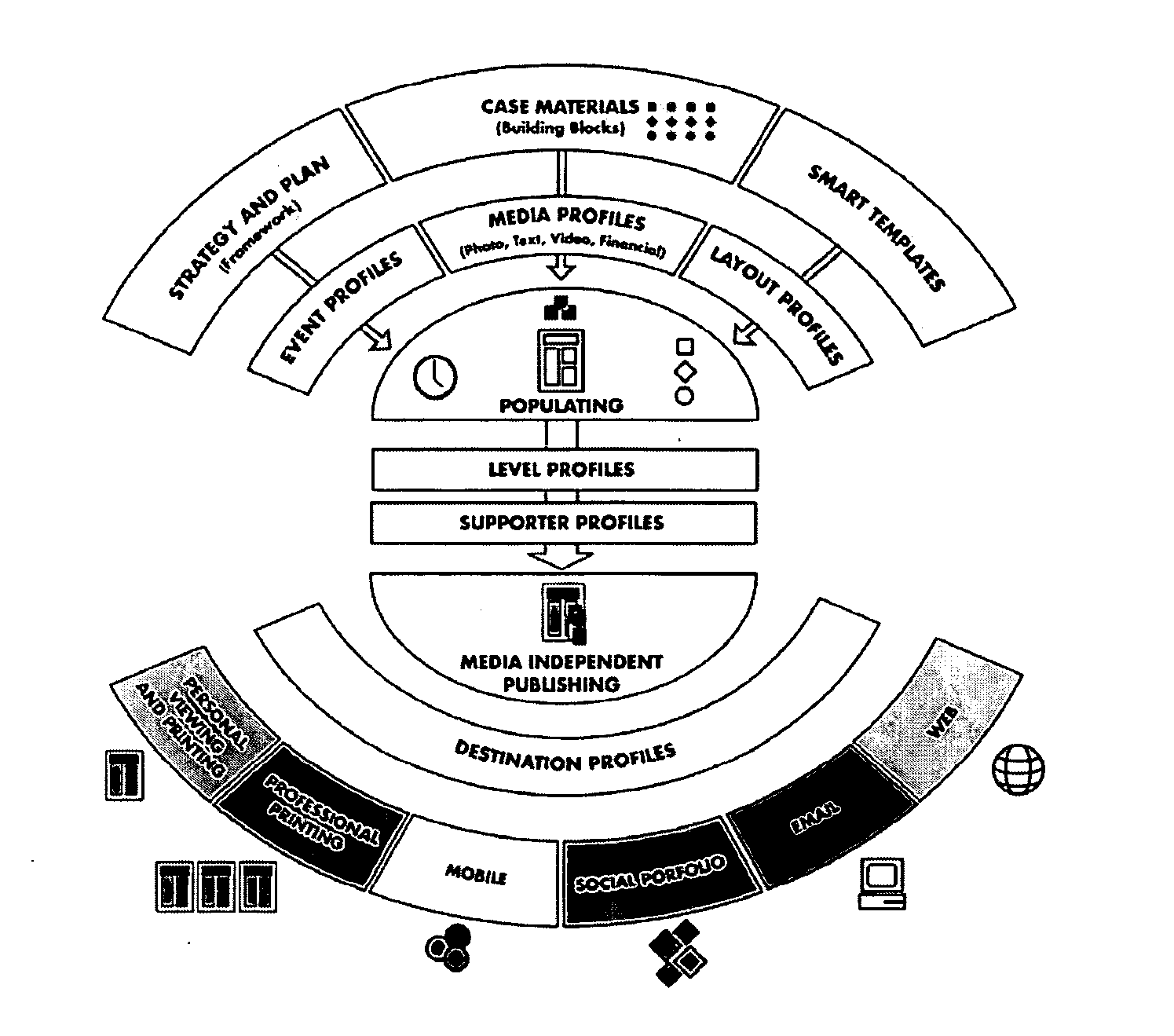

Personalized automatic publishing extensible layouts

InactiveUS20050081148A1Natural language data processingSpecial data processing applicationsPersonalizationDocumentation generator

A software-based system automatically generates personalized communications including arrangements for communicating with various databases, servers and client systems. A smart templates document generator uses multiple categories and types of profiles such as case materials, destination and layout, and supporter profiles, as well as event, level and document profiles. The system further utilizes substantially or completely media independent communications of materials involving database and communications software architectures, input device / output display synchronization techniques, and graphics rendering software implementations.

Owner:PAPILIA PATENTS

Graphene micro-sheet used for waterborne anticorrosive coating and preparation method thereof

InactiveCN106566303ADefects that reduce corrosion resistanceEasy to peelAnti-corrosive paintsSolubilityGraphite

The invention discloses a graphene micro-sheet used for a waterborne anticorrosive coating and a preparation method thereof. According to the invention, graphite is stripped to prepare the graphene micro-sheet by utilizing mechanical shearing force, so the lamellar structure of graphene is protected, and the corrosion resistance of graphene lamella is avoided from decrease due to damage of the graphene lamella; meanwhile, in the process of preparing the graphene micro-sheet, a surfactant is utilized for surface modification of the prepared graphene micro-sheet, so the water solubility of the graphene micro-sheet is increased; the modified graphene is coated with a shell material, so a modified graphene microcapsule with a shell is formed, and the modified graphene is prevented from agglomeration during storage and formulation; and the shell is a macromoleclar polymer, so the compatibility of graphene with materials in the anticorrosive coating can be improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

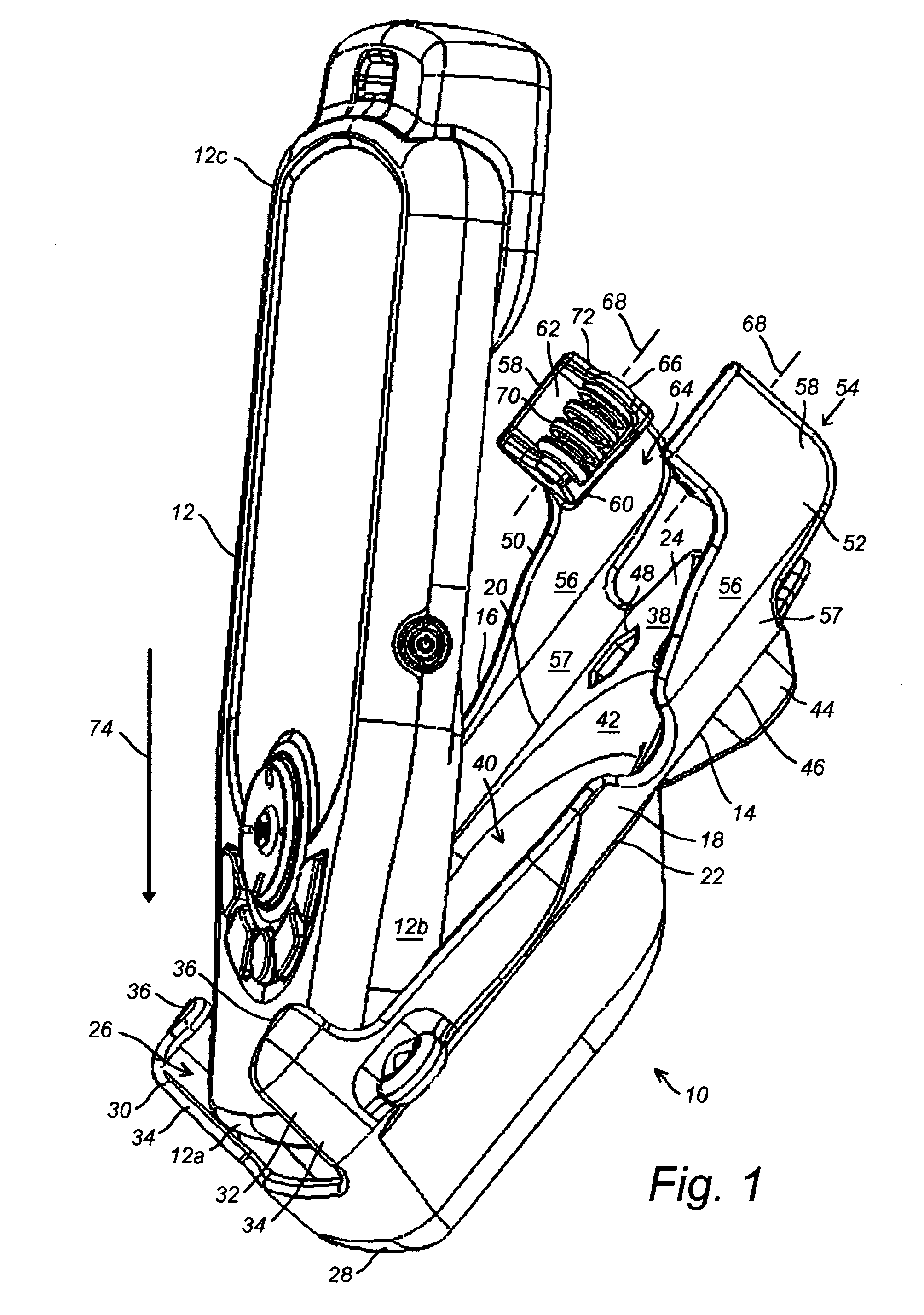

Portable device holder

A quick release device holder for portable electronics devices that protects soft and impressionable housing materials from damage during insertion and removal. The quick release device holder includes a backing plane formed with a substantially rigid spine portion and a receiver pocket adjacent to a first end thereof. One or more latching arms extend from the backing plane spaced away from the receiver pocket, each of the one or more latching arms further including a resiliently flexible stem portion coupled to the backing plane and having a head portion spaced away from the backing plane. The head portion further includes one or more rollers coupled thereto in a position spaced away from an interior surface of the backing plane, and a retention tongue between the one or more rollers and the interior surface of the backing plane and being set back from a circumference of the one or more rollers.

Owner:CARNEVALI JEFFREY D

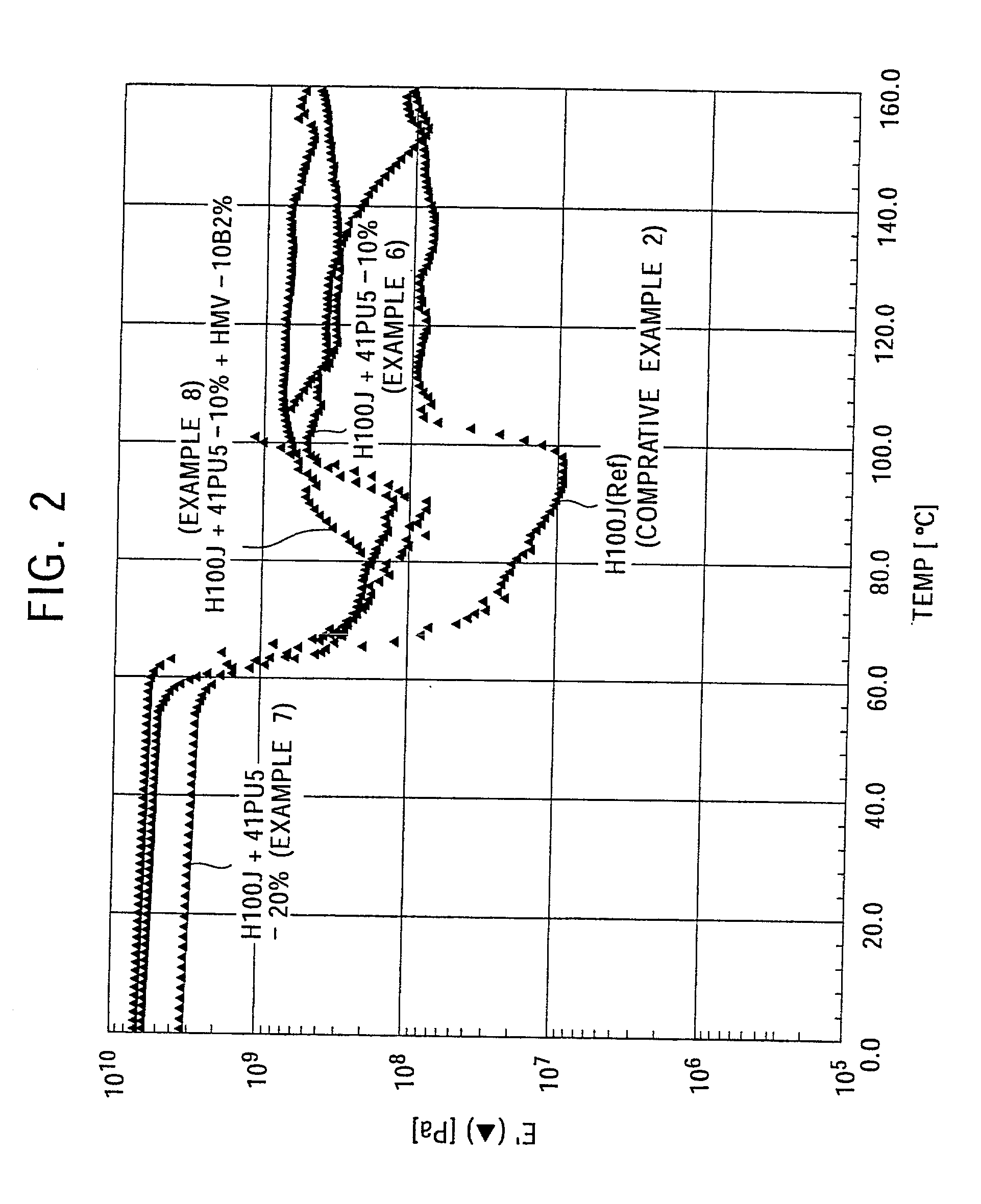

Biodegradable resin material and method for producing the same

Mica is incorporated into a biodegradable resin material comprised mainly of polylactic acid, for example, into polylactic acid which is an aliphatic polyester resin. It is desired to incorporate into polylactic acid mica and a carbodiimide compound as an additive for suppressing hydrolysis of polylactic acid. Further, the biodegradable resin composition is subjected to aging by heating and desirably further using an electromagnetic wave or the like to suppress rapid lowering of the storage elastic modulus, and the biodegradable resin composition is used as a material for household electric appliances and housing materials.

Owner:SONY CORP

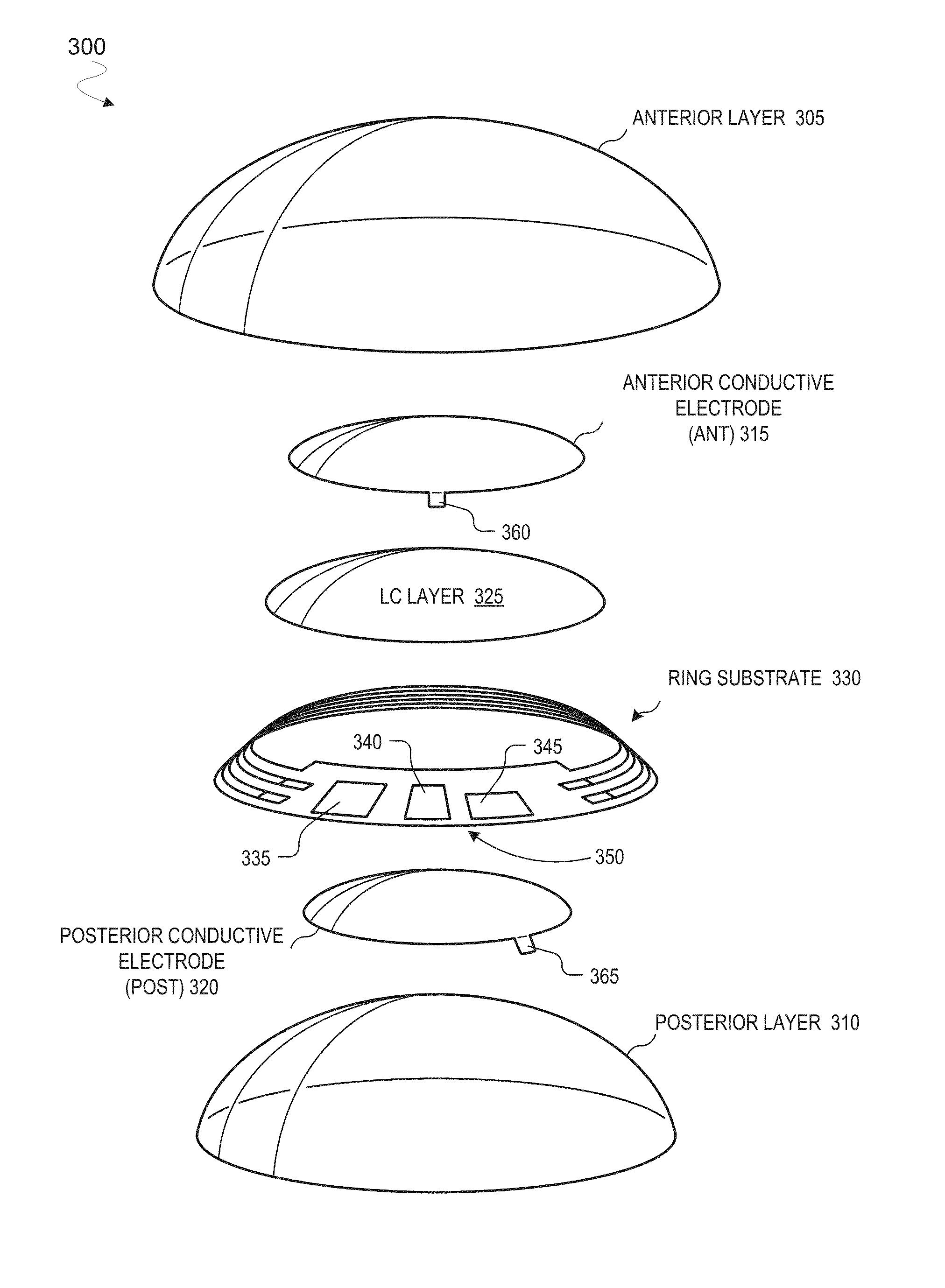

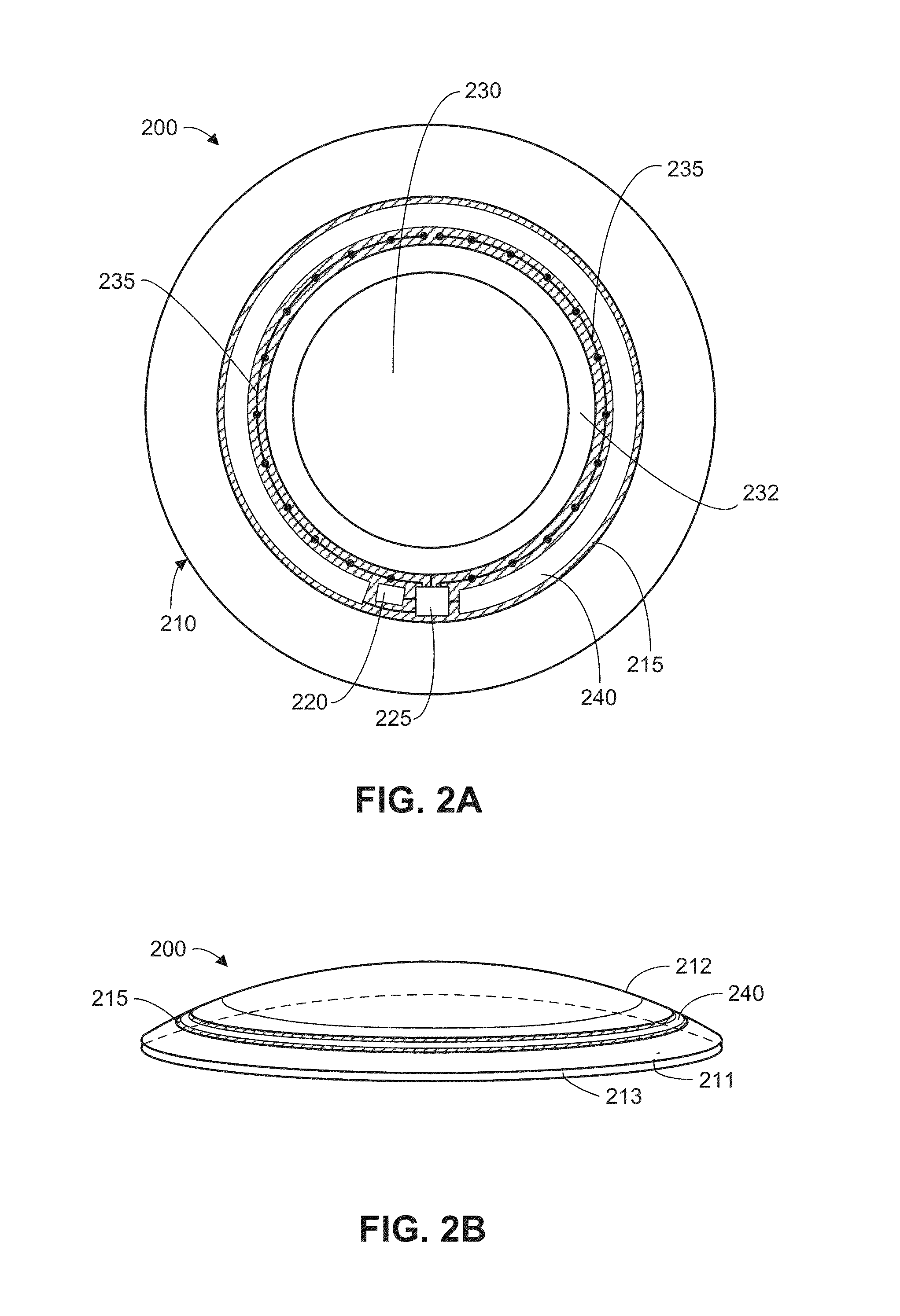

Eye-mountable device to provide automatic accommodation and method of making same

Techniques and mechanisms for providing an eye-mountable device including an accommodation actuator. In an embodiment, fabrication of the eye-mountable device includes sealing layers of enclosure material to form a lens enclosure comprising a pinch-off region where the layers of enclosure material physically contact one another. The accommodation actuator includes a liquid crystal layer disposed between the layers of enclosure material in a central region around which the pinch-off region extends. In another embodiment, electrodes are disposed in the central region each between the liquid crystal layer and a respective one of the layers of enclosure material. The liquid crystal layer isolates the electrodes from one another in the central region.

Owner:TWENTY TWENTY THERAPEUTICS LLC

Light scattering polycarbonate composition for light emitting diode (LED) lighting and use thereof

InactiveCN102134383AHigh transparencyGood light uniformityPoint-like light sourceSemiconductor devices for light sourcesMicrospherePolystyrene

The invention discloses a light scattering polycarbonate composition for LED lighting and use thereof. The composition comprises polycarbonate and a light scattering agent, wherein the light scattering agent is core-shell light scattering powder which takes a glass microsphere, silicon dioxide, a polysiloxane microsphere or polystyrene as a core and acrylate polymer or methacrylate polymer as a shell. The light scattering polycarbonate composition for LED lighting, which is disclosed by the invention, has higher transparency and better light homogenizing effect than other light scattering compositions. The composition disclosed by the invention can be used as a shell material in the field of lighting or display such as LED lamps, fluorescent lamps and incandescent lamps.

Owner:JINAN UNIVERSITY

Micro optical probe of endoscope

ActiveCN102401995AImmune to environmental factorsAchieve high volumeSurgeryDiagnostic recording/measuringOptomechatronicsEndoscope

The invention discloses a micro optical probe of endoscope, which comprises an MEMS microscope, a circuit board, a self focusing optical assembly, a locating bottom plate and a housing; the micro optical probe of endoscope is characterized in that: the endoscope probe is designed by using integrated symmetrical structure, the MEMS microscope; the circuit board and the self focusing optical assembly are assembled on the locating bottom plate according to design requirements of optomechatronics to form a probe body, and a probe housing is formed by injection molding or casting and is tightly connected with the probe body. The housing opposite to the microscope surface of the MEMS microscope can be formed with an optical window, or the housing material is transparent to the used light. The probe housing is formed at a time by injection molding / casting technology, and this structure can protect the MEMS microscope from being influenced with environment factor and can bear a certain vibration impact and random shock; the sealed probe can work in various liquid environments; and large-batch and low-cost processing production of probes can be realized, and the aim of disposable probes will be fulfilled.

Owner:无锡微文半导体科技有限公司

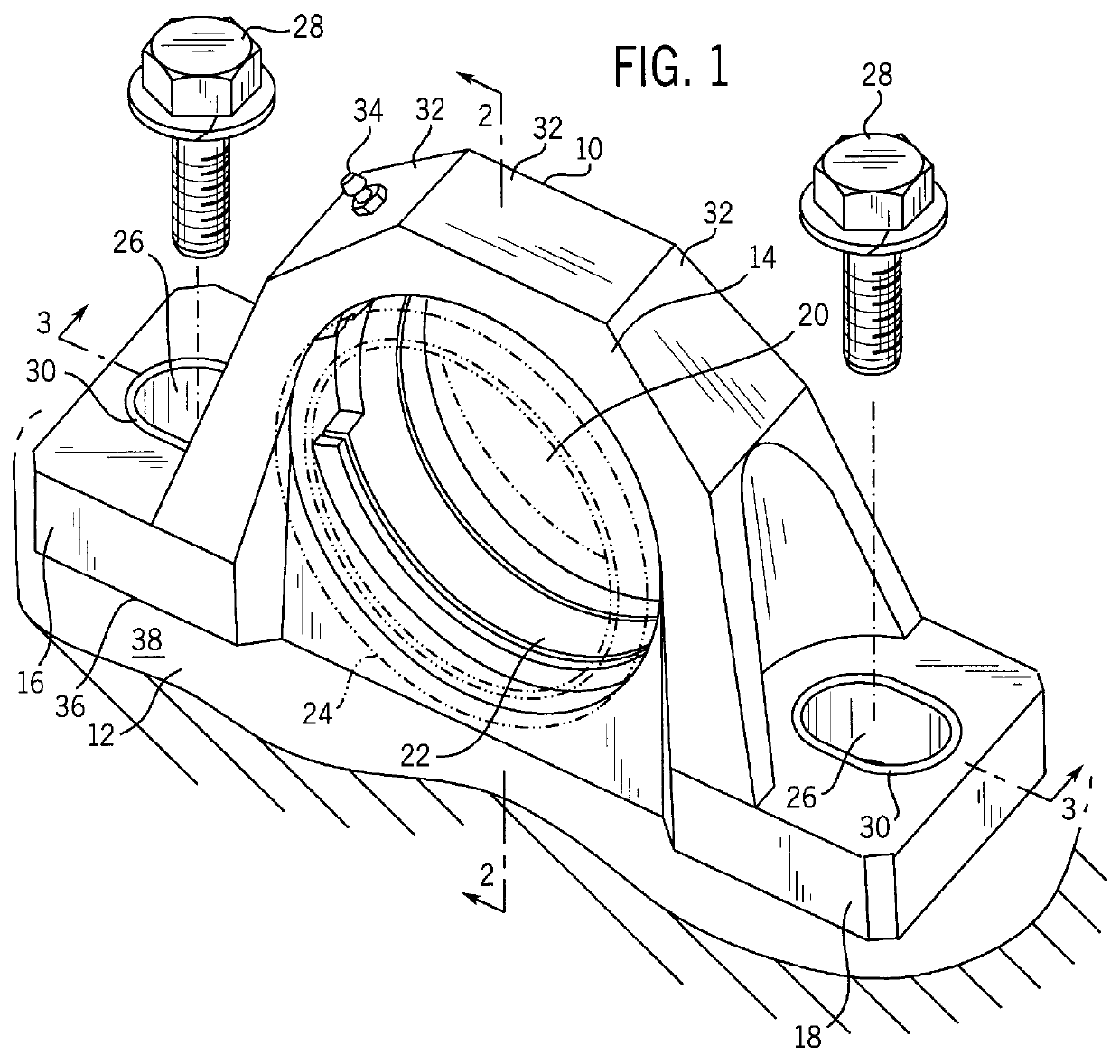

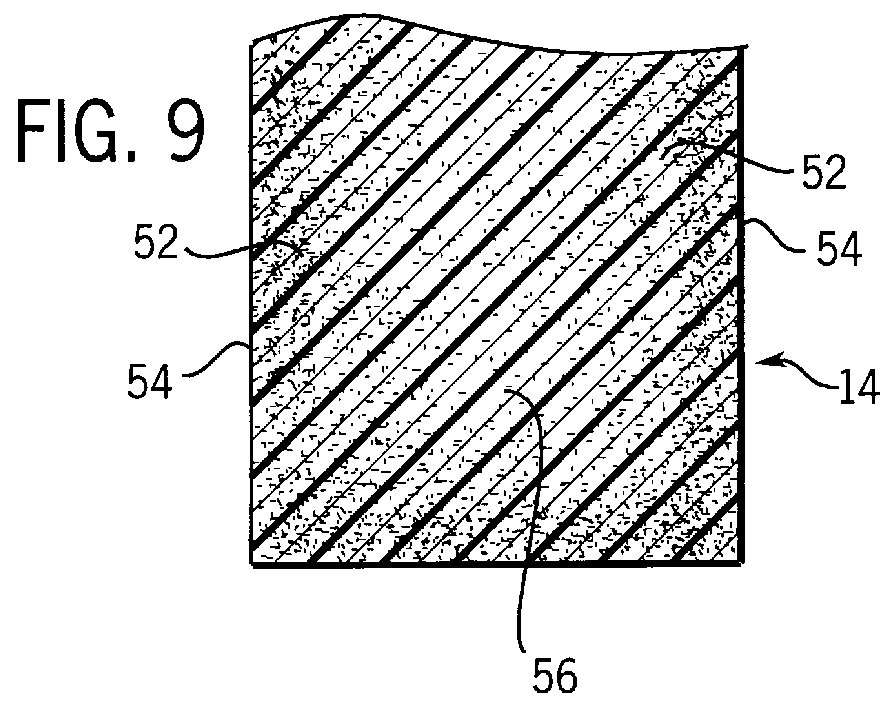

Molded polymeric bearing housing and method for making same

A molded polymeric bearing housing is formed of a moldable polymer base material in combination with a glass fiber reinforcing component. A foaming agent is added to the base material to create a fine structural foam within interior regions of the housing. A density gradient is established between regions adjacent to the surfaces of the housing and the internal regions, thereby reducing the need for reinforcing ribs particularly in a base or mounting portion of the housing. An antimicrobial agent may be added to the housing material to inhibit the growth and proliferation of fungi, molds, bacteria, and so forth. Structural features of the housing may be formed subsequent to the molding process, such as by turning operations. Metal inserts may be provided to avoid crushing of regions of the housing, such as by attachment fasteners. The housing forms a mounting base surface in a single plane coextensive with the footprint of the housing. When the housing is placed in service moisture and debris is prevented from collecting below the housing by conformity of the mounting base surface with the machine support surface. The housing may be formed in a variety of styles, including pillow block styles, tapped base pillow block styles, two and four bolt flange styles, take up frame styles, flange bracket styles and so forth.

Owner:BALDOR ELECTRIC COMPANY

Nanowhiskers with pn junctions, doped nanowhiskers, and methods for preparing them

InactiveUS7432522B2Permitted diffusionReduce the amount requiredPolycrystalline material growthNanoinformaticsHeterojunctionNon doped

Nano-engineered structures are disclosed, incorporating nanowhiskers of high mobility conductivity and incorporating pn junctions. In one embodiment, a nanowhisker of a first semiconducting material has a first band gap, and an enclosure comprising at least one second material with a second band gap encloses said nanoelement along at least part of its length, the second material being doped to provide opposite conductivity type charge carriers in respective first and second regions along the length of the of the nanowhisker, whereby to create in the nanowhisker by transfer of charge carriers into the nanowhisker, corresponding first and second regions of opposite conductivity type charge carriers with a region depleted of free carriers therebetween. The doping of the enclosure material may be degenerate so as to create within the nanowhisker adjacent segments having very heavy modulation doping of opposite conductivity type analogous to the heavily doped regions of an Esaki diode. In another embodiment, a nanowhisker is surrounded by polymer material containing dopant material. A step of rapid thermal annealing causes the dopant material to diffuse into the nanowhisker. In a further embodiment, a nanowhisker has a heterojunction between two different intrinsic materials, and Fermi level pinning creates a pn junction at the interface without doping.

Owner:QUNANO

Microcapsule incubated epoxide curing agent and preparing method thereof

InactiveCN101016369AFast curingThe curing agent is microcapsule latent fastMicroballoon preparationMicrocapsule preparationEpoxySolvent

The invention discloses a making method of micro-capsule latent typed epoxy resin as hardener, which comprises the following steps: adopting acrylic ester polymer as case material; making epoxy resin hardener 2-phenylimidazole (2PZ) as bag core material; producing the product through solvent evaporating method; displaying excellent compatible property without releasing easily under normal temperature; reserving and transmitting conveniently.

Owner:ZHEJIANG UNIV

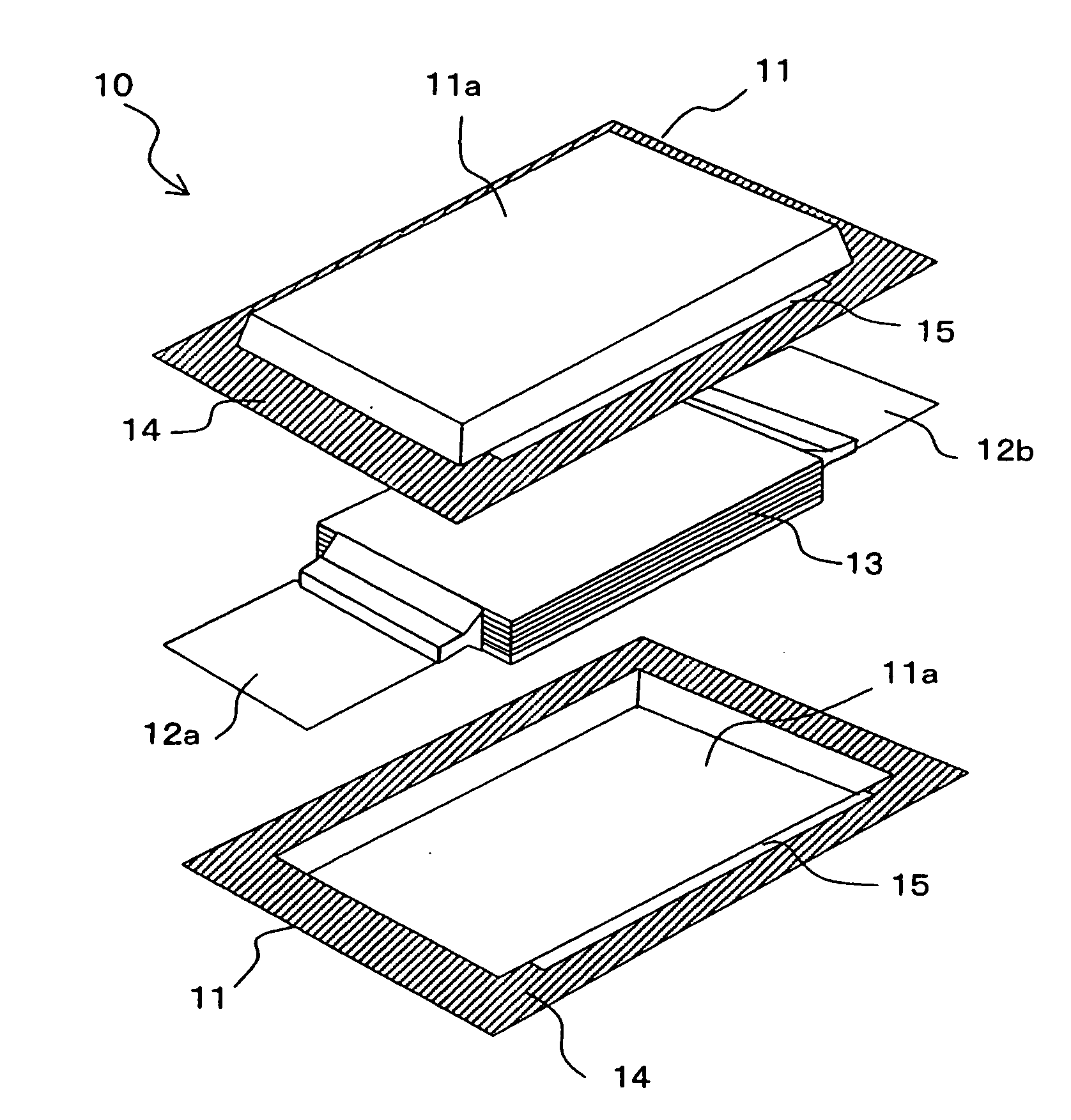

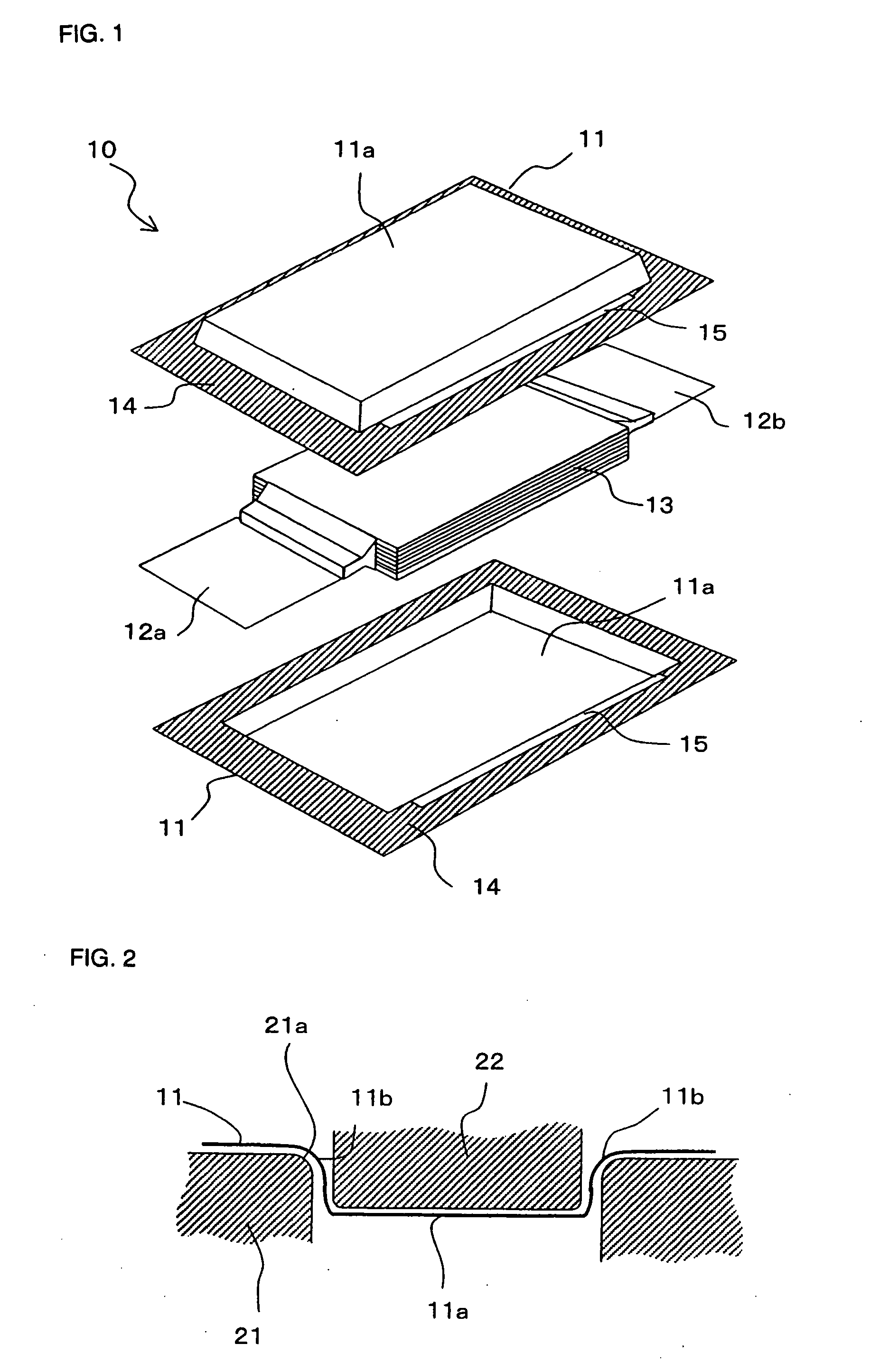

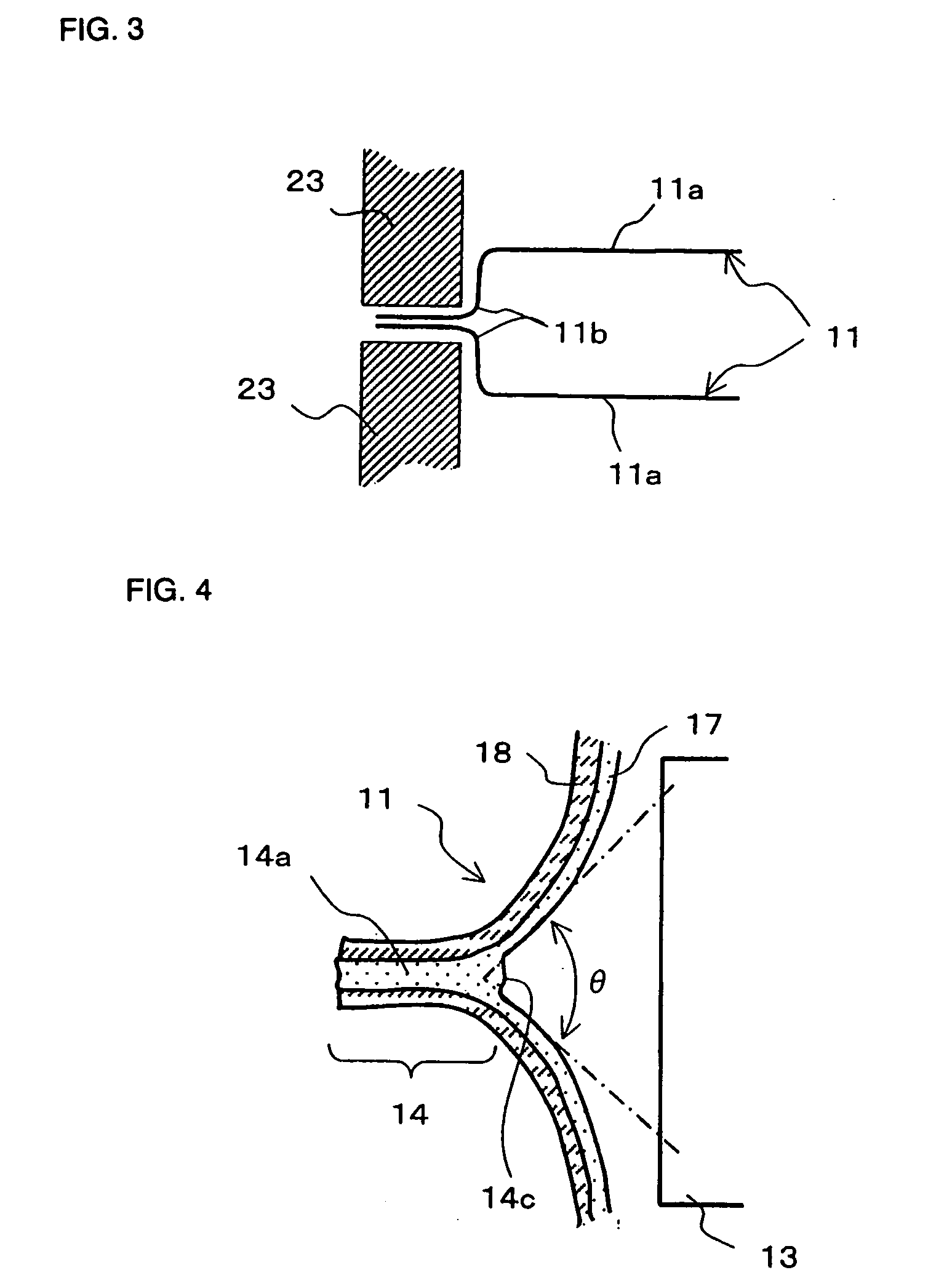

Film-packaged electric device and its manufacturing method

ActiveUS20060210872A1Blocking may occurSimply formedFinal product manufactureSmall-sized cells cases/jacketsEngineeringClose contact

The occurrence of micro-crack is prevented at the root of a thermally sealed area of casing materials even if a thick electric device element is sealed. Film covered battery 10 has cell element 13 to which leads 12a, 12b are connected, and casing films 11 for sealing cell element 13 with leads 12a, 12b extended therefrom. Casing films 11 are thermally sealed along the periphery to seal cell element 13. Thermally sealed area 13 of casing films 11 is positioned between both surfaces of cell element 13 in the thickness direction of cell element 13. On a side of casing films 11 from which leads 12a, 12b are not extended, close contact zone 15, in which casing films 11 are not thermally sealed to each other but are in close contact with each other, is formed continuously to a space which receives cell element 13. Close contact zone 15 has a length of one-half or more of the distance from one end to the other end of an inner edge of thermally sealed area 14.

Owner:NEC CORP

Removal of oxygen from metal oxides and solid solutions by electrolysis in a fused salt

InactiveUS20040159559A1Polycrystalline material growthFrom normal temperature solutionsMolten saltOxygen

The present invention pertains to a method for removing a substance (X) from a solid metal or semi-metal compound (M<1>X) by electrolysis in a melt of M<2>Y, which comprises conducting the electrolysis under conditions such that reaction of X rather than M<2 >deposition occurs at a electrode surface, and that X dissolves in the electrolyte M<2>Y. The substance X is either removed from the surface (i.e., M<1>X) or by means of diffusion extracted from the case material. The temperature of the fused salt is chosen below the melting temperature of the metal M<1>. The potential is chosen below the decomposition potential of the electrolyte.

Owner:METALYSIS

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS20050010018A1Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolCrystallization temperature

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3-40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80-220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS7128863B2Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolPolymer science

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3–40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80–220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com