Microcapsule incubated epoxide curing agent and preparing method thereof

A technology of epoxy resin curing and microcapsules, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of long curing time and high curing temperature, and achieve simple preparation method, stable yield and product performance, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Take sodium lauryl sulfate as emulsifier, take dichloromethane as solvent

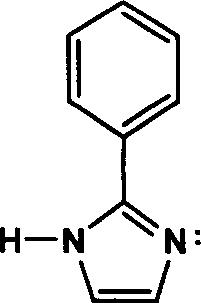

[0020] Dissolve 1g polymethyl methacrylate and 1g 2-phenylimidazole in 30ml dichloromethane solvent, the oily phase of gain is added in the aqueous solution that contains 0.5wt% sodium lauryl sulfate, in 1000r / min mechanical Disperse under stirring for 30 minutes to form a uniform and stable emulsion, then add the resulting emulsion to 200ml of an aqueous solution containing 0.5wt% sodium lauryl sulfate, keep the temperature at 30°C, and stir for 4 hours at a mechanical stirring intensity of 1000r / min. Then it was centrifuged, washed 5 times with distilled water, and dried in an oven at 40°C for 24 hours to obtain the product.

Embodiment 2

[0021] Embodiment 2: take gelatin as emulsifier, take dichloromethane as solvent

[0022] Dissolve 0.5g of polymethyl methacrylate and 1g of 2-phenylimidazole in 20ml of dichloromethane solvent, add the resulting oil phase to 30ml of aqueous solution containing 3wt% gelatin, and disperse for 60min under mechanical stirring at 1000r / min to form To obtain a uniform and stable emulsion, add the obtained emulsion into 300 ml of an aqueous solution containing 3 wt % gelatin, keep the temperature at 40° C., and stir for 8 hours at a mechanical stirring intensity of 800 r / min. Then it was centrifuged, washed 5 times with distilled water at 40°C, and dried in an oven at 40°C for 48 hours to obtain the product.

Embodiment 3

[0023] Embodiment 3: Take Tween and Span as emulsifying agent, take dichloromethane as solvent

[0024] Dissolve 0.5g polymethyl methacrylate, 2.5g 2-phenylimidazole and 5wt% Span in 30ml dichloromethane, add the gained oil phase in 50ml containing the aqueous solution of 5wt% Tween, at 1000r / min Disperse under mechanical stirring for 60 minutes to form a uniform and stable emulsion, then add the obtained emulsion to 300ml aqueous solution containing 2wt% Tween, keep the temperature at 36°C, and stir for 5 hours at a mechanical stirring intensity of 500r / min. Then it was centrifuged, washed 5 times with distilled water, and dried in an oven at 40°C for 24 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com