Photo-curing conductive adhesive for touch panel

A touch panel and conductive adhesive technology, applied in the field of conductive adhesive, can solve problems such as energy consumption, damage to flexible substrate materials, insufficient sintering temperature, etc., achieve high conductivity and high resolution, improve the rate of hardening, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A photosensitive hardening conductive adhesive for a touch panel according to a preferred embodiment of the present invention will be described below.

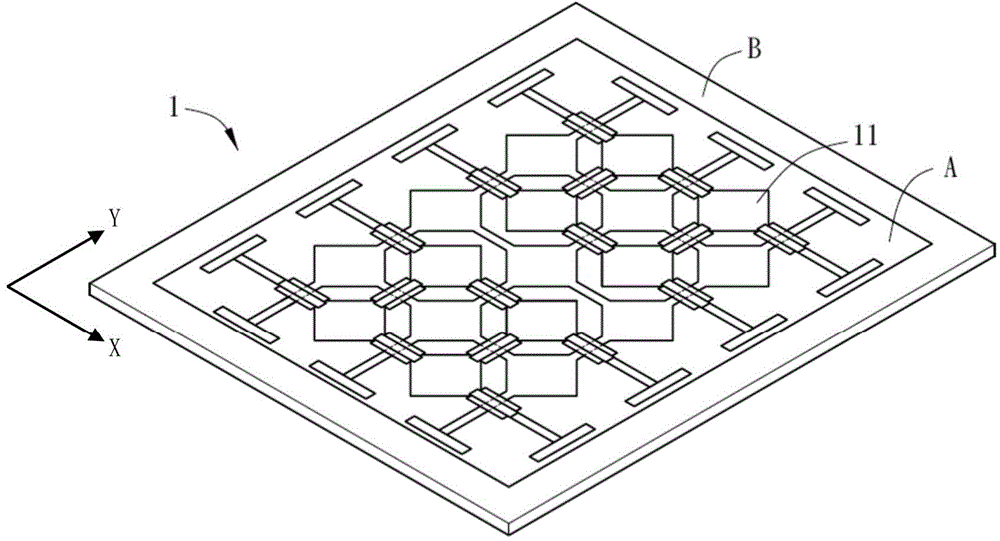

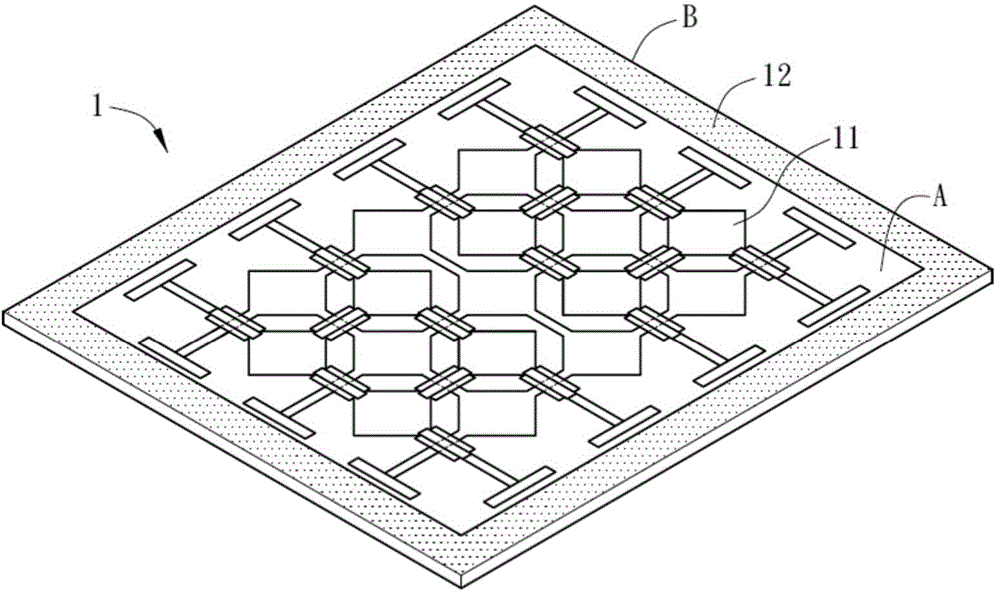

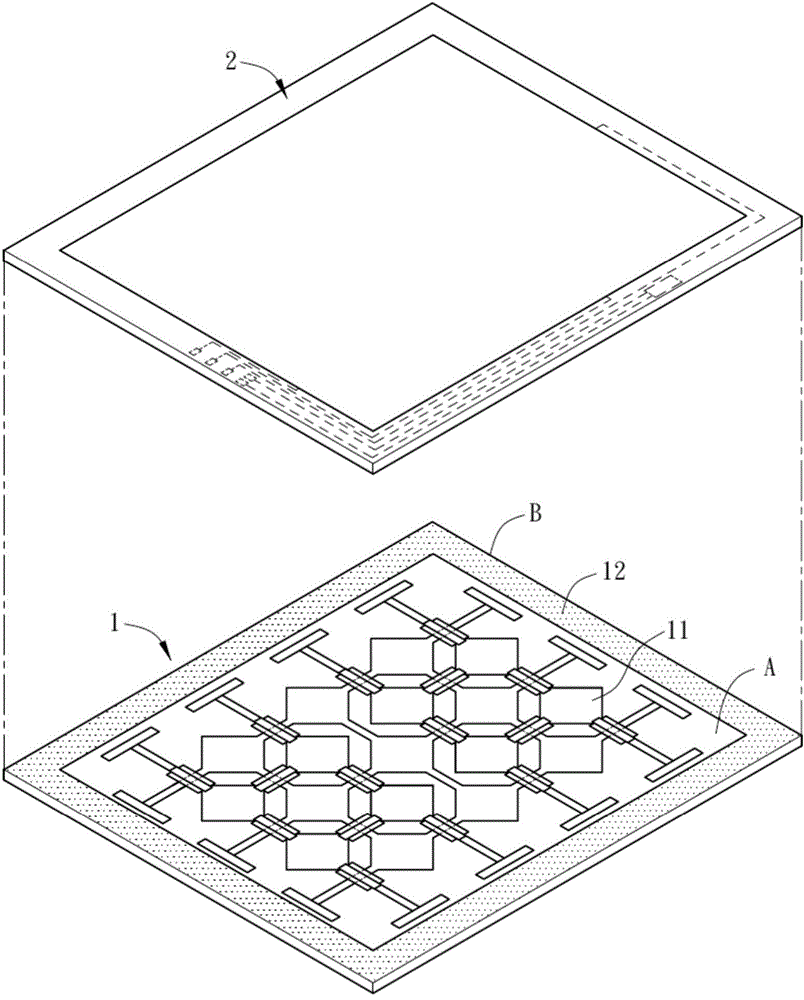

[0029] Please refer to Figure 1A to Figure 1D , and combined with the following description to understand the manufacturing process of the touch panel using the photosensitive hardening conductive adhesive of the present invention.

[0030] First of all, the photosensitive hardening conductive adhesive described in the present invention is used in touch panels, especially suitable for touch panels using soft substrates (or called flexible substrates), so as to achieve ultra-thin touch panels and flexibility. Wherein, the flexible substrate is, for example, flexible glass, a plastic plate or a plastic film, and the plastic material may specifically be polyethylene terephthalate (PET).

[0031] Such as Figure 1A As shown, in practice, a plurality of conductive patterns 11 are formed on the touch area A on the flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com