Equipment for inner overflow and outer overflow down-draw molding of glass pipe, and design method thereof

A glass tube and equipment technology, which is used in the field of equipment for down-draw forming glass tubes with internal and external overflows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

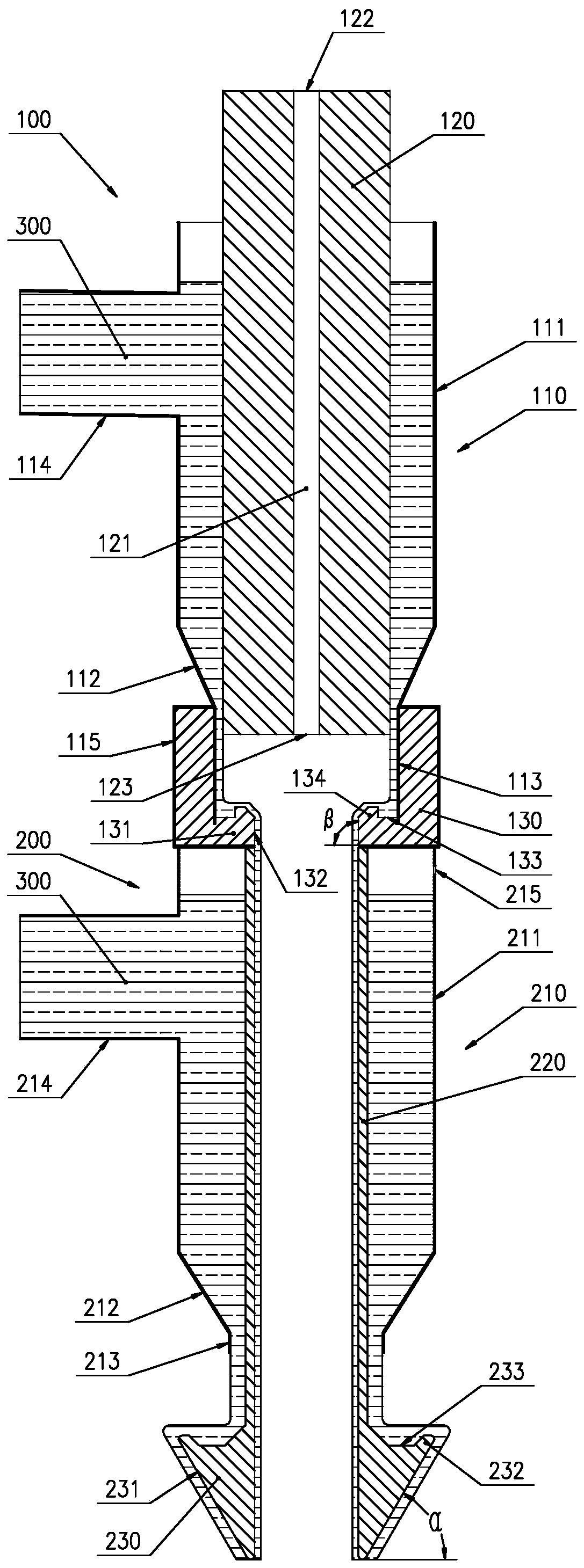

Method used

Image

Examples

Embodiment

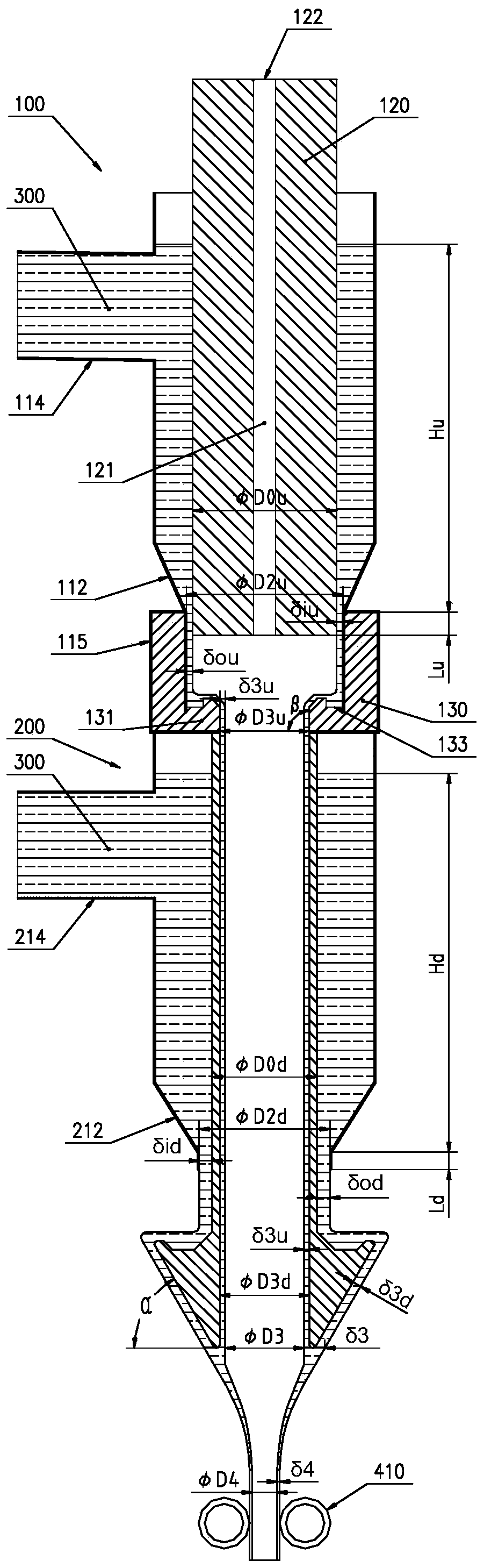

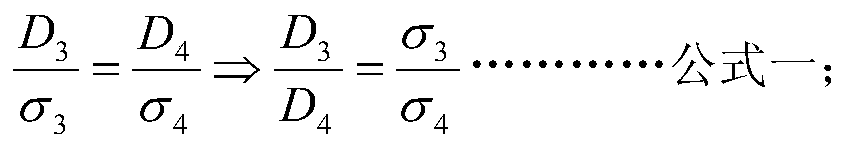

[0124] See Table 1 and Table 2 for the dimensional parameters and physical simulation test parameters of a glass tube with internal and external overflow down-drawing. The viscosity of glass molding is simulated with high-viscosity silicone oil. The experimental results are shown in Table 3. The glass tube diameter of the glass tube that this equipment is used to make is 3.6598cm, and the tube thickness is 0.2cm; the shrinkage ratio of the tube diameter is D 3 D. 4 is 3.35.

[0125] Table 1: Design data of simulation experiments for 100 parts of the inner overflow device

[0126]

[0127] Table 2: The design data of the simulation experiment carried out on part 200 of the overflow device

[0128]

[0129] Table 3: The thickness σ of the silicone oil just leaving the overflow pan 300 in the simulation experiment 3 Test data with thickness deviation

[0130]

[0131] Analysis of test results:

[0132] The maximum value of the thickness deviation is 3.69%, the minim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com