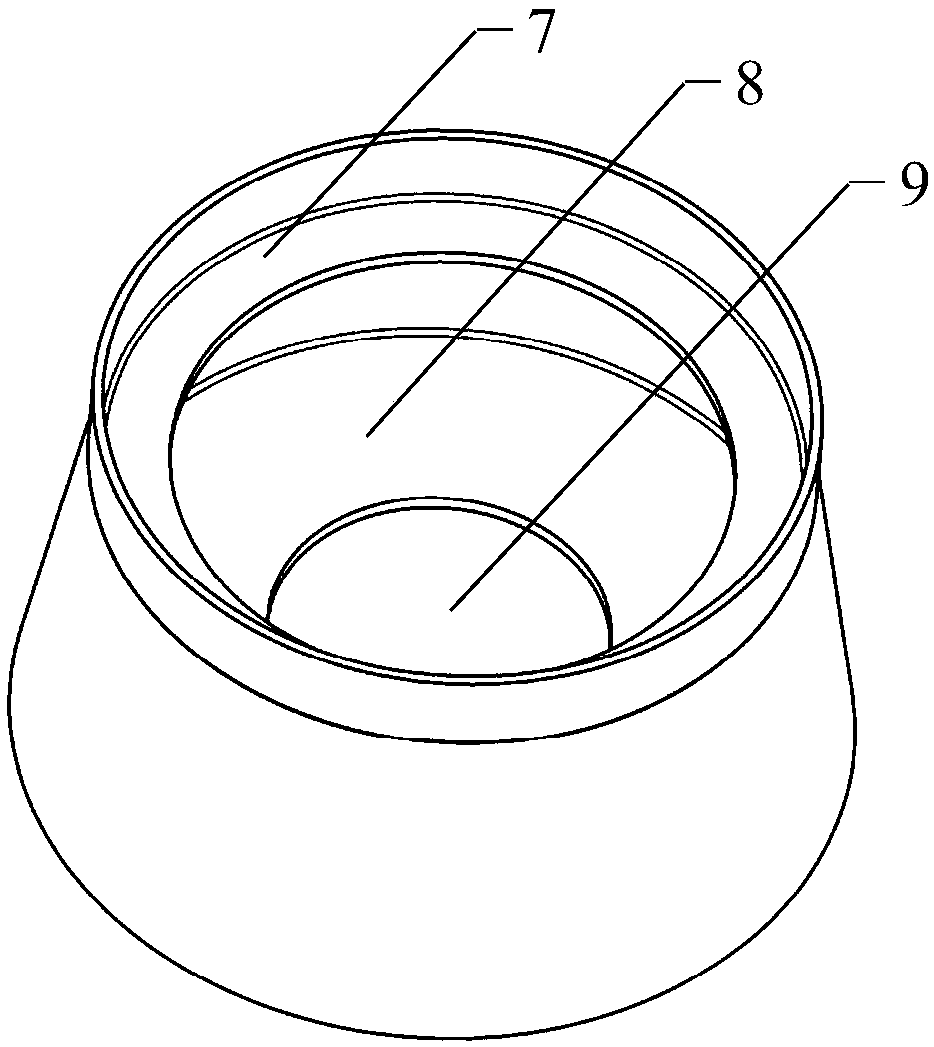

RTM (resin transfer molding) mold for partition type rotating structure composite parts

A composite material and rotary structure technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of poor rigidity of the inner mandrel, unsuitable RTM molding process, and easy deformation, so as to reduce manufacturing costs and improve internal and external surfaces. The effect of excellent quality and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation process of the composite parts with segmental plus rotation structure is as follows:

[0038] (1) Lay the dry pre-shaped fabric on the boss 2-1 of the lower mold 2 according to the design, and perform vacuum pre-setting on the flange prefabricated body after the paving is completed;

[0039] (2) Connect the U-shaped core mold 3-1 and the C-shaped forming mold 3-2 through bolts to form a combined inner core mold 3 in the middle section, and lay the outer layer of the C-shaped forming mold 3-2 according to the design. C-type prefabricated body, and preform the prefabricated body in vacuum;

[0040] (3) Place the combined inner core mold 3 of the middle partition section in the positioning groove 2-2 of the lower mold 2, and carry out vacuum pre-setting on the lower mold 2 and the combined inner core mold 3 of the middle partition section, so that the middle partition section is combined The type inner mandrel 3 completes precise positioning in the positio...

specific Embodiment 1

[0047] Typical structure such as figure 1 As shown, the three-section rotary structure composed of upper and lower flanges has dimensions: height 200mm, diameter of the large end 400mm, and diameter of the small end 300mm. It is prepared by dry pre-shaped fabric, and then injected with low-viscosity resin through the RTM process. , and finally solidify into shape. We have adopted the solution of the present invention, and all components of the mold are made of P20 steel.

[0048] The upper mold 1 is designed as a female mold, and the slope of the upper mold 1 side to the inner surface is 15°; the bottom surface is a plane, and the sealing grooves 1-1 and 1-2 designed on the bottom plane have a width of 4.5mm and a depth of 5.5mm; the length of the mouth positioning table 1-3 is 40mm, the width is 50mm, the height is 10mm, and the slope is 10°;

[0049] The lower mold 2 is designed as a female mold, and the slope of the inner surface of the lower mold 2 is 15°; the bottom sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com