Rolling carving machine for metal pipe fittings

A technology of metal pipe fittings and cutting plotters, which is applied in stamping, printing and other directions, can solve the problems of not being suitable for mass production, not suitable for mass production, and slow speed of manual lettering, so as to improve product quality, shorten production cycle, and ensure product quality. The effect of surface quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

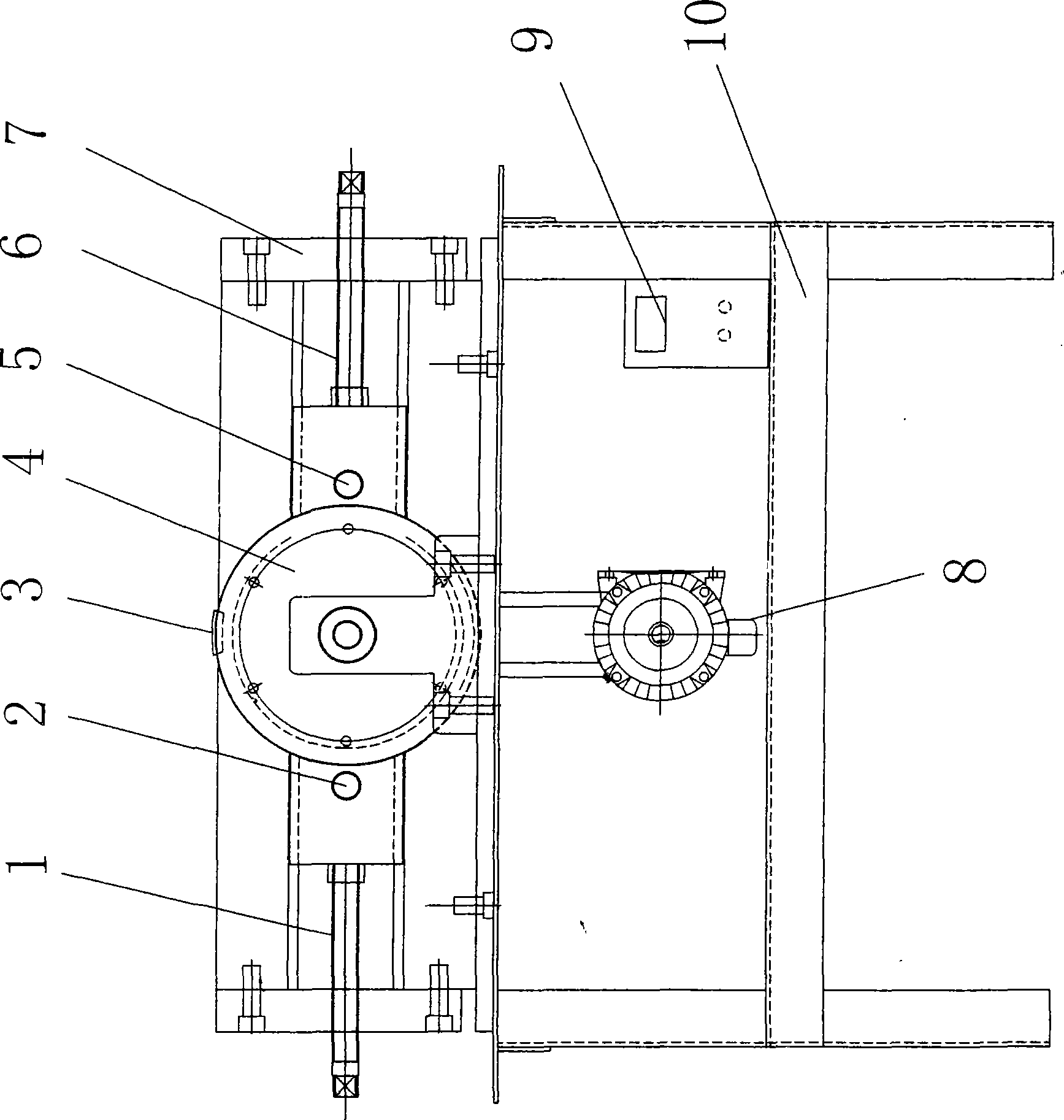

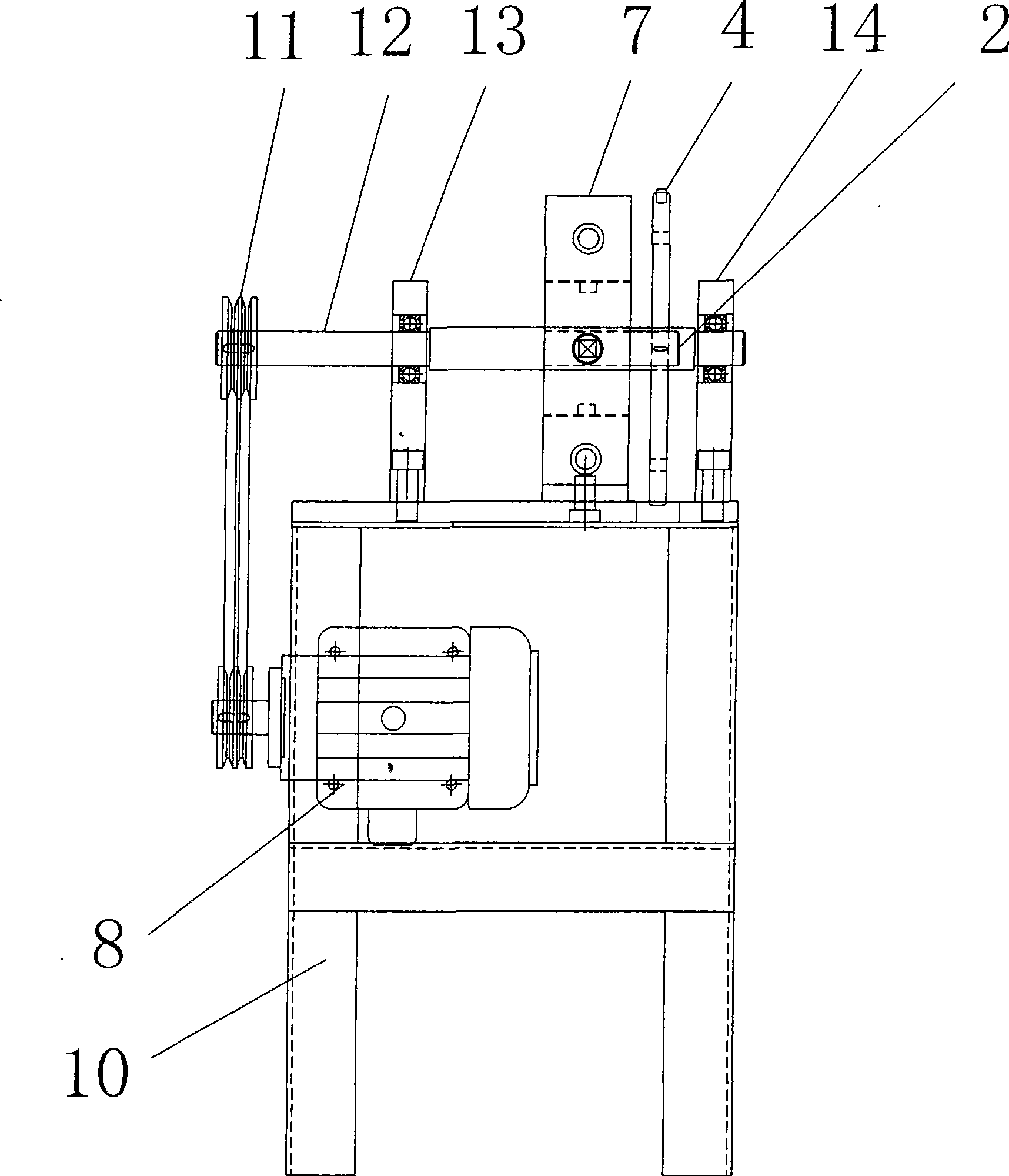

[0015] The present invention mainly consists of a frame 10 with a motor 8 and a controller 9, a front support frame 14 and a rear support frame 13 placed on the top of the frame 10, and a character wheel 4 placed between the front and rear support frames 14 and 13. The transmission shaft 12 is placed on the fixed frame 7 on both sides of the word rolling wheel 4 on the upper part of the frame 10, and the left pressure bearing shaft 2 with the left adjusting bolt 1 and the right pressure bearing shaft 5 with the right adjusting bolt 6 are placed on the fixed frame 7. Composition; one end of the transmission shaft 12 is connected with the motor 8 through the pulley 11 .

[0016] When working, first install the steel characters 3 that need to be engraved on the pipe fittings in the character roller 4, and fix them tightly with bolts without loosening; according to the inner diameter of the metal pipe fittings to be produced, replace the left bearing shaft 2 and the right bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com