Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve ovality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

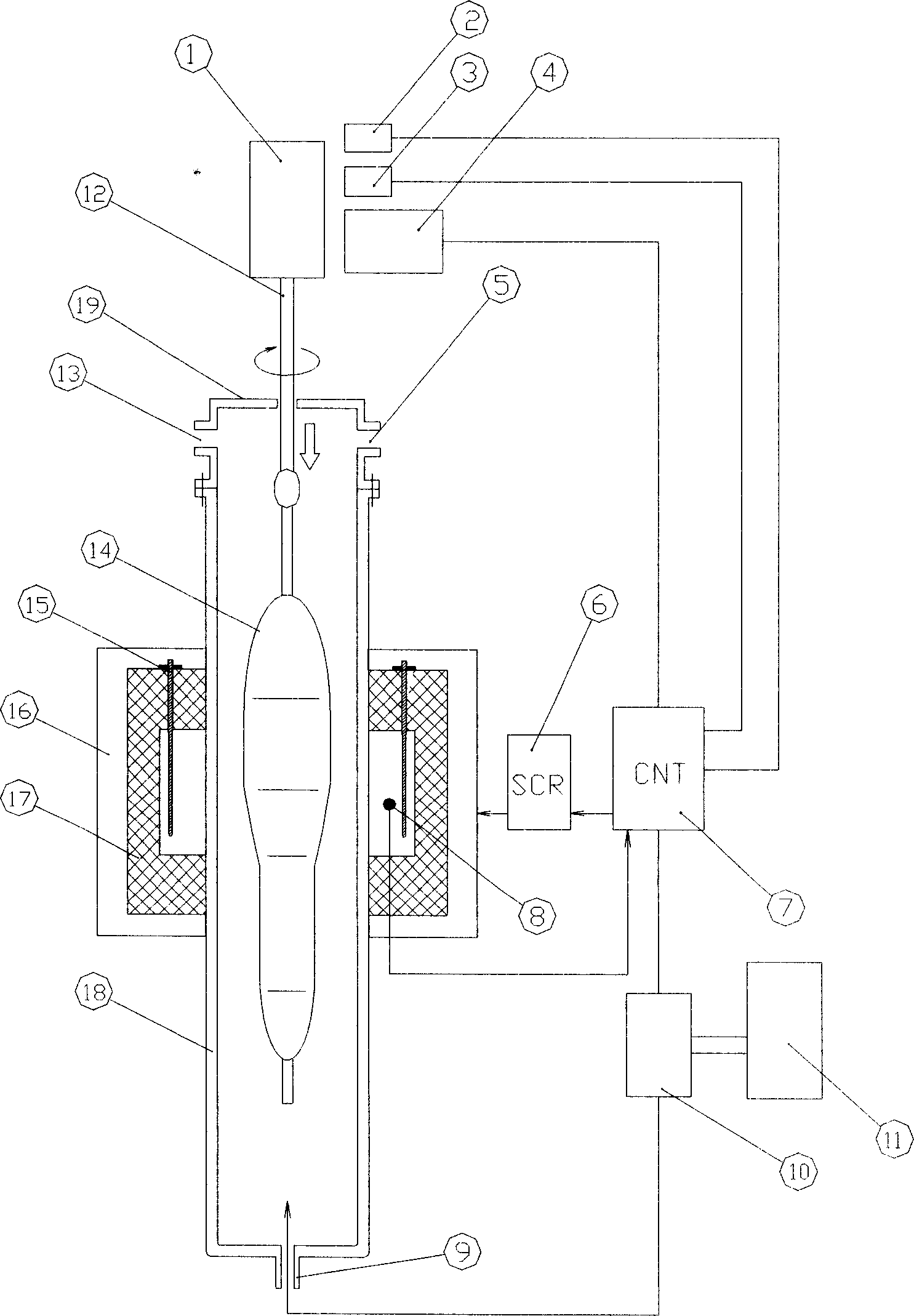

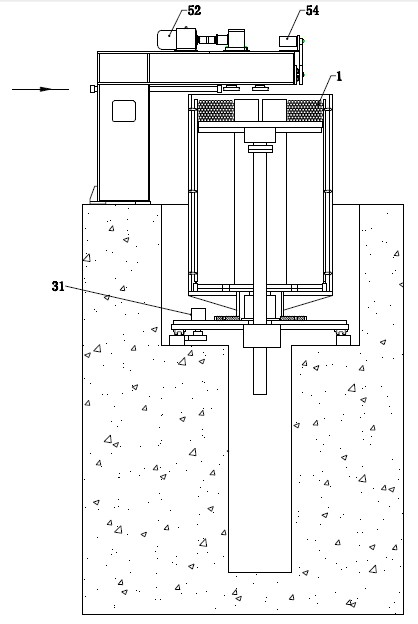

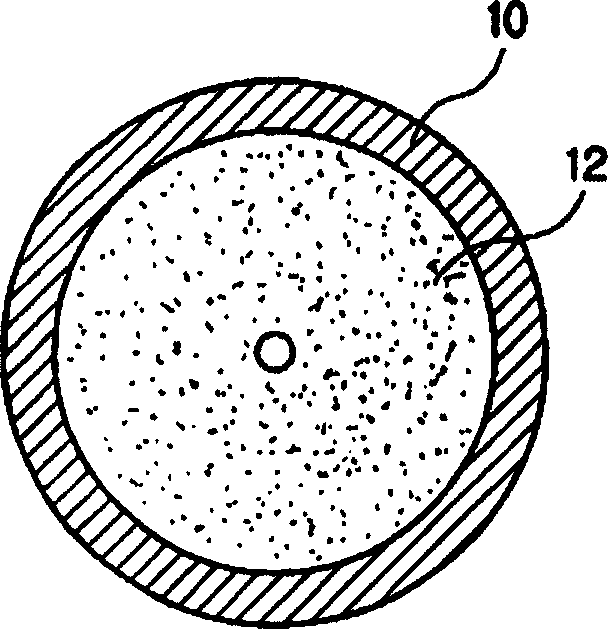

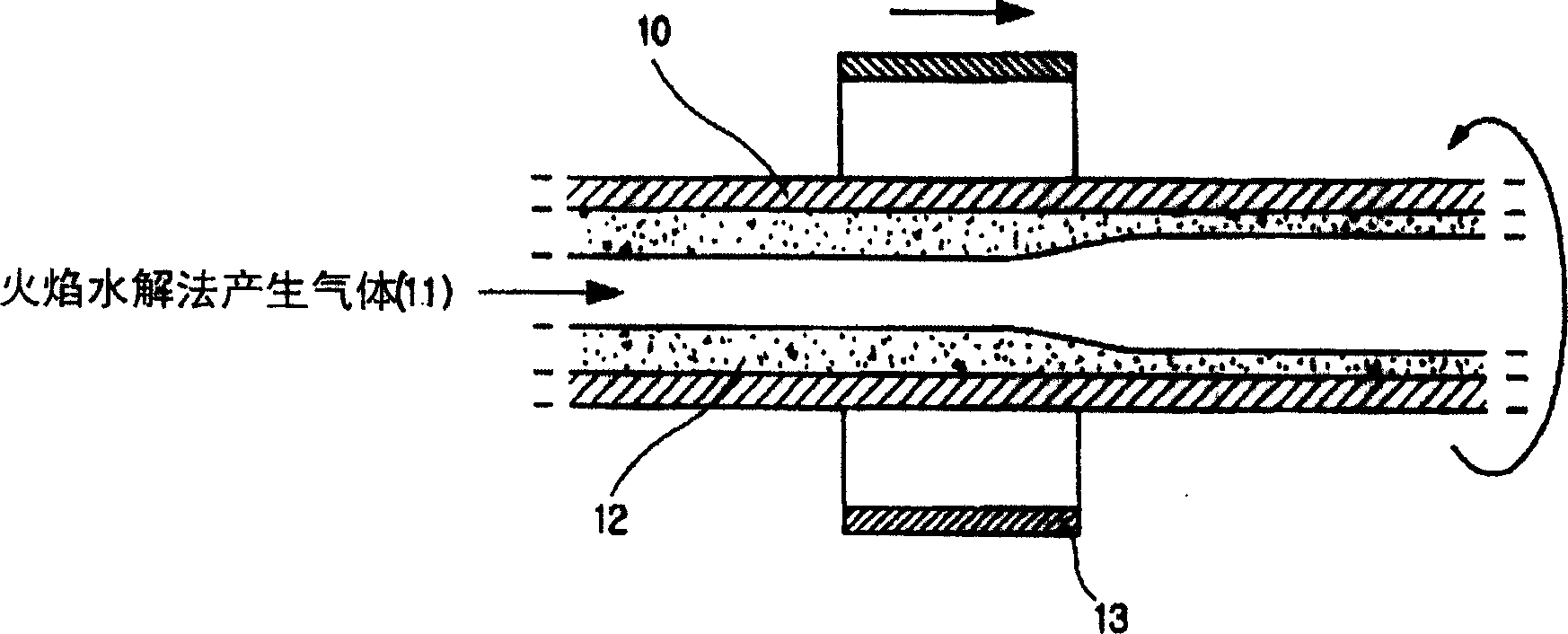

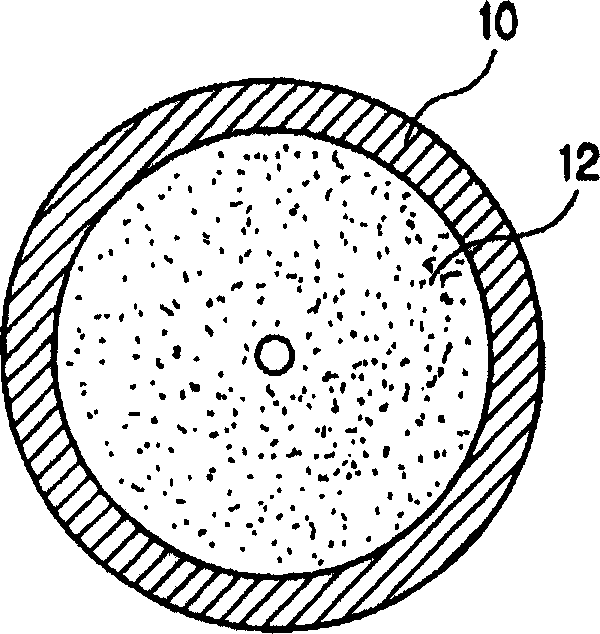

Sintering device of loose body optical fiber prefabricated rod

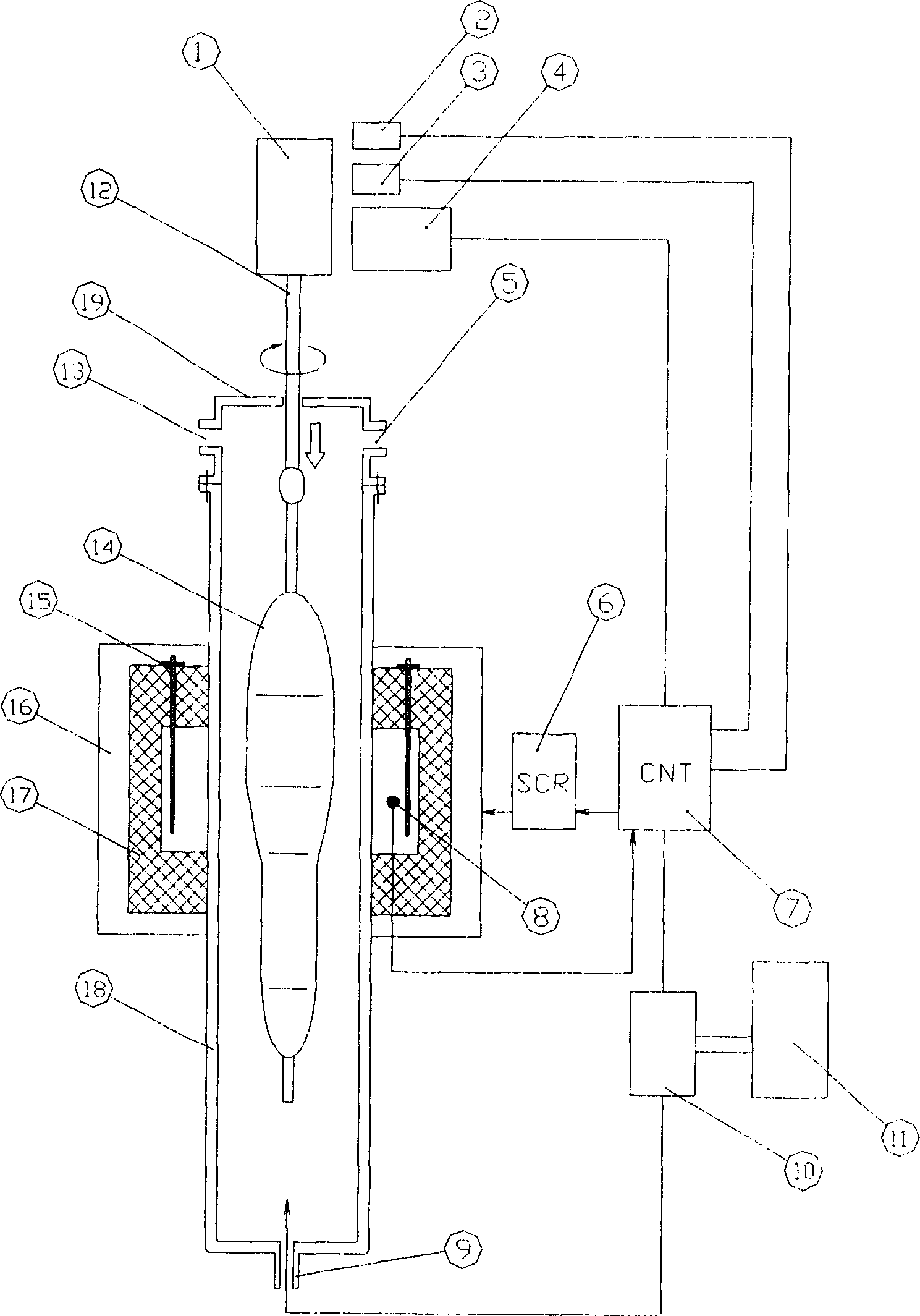

A sintering apparatus for prefabricatnig the loosen optical fibre rod is composed of sintering quartz pipe with gas inlet and cover, heating unit with casing, insulating material and heater, moving controller, position sensor, gas supplying unit, temp sensor with heating driver, and controller.

Owner:JIANGSU FASTEN PHOTONICS

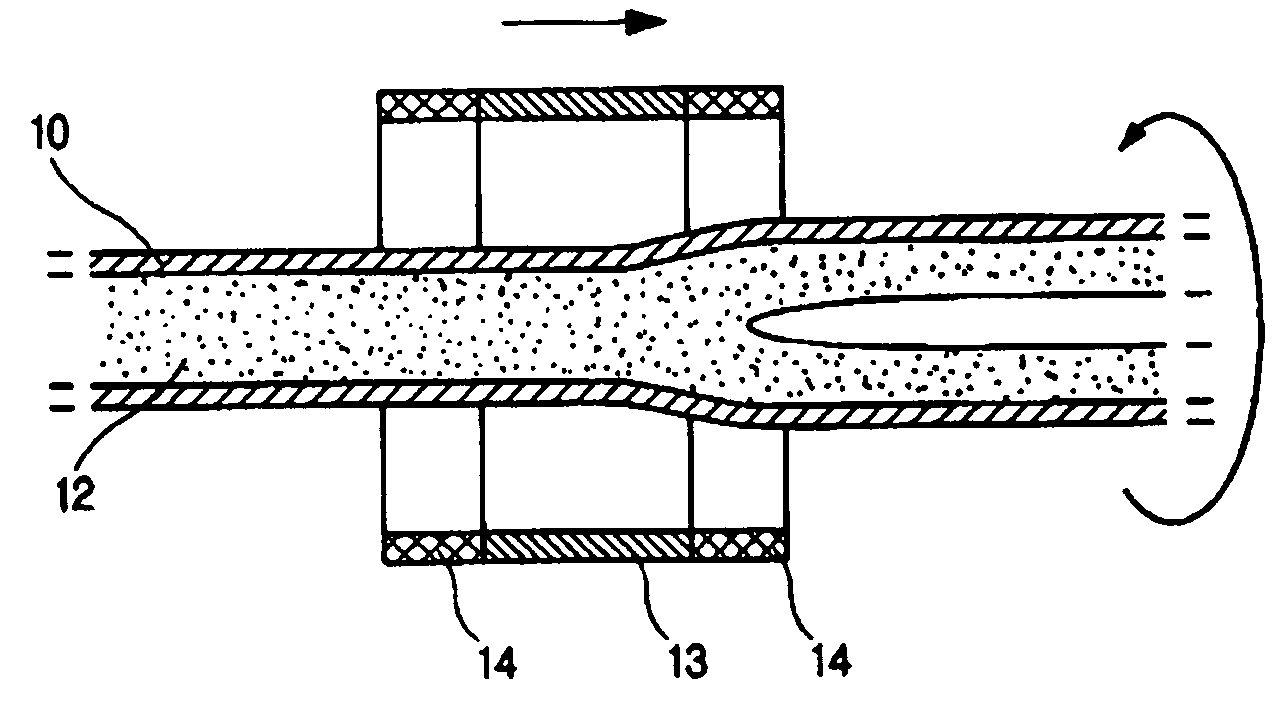

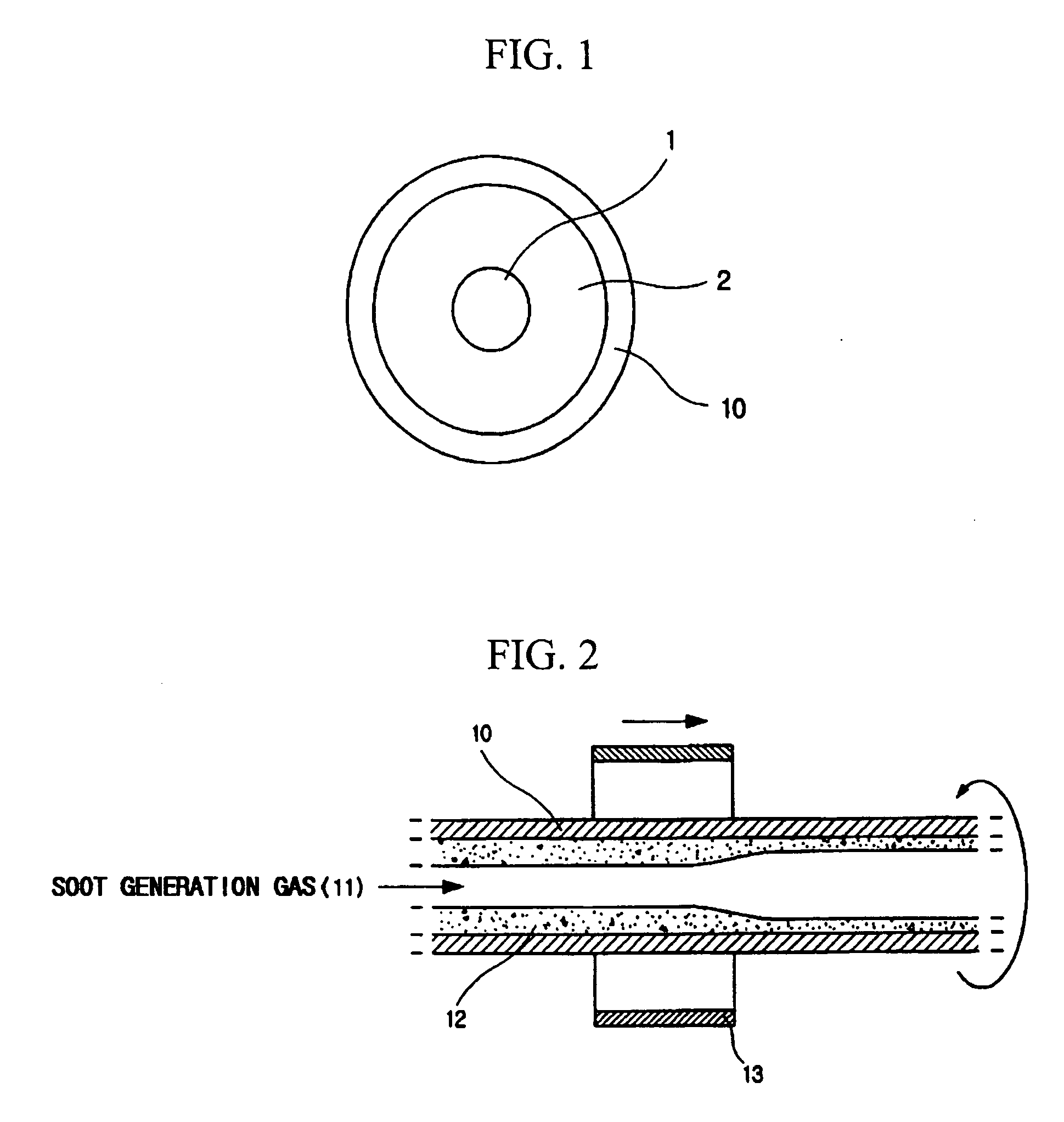

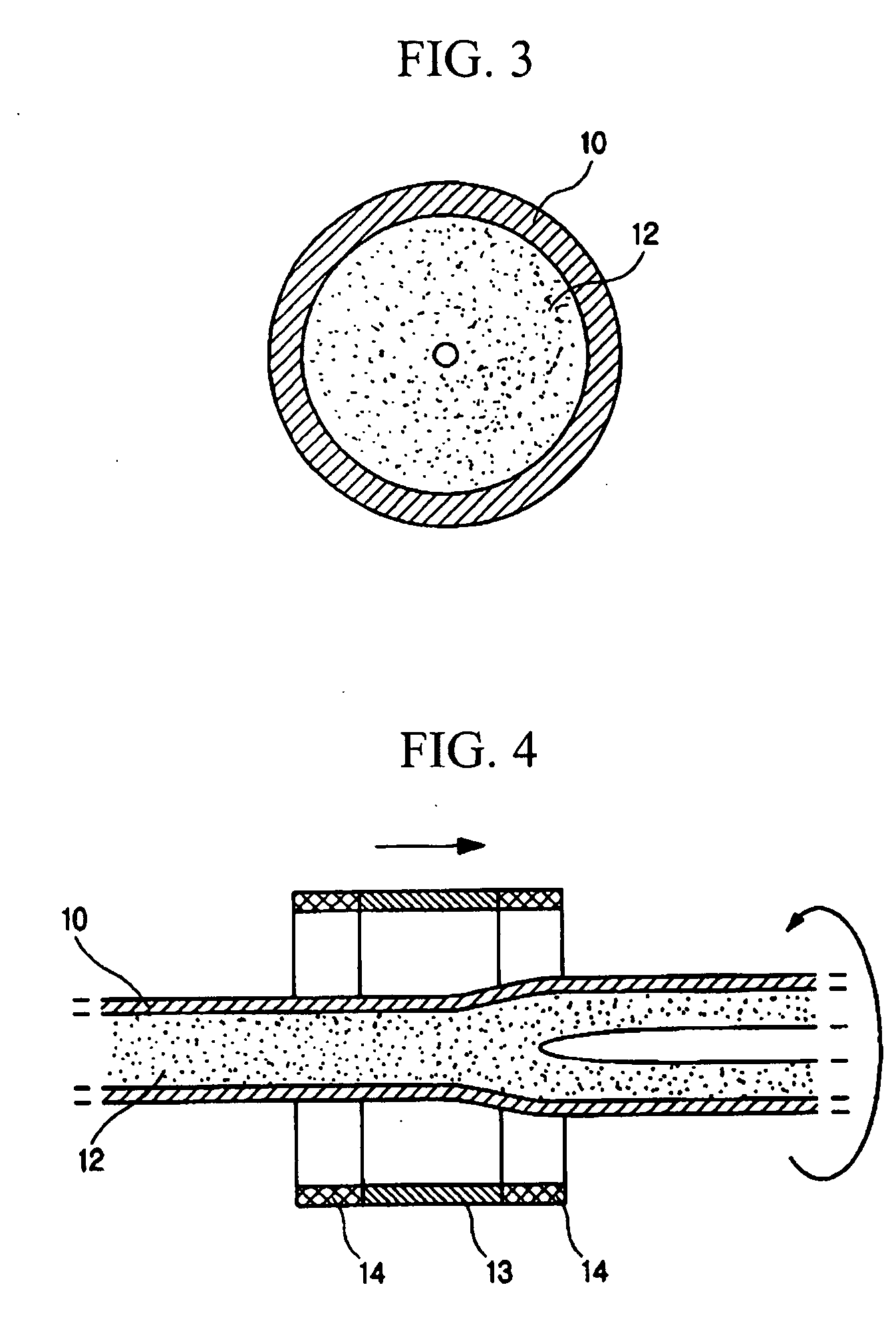

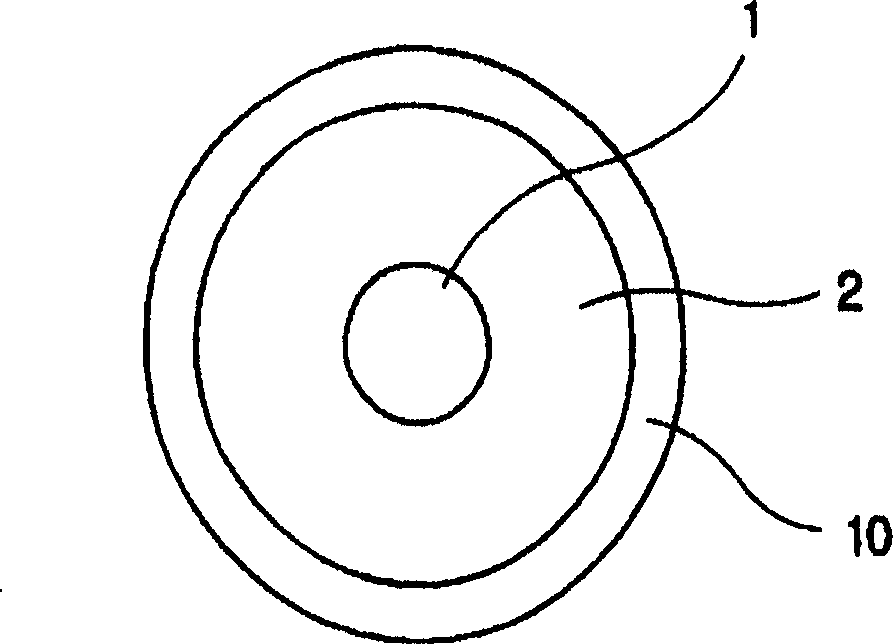

Method for making optical fiber preform having ultimately low pmd through improvement of ovality

InactiveUS20050103057A1Improve ovality and pmdImprove ovalityGlass making apparatusGlass productionOvalityPolarization mode dispersion

A method for making an optical fiber preform having an ultimately low PMD (Polarization Mode Dispersion) through improvement of ovality is provided. This method has several collapse steps for collapsing an optical fiber preform having a clad / core deposition layer formed in a preform tube in which a rate of collapse is 0.01-0.06 mm / min at each collapsing step. By using this method, ovality and PMD of the optical fiber preform may be improved.

Owner:LG CABLE LTD (KR)

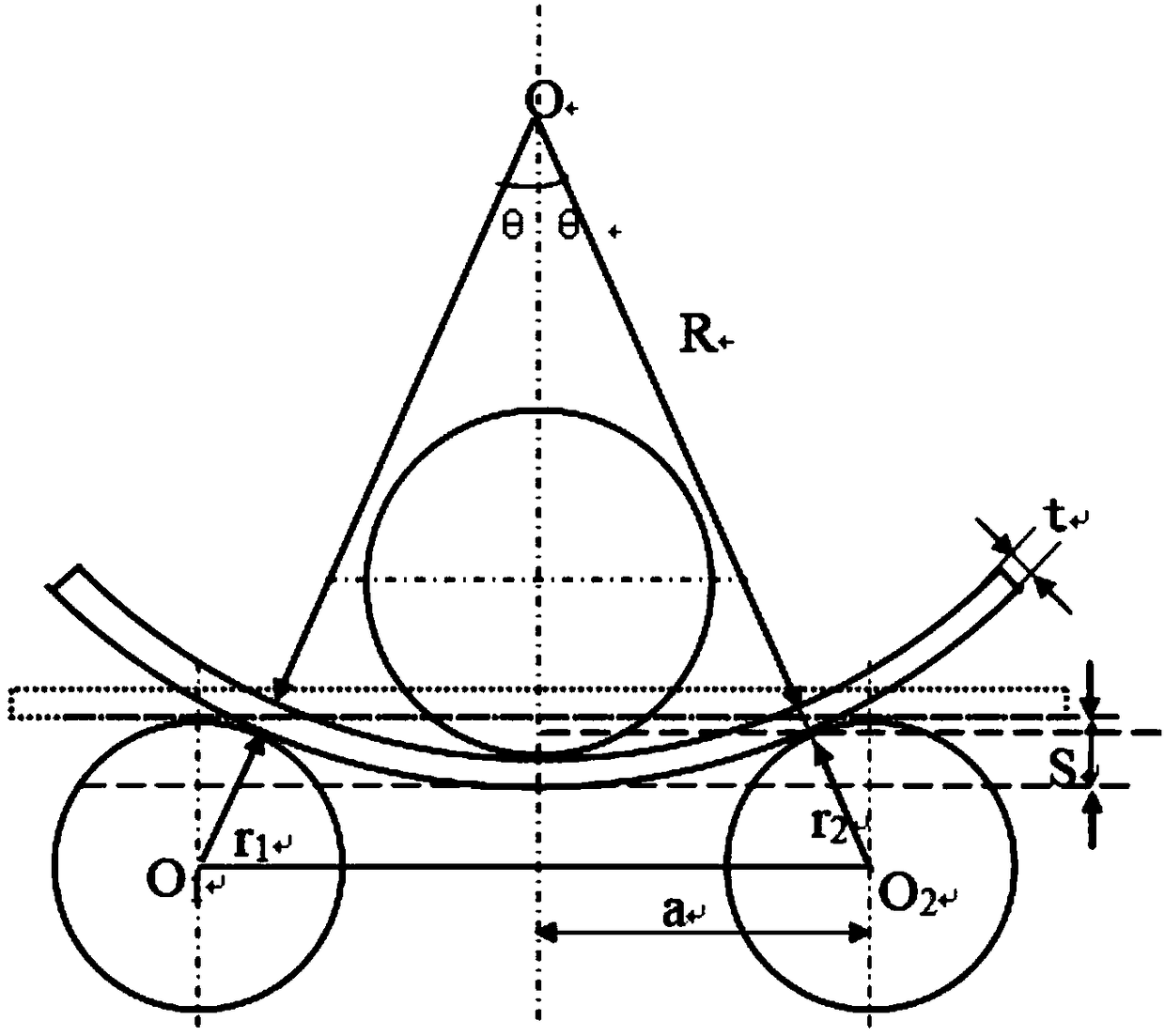

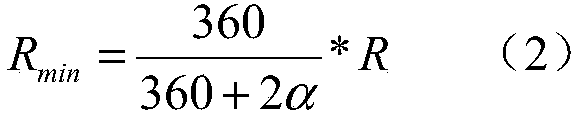

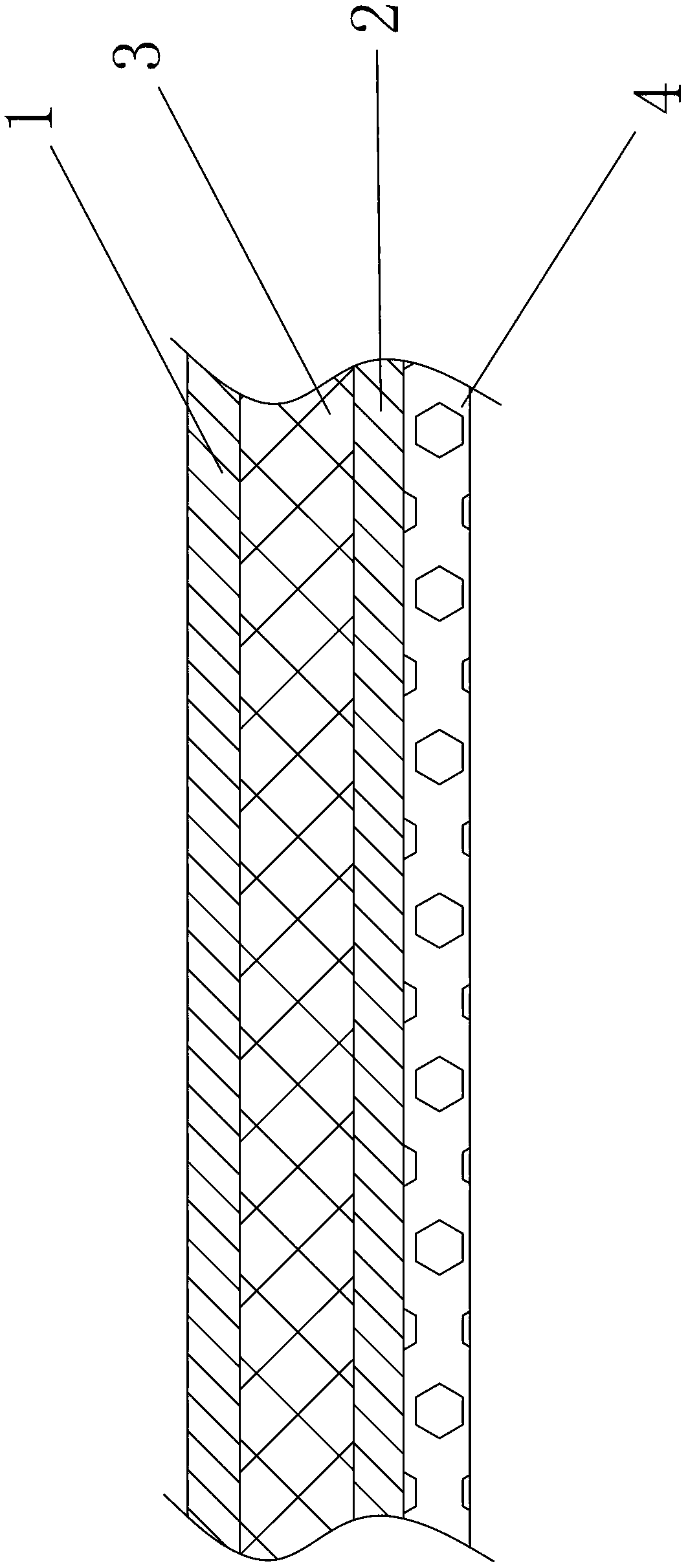

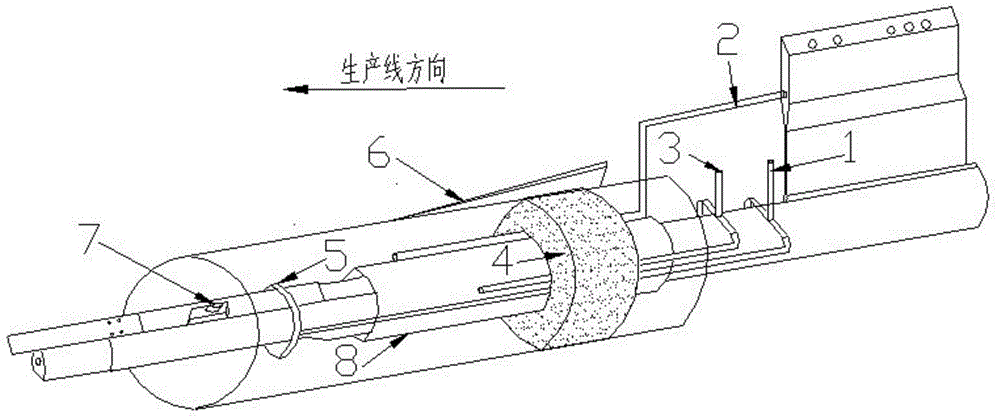

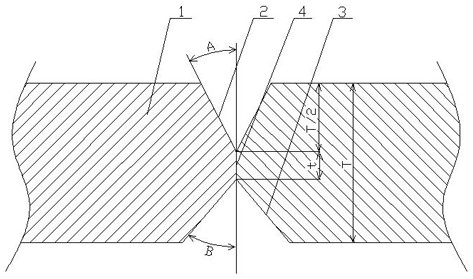

Machining process of high-strength steel coil pipe

The invention relates to a machining process of a high-strength steel coil pipe. The machining process of the high-strength steel coil pipe sequentially comprises the following steps of blanking, edgemilling and beveling, pre-bending, three-roller type plate rolling machine roller bending, straight seam welding and ring welding; before the plate rolling machine roller bending is carried out, theresilience of a steel plate is measured firstly, then the pipe coiling diameter is calculated when an actual pipe forming is carried out, the total lower displacement amount of an upper working rolleris calculated in the pipe coiling forming process, the pass displacement of the upper working roller is determined, and the pipe coiling machining is completed through a plurality of plate rolling; the pass displacement of the upper working roller is gradually decreased, and the first-pass displacement amount accounts for 50% or above of the total lower displacement amount, and the first three pass total displacement finishes 90% or above of the total lower displacement amount, and the upper working roller is basically in place when at least the antepenultimate pass is carried out. Accordingto the process, the displacement of the working roller can be effectively controlled, so that a high-strength steel plate with a proper size can prepare a dredging pipe with good straightness on a plate rolling machine, the gap of a pipe body does not exceed 3 mm at the end of the plate rolling, and welding can be carried out without circle rolling is performed, and the ovality of the pipe body isless than or equal to 2 mm.

Owner:CCCC TIANJIN DREDGING +1

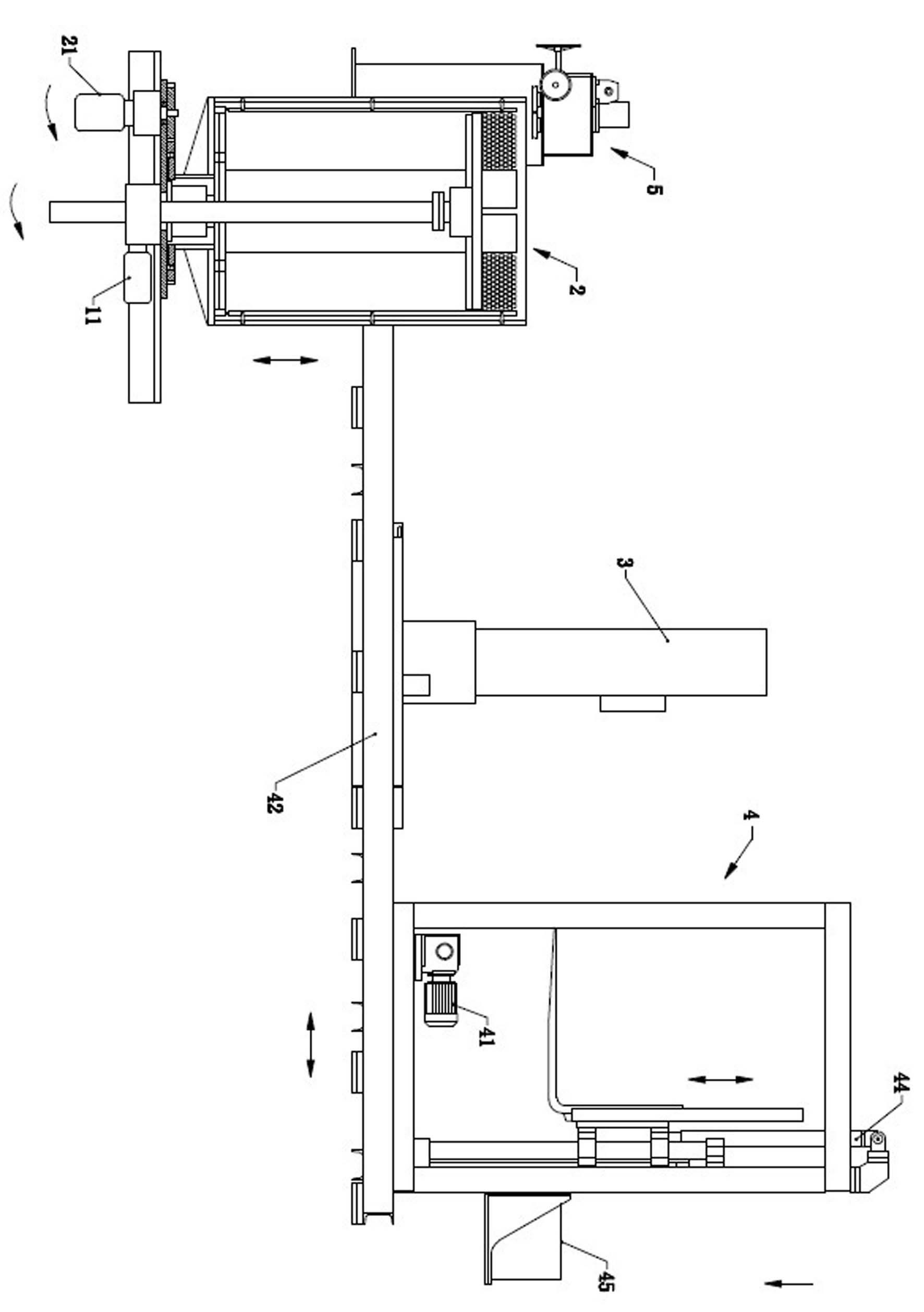

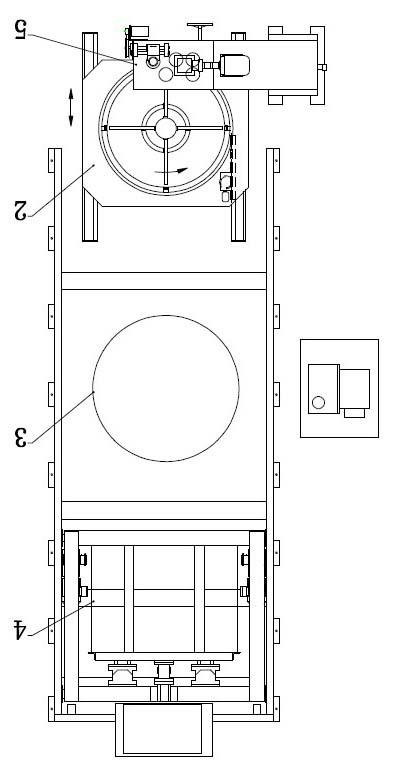

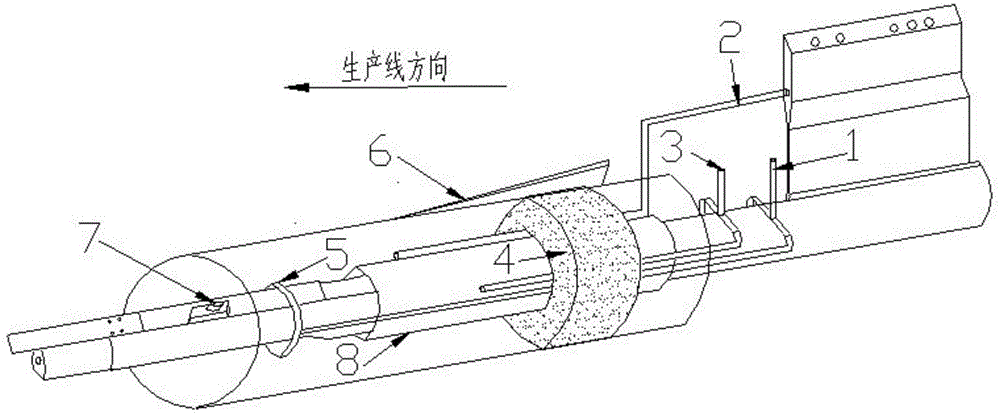

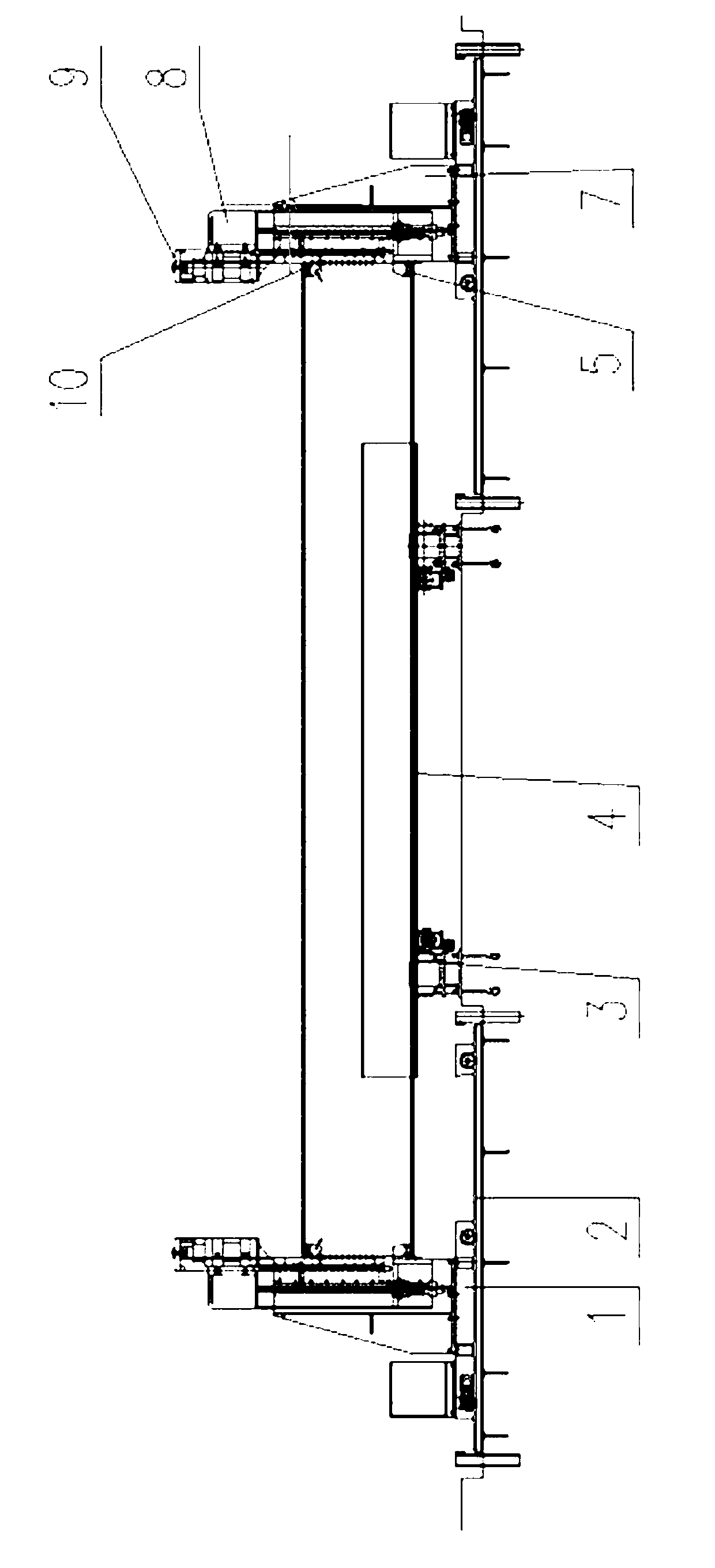

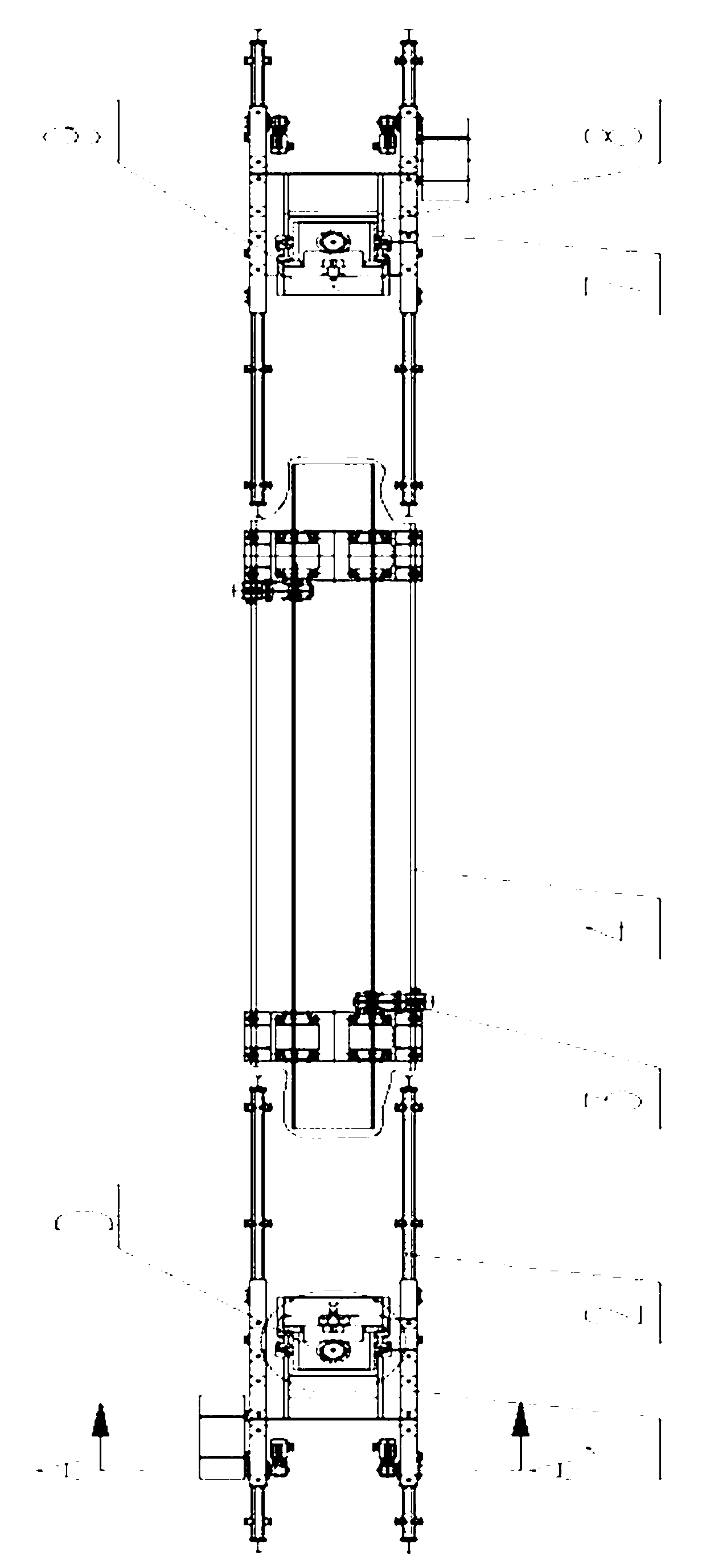

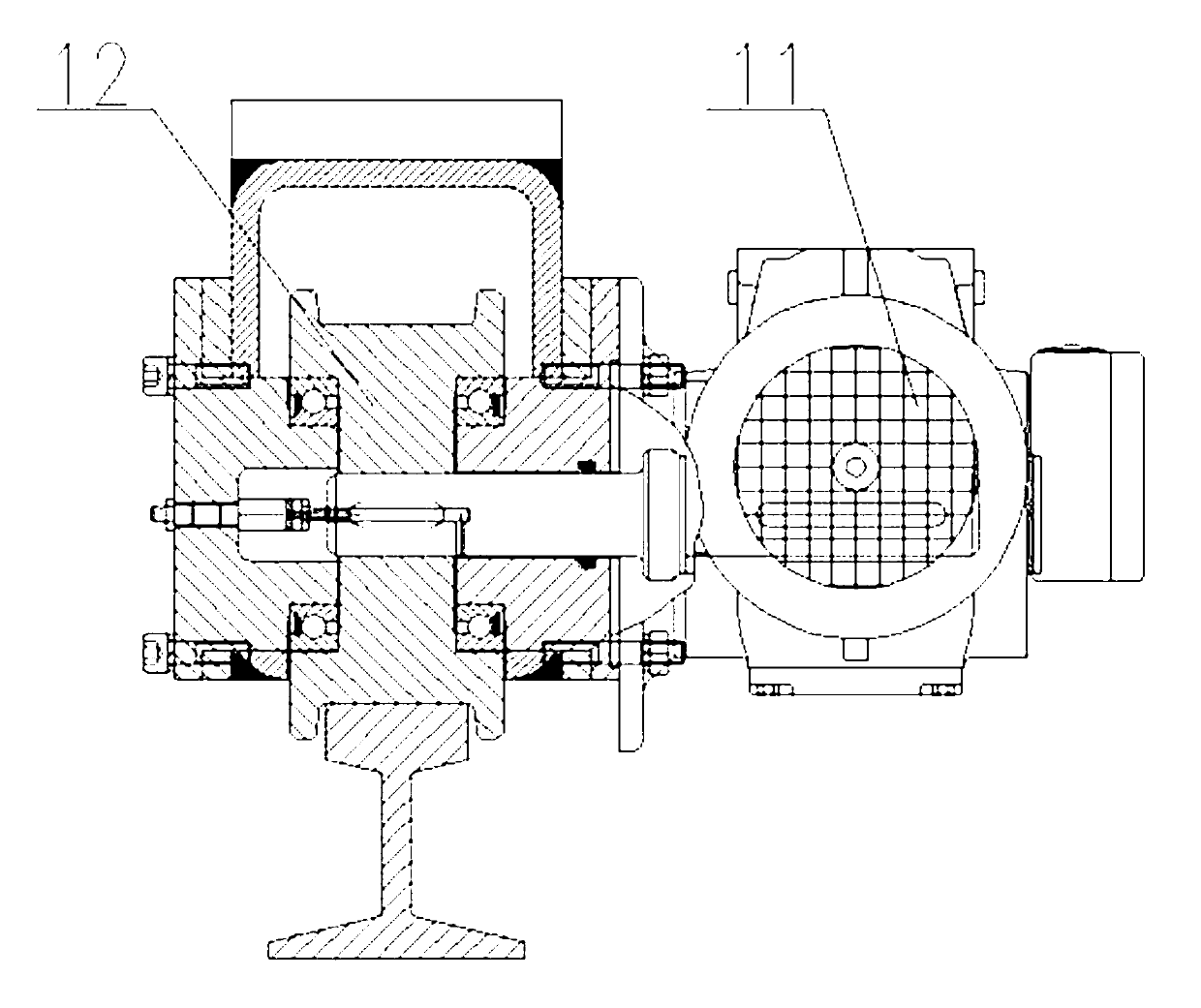

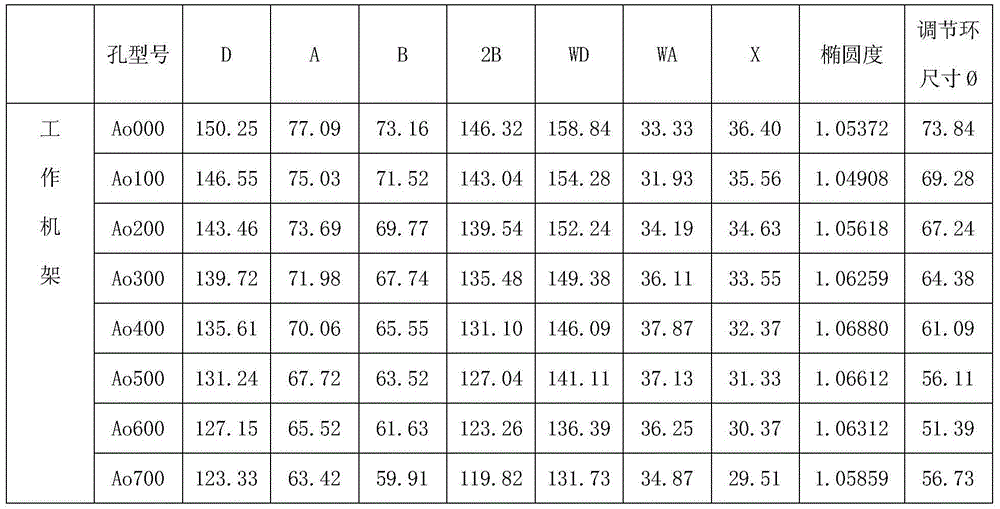

Non-ferrous metal tube collecting equipment

The invention discloses non-ferrous metal tube collecting equipment, which comprises a forming device for bending a straightened non-ferrous metal tube, a collecting device for coiling the formed non-ferrous metal tube, a coil packaging device and a discharging device, wherein the collecting device comprises a rotary driving device, a lifting driving device and a horizontal moving device. The non-ferrous metal tube coiling equipment has the advantage that the non-ferrous metal tube collecting device is arranged behind on-line annealing to form a set of continuous production device, so the equipment cost and production cost of a manufacture are reduced greatly together with energy consumption and labor cost, and the equipment is more automatic than before. The non-ferrous metal tube collecting method is to collect, form and coil the tube after annealing and improves the ovality of the non-ferrous metal tube considerably. When the equipment is used for collecting the tube, the coil height can be set randomly and may reach 2,000 millimeters.

Owner:SUZHOU AOZHI INTELLIGENT EQUIP CO LTD

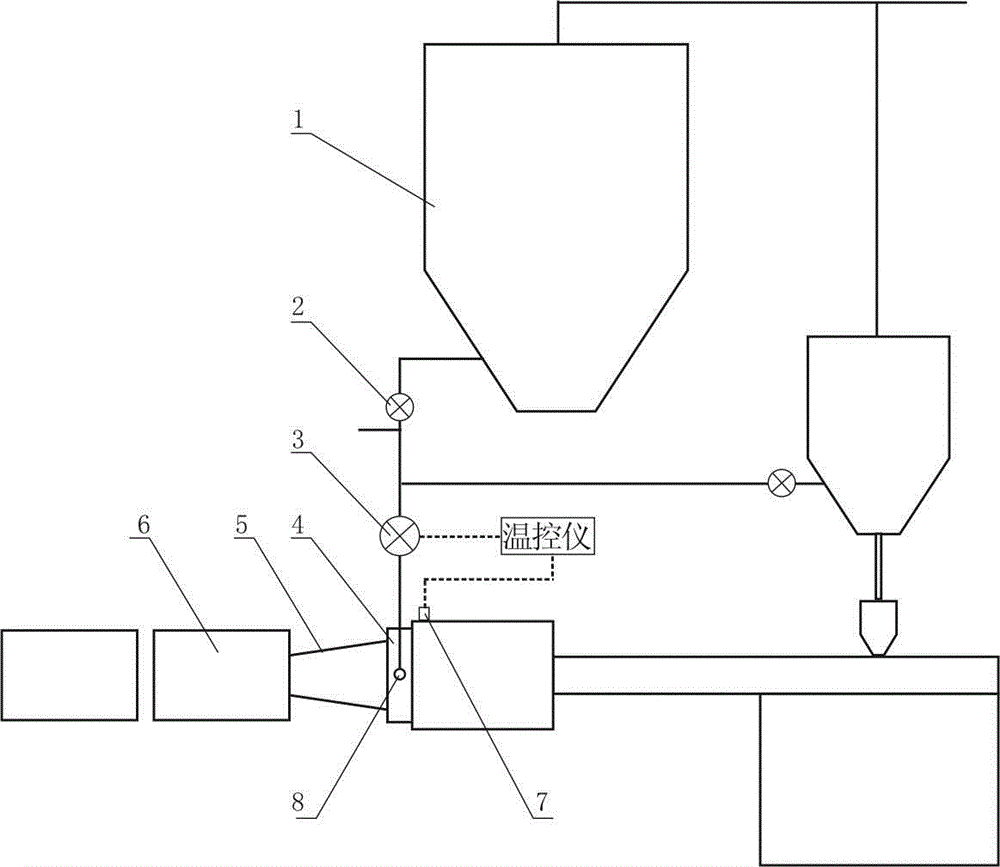

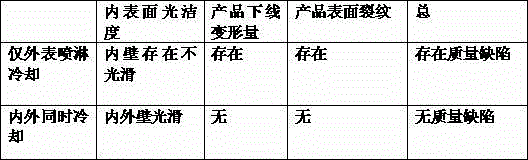

Waste heat recovering and utilizing system and method of plastic pipe production line

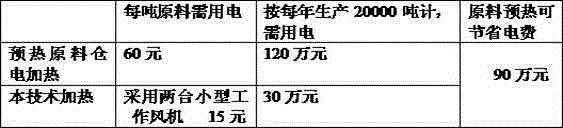

InactiveCN104527013ABalance the temperature difference between inside and outsideUniform textureThermodynamicsProcess engineering

The invention discloses a waste heat recovering and utilizing system and method of a plastic pipe production line. The waste heat recovering and utilizing system comprises a heat recovering device arranged at an extrusion molding core mould, wherein the heat recovering device is connected with a raw material preheating bin; the heat recovering device comprises a heat recovering hole connected in from the core mould and connected with the center of an extruded plastic pipe. The waste heat recovering and utilizing method disclosed by the invention comprises the following steps: obtaining the temperature of the center of the plastic pipe of the extrusion core mould; sucking the heat by adopting a negative pressure fan; conveying the heat to the raw material preheating bin and other heat utilizing occasions; detecting the temperature in the core mould in real time, regulating a working parameter of the negative pressure fan; and detecting the temperature in the raw material preheating bin in real time so as to regulate inlet air heat. According to the waste heat recovering and utilizing system and method, high-temperature air is sucked from the interior of the plastic pipe and the sucked heat is used in production. Because the inner wall of the plastic pipe is effectively cooled, the difference of the temperatures inside and outside the plastic pipe is balanced, and no cracks are easily formed. Because the cooling speed of the plastic pipe is relatively high, the delivery speed of the pipe is high, and the yield is increased. Meanwhile, heat energy is recycled, so that the energy consumption is reduced.

Owner:SICHUAN QINGCHUAN PIPES CO LTD

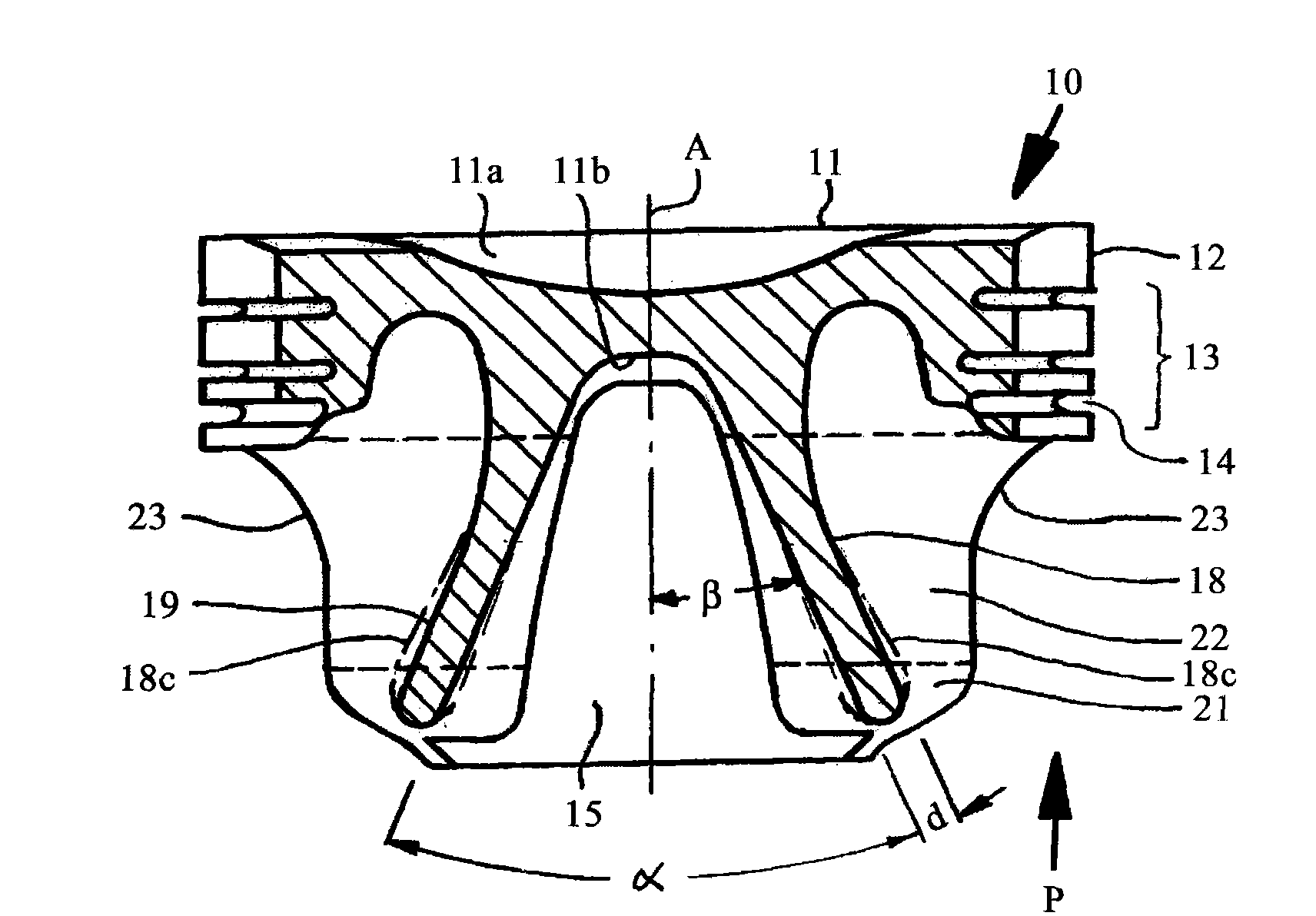

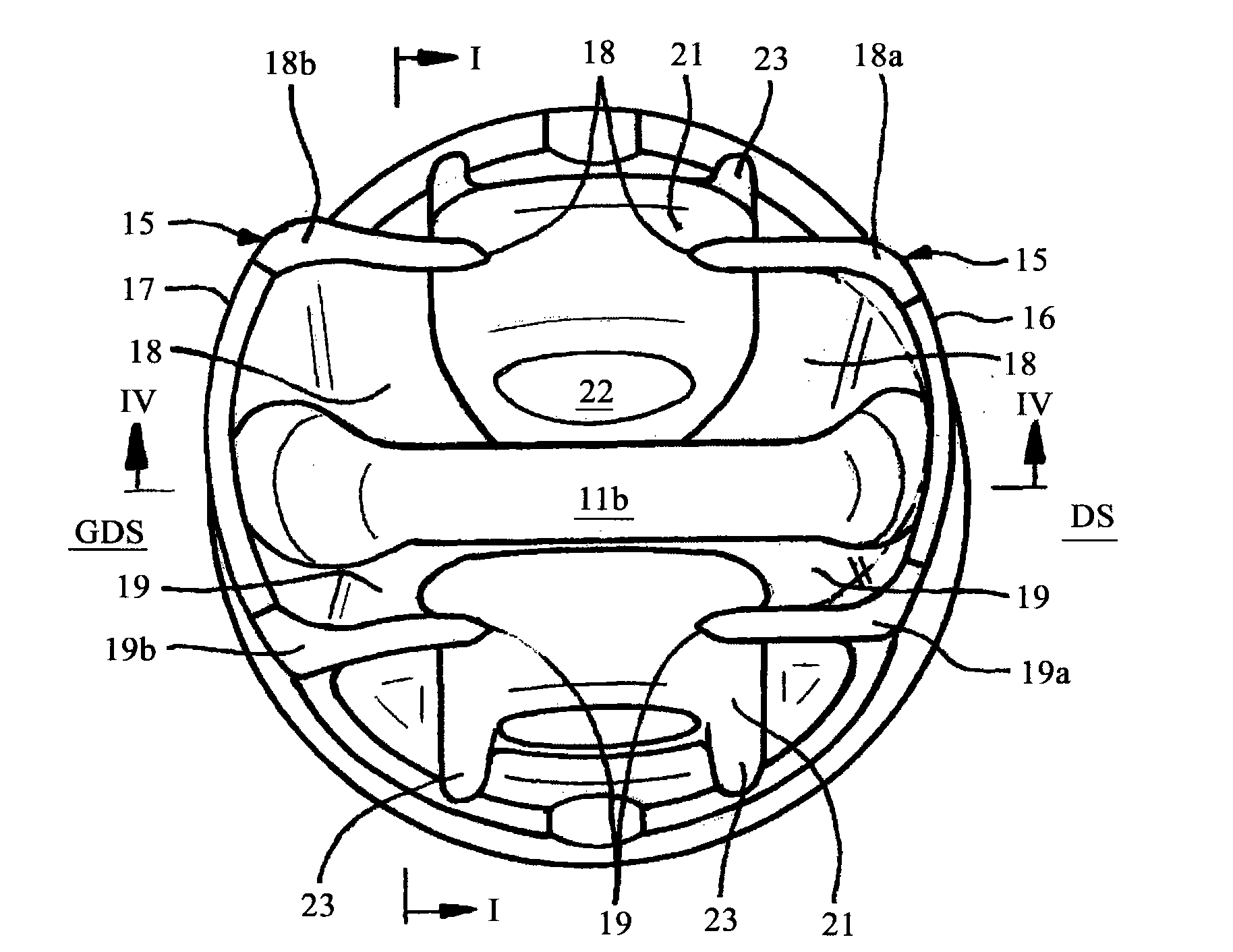

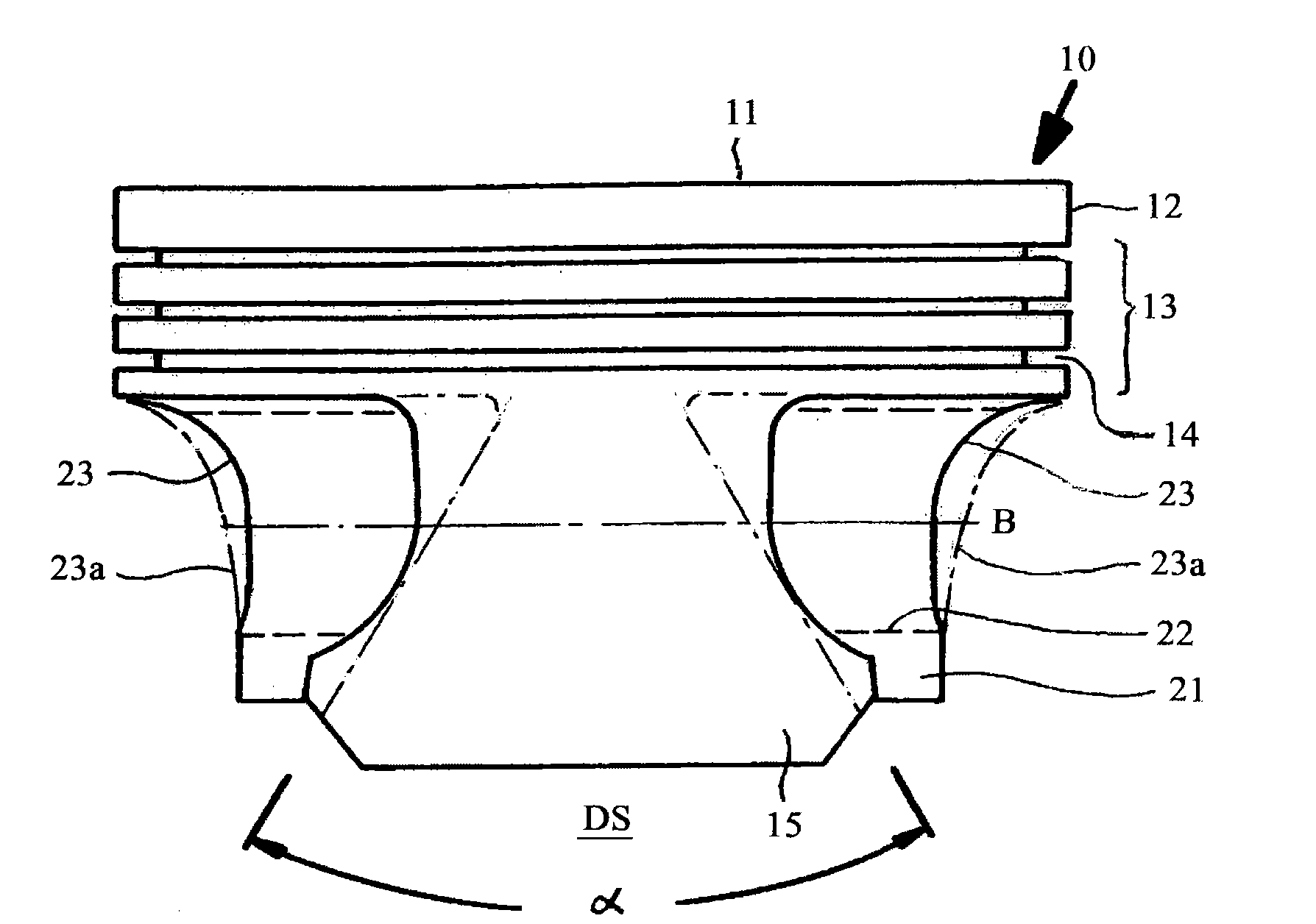

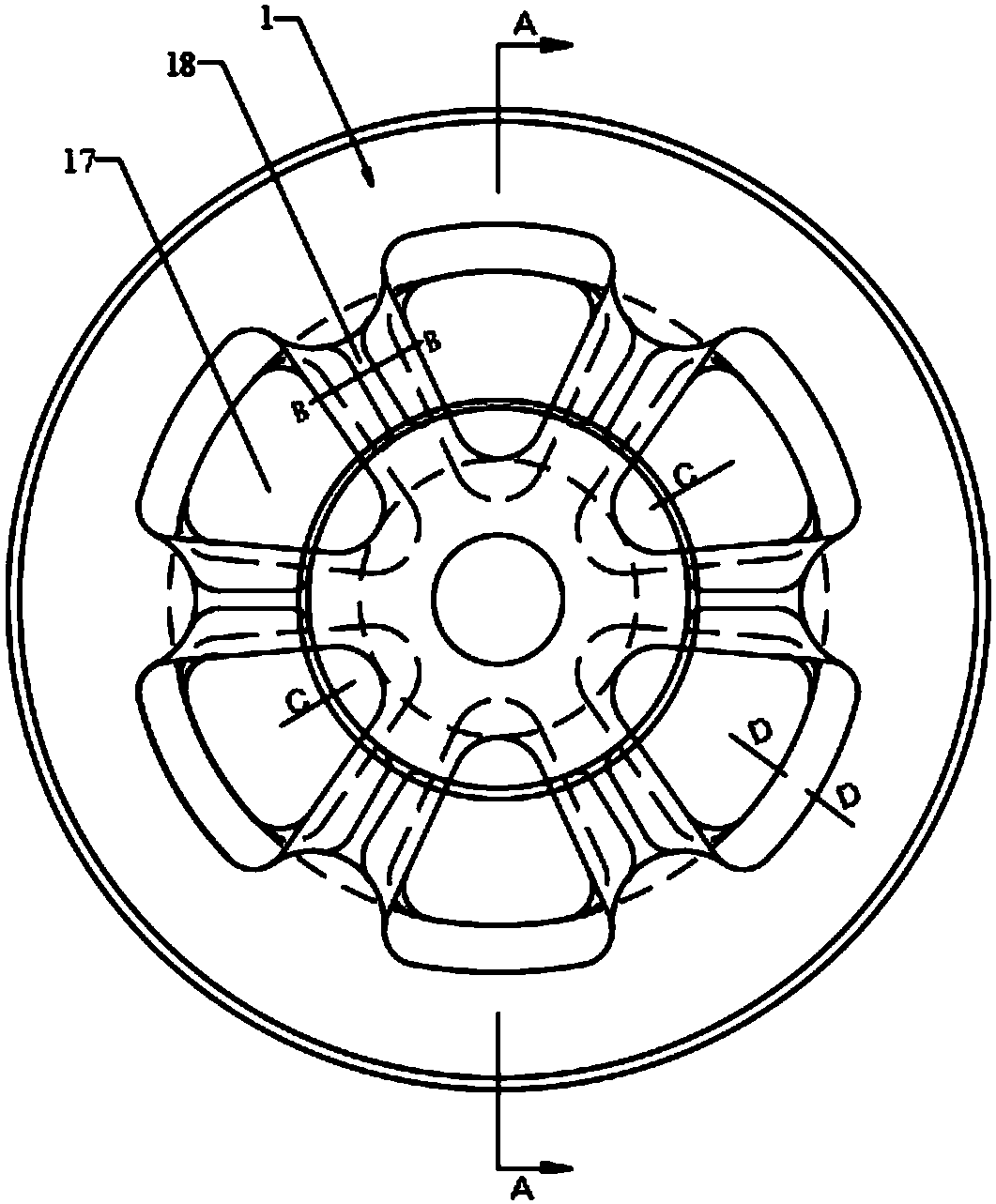

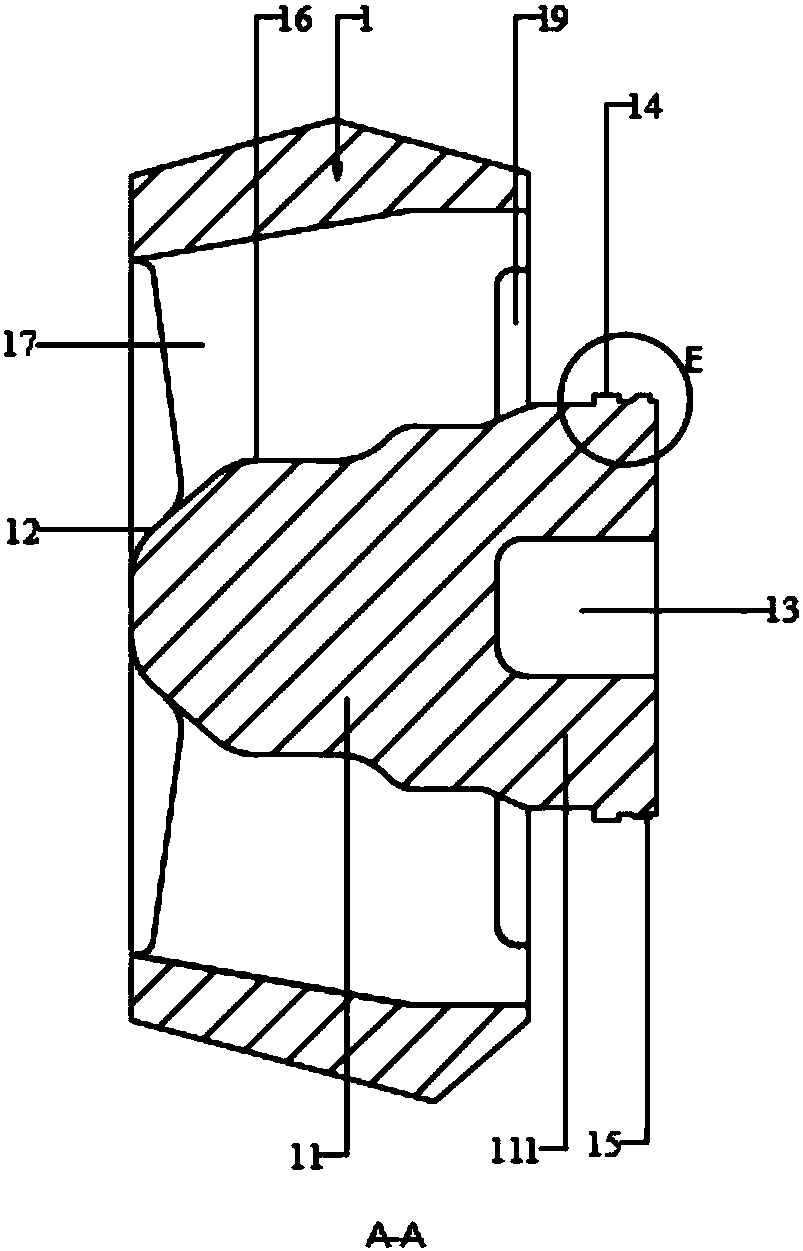

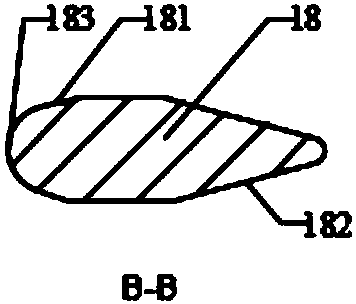

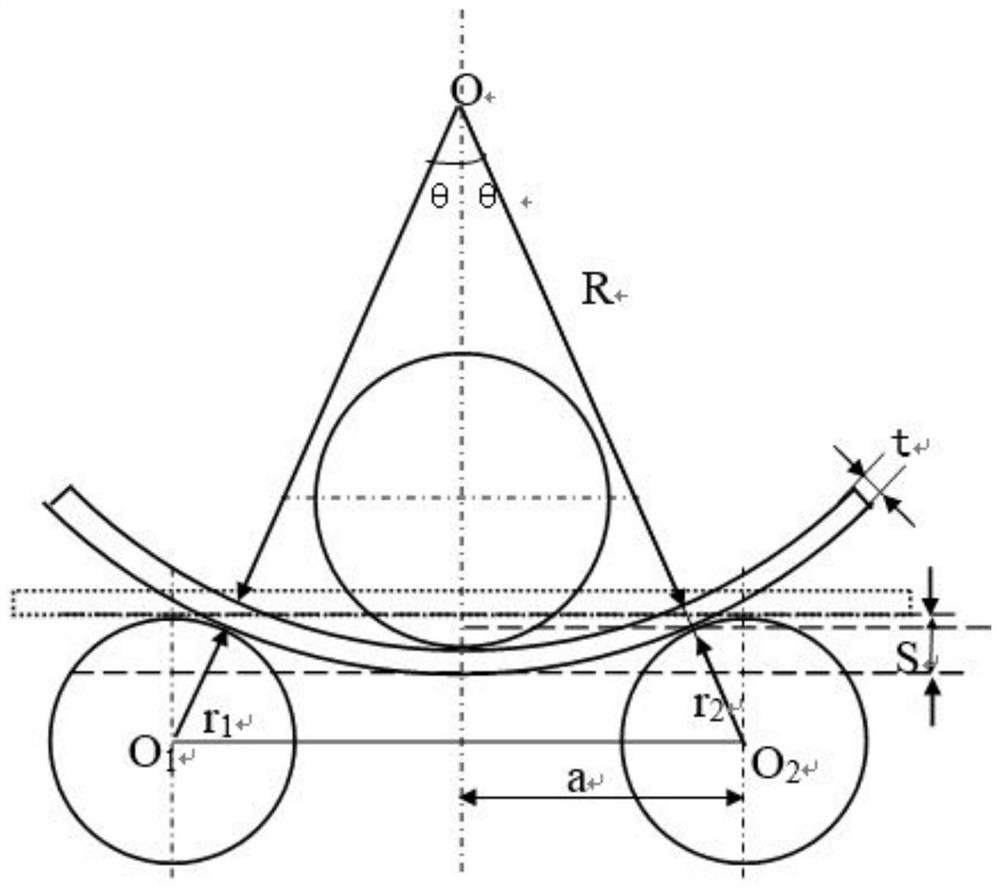

Piston for an internal combustion engine

ActiveCN101668938ANo crackAdvantage expansion planPlungersMachines/enginesInternal combustion enginePiston

The present invention relates to a piston (10) for an internal combustion engine, comprising a piston head (11), a peripheral fire land (12), and a peripheral ring section (13) comprising ring grooves(14), and a piston skirt (15) comprising two skirt walls (16, 17) on the pressure side (DS) and the counterpressure side (GDS) of the piston (10) and two box walls (18, 19) recessed relative to the ring section and connecting the skirt walls (18, 19), wherein the box walls (18, 19) have pin hubs (21) comprising hub bore holes (22). According to the invention, the skirt wall (16) located on the pressure side (DS) is shorter in the circumferential direction of the piston (10) than the skirt wall (17) located on the counterpressure side (GDS).

Owner:MAHLE INT GMBH

Method for rolling high-precision titanium alloy pipes

ActiveCN104148439AImprove ovalityEliminate bumpsWork treatment devicesMetal rolling arrangementsMetallurgyMicrometer

The invention relates to a method for rolling high-precision titanium alloy pipes. A prepared titanium alloy pipe billet is rolled in a combination way of two rollers and three rollers, and the rolling method adopts single feeding and double slew. The value Q of two-roller rolling is 0.4-2, the value Q of multiple-roller rolling is 0.4-9, and the amount of clearance is 0.2-2mm. The rolled finished pipe is processed in a way of outer surface grinding and inner surface honing to obtain the titanium alloy pipes, wherein the outer surface roughness Ra is less than or equal to 0.6 micrometers, the inner surface roughness Ra is less than or equal to 0.2 micrometers, the outside-diameter size tolerance is less than or equal to 0.04mm, the inside-diameter size tolerance is less than or equal to 0.03mm, and the wall-thickness size tolerance is less than or equal to 3 percent of a nominal wall thickness. Compared with the prior art, the method has the advantages that the size tolerance precision of the obtained products is relatively high, and the inside and outside surface quality is relatively good.

Owner:宁夏中色金航钛业有限公司

Composite aluminum foil

InactiveCN103236296AGood adhesionSmooth appearanceConductive layers on insulating-supportsMetal layered productsPolyesterSocial benefits

The invention relates to a composite aluminum foil, which comprises a first aluminum foil layer, a second aluminum foil layer and a plastic reinforcing layer, wherein the first aluminum foil layer, the plastic reinforcing layer and the second aluminum foil layer are sequentially arranged, the adjacent layers are respectively compounded together by glue, the surface of the second aluminum foil layer is compounded with an adhering layer, the adhering layer is a polyester adhering thin film, the polyester is grafted and modified with maleic anhydride, and the adhering layer is compounded with the second aluminum foil layer together by glue. The composite aluminum foil has the advantages that the common problem of design and manufacturing technique of a coaxial cable is solved, the quality stability and the suitability of the cable are improved, and the social benefits are obvious; the adhering performance of the cable product is improved, the cost is low, and the process property is favorably prompted to be further improved; and the technique of the composite aluminum foil plays a leading role in the industry and has a great promoting function for market broadening and brand promotion.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

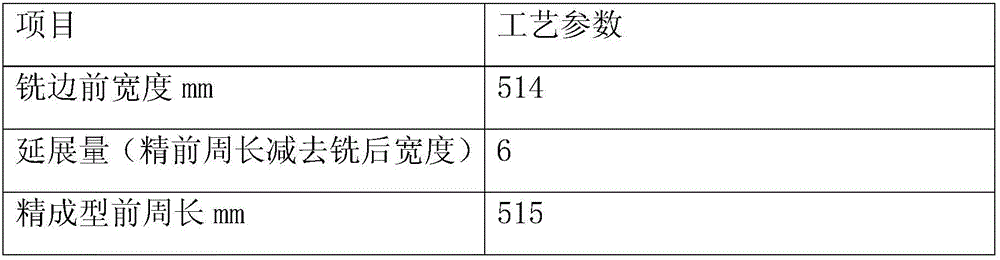

Production method of anticorrosion wear-resistant stainless steel HFW welding pipe with outer diameter of 108-660.4mm

ActiveCN104999277AImprove corrosion resistanceWith magnetic propertiesPipeline systemsOther manufacturing equipments/toolsHeat-affected zoneWear resistant

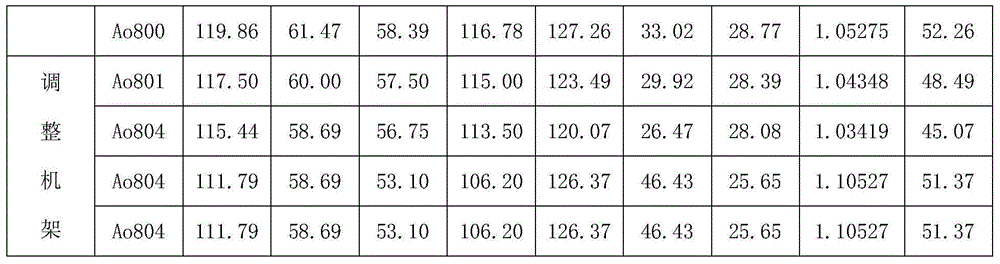

The invention provides a production method of an anticorrosion wear-resistant stainless steel HFW welding pipe with an outer diameter of 108-660.4mm, According to the method, the welding pipe is molded and sized by adjusting molding and sizing four-roll rigid rack equipment, oval precision of the welding pipe is up to + / -0.2mm and straightness of the welding pipe is up to 0.2mm / m; welding spots are protected by argon in a high frequency welding process of the welding pipe; a heat treatment temperature control range of welding seams of the welding pipe is between 800-900 DEG C, the welding seams and heat affected zone parts are subject to normalizing heat treatment and heat preservation time is 30-60s; pipe body positions at two sides of the welding seams are cooled by circulating water during air cooling, temperature is transferred to the welding seam positions of the pipe body of the welding body, overhigh temperature of the welding seams before the welding seams enter a water cooling section is prevented, and welding quality is not affected by structural transformation. The production method has the beneficial effects that the welding pipe produced by the method has better anticorrosion performance and magnetic conductive property, the straightness and ovality of the welding pipe are improved by 30%, equipment fault rate is reduced to 0.3% from 3%, service life is doubled, and the length of a one machine conveyor belt is improved to 6000m from 3000m.

Owner:TIANJIN PIPE GROUP CORP

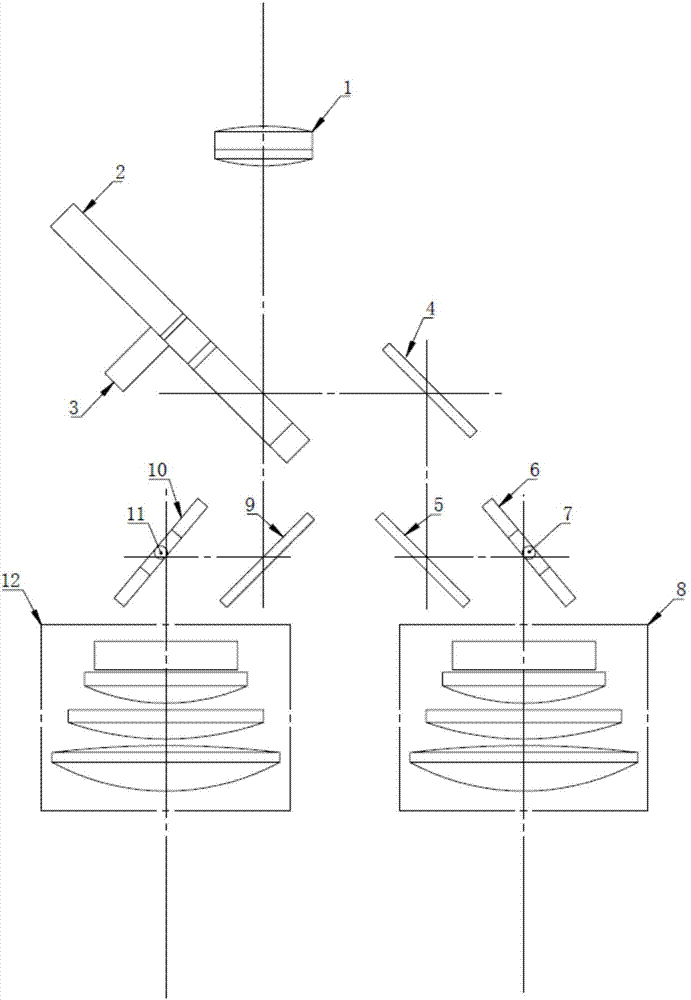

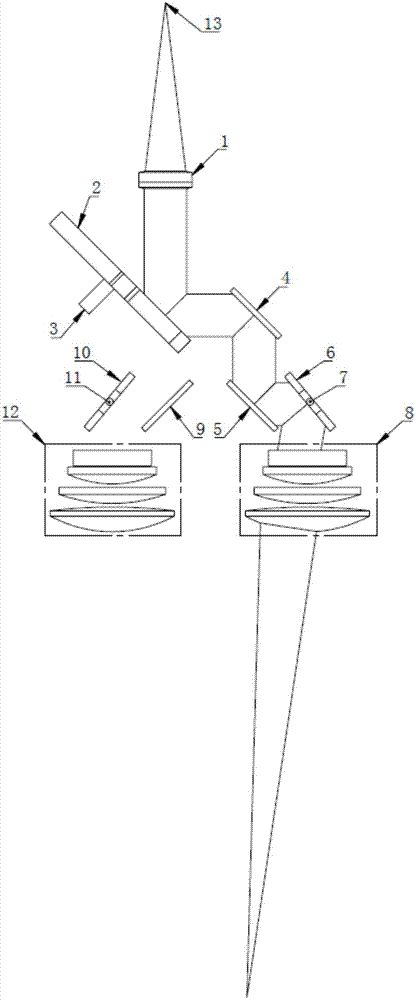

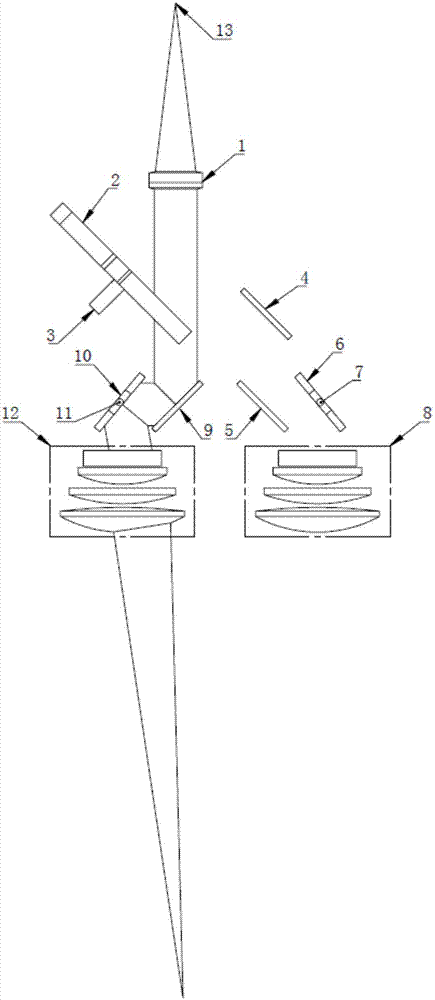

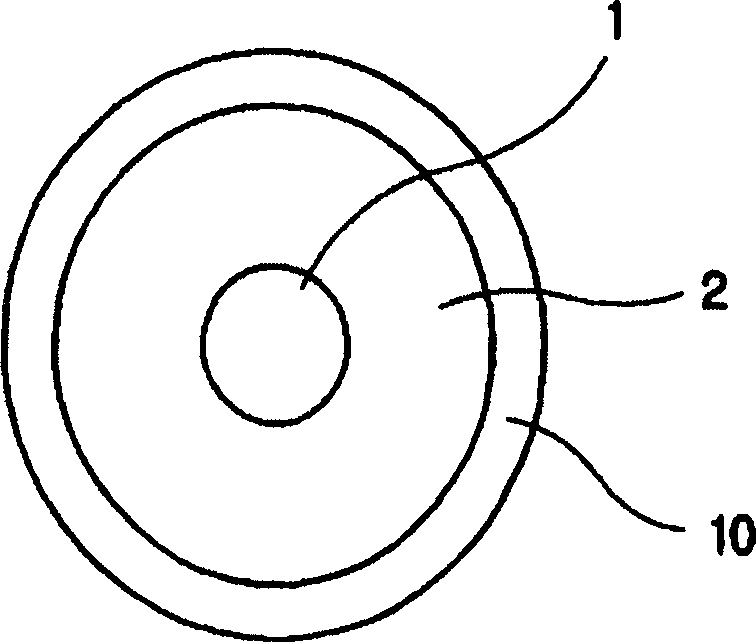

Laser texturing optical system based on chopping reflectors and galvanometers

InactiveCN107335924AImprove processing efficiencyWide range of applicationsLaser beam welding apparatusGalvanometerResonator

The invention discloses a laser texturing optical system based on a chopping mirror and a vibrating mirror, comprising an aberration-eliminating collimator mirror group, a chopping mirror, a first mirror, a second mirror, a third mirror, a A vibrating mirror, a second vibrating mirror, a first f-θ mirror, and a second f-θ mirror; wherein, the aberration-absorbing collimating mirror group can be replaced by an aberration-eliminating aspheric mirror. The chopper reflector and vibrating mirror laser texturing optical system provided by the present invention, through the intermittent mirror tuning function of the chopper reflector, based on the one-dimensional vibrating mirror scanning function, has the advantages of high processing efficiency and wide application range, and is suitable for pulse Laser texturing of fiber lasers is especially suitable for orderly laser texturing of high-power pulsed fiber lasers in planar translation and rotation systems.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

Method for making optical fiber preform having ultimately low PMD through improvement of ovality

InactiveCN1592860AImprove ovalityGlass making apparatusOptical light guidesPolarization mode dispersionOvality

A method for making an optical fiber preform having an ultimately low PMD (Polarization Mode Dispersion) through improvement of ovality is provided. This method has several collapse steps for collapsing an optical fiber preform having a clad / core deposition layer formed in a preform tube in which a rate of collapse is 0.01-0.06 mm / min at each collapsing step. By using this method, ovality and PMD of the optical fiber preform may be improved.

Owner:LG CABLE INC

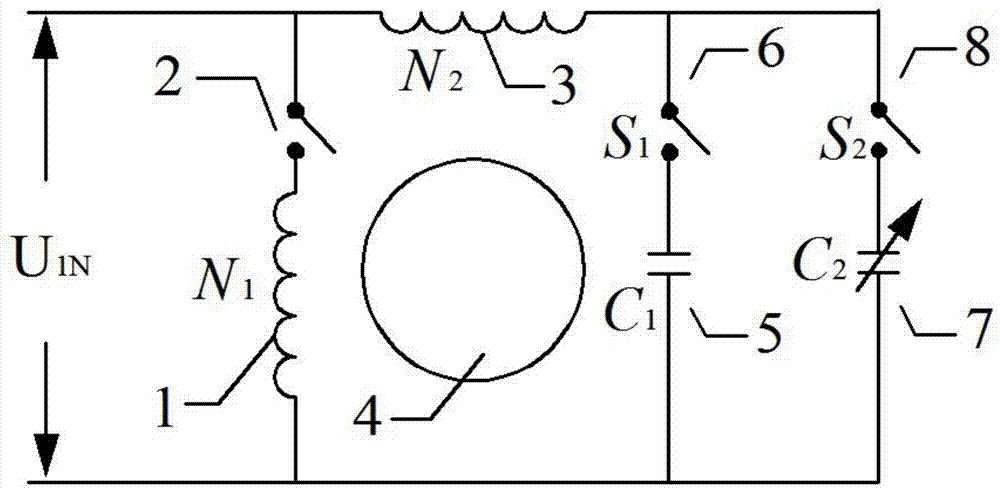

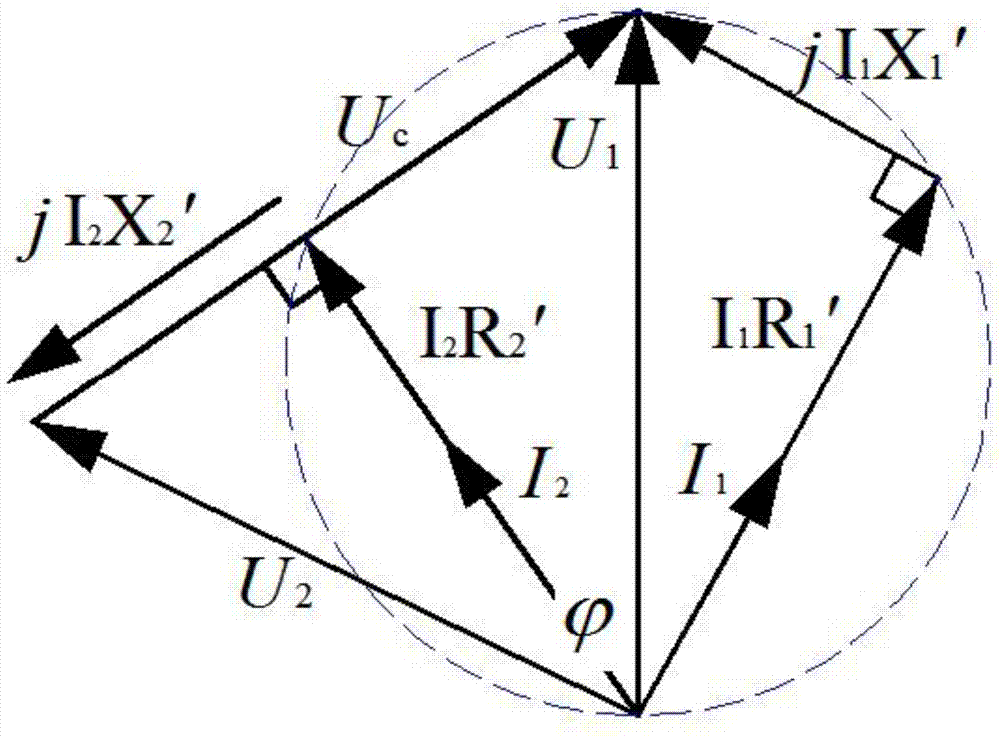

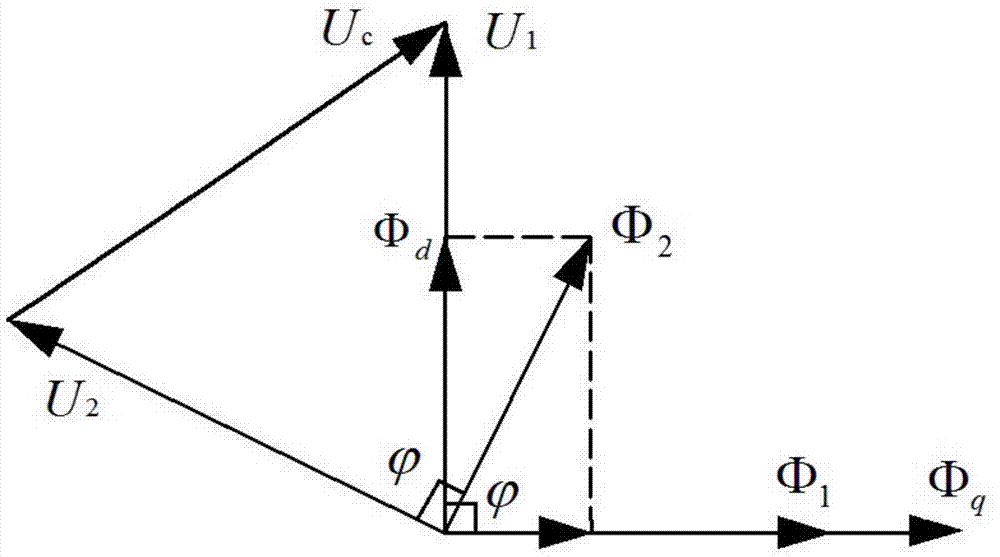

Control method for inhibiting single-phase capacitor run motor vibration noise

InactiveCN104852666ASuppress vibration noiseExpand the scope of useMotor control for motor oscillations dampingOvalitySingle phase

The present invention provides a control method for inhibiting single-phase capacitor run motor vibration noise. The circuit of the method comprises a primary winding, a secondary winding, a start capacitor and an adjustable run capacitor. The induction electromotive force of the secondary winding when the primary winding is powered and the secondary winding is disconnected and the induction electromotive force of the primary winding when the secondary winding is powered and the primary winding is disconnected are detected when a motor is in a no-load operation, and the effective turn ratio of the primary winding and the secondary winding is obtained. Rated voltage is applied to the motor to allow the motor to drive a load to run, a start capacitor is disconnected after normal running, the adjustable run capacitor is connected, the voltage of the primary winding, the secondary winding and the adjustable run capacitor at that time are detected, the ovality information of a gap magnetic field is obtained, the capacitance value of the adjustable run capacitor is changed according to the information, the vibration noise in common single-phase capacitor run motor load running can be effectively inhibited, the adjustable run capacitor can be changed according to different loads dragged by the motor, and the vibration noise is small when multiple types of loads are dragged by the motor.

Owner:JIAXING UNIV

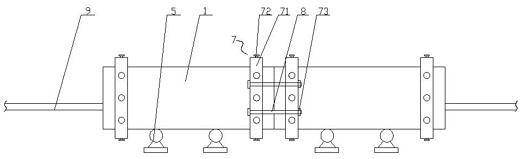

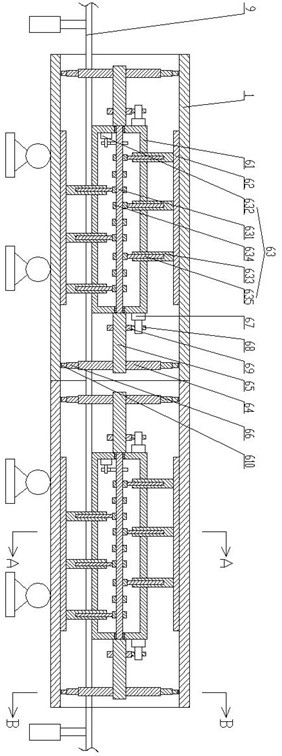

Steel pipe end rounding machine

The invention discloses a steel pipe end rounding machine, which comprises a body, wherein two sections of rails are symmetrically arranged on the body; a driving vehicle is arranged on the rail; rotating rollers are arranged between the two sections of rails; a steel pipe is arranged between two rotating rollers; a fixing seat is arranged on the driving vehicle; a lower adjusting cylinder is arranged on the fixing seat; a piston rod of the lower adjusting cylinder is arranged at the lower end of a die bracket; the lower part of the die bracket is provided with a lower rounding die; the upper end of the die bracket is provided with a tension cylinder; a piston rod of the tension cylinder is connected with an upper rounding die; the upper rounding die is arranged on a lifting sliding rack; and the lifting sliding rack is arranged on the die bracket. The steel pipe end rounding machine is ingenious in structure and reasonable in design, and the function of improving the ovality of the pipe end of the steel pipes of different lengths and specifications.

Owner:天水天力特种管有限公司

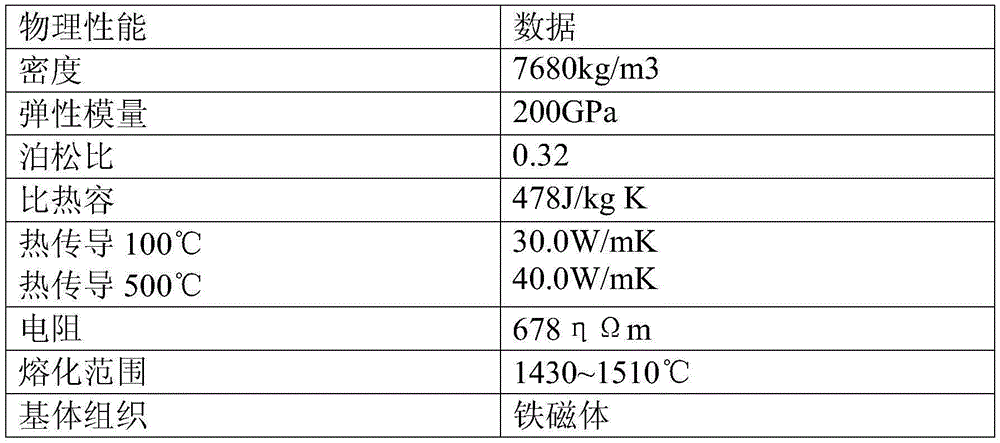

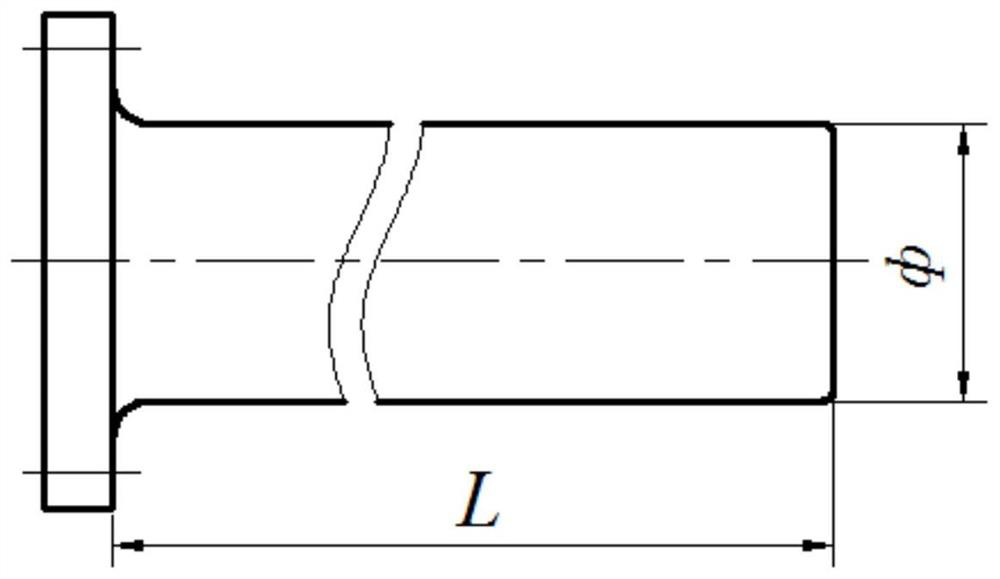

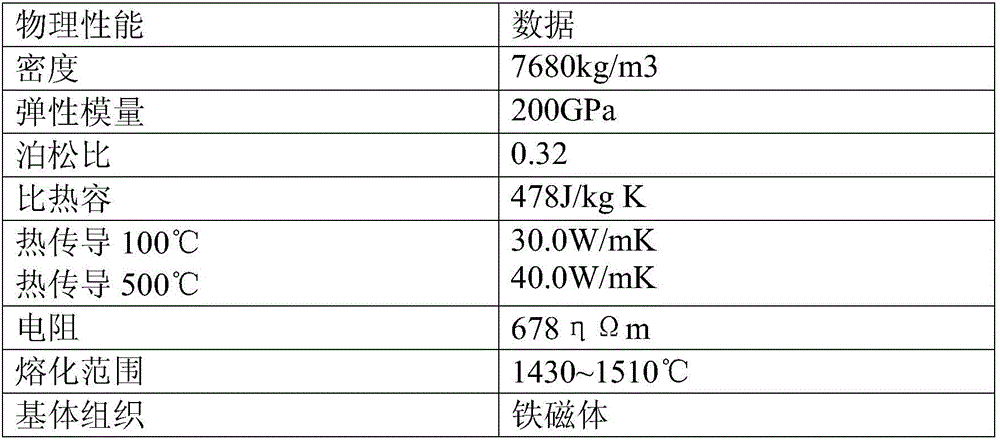

Preparation process of anti-CO2-corrosion oil well pipe with steel grade of less than 150ksi produced by CPE unit

The invention discloses a preparation process of an anti-CO2-corrosion oil well pipe with a steel grade of less than 150ksi produced by a CPE unit. The process comprises the following steps: smelting each component by virtue of a converter according to the mass percentage proportion of each component, and performing continuous casting and continuous rolling on molten steel which is smelted by the converter to prepare a pipe billet, wherein the pipe billet comprises the following components in percentage by mass: 0.13-0.23% of C, 0.11-0.41% of Si, 0.8-1.0% of Mn, 5.0-6.0% of Cr, 0.05-0.45% of Mo, 0.02-0.04% of Al and the balance of Fe and inevitable impurities, and the total mass percentages are 100%. A steel pipe rolled by virtue of the process disclosed by the invention is good in surface quality and high in size precision, the anti-collapse performance of a pipe body can be effectively improved, the improvement of the anti-CO2-corrosion performance of the steel pipe can also be facilitated, the mechanical performance of the steel pipe can reach less than 150ksi, and the steel pipe is suitable for mining application of deep wells and ultra deep wells.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

Wire drawing system for steel wire drawing

PendingCN114273446AGuaranteed surface qualityReduce labor intensityDrawing diesMachine maintenanceStructural engineering

The invention discloses a wire drawing system for drawing a steel wire. The wire drawing system comprises a wire drawing machine, a guide roller frame and a rotary wire drawing device which are arranged in sequence, the wire drawing machine comprises a pay-off rack, the pay-off rack comprises a machine base and a pay-off channel arranged on the machine base, one end of the pay-off channel is connected with the wire drawing machine, and a bearing cover plate is arranged at a port of the other end of the pay-off channel; a pay-off roller is arranged on one side of the bearing cover plate; the guide roller frame comprises a machine base, a fixed box body arranged on the machine base and a guide roller set, the guide roller set is arranged in the fixed box body, and a steel wire passing opening is formed between guide rollers in the guide roller set; the rotary wire drawing device comprises a base and a box body arranged on the base, a barrel is arranged in the box body, a wire drawing cavity and a wire drawing die are sequentially arranged in the barrel body, the barrel body is sleeved with a worm gear, and the worm gear is connected with a worm. The rotating service life is prolonged, the workload of machine maintenance workers is reduced, the maintenance cost is reduced, the stopping maintenance time is shortened, and the working efficiency is improved.

Owner:JIANGYIN FASTEN STEEL PRODS +1

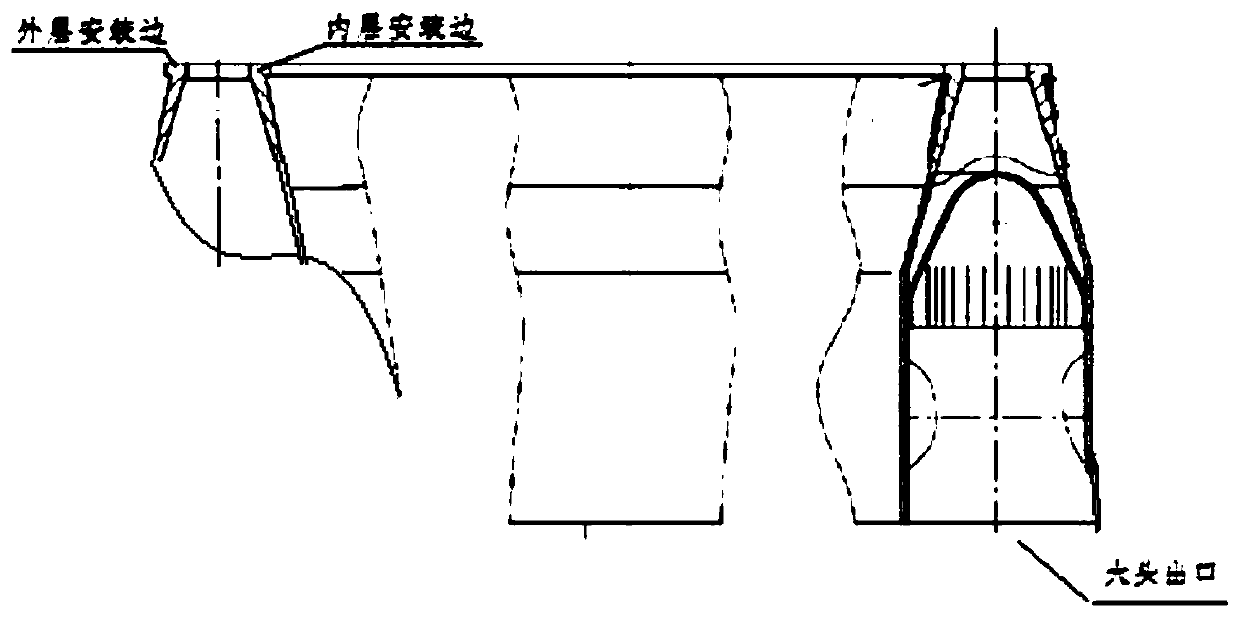

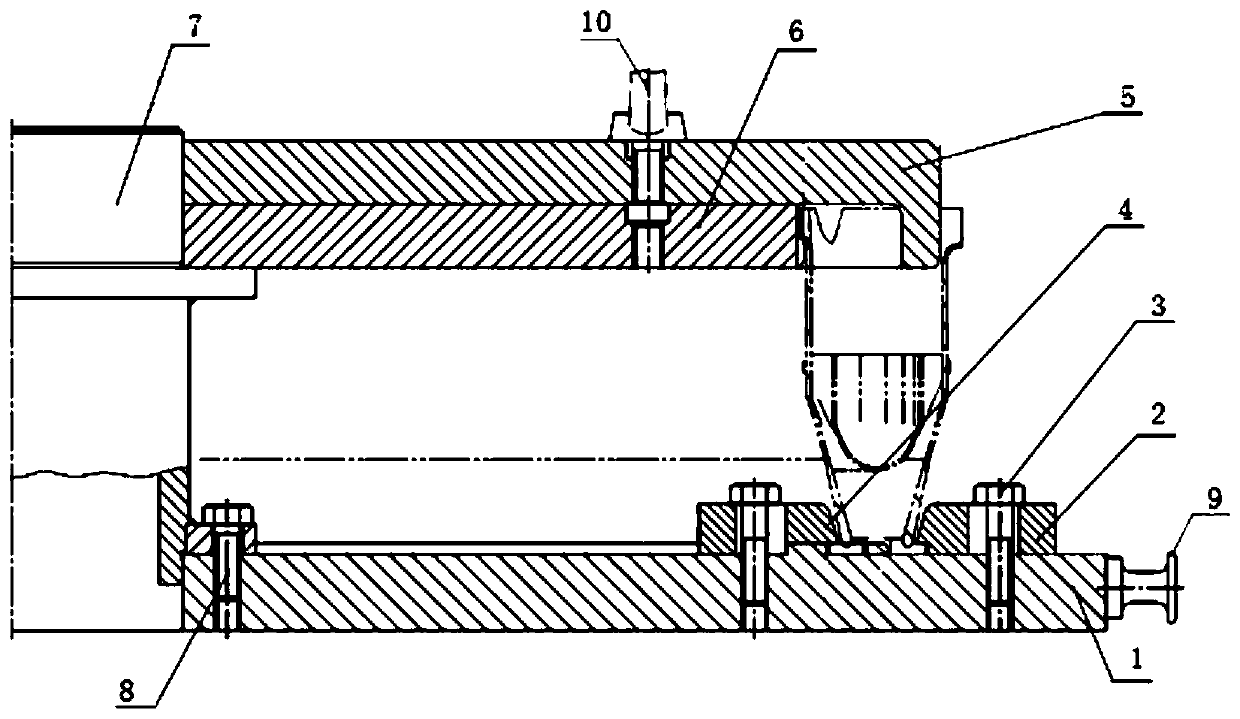

Limiting device for heat treatment of double-layer-structure welding assembly and clamping method

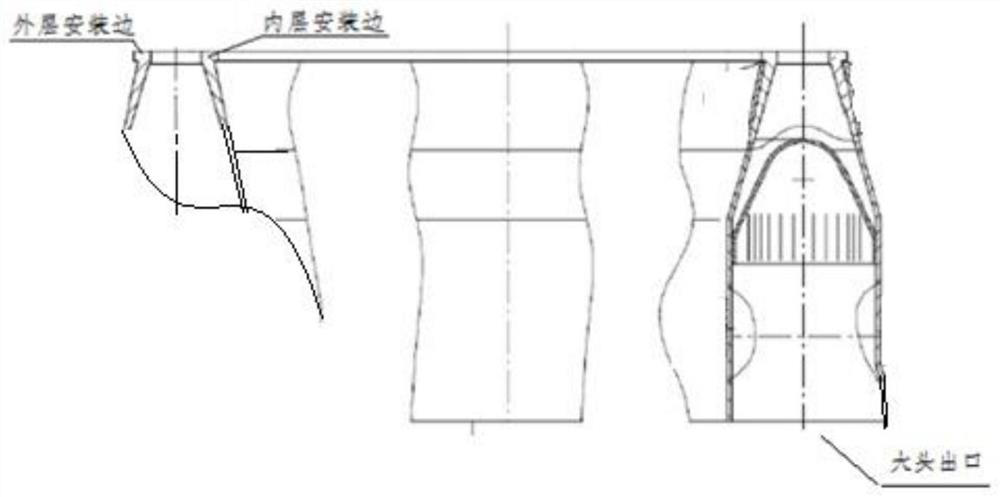

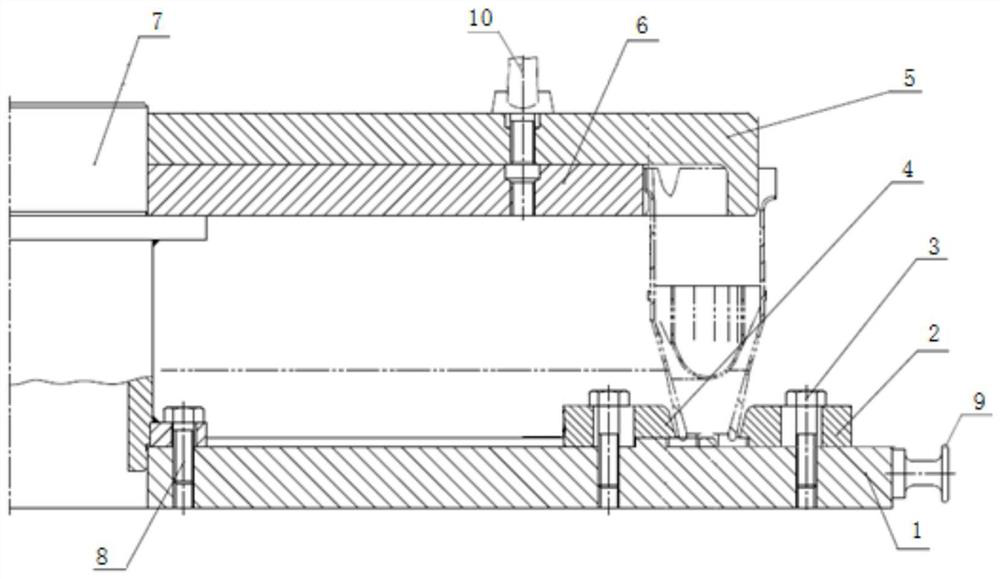

ActiveCN110819788ASimple structureReduce processing costsFurnace typesHeat treatment furnacesCircular discMaterials science

The invention discloses a limiting device for heat treatment of a double-layer-structure welding assembly and a clamping method. The limiting device comprises an outer disc, an inner disc, a chassis,a centering shaft and a pressing plate, wherein the outer disc, the inner disc and the chassis are all disc parts with center holes and are assembled on the centering shaft; the peripheral surface ofthe outer disc is a first annular outer cylindrical surface; the first annular outer cylindrical surface is tightly attached to the inner surface of an outer layer structure of the double-layer-structure welding assembly; the peripheral surface of the inner disc is a second annular outer cylindrical surface; the second annular outer cylindrical surface is tightly attached to the outer surface of an inner layer structure of the double-layer-structure welding assembly; the pressing plate is connected with the upper end surface of the chassis through a first bolt; and an outer layer mounting edgeand an inner layer mounting edge of the double-layer-structure welding assembly are positioned between the pressing plate and the upper end surface of the chassis. The limiting device is adopted forclamping, so that the concentricity of the inner layer mounting edge and the outer layer mounting edge after heat treatment is guaranteed, the ovality of the inner layer mounting edge and the outer layer mounting edge is controlled, the concentricity of the inner layer mounting edge, the outer layer mounting edge and a large-end outlet section is guaranteed, the workload of calibration is reducedprior to turning, and the assembly requirements are met.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Aluminum alloy large round tube die

InactiveCN107838217AReduce pressure areaReduce consumptionExtrusion diesUltimate tensile strengthWork zone

The invention relates to the technical field of die processing, and in particular, relates to an aluminum alloy large round tube die including an upper die and a lower die which are connected with each other; the middle of the upper die is provided with a tongue core, and the tongue core is arranged from a feed end of the upper die to a discharge end of the upper die; the tongue core is a frustumstructure having a spherical bulge at one end, and the spherical bulge is located at one side, close to the feed end of the upper die, of the tongue core; the other side, close to the discharge end ofthe upper die, of the tongue core includes a cylinder extending out of the upper die; the center of the end face of the cylinder is provided with a U-shaped through-hardening hole; the cylinder is provided with a first work zone and a second work zone successively along the direction from the feed end of the upper die to the discharge end of the upper die, and the cross section of the tongue corealong the direction from the feed end of the upper die to the discharge end of the upper die is step-like. The aluminum alloy large round tube die has the beneficial effects that the aluminum alloy large round tube die can effectively reduce the extrusion force, improves the strength of the die, improves the production efficiency, reduces the consumption of the die, and solves the problems of hard alloy ellipses and weld joints.

Owner:FUJIAN NANPING ALUMINUM

Processing technology of high-strength steel coiled pipe

The invention relates to a machining process of a high-strength steel coil pipe. The machining process of the high-strength steel coil pipe sequentially comprises the following steps of blanking, edgemilling and beveling, pre-bending, three-roller type plate rolling machine roller bending, straight seam welding and ring welding; before the plate rolling machine roller bending is carried out, theresilience of a steel plate is measured firstly, then the pipe coiling diameter is calculated when an actual pipe forming is carried out, the total lower displacement amount of an upper working rolleris calculated in the pipe coiling forming process, the pass displacement of the upper working roller is determined, and the pipe coiling machining is completed through a plurality of plate rolling; the pass displacement of the upper working roller is gradually decreased, and the first-pass displacement amount accounts for 50% or above of the total lower displacement amount, and the first three pass total displacement finishes 90% or above of the total lower displacement amount, and the upper working roller is basically in place when at least the antepenultimate pass is carried out. Accordingto the process, the displacement of the working roller can be effectively controlled, so that a high-strength steel plate with a proper size can prepare a dredging pipe with good straightness on a plate rolling machine, the gap of a pipe body does not exceed 3 mm at the end of the plate rolling, and welding can be carried out without circle rolling is performed, and the ovality of the pipe body isless than or equal to 2 mm.

Owner:CCCC TIANJIN DREDGING +1

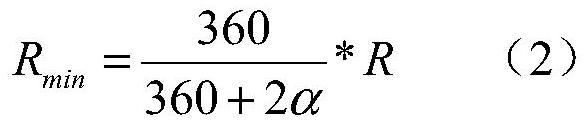

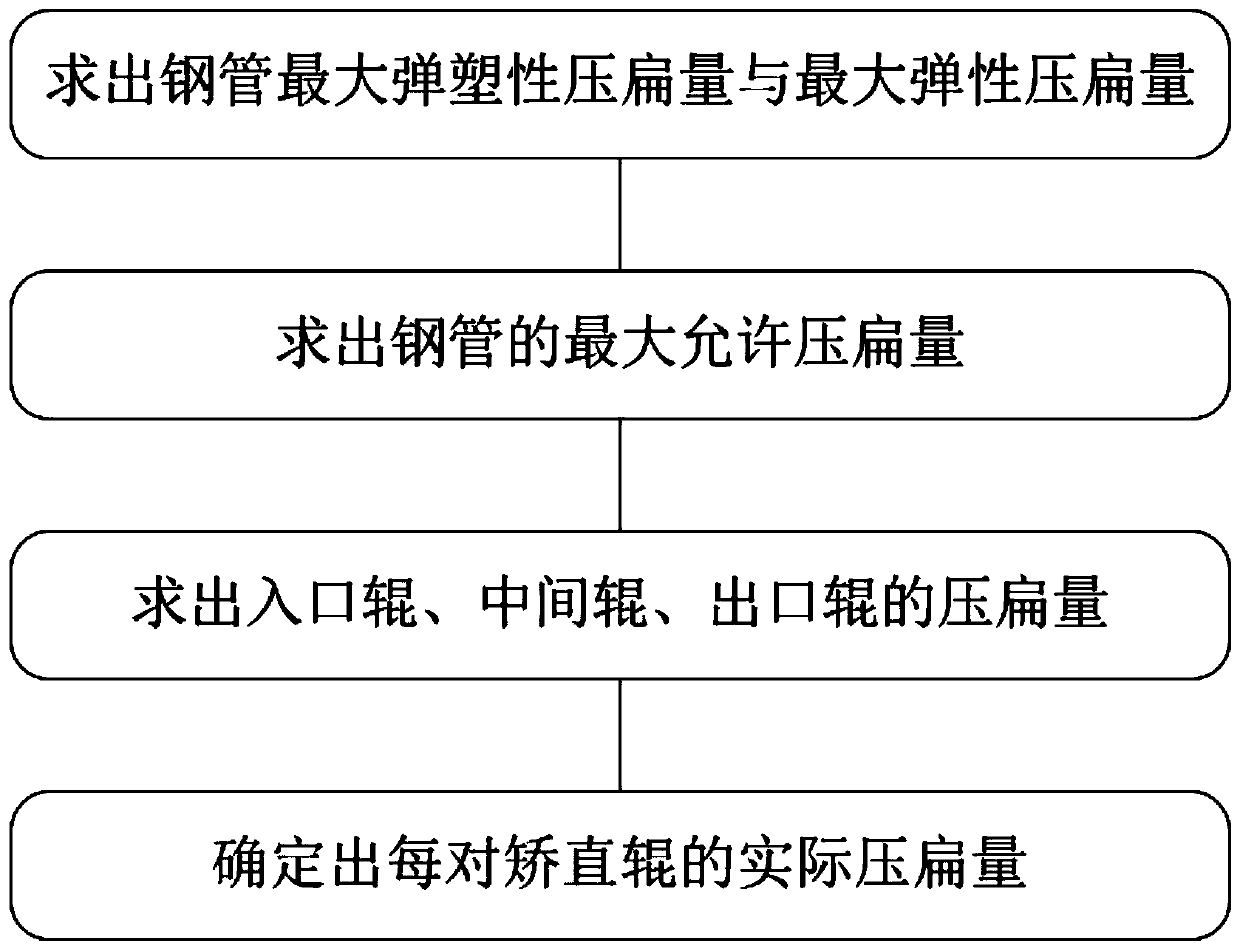

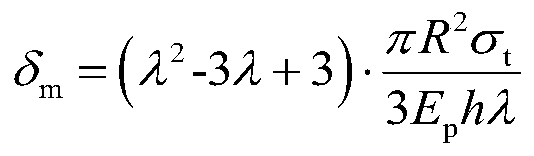

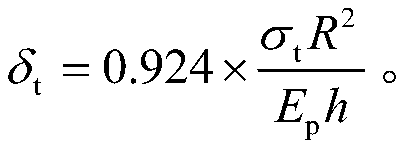

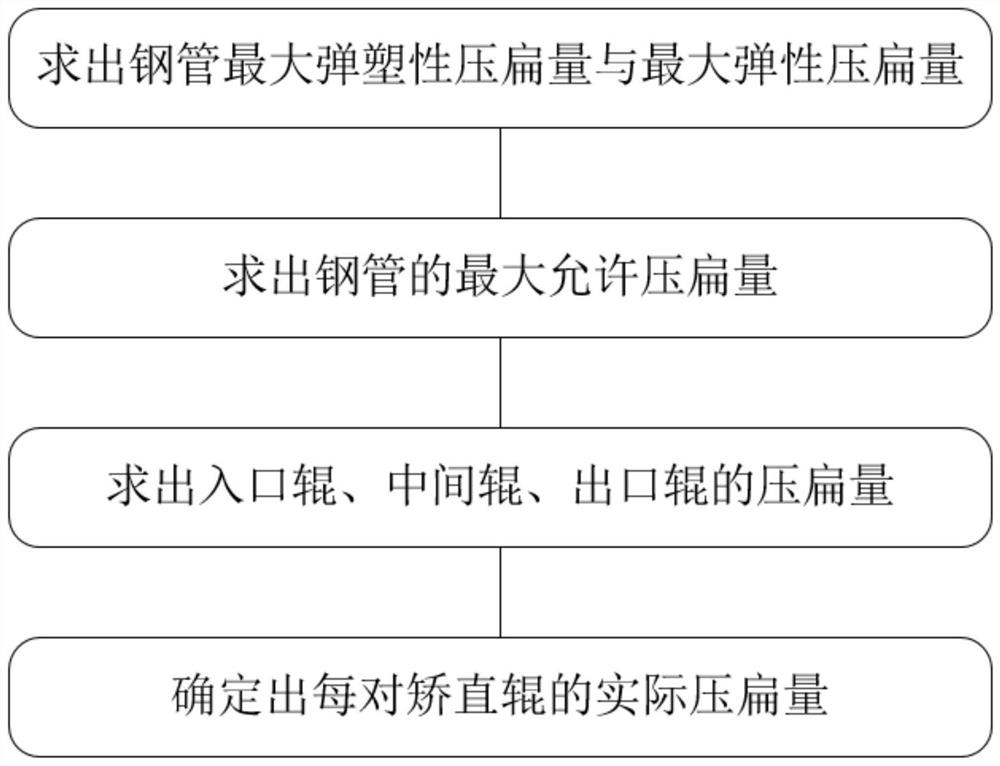

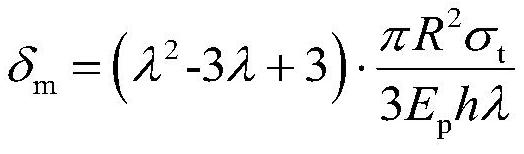

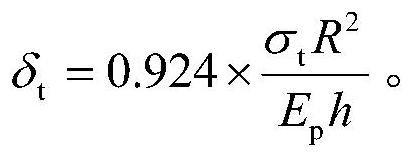

Setting method of super large diameter seamless steel tube straightening roll flattening rate

The invention belongs to the technical field of seamless steel tube multi-roll straightening, and specifically relates to a setting method of super large diameter seamless steel tube straightening roll flattening rate. The method comprises the following steps: solving maximal elastic-plastic flattening rate delta m and maximal elastic flattening rate delta t of a steel tube; according to a corresponding relation between wall thickness and the maximal allowed flattening rate of the steel tube, solving the maximal allowed flattening rate delta a of the steel tube; comparing the maximal elastic-plastic flattening rate delta m with the maximal allowed flattening rate delta a, taking a smaller value of the delta m and the delta a as flattening rate delta 2 of an intermediate roll, wherein flattening rate delta 1 of an entrance roll is equal to k1 delta 2, and flattening rate delta 3 of an exit roll is equal to k2 delta 2; according to a principle of satisfying actual flattening rate of a thin wall tube and a thick wall tube, determining actual flattening rate of each pair of straightening rolls, and realizing an aim of differentiated adjustment for straightening roll flattening rate bymeans of a pressing down system. The method, by setting the straightening roll flattening rate, can effectively improve ovality of the straightened steel tube and improve product straightening precision. The method is used for setting straightening roll flattening rate.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A limit device and clamping method for heat treatment of a double-layer structure welded assembly

ActiveCN110819788BSimple structureReduce processing costsFurnace typesHeat treatment furnacesCircular discEngineering

The present invention discloses a limited device and clamping method for the heat treatment of double -layer structure welding composition. The limit device includes the outer disk, inner plate, chassis, attentive shaft, and pressure plate.The disk, and the three are assembled on the heart axis.The outer surface of the outer disk is a first ring -shaped outer cylinder, and the inner surface of the inner surface of the outer structure of the first ring -shaped outer cylinder and the double -layer structure welding is tight;The outer surface of the inner structure of the inner structure of the second ring -shaped outer cylinder and the double -layer structure welding is tight; the upper end of the chassis is set with a pressure plate connected by the first bolt, and the outer installation edges of the outer layer of the double -layer structure welding component areThe inner layer is installed between the upper end of the pressure plate and the upper end of the chassis.The restriction device of the present invention is used for the installation of the installation of the inner and outer layers of the inner and outer layers of the inner and outer layers of the inner and outer layers.A pre -school volume to ensure assembly requirements.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

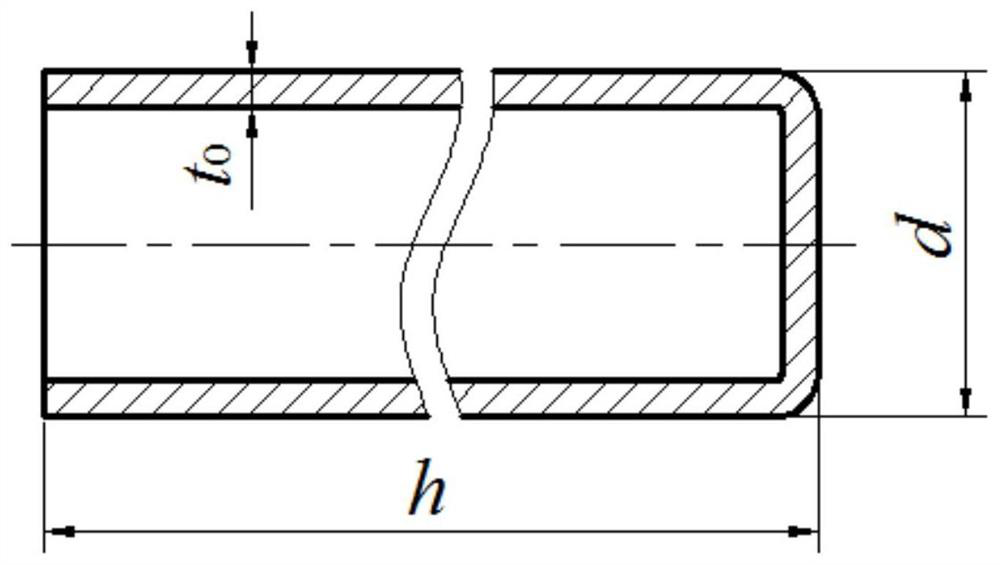

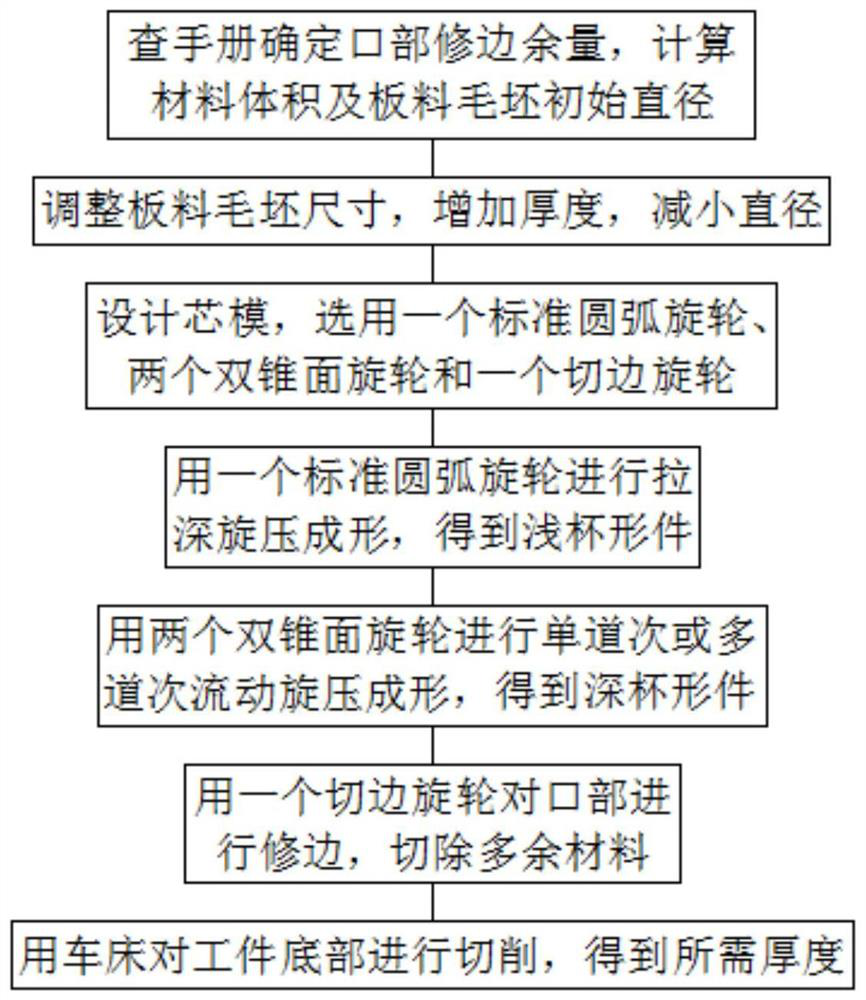

A precise plastic forming method for deep cup-shaped thin-walled parts

Owner:SOUTH CHINA UNIV OF TECH

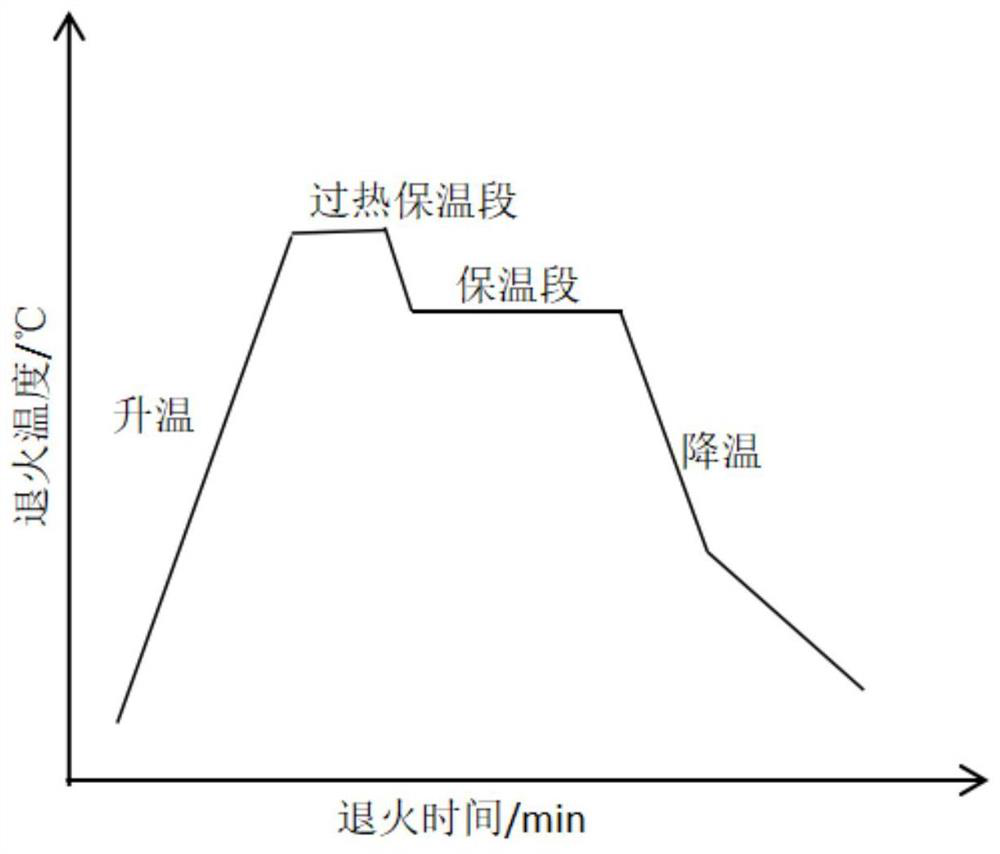

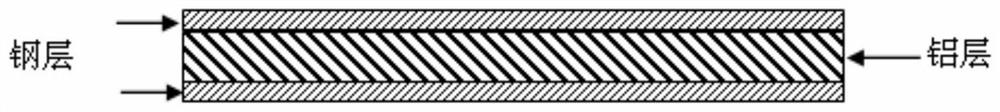

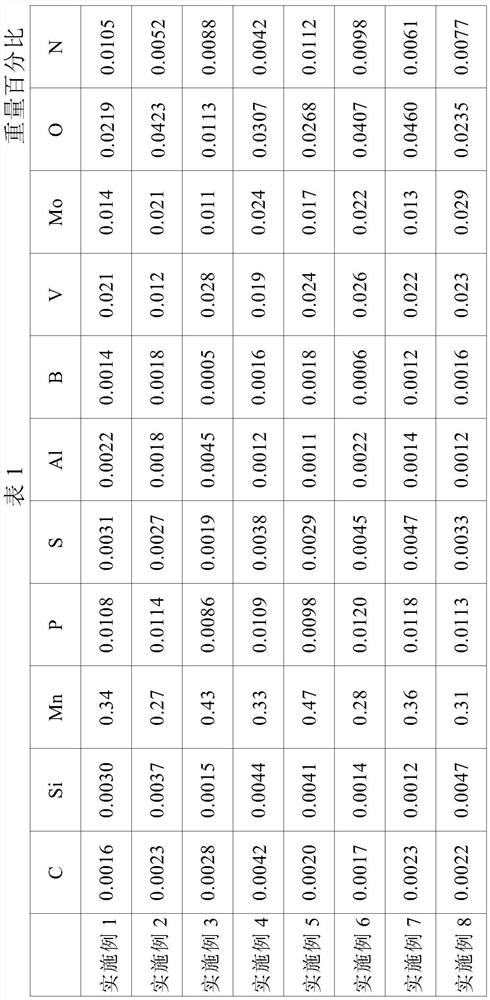

Aluminum-coated plate strip for kitchen ware and production method of aluminum-coated plate strip

ActiveCN114248508AImprove mechanical propertiesImproved interfacial bonding propertiesCooking-vessel materialsLamination ancillary operationsAluminum coatingUltimate tensile strength

The invention relates to an aluminum-coated plate strip for kitchen ware and a production method thereof, the aluminum-coated plate strip comprises at least one layer of aluminum strip and at least two layers of steel strips, the upper and lower surfaces of the aluminum strip are coated with the steel strips, and the steel strips comprise the following chemical components in percentage by weight: 0.0015-0.005% of C, 0.001-0.005% of Si, 0.25-0.50% of Mn, less than or equal to 0.012% of P, less than or equal to 0.006% of S, 0.001-0.005% of Al, 0.004-0.012% of N, 0.0005-0.002% of B, 0.01-0.05% of O, 0.01-0.03% of V, 0.01-0.03% of Mo and the balance of Fe and inevitable impurities; and meanwhile, N is greater than or equal to 1.4 B + 0.6 Al, and V-1. 93 (N-1. 4B-0.6 Al) is greater than or equal to 3.65 C. The aluminum-coated plate strip not only has the strength of steel, but also has the characteristics of good heat dissipation and portability of aluminum, and also has good aluminum coating and drawing properties, the tensile strength of the aluminum-coated plate strip is greater than or equal to 320 MPa, the elongation is greater than or equal to 28%, the strength is not obviously reduced after nitriding treatment, the nitriding treatment requirement in kitchen ware production is met, and the aluminum-coated plate strip can be used for producing and processing novel kitchen ware such as a frying pan.

Owner:BAOSHAN IRON & STEEL CO LTD

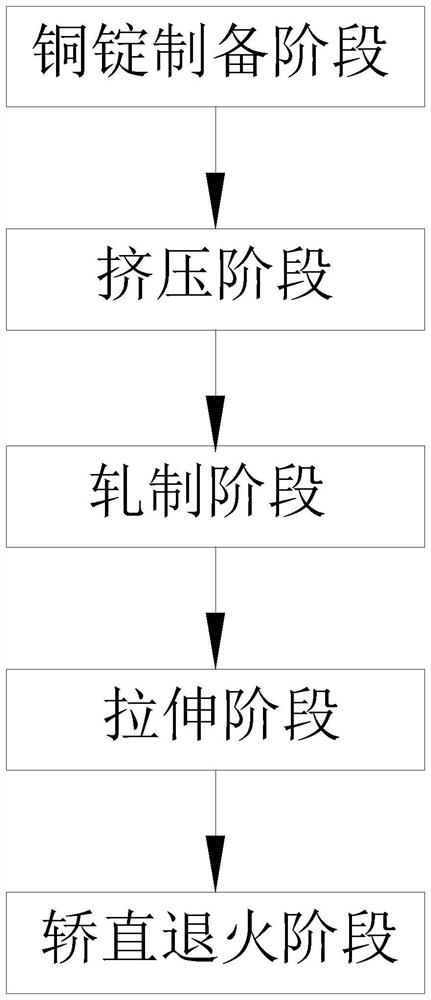

Preparation method of iron blue copper pipe

PendingCN114850238AOptimize product production stepsIncrease productivityIncreasing energy efficiencyMetal rolling arrangementsNon-ferrous metalPipe

The invention belongs to the technical field of non-ferrous metal processing, and particularly relates to a preparation method of an iron blue copper pipe, which comprises a copper ingot preparation stage, an extrusion stage, a rolling stage, a stretching stage and a straightening annealing stage, and solves the blank of the production of the existing iron blue copper pipe from raw materials to finished iron blue copper pipe products. The copper pipe is prepared after the copper ingot preparation stage, the extrusion stage, the rolling stage, the stretching stage and the straightening annealing stage, on the premise that the quality of the copper pipe is guaranteed, the product production steps are optimized, and the production efficiency is improved.

Owner:上海海亮铜业有限公司 +1

Steel grades below 150ksi produced by CPE units are CO resistant 2 Preparation process for corroded oil well pipes

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

Production method of corrosion-resistant and wear-resistant stainless steel hfw welded pipe with an outer diameter of 108-660.4mm

ActiveCN104999277BImprove corrosion resistanceWith magnetic propertiesPipeline systemsHigh frequency current welding apparatusHeat-affected zoneWear resistant

The invention provides a production method of an anticorrosion wear-resistant stainless steel HFW welding pipe with an outer diameter of 108-660.4mm, According to the method, the welding pipe is molded and sized by adjusting molding and sizing four-roll rigid rack equipment, oval precision of the welding pipe is up to + / -0.2mm and straightness of the welding pipe is up to 0.2mm / m; welding spots are protected by argon in a high frequency welding process of the welding pipe; a heat treatment temperature control range of welding seams of the welding pipe is between 800-900 DEG C, the welding seams and heat affected zone parts are subject to normalizing heat treatment and heat preservation time is 30-60s; pipe body positions at two sides of the welding seams are cooled by circulating water during air cooling, temperature is transferred to the welding seam positions of the pipe body of the welding body, overhigh temperature of the welding seams before the welding seams enter a water cooling section is prevented, and welding quality is not affected by structural transformation. The production method has the beneficial effects that the welding pipe produced by the method has better anticorrosion performance and magnetic conductive property, the straightness and ovality of the welding pipe are improved by 30%, equipment fault rate is reduced to 0.3% from 3%, service life is doubled, and the length of a one machine conveyor belt is improved to 6000m from 3000m.

Owner:TIANJIN STEEL PIPE MFG CO LTD

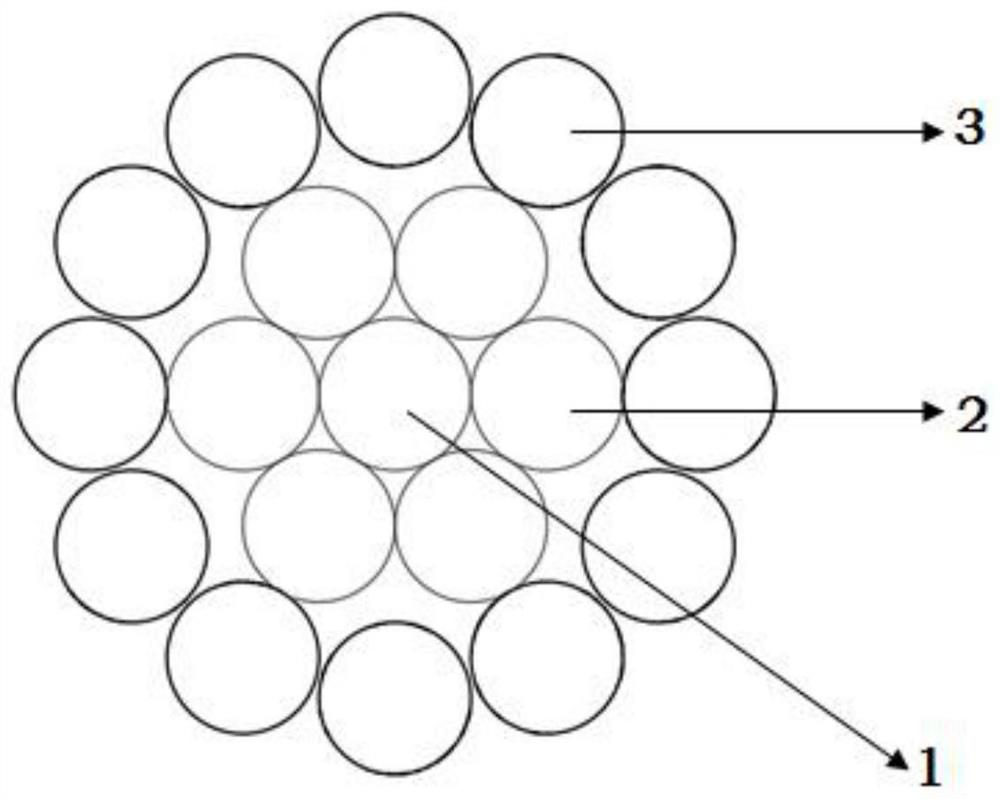

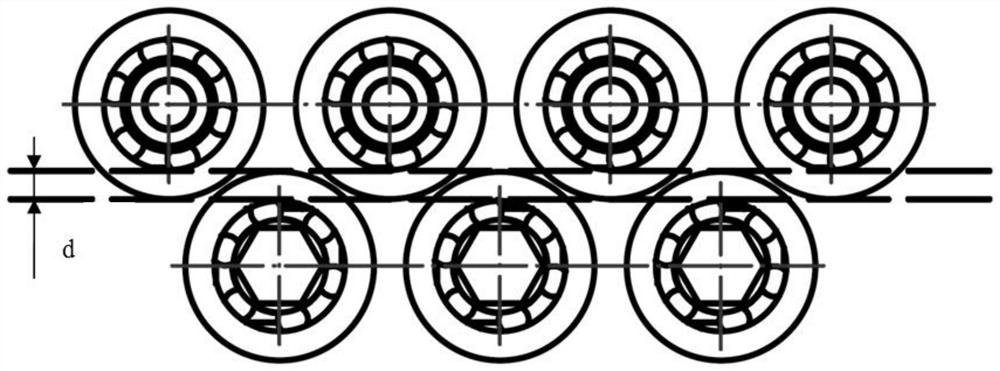

1*19 structure steel wire rope and preparation method thereof

PendingCN114250639AImprove ovalityControl OvalityRope making machinesManufacturing engineeringWire rope

The invention provides a 1 * 19 structure steel wire rope and a preparation method thereof, and the preparation method comprises the following steps: twisting and stranding one first steel wire monofilament and six second steel wire monofilaments into a core strand structure plied yarn; using a stranding machine to twist and strand the core strand structure plied yarns and 12 third steel wire monofilaments into a 1 * 19 structure steel wire rope; wherein the ratio of the over-twisting rotating speed of the stranding machine to the rotating speed of the machine tool is not lower than 0.2 and not higher than 0.3; a steel wire rope of a 1 * 19 structure penetrates through a plurality of straighteners, and the adjacent straighteners are vertically placed. By strictly controlling the ratio of the over-twisting rotating speed of the stranding machine to the rotating speed of the machine tool and reasonably using the straightener in a matched mode, the ovality of the galvanized steel wire rope of the 1 * 19 structure is improved, and the ovality of the steel wire rope can be effectively controlled within 2.5% of the thickness of the steel wire rope.

Owner:泰州兴达特种钢丝绳有限公司

Method for making optical fiber preform having ultimately low PMD through improvement of ovality

InactiveCN1281986CImprove ovalityImprove PMDGlass making apparatusOptical light guidesOptoelectronics

The present invention provides a method of manufacturing an optical fiber preform finally having low PMD (Polarization Mode Dispersion) through improvement of ellipticity. The method has several shrinking steps for shrinking an optical fiber preform having a cladding / core deposition layer formed in a preform tube, wherein the shrinking rate in each shrinking step is 0.01- 0.06mm / min. By using this method, the ovality and PMD of the optical fiber preform can be improved.

Owner:LG CABLE INC

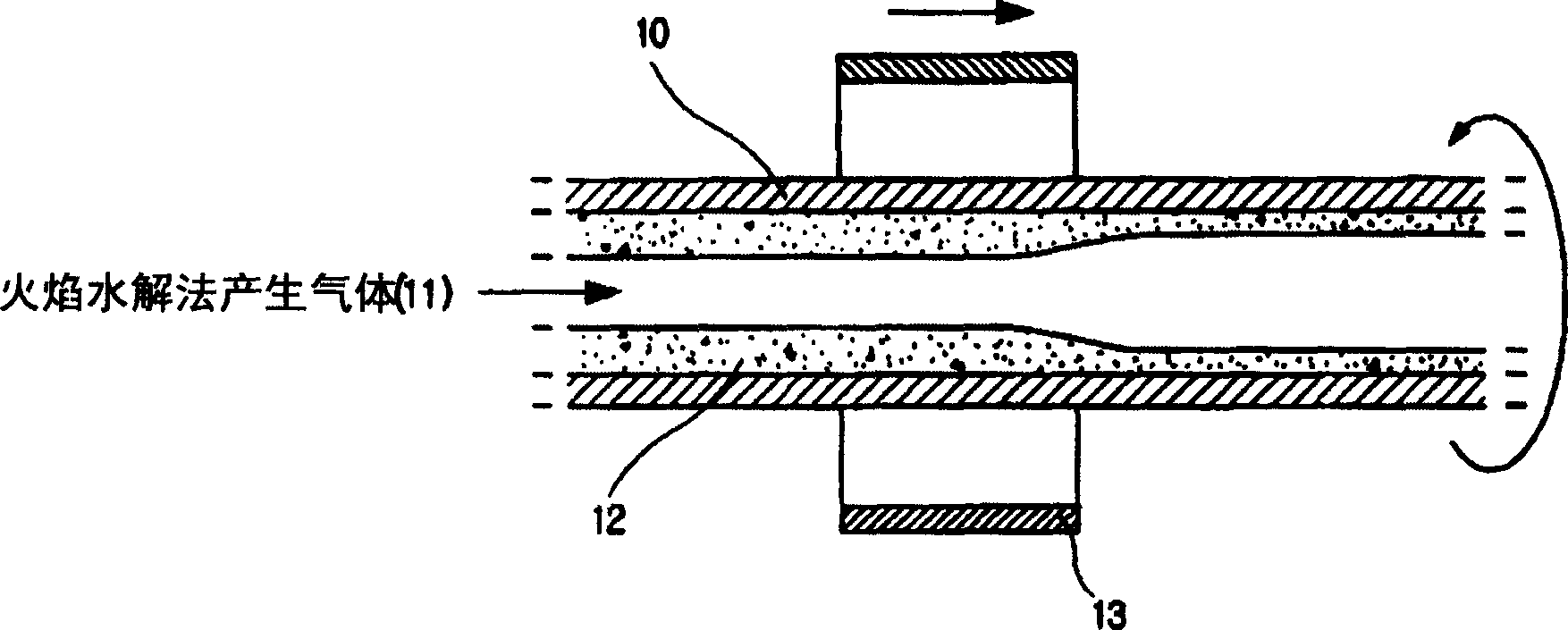

Sintering device of loose body optical fiber prefabricated rod

InactiveCN1277772CReduce overflowGuaranteed uniformityGlass shaping apparatusElectricityPosition sensor

A sintering apparatus for prefabricatnig the loosen optical fibre rod is composed of sintering quartz pipe with gas inlet and cover, heating unit with casing, insulating material and heater, moving controller, position sensor, gas supplying unit, temp sensor with heating driver, and controller.

Owner:JIANGSU FASTEN PHOTONICS

A method for setting the flattening amount of straightening rolls for super-large-diameter seamless steel pipes

The invention belongs to the technical field of multi-roller straightening of seamless steel pipes, and in particular relates to a method for setting the flattening amount of straightening rollers of super-large-diameter seamless steel pipes, comprising the following steps: calculating the maximum elastic-plastic flattening amount δ of steel pipes m and the maximum elastic flattening amount δ t ; According to the corresponding relationship between the wall thickness of the steel pipe and the maximum allowable flattening amount, the maximum allowable flattening amount δ of the steel pipe is obtained a ;Maximum elastoplastic flattening amount δ m and the maximum allowable flattening amount δ a For comparison, the smaller value of the two is used as the flattening amount δ of the intermediate roller 2 , the flattening amount δ of the entrance roller 1 =k 1 δ 2 , the flattening amount δ of the exit roller 3 =k 2 δ 2 ;According to the principle that the actual flattening amount of the thin-walled pipe and the thick-walled pipe meets the principle, the actual flattening amount of each pair of straightening rollers is determined, and then the purpose of differential adjustment of the flattening amount of the straightening rollers is realized by means of the pressing system. The invention can effectively improve the ellipticity of the steel pipe after straightening and improve the straightening precision of products by setting the flattening amount of the straightening rollers. The invention is used for setting the flattening amount of the straightening roller.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

An Unclear Root Welding Process for Wind Turbine Tower Tube Sections

ActiveCN113231721BAvoid pollutionCause wasteWelding/cutting auxillary devicesAuxillary welding devicesStress concentrationWeld strength

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com