Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improved interfacial bonding properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-reinforced titanium-based nanocomposite material and preparation method

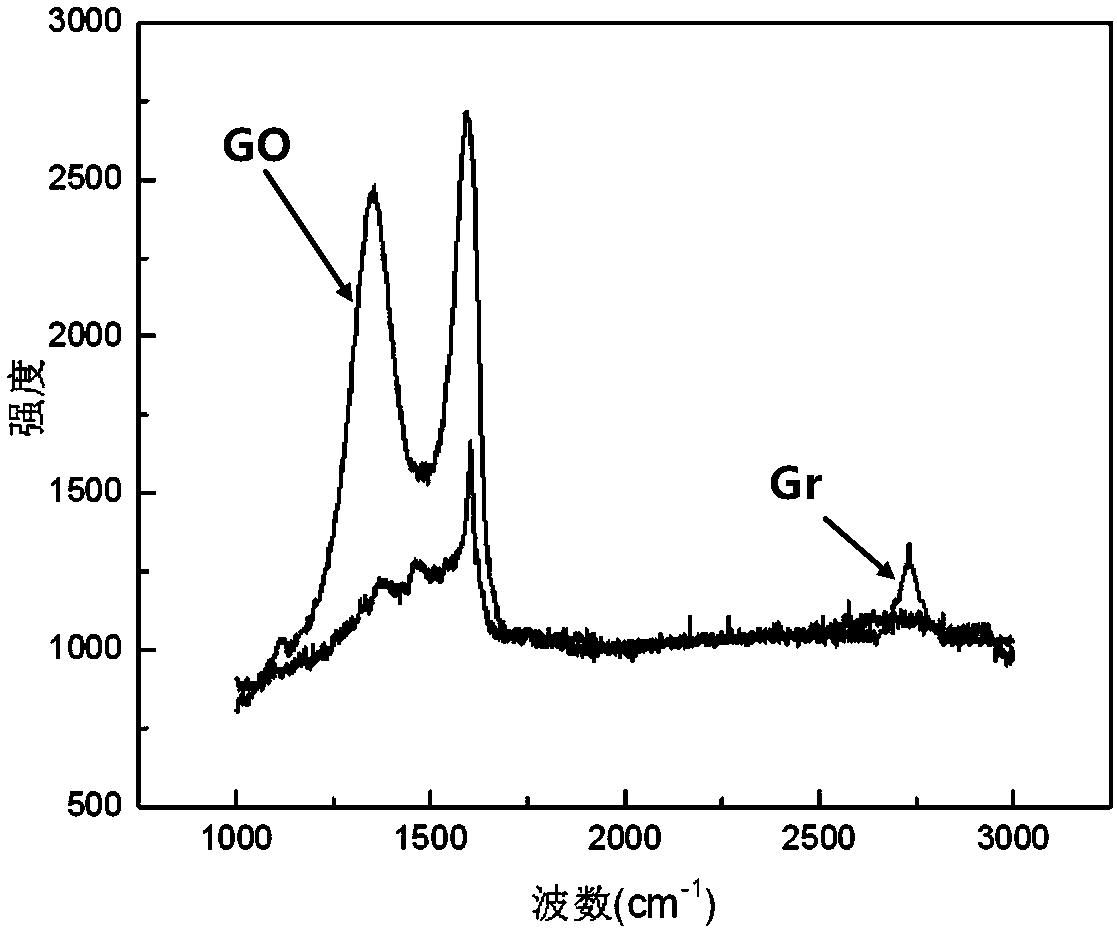

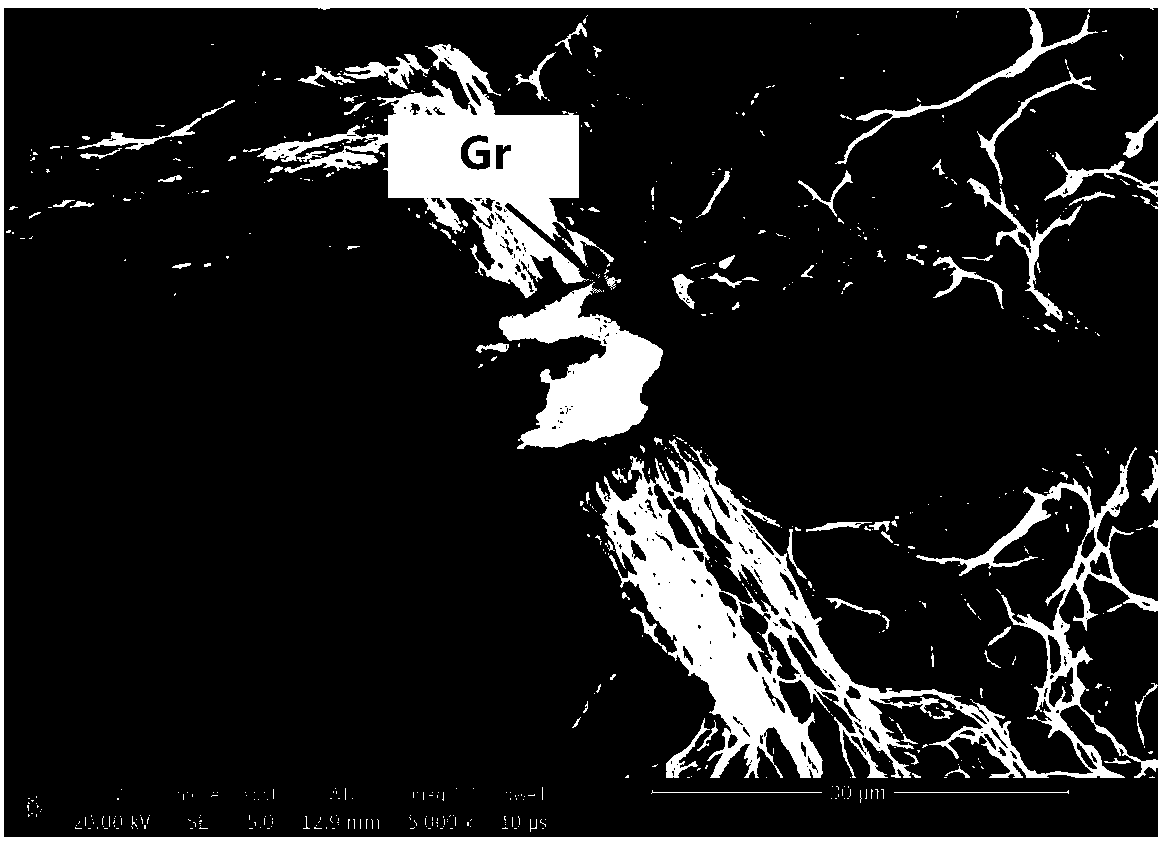

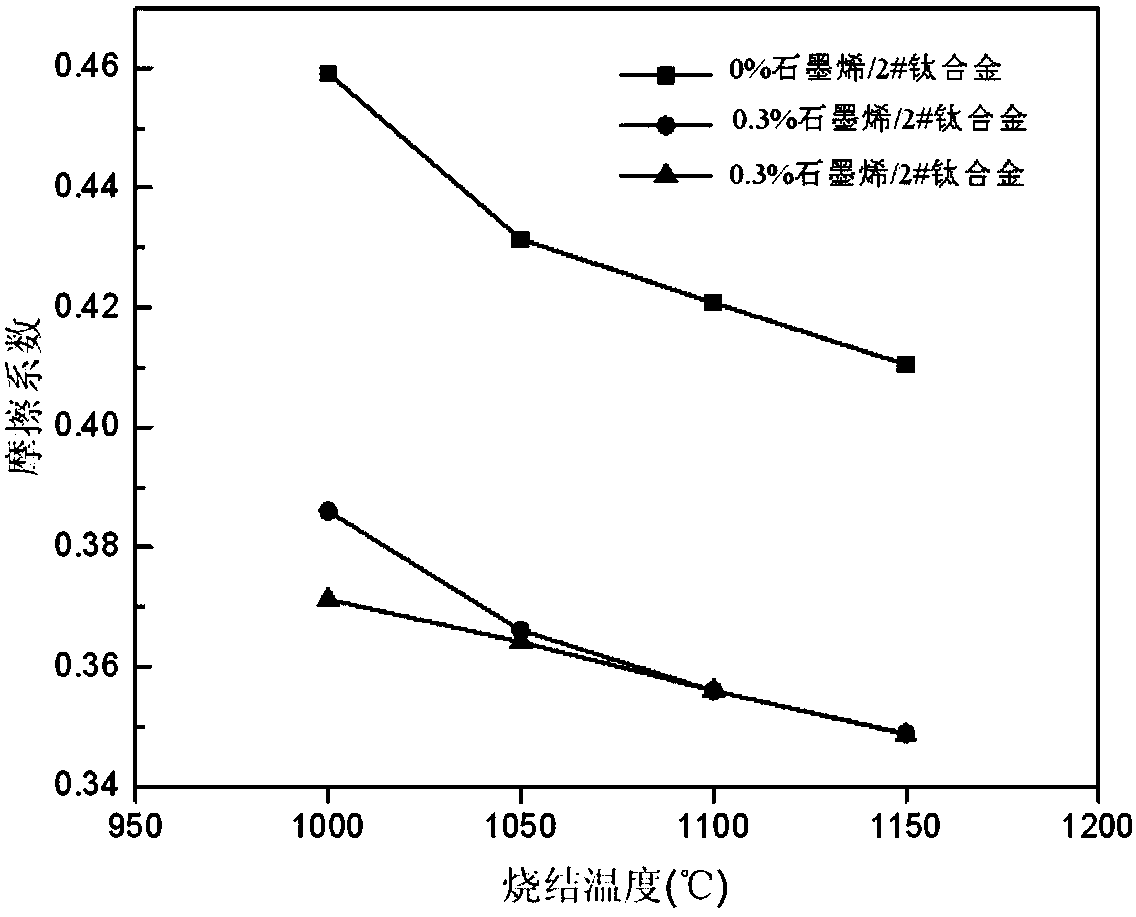

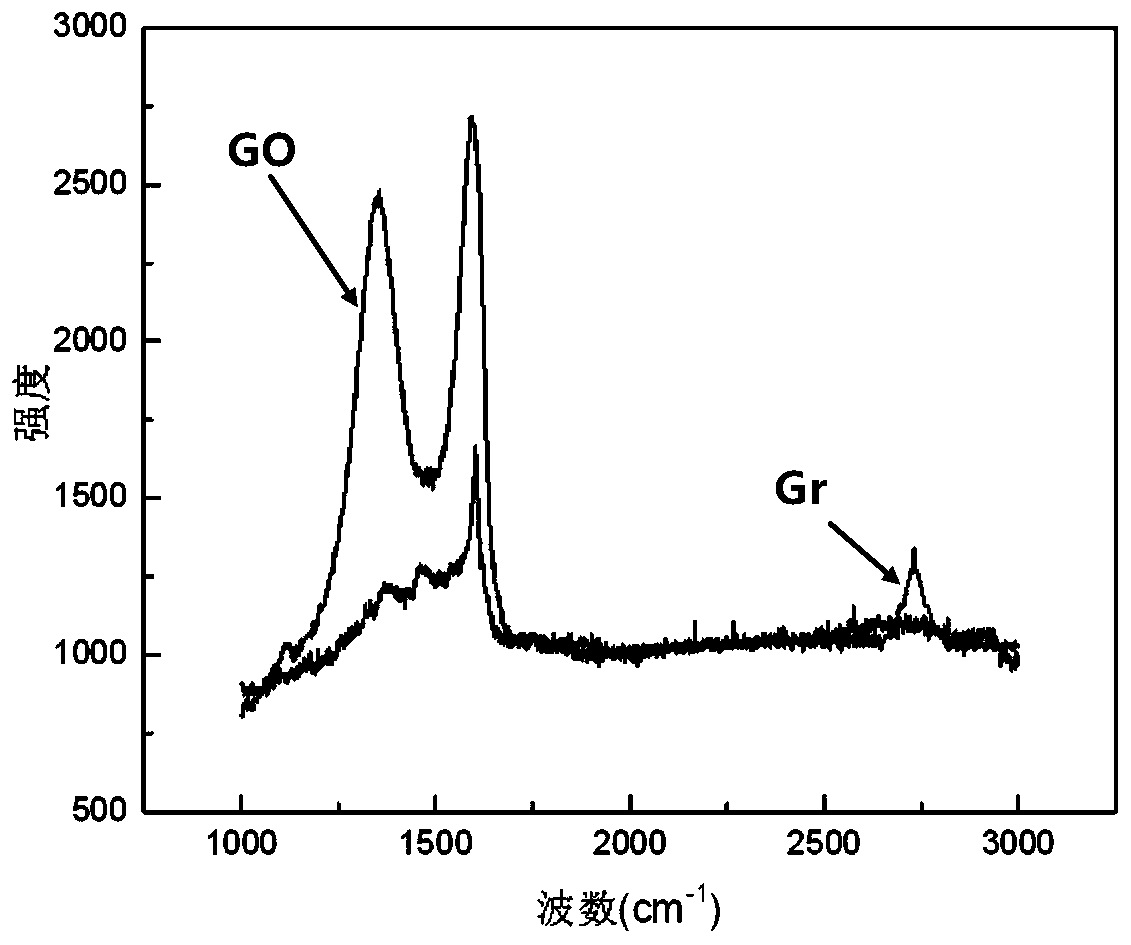

The invention belongs to the technical field of graphene composite materials and relates to a titanium-based nanocomposite material reinforced through graphene and a preparation method, in particularto a graphene-reinforced titanium-based nanocomposite material and a preparation method. Firstly, oxidized graphene nanosheets of 0.01 wt%-1.0 wt% of titanium alloy powder are weighed to be added intoabsolute ethyl alcohol to be stirred and mixed, then disperse treatment is conducted through an ultrasonic cell pulverizer, and an oxidized graphene solution is prepared; then the titanium alloy powder with the alloying element content being larger than 10 wt% and the oxidized graphene solution are stirred and mixed under inert protection, and oxidized graphene and titanium alloy powder compositepowder is obtained; and finally, the composite powder is loaded into a graphite mold to be sintered, through vacuum pumping and sintering forming, oxidized graphene is basically decomposed to form graphene, and therefore the graphene-reinforced titanium-based nanocomposite material with the excellent mechanical property is prepared. In the graphene-reinforced titanium-based nanocomposite material, the graphene is uniformly dispersed, and the preparation method is simple, efficient and suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

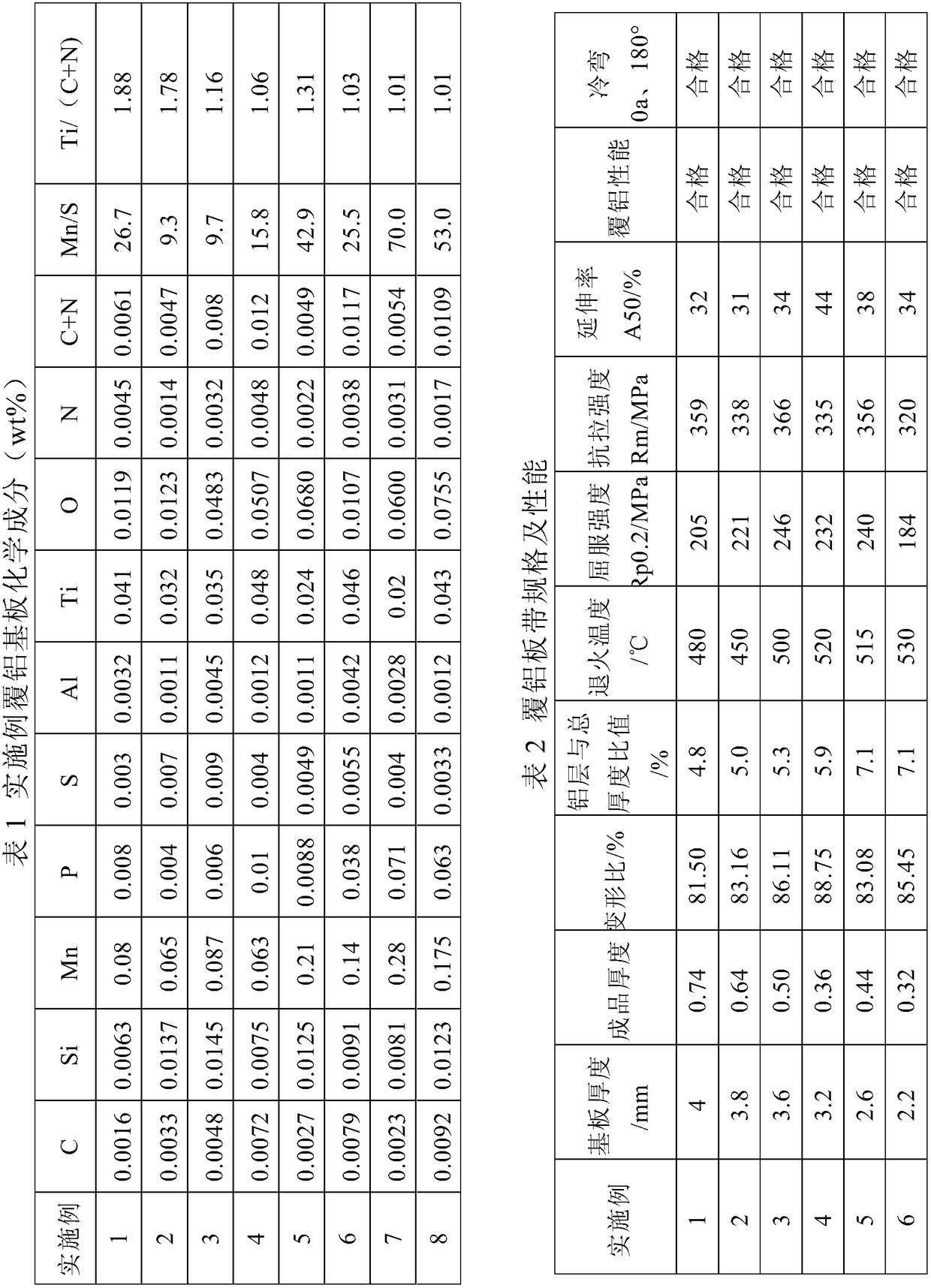

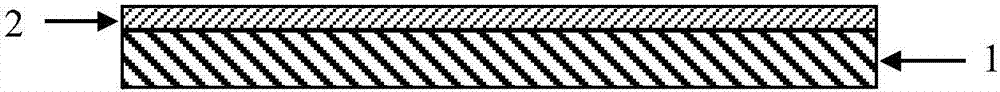

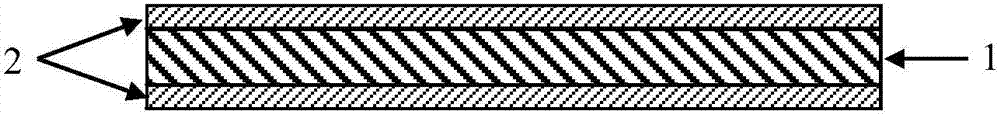

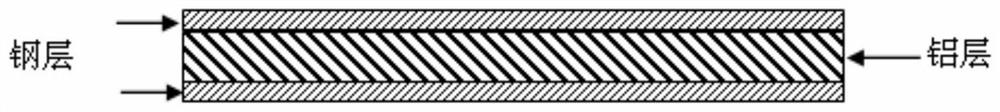

High-surface-quality aluminum-coated plate strip with easy stamping machining function and production method thereof

ActiveCN108796384AImprove plasticityImproved interfacial bonding propertiesFurnace typesMetal rolling arrangementsChemical compositionHigh surface

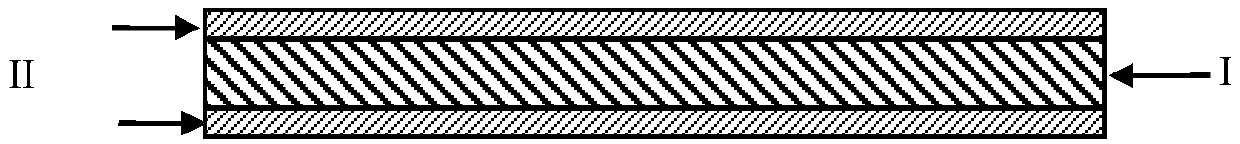

The invention provides a high-surface-quality aluminum-coated plate strip with an easy stamping machining function and a production method thereof. The aluminum-coated plate strip is composited of analuminum strip and a steel strip; the steel strip comprises the chemical compositions of, by weight, no more than 0.01% of C, 0.006-0.015% of Si, 0.05-0.3% of Mn, no more than 0.015% of P, no more than 0.01% of S, no more than 0.005% of Al, no more than 0.005% of N, 0-0.05% of Ti, 0.01-0.08% of O, and the balance Fe and unavoidable impurities; and the following formulas are met, specifically, C+N<=0.012%, Mn / S>=8, and Ti / (3.42N+4C)>=1. The aluminum-coated plate strip has good steel and aluminum bonding properties and adapts to single pass large deformation, and stamping machining performance and the high surface quality are achieved; and the aluminum-coated plate strip meets 300 MPa or above of tensile strength, the elongation exceeds 30%, and the aluminum-coated plate strip can replace analuminum-plated plate to be used for production of automobile engine sound-insulation covers, home appliance panels, food processing trays and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

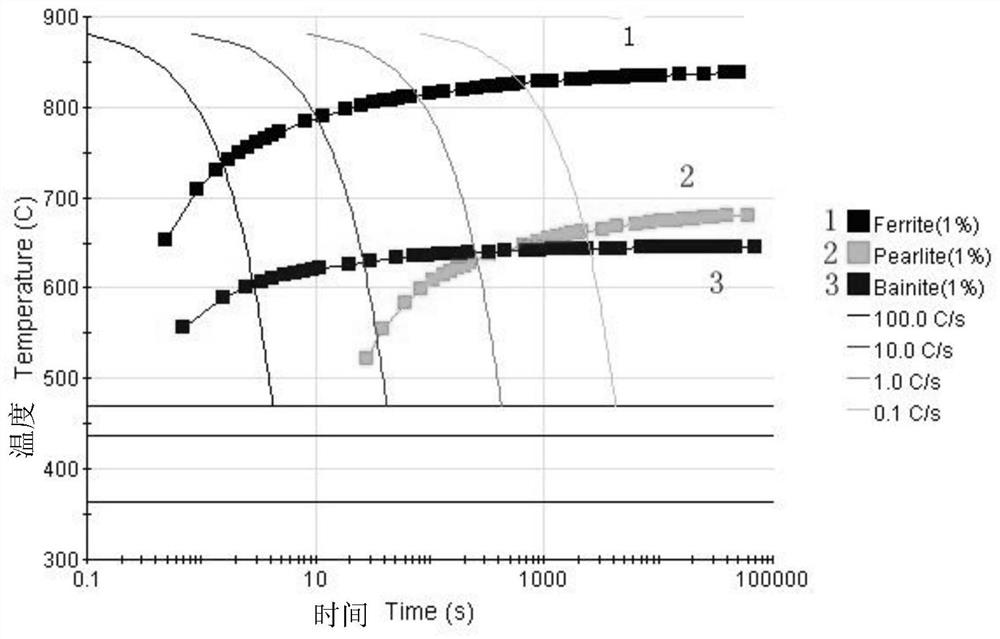

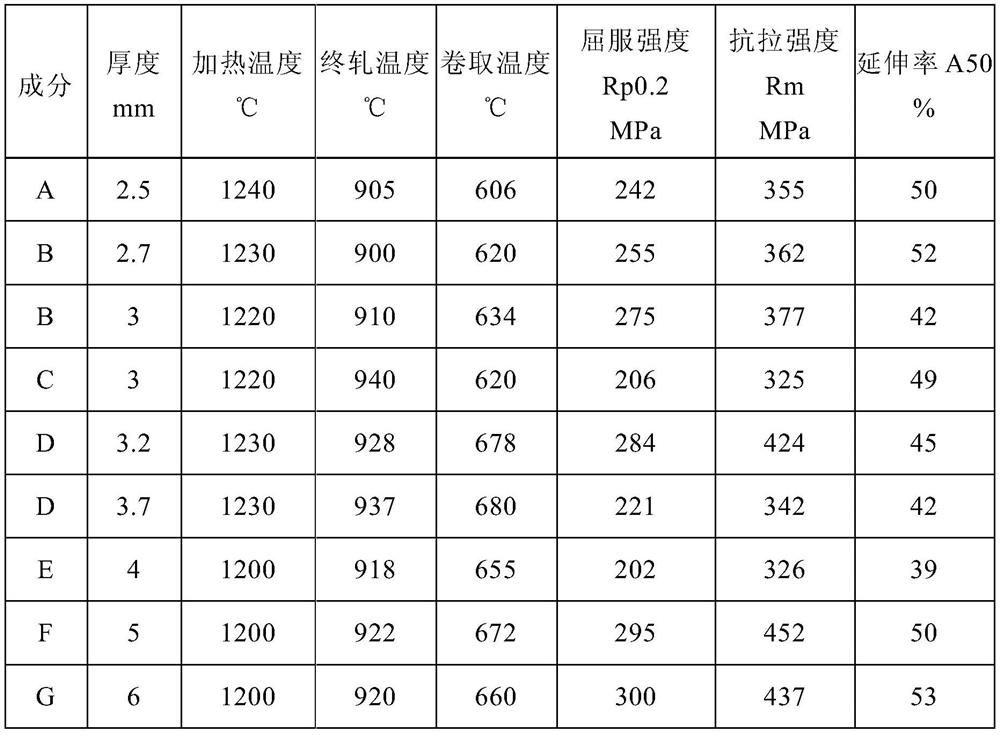

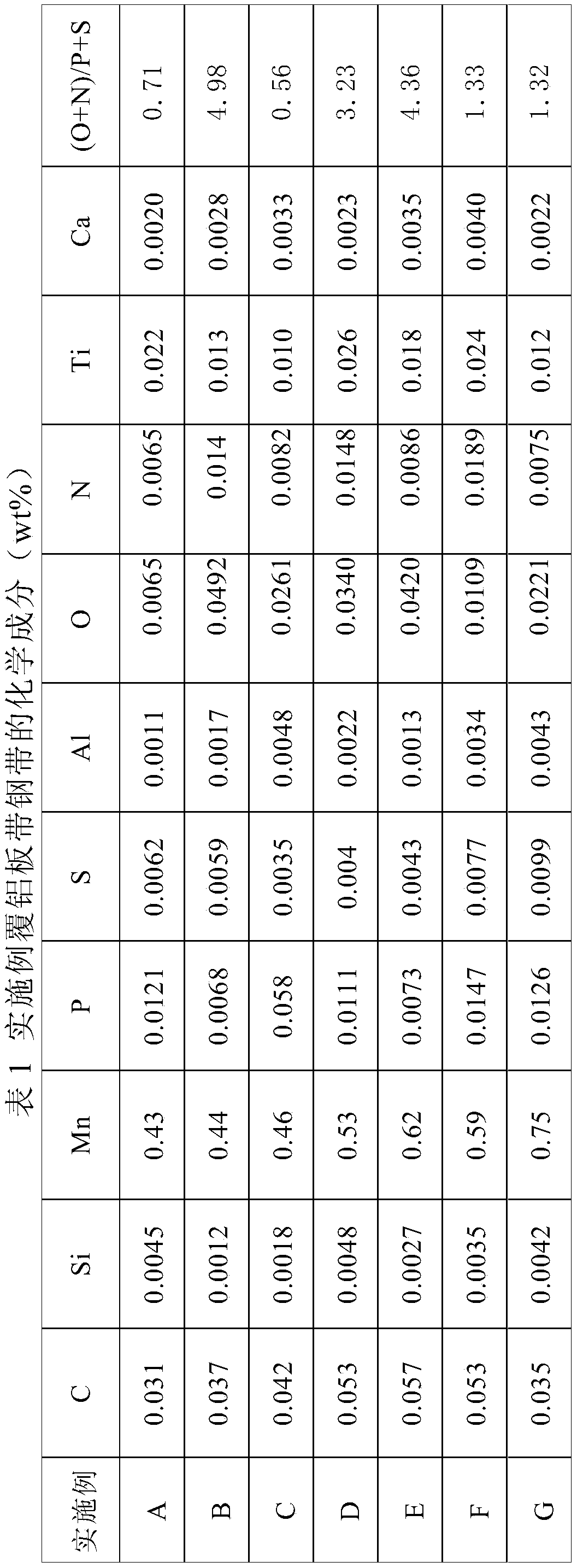

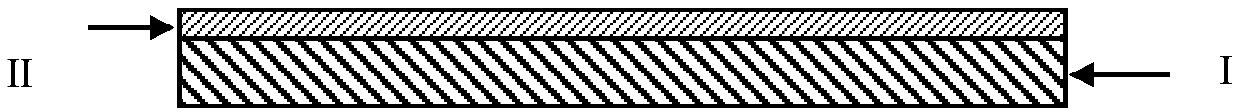

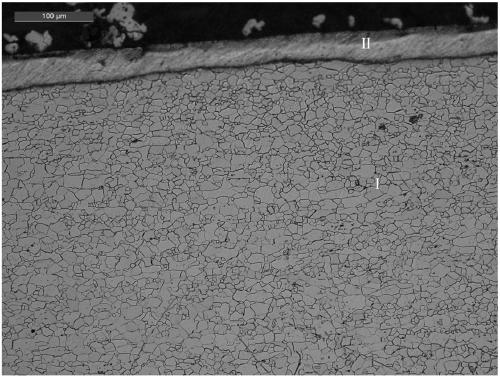

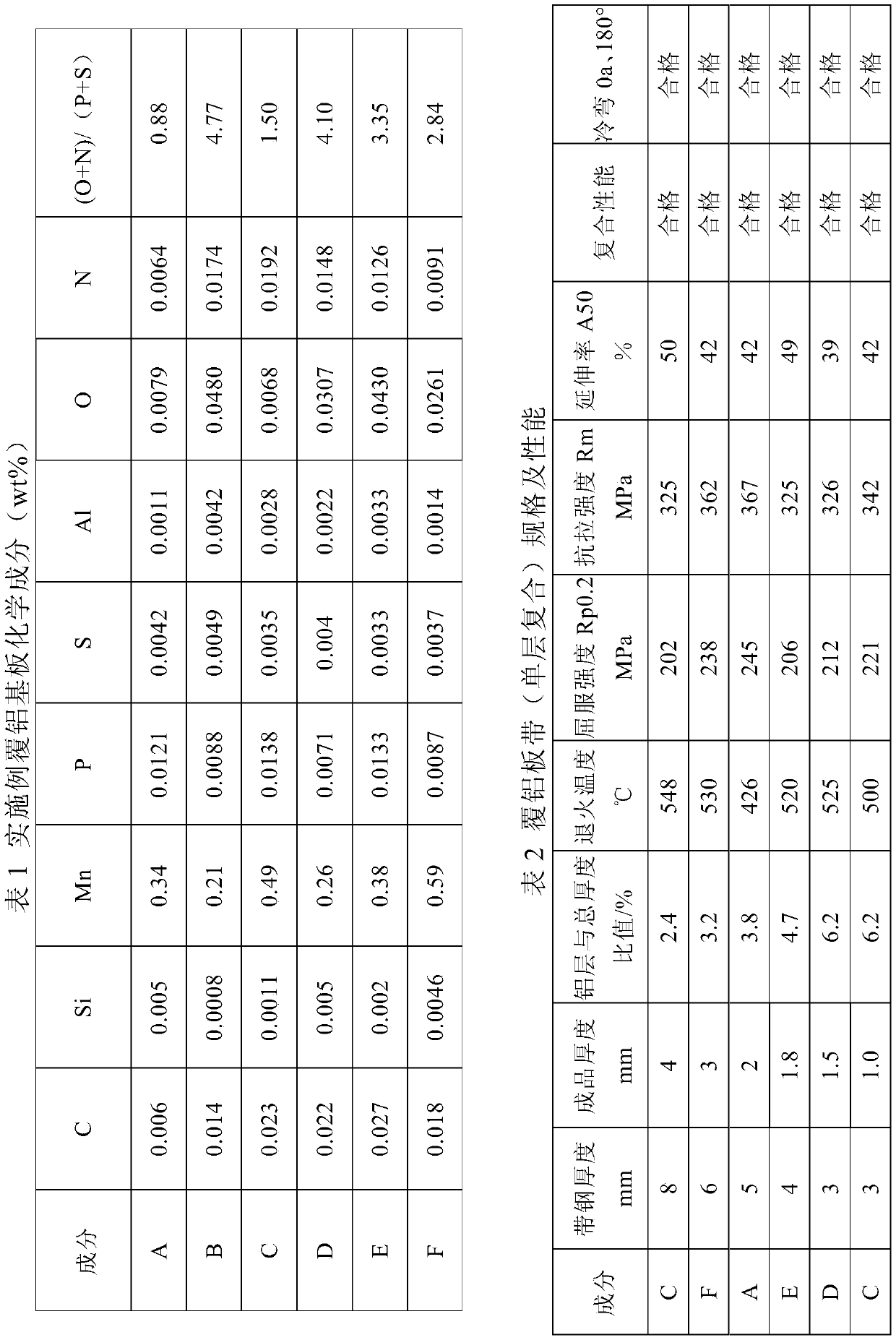

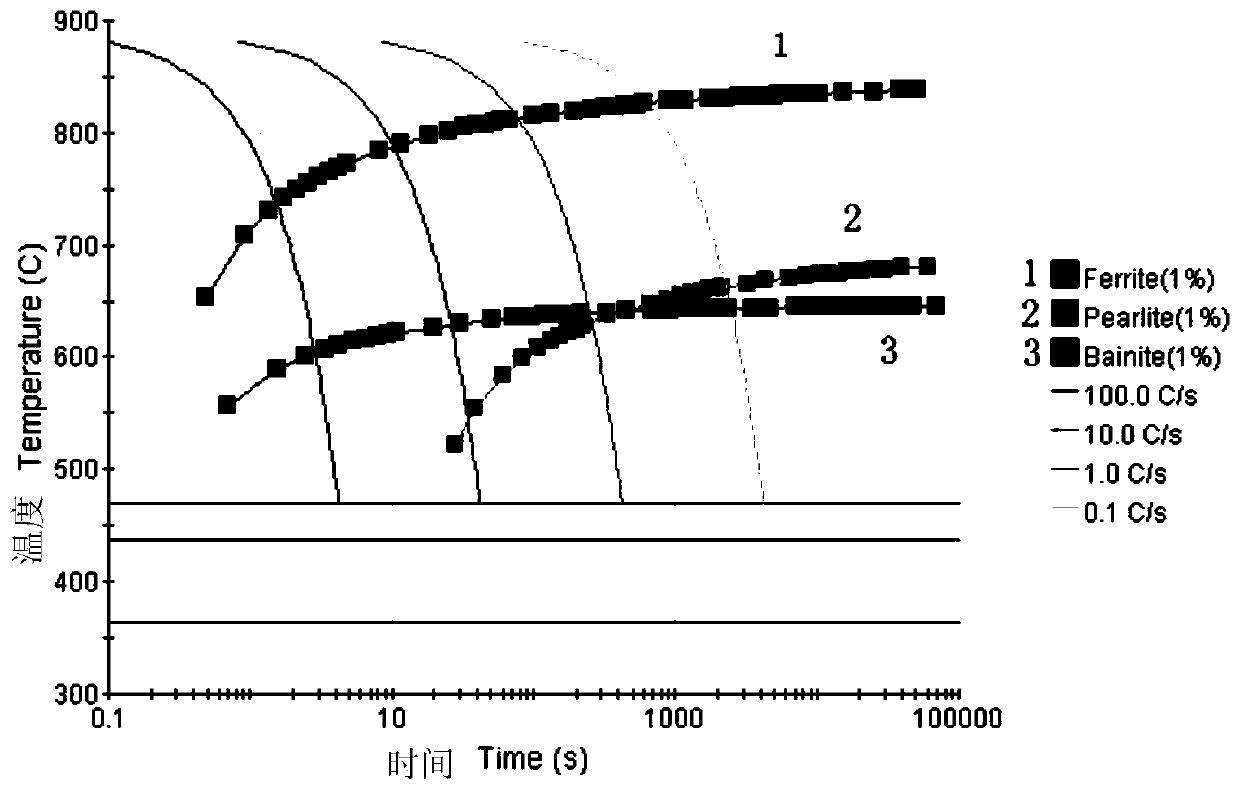

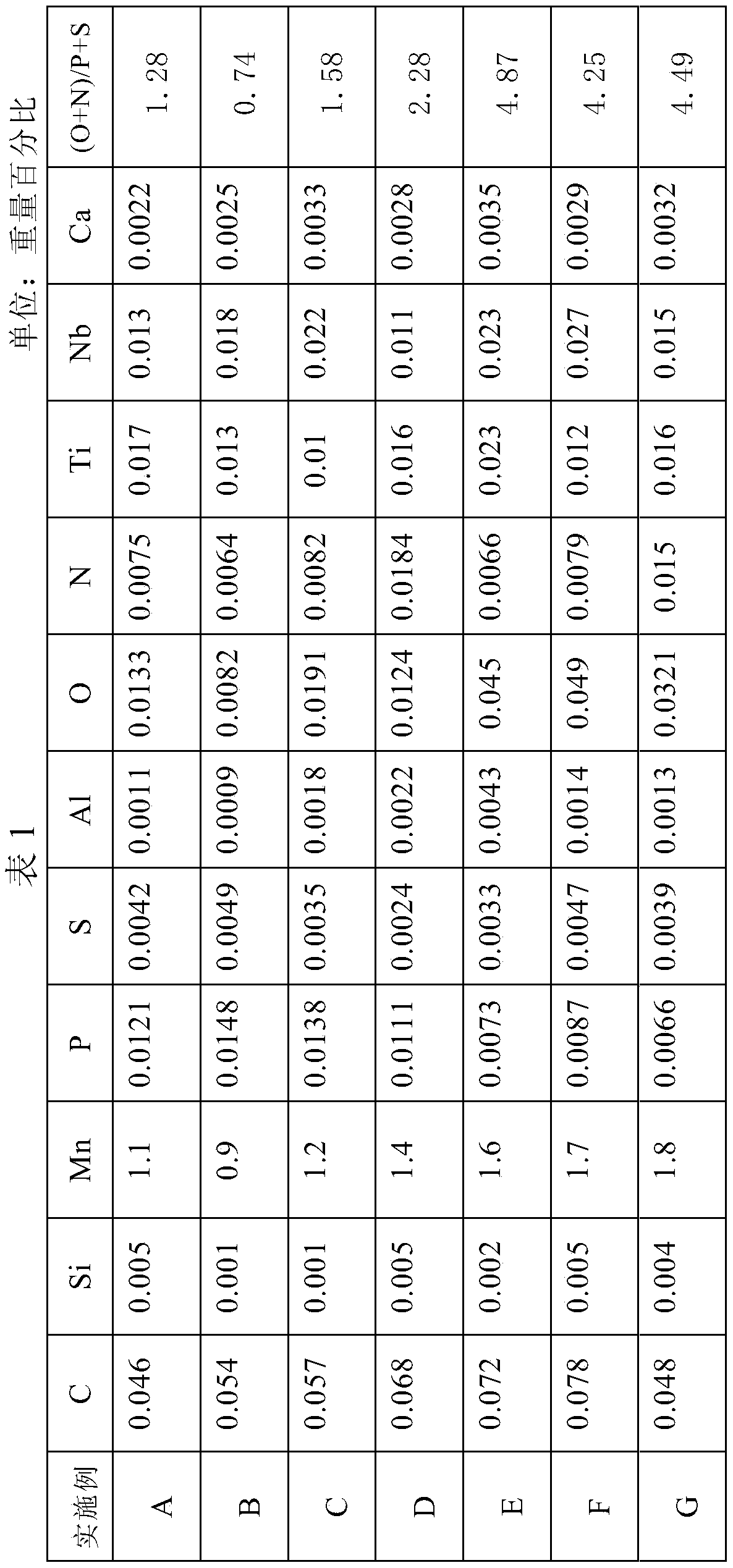

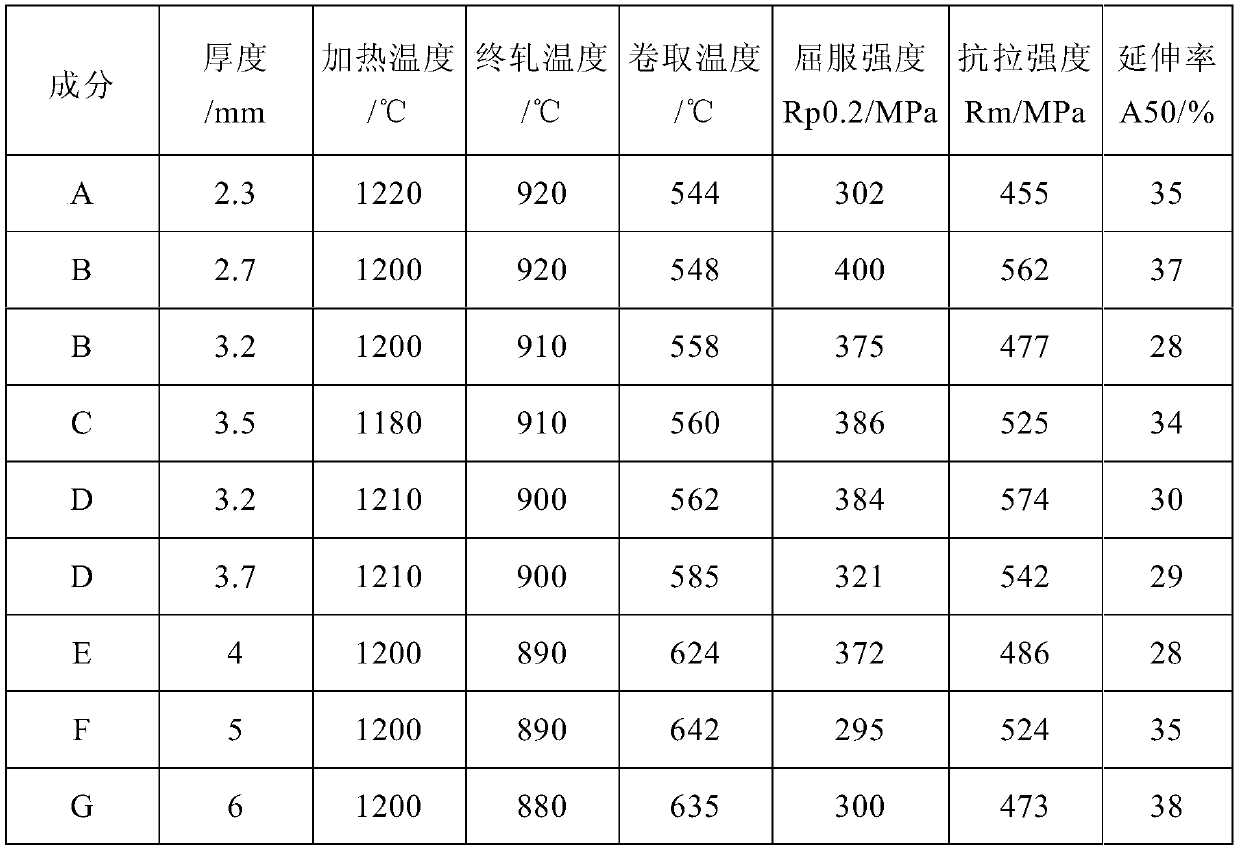

Aluminum-coated plate strip with excellent heat dissipating effect and production method thereof

ActiveCN107881410AImprove plasticityImproved interfacial bonding propertiesMetal rolling arrangementsSteel beltImpurity

The invention provides an aluminum-coated plate strip with an excellent heat dissipating effect and a production method thereof. The aluminum-coated plate strip is of a composite structure of an aluminum strip and a steel strip, and the steel strip comprises the components of, by weight, 0.005-0.03% of C, larger than 0 and smaller than or equal to 0.005% of Si, 0.2-0.6% of M, smaller than and equal to 0.015% of P, smaller than and equal to 0.005% of S, smaller than and equal to 0.005% of Al, 0.0062-0.02% of N, 0.006-0.05% of O and the balance Fe and inescapable impurities, wherein the conditions of O+N>=0.013% and 0.5<=(O+N) / (P+S)<=5 are met at the same time. The aluminum-coated plate strip has the strength of steel, is 200-320 MPa in yield strength and larger than or equal to 340 MPa in tensile strength, has the good plasticity and performance of cold bending, stamping machining and the like, has the characteristics of corrosion resistance, heat dissipation and beauty of aluminum, andcan be used for production of heat dissipating devices, heat dissipating pieces and wheels.

Owner:BAOSHAN IRON & STEEL CO LTD

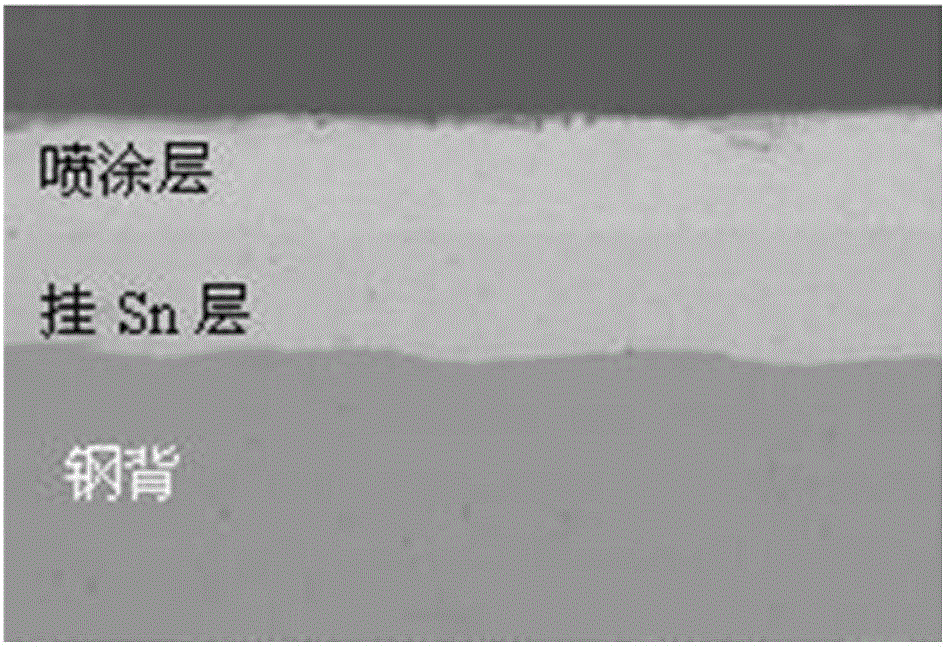

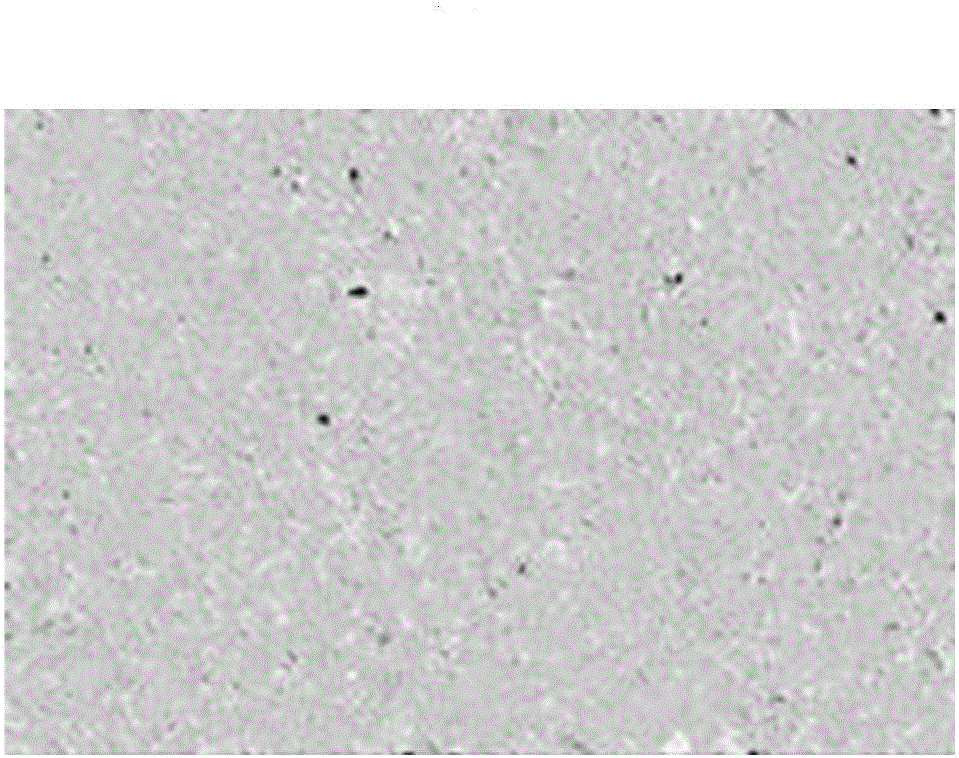

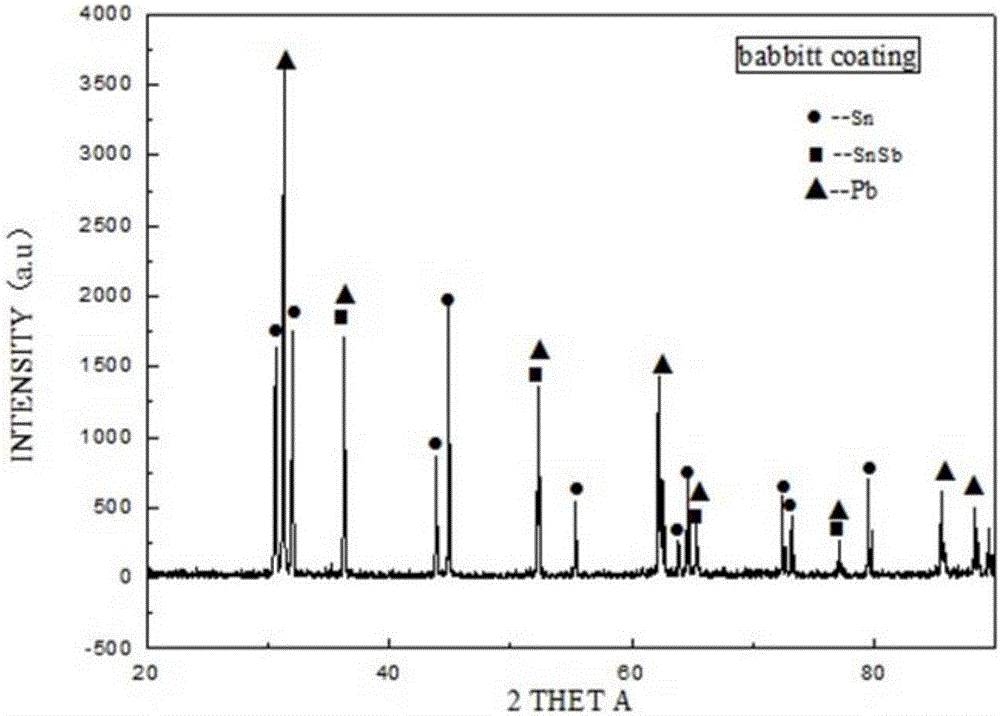

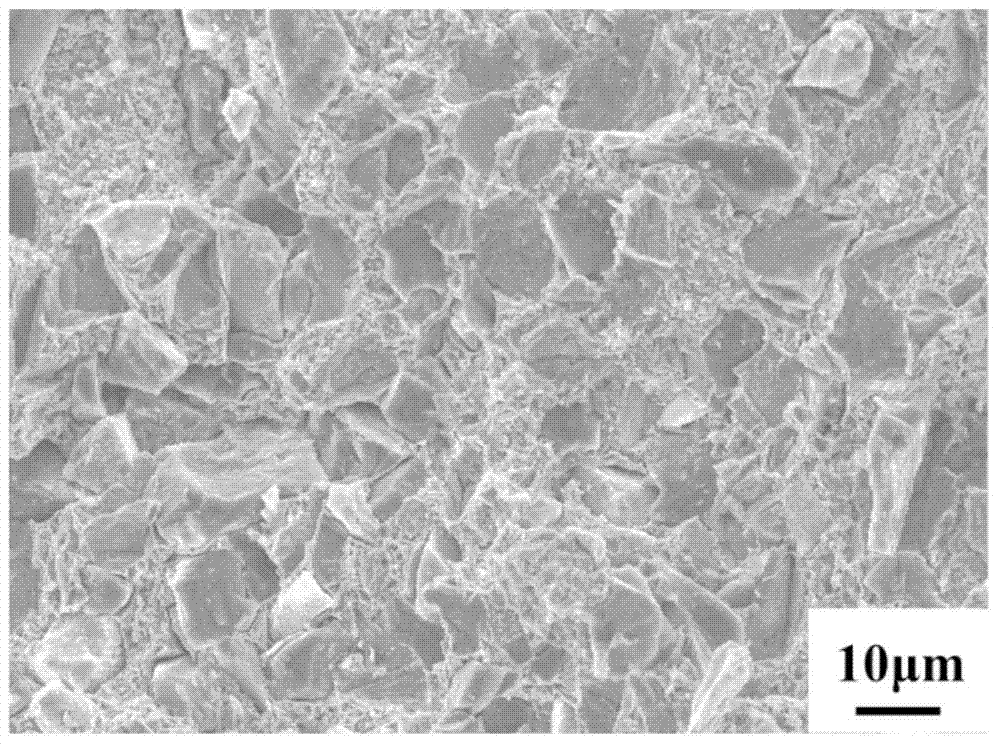

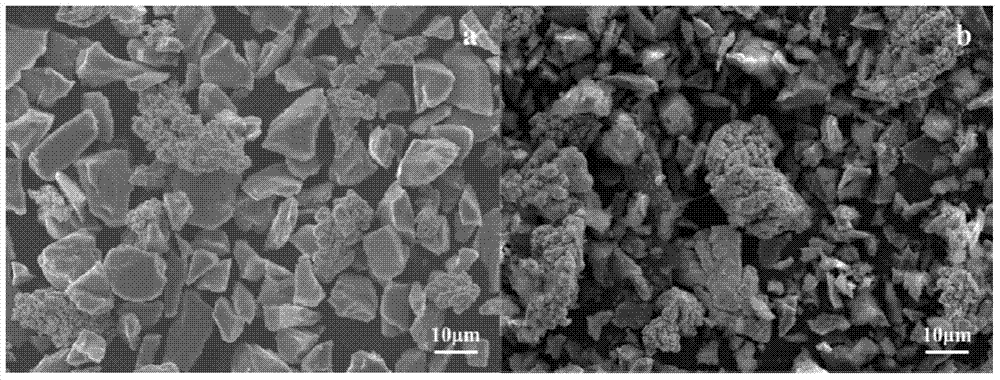

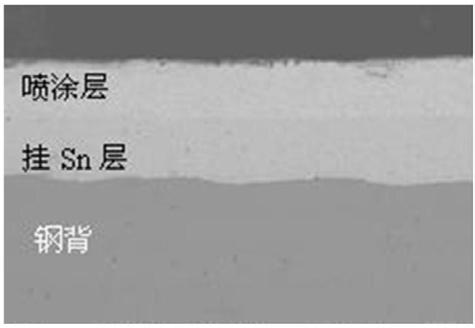

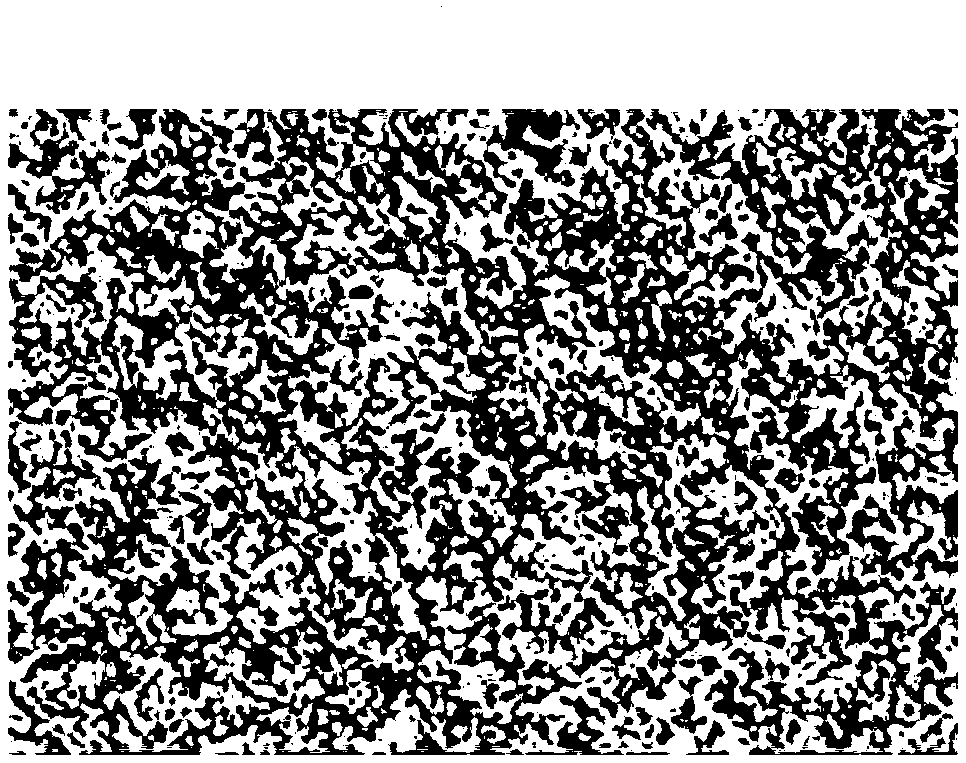

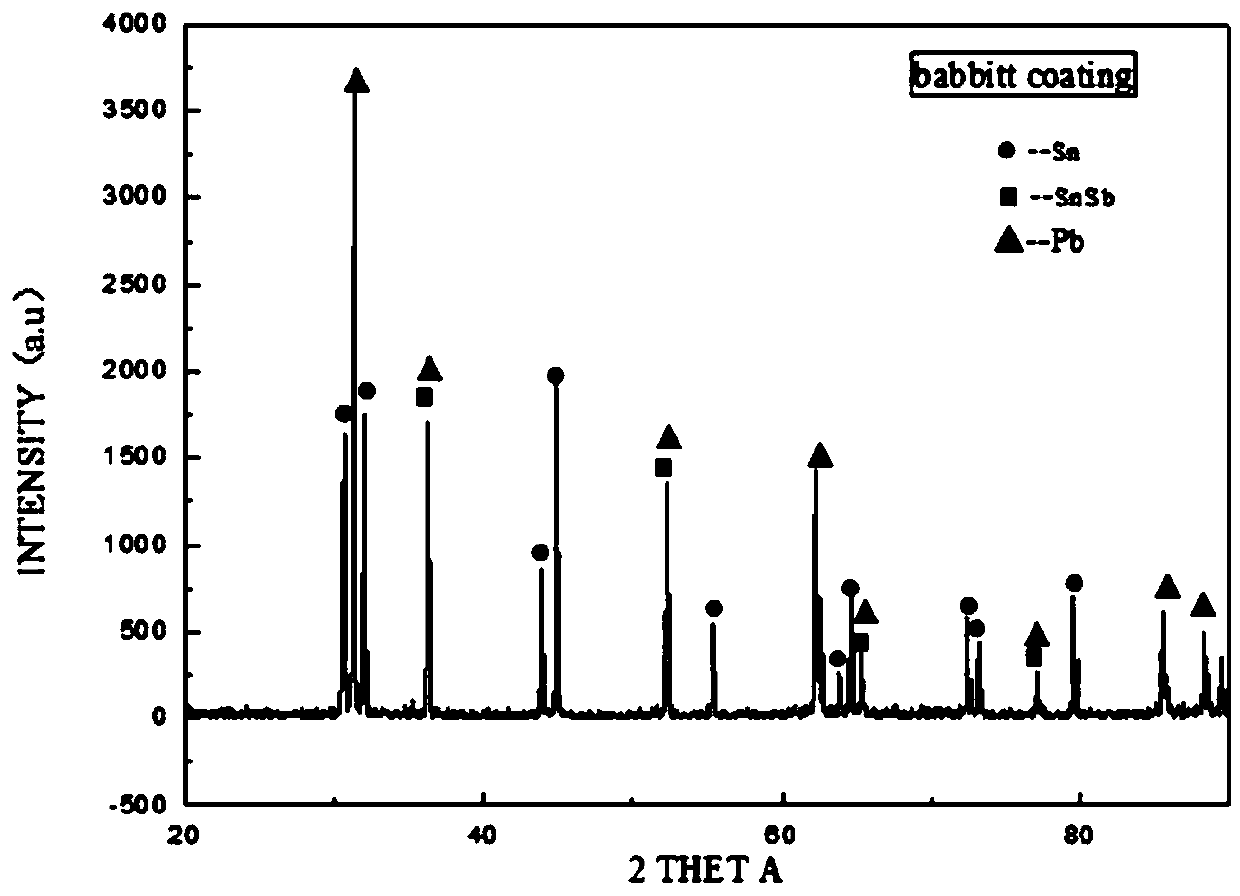

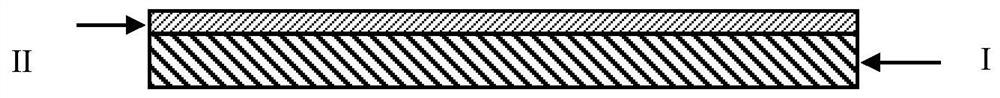

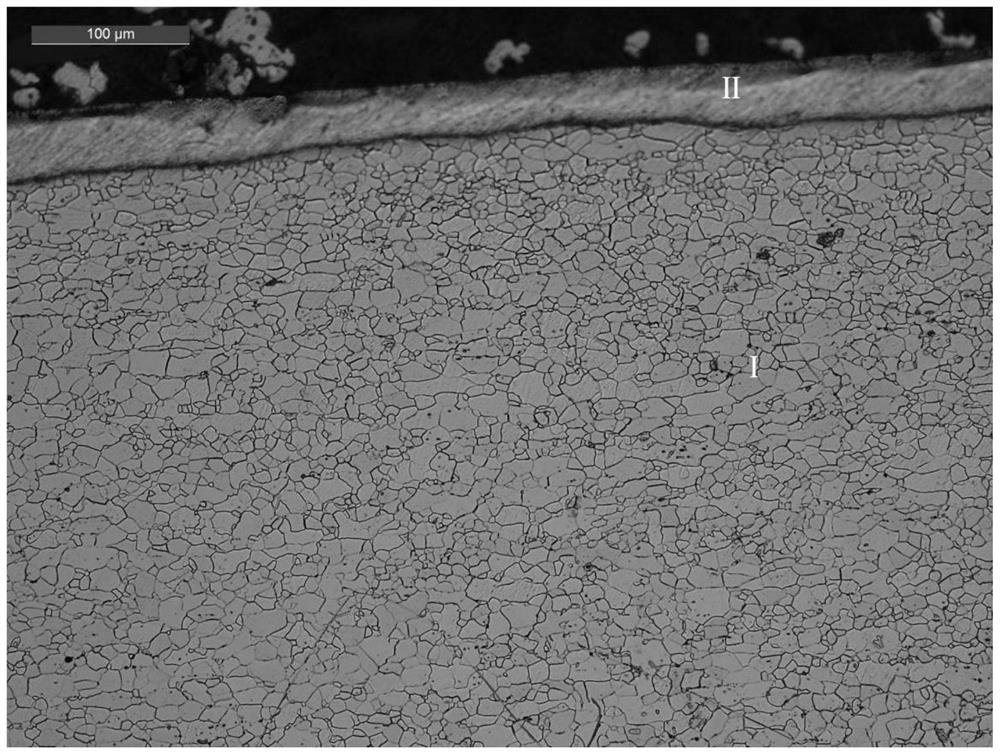

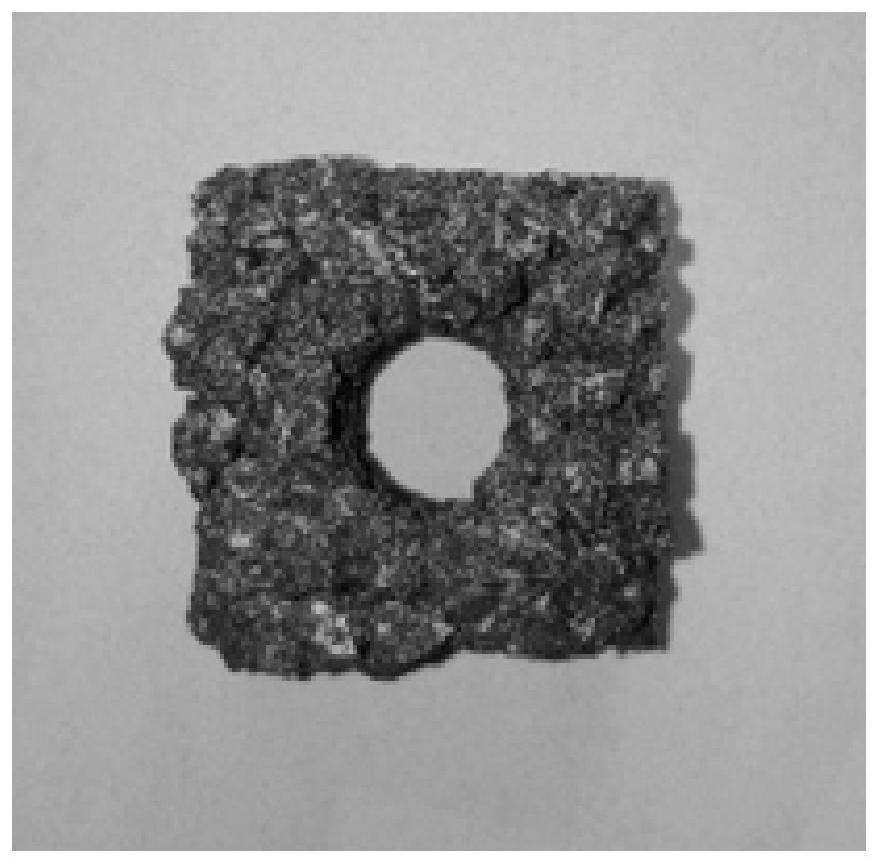

Method for coating bearing bush steel backing with Babbitt metal coating

ActiveCN106435563AImprove product qualityImprove the level ofHeat inorganic powder coatingSocial benefitsThermal spraying

The invention relates to the technical field of preparation and repair of sliding bearing Babbitt metal anti-friction layers. The novel cold spraying technology is introduced into manufacturing and repair remanufacturing of a Babbitt metal sliding bearing bush lining anti-friction layer, atomization powder feeding is adopted to obtain coating microstructures with uniform components and fine dispersely-distributed and uniformly-dense crystal grains and second phases through cold spraying, and the good interface bonding characteristic is obtained through tinning layer setting and sprayed thermal treatment; the defects of poor structure uniformity, thermal impact, stress, cracking and oxidizing burning losses existing in the technologies such as a traditional casting method, an overlaying method and a thermal spraying method are overcome, the bearing bush component preparation quality and level are improved, the bush burning frequency is decreased, stopping supercritical vibration is lowered, the stability, accuracy and reliability of a bearing transmission unit are improved, and the service life of the bearing transmission unit is prolonged; the method is rapid, efficient and environmentally friendly, is used for bearing bush manufacturing and repair remanufacturing, and has good economic benefits and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

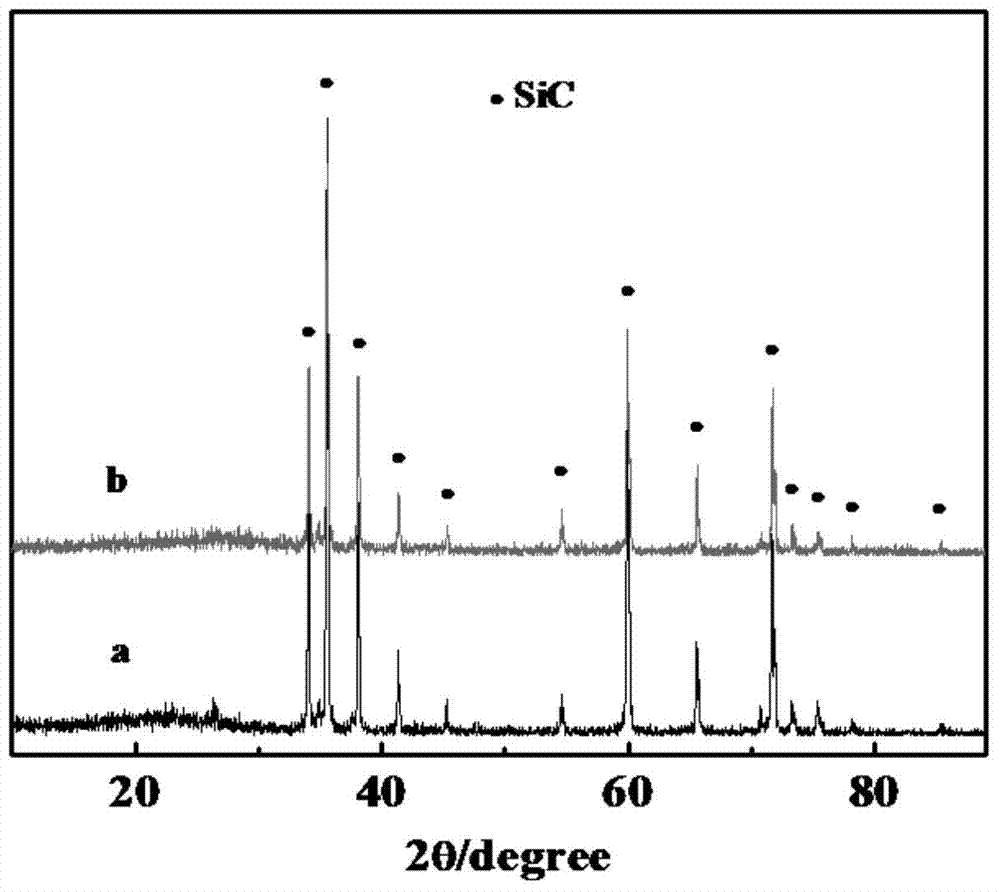

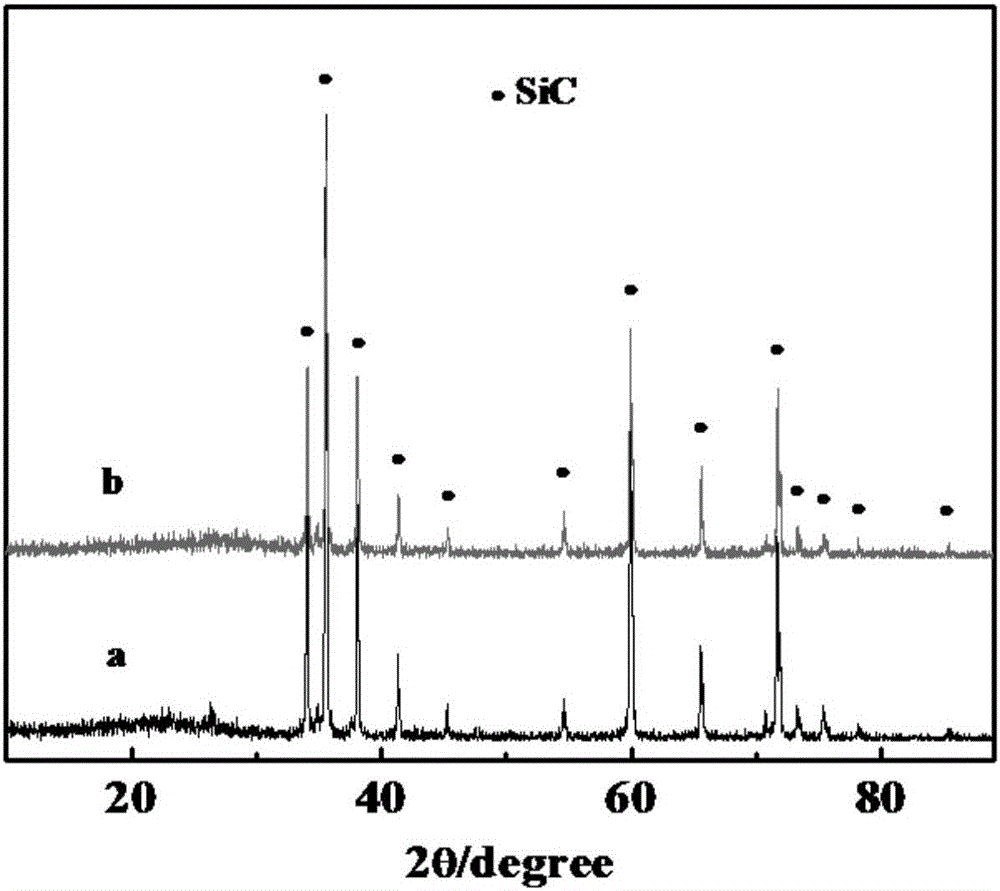

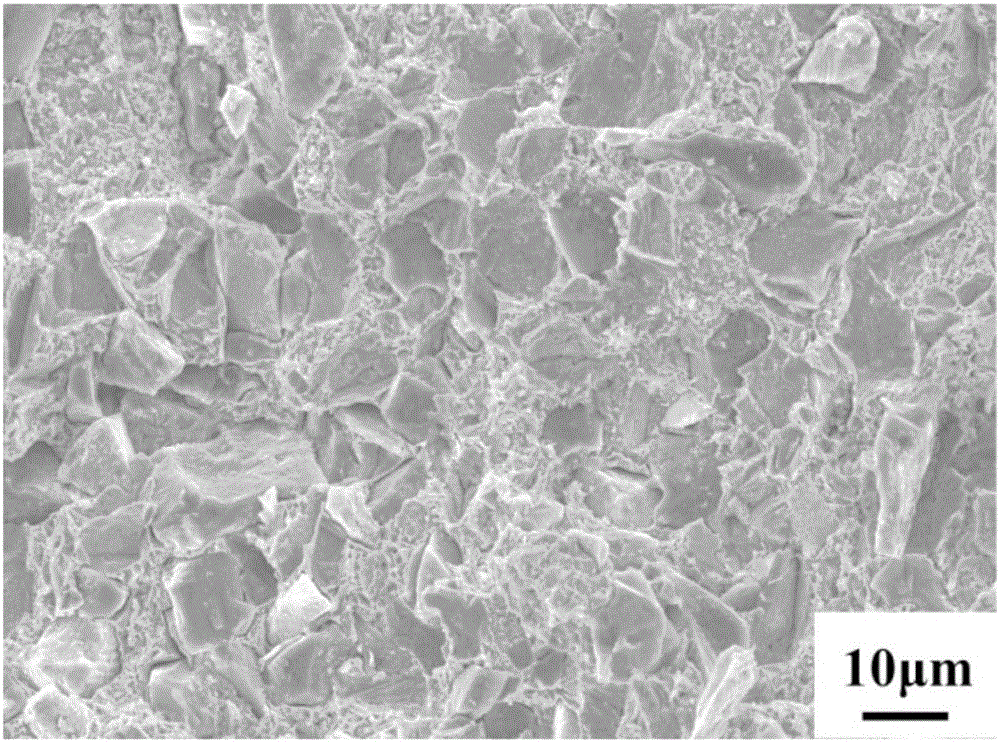

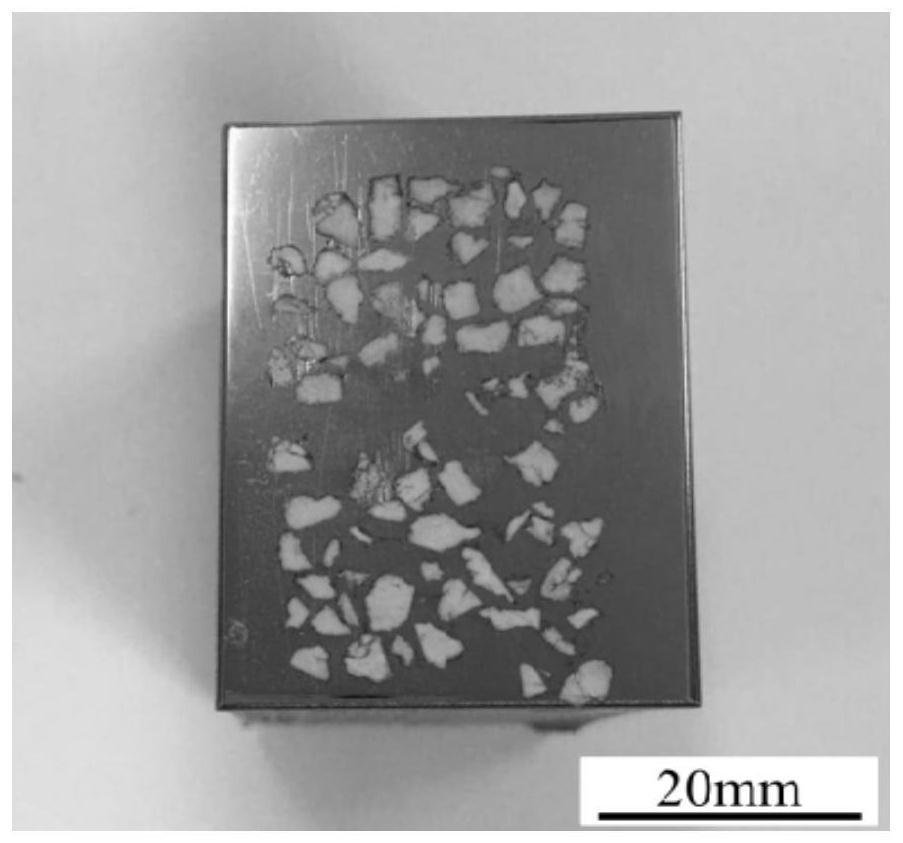

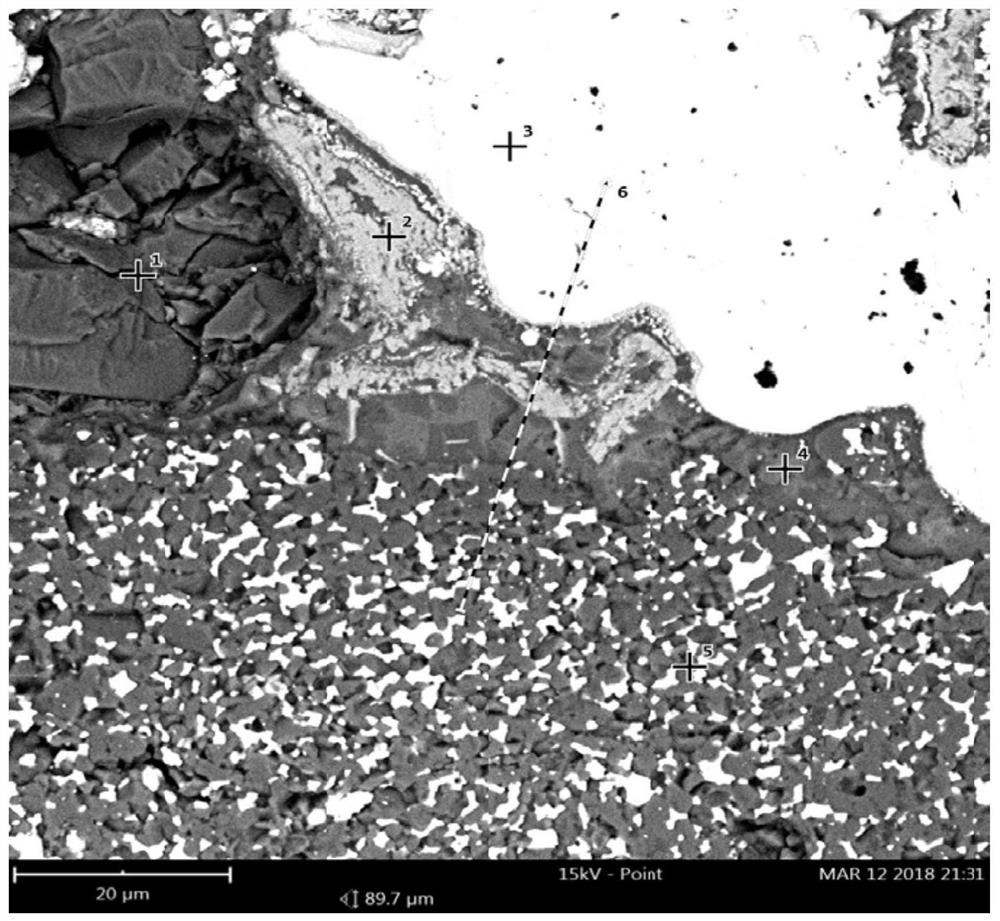

Low temperature glass phase enhanced SiCp/Cu composite material and preparation method thereof

ActiveCN104294071AImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Titanium fire preventing flame-retardant coating and preparation method thereof

InactiveCN108034857AImprove flame retardant propertiesImproved interfacial bonding propertiesMetallic material coating processesAluminiumComposite structure

The invention discloses a titanium fire preventing flame-retardant coating and a preparation method thereof. A laser cladding method is adopted to coat a titanium-aluminum intermetallic compound coating located on the surface of a titanium alloy matrix, and a compact Al2O3-enriched compound oxidation product can be formed on the surface after combination of the titanium-aluminum intermetallic compound coating. The preparation method includes the steps of preparation of titanium-aluminum intermetallic compound powder, drying treatment of the pre-cladded titanium-aluminum intermetallic compoundpowder, pretreatment of the titanium alloy matrix, laser cladding, heat treatment and the like. The flame-retardant property of the prepared titanium-aluminum intermetallic compound coating is improved to be more than twice that of the titanium alloy matrix, and meanwhile the combination degree of the coating and the matrix is good. Moreover, high strength of the coating is combined with high toughness of the matrix, and thus the composite structure which is tough inside and hard outside is more suitable for the service environment of aero-engines. The titanium fire preventing flame-retardantcoating is simple in preparation technology and has repeatability, the experimental cost is low and application prospects are broad.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Flame-retardant graphene titanium-aluminum-based composite material and preparation method

ActiveCN108411154AImprove flame retardant performanceImprove heat strengthTitanium alloyMechanical property

The invention belongs to the technical field of titanium alloy materials, and relates to a flame-retardant graphene titanium-aluminum-based composite material and a preparation method. The composite material is prepared from the following components in percentage by mass: 0.01 to 1 percent of graphene oxide and a titanium and aluminum compound. By adoption of a method of combining temperature-controlled mechanical stirring, vacuumizing treatment, hot isostatic pressing and the like, interface bonding characteristics of graphene oxide and titanium and aluminum compound mixed powder are improved, and the bulk density and the subsequent forming property of the mixed powder are improved; furthermore, the graphene oxide is basically decomposed to form graphene which is uniformly dispersed, so that the excellent mechanical property and the physical and chemical properties of the graphene are fully exerted; the flame retardant property of the obtained composite material is twice that of a common high-temperature titanium alloy or above, and the heat resistance is higher; and a brand-new technical scheme is provided for solving titanium fire of an aero-engine. The flame-retardant graphenetitanium-aluminum-based composite material is a novel material concept; a prepration process is short, can accurately control parameters, and is suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-strength aluminum-coated plate strip and production method thereof

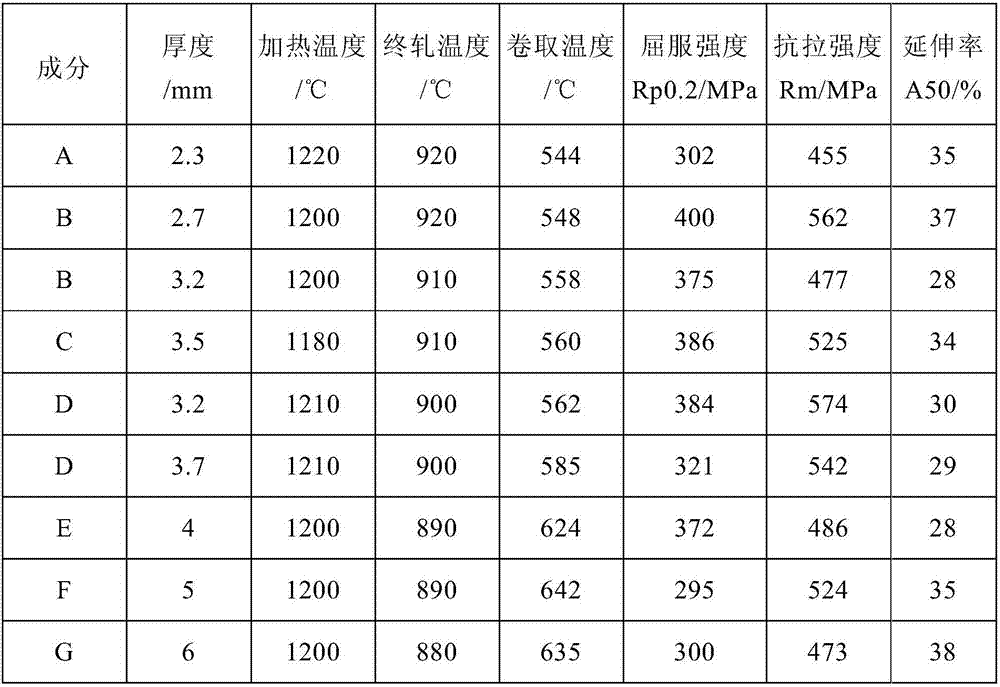

ActiveCN107881426AImprove plasticityImproved interfacial bonding propertiesUltimate tensile strengthImpurity

The invention discloses a high-strength aluminum-coated plate strip and a production method thereof. The high-strength aluminum-coated plate strip is of a structure composited by an aluminum strip anda steel strip. The steel strip comprises the chemical components of, by weight, 0.03%-0.06% of C, larger than 0% and smaller than or equal to 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P,no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sumof the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. The aluminum-coated plate strip has high strength of steel; as for the aluminum-coated plate strip, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate is larger than 28%; and meanwhile the aluminum-coated plate strip has the characteristicsof good properties of plasticity, cold-bending, stamping and the like, corrosion resistance of aluminum, heat dissipation and attractiveness and can be used for production of heat dissipation devices, heat dissipation pieces, wheels and corrosion resistant boxes.

Owner:BAOSHAN IRON & STEEL CO LTD

Lightweight aluminum coated sheet strip and production method thereof

ActiveCN107881412AHigh strengthGood cold bendingMetal rolling arrangementsChemical compositionStrip steel

The invention discloses a lightweight aluminum coated sheet strip and a production method thereof. The lightweight aluminum coated sheet strip is of an aluminum strip-steel strip composite structure.The steel strip comprises, by weight, 0.04-0.08% of C, greater than 0 and less than or equal to 0.005% of Si, 0.9-1.8% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, lessthan or equal to 0.005% of Al, 0.0062-0.02% of N, 0.006-0.05% of O, 0.002-0.004% of Ca, 0.01-0.03% of Ti, 0.01-0.03% of Nb and the balance Fe and inevitable impurities, wherein the sum of O and N isgreater than or equal to 0.013%, and 0.5<=(O+N) / (P+S)<=5. According to the aluminum coated sheet strip, the yield strength is 400 MPa or above, the tensile strength is 500-800 MPa, meanwhile, the elongation A50% is 18% or above, thus, the aluminum coated sheet strip has the strength of steel, the properties such as good plasticity, colding bending, stamping and the like and the characteristics ofcorrosion resistance, radiating performance and attractive appearance of aluminum, and can be used for production of radiators, radiating fins and wheels, and lightweight design can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of SICP/CU composite material reinforced by low temperature glass phase and preparation method thereof

ActiveCN104294071BImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

SiC/Cu composite material and preparation method thereof

ActiveCN104294077AImproved interfacial bonding propertiesAvoid interface reactionNon wettingHardness

The invention discloses a SiC / Cu composite material and a preparation method thereof. The continuous phase of the composite material is a glass phase, and SiC particles and Cu particles are uniform wrapped in the glass phase. The SiC / Cu composite material has the following advantages: the glass phase is filled between the SiC particles and the Cu particles, so the contact between the SiC particles and the Cu particles is avoided; and the low temperature glass phase forms interface layers on the surfaces of the SiC particles and the Cu particles, so the interface combination characteristic of the SiC / Cu composite material is effectively improved, the problems of non-wetting between a molten Cu phase and a SiC phase and easy interface reaction of the above two phases at a high temperature are solved, the interface bonding force is enhanced, and the hardness and the bending strength of the composite material are improved, thereby the composite material has good and stable comprehensive mechanical performances.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

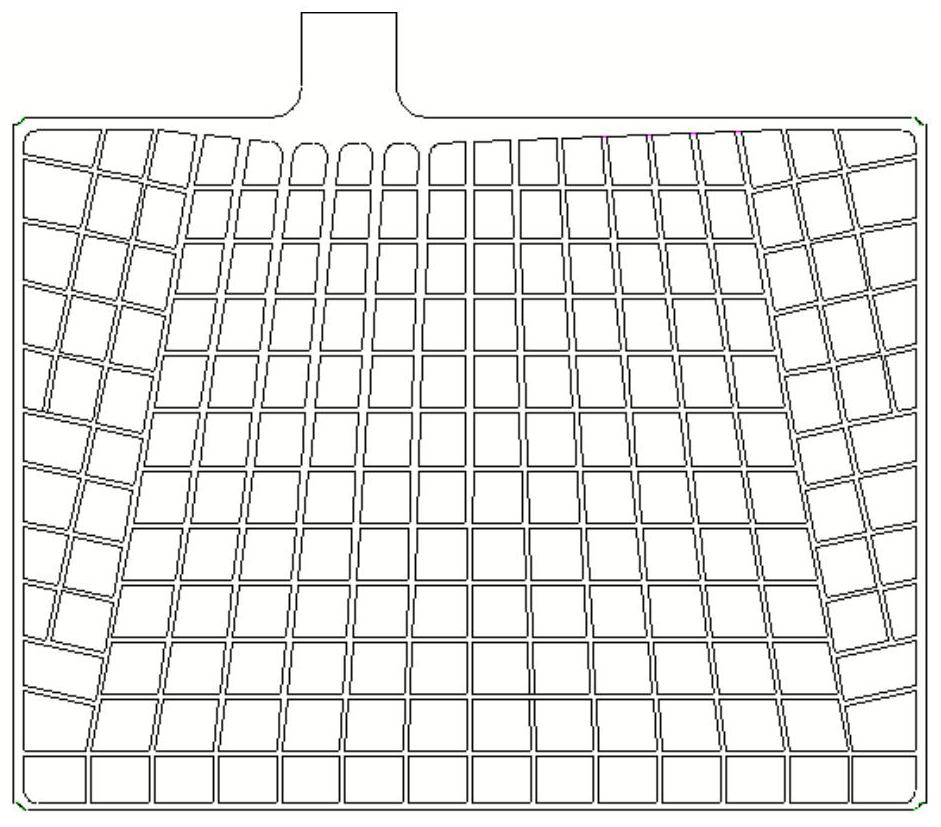

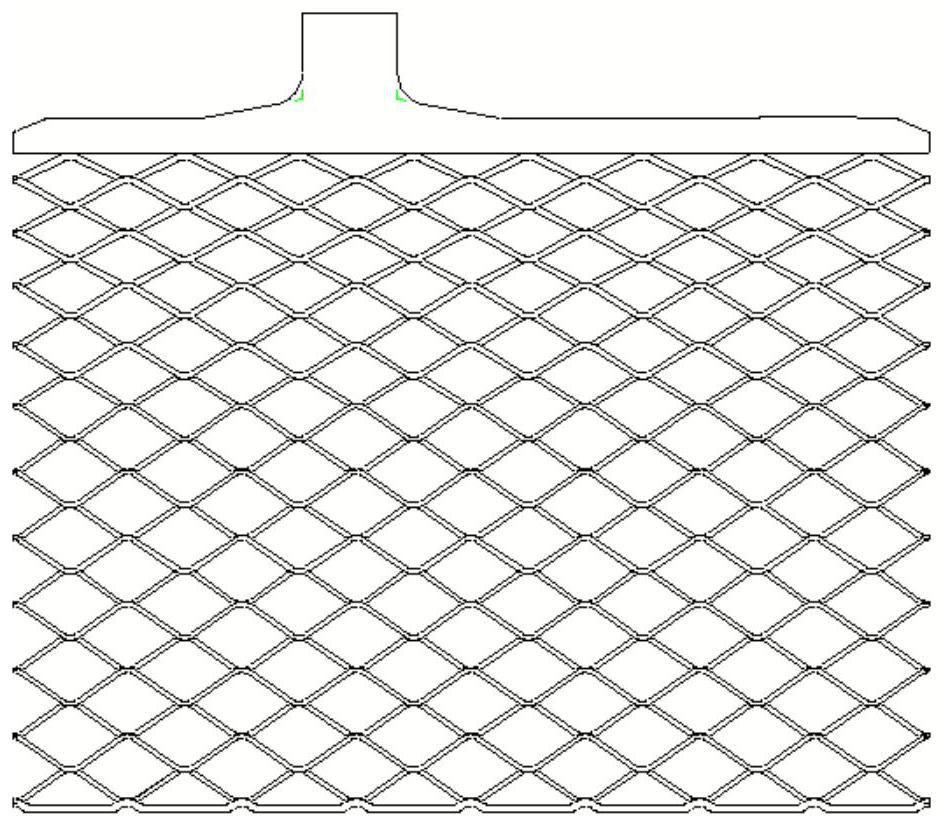

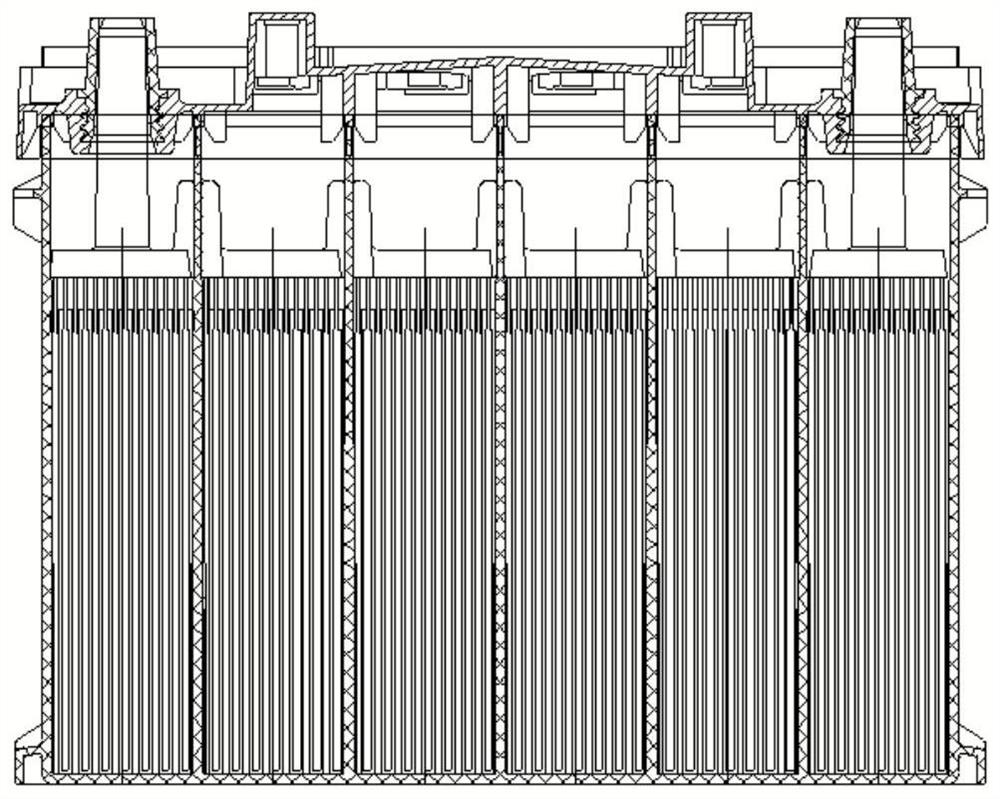

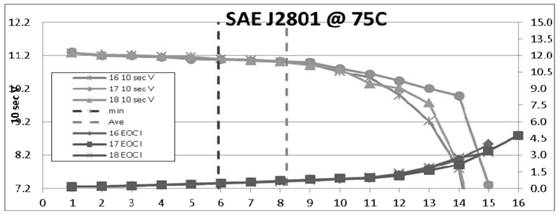

EFB start-stop battery for PHEV and manufacturing process

PendingCN112838219ALower internal resistanceImprove density distributionFinal product manufactureElectrode carriers/collectorsElectrical batteryProcess engineering

The invention belongs to the technical field of manufacturing of power systems for hybrid electric vehicles, and relates to an EFB start-stop battery for a PHEV and a manufacturing process. The EFB start-stop battery comprises an integral tank, a plurality of plate groups mounted in the integral tank and acid liquor in the integral tank, wherein each plate group consists of a positive plate and a negative plate which are alternately stacked. The positive plate adopts a punching net radioactive structure design, ribs of the positive plate are thick at the upper part and thin at the lower part, are radial and are formed in a staggered manner; the ribs of the negative plate grid are in thickness transition design and are formed in a staggered manner, and the area of grids formed by the staggered ribs is small in top and large in bottom; in the same plate group, the positive plate is encapsulated by a high-strength PE partition plate, the positive and negative tabs are connected in parallel in a cast-weld manner, and all the plate groups are connected in series; and the density of the acid liquor is controlled to be 1.275 to 1.285 g / ml. The deep discharge cycle life of the battery is remarkably prolonged, the charge receiving capability of the battery is remarkably improved, the key technical problem of an EFB start-stop battery for a PHEV automobile is solved, and the invention has great technical improvement value and production and popularization value.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

Titanium alloy compound material for dental department and preparation method thereof

InactiveCN109112438AImprove room temperature strengthImprove plasticityImpression capsDentistry preparationsFiberChemical composition

The invention discloses a titanium alloy compound material for dental department and a preparation method thereof. The titanium alloy compound material for the dental department is prepared from the following chemical components in percentage by weight: 2 to 3 percent of Cu, 3 to 5 percent of Zr, 0.05 to 0.1 percent of Ce, 0.02 to 0.1 percent of Ag, 10 to 15 percent of graphene oxide fibers and the balance of Ti. According to the titanium alloy compound material for the dental department, graphene oxide is added so that the mechanical property is greatly enhanced; compared with an alloy matrix, the composite material provided by the invention has the advantages that the plasticity is greatly improved when the room-temperature strength of the composite material is improved, and the corrosion resisting performance of the titanium alloy compound material for the dental department is ensured; an inert gas protected stirring method is used for preparing mixed slurry of the graphene oxide and alloy powder, the interface bonding property of the graphene oxide and the alloy powder is improved, and oxidization of the alloy powder is avoided, so that the molding property of subsequent powdersintering is improved; a processing technology of the preparation method is simple, and the preparation method is easy to popularize in a large scale.

Owner:佛山市佛冠义齿有限公司

High-strength steel for aluminum-coated base plate and production method thereof

The invention discloses steel for an aluminum-coated base plate and a production method thereof. The steel comprises, by weight, 0.03%-0.06% of C, no more than 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P, no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sum of the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. According to the steel for the aluminum-coated base plate, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate A50% is 28% or above; the steel can be used for production of an aluminum-coated plate strip, the related plate strip can be composited with materials such as aluminum with better radiating performance, accordingly, the radiating problem of wheels is solved, and the steel is used for manufacturing the wheels, radiating devices, corrosion resistant boxes and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of graphene-reinforced titanium-based nanocomposite material and preparation method thereof

The invention belongs to the technical field of graphene composite materials and relates to a titanium-based nanocomposite material reinforced through graphene and a preparation method, in particularto a graphene-reinforced titanium-based nanocomposite material and a preparation method. Firstly, oxidized graphene nanosheets of 0.01 wt%-1.0 wt% of titanium alloy powder are weighed to be added intoabsolute ethyl alcohol to be stirred and mixed, then disperse treatment is conducted through an ultrasonic cell pulverizer, and an oxidized graphene solution is prepared; then the titanium alloy powder with the alloying element content being larger than 10 wt% and the oxidized graphene solution are stirred and mixed under inert protection, and oxidized graphene and titanium alloy powder compositepowder is obtained; and finally, the composite powder is loaded into a graphite mold to be sintered, through vacuum pumping and sintering forming, oxidized graphene is basically decomposed to form graphene, and therefore the graphene-reinforced titanium-based nanocomposite material with the excellent mechanical property is prepared. In the graphene-reinforced titanium-based nanocomposite material, the graphene is uniformly dispersed, and the preparation method is simple, efficient and suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

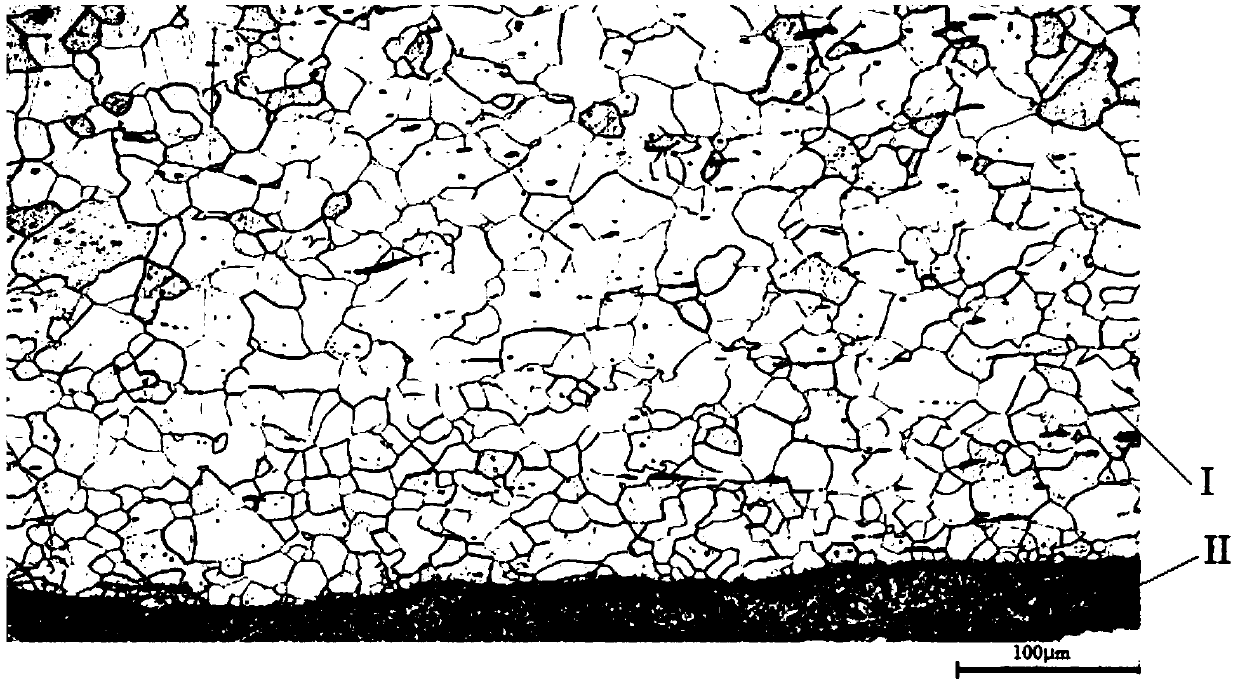

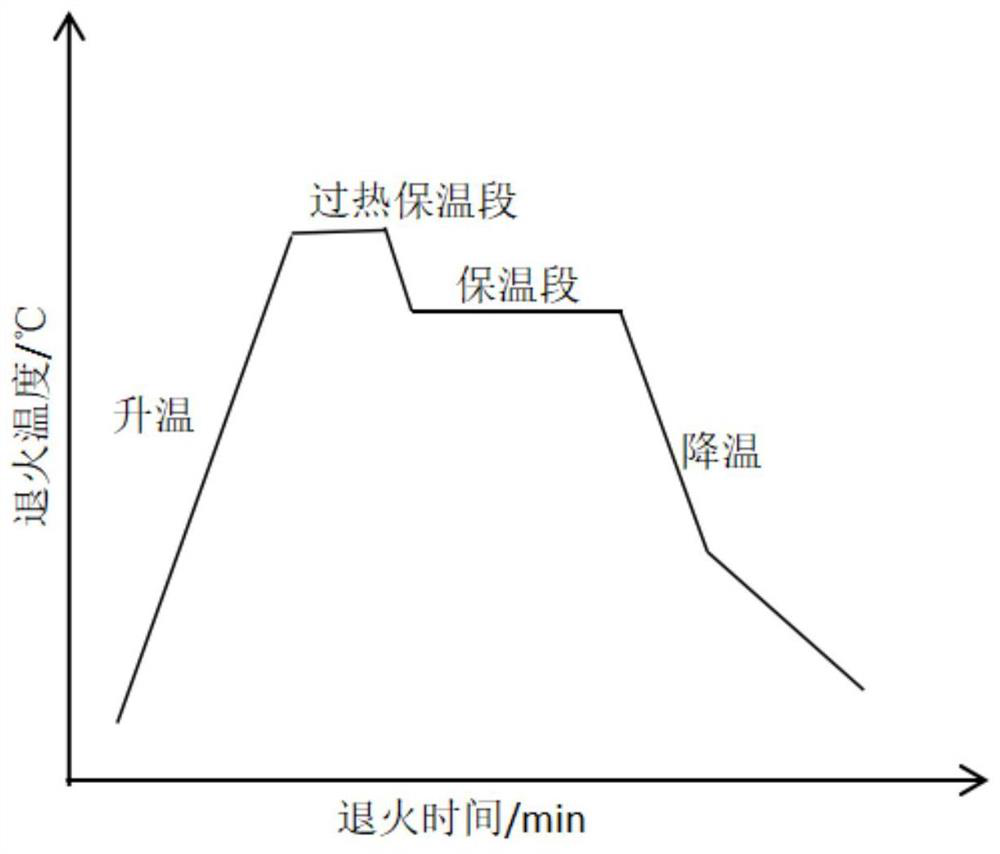

Aluminum-clad strip and manufacturing method thereof

ActiveCN111349868AImprove mechanical propertiesImprove plasticityFurnace typesHeat treatment furnacesSteel beltMechanical properties of carbon nanotubes

The invention discloses an aluminum-clad strip comprising a steel substrate and an aluminum layer covering the surface of the steel substrate. The steel substrate comprises, by mass percentage, largerthan 0 and not larger than 0.02% of C, larger than 0 and not larger than 0.005% of Si, 0.05%-0.5% of Mn, 0.018%-0.03% of P, not larger than 0.005% of Al, 0.0040%-0.010% of N, 0.01%-0.04% of Ti, 0.02%-0.050% of O and the balance Fe and inevitable impurities. In addition, the invention further discloses a manufacturing method of the aluminum-clad strip. The manufacturing method comprises the stepsof (1) manufacturing a steel strip and an aluminum strip; (2) conducting surface treatment on the steel strip and the aluminum strip; (3) covering the surface of the steel strip with the aluminum strip and conducting indoor temperature rolling; (4) conducting annealing; and (5) conducting finishing and straightening. The aluminum-clad strip has good mechanical performance, and the bonding performance of a steel-aluminum interface is excellent.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel for aluminum-clad substrate and production method thereof

ActiveCN107881422BImprove plasticityImproved interfacial bonding propertiesAluminum substrateUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

A high-strength aluminum-clad strip and its production method

ActiveCN107881426BImprove plasticityImproved interfacial bonding propertiesChemical compositionHigh intensity

The invention discloses a high-strength aluminum-coated plate strip and a production method thereof. The high-strength aluminum-coated plate strip is of a structure composited by an aluminum strip anda steel strip. The steel strip comprises the chemical components of, by weight, 0.03%-0.06% of C, larger than 0% and smaller than or equal to 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P,no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sumof the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. The aluminum-coated plate strip has high strength of steel; as for the aluminum-coated plate strip, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate is larger than 28%; and meanwhile the aluminum-coated plate strip has the characteristicsof good properties of plasticity, cold-bending, stamping and the like, corrosion resistance of aluminum, heat dissipation and attractiveness and can be used for production of heat dissipation devices, heat dissipation pieces, wheels and corrosion resistant boxes.

Owner:BAOSHAN IRON & STEEL CO LTD

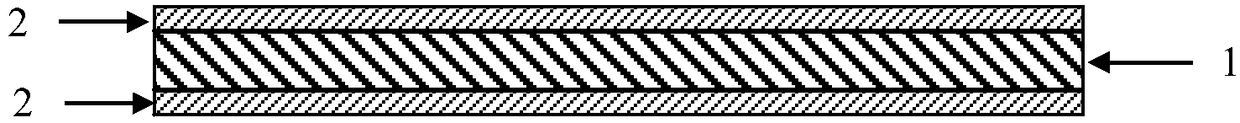

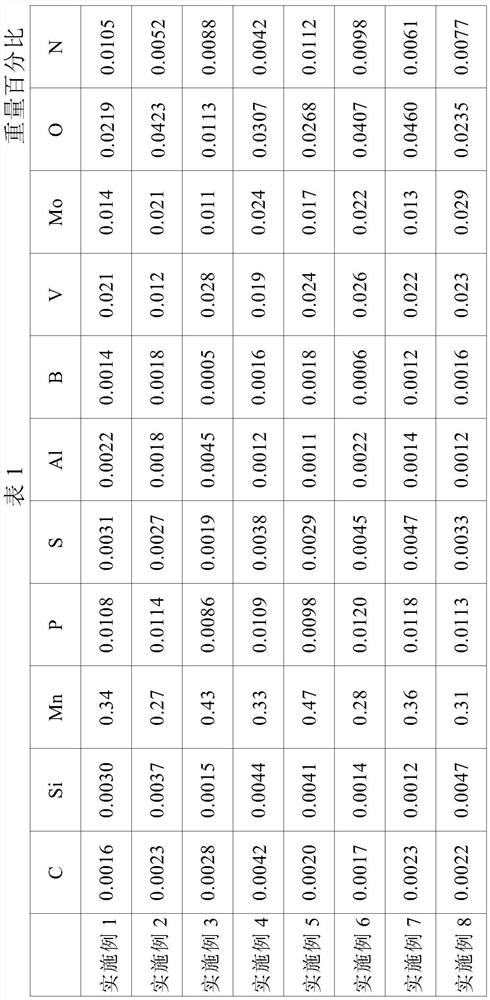

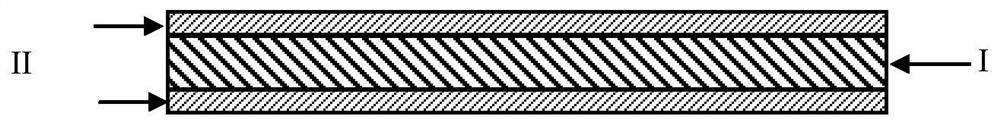

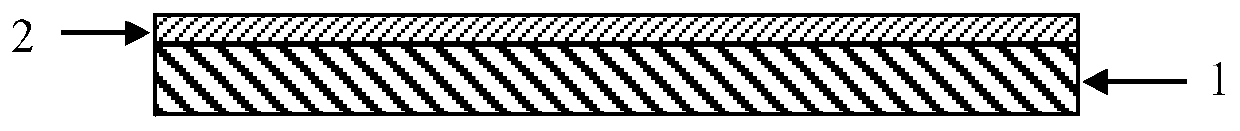

Aluminum-coated plate strip for kitchen ware and production method of aluminum-coated plate strip

ActiveCN114248508AImprove mechanical propertiesImproved interfacial bonding propertiesCooking-vessel materialsLamination ancillary operationsAluminum coatingUltimate tensile strength

The invention relates to an aluminum-coated plate strip for kitchen ware and a production method thereof, the aluminum-coated plate strip comprises at least one layer of aluminum strip and at least two layers of steel strips, the upper and lower surfaces of the aluminum strip are coated with the steel strips, and the steel strips comprise the following chemical components in percentage by weight: 0.0015-0.005% of C, 0.001-0.005% of Si, 0.25-0.50% of Mn, less than or equal to 0.012% of P, less than or equal to 0.006% of S, 0.001-0.005% of Al, 0.004-0.012% of N, 0.0005-0.002% of B, 0.01-0.05% of O, 0.01-0.03% of V, 0.01-0.03% of Mo and the balance of Fe and inevitable impurities; and meanwhile, N is greater than or equal to 1.4 B + 0.6 Al, and V-1. 93 (N-1. 4B-0.6 Al) is greater than or equal to 3.65 C. The aluminum-coated plate strip not only has the strength of steel, but also has the characteristics of good heat dissipation and portability of aluminum, and also has good aluminum coating and drawing properties, the tensile strength of the aluminum-coated plate strip is greater than or equal to 320 MPa, the elongation is greater than or equal to 28%, the strength is not obviously reduced after nitriding treatment, the nitriding treatment requirement in kitchen ware production is met, and the aluminum-coated plate strip can be used for producing and processing novel kitchen ware such as a frying pan.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for spraying babbitt coating on steel back of bearing bush

ActiveCN106435563BImprove product qualityImprove the level ofHeat inorganic powder coatingThermal sprayingMaterials science

The invention relates to the technical field of preparation and repair of sliding bearing Babbitt metal anti-friction layers. The novel cold spraying technology is introduced into manufacturing and repair remanufacturing of a Babbitt metal sliding bearing bush lining anti-friction layer, atomization powder feeding is adopted to obtain coating microstructures with uniform components and fine dispersely-distributed and uniformly-dense crystal grains and second phases through cold spraying, and the good interface bonding characteristic is obtained through tinning layer setting and sprayed thermal treatment; the defects of poor structure uniformity, thermal impact, stress, cracking and oxidizing burning losses existing in the technologies such as a traditional casting method, an overlaying method and a thermal spraying method are overcome, the bearing bush component preparation quality and level are improved, the bush burning frequency is decreased, stopping supercritical vibration is lowered, the stability, accuracy and reliability of a bearing transmission unit are improved, and the service life of the bearing transmission unit is prolonged; the method is rapid, efficient and environmentally friendly, is used for bearing bush manufacturing and repair remanufacturing, and has good economic benefits and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Corrosion-inhibiting aluminum-clad strip and manufacturing method thereof

The invention discloses a corrosion-inhibiting aluminum-clad strip, which comprises a steel substrate and an aluminum layer coated on the surface of the steel substrate; the mass percentage ratio of chemical elements of the steel substrate is: 0<C≤0.02%, 0< Si≤0.005%, Mn: 0.05‑0.5%, P: 0.018‑0.03%, Al≤0.005%, Cu: 0.04‑0.1%, Cr: 0.1‑0.25%, N: 0.0040‑0.010%, Ti: 0.01‑0.04 %, O: 0.02‑0.050%, the balance being Fe and other unavoidable impurities. In addition, the present invention also discloses a method for manufacturing the above-mentioned corrosion-inhibiting aluminum-clad strip, which includes the steps of: (1) preparing the steel strip and the aluminum strip; (2) performing surface treatment on the steel strip and the aluminum strip; 3) Covering the aluminum strip on the surface of the steel strip and rolling at room temperature; (4) Annealing; (5) Finishing and straightening.

Owner:BAOSHAN IRON & STEEL CO LTD

Corrosion inhibition aluminum-coated plate strip and manufacturing method thereof

ActiveCN111349849ASectional Corrosion InhibitionSolve the ubiquitous cross-sectional corrosion problemSteel beltCorrosion

The invention discloses a corrosion inhibition aluminum coated plate strip. The corrosion inhibition aluminum coated plate strip comprises a steel base plate and an aluminum layer coated on the surface of the steel base plate. The steel base plate comprises chemical elements: by mass, more than 0 and less than or equal to 0.02% of C, more than 0 and less than or equal to 0.005% of Si, 0.05-0.5% ofMn, 0.018-0.03% of P, less than or equal to 0.005% of Al, 0.04-0.1% of Cu, 0.1-0.25% of Cr, 0.0040-0.010% of N, 0.01-0.04% of Ti, 0.02-0.050% of O, and the balance Fe and other inevitable impurities.In addition, the invention further discloses a manufacturing method of the corrosion inhibition aluminum coated plate strip. The manufacturing method comprises the steps of (1) manufacturing a steelstrip and an aluminum strip; (2) conducting surface treatment on the steel strip and the aluminum strip; (3) coating the surface of the steel strip with the aluminum strip and then conducting indoor-temperature rolling; (4) conducting annealing; and (5) conducting finishing and straightening.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum clad strip with excellent heat dissipation effect and production method thereof

ActiveCN107881410BImprove plasticityImproved interfacial bonding propertiesMetal rolling arrangementsUltimate tensile strengthSteel belt

Owner:BAOSHAN IRON & STEEL CO LTD

A light-weight design aluminum-clad substrate and its production method

The invention discloses a lightweight designed aluminum-coated base plate and a production method thereof. The components of the aluminum-coated base plate comprise, by weight, 0.04-0.08% of C, greater than zero and no more than 0.005% of Si, 0.9-1.8% of Mn, no more than 0.015% of P, no more than 0.005% of S, no more than 0.005% of Al, 0.0062-0.02% of N, 0.05-0.06% of O, 0.002-0.004 of Ca, 0.01-0.03% of Ti, 0.01-0.03% of Nb, and the balance Fe and unavoidable impurities; and meanwhile the conditions that O+N is greater than or equal to 0.013%, and (O+N) / (P+S) is greater than or equal to 0.5 and less than or equal to 5 are met. The yield strength of the aluminum-coated base plate is 400 MPa or above, the tensile strength is 500-800 MPa, meanwhile, the elongation rate A50% is 18% or above, and the plasticity is excellent. The aluminum-coated base plate is mainly used for production of aluminum-coated plate strips and can be used for manufacturing automobile wheels and heat dissipation elements, corrosion-resistant boxes and the like, and lightweight design is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel for high-strength aluminum-clad substrate and production method thereof

The invention discloses steel for an aluminum-coated base plate and a production method thereof. The steel comprises, by weight, 0.03%-0.06% of C, no more than 0.005% of Si, 0.4%-0.8% of Mn, no more than 0.015% of P, no more than 0.005% of S, no more than 0.005% of Al, 0.0062%-0.02% of N, 0.006%-0.05% of O, 0.002%-0.004% of Ca, 0.01%-0.03% of Ti and the balance Fe and inevitable impurities; and meanwhile, the sum of the contents of O and N is larger than or equal to 0.013%, and the relation of 0.5<=(O+N) / (P+S)<=5 is met. According to the steel for the aluminum-coated base plate, the yield strength is 280-400 MPa, the tensile strength is 420 MPa or above, and the elongation rate A50% is 28% or above; the steel can be used for production of an aluminum-coated plate strip, the related plate strip can be composited with materials such as aluminum with better radiating performance, accordingly, the radiating problem of wheels is solved, and the steel is used for manufacturing the wheels, radiating devices, corrosion resistant boxes and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of aluminum-clad strip and its manufacturing method

ActiveCN111349868BImprove mechanical propertiesImprove plasticityFurnace typesHeat treatment furnacesSteel beltSurface preparation

The invention discloses an aluminum-clad strip, which comprises a steel substrate and an aluminum layer coated on the surface of the steel substrate; the mass percentage ratio of chemical elements of the steel substrate is: 0<C≤0.02%, 0<Si≤0.005 %, Mn: 0.05‑0.5%, P: 0.018‑0.03%, Al≤0.005%, N: 0.0040‑0.010%, Ti: 0.01‑0.04%, O: 0.02‑0.050%, the balance being Fe and other unavoidable of impurities. In addition, the present invention also discloses a method for manufacturing the above-mentioned aluminum-clad strip, which includes the steps of: (1) preparing the steel strip and the aluminum strip; (2) performing surface treatment on the steel strip and the aluminum strip; (3) The aluminum strip is covered on the surface of the steel strip for room temperature rolling; (4) annealing; (5) finishing and straightening. The aluminum-clad plate strip has good mechanical properties, and the steel-aluminum interface bonding performance is excellent.

Owner:BAOSHAN IRON & STEEL CO LTD

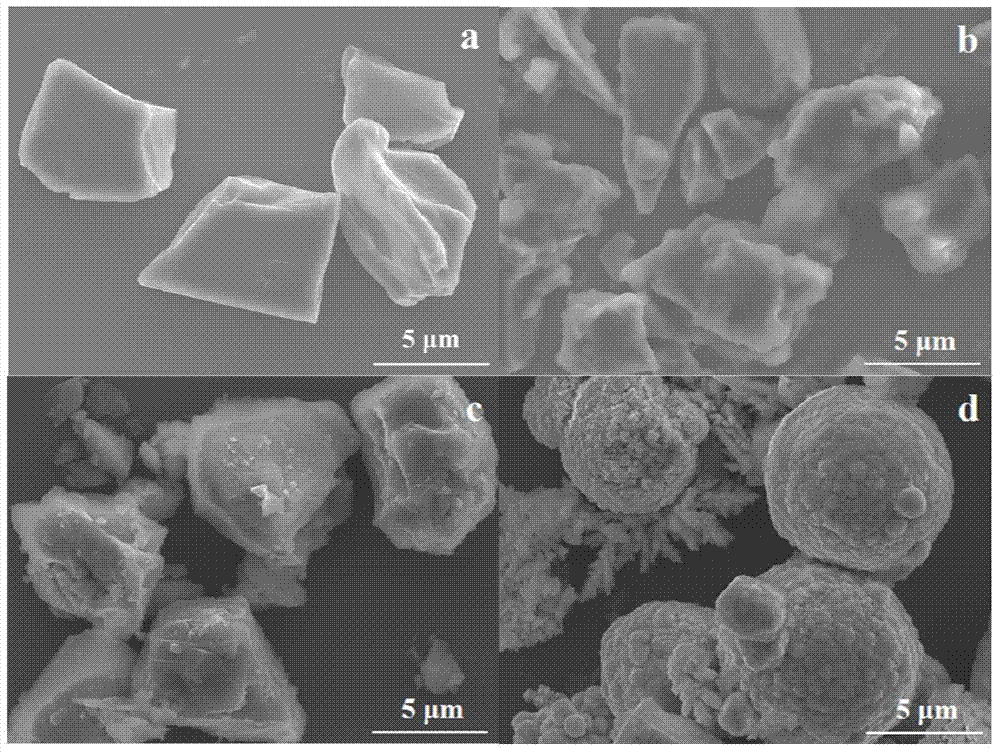

A kind of fe-cr-ni-ti powder coated honeycomb zta ceramic preform and its preparation and application

ActiveCN109053215BImproved interfacial bonding propertiesImprove wettabilityTransportation and packagingMetal-working apparatusParaffin waxSilicic acid

The invention belongs to the field of material processing, and discloses a honeycomb ZTA ceramic prefabricated body coated with Fe-Cr-Ni-Ti micropowder, a preparation method and application thereof. Fe, Cr, and Ni elements are the main elements in chromium-based cast iron and high manganese steel. After alloying with Ti powder, it is beneficial to reduce the melting temperature of pure Ti powder. It is conducive to the formation of molten Ti, and through the diffusion reaction between Ti and oxygen in ZTA ceramics, a metal-ceramic bonding interface with high bonding strength is realized. In addition, water glass and CO 2 The reaction produces silicic acid with a certain connection strength, which promotes the bonding between ZTA ceramic particles and the shaping of the preform, and is beneficial to the preform's resistance to the erosion of poured liquid metal. In addition, paraffin wax is used as a pore-forming agent, which is beneficial to the uniform distribution and communication of cavities in the preform. Therefore, it can be well applied to the preparation of metal matrix composites.

Owner:JINAN UNIVERSITY

12V low-voltage electrical system AGM manufacturing process for BEV and battery

InactiveCN112885988AReduce corrosion rateAccelerated corrosionElectrode rolling/calenderingFinal product manufactureManufacturing technologyElectrical battery

The invention belongs to the technical field of pure electric new energy vehicle low-voltage electrical system manufacturing, and particularly relates to a 12V low-voltage electrical system AGM battery manufacturing process for a BEV and a battery. The manufacturing process comprises the steps of lead belt manufacturing, polar plate forming and lead paste preparing and smearing, wherein the apparent density of positive electrode lead paste is controlled to be 4.3-4.5 g / mL, and the apparent density of negative electrode lead paste is controlled to be 4.2-4.4 g / mL; then the polar plate is put into an adjustable curing chamber for polar plate curing and drying, the temperature of the curing chamber is controlled to be 50-70 DEG C, the relative humidity is controlled to be 100%-20%, and the curing time is 72-80 h; the positive electrode is encapsulated by adopting a high-porosity and high-resilience AGM partition plate, the rough surface faces the negative electrode, all positive and negative electrode tabs in the electrode group are compressed into a groove after being subjected to cast welding and parallel connection, and finally an acid adding process is carried out. The AGM battery produced by adopting the process has deep discharge cycle life in a partial charge state at a high temperature state and low-temperature cold start performance after long-term storage, and the key technical problem of a 12V low-voltage electrical system AGM battery for an existing BEV pure electric vehicle is solved.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

A high-surface-quality aluminum-clad strip that is easy to be stamped and processed and its production method

ActiveCN108796384BImprove plasticityImproved interfacial bonding propertiesFurnace typesMetal rolling arrangementsHigh surfaceImpurity

The invention provides a high-surface-quality aluminum-coated plate strip with an easy stamping machining function and a production method thereof. The aluminum-coated plate strip is composited of analuminum strip and a steel strip; the steel strip comprises the chemical compositions of, by weight, no more than 0.01% of C, 0.006-0.015% of Si, 0.05-0.3% of Mn, no more than 0.015% of P, no more than 0.01% of S, no more than 0.005% of Al, no more than 0.005% of N, 0-0.05% of Ti, 0.01-0.08% of O, and the balance Fe and unavoidable impurities; and the following formulas are met, specifically, C+N<=0.012%, Mn / S>=8, and Ti / (3.42N+4C)>=1. The aluminum-coated plate strip has good steel and aluminum bonding properties and adapts to single pass large deformation, and stamping machining performance and the high surface quality are achieved; and the aluminum-coated plate strip meets 300 MPa or above of tensile strength, the elongation exceeds 30%, and the aluminum-coated plate strip can replace analuminum-plated plate to be used for production of automobile engine sound-insulation covers, home appliance panels, food processing trays and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

A flame-retardant graphene titanium-aluminum matrix composite material and preparation method thereof

ActiveCN108411154BImprove flame retardant performanceImprove heat strengthTitanium alloyGraphite oxide

The invention belongs to the technical field of titanium alloy materials, and relates to a flame-retardant graphene titanium-aluminum-based composite material and a preparation method. The composite material is prepared from the following components in percentage by mass: 0.01 to 1 percent of graphene oxide and a titanium and aluminum compound. By adoption of a method of combining temperature-controlled mechanical stirring, vacuumizing treatment, hot isostatic pressing and the like, interface bonding characteristics of graphene oxide and titanium and aluminum compound mixed powder are improved, and the bulk density and the subsequent forming property of the mixed powder are improved; furthermore, the graphene oxide is basically decomposed to form graphene which is uniformly dispersed, so that the excellent mechanical property and the physical and chemical properties of the graphene are fully exerted; the flame retardant property of the obtained composite material is twice that of a common high-temperature titanium alloy or above, and the heat resistance is higher; and a brand-new technical scheme is provided for solving titanium fire of an aero-engine. The flame-retardant graphenetitanium-aluminum-based composite material is a novel material concept; a prepration process is short, can accurately control parameters, and is suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com