Steel for aluminum-clad substrate and production method thereof

A production method and substrate technology, applied in the field of low-alloy steel manufacturing, can solve the problems of poor heat dissipation and high composition of steel plate wheels, and achieve the effects of excellent cold-bending processing performance, reduced production costs, and good deep-drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

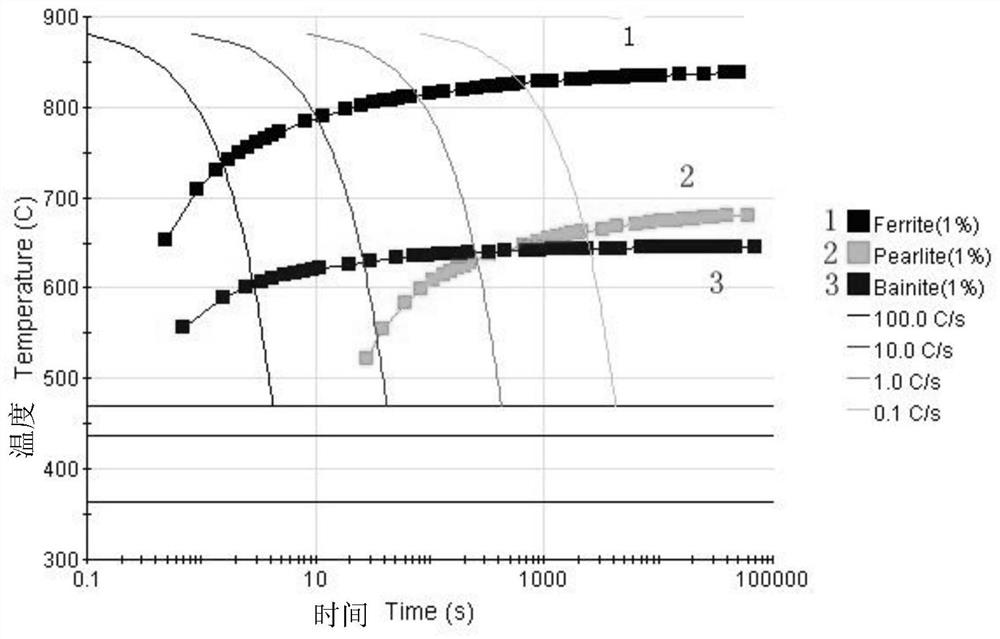

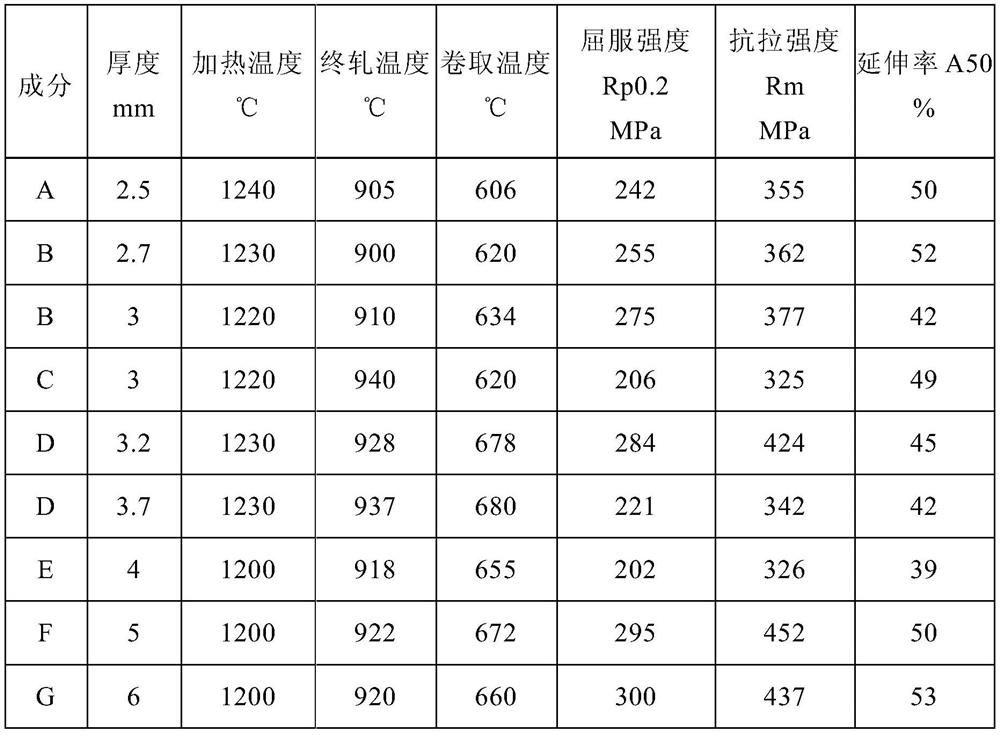

[0043] According to the chemical composition requirements of the steel of the present invention, steelmaking is carried out in a 500kg vacuum induction furnace, and the obtained chemical composition is shown in Table 1, and cast into a 100kg steel ingot, the heating temperature is 1220°C, the final rolling temperature is 900-940°C, and the coiling temperature is 600-680°C .

[0044] The mechanical properties of the steel examples of the present invention are shown in Table 1. Comparing the composition and performance with similar steel types. Wherein comparative example 1 is Chinese Patent Publication No. CN101280387A "a kind of steel strip for automobile wheel rim and its manufacturing method", comparative example 2 is Chinese Patent Publication No. CN102296230A "hot-rolled steel for automobile wheel rim and production process thereof", for Scale 3 is Chinese Patent Publication No. CN104294144A "A steel for automobile wheel rim with tensile strength ≥ 380MPa and its producti...

Embodiment 2

[0049] According to the composition requirements of the present invention, the steel of the present invention is smelted on a 500kg vacuum induction furnace in a laboratory. The chemical composition is shown in Table 2. The billet heating temperature is above 1200-1250°C, the final rolling temperature is 900-940°C, the coiling temperature is 600-680°C, and then air-cooled to room temperature. The mechanical properties are shown in Table 2.

[0050] Table 1 Unit: weight percentage

[0051] Element C Si mn P S Al O N (O+N) / (P+S) A 0.007 0.0035 0.243 0.0121 0.0022 0.0011 0.0119 0.0061 1.26 B 0.017 0.0012 0.254 0.0088 0.0039 0.0042 0.0480 0.0124 4.76 C 0.023 0.0021 0.469 0.0138 0.0045 0.0028 0.0068 0.0092 0.87 D 0.022 0.0025 0.263 0.0111 0.0041 0.0022 0.0107 0.0148 1.68 E 0.027 0.0042 0.361 0.0133 0.0033 0.0033 0.0430 0.0186 3.71 F 0.013 0.0005 0.259 0.0147 0.0031 0.0018 0.0063 0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com