Method for coating bearing bush steel backing with Babbitt metal coating

A babbitt alloy and bearing steel technology, which is applied in the field of preparation and repair of babbitt alloy anti-friction layer of sliding bearings, can solve the problems of inclusions, sticking equipment, unstable product quality, etc., and achieve good economic benefits and social benefits. Benefit, reduce downtime over-critical vibration, improve the quality and level of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

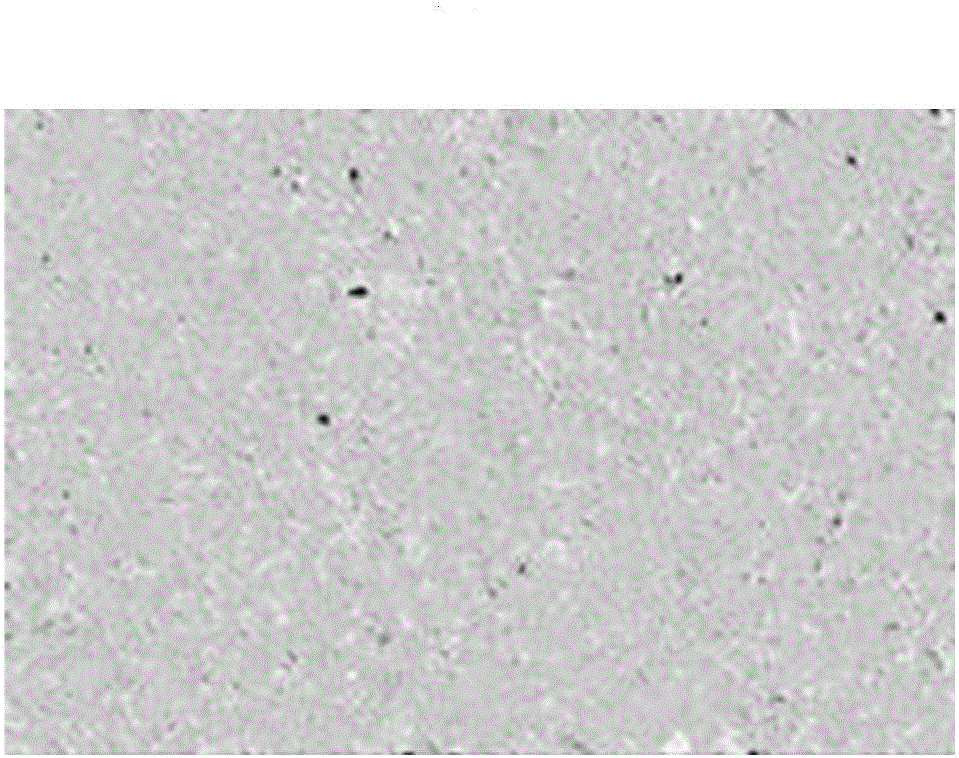

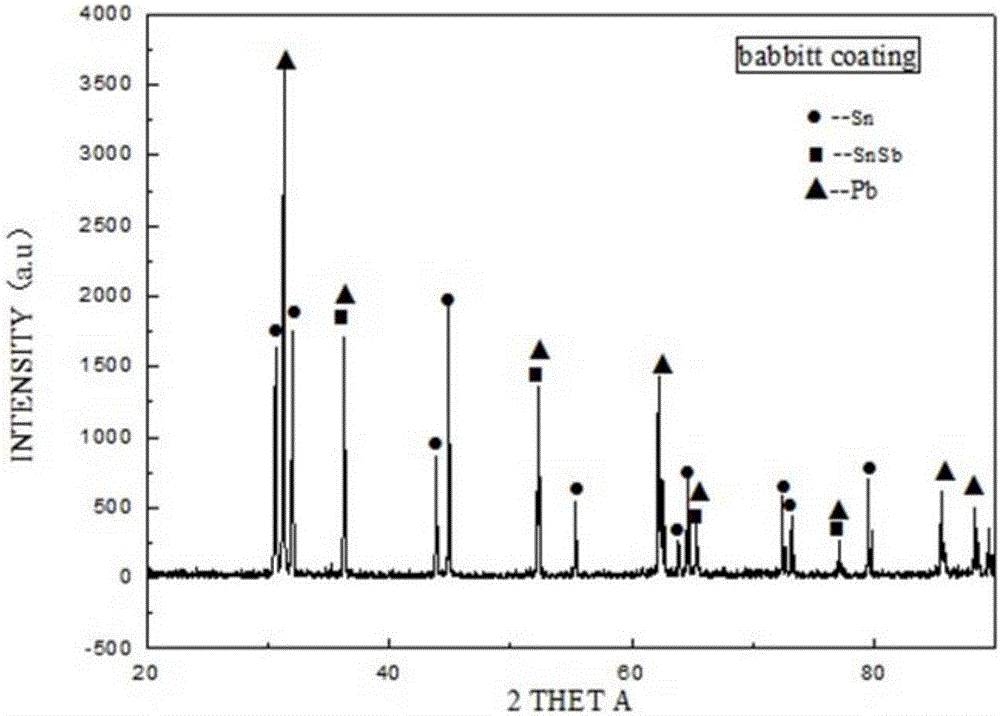

[0038] The coating material adopts Babbitt alloy powder sold in the market. The particle size and main components of the powder are: Babbitt alloy powder with a particle size of 20-40 microns, the main component is Sn, and the balance: 3.5%≤Cu≤4.5% , 7.5%≤Sb≤8.5%.

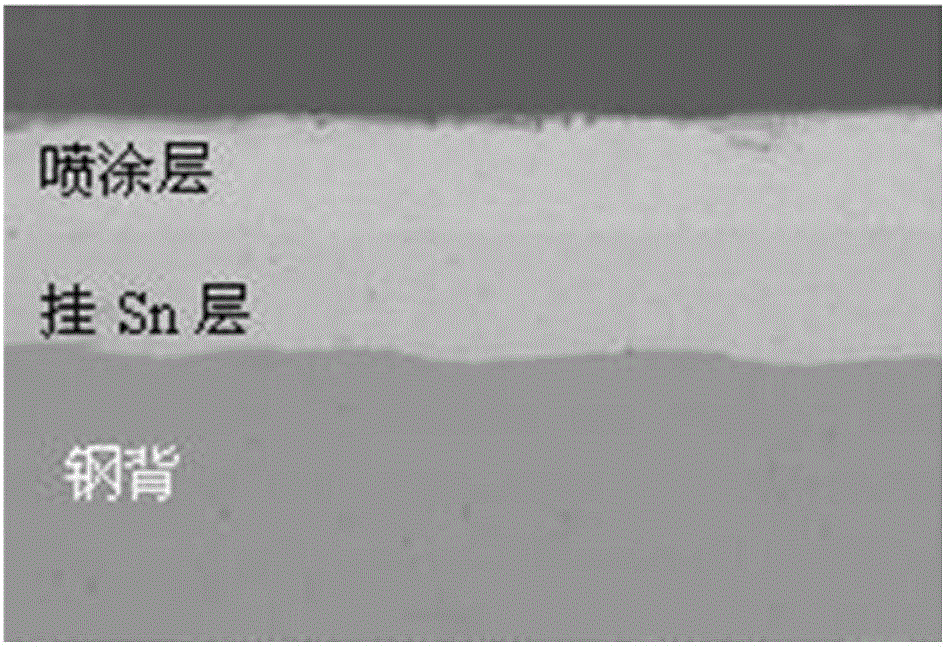

[0039] The base material of bearing bush steel back is No. 45 steel. Before spraying, the base is pickled to remove scale, and then cleaned with water. Then carry out flux treatment, the solvent is mainly composed of zinc chloride and ammonium chloride, and the flux is made into a relatively concentrated aqueous solution (the composition ratio of zinc chloride and ammonium chloride is 25:1, and the concentration of the aqueous solution is 85%); The substrate is dip-coated in molten tin at 310°C for 1 min; then take it out and cool it to room temperature.

[0040] When spraying, the base workpiece is fixed on the CNC mobile work platform, and the spray gun is fixed directly above the work platform. When spraying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com