EFB start-stop battery for PHEV and manufacturing process

A manufacturing process and battery technology, applied in the field of PHEV automobile EFB start-stop battery and manufacturing process, to achieve the effect of improving current density distribution, improving electrochemical performance, and reducing grid internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The embodiments of the present application will be described in detail below with reference to the accompanying drawings and embodiments, thereby using techniques for application techniques to solve technical problems and achieving technology efficacy, and is implemented and implemented.

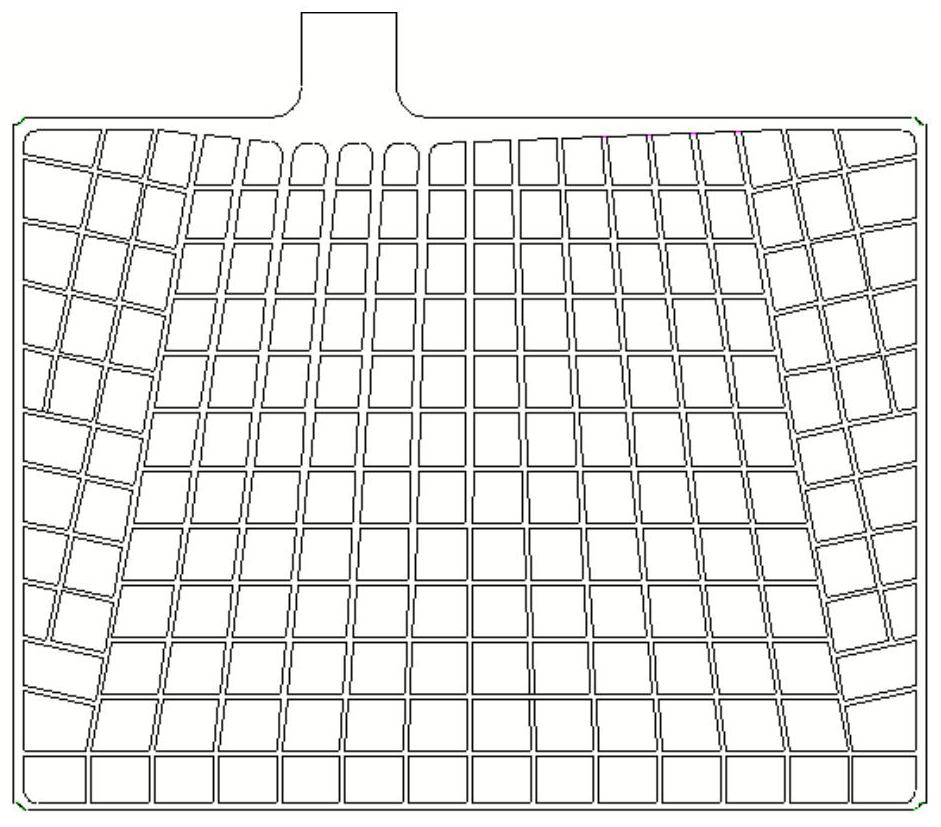

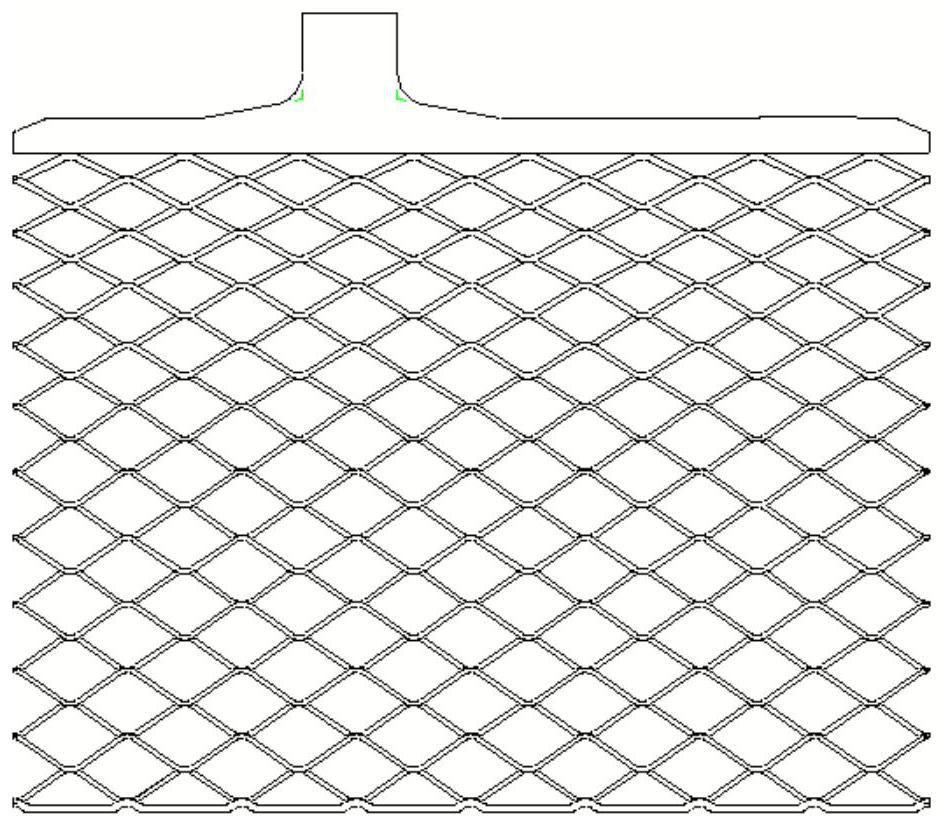

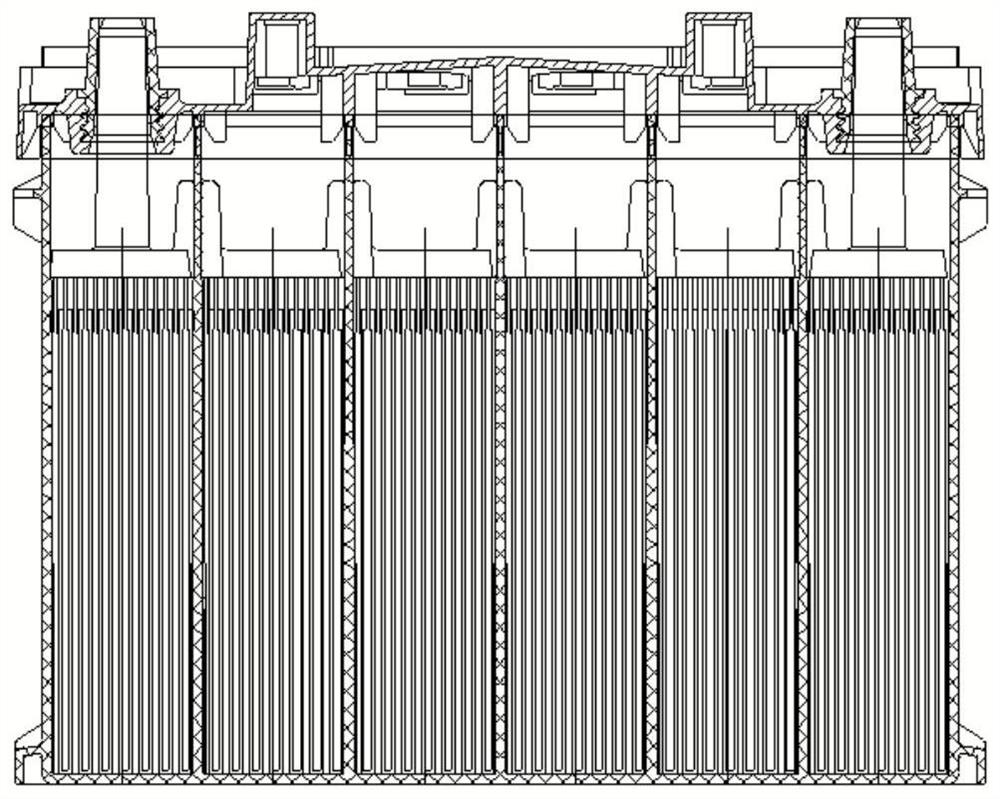

[0033]Figure 1 - Figure 3A PHEV vehicle is used for the present invention, which includes an overall tank that is mounted in a plurality of pole groups in the integral slot and a total tank to serve 1.280 g / ml of acid solution in the overall tank. It consists of alternating positive electrode plates and negative electrode plates, and the surface of the positive electrode plate is applied to the surface of the positive electrode lead paste, and the surface of the negative plate is applied 95g negative electrode lead paste. Such asfigure 1 As shown, the positive electrode plate is designed with a junking radioactive structure, and the rib is thick and thin, and is radiated, and the rib is stagg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com