Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve charge reception capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super battery consisting of plumbic acid capacitance and preparation method thereof

InactiveCN101728090AImprove charge reception capabilityImproved high-current discharge characteristicsHybrid capacitor electrolytesElectrolytic capacitorsActivated carbonCapacitance

The invention discloses a super battery consisting of plumbic acid capacitance and a preparation method thereof. The super battery comprises a positive plate and a negative plate; a grid of the negative plate is used as a current collector; and 1 to 90 percent of lead plaster in the negative plate of the conventional plumbic acid battery is replaced by active carbon. The invention also discloses a preparation method for the negative plate. The charge receiving capability of the plumbic acid battery of the invention is greatly enhanced, the high-current discharge property is remarkably improved, the water loss of the plumbic acid battery is obviously reduced, and the corrosion of the lead grid of the plumbic acid battery is obviously reduced; the service life is averagely increased by over 80 percent, and the volumetric specific energy reaches 100Wh / l; and the using amount of lead is reduced by 10 to 50 percent, and the consumption of the lead is greatly reduced.

Owner:湖南科力远高技术集团有限公司

Matching and sorting method for lead-acid storage batteries

ActiveCN103560278AImprove cycle lifeImprove uniformitySecondary cells charging/dischargingLead-acid accumulators constructionState of artCharge discharge

The invention provides a matching and sorting method for lead-acid storage batteries and aims to solve the problems in the prior art that the consistency of storage batteries in a storage battery pack is poor and the service life is short. According to the matching and sorting method, sorted storage battery plates are assembled and sorted storage batteries with similar capacities and open-circuit voltage are matched to form one group by adopting a quantitative acid adding manner. The cycle life of the storage battery pack is obviously prolonged, the initial capacity of the storage battery pack is improved by 5%, and the charging receiving capability and the low-temperature performance of the storage battery pack are obviously enhanced. According to the matching and sorting method, the defects that the cycle life of the batteries is short and the consistency of the storage battery pack is poor are overcome; the batteries are suitable for being subjected to charge-discharge cycles under various environment temperatures so that the cycle life of the batteries is prolonged to be more than 500 times.

Owner:CHAOWEI POWER CO LTD

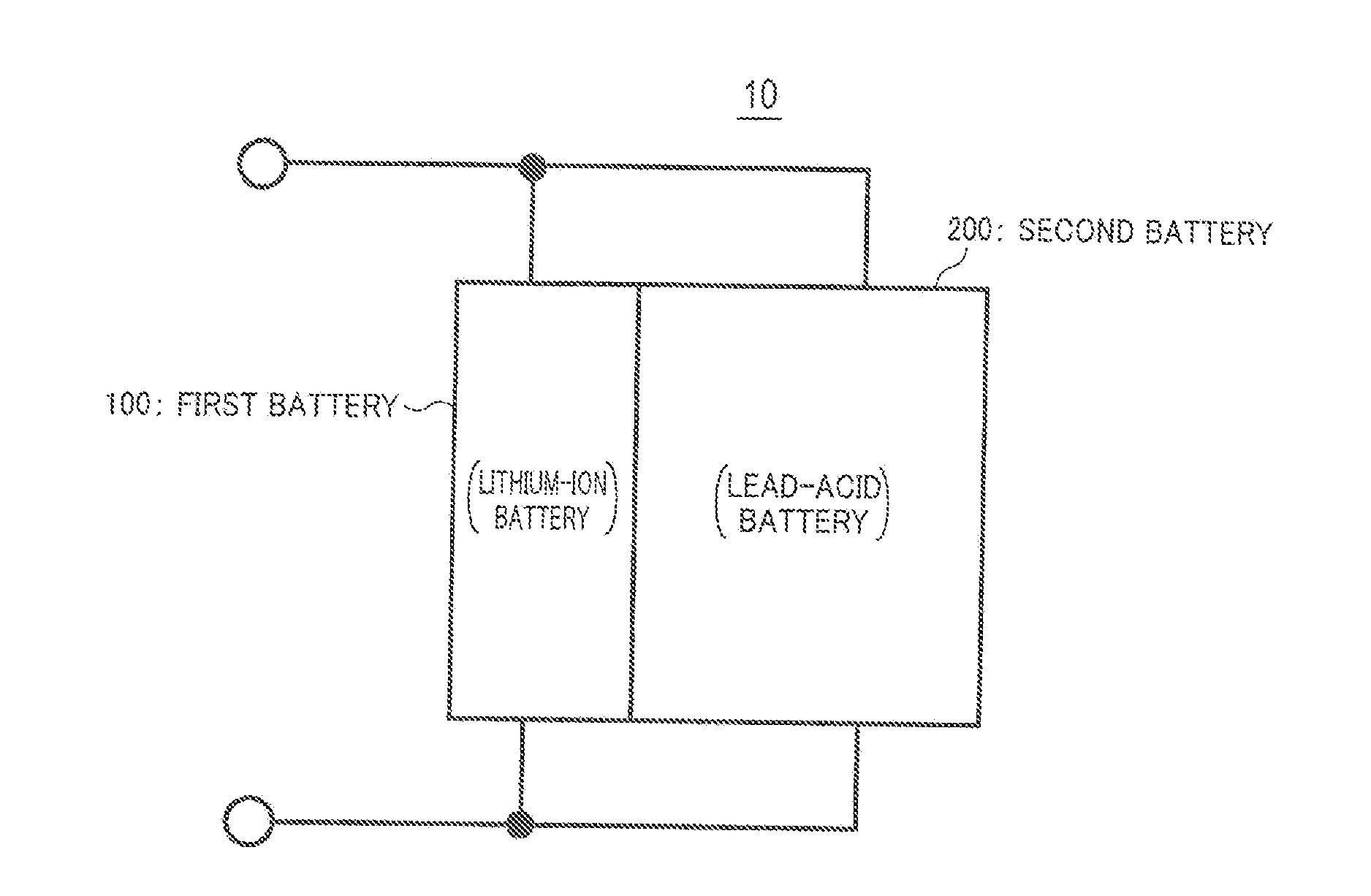

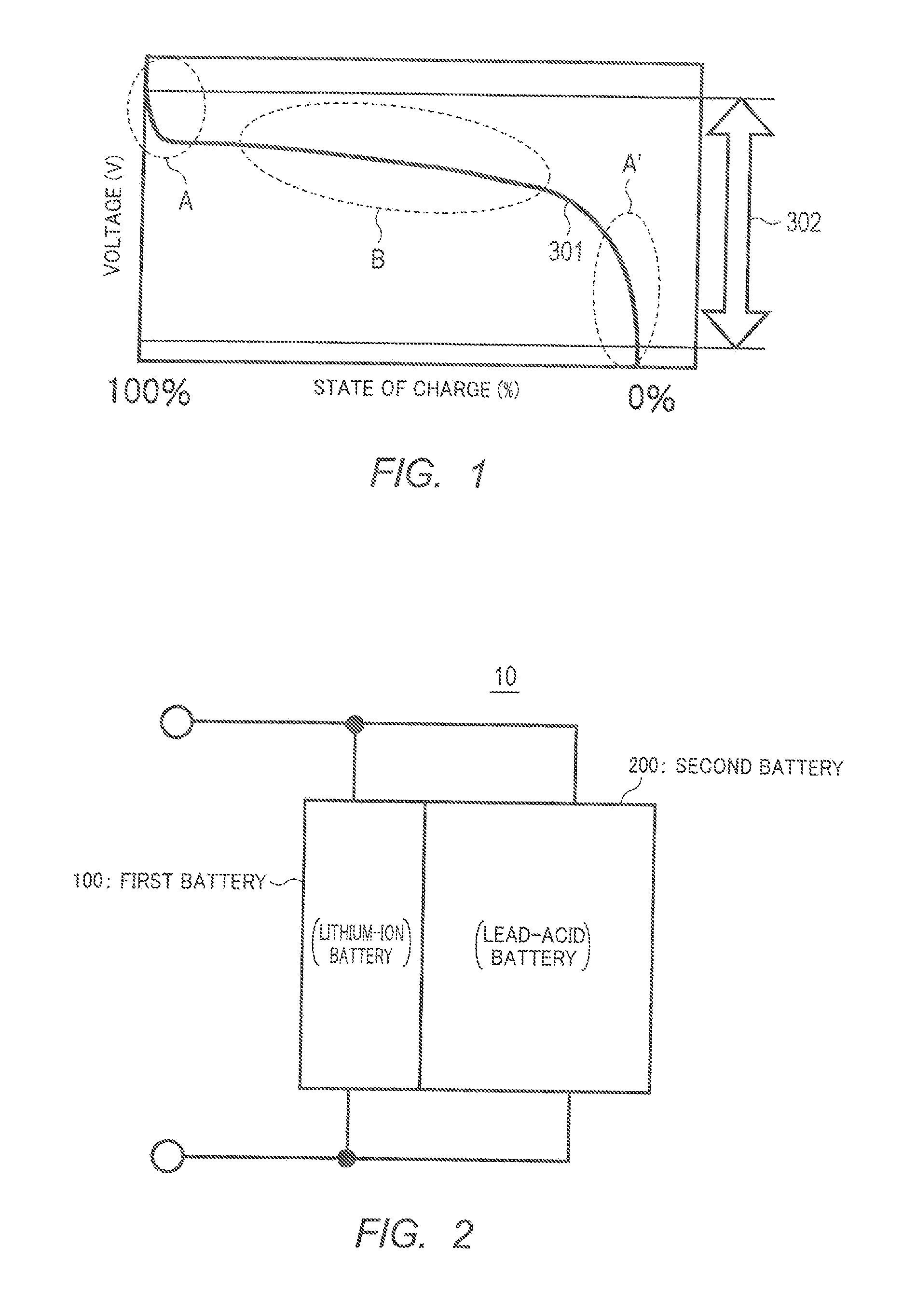

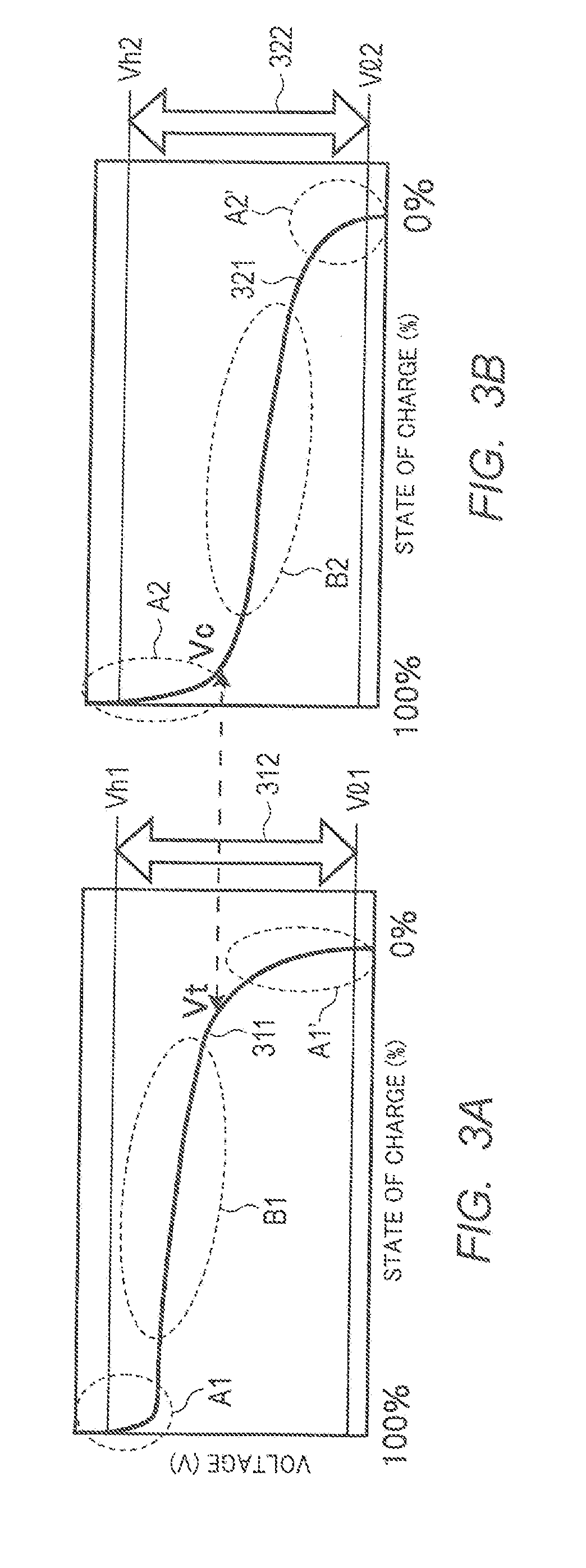

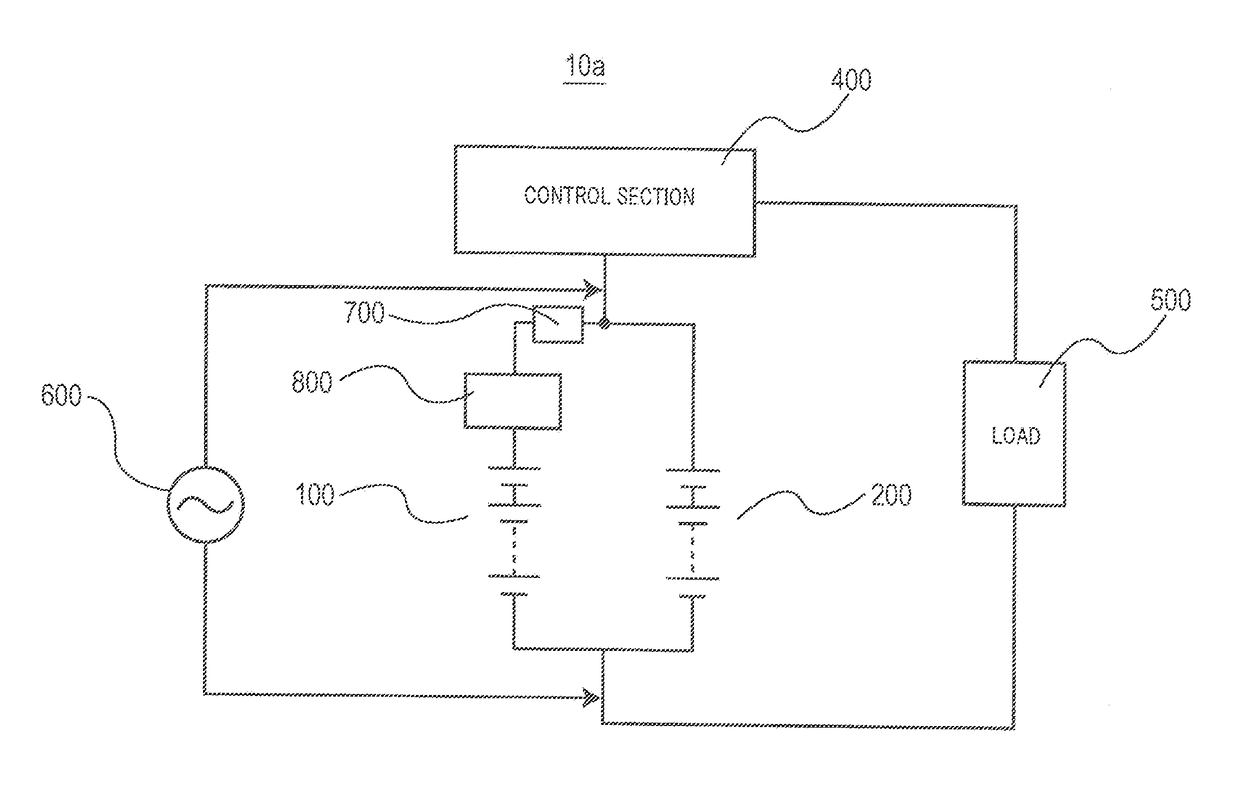

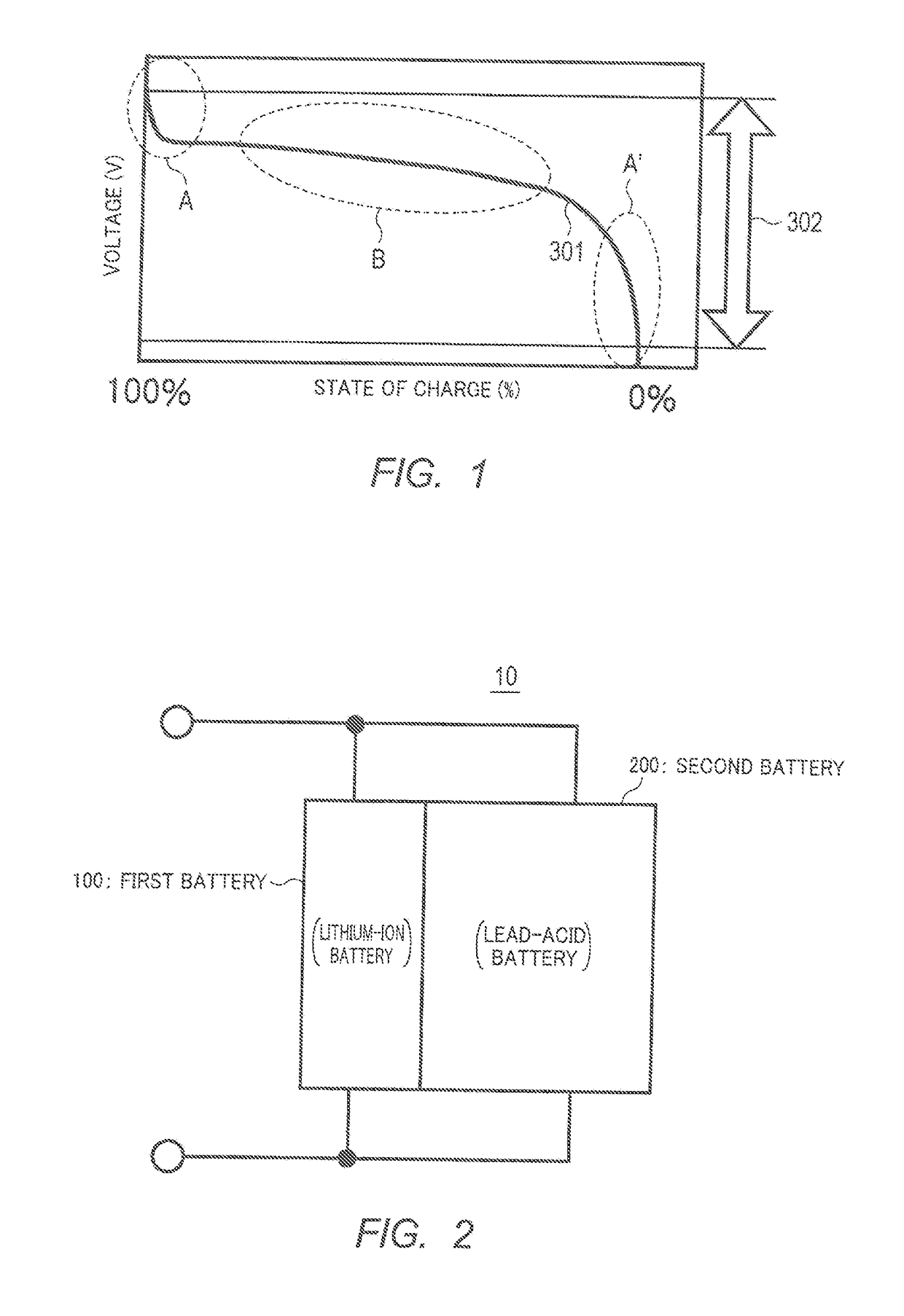

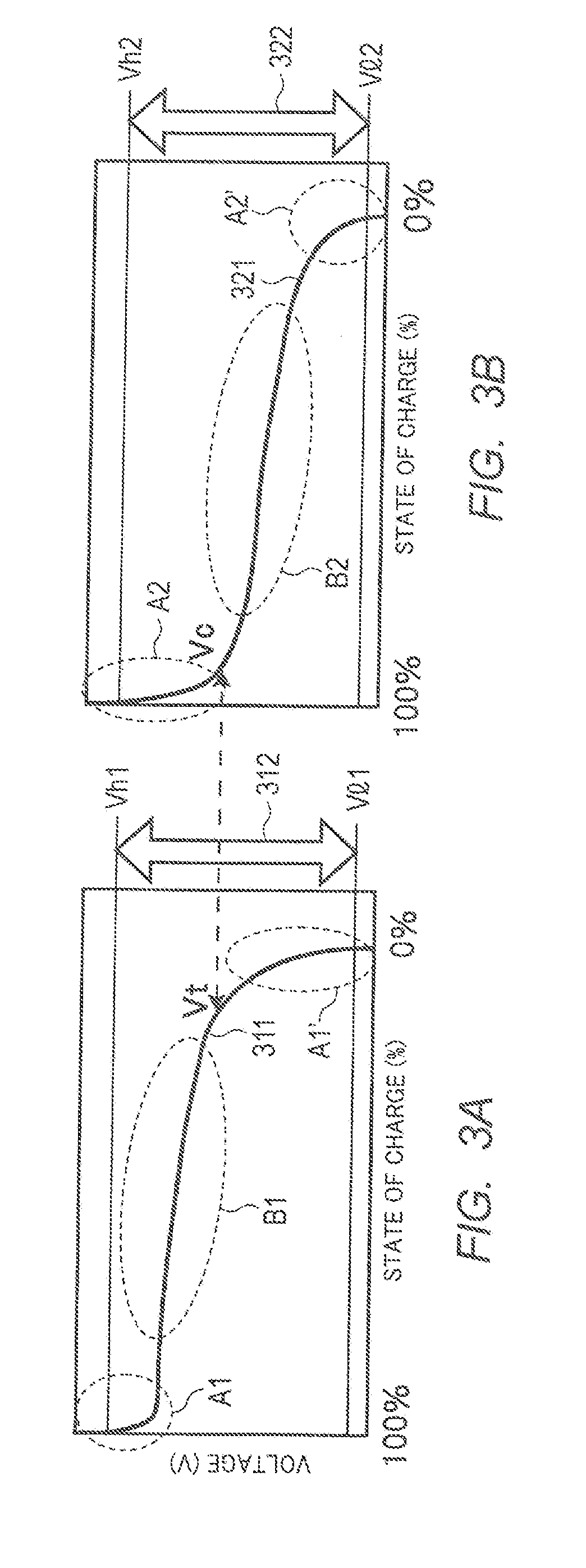

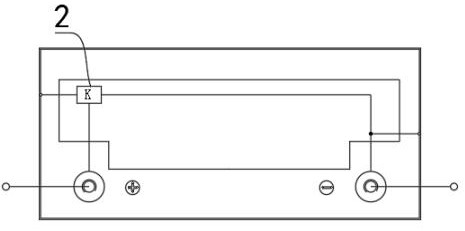

Battery system

ActiveUS20160049814A1Increase capacityImprove charge reception capabilityIndicating/monitoring circuitsElectric powerElectrical batteryEngineering

The battery system is a combined system of a first battery and a second battery. The discharging curve (discharging characteristic) (311) of the first battery has a stable region (B1). The discharging curve (discharging characteristic) (321) of the second battery has a stable region (B2) in the range of voltage lower than the voltage in the stable region (B1) of the first battery and also has an unstable region (A2) in the range of voltage overlapping the voltage in the stable region (B1) of the first battery. The first battery and the second battery are connected in parallel so that, in a discharging process, the discharging state of the entire battery shifts from the stable region (B1) of the first battery to the stable region (B2) of the second battery.

Owner:MAMORU AOKI

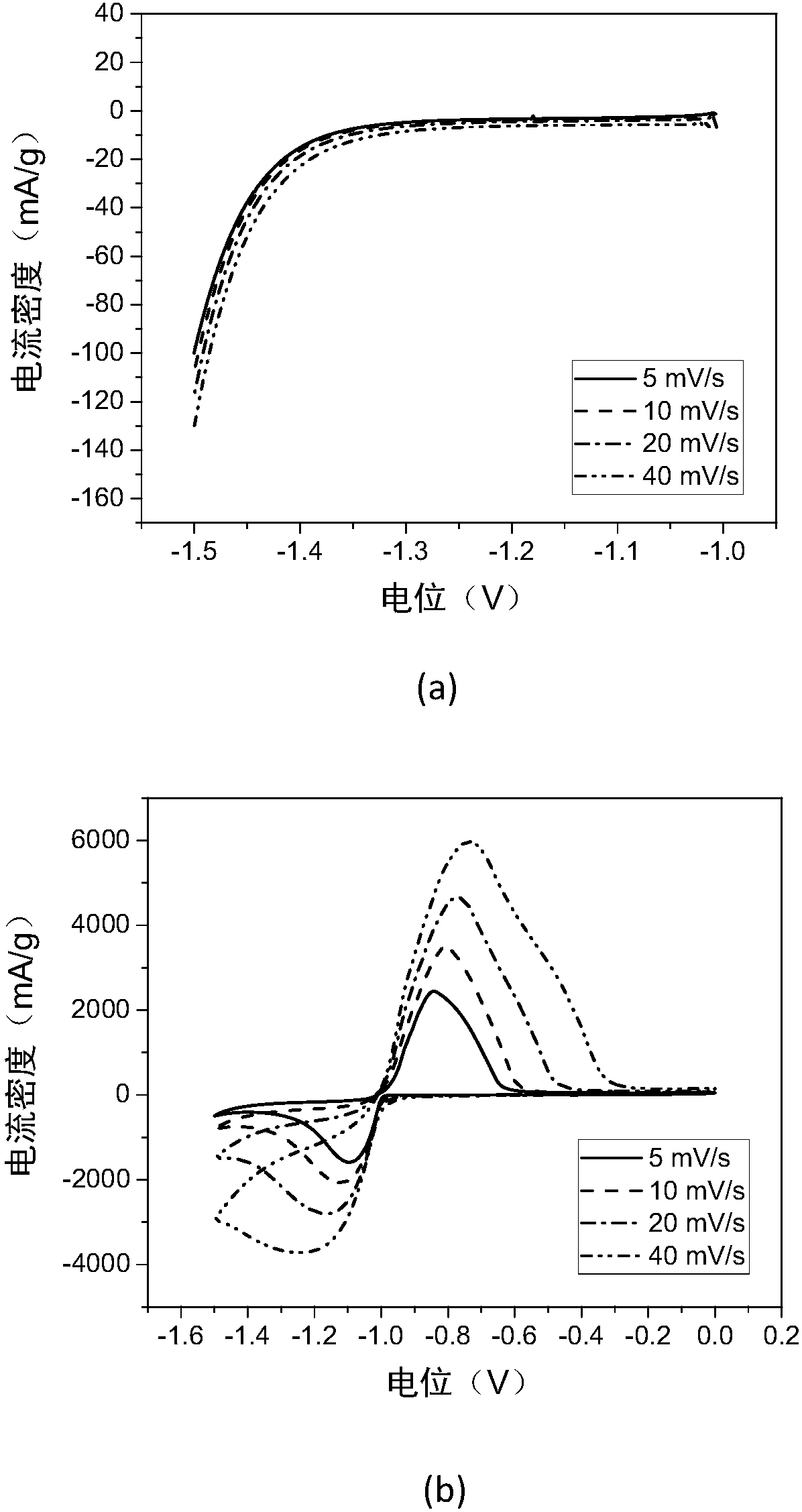

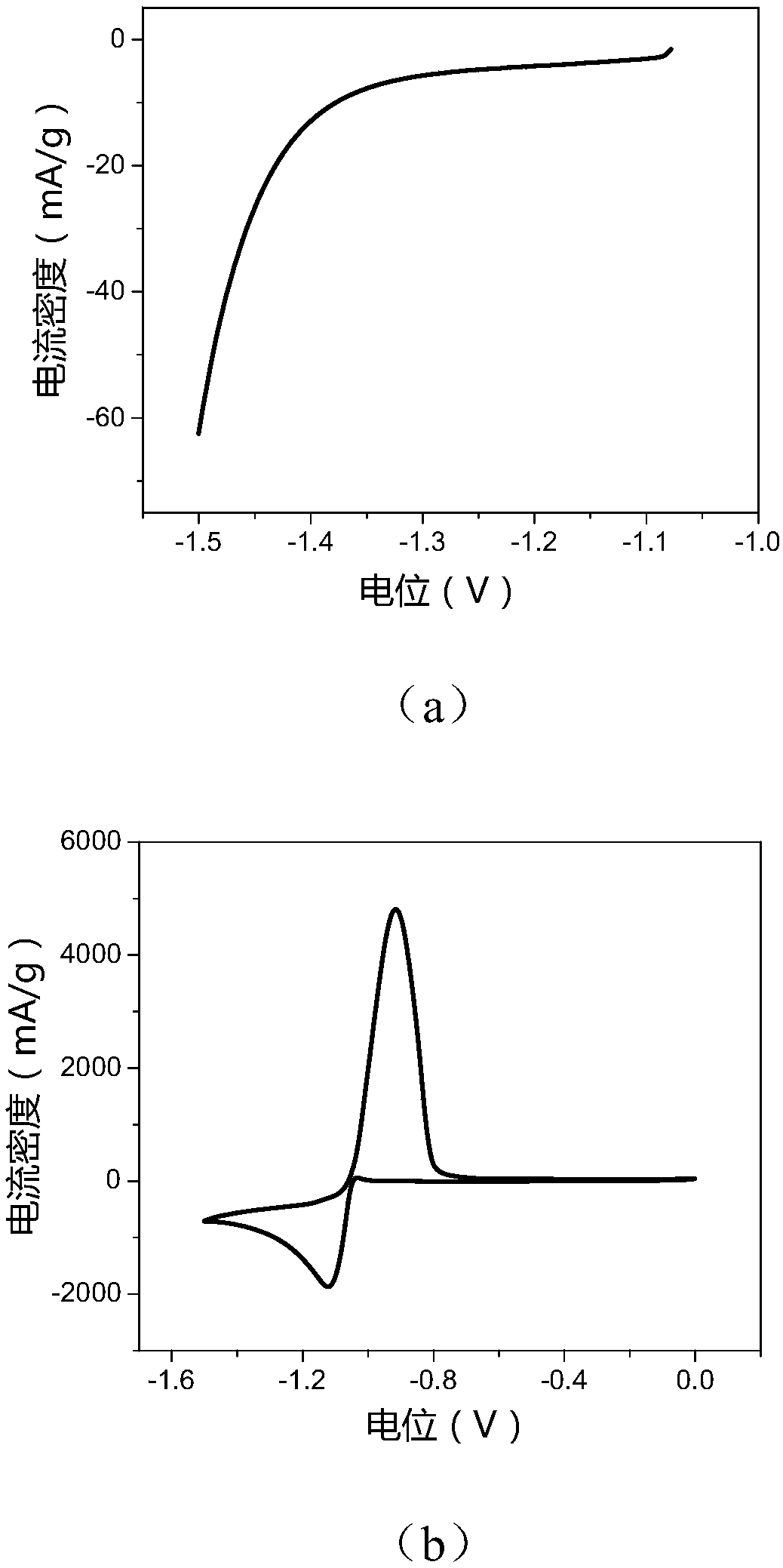

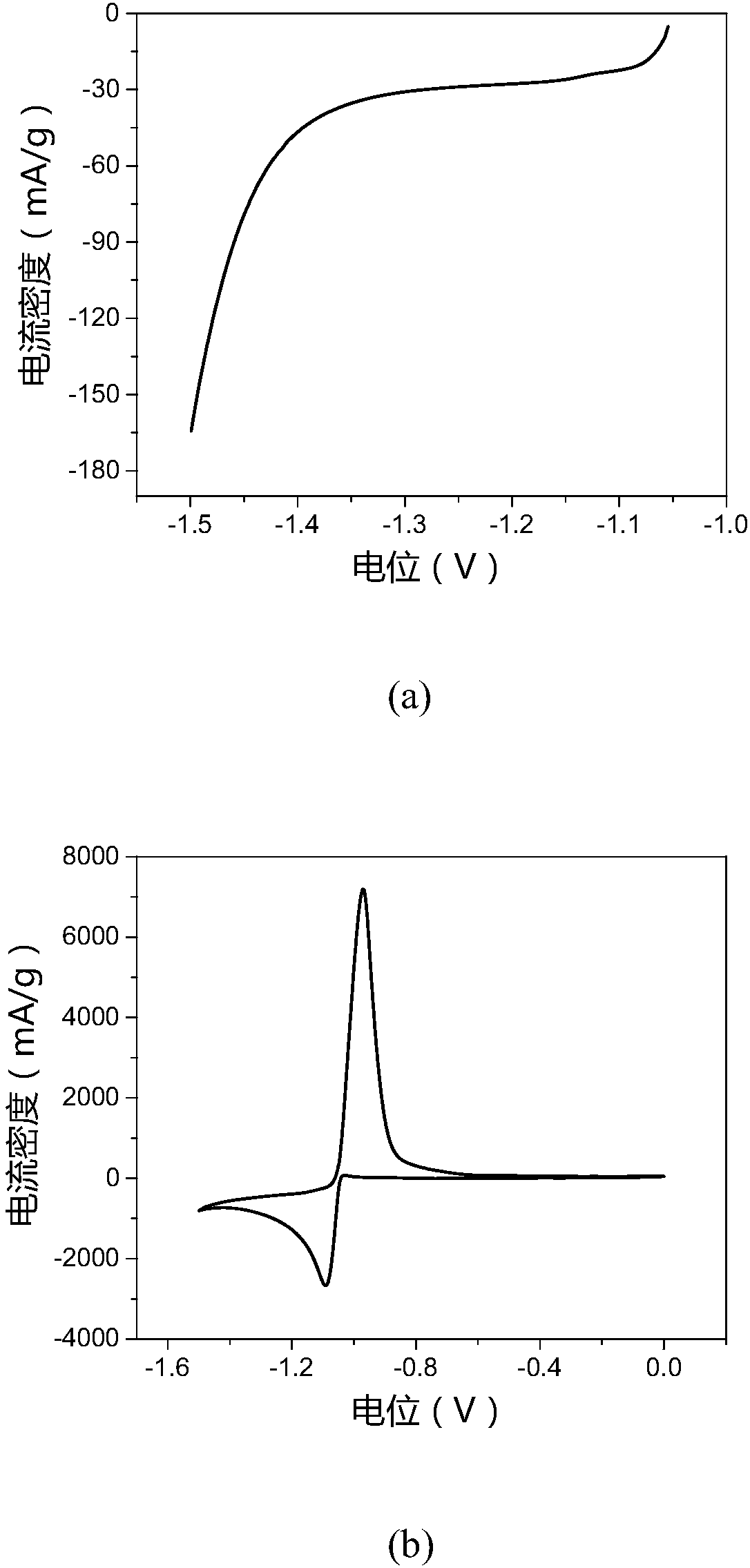

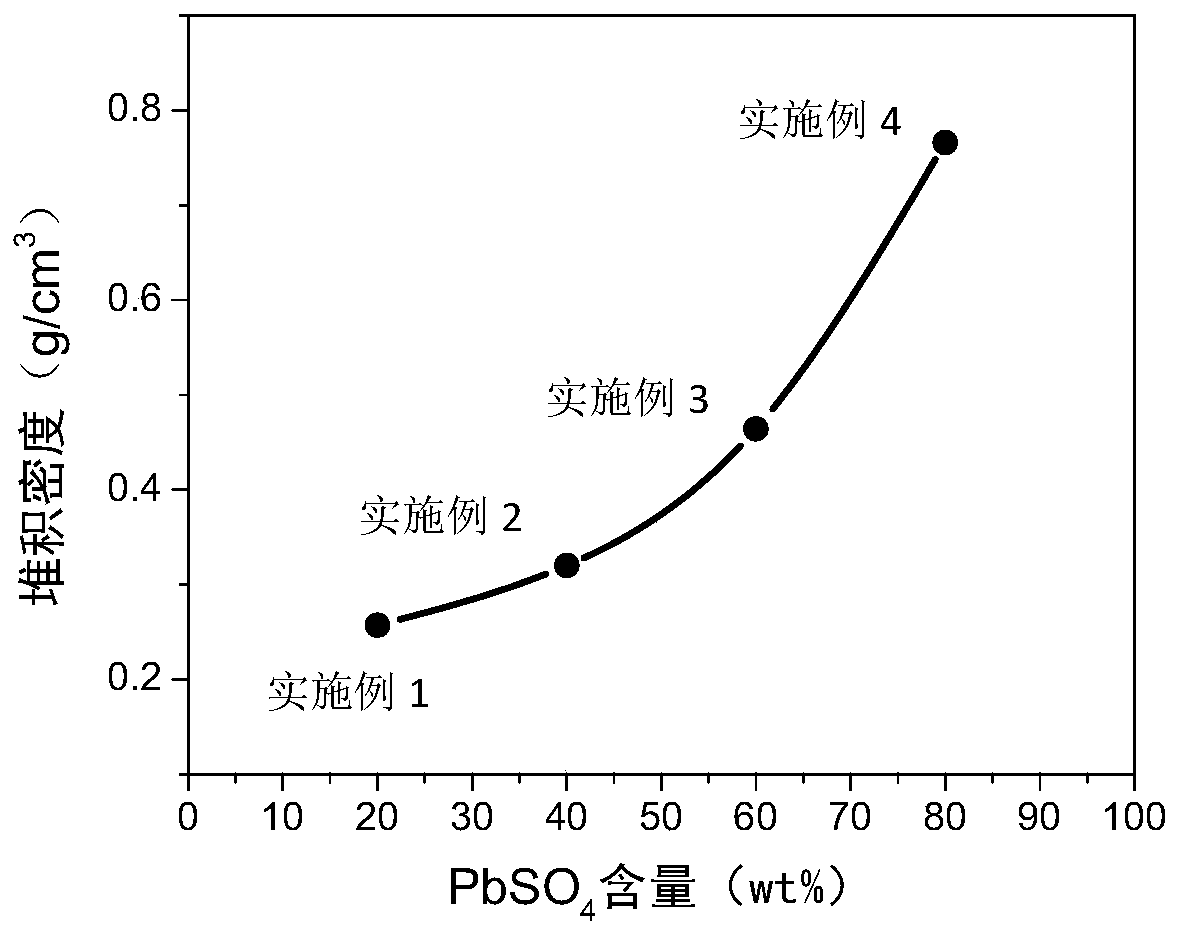

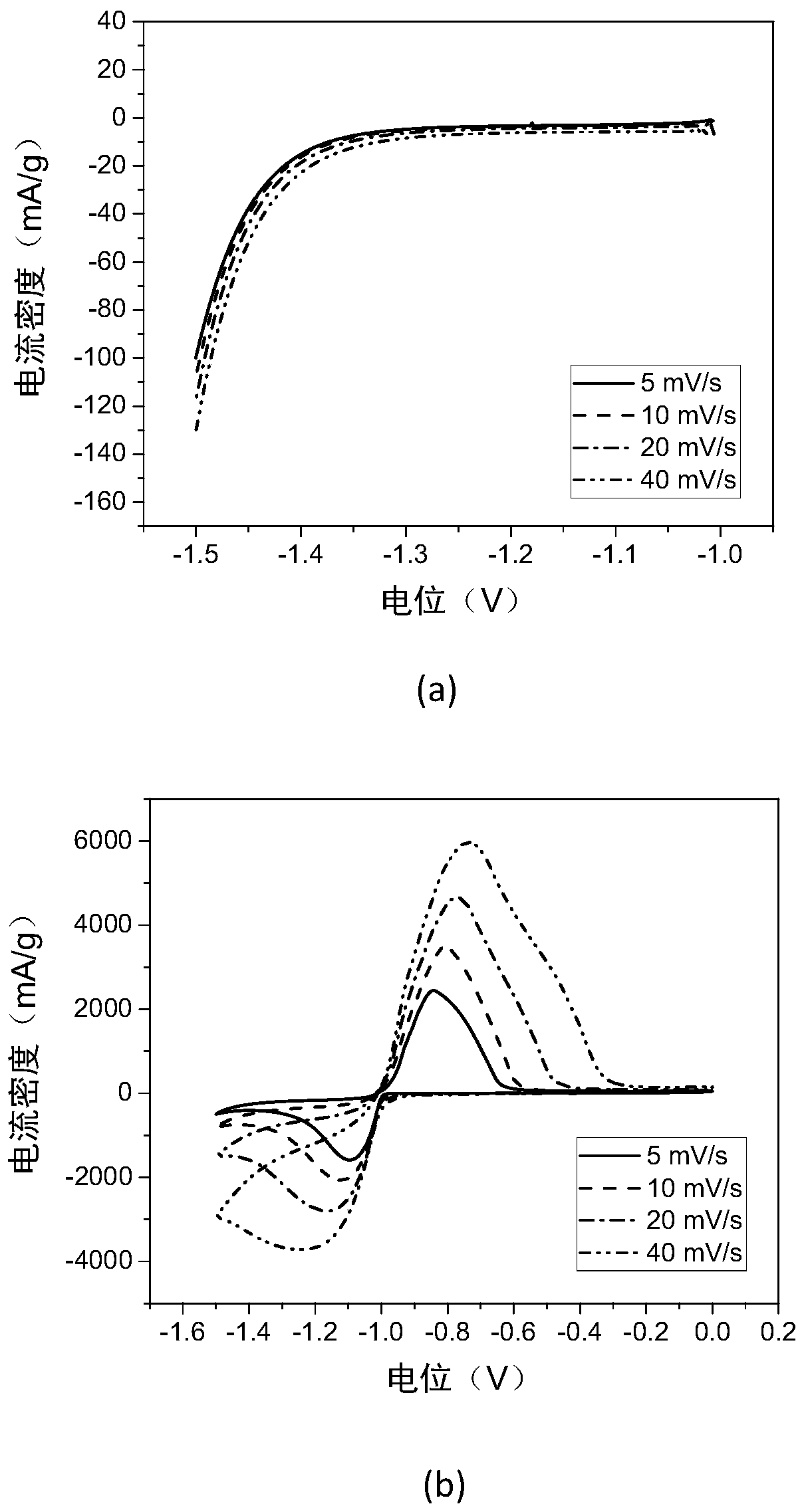

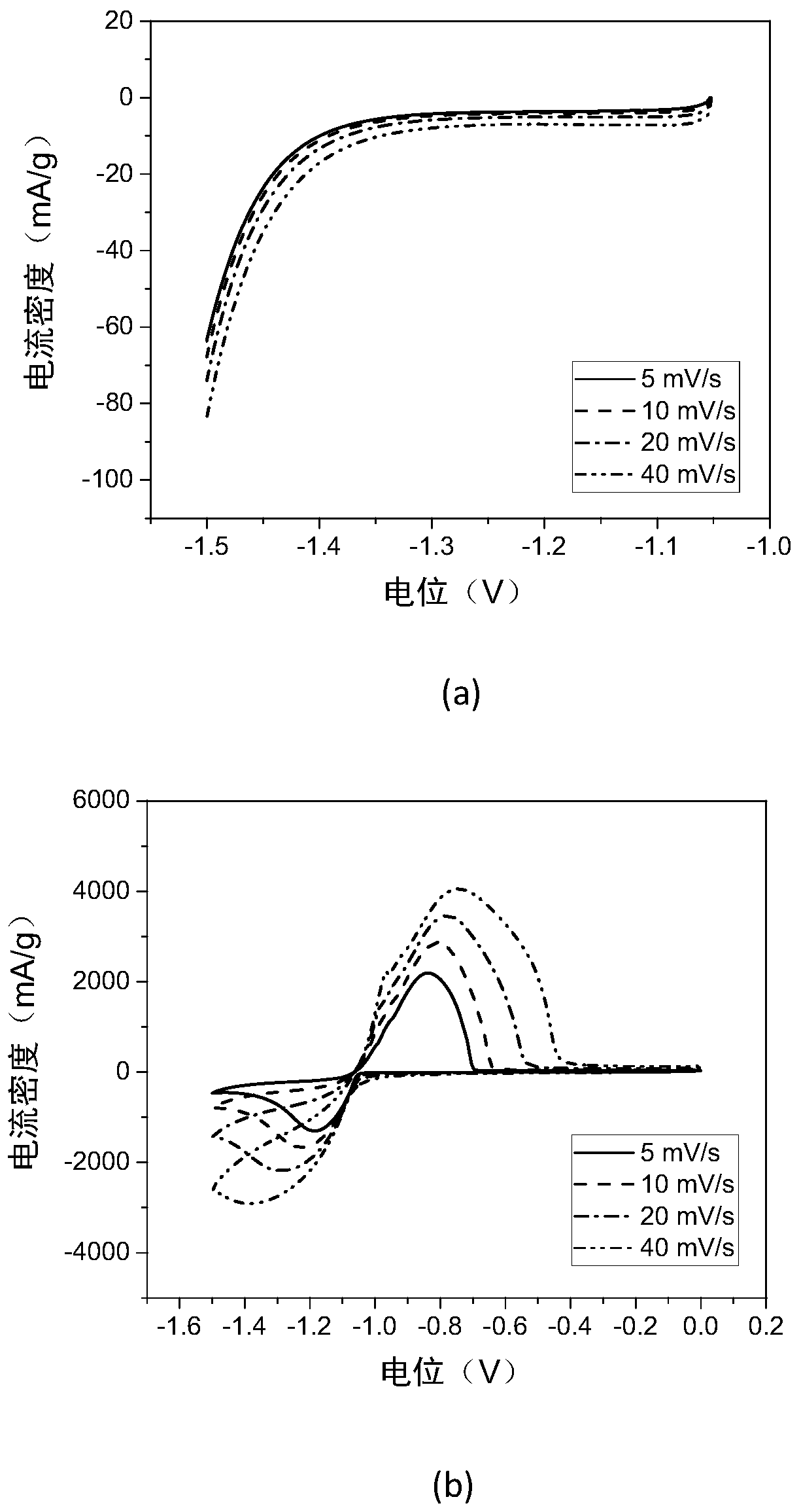

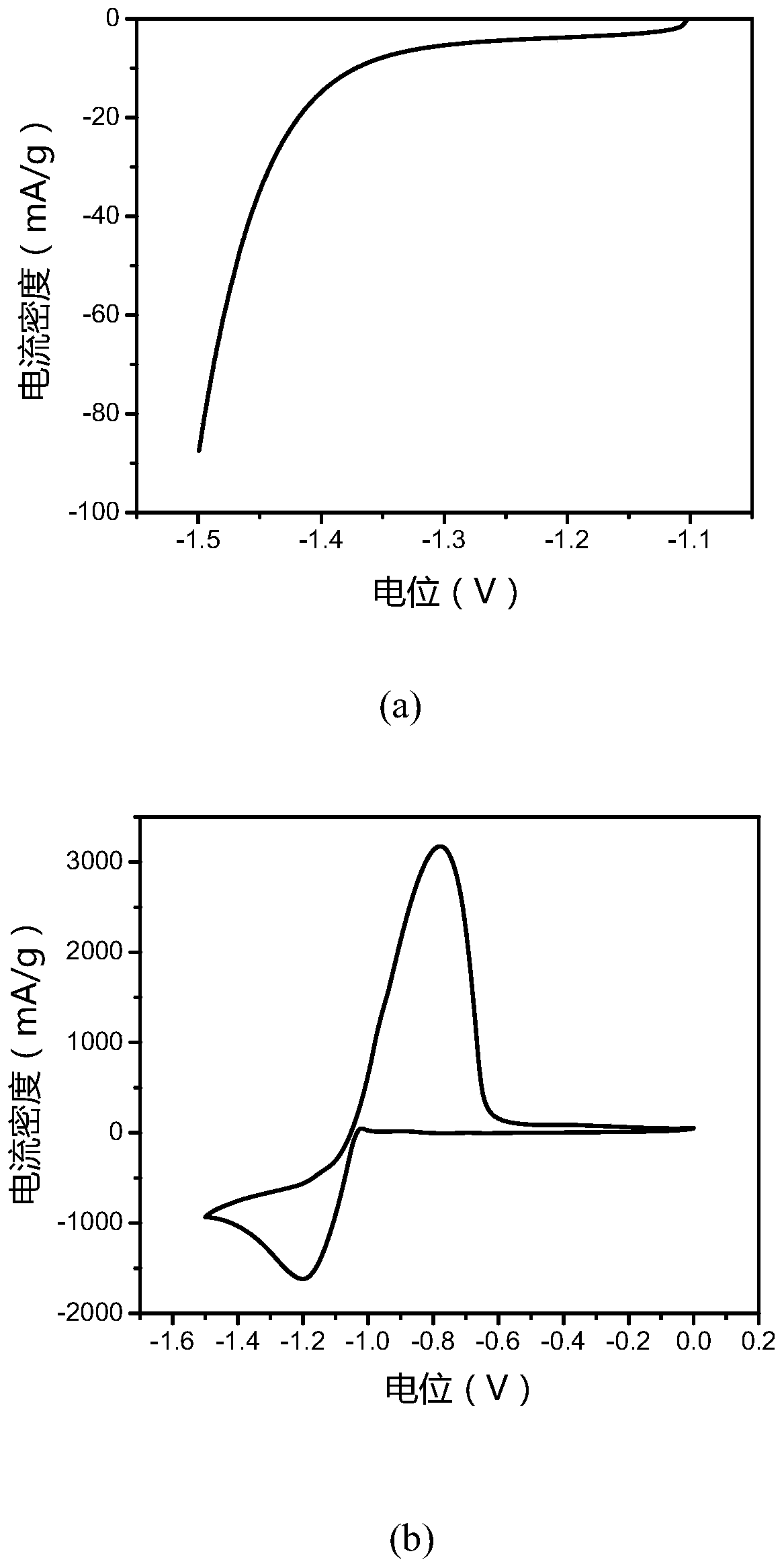

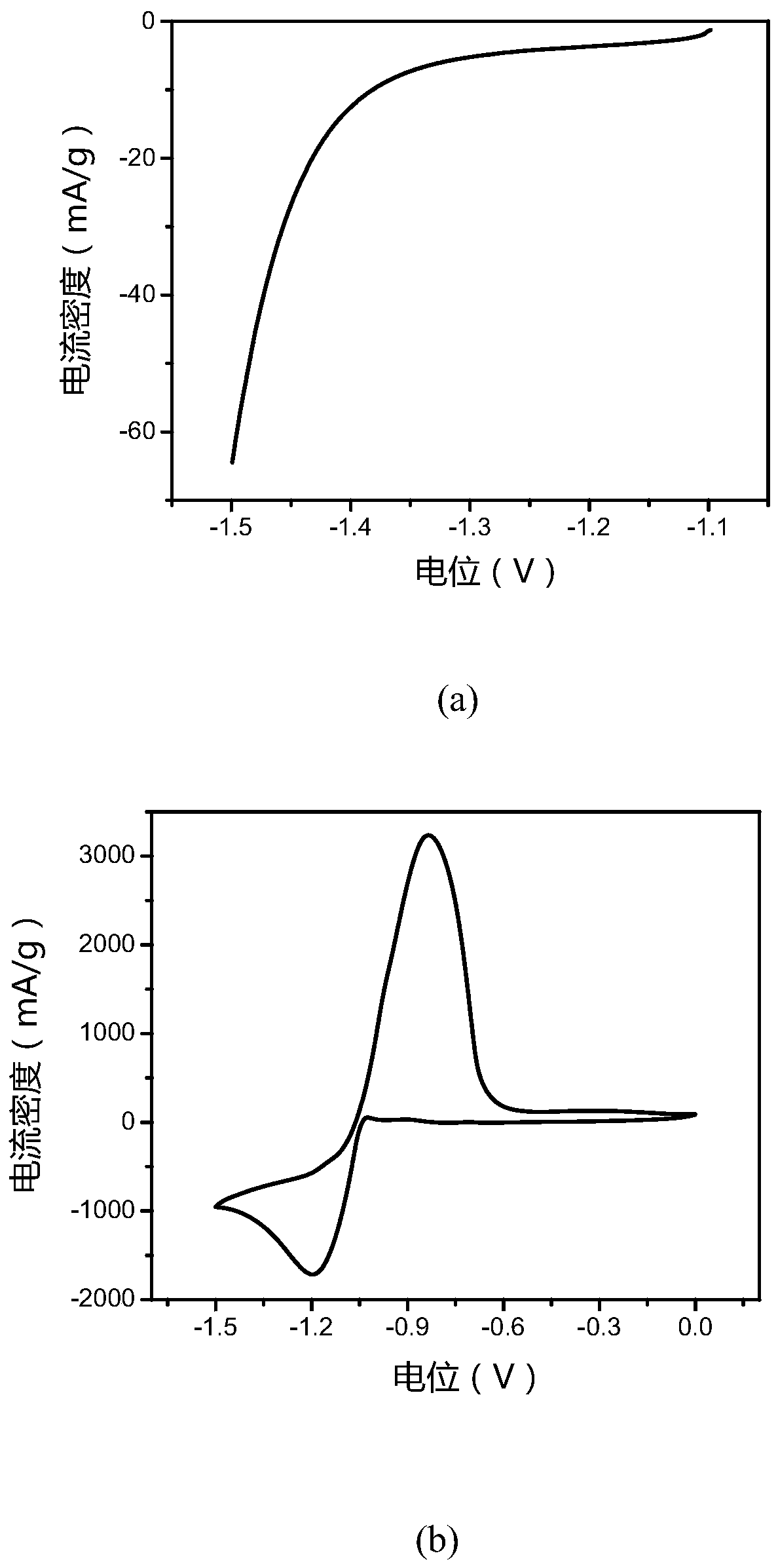

Preparation method for composite negative electrode of lead-carbon battery, and composite negative electrode and application thereof

ActiveCN107845777AImprove performanceHigh bulk densityLead-acid accumulatorsLead-acid accumulator electrodesActivated carbonPorous carbon

The invention relates to a preparation method for a composite negative electrode of a lead-carbon battery, and the composite negative electrode and application thereof. The preparation method comprises the following steps: producing lead sulfate in porous carbon in situ so as to improve the bulk density of a carbon material and reduce the density difference between the carbon material and lead powder; and then uniformly mixing modified activated carbon, lead powder and additives by using a shearing process so as to prepare the high-performance composite negative electrode for the lead-carbon battery. The composite negative electrode for the lead-carbon battery prepared by using the method has higher charge-discharge reversibility, longer charge-discharge cycle life and higher charge acceptance than conventional lead-acid batteries, and is easy to realize large-scale production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

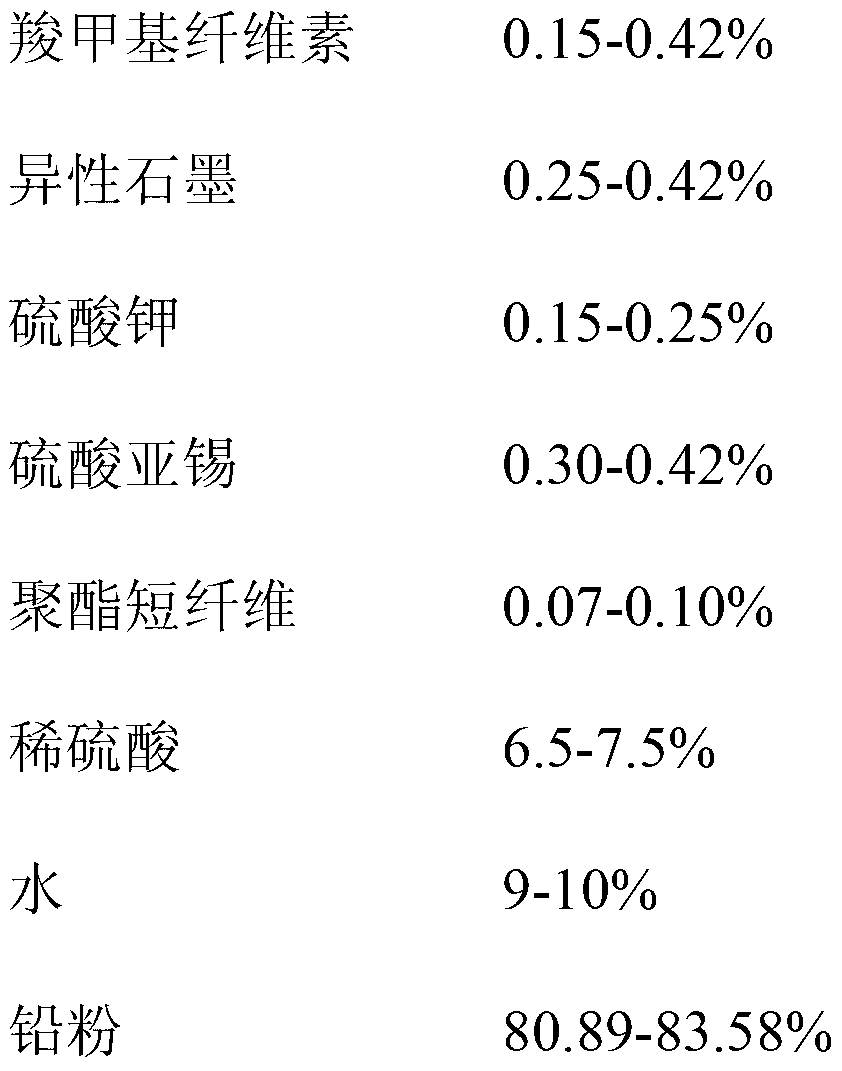

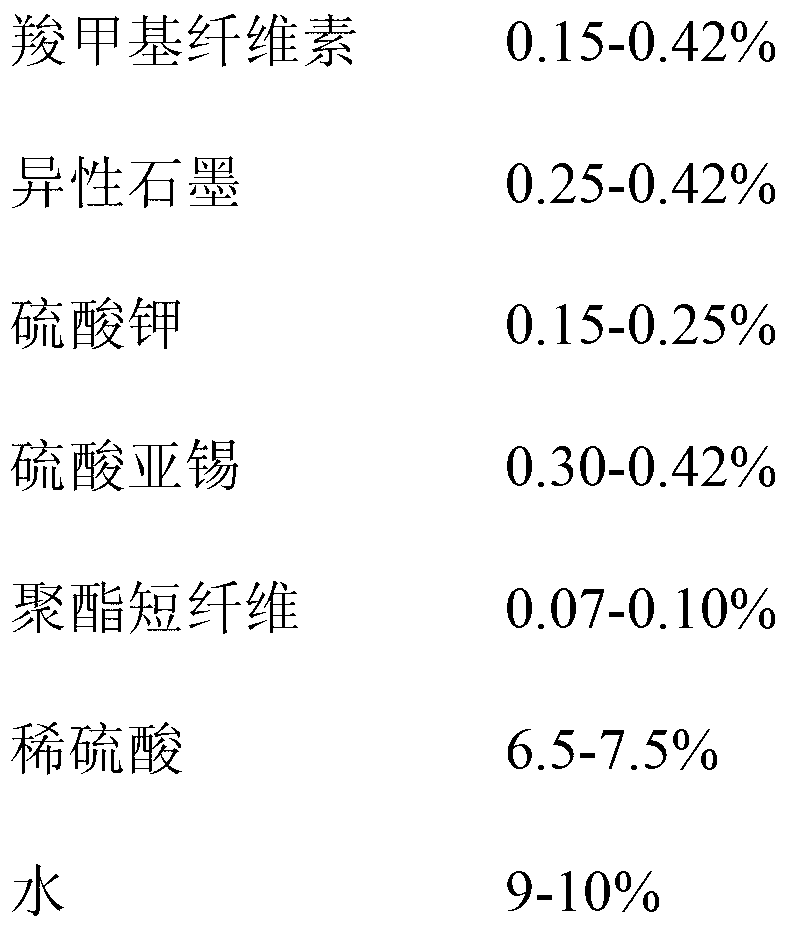

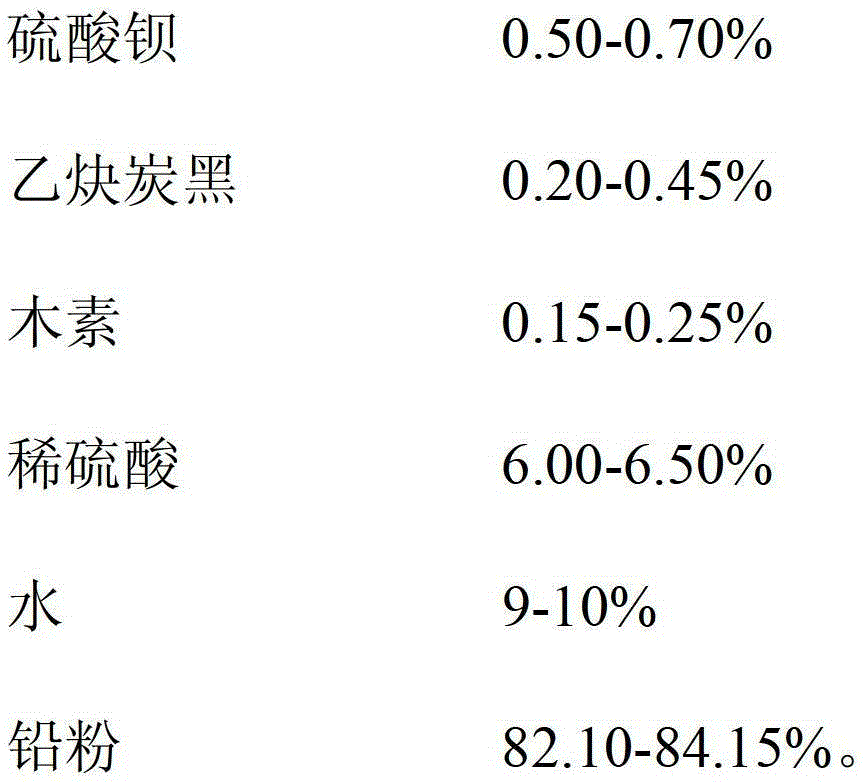

Deep circulation storage battery container formation diachylon

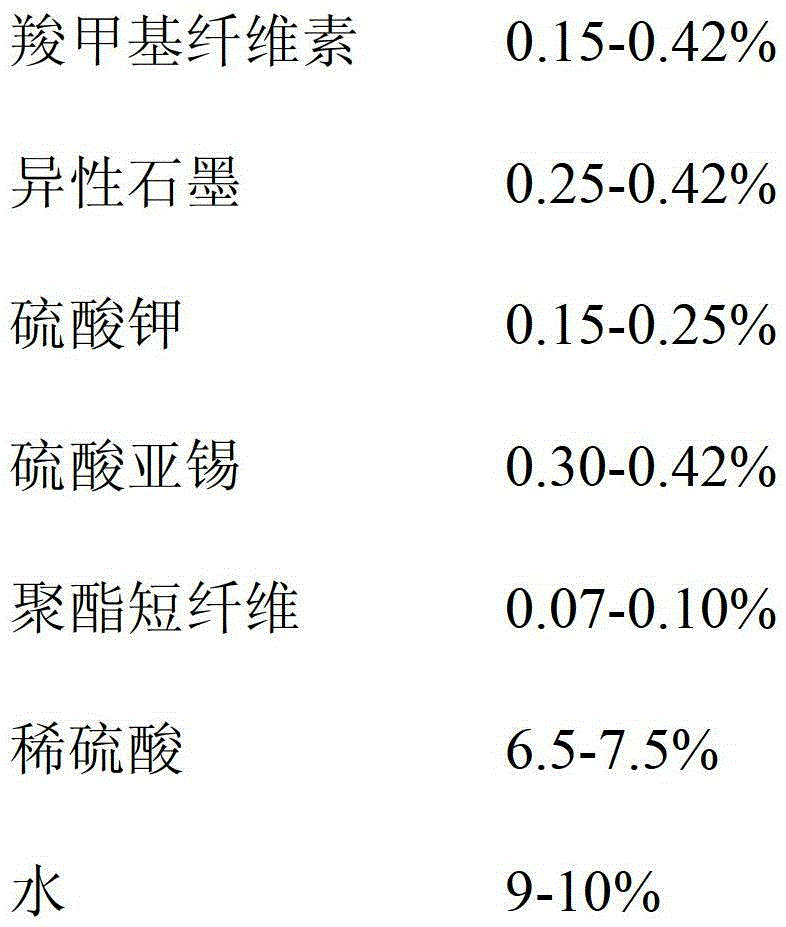

ActiveCN103219512AImprove conductivityImprove charge reception capabilityCell electrodesCarboxymethyl cellulosePolyester

The present invention discloses a deep circulation storage battery container formation diachylon, and is to solve the technical problem of short circulation life of conventional storage batteries. The diachylon of the present invention includes a positive diachylon and a negative diachylon. The positive diachylon includes the components by weight: 0.15-0.42% of carboxymethyl cellulose, 0.25-0.42% of anisotropy graphite, 0.15-0.25% of potassium sulfate, 0.30-0.42% of stannous sulfate, 0.07-0.10% of polyester staple fibers, 6.5-7.5% of dilute sulfuric acid, 9-10% of water, and 80.89-83.58% of a lead powder; and the negative diachylon includes the components by weight: 0.50-0.70% of barium sulfate, 0.20-0.45% of acetylene black, 0.15-0.25% of lignin, 6.00-6.50% of dilute sulfuric acid, 9-10% of water, and 82.10-84.15% of a lead powder.

Owner:CHAOWEI POWER CO LTD

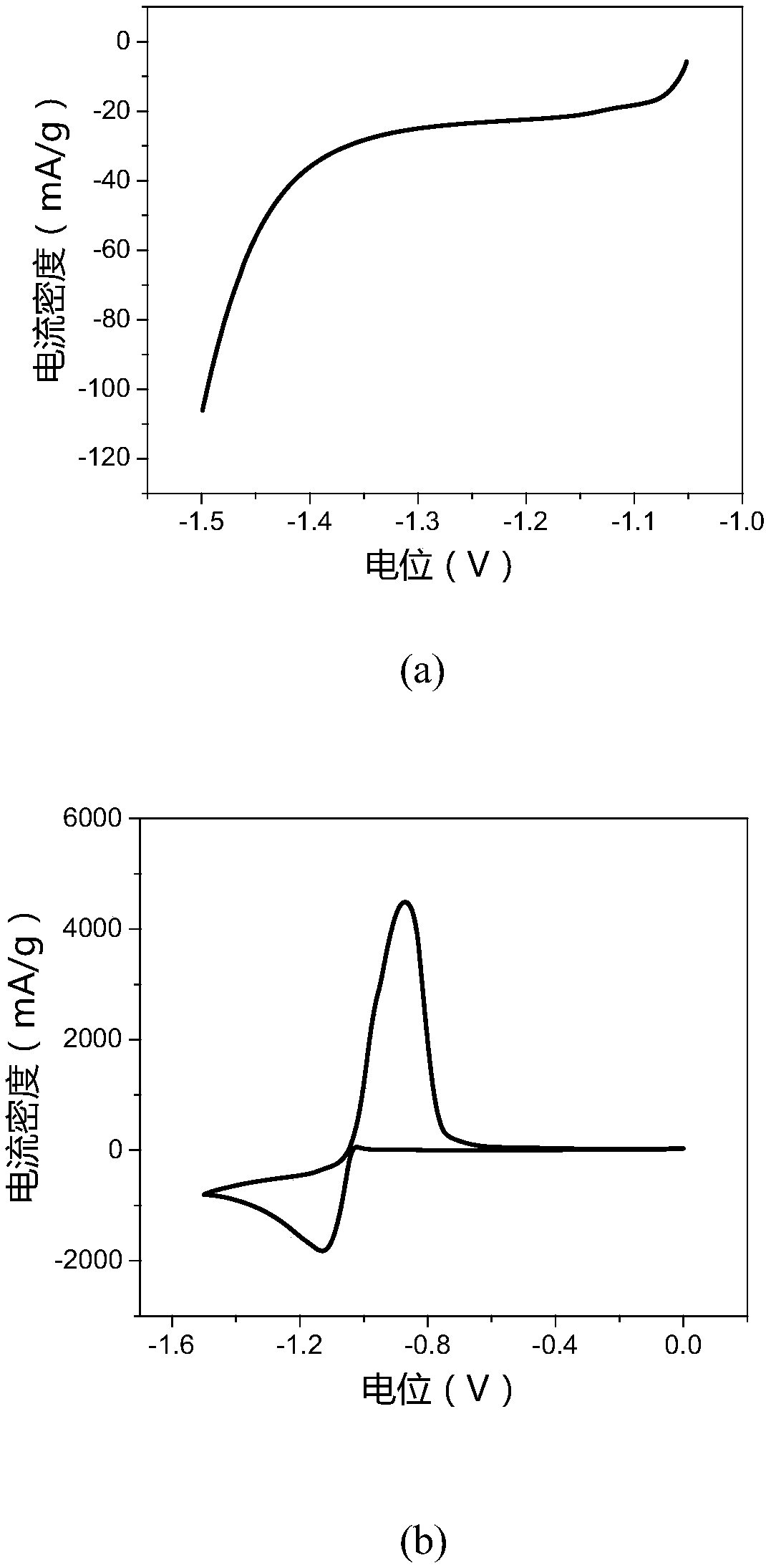

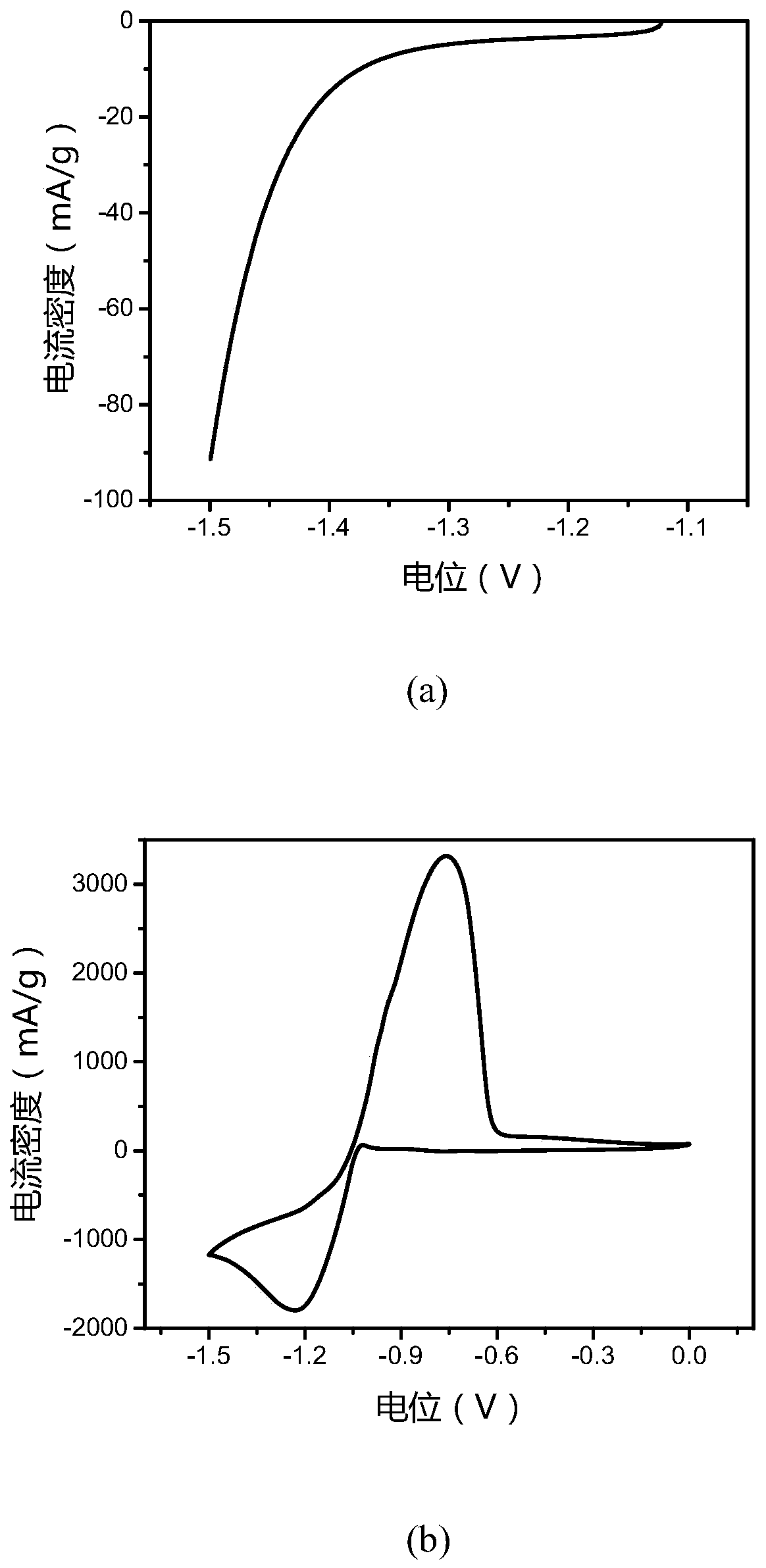

Graphitized active carbon-based composite additive, preparation method and applications thereof

InactiveCN108123103AHigh specific surface areaImprove electronic conductivityElectrochemical generatorsHybrid capacitor electrodesActive carbonCharge and discharge

The invention relates to a graphitized active carbon-based composite additive, a preparation method and applications thereof, wherein the additive is metal-element-containing graphitized active carbonparticles, the carbon particles contain 0.1-50 wt% of carbon with a graphite structure, the specific surface area of the active carbon particles is 100-3000 m<2> / g, the electric conductivity of the active carbon particles is 0.01-100 S / cm, the metal element is one or more than two selected from Sn, Pb, Bi, Ce, In and Zn, and the metal element content in the additive is 0.01-30 wt%. According to the present invention, the lead-carbon battery negative electrode prepared by using the graphitized active carbon as the additive has advantages of high charge and discharge reversibility, high chargeand discharge cycle life and high charge acceptance compared to the conventional lead acid battery negative electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

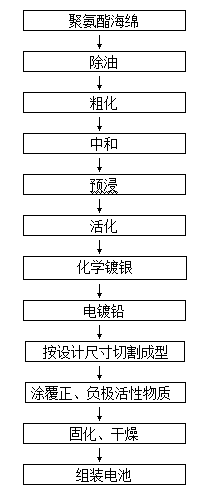

Manufacturing method of lead-carbon battery used for pure electric vehicle

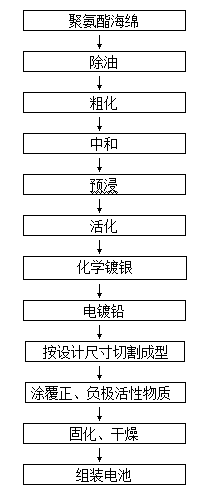

InactiveCN102916227AHigh mechanical strengthLow mechanical strengthFinal product manufactureElectrode carriers/collectorsElectrical batteryElectric cars

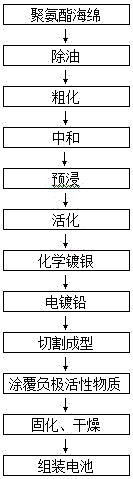

The invention relates to a manufacturing method of a lead-carbon battery used for a pure electric vehicle. The manufacturing method of the lead-carbon battery is characterized in that the manufacturing method comprises the following steps: step 1) orderly removing oil of polyurethane sponge, coarsening, neutralizing, presoaking, activating, and chemically silvering the polyurethane sponge, and finally carrying out electrification and lead plating on the polyurethane sponge to obtain foamed lead material; step 2) cutting and shaping the foamed lead material, respectively coating positive and negative active materials, and adding carbon black into the negative active material to be used as an additive; and step 3), solidifying and drying positive and negative electrode plates, and then assembling the positive and negative electrode plates into a finished battery. The manufacturing method can obviously enhance the performance of the battery.

Owner:WUHAN INTEPOWER CO LTD

High-performance storage battery negative electrode lead paste for renewable energy storage and preparation method thereof

InactiveCN110071286AExtended service lifeImprove charge reception capabilityCell electrodesIonHumic acid

The invention discloses a high-performance storage battery negative electrode lead paste for renewable energy storage, which comprises the following raw materials by weight: 81-82 parts of lead powder, 8-9.5 parts of 1.325 density dilute sulfuric acid, 7.3-8.5 parts of deionized water; 3-5 parts of sodium carboxymethylcellulose, 0.15-0.25 parts of barium sulfate, 0.12-0.22 parts of sodium lignosulphonate, 0.2-0.35 parts of humic acid, 0.1-0.2 parts of carbon black, 0.07-0.12 parts of short-staple, 0.002-0.005 parts of graphite alkene. The invention also provides a preparation method of the high-performance storage battery negative electrode lead paste for renewable energy storage. According to the invention, the charging receiving capacity of the negative plate is improved by adding graphene, the negative plate conversion environment is improved, and the problem that the negative plate cannot be converted due to the generation of coarse lead sulfate crystal particles on the surface ofthe negative plate is avoided, so that the service life of the battery is prolonged, the development requirement is met, and the negative plate is suitable for large-scale popularization.

Owner:ZHAOQING LEOCH BATTERY TECH

EFB start-stop battery for PHEV and manufacturing process

PendingCN112838219ALower internal resistanceImprove density distributionFinal product manufactureElectrode carriers/collectorsElectrical batteryProcess engineering

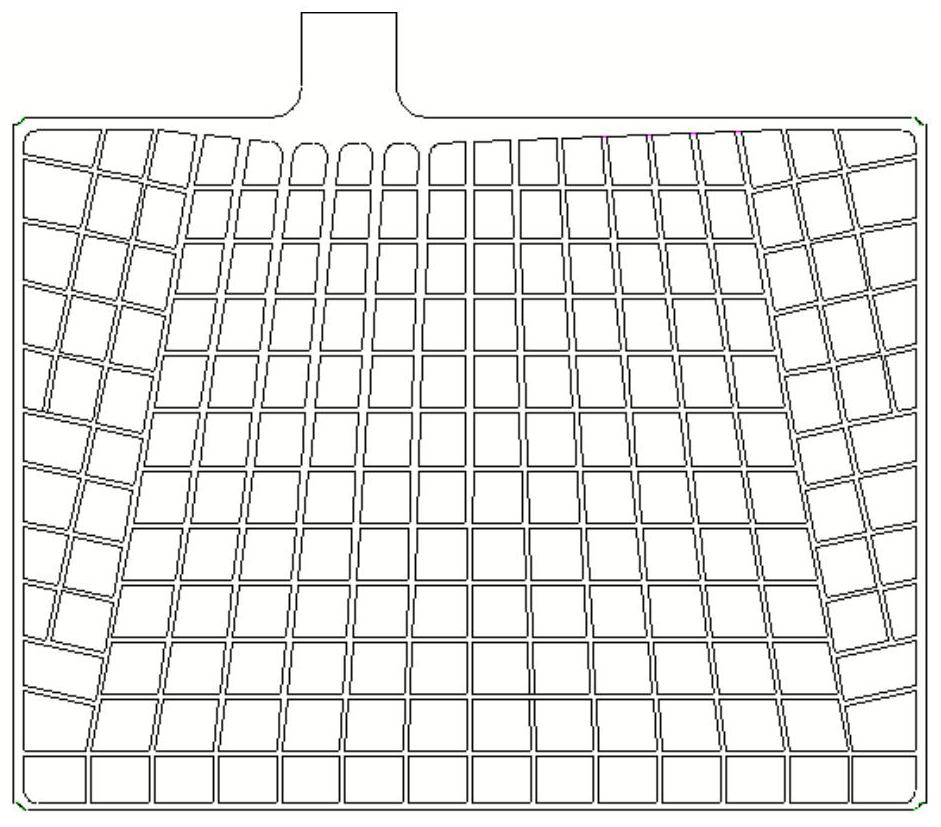

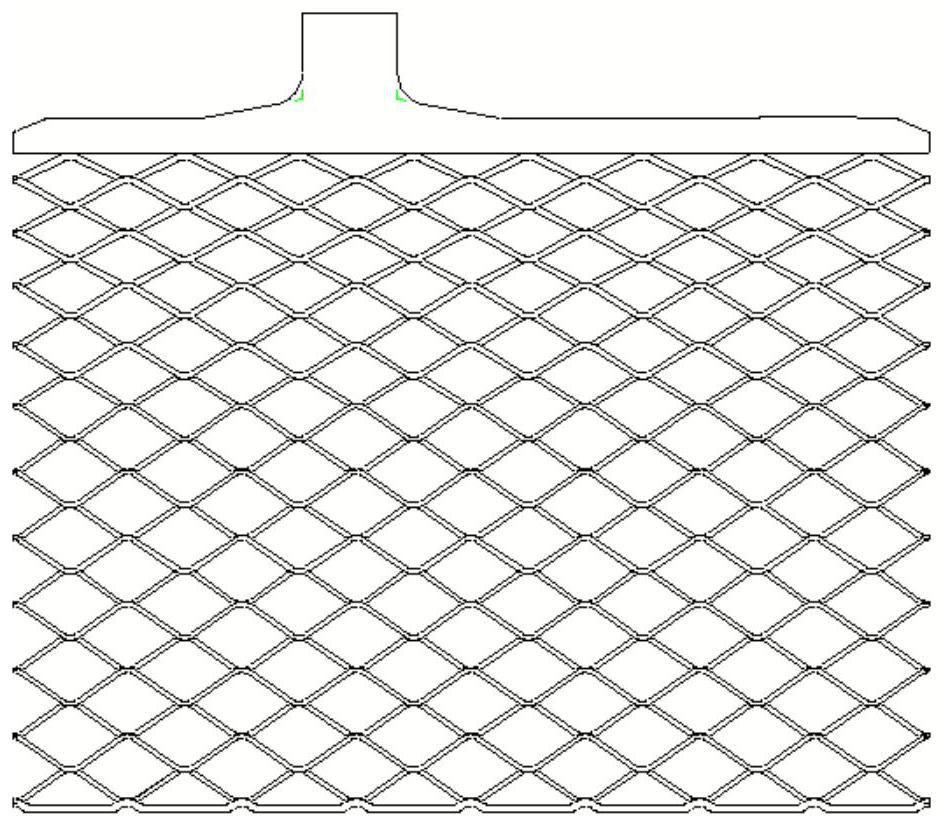

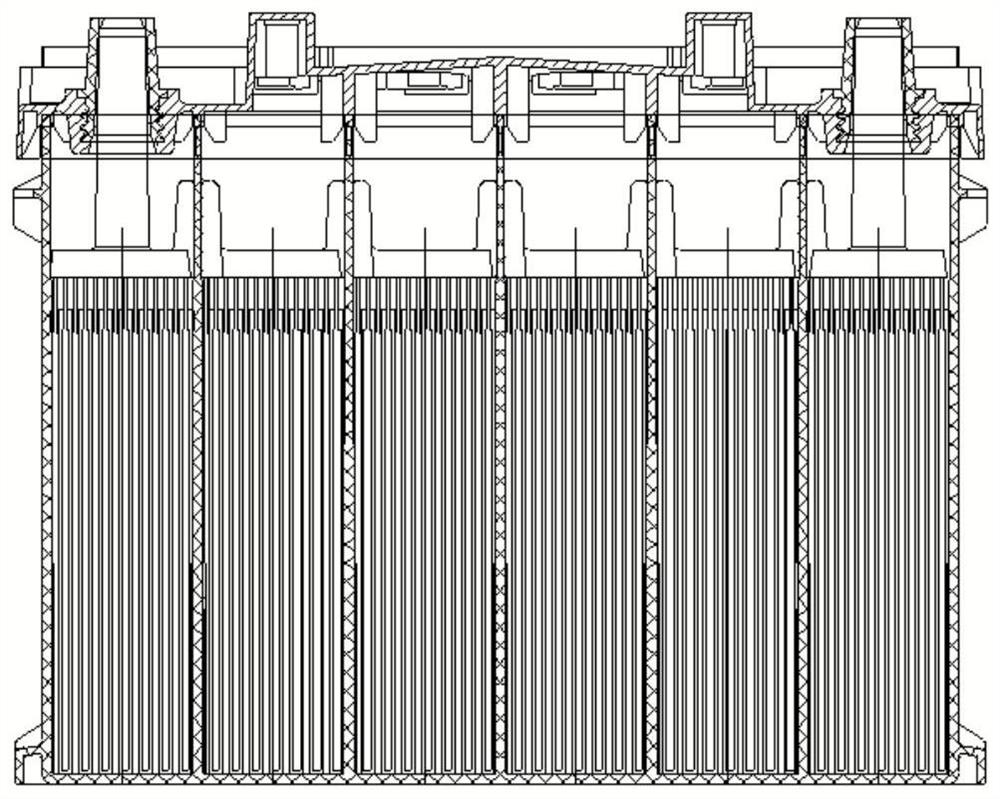

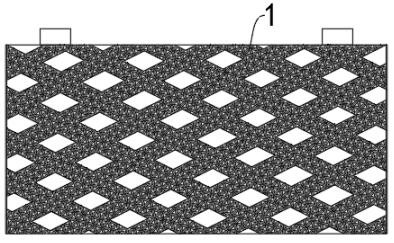

The invention belongs to the technical field of manufacturing of power systems for hybrid electric vehicles, and relates to an EFB start-stop battery for a PHEV and a manufacturing process. The EFB start-stop battery comprises an integral tank, a plurality of plate groups mounted in the integral tank and acid liquor in the integral tank, wherein each plate group consists of a positive plate and a negative plate which are alternately stacked. The positive plate adopts a punching net radioactive structure design, ribs of the positive plate are thick at the upper part and thin at the lower part, are radial and are formed in a staggered manner; the ribs of the negative plate grid are in thickness transition design and are formed in a staggered manner, and the area of grids formed by the staggered ribs is small in top and large in bottom; in the same plate group, the positive plate is encapsulated by a high-strength PE partition plate, the positive and negative tabs are connected in parallel in a cast-weld manner, and all the plate groups are connected in series; and the density of the acid liquor is controlled to be 1.275 to 1.285 g / ml. The deep discharge cycle life of the battery is remarkably prolonged, the charge receiving capability of the battery is remarkably improved, the key technical problem of an EFB start-stop battery for a PHEV automobile is solved, and the invention has great technical improvement value and production and popularization value.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

Storage battery positive electrode lead paste and preparation method thereof

InactiveCN108390040AReasonable ratioIncrease profitLead-acid accumulatorsCell electrodesIonRare-earth element

The invention discloses storage battery positive electrode lead paste, which is prepared from the following raw materials in parts by weight: 60 to 70 parts of lead powder, 15 to 28 parts of regenerated lead powder, 13 to 19 parts of deionized water, 7 to 12 parts of sulfuric acid solution, 1 to 2 parts of polyester staple fiber, 3 to 6 parts of pure graphene, 1 to 2 parts of stannous sulfate, 2 to 4 parts of polyaniline nanometer solution, 0.5 to 1 part of rare-earth elements, 0.3 to 0.7 part of humic acid, 1 to 2 parts of sodium sulfate, 2 to 4 parts of acetylene black and 1 to 3 parts of dispersing agents. The storage battery positive electrode lead paste can effectively solve the problem of fast attenuation of the circulation service life due to insufficient charging and low discharging volume of an existing lead storage battery for an electric bicycle under the low-temperature condition.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Storage battery low-temperature charging and discharging method based on temperature compensation

ActiveCN111682274AAvoid life-shortening conditionsMeet the needs of low temperature and sufficient chargingLead-acid accumulatorsSecondary cells charging/dischargingFloating chargeElectrical battery

The invention discloses a storage battery low-temperature charging and discharging method based on temperature compensation. The method comprises the following steps that 1) when the environment temperature is lower than -10 DEG C during charging and discharging of a battery, a temperature compensation device is started to raise the temperature; (2) in a low-current 0.05-0.1 CA pre-charging judgment stage, charging reaches 0.3-0.4 H, if the voltage of a single battery cell does not reach 2V, the charger gives an alarm to display abnormality, and charging is ended; 3) segmented charging, concretely, in the first stage, the constant current is 0.21-0.24 CA until the voltage of a battery cell is 2.4 V, or the charging time reaches 1-4H; in the second stage, the constant current is 0.1-0.2 CAuntil the single-cell voltage of the battery is 2.45 V or the charging time reaches 3-8H; in the third stage, the current is limited to be 0.01-0.05 CA, the constant voltage of a single cell of the battery is 2.48 V, the current is lower than 0.01, or charging reaches 1-2H; in the fourth stage, the constant current is 0.07-0.08 CA until the voltage of a single cell of the battery is 2.5 V and thecharging time reaches 0.5 H; and in the fifth stage, the voltage of the cell of the battery is limited to 2.29-2.3 V, and the current is limited to 0.005-0.02 CA for long-time floating charge. According to the storage battery low-temperature charging and discharging method based on temperature compensation, the problem that the service life is shortened due to insufficient charging of the storagebattery at a low temperature can be avoided.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

Preparation method of lead storage battery cathode lead paste containing superconducting material additive

InactiveCN105375024AEasy to prepareThe steps are well designedCell electrodesElectrical batteryBarium sulfate

The invention discloses a preparation method of a lead storage battery cathode lead paste containing a superconducting material additive. The lead storage battery cathode lead paste comprises lead powder, water, sulfuric acid, a superconducting material, a short fiber, superfine barium sulfate, acetylene black, lignin and humic acid. The preparation method of the lead storage battery cathode lead paste containing the superconducting material additive disclosed by the invention is simple and convenient, and reasonable in step design; and the preparation method of the lead storage battery cathode lead paste containing the superconducting material additive can be relatively quickly obtained. With the superconducting material as the additive of the lead storage battery cathode lead paste, the superconducting material can be well blended with active substances of the lead paste; the conductivity and the microstructure of a negative plate can be effectively improved; deposition of mass sulfate in the discharge process is hindered; the charge acceptance of a battery is improved; and the preparation method can be widely applicable to various lead-acid storage battery products.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Battery apparatus

ActiveUS9837834B2Increase capacityImprove charge reception capabilityIndicating/monitoring circuitsSecondary cellsEngineeringVoltage range

The battery system is a combined system of a first battery and a second battery. The discharging curve (discharging characteristic) (311) of the first battery has a stable region (B1). The discharging curve (discharging characteristic) (321) of the second battery has a stable region (B2) in the range of voltage lower than the voltage in the stable region (B1) of the first battery and also has an unstable region (A2) in the range of voltage overlapping the voltage in the stable region (B1) of the first battery. The first battery and the second battery are connected in parallel so that, in a discharging process, the discharging state of the entire battery shifts from the stable region (B1) of the first battery to the stable region (B2) of the second battery.

Owner:MAMORU AOKI

Positive lead plaster containing superconducting material additive for lead storage battery

InactiveCN105470502AImprove charge reception capabilityImprove conductivityLead-acid accumulatorsCell electrodesFiberElectrical battery

The invention discloses a positive lead plaster containing a superconducting material additive for a lead storage battery. The positive lead plaster comprises the following components in parts by weight: 80-83 parts of lead powder, 10-15 parts of water, 4-10 parts of sulfuric acid, 0.1-0.5 part of a superconducting material and 0.1-0.2 part of a staple fiber. According to the positive lead plaster containing the superconducting material additive for the lead storage battery disclosed by the invention, with the superconducting material as the additive of the positive lead plaster for the lead storage battery, the superconducting material can be well fused with active materials of the lead plaster; the conductivity and the microstructure of a positive plate can be effectively improved; deposition of mass sulfate in a discharge process is hindered; the charge acceptance of the battery is improved; and the positive lead plaster can be widely applicable to various lead-acid storage battery products.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Preparation method of lead accumulator anode lead paste containing superconducting material additive

InactiveCN105355916AEasy to prepareThe steps are well designedCell electrodesFiberElectrical battery

The invention discloses a preparation method of a lead accumulator anode lead paste containing a superconducting material additive. The lead accumulator anode lead paste comprises the components in parts by weight: 80-83 parts of a lead powder, 10-15 parts of water, 4-10 parts of sulfuric acid, 0.1-0.5 part of a superconducting material and 0.1-0.2 part of short fibers. The preparation method of the lead accumulator anode lead paste containing the superconducting material additive is simple and convenient, is reasonable in step design, and can relatively rapidly obtain the lead accumulator anode lead paste containing the superconducting material additive. With the superconducting material as the lead accumulator anode lead paste additive, the superconducting material can be well fused with lead paste active substances, the electrical conductivity and a microstructure of an anode plate can be effectively improved, large-volume deposition of sulfate in a discharge process is hindered, the charge acceptance capacity of batteries is increased, and the lead accumulator anode lead paste can be widely applicable to all kinds of lead-acid accumulator products.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Lead storage battery containing superconducting material additive

InactiveCN105390668AImprove charge reception capabilityImprove conductivityFinal product manufactureLead-acid accumulator electrodesElectrical batteryMaterials science

The invention discloses a lead storage battery containing a superconducting material additive. The lead storage battery comprises a positive electrode plate and a negative electrode plate, wherein the positive electrode plate comprises positive electrode lead plaster; and the negative electrode plate comprises negative electrode lead plaster. The lead storage battery containing the superconducting material additive comprises the positive electrode plate and the negative electrode plate, wherein the positive electrode plate comprises the positive electrode lead plaster; and the negative electrode plate comprises the negative electrode lead plaster. A superconducting material is taken as an additive of the positive electrode lead plaster of the lead storage battery, wherein the superconducting material can be well fused with active substances of the lead plaster, can effectively improve the conductivity and microstructure of the positive electrode plate, prevent the deposition of large-area sulfate in a discharging process and improve the charge acceptance of the battery. The superconducting material is taken as an additive of the negative electrode lead plaster of the lead storage battery, wherein the superconducting material can be well fused with active substances of the lead plaster, can effectively improve the conductivity and microstructure of the negative electrode plate, prevent the deposition of large-area sulfate in the discharging process and improve the charge acceptance of the battery. The lead storage battery containing the superconducting material additive can be widely suitable for various lead-acid storage battery products.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Lead accumulator cathode lead paste containing superconducting material additive

InactiveCN105355915AImprove charge reception capabilityImprove conductivityCell electrodesFiberElectrical battery

The invention discloses a lead accumulator cathode lead paste containing a superconducting material additive. The lead accumulator cathode lead paste includes the components in parts by weight: 80-83 parts of a lead powder, 10-15 parts of water, 4-10 parts of sulfuric acid, 0.1-0.5 part of a superconducting material, 0.05-0.06 part of short fibers, 0.5-1.5 parts of ultrafine barium sulfate, 0.2-0.5 part of acetylene black, 0.1-0.3 part of lignin, and 0.1-0.3 part of humic acid. The lead accumulator cathode lead paste containing the superconducting material additive takes the superconducting material as the lead accumulator cathode lead paste additive, the superconducting material can be well fused with lead paste active substances, the electrical conductivity and a microstructure of a cathode plate can be effectively improved, large-volume deposition of sulfate in a discharge process is hindered, the charge acceptance capacity of batteries is increased, and the lead accumulator cathode lead paste can be widely applicable to all kinds of lead-acid accumulator products..

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

A kind of preparation method of lead-acid storage battery lead paste mixed with graphene

ActiveCN104835941BAchieve decentralizationImprove charge reception capabilityLead-acid accumulator electrodesPower flowLead oxide

The invention discloses a preparation method of a graphene-doped lead acid battery lead paste. The method comprises the following steps: adding 0.1-5 parts of aqueous disperser in 100 parts of deionized water, stirring at high speed and mixing, slowly adding 0.5-5 parts of graphene to prepare a graphene aqueous dispersion liquid; slowly adding 39-130 parts of sulfuric acid with concentration being 98% in 100 parts of deionized water to obtain dilute sulfuric acid; adding 0.1-5 parts of aqueous disperser in the dilute sulfuric acid for stirring at high speed and mixing, slowly adding 0.5-5 parts of graphene to prepare the graphene dilute sulfuric acid dispersion liquid; slowly adding 8-15 parts of the graphene aqueous dispersion liquid in 100 parts of leadoxide mixing material flow for stirring and mixing; adding 5.3-20 parts of graphene dilute sulfuric acid dispersion liquid in the material flow, and stirring and mixing during a conveying process to form a lead paste. The method can fully disperse graphene in a lead acid battery active substance, charge acceptance as well as heavy current charge and discharge performance of the lead acid battery can be greatly increased, and usage life of the storage battery can be prolonged.

Owner:SINO INNOV SEMICON (PKU) CO LTD

Preparation method of lead-carbon battery composite negative electrode, composite negative electrode and application thereof

ActiveCN107845777BImprove performanceHigh bulk densityLead-acid accumulatorsLead-acid accumulator electrodesActivated carbonElectrical battery

The invention relates to a preparation method for a composite negative electrode of a lead-carbon battery, and the composite negative electrode and application thereof. The preparation method comprises the following steps: producing lead sulfate in porous carbon in situ so as to improve the bulk density of a carbon material and reduce the density difference between the carbon material and lead powder; and then uniformly mixing modified activated carbon, lead powder and additives by using a shearing process so as to prepare the high-performance composite negative electrode for the lead-carbon battery. The composite negative electrode for the lead-carbon battery prepared by using the method has higher charge-discharge reversibility, longer charge-discharge cycle life and higher charge acceptance than conventional lead-acid batteries, and is easy to realize large-scale production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A kind of manufacturing method of lead-carbon battery for pure electric vehicle

InactiveCN102916227BHigh mechanical strengthLow mechanical strengthFinal product manufactureElectrode carriers/collectorsElectrical batteryElectric cars

The invention relates to a manufacturing method of a lead-carbon battery used for a pure electric vehicle. The manufacturing method of the lead-carbon battery is characterized in that the manufacturing method comprises the following steps: step 1) orderly removing oil of polyurethane sponge, coarsening, neutralizing, presoaking, activating, and chemically silvering the polyurethane sponge, and finally carrying out electrification and lead plating on the polyurethane sponge to obtain foamed lead material; step 2) cutting and shaping the foamed lead material, respectively coating positive and negative active materials, and adding carbon black into the negative active material to be used as an additive; and step 3), solidifying and drying positive and negative electrode plates, and then assembling the positive and negative electrode plates into a finished battery. The manufacturing method can obviously enhance the performance of the battery.

Owner:WUHAN INTEPOWER CO LTD

Super battery consisting of plumbic acid capacitance and preparation method thereof

InactiveCN101728090BImprove charge reception capabilityImproved high-current discharge characteristicsHybrid capacitor electrolytesElectrolytic capacitorsActivated carbonCapacitance

The invention discloses a super battery consisting of plumbic acid capacitance and a preparation method thereof. The super battery comprises a positive plate and a negative plate; a grid of the negative plate is used as a current collector; and 1 to 90 percent of lead plaster in the negative plate of the conventional plumbic acid battery is replaced by active carbon. The invention also discloses a preparation method for the negative plate. The charge receiving capability of the plumbic acid battery of the invention is greatly enhanced, the high-current discharge property is remarkably improved, the water loss of the plumbic acid battery is obviously reduced, and the corrosion of the lead grid of the plumbic acid battery is obviously reduced; the service life is averagely increased by over80 percent, and the volumetric specific energy reaches 100Wh / l; and the using amount of lead is reduced by 10 to 50 percent, and the consumption of the lead is greatly reduced.

Owner:湖南科力远高技术集团有限公司

A kind of lead-acid storage battery group selection method

ActiveCN103560278BImprove cycle lifeHigh initial capacitySecondary cells charging/dischargingLead-acid accumulators constructionState of artEngineering

The invention provides a matching and sorting method for lead-acid storage batteries and aims to solve the problems in the prior art that the consistency of storage batteries in a storage battery pack is poor and the service life is short. According to the matching and sorting method, sorted storage battery plates are assembled and sorted storage batteries with similar capacities and open-circuit voltage are matched to form one group by adopting a quantitative acid adding manner. The cycle life of the storage battery pack is obviously prolonged, the initial capacity of the storage battery pack is improved by 5%, and the charging receiving capability and the low-temperature performance of the storage battery pack are obviously enhanced. According to the matching and sorting method, the defects that the cycle life of the batteries is short and the consistency of the storage battery pack is poor are overcome; the batteries are suitable for being subjected to charge-discharge cycles under various environment temperatures so that the cycle life of the batteries is prolonged to be more than 500 times.

Owner:CHAOWEI POWER CO LTD

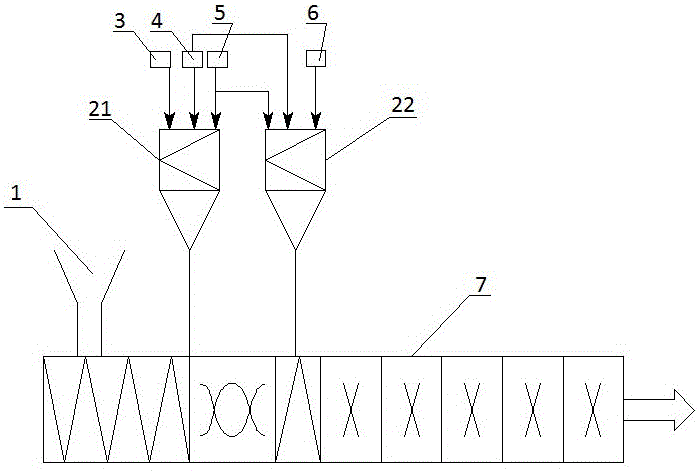

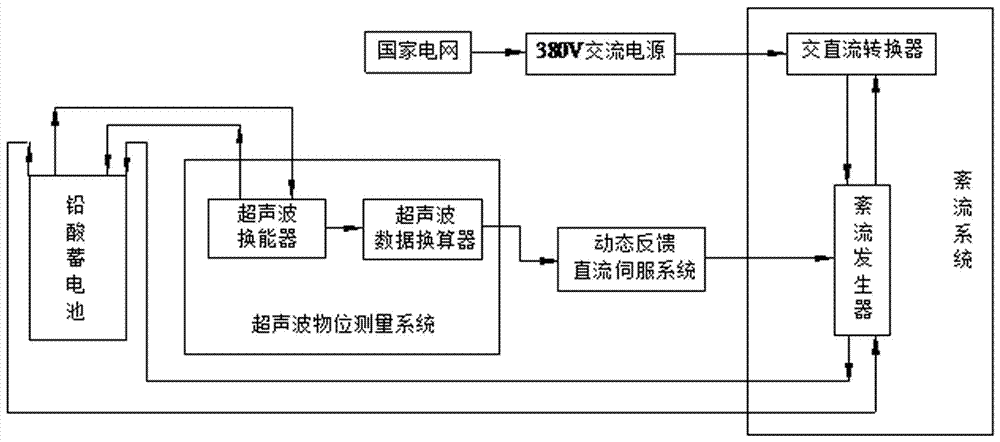

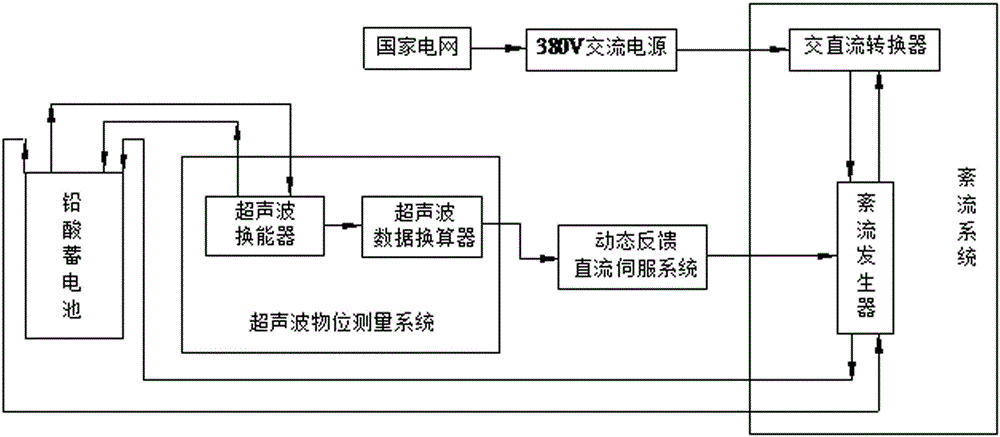

Lead-acid battery internalization activator, internalization system and internalization method

ActiveCN104993179BElimination of electrochemical internal resistanceImprove charge reception capabilitySecondary cells servicing/maintenancePhosphateGas phase

The invention discloses a lead-acid storage battery container formation exciting agent, which is formed by mixing of fumed silica, a curing agent and deionized water. The curing agent includes anhydrous sodium sulfate, lithium tetraborate, sodium dodecyl sulfate, fatty alcohol polyoxyethylene ether sodium sulfate, dibutyltin dilaurate, N.N-dihydroxyethyl alkyl amide, polyacrylamide, stannous sulfate, sodium polyacrylate, potassium dihydrogen phosphate, and aluminum oxide. The invention also discloses a lead-acid storage battery container formation system, which consists of a lead-acid storage battery, an ultrasonic material level measurement system, a dynamic feedback direct current servo system, and a turbulence system. The invention also discloses a lead-acid storage battery container formation method, which includes: injecting an electrolyte solution containing the container formation exciting agent into the lead-acid storage battery, carrying out collection, processing and data conversion by the container formation system, and performing adjustment to a rational turbulence state. The container formation technology can reduce the electrochemical internal resistance of the storage battery in the container formation process, and the generated heat can meet the parameters required by a charging process without external forced cooling.

Owner:宁波蜂巢新材料科技有限公司

Lead-acid storage battery container formation exciting agent, container formation system and container formation method

ActiveCN104993179AImprove stabilityLower resistanceSecondary cells servicing/maintenancePhosphateGas phase

The invention discloses a lead-acid storage battery container formation exciting agent, which is formed by mixing of fumed silica, a curing agent and deionized water. The curing agent includes anhydrous sodium sulfate, lithium tetraborate, sodium dodecyl sulfate, fatty alcohol polyoxyethylene ether sodium sulfate, dibutyltin dilaurate, N.N-dihydroxyethyl alkyl amide, polyacrylamide, stannous sulfate, sodium polyacrylate, potassium dihydrogen phosphate, and aluminum oxide. The invention also discloses a lead-acid storage battery container formation system, which consists of a lead-acid storage battery, an ultrasonic material level measurement system, a dynamic feedback direct current servo system, and a turbulence system. The invention also discloses a lead-acid storage battery container formation method, which includes: injecting an electrolyte solution containing the container formation exciting agent into the lead-acid storage battery, carrying out collection, processing and data conversion by the container formation system, and performing adjustment to a rational turbulence state. The container formation technology can reduce the electrochemical internal resistance of the storage battery in the container formation process, and the generated heat can meet the parameters required by a charging process without external forced cooling.

Owner:宁波蜂巢新材料科技有限公司

Partially graphitized activated carbon-based composite additive and preparation, negative electrode and application

ActiveCN108123137BLarge specific surface areaLimit growthLead-acid accumulatorsLead-acid accumulator electrodesElectrical batteryCarbon particle

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A kind of lead storage battery positive plate lead paste formula

ActiveCN110071267BImprove cycle performanceProtect against softeningLead-acid accumulatorsCell electrodesFiberCarbon fibers

The invention discloses a lead paste formula for a positive plate of a lead storage battery, which includes lead powder and additives, the additives include silica sol and carbon fiber, the addition of the silica sol is 1.0% to 5.0% of the weight of the lead powder, the carbon fiber The amount added is 0.05% to 0.25% of the weight of the lead powder. The formula of the lead paste for the positive plate of the lead storage battery of the present invention is by adding silica sol and carbon fiber as additives in the positive electrode paste, the addition of the silica sol is 1.0% to 5.0% of the weight of the lead powder, and the addition of the carbon fiber is 1% of the weight of the lead powder. 0.05% to 0.25%, can greatly improve the mechanical strength and charge receiving capacity of the positive electrode paste, protect the positive electrode paste crystal from softening during the cycle to the greatest extent, and significantly improve the cycle performance of the lead-acid battery.

Owner:TIANNENG BATTERY GROUP

A kind of manufacturing method of lead-carbon battery for micro-hybrid electric vehicle

InactiveCN102800898BReduce weightLarge specific surface areaCell electrodesFinal product manufactureSilver plateBiological activation

The patent of the present invention relates to a method for manufacturing a lead-carbon battery for a micro-hybrid electric vehicle, which is characterized in that it includes the following steps: step 1), the polyurethane sponge is degreased, roughened, neutralized, pre-soaked, activated, Electroless silver plating is finally electroplated with lead to obtain foamed lead material; step 2), cutting the above-mentioned foamed lead material into shape, coating the negative electrode active material, adding carbon black as an additive to the active material; step 3), the negative plate is cured, After drying, it is assembled with the positive plate made by ordinary gravity casting method to form a finished battery. The method of the invention can greatly improve the performance of the lead-acid battery.

Owner:WUHAN INTEPOWER CO LTD

Deep circulation storage battery container formation diachylon

ActiveCN103219512BImprove conductivityImprove charge reception capabilityCell electrodesPolyesterCarboxymethyl cellulose

The present invention discloses a deep circulation storage battery container formation diachylon, and is to solve the technical problem of short circulation life of conventional storage batteries. The diachylon of the present invention includes a positive diachylon and a negative diachylon. The positive diachylon includes the components by weight: 0.15-0.42% of carboxymethyl cellulose, 0.25-0.42% of anisotropy graphite, 0.15-0.25% of potassium sulfate, 0.30-0.42% of stannous sulfate, 0.07-0.10% of polyester staple fibers, 6.5-7.5% of dilute sulfuric acid, 9-10% of water, and 80.89-83.58% of a lead powder; and the negative diachylon includes the components by weight: 0.50-0.70% of barium sulfate, 0.20-0.45% of acetylene black, 0.15-0.25% of lignin, 6.00-6.50% of dilute sulfuric acid, 9-10% of water, and 82.10-84.15% of a lead powder.

Owner:CHAOWEI POWER CO LTD

A low-temperature charging and discharging method for batteries based on temperature compensation

ActiveCN111682274BIncrease temperatureIncrease profitLead-acid accumulatorsSecondary cells charging/dischargingThermodynamicsBattery charge

A method for charging and discharging batteries at low temperature based on temperature compensation, comprising the following steps: 1) when the ambient temperature is lower than -10°C during battery charging and discharging, the temperature compensation device is activated to raise the temperature; 2) a small current 0.05-0.1C pre-charge determination , charging reaches 0.3-0.4H, if the cell voltage of the battery does not reach 2V, the charger will alarm and display abnormality, and the charging will end; 3) Segmented charging: the first stage: constant current 0.21-0.24C to cell voltage 2.4V ;Second stage: constant current 0.1‑0.2C to battery cell voltage 2.45V; third stage: current limit 0.01‑0.05C, battery cell voltage constant voltage 2.48V, current lower than 0.01A; fourth stage: constant Current 0.07‑0.08C to battery cell voltage 2.5V, charging up to 0.5H; fifth stage: battery cell voltage limit 2.29‑2.3V, current limit 0.005‑0.02C long-term float charge. This method can avoid the problem of shortened service life caused by insufficient charging of the storage battery at low temperature.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

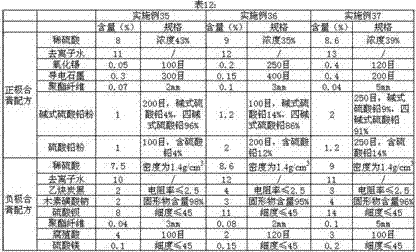

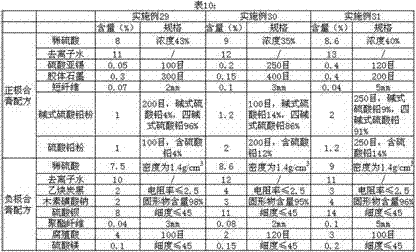

Internalization of lead-acid batteries into paste

ActiveCN105280916BImprove low temperature performanceImprove charge reception capabilityCell electrodesPolyesterFiber

The invention provides a composite paste for an inner formation of a lead-acid storage battery. Positive composite paste lead powder comprises the following chemical components of a positive composite paste in percentage by mass: 8%-9% of 35%-43% dilute sulphuric acid, 11%-13% of deionized water, 0.05%-0.4% of tin oxide or stannous mono-sulphate, 0.15%-0.4% of colloidal graphite or conductive graphite, 0.04%-0.1% of a short fiber or polyester fiber, 1%-2% of basic lead sulphate powder and 1%-2% of lead sulfate powder; and negative composite paste lead powder comprises the following chemical components of a negative composite paste in percentage by mass: 7.5%-9% of 35%-43% dilute sulphuric acid, 10%-12% of deionized water, 2%-4% of acetylene carbon black, 2%-4% of sodium lignosulphonate, 8%-14% of barium sulfate, 0.04%-0.1% of the short fiber or polyester fiber, 2%-4% of humic acid and 0.1%-0.2% of magnesium sulfate. By the technical scheme, the initial capacity of the lead-acid storage battery can be significantly improved; and the lifetime of the battery can be prolonged.

Owner:济源市万洋绿色能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com